Washing control method and washing machine

A laundry control and washing machine technology, which is applied in the control device of washing machine, washing device, textile and paper making, etc., can solve the problems of poor cleaning effect and low laundry efficiency, and achieve improved cleaning effect, improved laundry efficiency, and shortened flow the effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

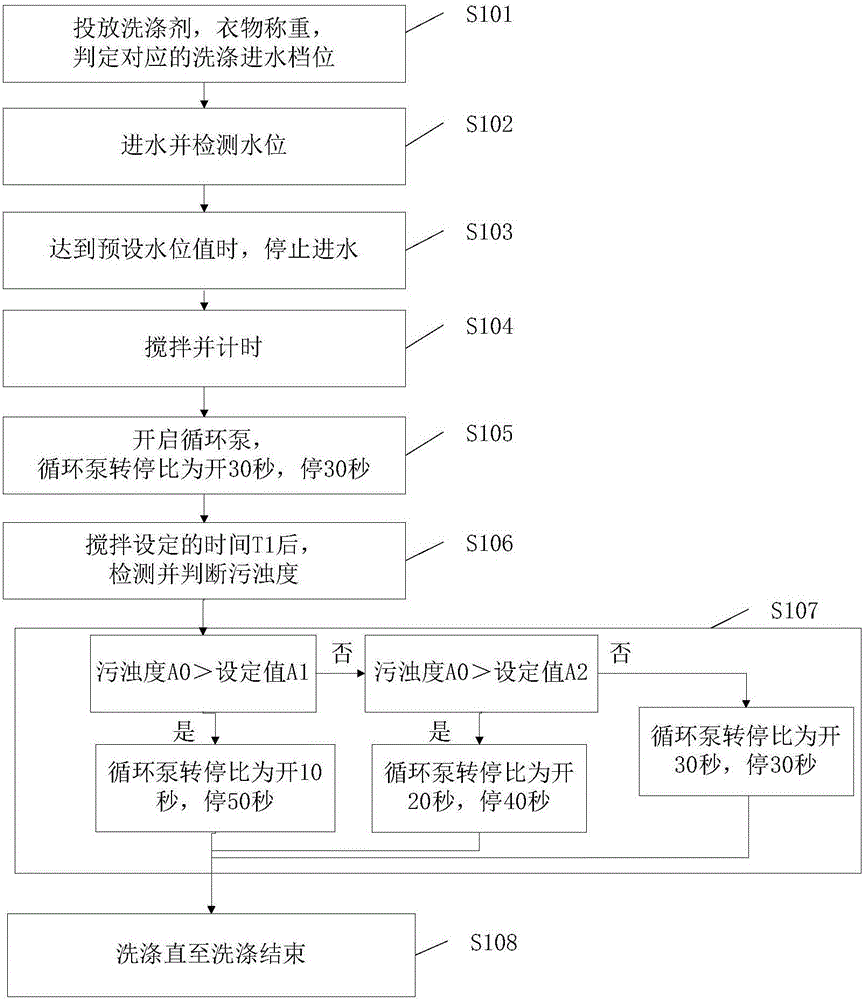

[0045] The laundry control method provided in this embodiment strips off the dirt on the laundry through the rotating and beating action of the inner cylinder and the soaking of the laundry by the circulating water after the circulation pump is turned on. At this time, for example, the circulation pump can be set to open for 30 seconds and stop for 30 seconds. After the preset time T1 elapses, for example, T1 is 2 minutes, the degree of turbidity of the washing water is detected by outputting the result detected by the dirt detection unit. It should be noted that the preset time T1 here can be adjusted and set according to specific conditions.

[0046] Further, according to the degree of turbidity of the washing water, determining the flow time of the external circulation of the washing water in the outer tub specifically includes:

[0047] Before detecting the turbidity of the washing water, determine the flow time of the external circulation of the washing water in the oute...

Embodiment 2

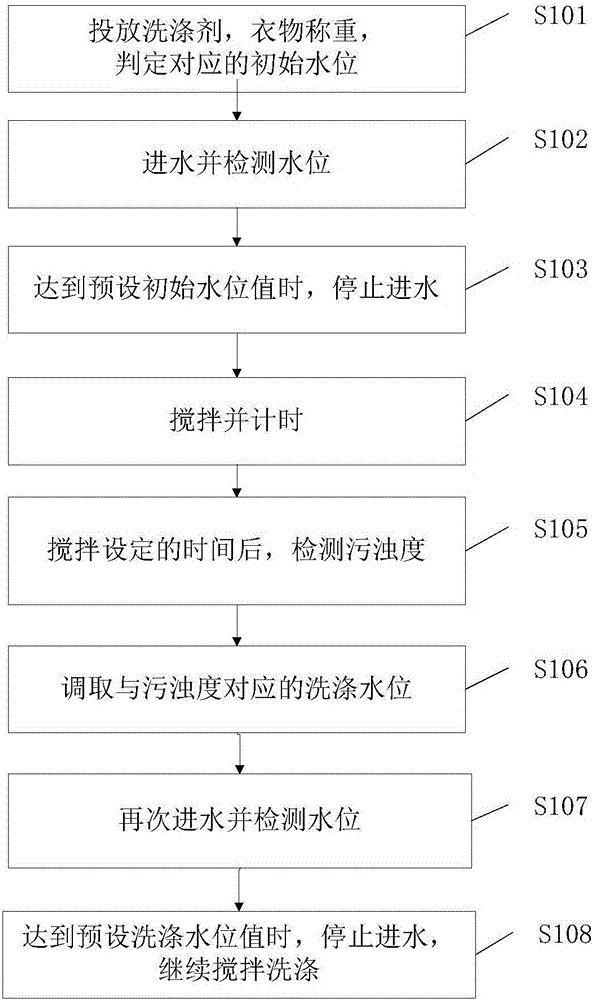

[0055] Such as figure 1 As shown, the laundry control method provided in this embodiment, the steps include:

[0056] Step S101, add detergent, weigh the clothes, and determine the corresponding washing water intake level; after the clothes are put into the washing tub before water intake, the washing tub rotates for a period of time, and the current weight of the clothes is determined by the relevant parameters of the motor, according to the weight of the clothes The weight presets the initial water level.

[0057] Step S102, enter water and detect the water level; the method for controlling the water intake of the washing machine according to the present invention can use a water level sensor to measure the water level, wherein the sensor can be a traditional external water level sensor or a built-in water level sensor, and the sensor can be an inductor Type water level sensor, it can also be a direct output voltage type water level sensor, it can also be a direct output fr...

Embodiment 3

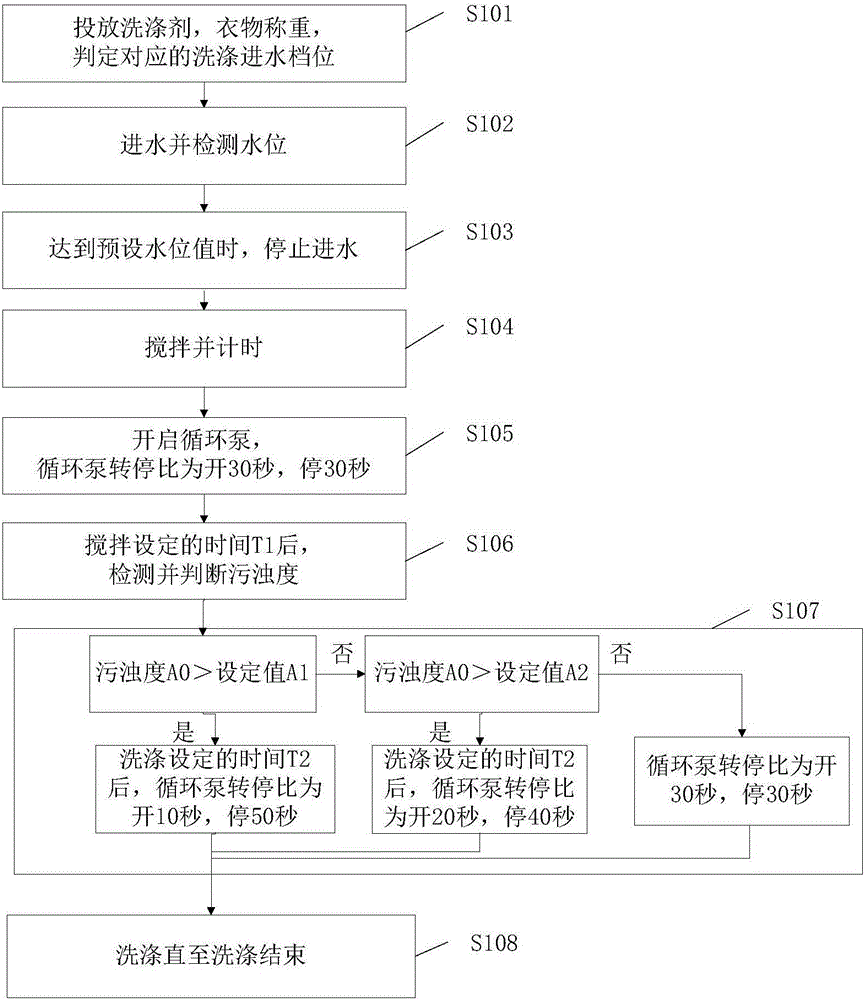

[0072] Such as figure 2 As shown, the laundry control method provided in this embodiment can reduce the rotation and stop ratio of the circulation pump within the preset period of time before the end of washing, and can activate a lower cycle pump of the washing machine during the preset period of time during the washing process. The turn-stop ratio, such as 5 minutes before the end of the washing, makes it possible to maintain a suitable turn-stop ratio of the circulating pump during most of the laundry process, so that the dissolved water of the washing powder can be evenly soaked into the laundry. In the last period of time, the most dirty substances in the washing water, by shortening the flow time of the outer circulation of the washing water, prevent the washing water with more dirt from being sprayed on the clothes again, and further improve the washing effect. The steps include:

[0073] Step S101, add detergent, weigh the clothes, and determine the corresponding wash...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com