Fabric sizing machine

A fabric and pulping machine technology, used in textile processing machine accessories, textile material processing, processing textile material rollers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

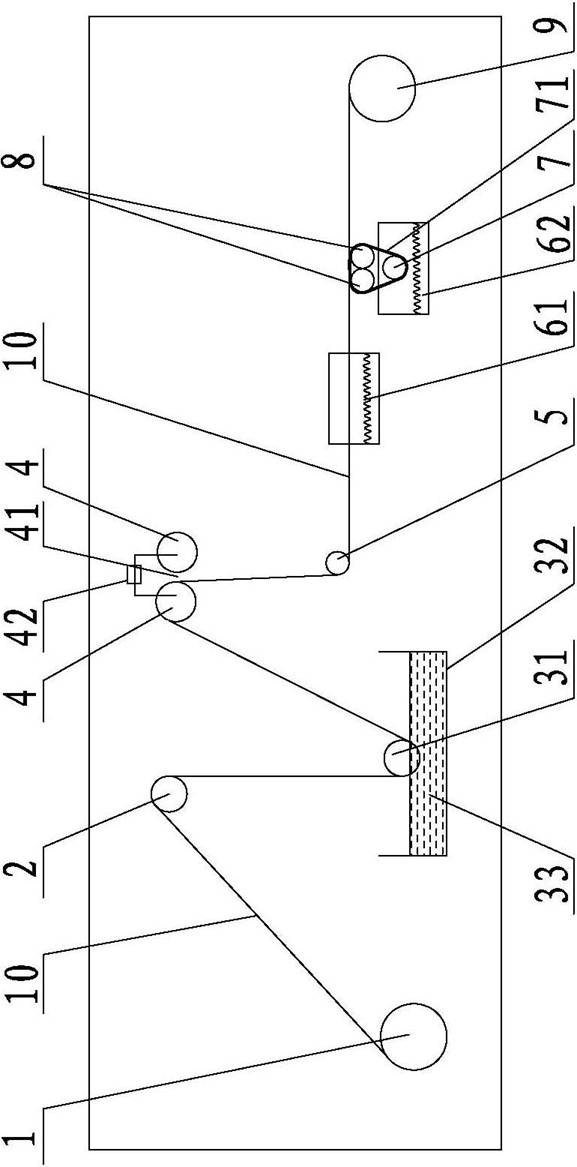

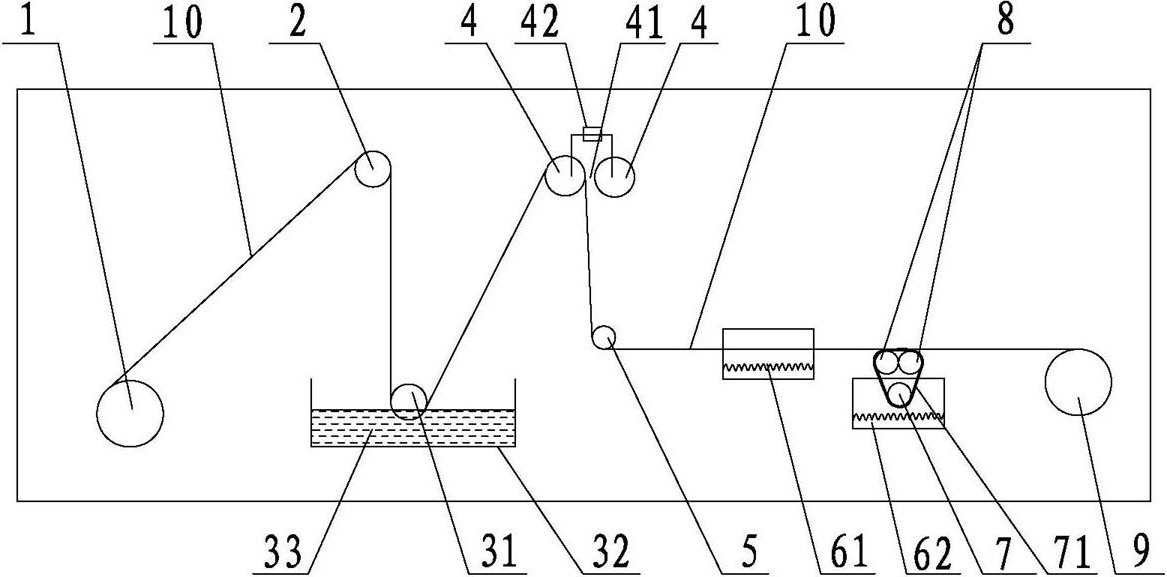

[0016] Please refer to the attached figure 1 Shown, the present invention is a kind of fabric sizing machine, and it is used for sizing and drying of fabric 10, and it comprises unwinding roller 1, drive roller 2, sizing roller 31, sizing tank 32, a pair of squeezing roller 4, the first The second drive roller 5, the first oven 61, the second oven 62, the heating roller 7, the supporting roller 8, the winding device 9 and other accessories are assembled and formed.

[0017] Wherein, the fabric 10 passes through the unwinding roller 1 , the driving roller 2 and the sizing roller 31 sequentially and enters the sizing tank 32 , and the fabric 10 is subjected to a sizing treatment in the sizing tank 32 . The sizing roller 31 is located in the sizing tank 32 , and the sizing tank 32 accommodates the slurry 33 , and the sizing roller 31 is partially immersed in the slurry 33 . The driving roller 2 is located above the sizing tank 32 .

[0018] There is a gap 41 between the pair o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com