Patents

Literature

110results about How to "Will not affect the installation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

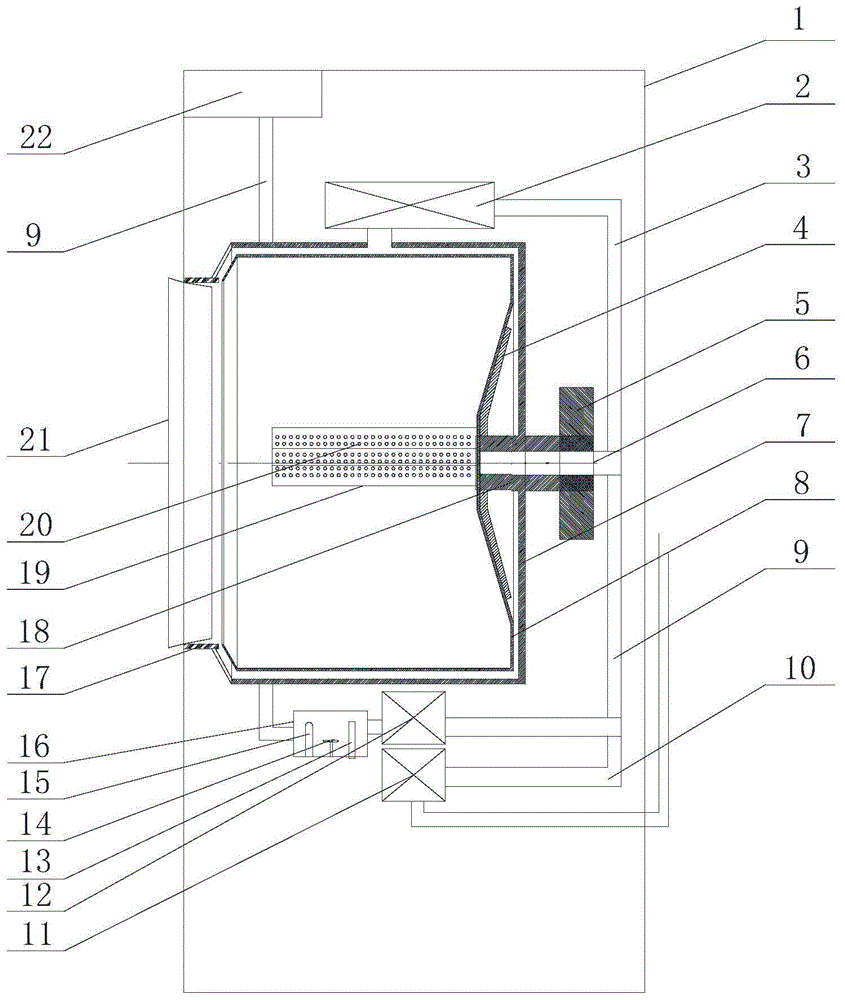

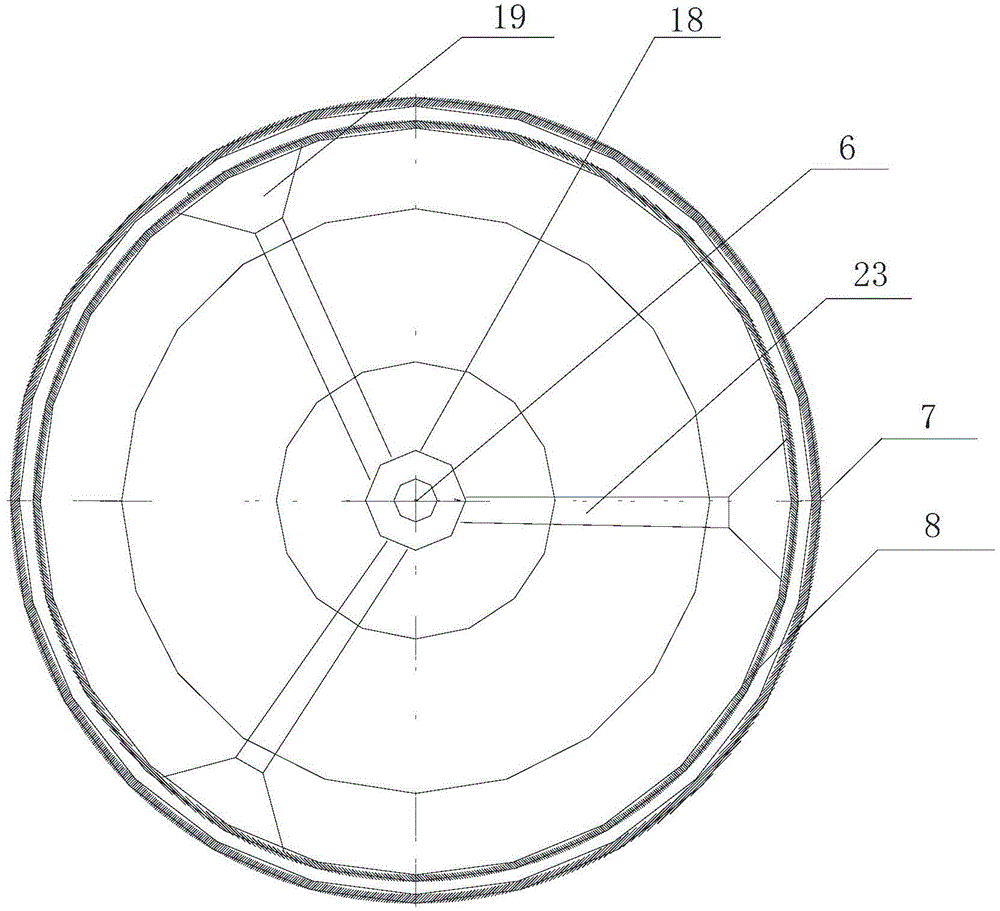

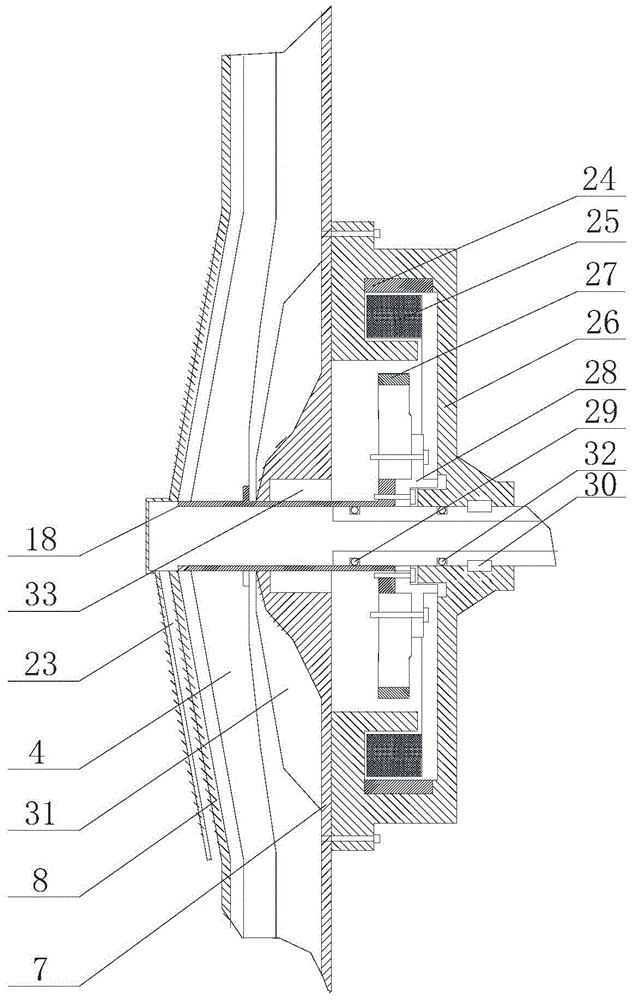

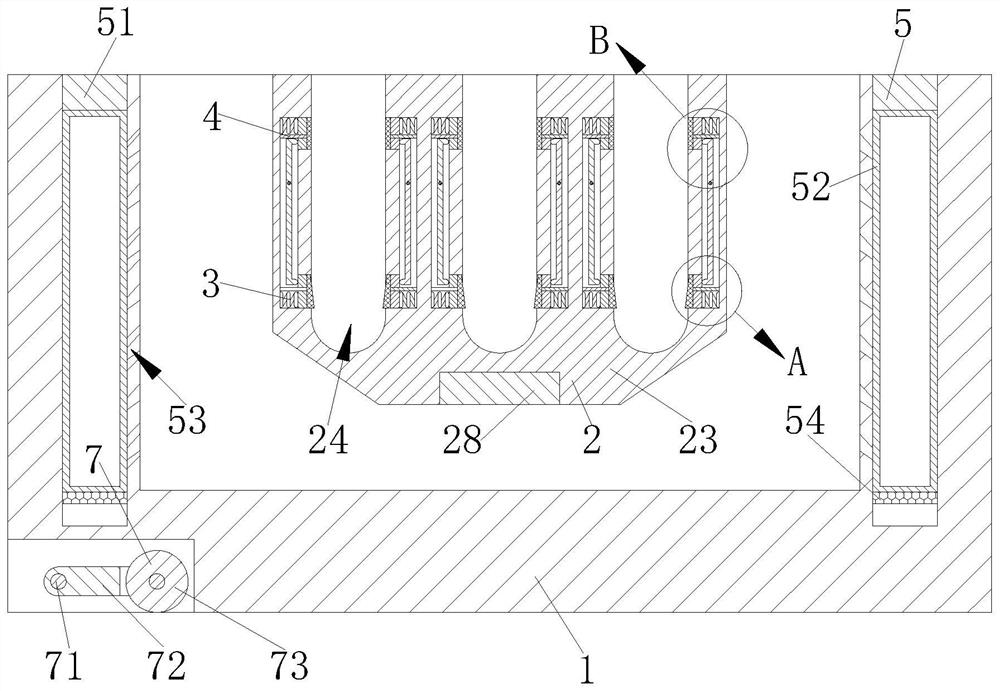

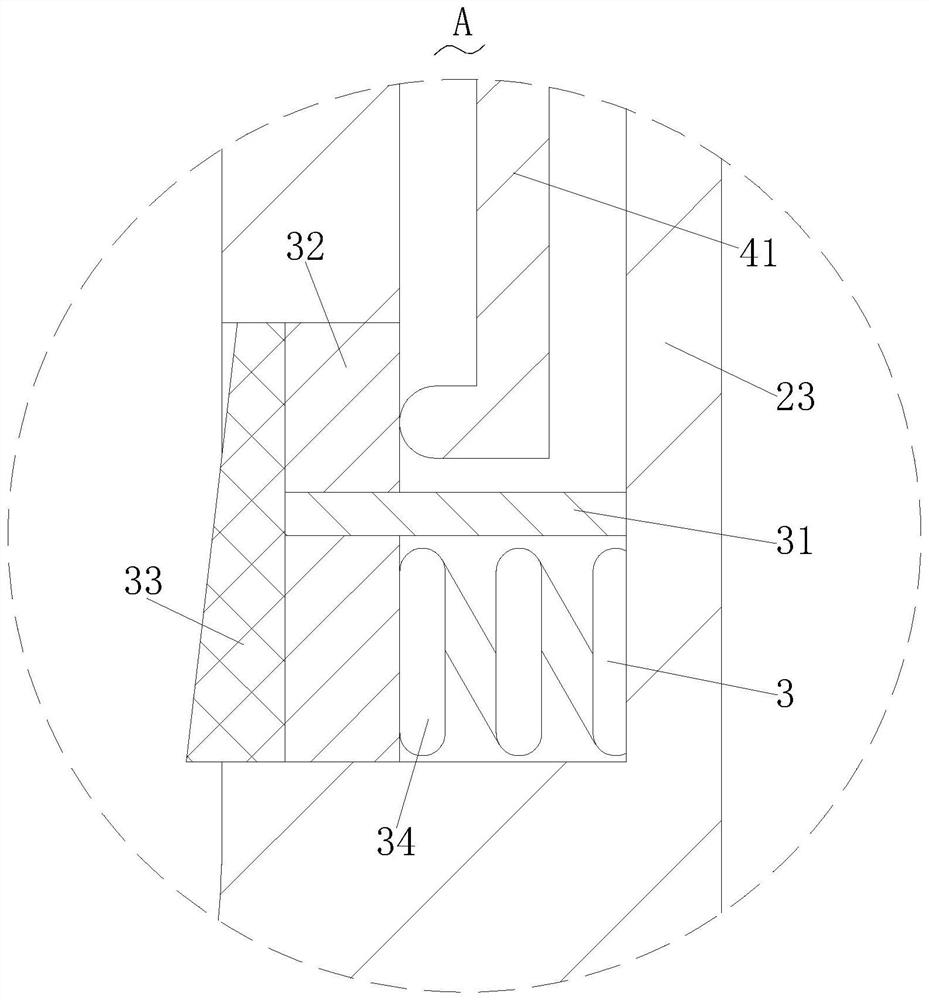

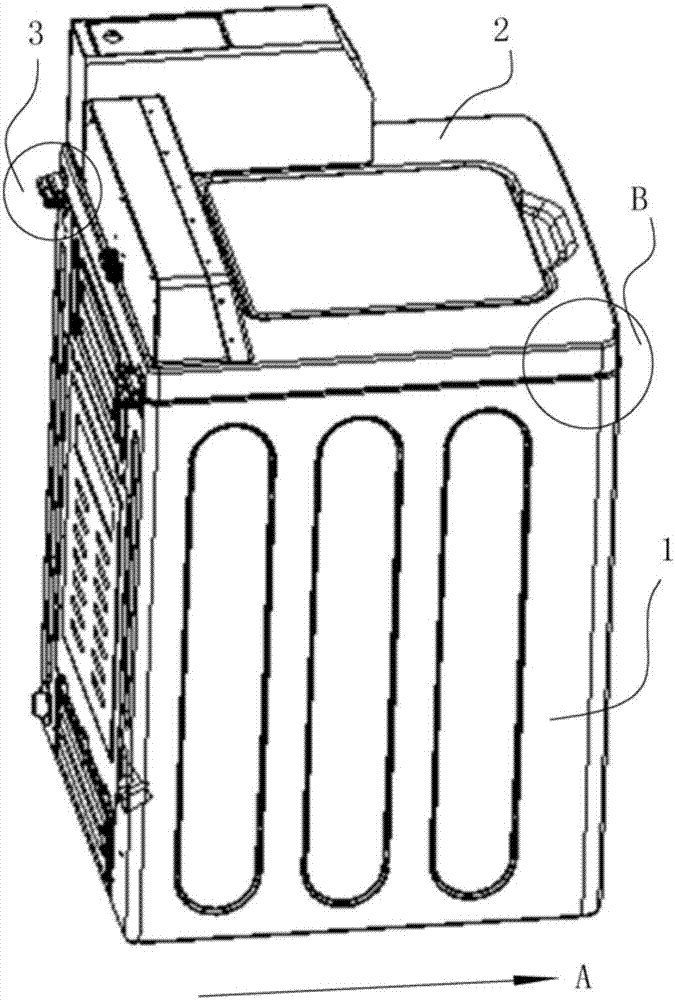

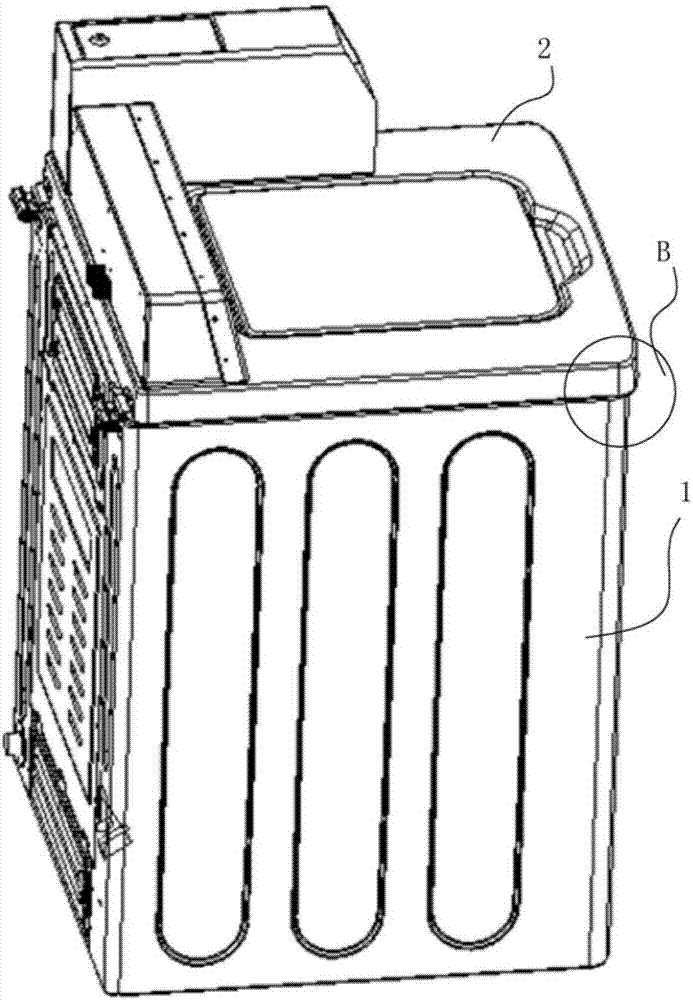

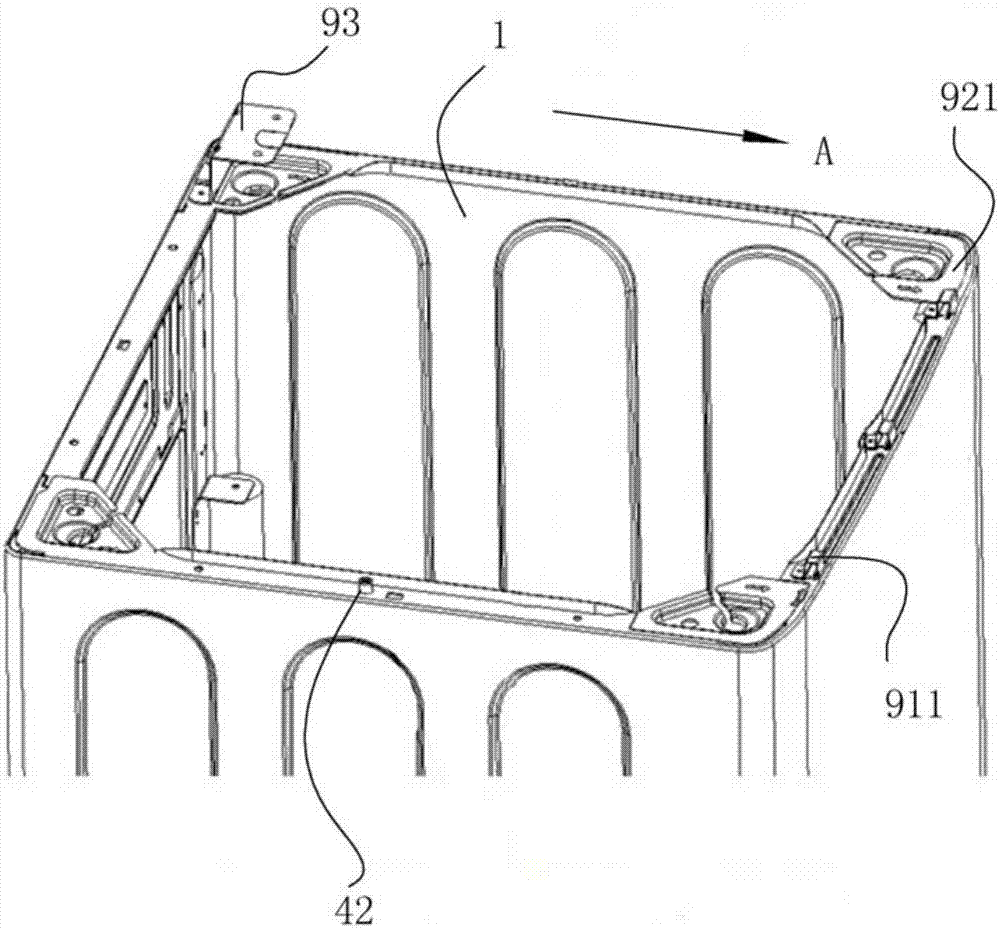

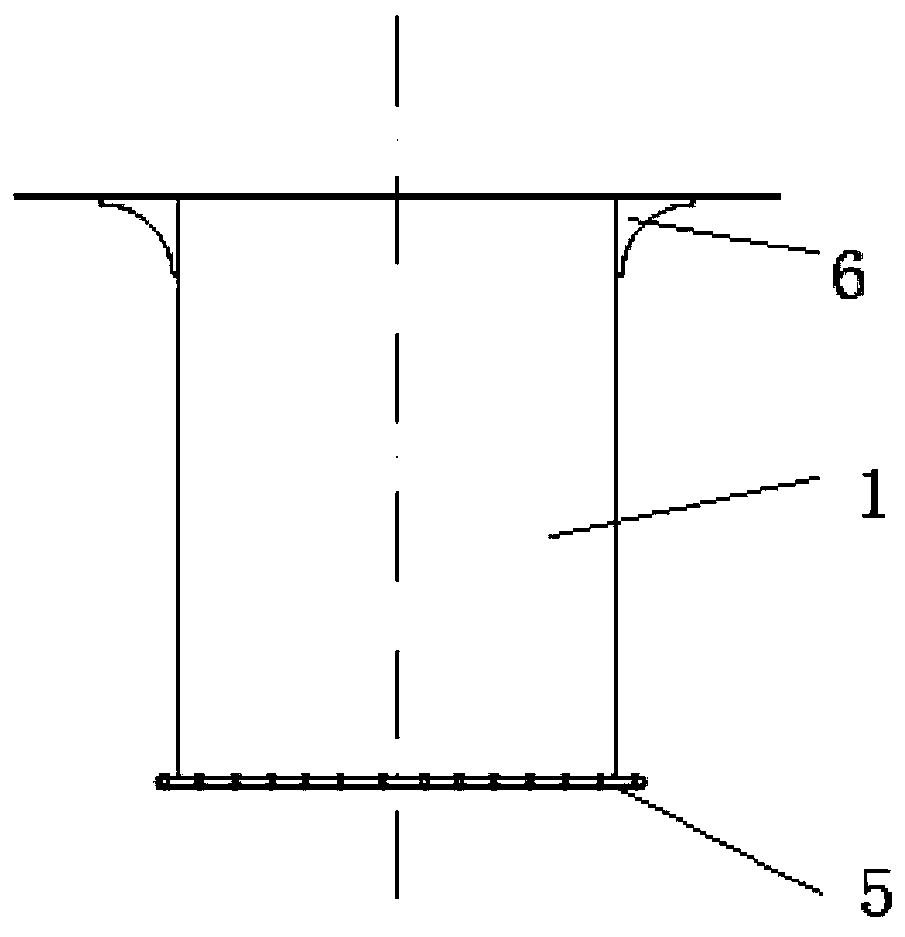

A water-saving drum washing machine

ActiveCN105696248AReduce the amount of waterRealize the purpose of saving waterOther washing machinesWashing machine with receptaclesWater savingMechanical engineering

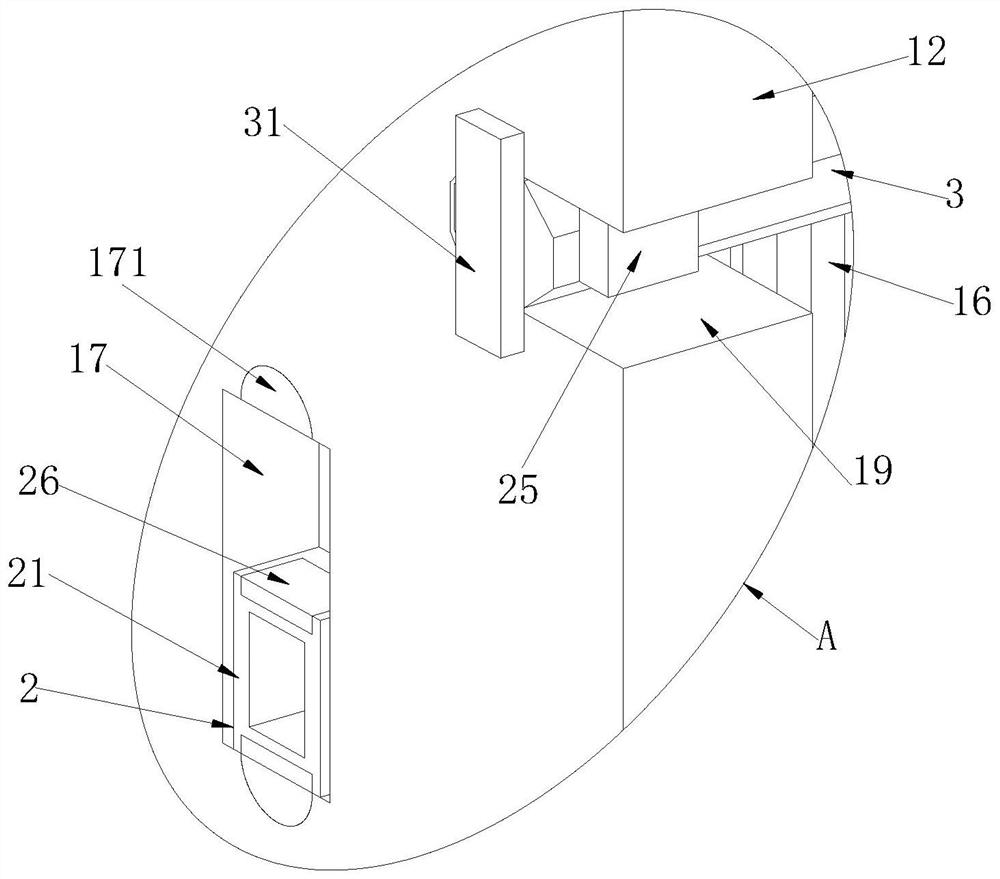

The invention provides a water-saving drum washing machine comprising an outer drum, an inner drum disposed in the outer drum and a water inlet pipeline communicating with the inner drum. The inner drum and the outer drum are installed on a central shaft coaxially. The inner drum is a holeless inner drum. The inner wall of the inner drum is provided with a plurality of lifting devices; the central shaft is internally provided with a hollow structure; the water inlet pipeline and the lifting devices communicate with the hollow structure. The lifting devices are provided with a plurality of water outlets. The technical objective of saving water is mainly achieved by using the holeless inner drum and making the space between the inner drum and the outer drum free of water in a washing process. Since the holeless inner drum is used, the structure of the water-saving washing machine is redesigned for water feeding and water drainage of the washing machine; further a water feeding and drainage system, a washing and spinning system and an airing drying and drying system are improved.

Owner:QINGDAO HAIER DRUM WASHING MACHINE

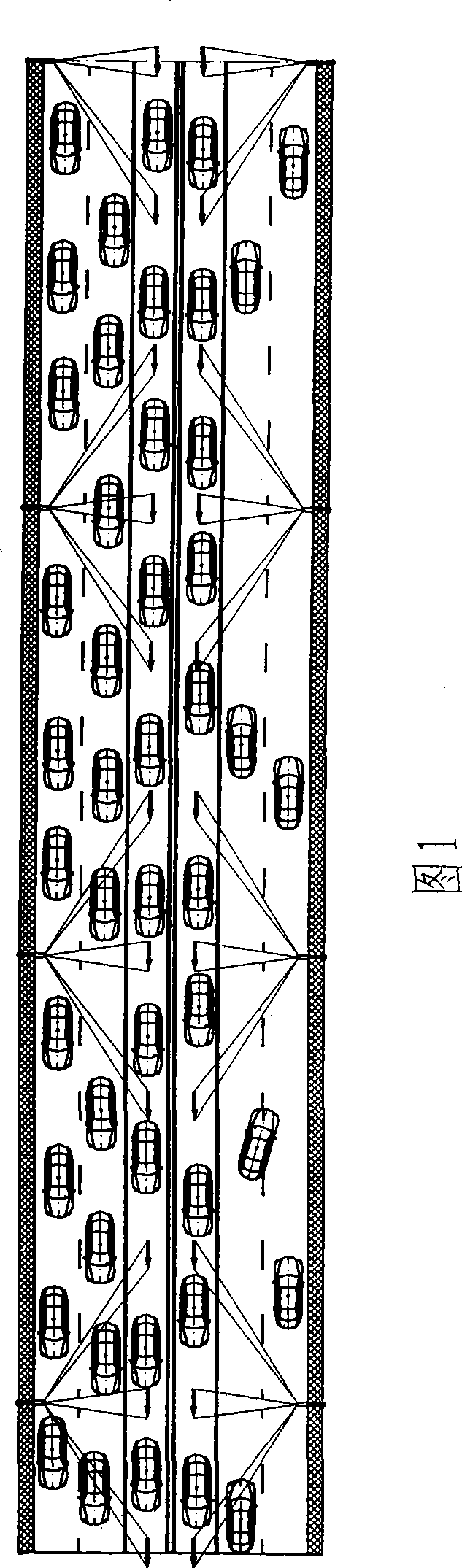

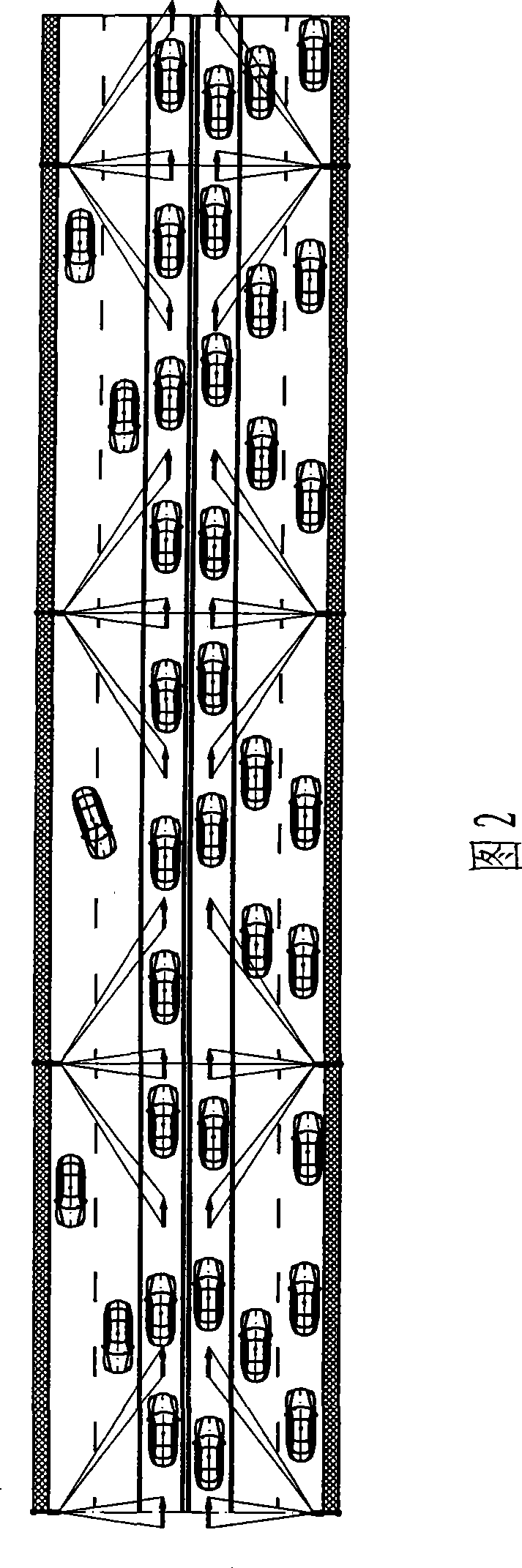

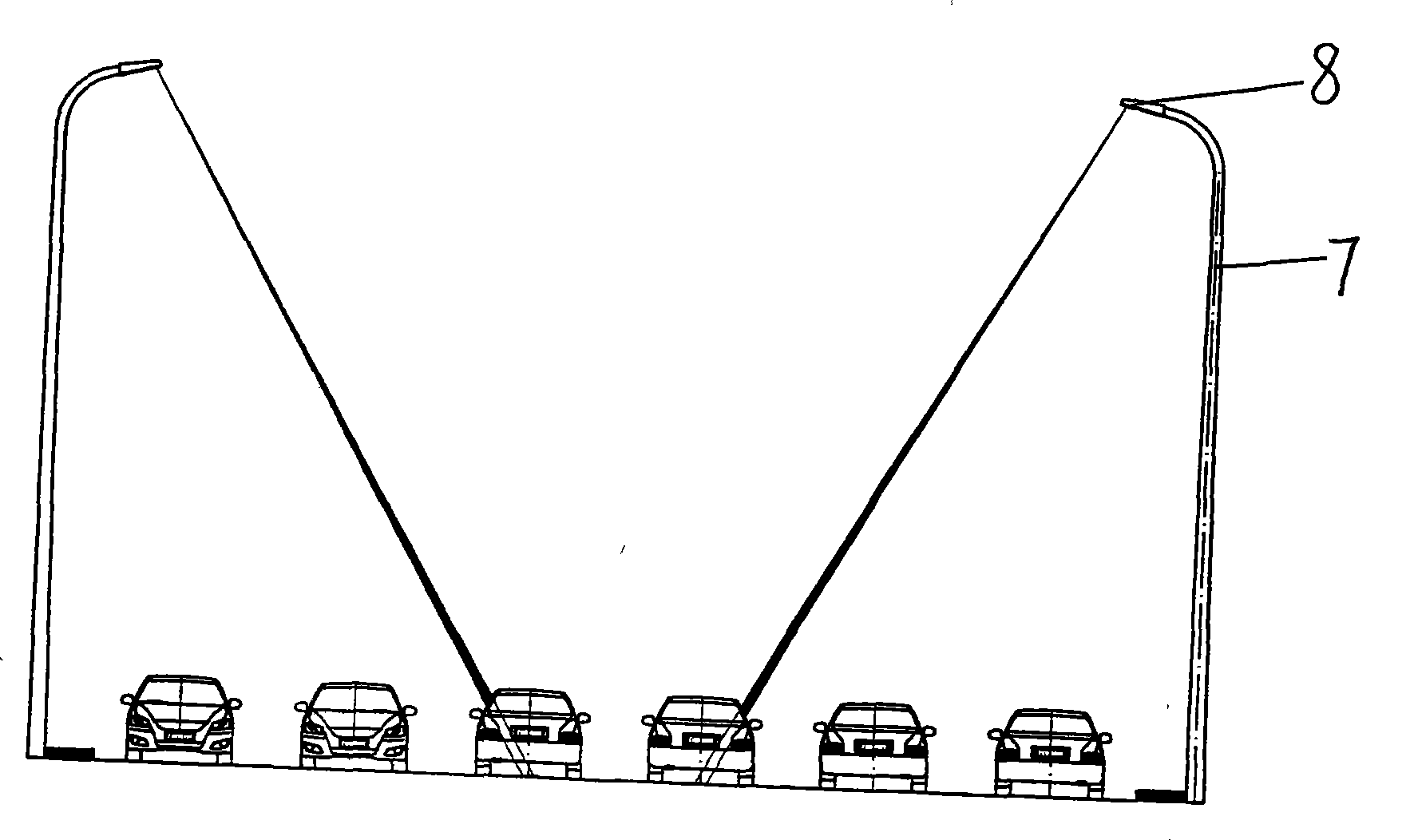

Traffic sign line labeling method and system thereof

InactiveCN101393688AIncrease brightnessImprove directionalityArrangements for variable traffic instructionsTraffic signalsLight beamEngineering

The invention relates to a method and a system for making a traffic sign marking. The traffic sign marking comprises a traffic sign and a traffic marking, and also traffic facilities; a laser generator is used for generating laser to form three-dimensional or two-dimensional traffic sign marking, and the laser beam generated by the laser generator can be adjusted to change the traffic sign marking. By adopting the method and the system, the vacant lane in the opposite direction can be utilized to relieve the pressure of traffic jam sections and solve the problem that traffic jam appears in the downtown direction and less cars go in the uptown direction when people go to work, and the traffic jam appears in the uptown direction and less cars go in the downtown direction when people get off work.

Owner:高玉宗

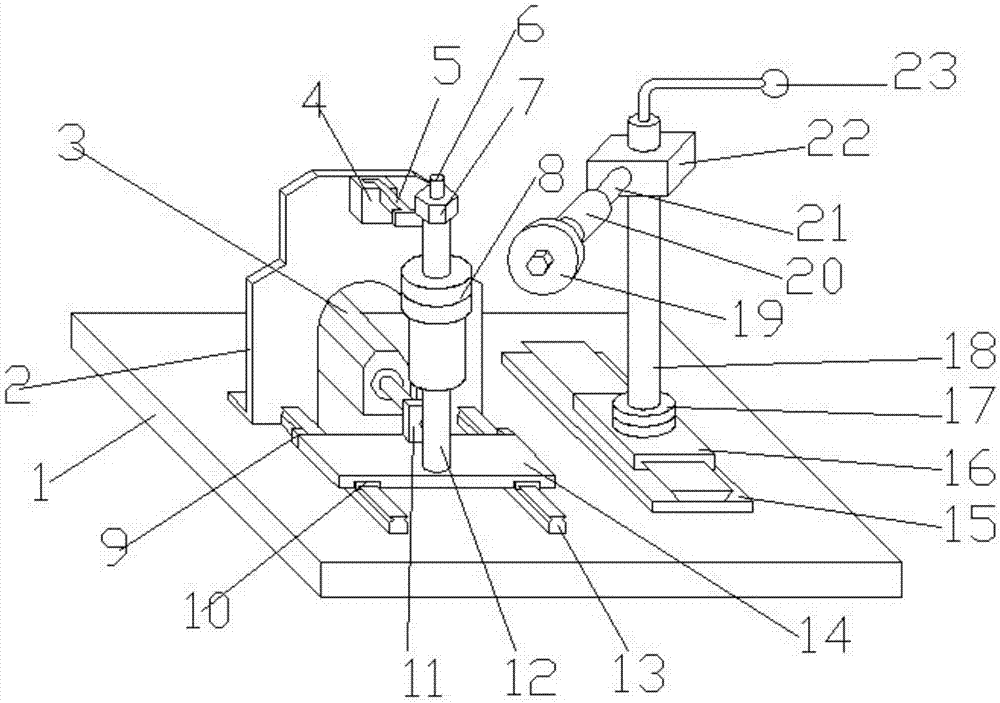

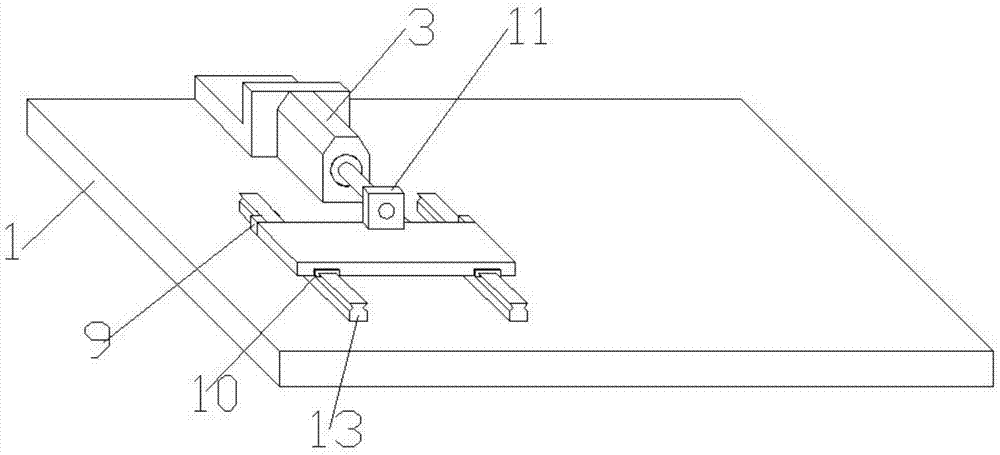

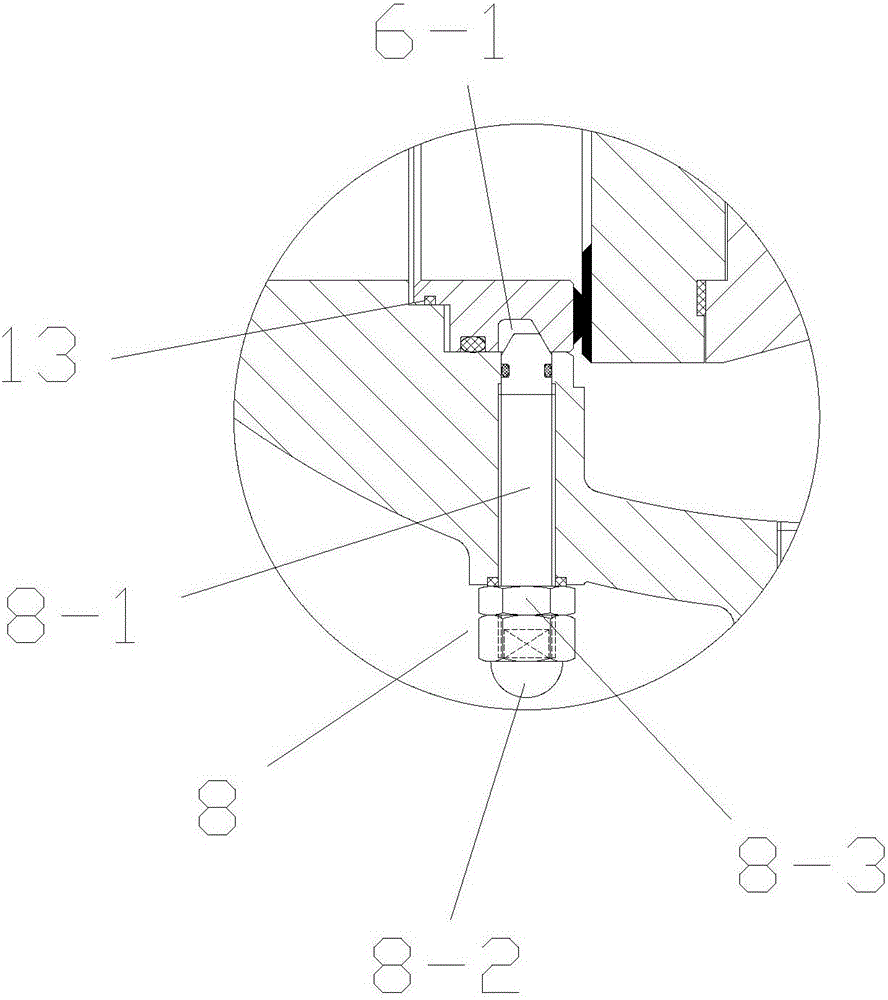

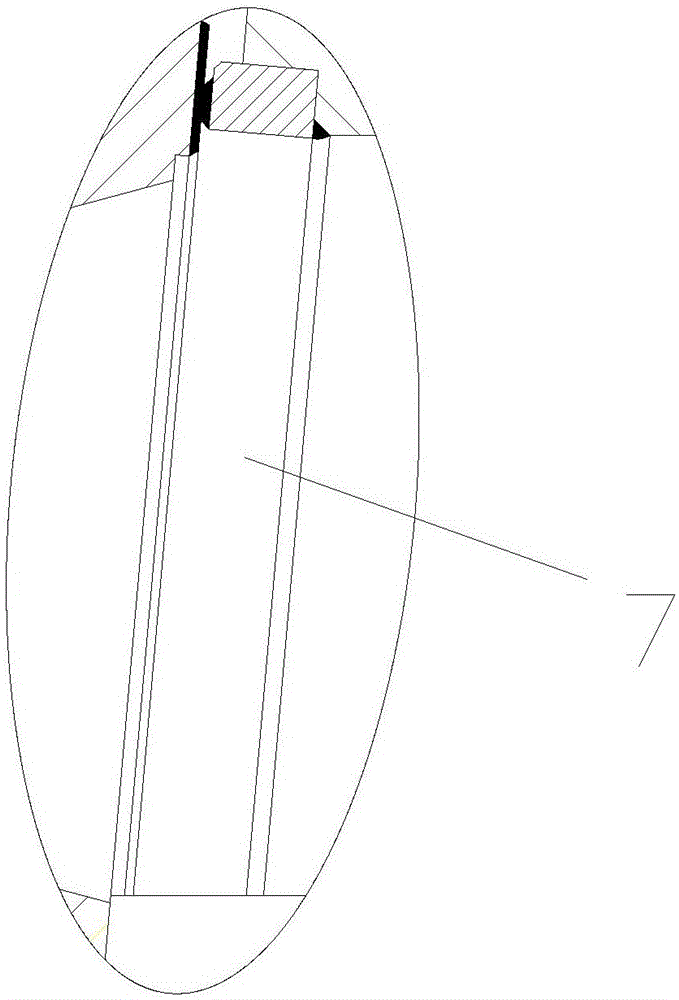

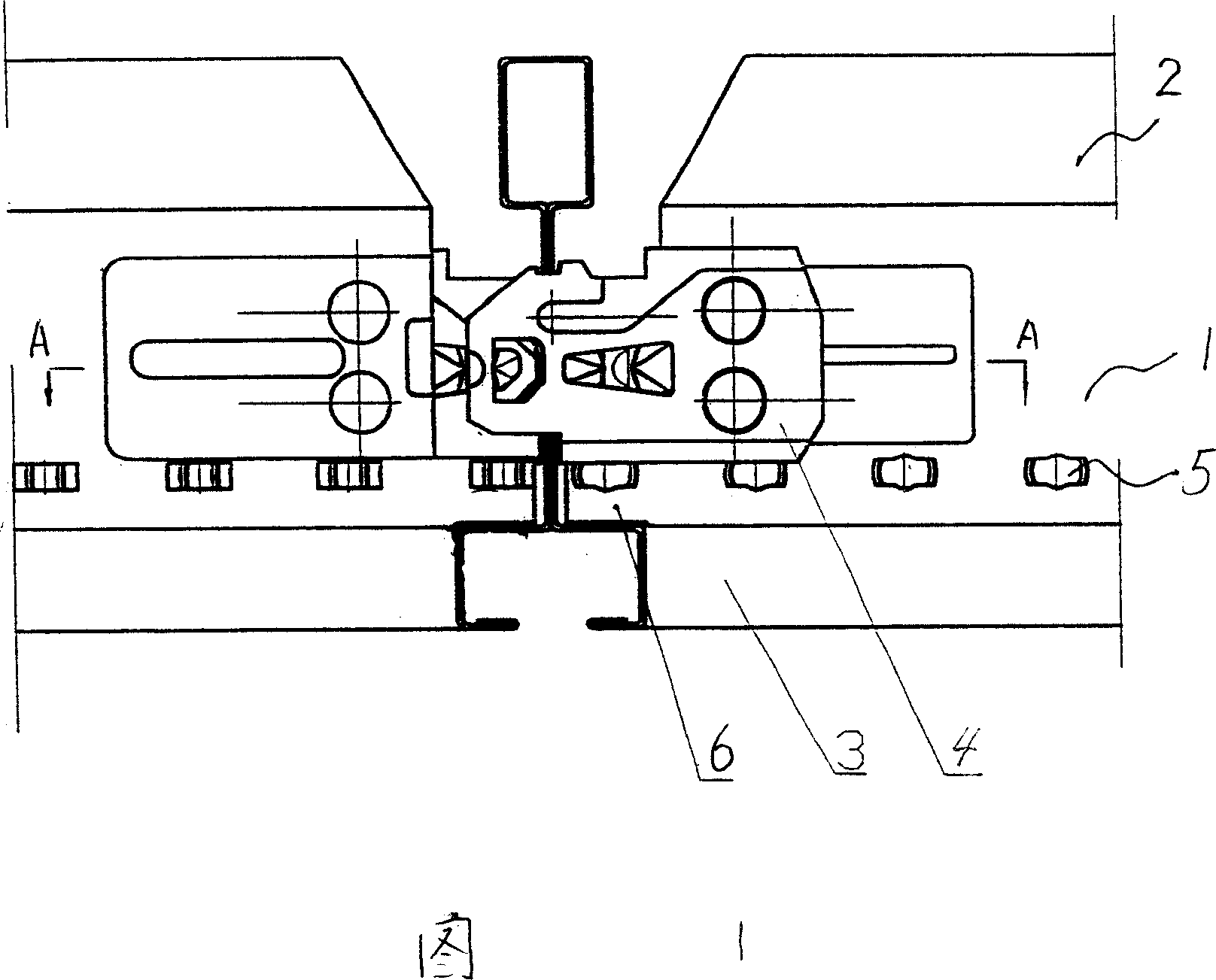

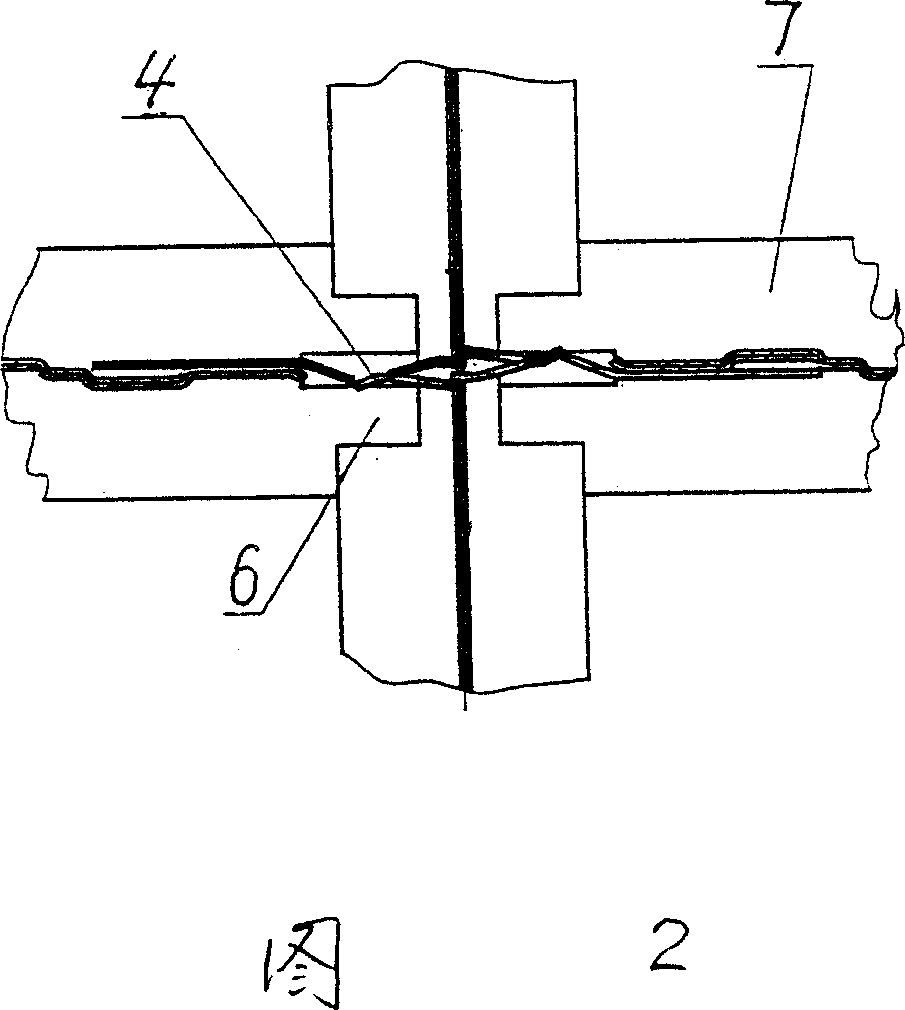

Mechanical gear machining device and using method thereof

InactiveCN105436627AReasonable designWill not affect the installationGear-cutting machinesGear teethEngineeringMachining

The invention discloses a mechanical gear machining device which comprises an installation plate, a supporting plate, a horizontal air cylinder, a clamping groove, a brush, a supporting column, a fixing nut, a clamping seat, limiting blocks, a sliding groove, a connection block, a vertical air cylinder, sliding rails, a sliding table, a guide rail, a sliding seat, a rotary table, a fixed column, a tool, a motor, an adjusting column, an installation block and an operation handle. The mechanical gear machining device has the beneficial effects that gear chamfering, tooth crest chamfering and the like can be conducted in a multi-angle mode; the sliding table can slide on the sliding rails under the traction of the horizontal air cylinder, and the tool can conduct multi-face machining on a gear conveniently during machining; the two rubber limiting blocks are fixed to the side edges, close to the supporting plate, of the sliding table, so that the sliding table is prevented from knocking into the supporting plate during movement; the brush is a wire brush and can be detached freely from the interior of the clamping groove, and deburring treatment can be conducted on the gear through the wire brush; the position of the installation block can be adjusted up and down on the fixed column, and specific adjustment can be conducted on gears of different specifications.

Owner:CHONGQING JIANGJIN HUAMAO MACHINERY CO LTD

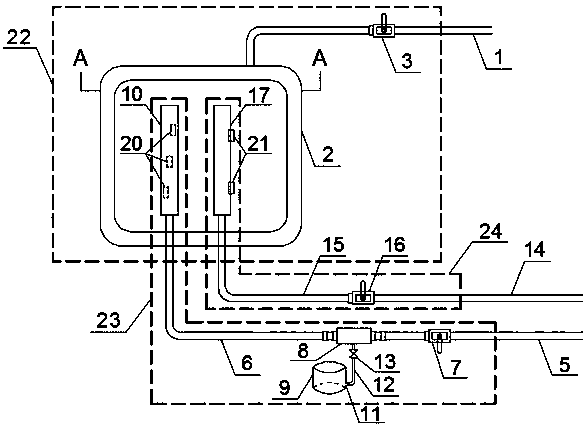

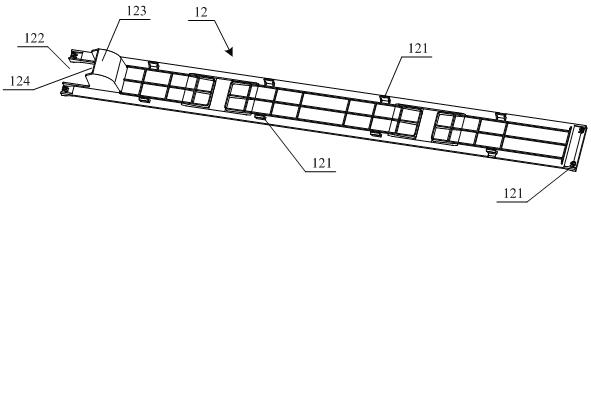

Belt conveyor transfer point closed dust controlling and removing system and dust removing method

ActiveCN107128645APrevent escapeImprove dust collection efficiencyConveyorsDust removalAdhesiveComputer module

The invention discloses a belt conveyor transfer point closed dust controlling and dust removing system. The dust removing system comprises a closed dust controlling module, a dust adhesive dust suppression module and an atomized dust settling module, wherein the dust adhesive dust suppression module and the atomized dust settling module are located below the closed dust controlling module. The closed dust controlling module comprises an annular dust retardation air curtain generator connected with a pressure ventilation pipe. The dust adhesive dust suppression module comprises a dust adhesive solution transmission and distribution pipe connected with a water supply pipe I. The atomized dust settling module comprises a pressure water pipe connected with a water supply pipe II. In addition, the invention provides a method for conducting dust removing through the belt conveyor transfer point closed dust controlling and removing system. By the adoption of the belt conveyor transfer point closed dust controlling and removing system and the dust removing method, the problem that dust is diffused at a transfer point is solved, the dust removing efficiency is improved, influences on operation of a belt at the transfer point and inspection of workers are avoided, the situation that a dust generation area is disturbed by the external environment is avoided, and the dust generating amount can be reduced fundamentally.

Owner:CHINA UNIV OF MINING & TECH

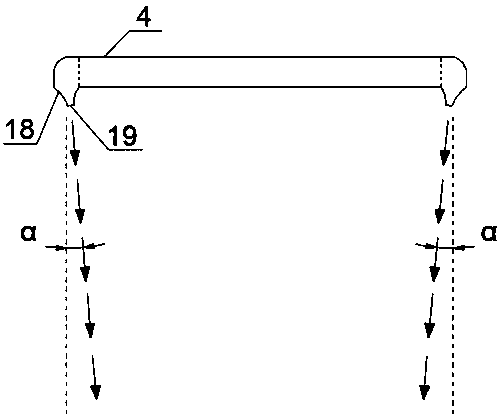

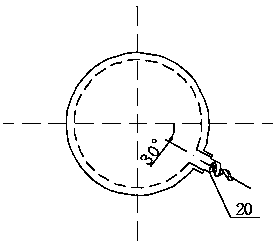

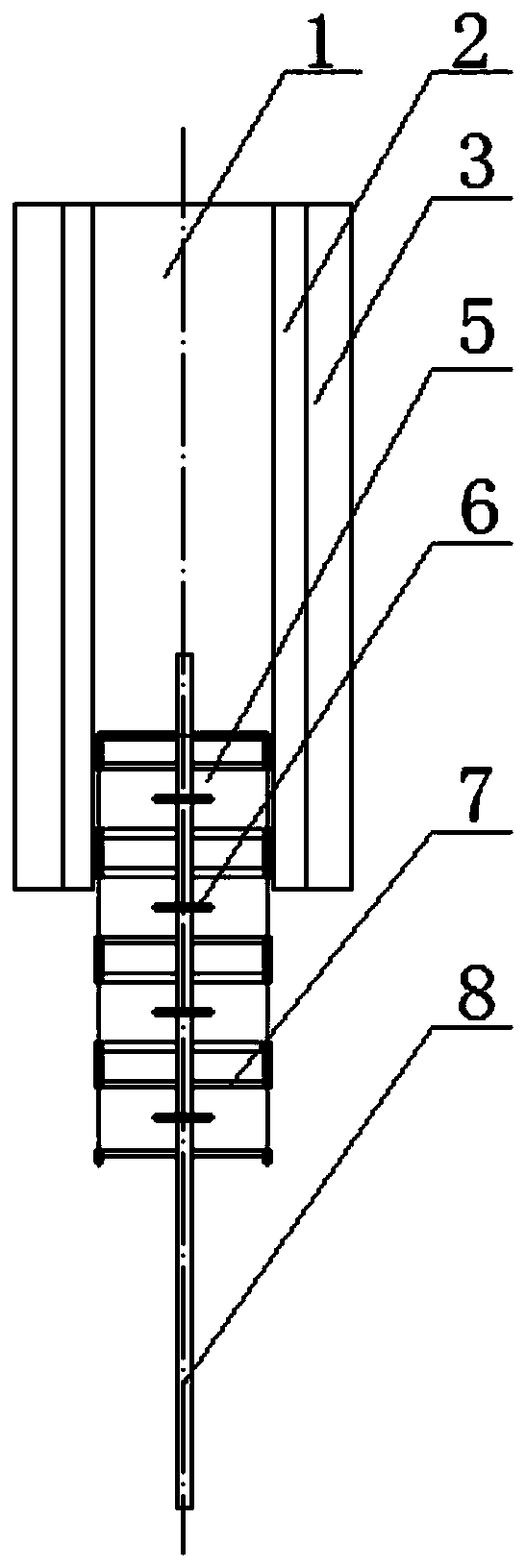

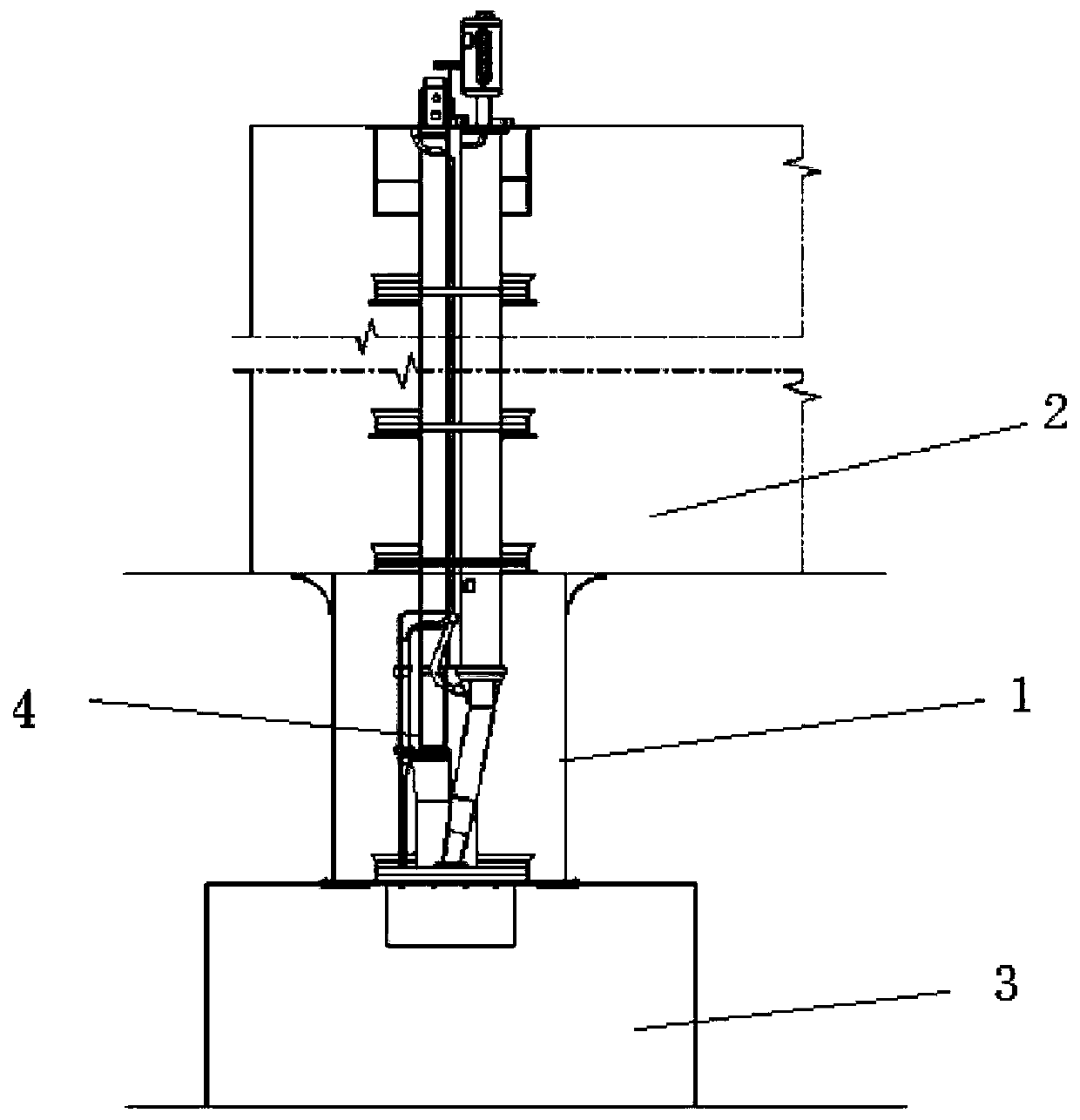

Method and device for inhibiting size of austenite grains at corners of continuous casting slab

InactiveCN110860662AImprove Narrow Face QualityPromoting disperse distribution precipitationAustenite grainNarrow face

The invention discloses a method and device for inhibiting size of austenite grains at corners of a continuous casting slab, and belongs to the technical field of metallurgical continuous casting. Thedevice comprises a wide-face copper plate fixed to a wide-face supporting plate and a narrow-face copper plate fixed to a narrow-face supporting plate, wherein the upper end face of the narrow-face copper plate is flush with the upper end face of the wide-face copper plate; the lower end face of the narrow-face copper plate is 100-300mm shorter than the lower end face of the wide-face copper plate; foot roller supports are symmetrically fixed to the lower end face of the narrow-face supporting plate; foot rollers are symmetrically arranged on the foot roller supports; the inner roller face formed by the foot rollers positioned on one side and the inner wall of the narrow-face copper plate are positioned on the same plane; a spraying rod is fixed to the foot roller supports through spraying rod supports; and one end of a spraying branch pipe is fixed to the spraying rod and communicates with an inner cavity of the spraying rod, and a nozzle is mounted at the other end of the spraying branch pipe. The heat transfer condition is improved, the cooling rate is increased, surface grain refinement and dispersion distribution and precipitation of precipitates in crystals are effectively promoted, and the quality of the narrow face of the casting slab is improved.

Owner:MAANSHAN IRON & STEEL CO LTD

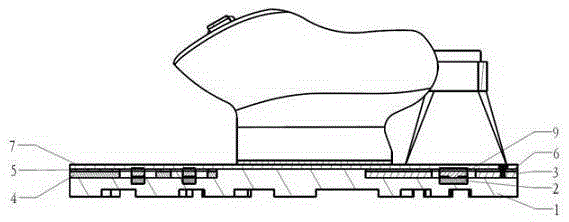

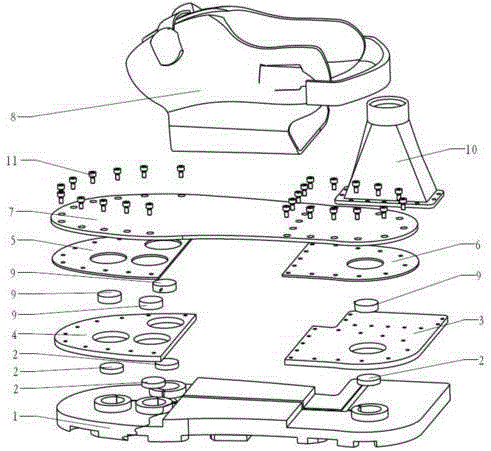

Wearable foot pressure acquisition device

InactiveCN105249970AEasy to collectEasy to installDiagnostic recording/measuringSensorsEngineeringPressure sensor

The invention discloses a wearable foot pressure acquisition device. The wearable foot pressure acquisition device comprises four pressure sensors (9), a foot bottom layer (1), a foot top layer (7), a front bottom layer (4), a rear bottom layer (3), a front top layer (5), a rear top layer (6), a strap (8), a support (10), gaskets (2) and bolts (11). When a user is in the moving process, the foot of the user compresses the foot bottom layer (1) and the foot top layer (7) to extrude the pressure sensors (9), and the four pressure sensors (9) collect pressure signals of different parts of the foot in the walking process of the user; acquisition accuracy of the pressure sensors (9) is guaranteed through the elasticity of rubber of the foot top layer (7) and the foot bottom layer (1), and discomfort caused by the pressure sensors (9) to the foot is reduced. The wearable foot pressure acquisition device is convenient to wear, requirements of different users can be met, and the wearable foot pressure acquisition device can adapt to deformation of the foot in the walking process of the user.

Owner:BEIJING MECHANICAL EQUIP INST

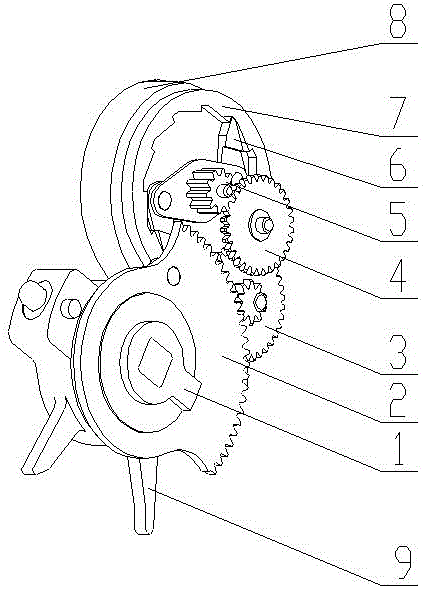

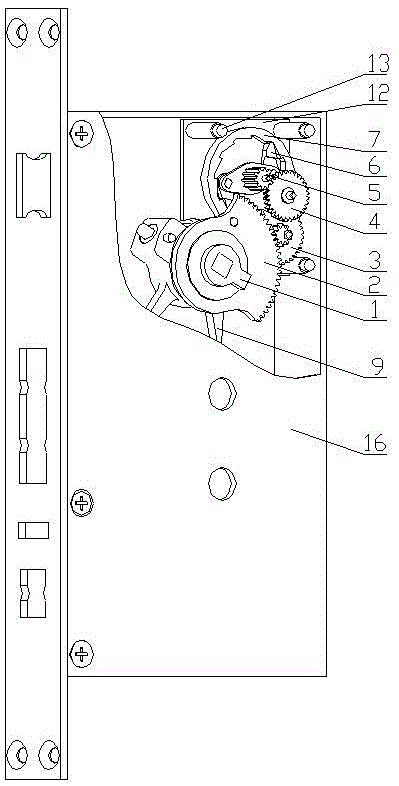

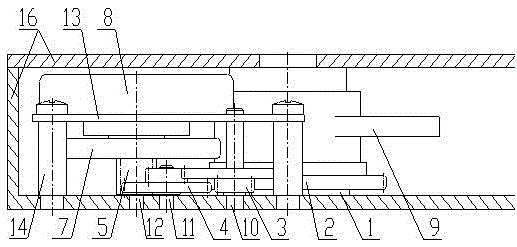

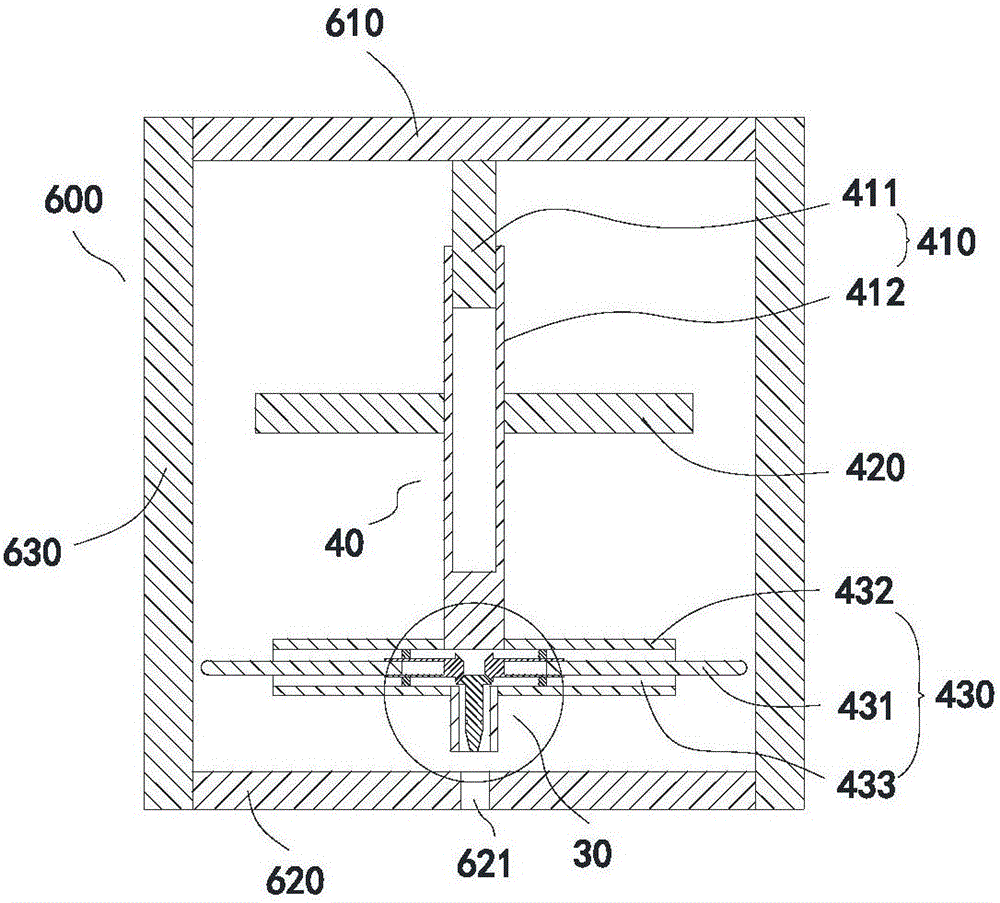

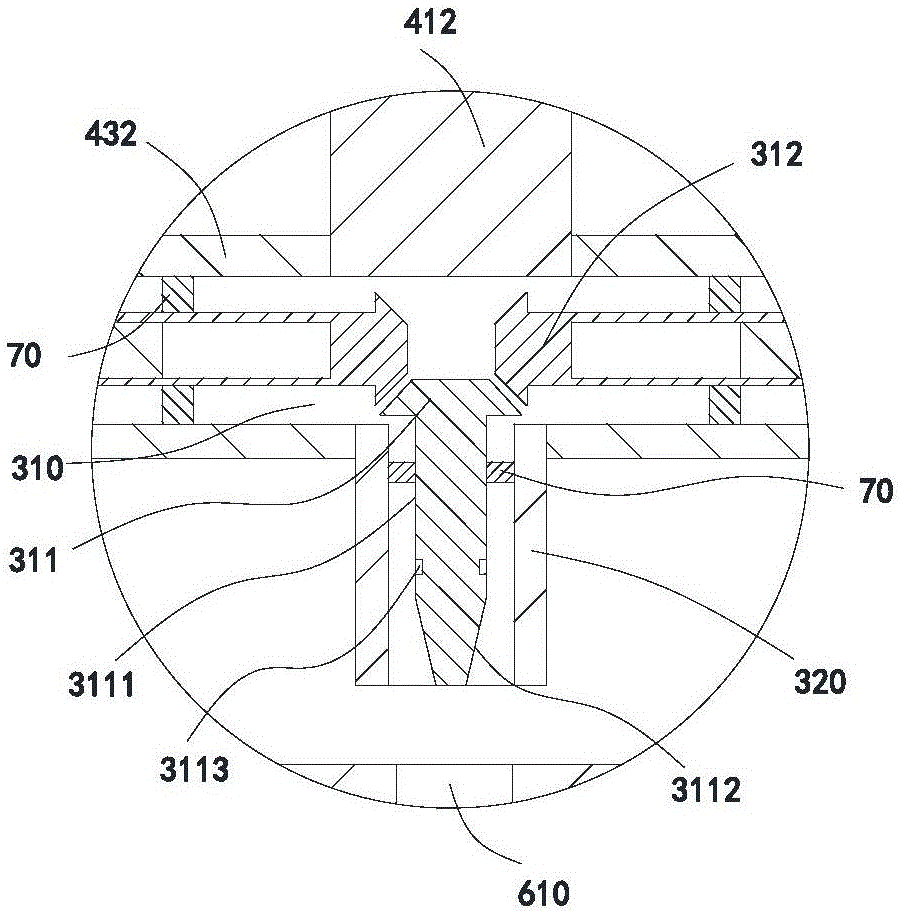

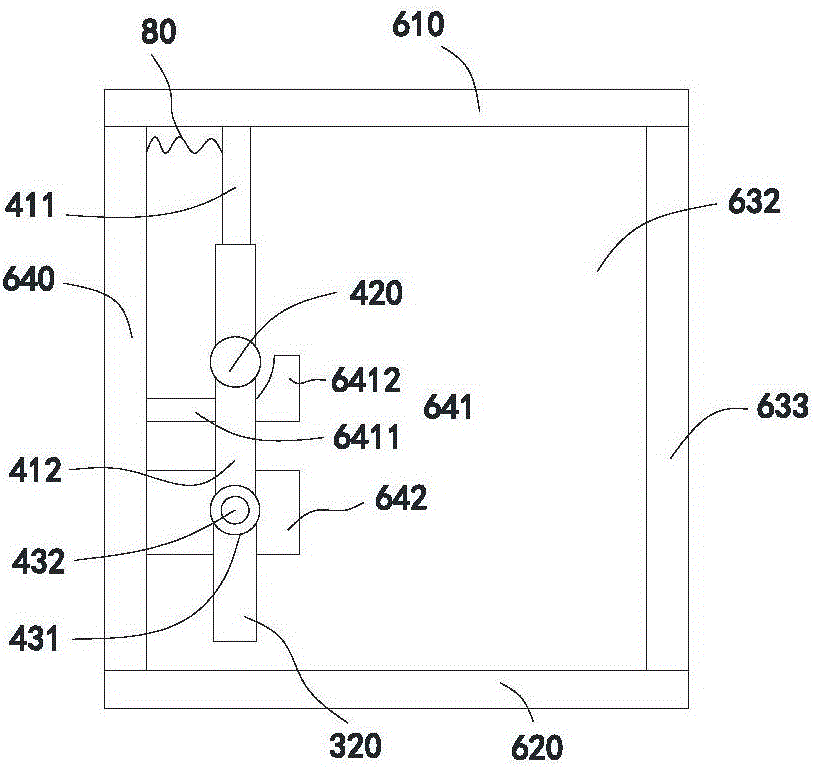

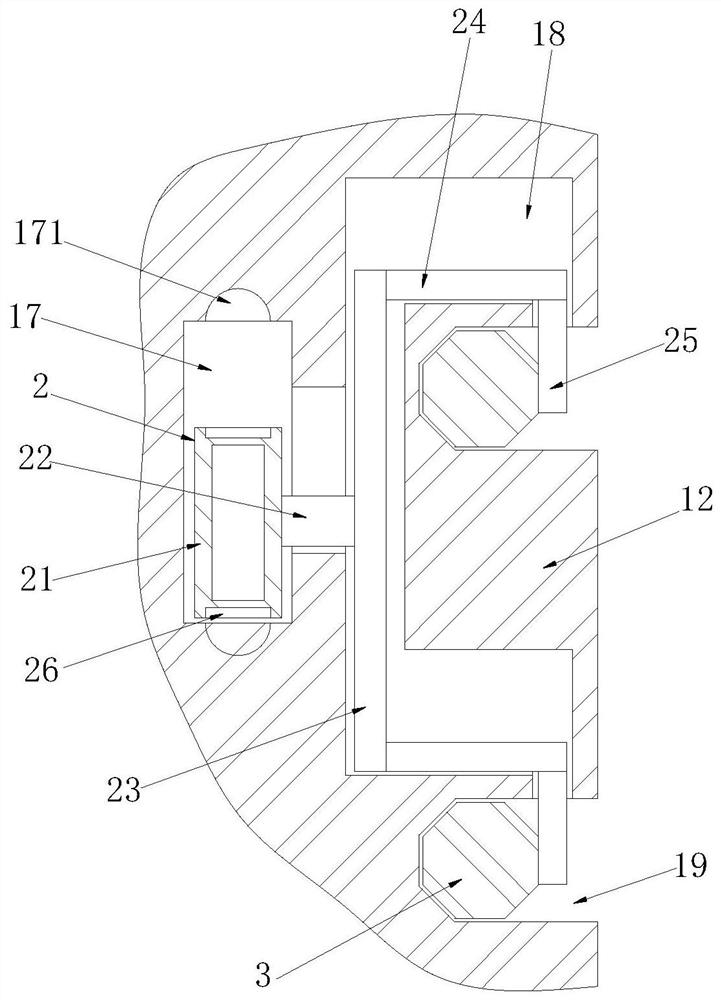

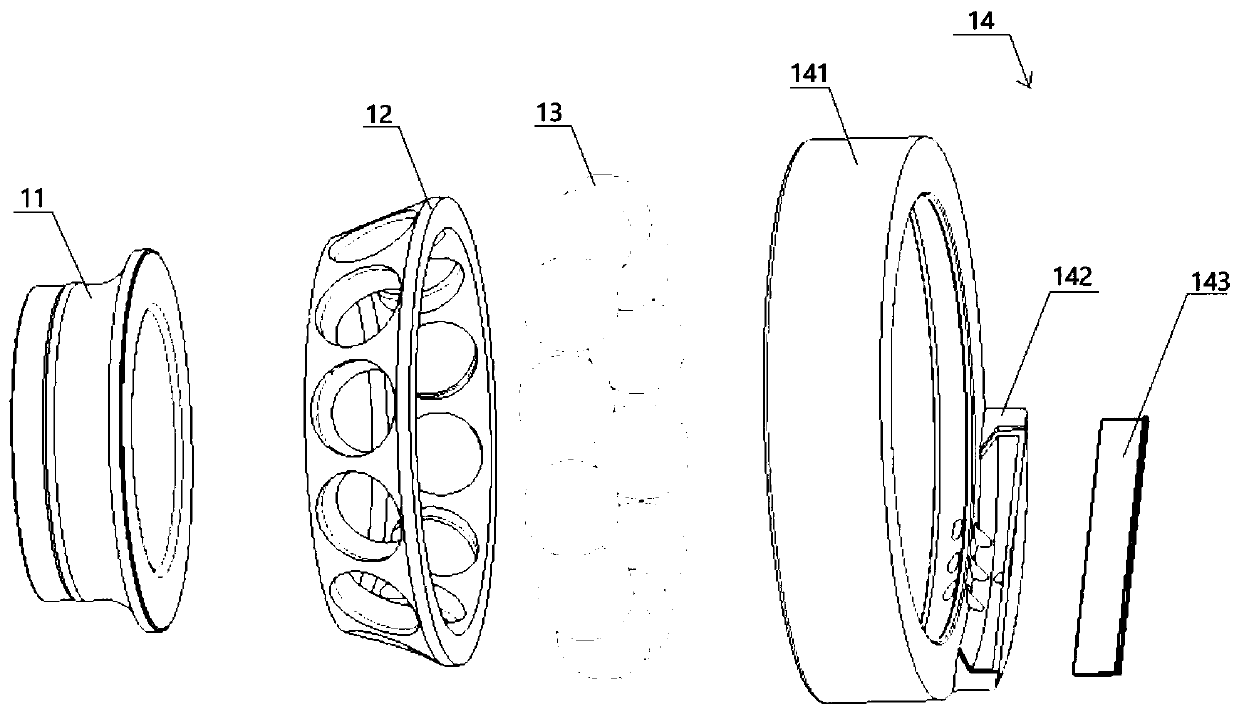

Power generation device in lock body of door lock

PendingCN105649899ACompact structureSmall sizeFrom muscle energyNon-mechanical controlsClutchElectric generator

A power generation device in a lock body of a door lock is characterized by comprising an input shaft, an input gear, a gearing-up mechanism, a micro generator, a clutch rotating shaft component and a lock body casing. Except the lock body casing, other parts are installed in the lock body, a sector gear is installed on the input shaft to rotate together with the input shaft, the input shaft and an outer door handle are coaxial, and the input shaft is driven by the outer door handle. An outside mechanism controls connection relations of the clutch rotating shaft component and the input shaft by controlling a clutch pin on the clutch rotating shaft component. When a door does not need to be opened, the outer door handle drives the input shaft to rotate, drives the generator is generate electricity and does not drive the clutch rotating shaft component to rotate. When the door needs to be opened, the outer door handle drives the input shaft to rotate, drives the generator to generate electricity and drives the clutch rotating shaft component to rotate.

Owner:北京摇光智能科技有限公司

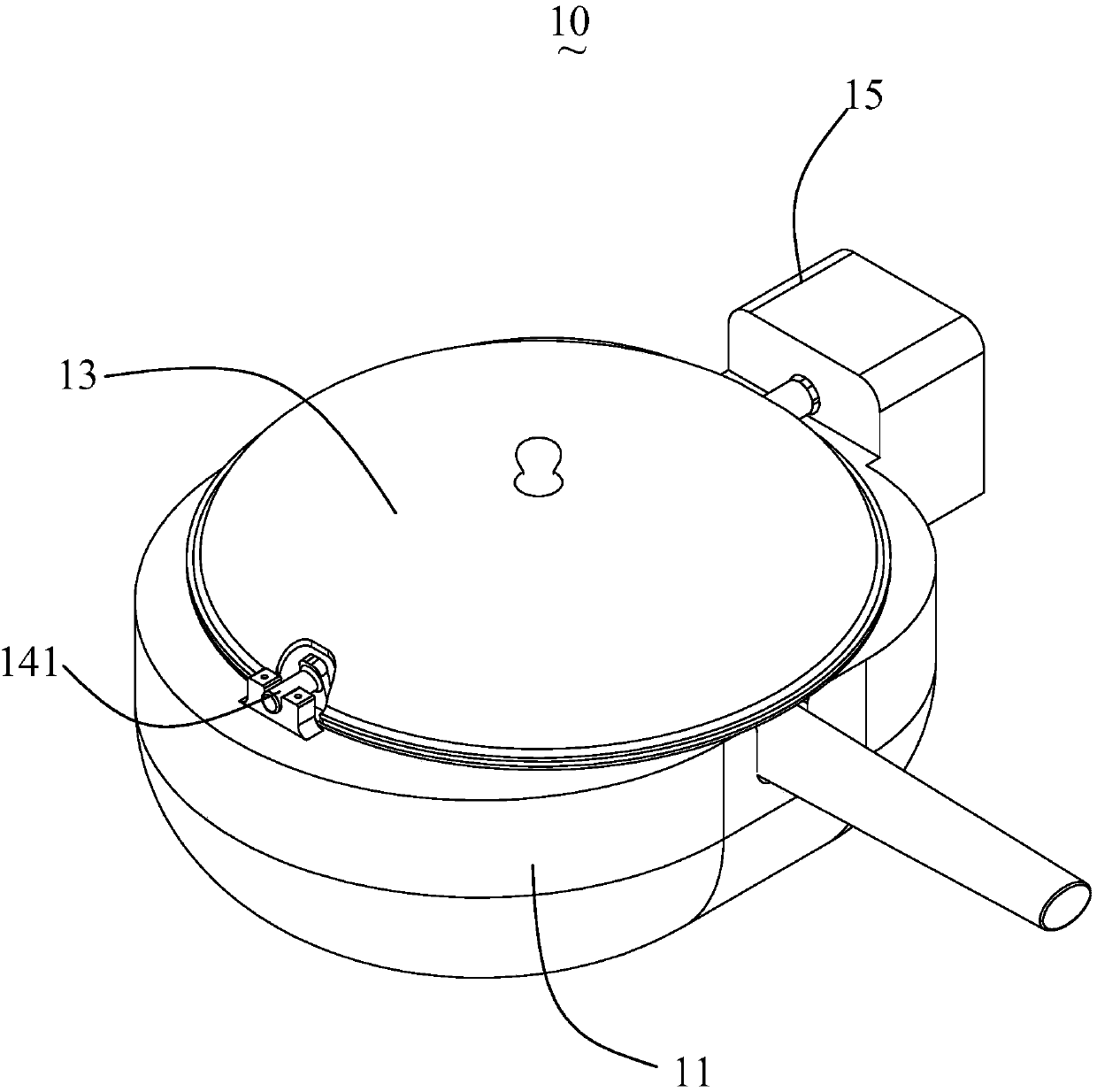

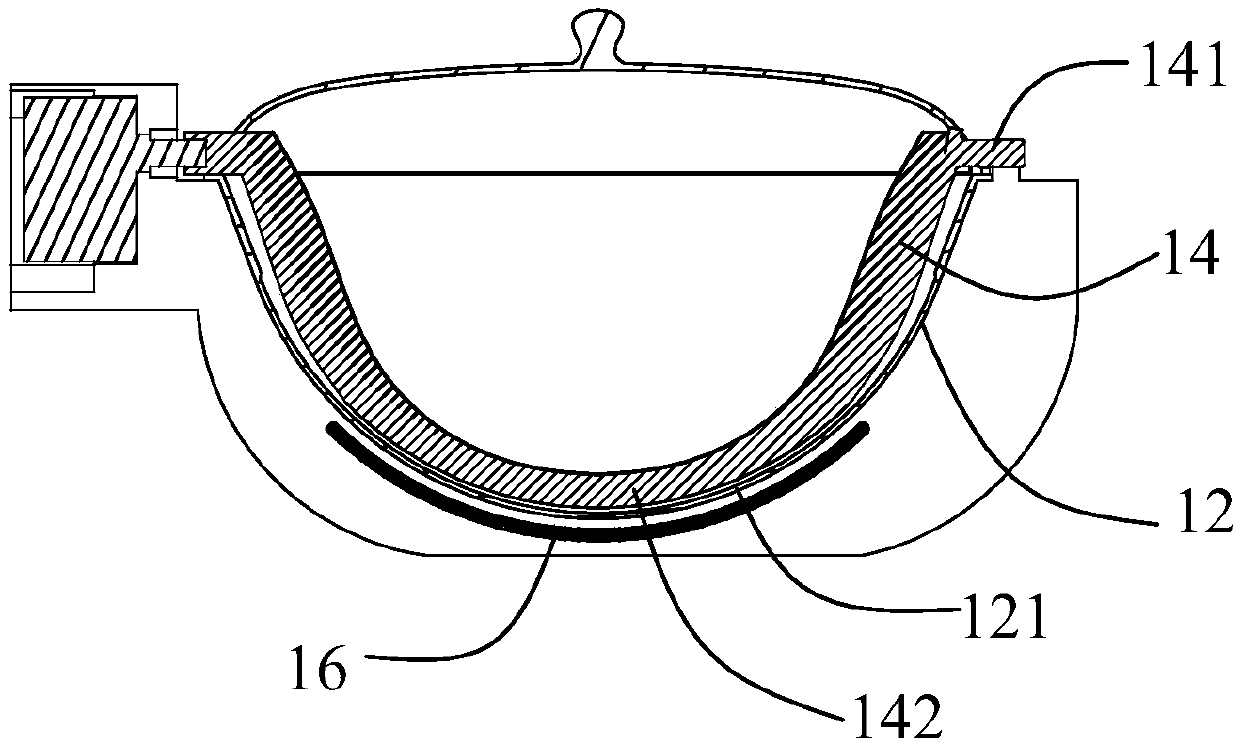

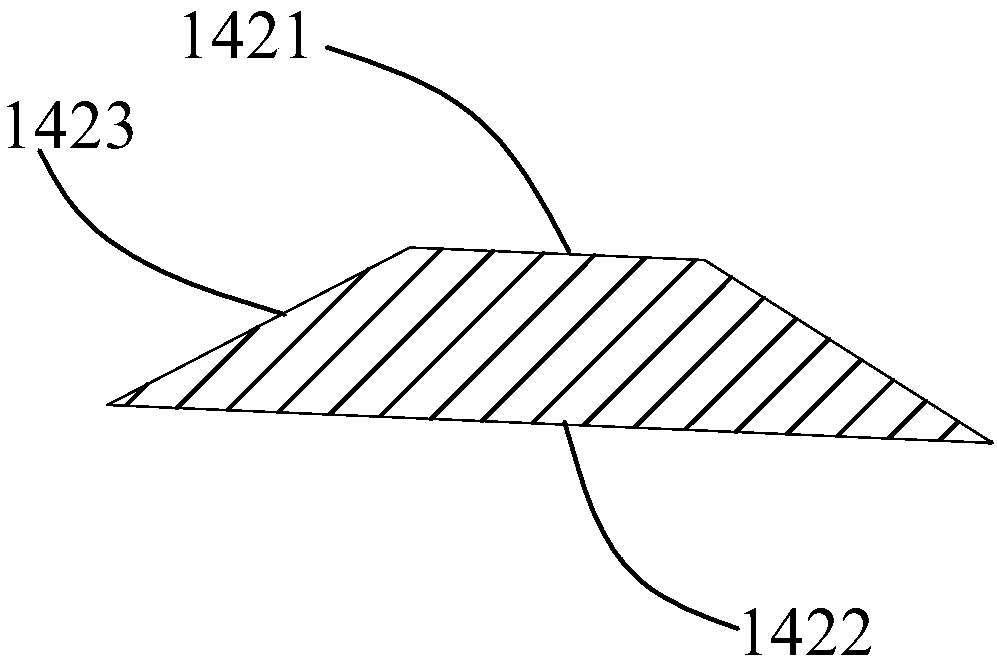

Cooking method implemented by cooking utensil

The invention relates to a cooking method implemented by a cooking utensil. The cooking utensil comprises a pot, a pot lid, a stirring paddle and a driving mechanism. The stirring paddle can be drivenby the driving mechanism to move, and is arranged in the pot in such a manner that the stirring paddle can transversely swing; the stirring paddle at least comprises a cambered section in the lengthdirection, the inner wall of the pot comprises a cambered surface, and the cambered surface adapts to the shape of the cambered section when the cambered section swings. The cooking method at least includes a stir-frying phase. The stirring paddle can be driven by the driving mechanism to swing back and forth in the pot in the stir-frying phase, food materials can be scooped up by a turner formedby a bottom surface and side surfaces of the cambered section, can be turned over and can fall back, and swing angles and the swing frequencies of the stirring paddle can be adaptively adjusted according to the characteristics of the food materials, the quantities of the food materials and cooking modes. Compared with the prior art, the cooking method has the advantages that upper and lower layersof food materials can be continuously repositioned to be repeatedly stir-fried, the swing angles and the swing frequencies of the stirring paddle can be adaptively adjusted according to the characteristics of the food materials, the quantities of the food materials and the cooking modes, accordingly, the food materials, spices and the like can be uniformly mixed with one another, and the food materials have good mouth feel.

Owner:JOYOUNG CO LTD

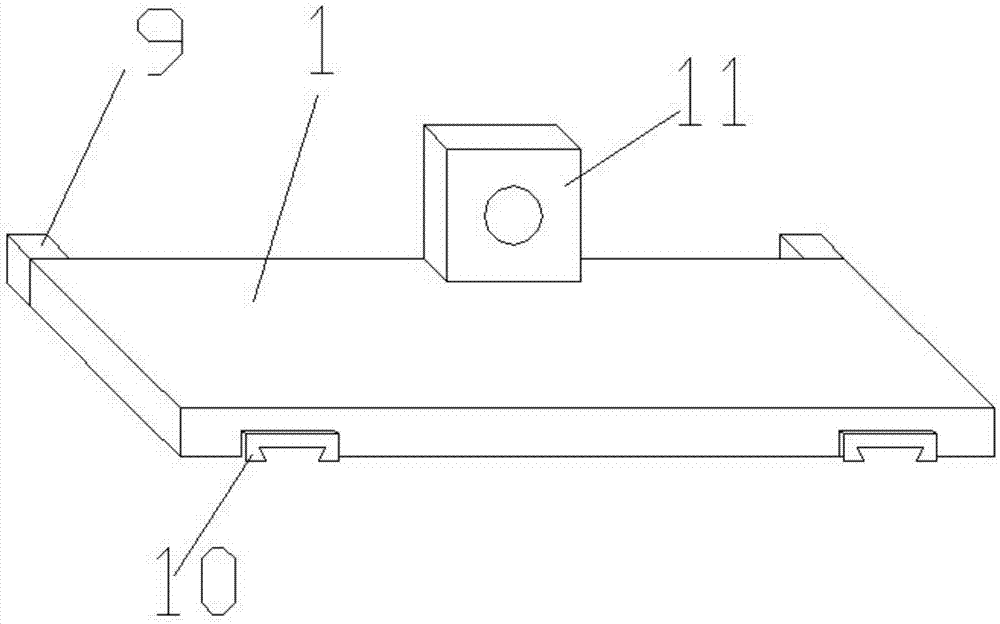

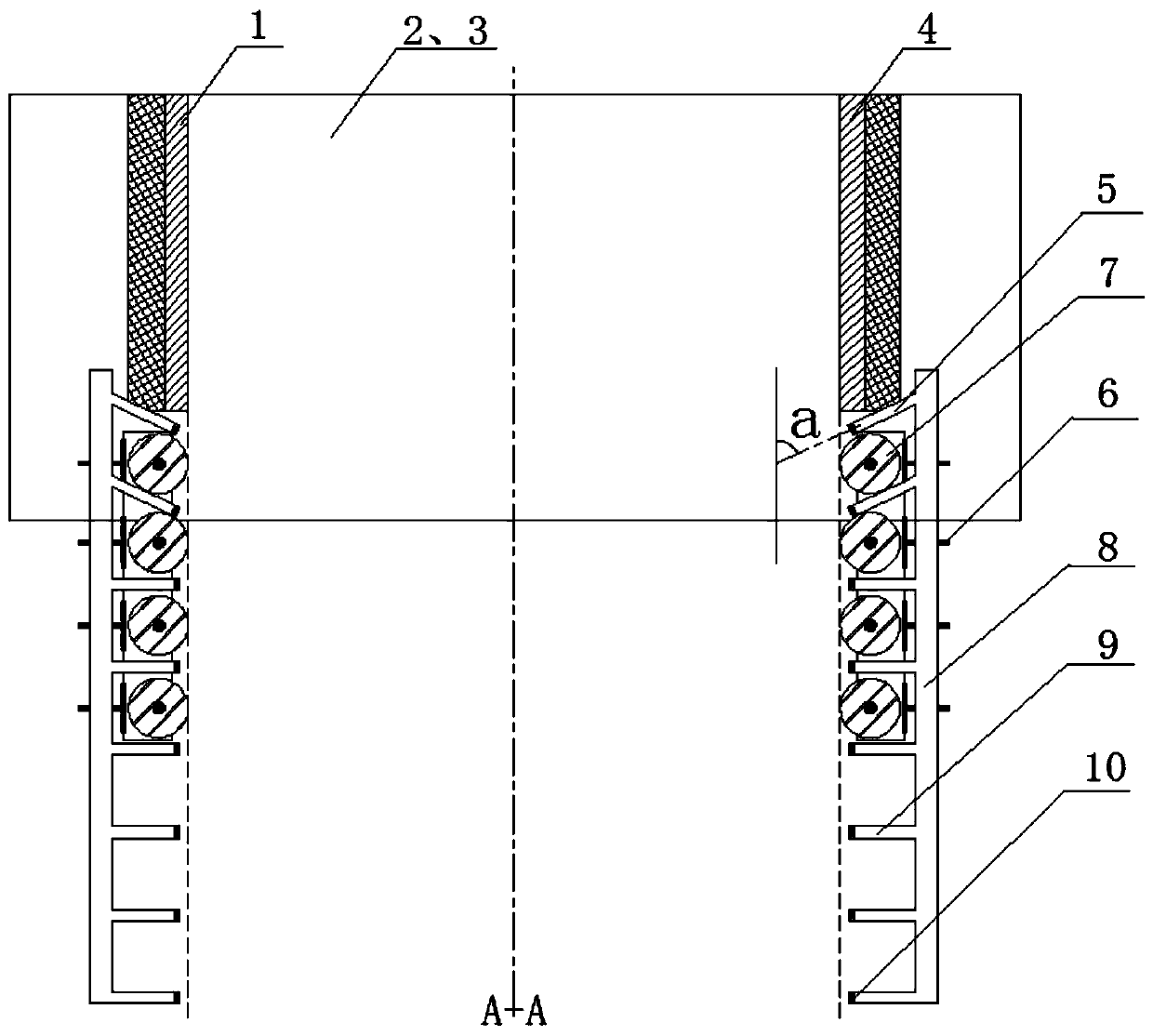

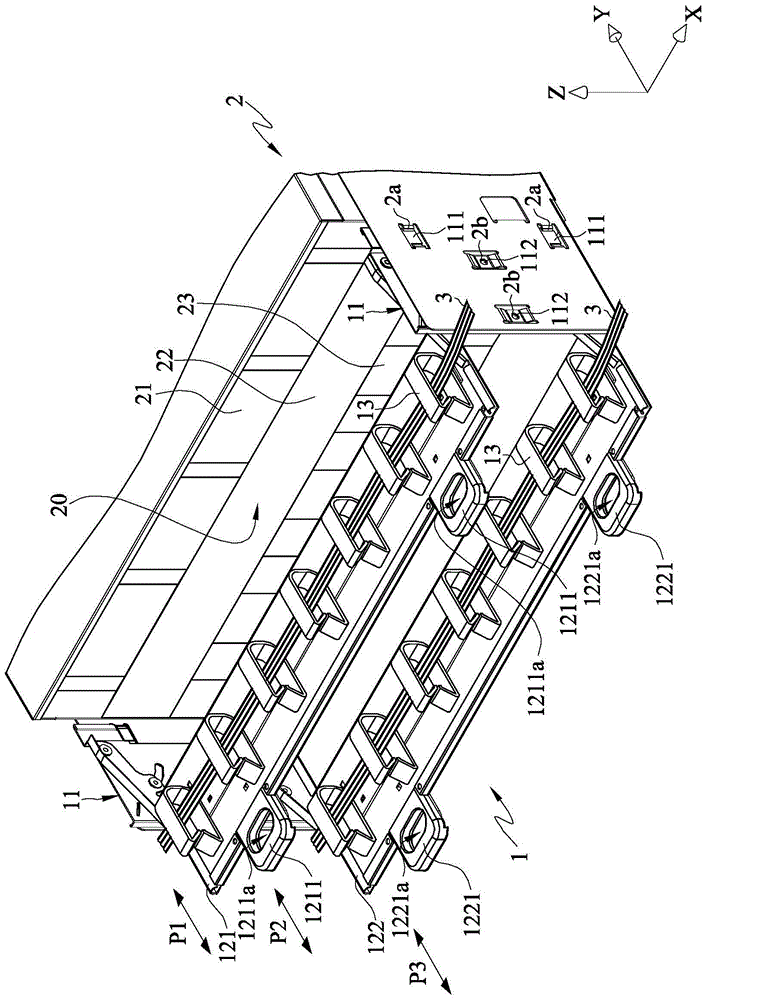

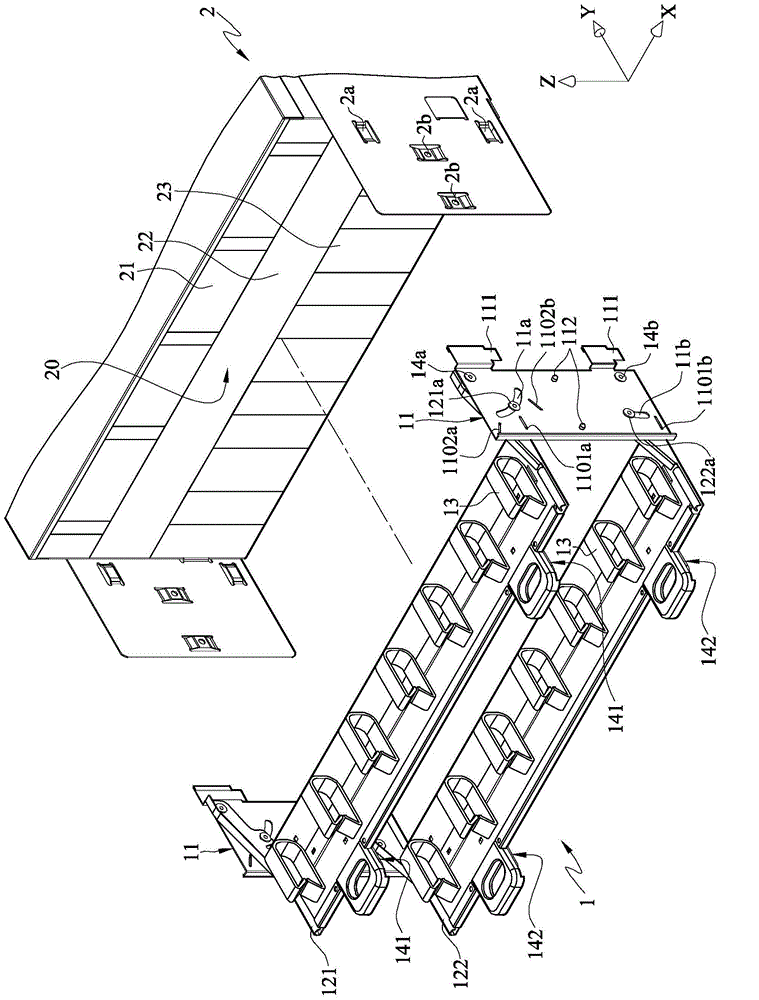

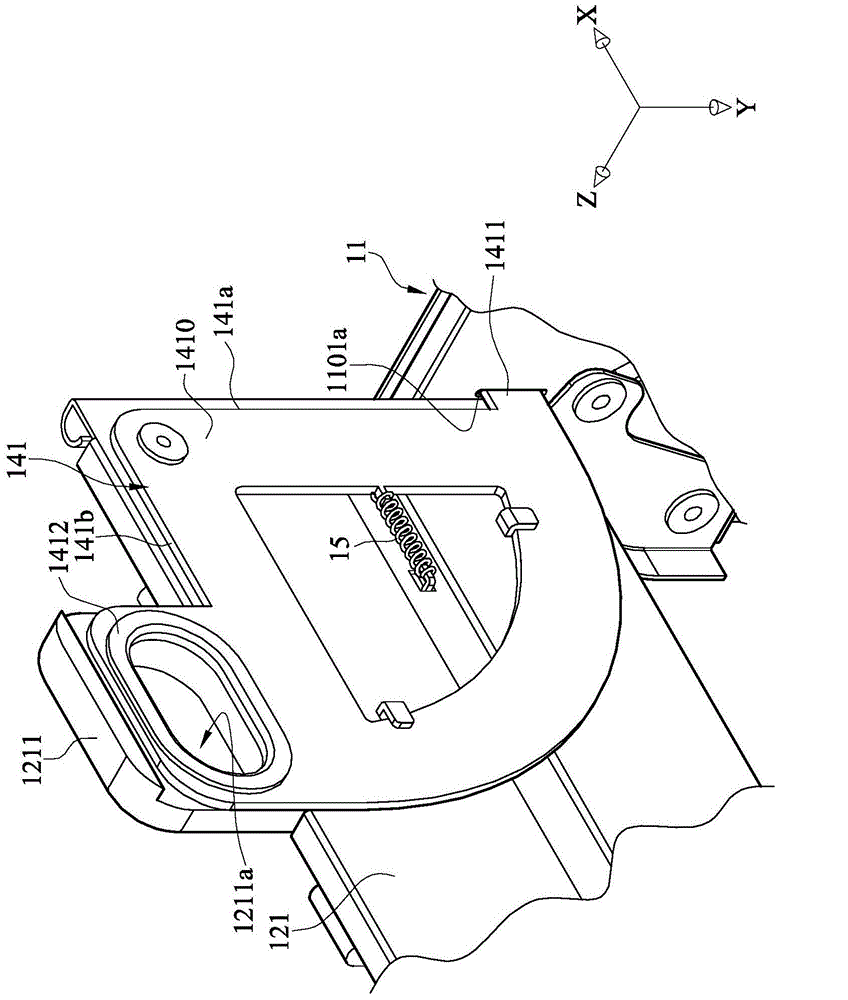

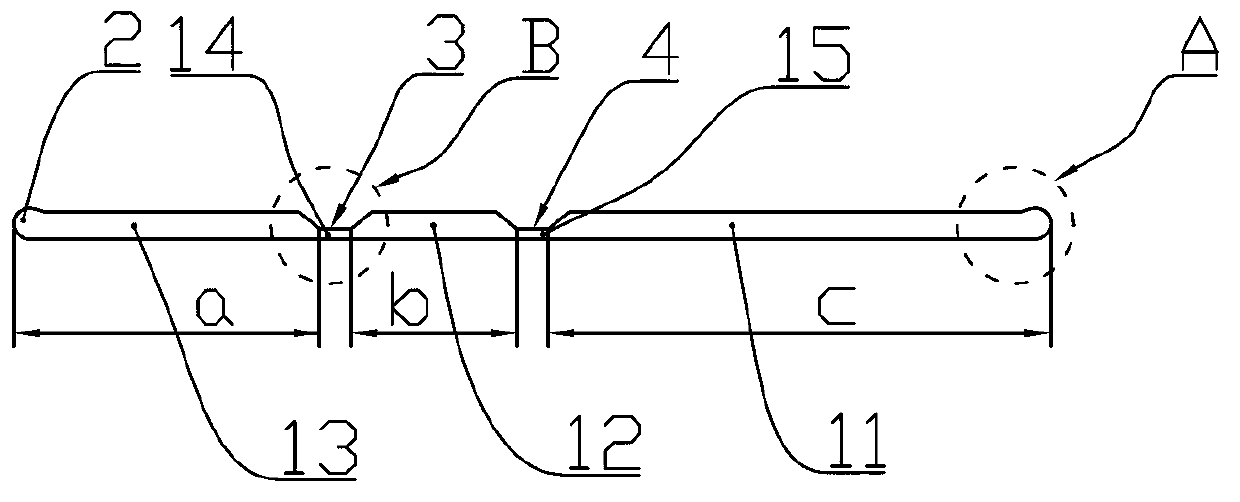

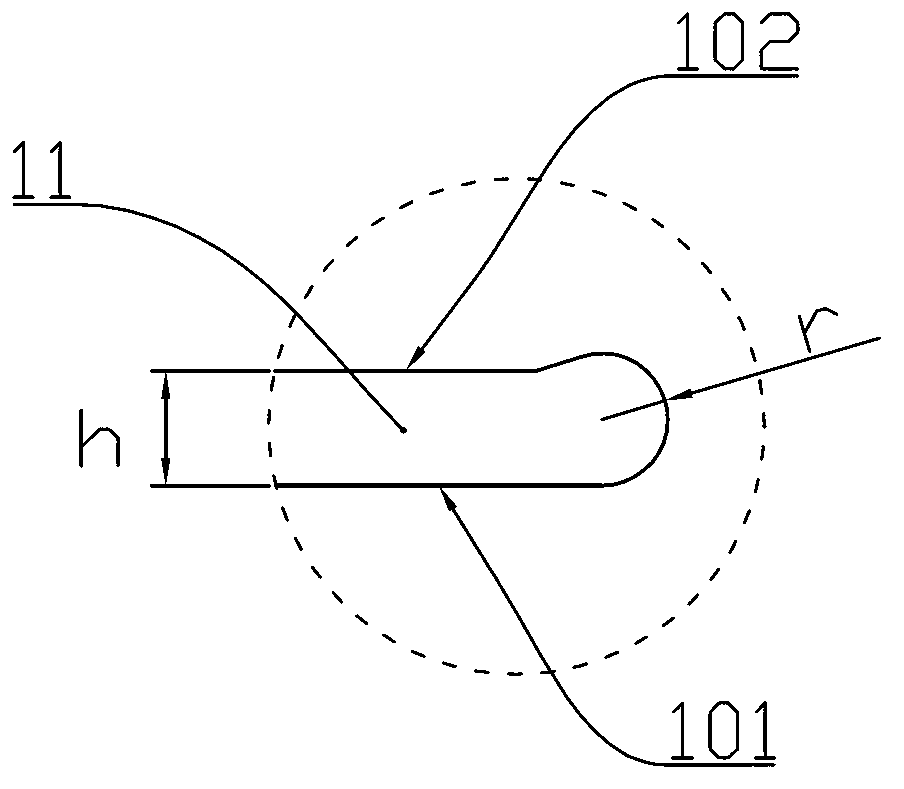

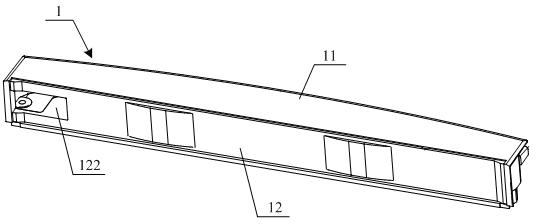

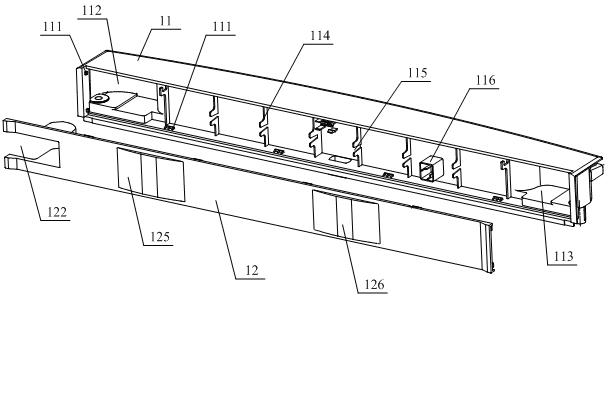

Line arranging structure

InactiveCN104661472AWill not affect the installationDoes not affect disassemblyCircuit arrangements on support structuresEngineeringMechanical engineering

The invention relates to a line arranging structure which is assembled on a machine body and is used for arranging a line of the machine body. The machine body is provided with an assembly opening. The assembly opening is used for enabling at least one element to enter and get out of the machine body along at least one mounting path. The line arranging structure comprises a seat body, at least one tray and at least one line arranging clamp. The seat body is mounted in the assembly opening of the machine body. The tray is movably arranged on the seat body and has a first position and a second position relative to the seat body. When the tray is positioned in the first position, the tray blocks the mounting path. When the tray is positioned in the second position, the tray is far away from the mounting path. The line arranging clamp is arranged on the tray and is used for arranging the line.

Owner:INVENTEC PUDONG TECH CORPOARTION +1

Corner line structure

ActiveCN103276878AWill not affect the installationEasy to pack and transportBuilding constructionsEngineeringLine structure

The invention discloses a corner line structure comprising a first wall surface, a second wall surface, a third wall surface, a first folding part and a second folding part. The first wall surface, the first folding part, the second wall surface, the second folding part and the third wall surface are connected in sequence. The three wall surfaces and the two folding parts are integrally formed by extrusion molding. The two folding parts are arranged among the three wall surfaces and can be bent in two directions as required, so that the corner line can be mounted at external or internal corners; the folding parts are bendable, so that the wall surfaces on two sides of the folding parts are tightly connected to walls on two sides of a corner; and even the wall corner is not strictly vertical, mounting is not affected. In addition, the corner line is in a sheet form when not folded, and packaging and transporting are facilitated and deformation rarely occurs.

Owner:ZHEJIANG HUAXIAJIE MACROMOLECULE BUILDING MATERIAL

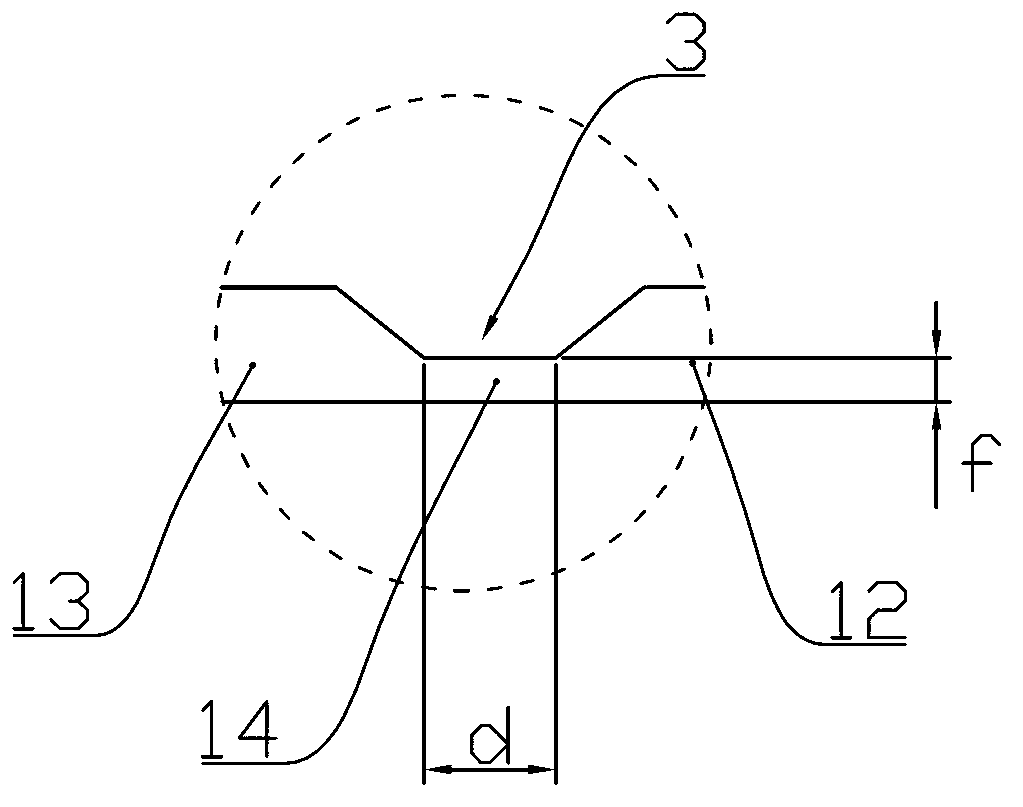

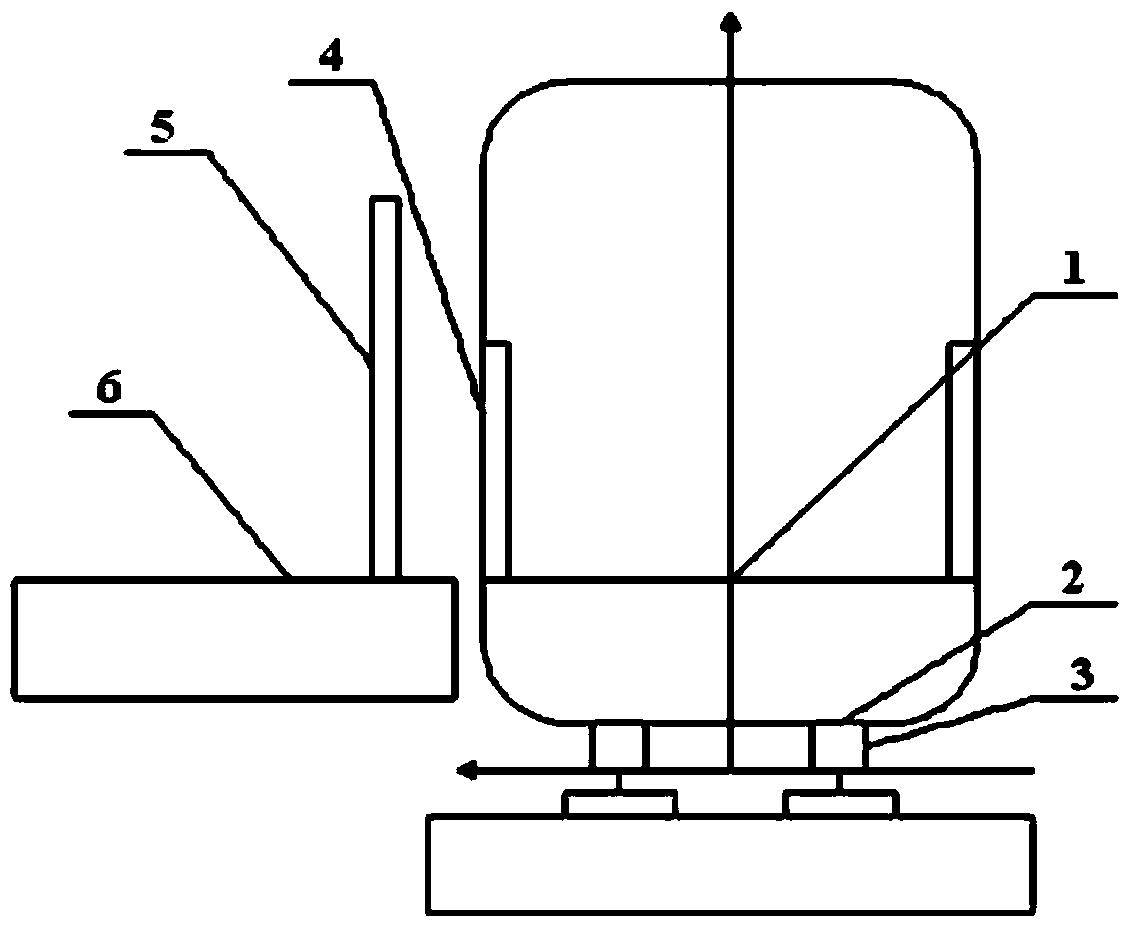

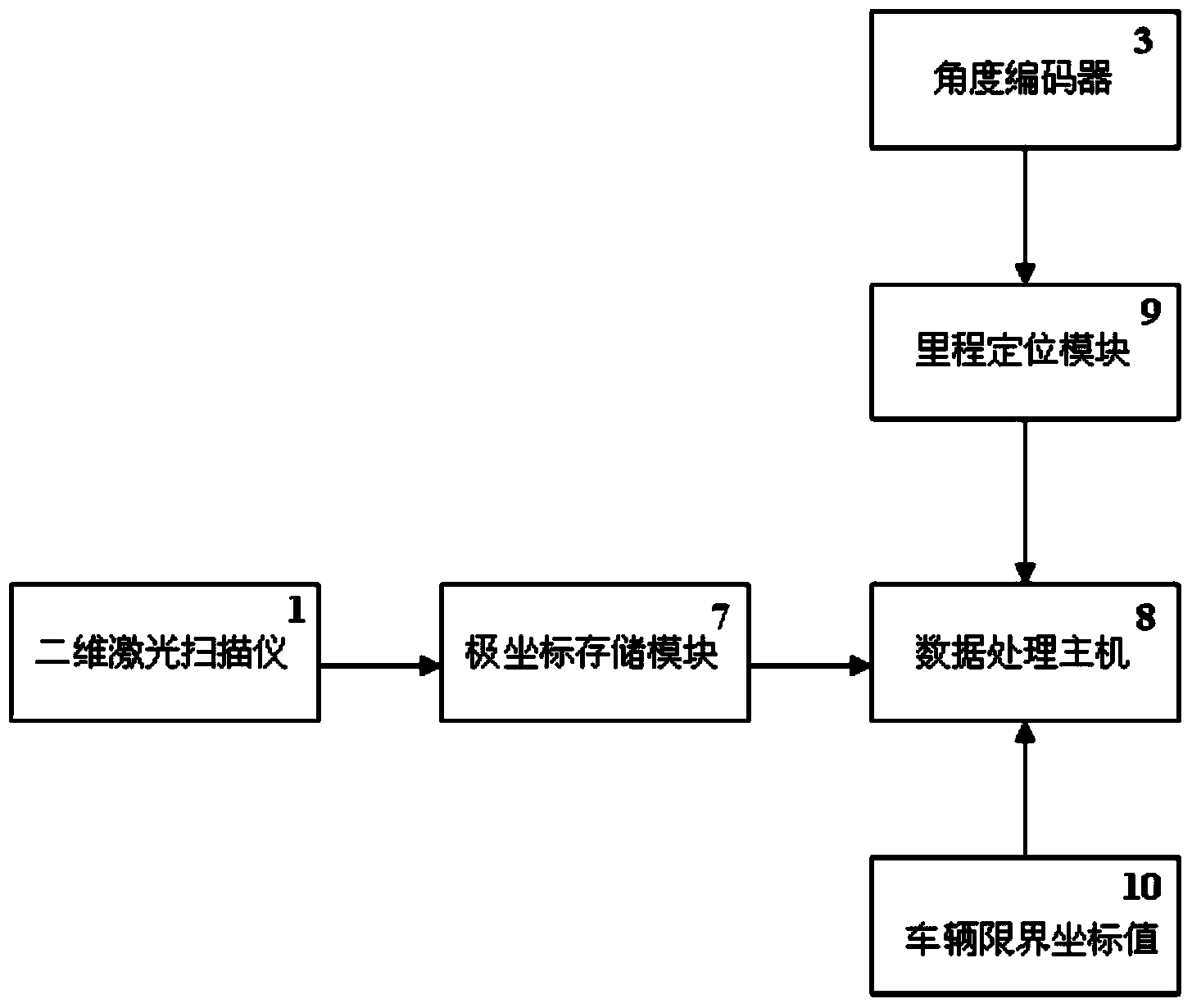

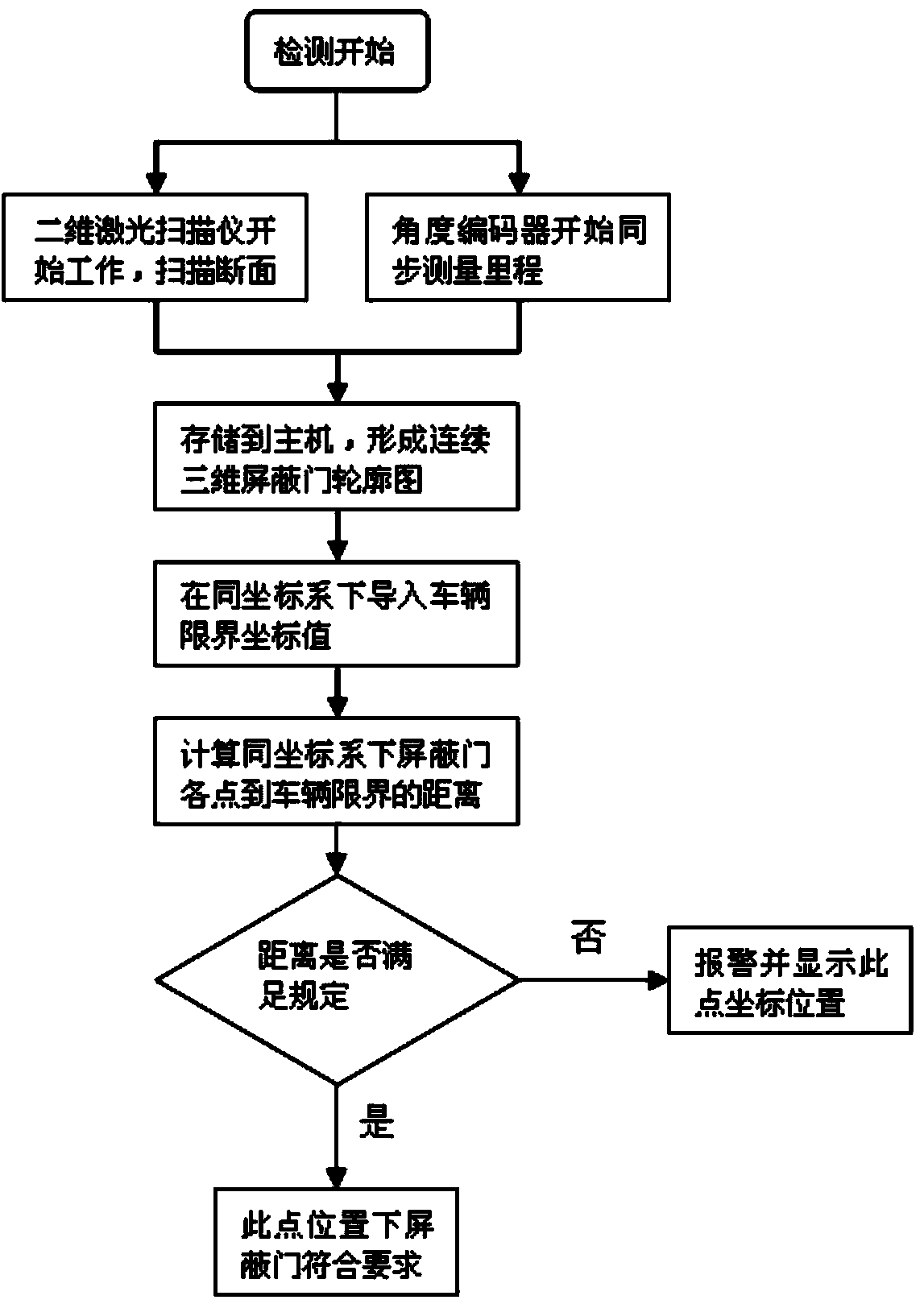

Method for detecting whether distance between subway platform shielded gate and vehicle body is safe

InactiveCN104266598AImprove detection accuracyEasy to maintain and testUsing optical meansCar doorEngineering

The invention discloses a method for detecting whether the distance between a subway platform shielded gate and a vehicle body is safe. According to the method, a two-dimensional laser scanner is installed at the point where the midperpendicular of the rear surface of a railway vehicle intersects with the plane where the bottom edges of vehicle doors are located, an angle encoder is installed on the head of an axle, a polar coordinate storage module, a data processing host and a mileage positioning module are installed in a compartment, spatial three-dimensional coordinates are obtained through processing of the data processing host by means of the distance between the scanner and the shielded gate obtained by the two-dimensional laser scanner and the advancing mileage of the vehicle obtained by the angle encoder and the mileage positioning module, then specified vehicle limit coordinate values are introduced to the same three-dimensional coordinate system, and the actual distance between the vehicle body and the shielded gate is measured and then compared with the specific safety distance so that whether the distance between the shielded gate and the vehicle meets safety requirements can be judged. According to the method, vehicle-mounted dynamic detection is achieved, detection precision is improved, operation is easy, realizing cost is low, and application and popularization are facilitated.

Owner:SHANGHAI UNIV OF ENG SCI

Anti-theft device for instrument at petroleum well head and petroleum exploitation pipeline

The invention provides an anti-theft device for an instrument at a petroleum well head and a petroleum exploitation pipeline and belongs to the field of safety and theft prevention. The device comprises a lock cylinder mechanism, a spring bolt mechanism, a handle and a locking shell. The locking shell comprises a top wall, a bottom wall and a fence. The bottom wall is fixed on a metal tube of the instrument at the petroleum well head, the fence is provided with an opening, a cover plate is arranged at the opening, and the cove plate is rotatably connected to the top wall. The spring bolt mechanism comprises a telescopic rod, a first-level locking rod and a second-level locking rod; the first-level locking rod is connected to the telescopic rod, and the second-level locking rod is connected to the telescopic rod. A first-level locking part and a second-level locking part are arranged on the cover plate. The lock cylinder mechanism has a driving assembly which is in driving connection to the second-level locking rod. The handle comprises a diameter-variable locking end. The anti-theft device for the instrument at the petroleum well head is directly mounted out of the instrument to wrap the instrument, so that not only is use of the instrument not affected, but also the instrument is prevented from being likely to be damaged or stolen; the instrument is safer to use, and the maintenance and replace costs are lowered.

Owner:CHINA PETROLEUM & CHEM CORP

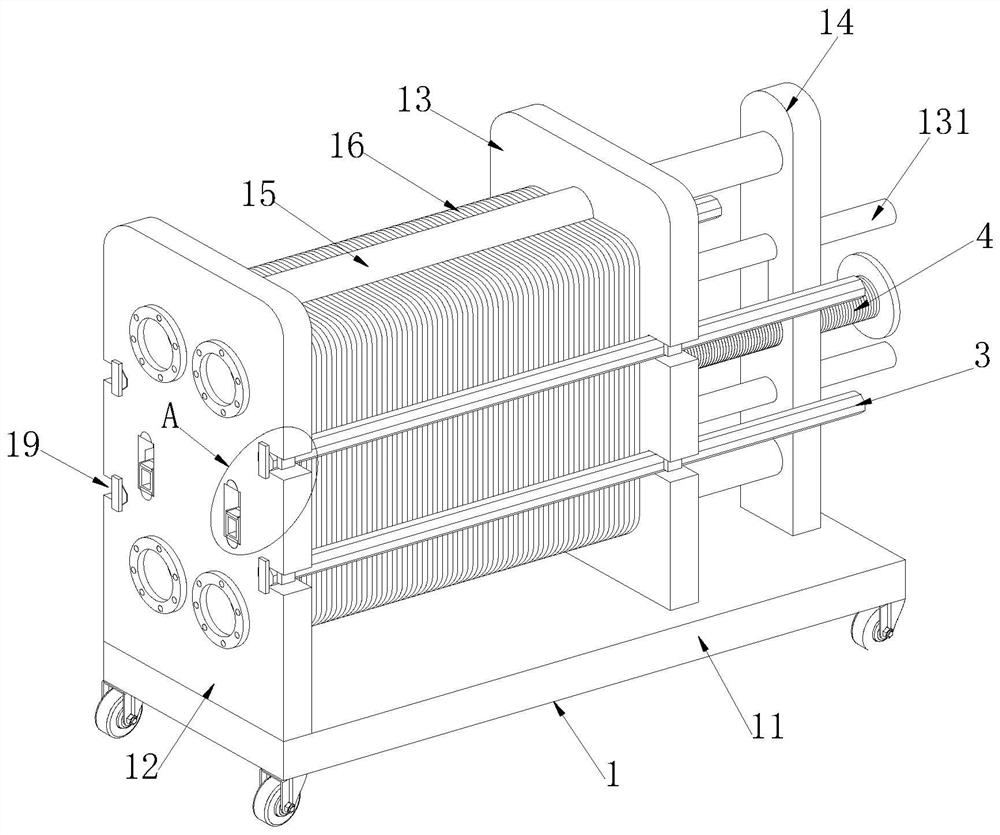

Plate heat exchanger convenient to disassemble and used for geothermal recharge system

ActiveCN112146487AEasy to disassembleSolve the problem of disassembly and cleaning efficiencyHeat exchanger casingsStationary plate conduit assembliesPlate heat exchangerEngineering

The invention discloses a plate heat exchanger convenient to disassemble and used for a geothermal recharge system, and relates to the technical field of plate heat exchangers. The plate heat exchanger comprises a heat exchanger assembly, a buckle mechanism, limiting rods and a driving mechanism, wherein the buckle mechanism is movably arranged inside the heat exchanger assembly, the limiting rodsare movably arranged on the two sides of the heat exchanger assembly, the driving mechanism is movably arranged inside the heat exchanger assembly, and the heat exchanger assembly comprises a mounting base plate, a positioning rod and a heat exchange plate sheet body. According to the plate heat exchanger, the heat exchanger assembly, the buckle mechanism and the driving mechanism are arranged, an operation block is moved upwards so that a movable rod can drive a positioning plate to release the limitation on the limiting rods, then the limiting rods can be pulled out of a containing groove,meanwhile, a driving rod is rotated to pull a movable plate to release the clamping on the heat exchange plate sheet body, and as a result, the problems that when a heat exchange plate sheet of a conventional heat exchanger is cleaned, a plurality of bolts need to be disassembled in sequence, time and labor are consumed in the process, and the disassembling and cleaning efficiency of the heat exchange plate sheet is influenced are solved.

Owner:HENAN WANJIANG NEW ENERGY DEV CO LTD

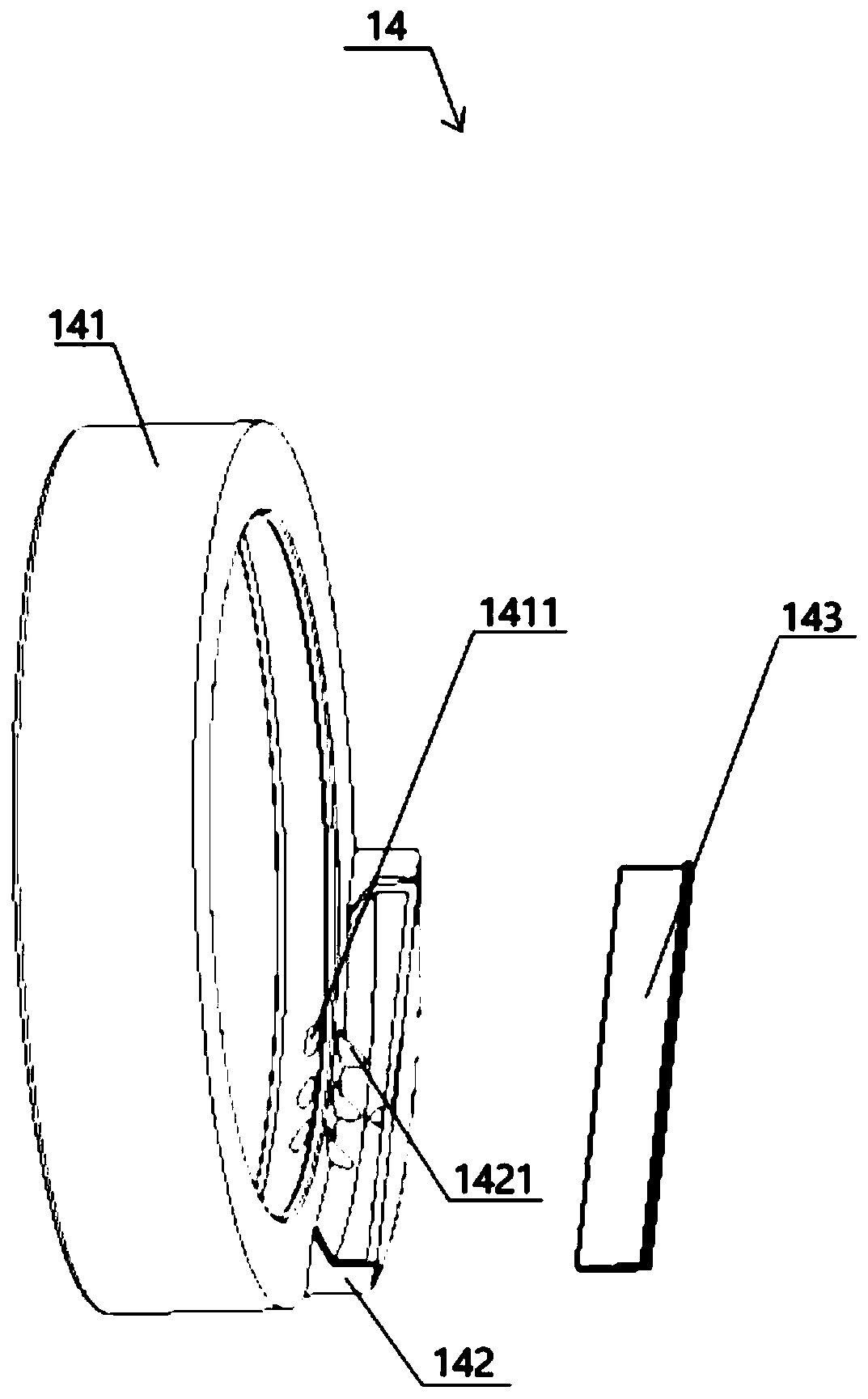

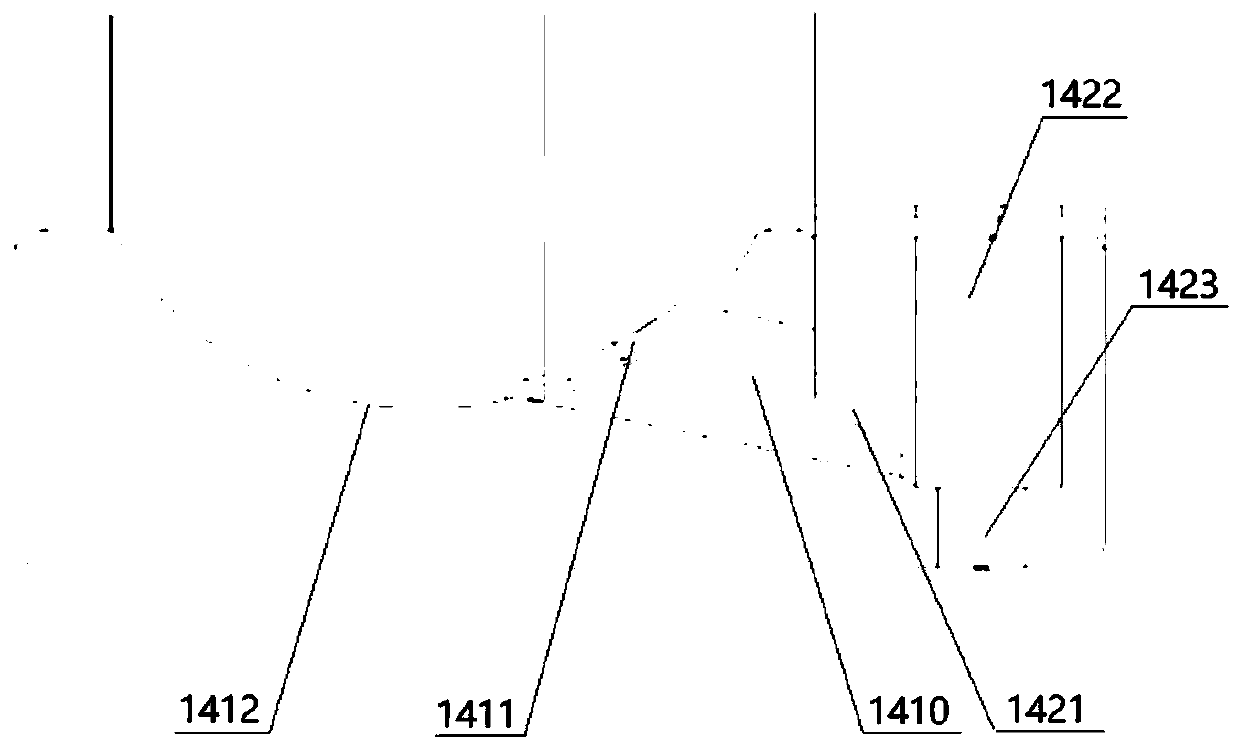

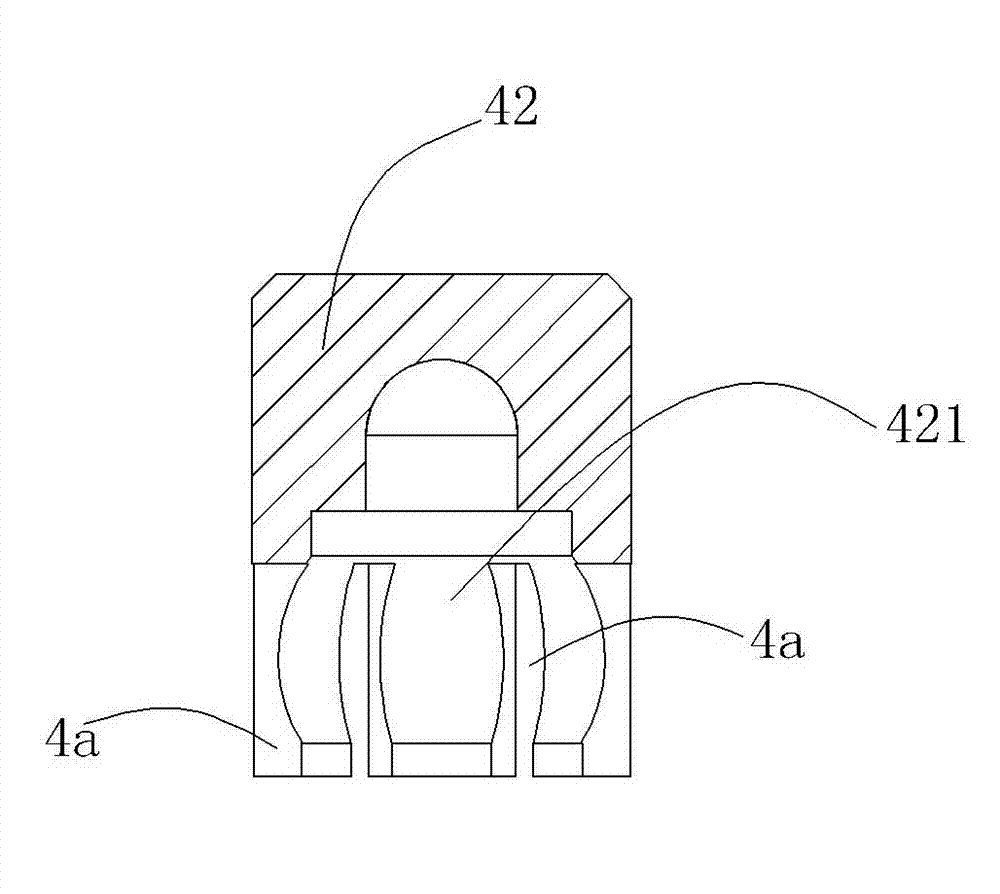

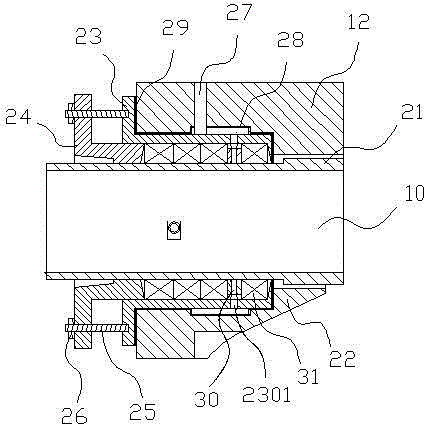

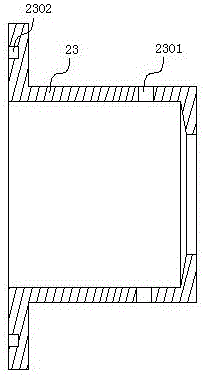

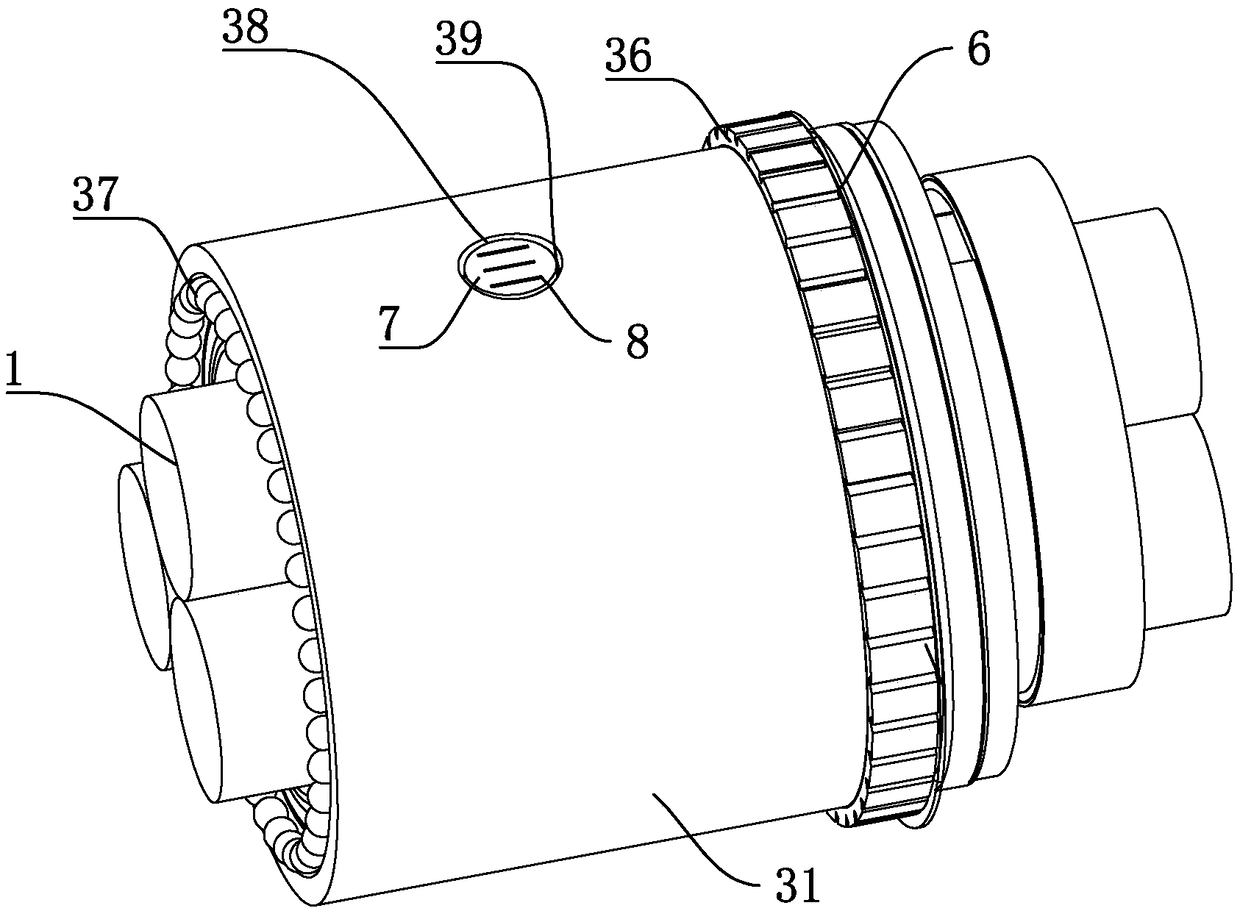

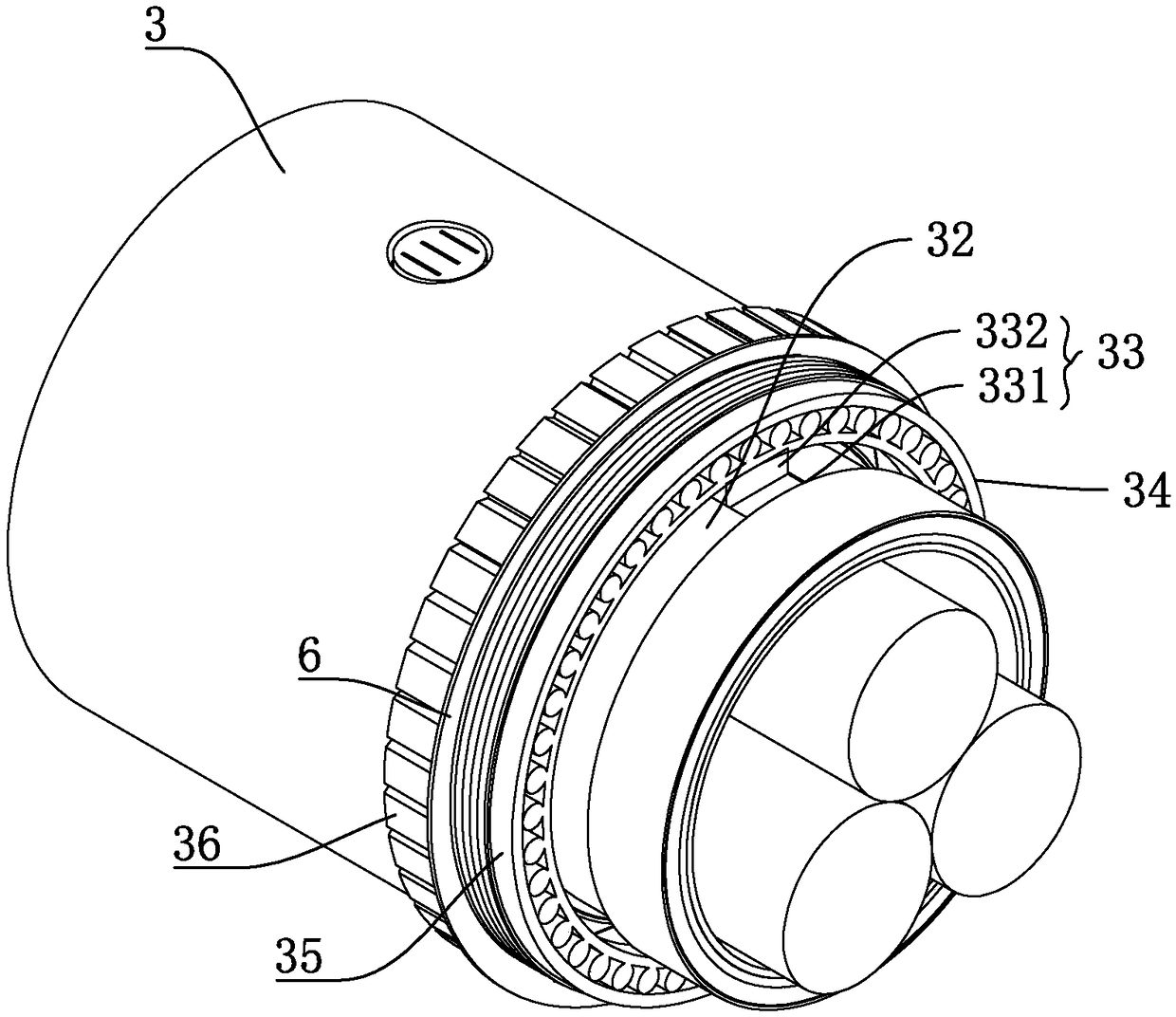

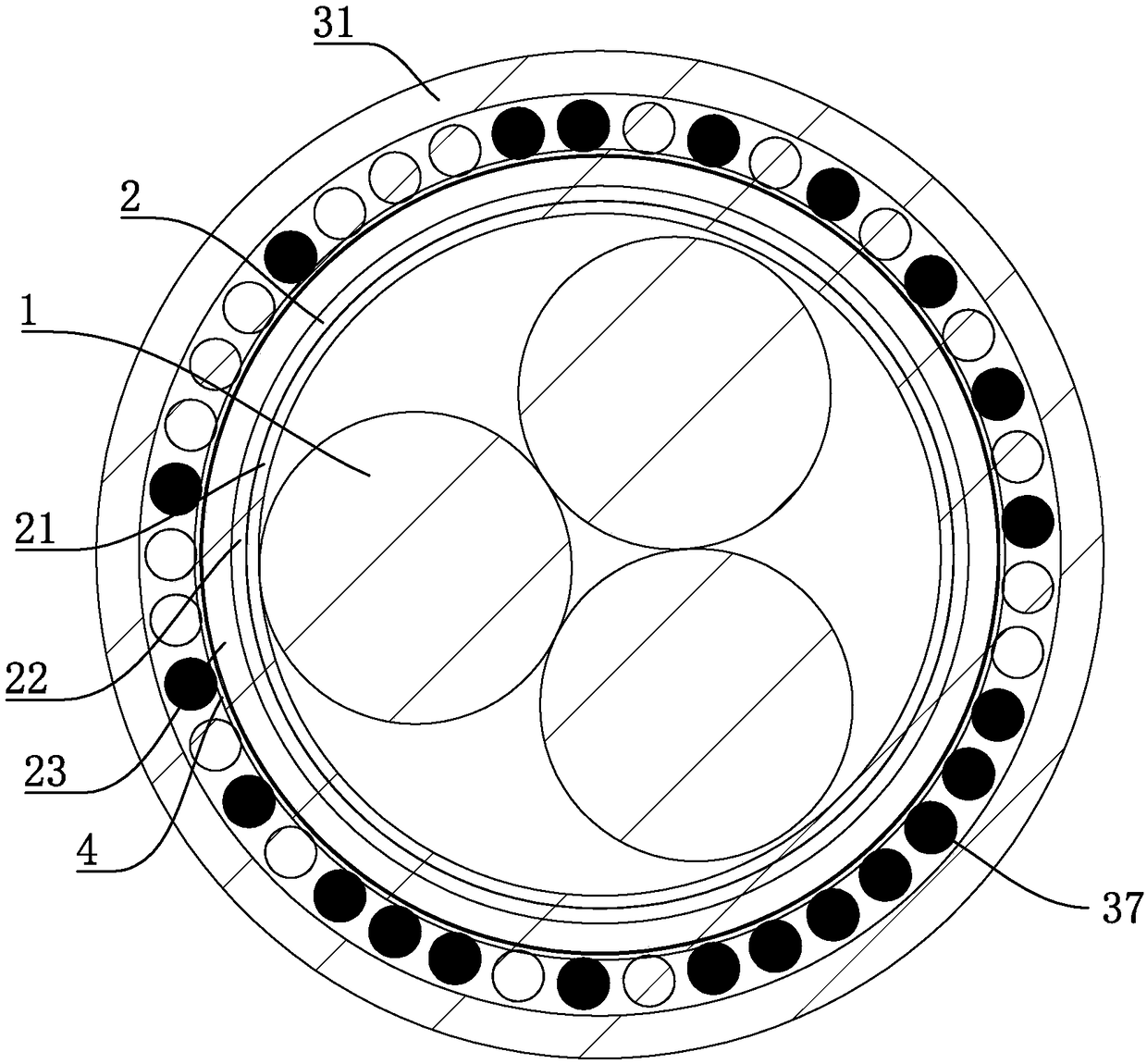

Bearing and bearing outer ring

InactiveCN110374997ADischarge in timeGuaranteed Lubrication RequirementsBall bearingsBearing componentsEngineeringAxial distance

The embodiment of the invention provides a bearing and a bearing outer ring. The bearing outer ring comprises a bearing outer ring body and an lubricating oil containing part, wherein a lubricating oil hole is formed in a roller way part of the bearing outer ring body; the lubricating oil containing part is fixed on the end surface of the bearing outer ring body; the lubricating oil containing part comprises an inner surface and an outer surface which are arranged along the radial direction of the bearing outer ring body; the axial distance of the inner surface and the bearing outer ring bodyis larger than or equal to the radius of the inner ring surface of the bearing outer ring body; the axial distance of the outer surface and the bearing outer ring body is smaller than or equal to theradius of the outer ring surface of the bearing outer ring body; the lubricating oil hole communicates with a roller way space of the bearing outer ring body and a containing cavity of the lubricatingoil containing part; and roller way oil ports of the lubricating oil hole is located between the inner surface and the outer surface. According to the bearing and the bearing outer ring, the lubricating effect of the bearing is ensured, impurity removal is facilitated, and meanwhile, the sealing requirement is reduced.

Owner:SCHAEFFLER TECH AG & CO KG

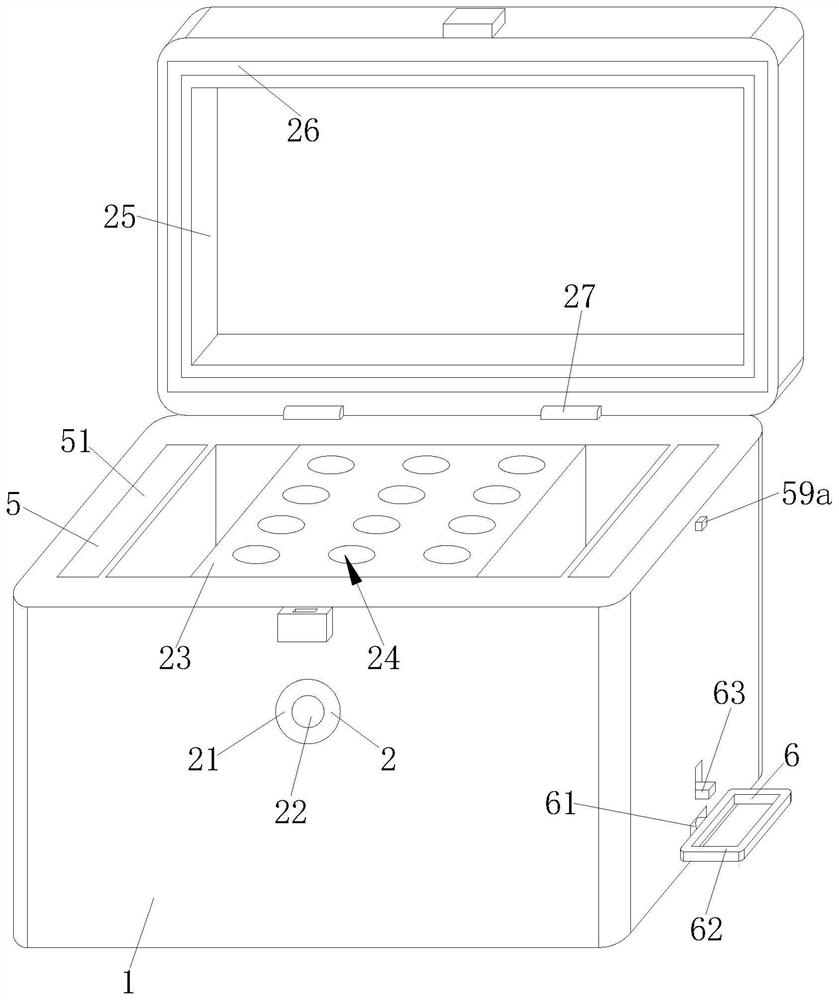

DNA extraction kit

ActiveCN112918867AAvoid LeakageImprove transportation safetyShock-sensitive articlesContainers preventing decayDNA extractionBiology

The invention relates to the field of kits, and particularly discloses a DNA extraction kit. The DNA extraction kit comprises a kit body, a rotating structure, a fixing structure, a clamping structure, a freezing structure, a drawing structure and a moving structure. The rotating structure is installed inside the kit body, so that the sealing protection effect on the kit body can be achieved, and it can be ensured that a test tube placed inside the kit body is always in a vertical state, thus, the circumstance that the test tube leaks liquid when the kit body is transported can be avoided, and the transportation safety of reagents is greatly improved; in cooperation with the freezing structure installed inside the kit body, the refrigeration effect on the reagents placed inside the kit body can be achieved, water drops condensed outside can be collected and treated in a centralized mode, rapid assembling and disassembling can be realized, and the operation is facilitated; and the fixing structure is arranged inside the rotating structure for placing the test tube, so that the outer side wall of the inserted test tube can be locked and fixed, the circumstance that the test tube shakes when the reagents are transported is avoided, and liquid leakage is prevented.

Owner:珠海宝锐生物科技有限公司

Assembly type door leaf and assembly method thereof

PendingCN112096246AMeet strength and impact resistance requirementsEasy to operateCorner/edge jointsNoise insulation doors/windowsEngineeringStructural engineering

The invention discloses an assembly type door leaf. The assembly type door leaf comprises a door leaf panel and a door leaf side sealing assembly, wherein the door leaf panel is used for being connected to form a main part of the door leaf in inserted and clamped modes; the door leaf side sealing assembly is connected with the door leaf panel in inserted and clamped modes and used for achieving side edge inserted and clamped type plugging of the door leaf panel; the door leaf panel is provided with a cavity with any width to be cut, and the inner side face of the door leaf panel is evenly provided with a plurality of oppositely-inserted clamping structures; the door leaf side sealing assembly comprises an inserting and clamping mounting piece and a door leaf side sealing piece; and the inserting and clamping mounting piece is inserted into the cavity with any width to be cut of the door leaf panel, and the door leaf side sealing piece is connected with the inserting and clamping mounting piece in inserted and clamped modes. The invention further discloses an assembling method of the assembly type door leaf. According to the assembly type door leaf, the door leaf panel, the door leaf inserting and clamping assembly piece and the door leaf side sealing assembly are assembled in inserted and clamped modes, the door leaf can be cut at will in the width direction according to the requirements of different house types, after cutting, the door leaf side sealing assembly and the door leaf panel can be assembled in inserted and clamped modes, and on-site rapid edge sealing can be achieved.

Owner:ZHEJIANG YASHA DECORATION

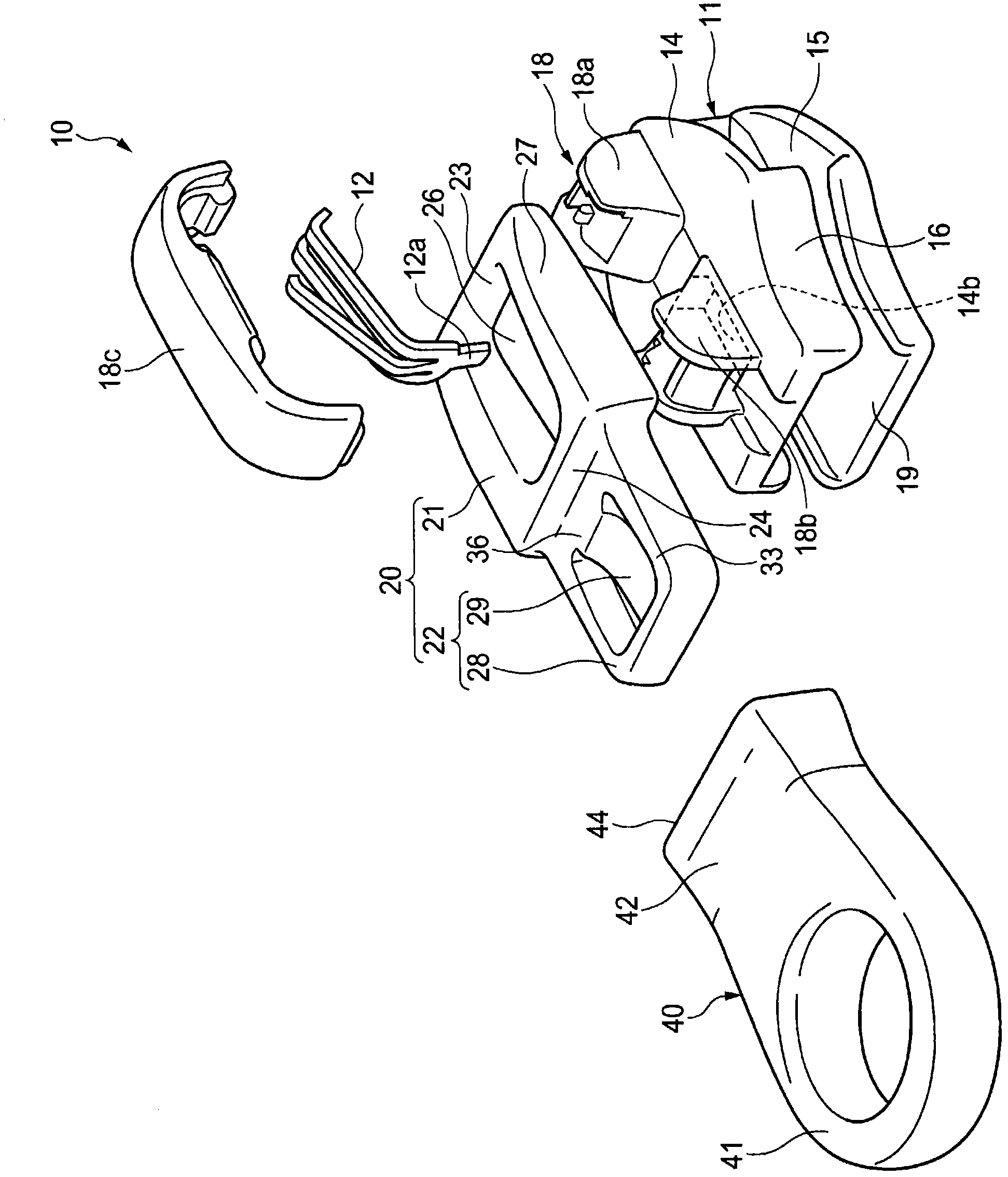

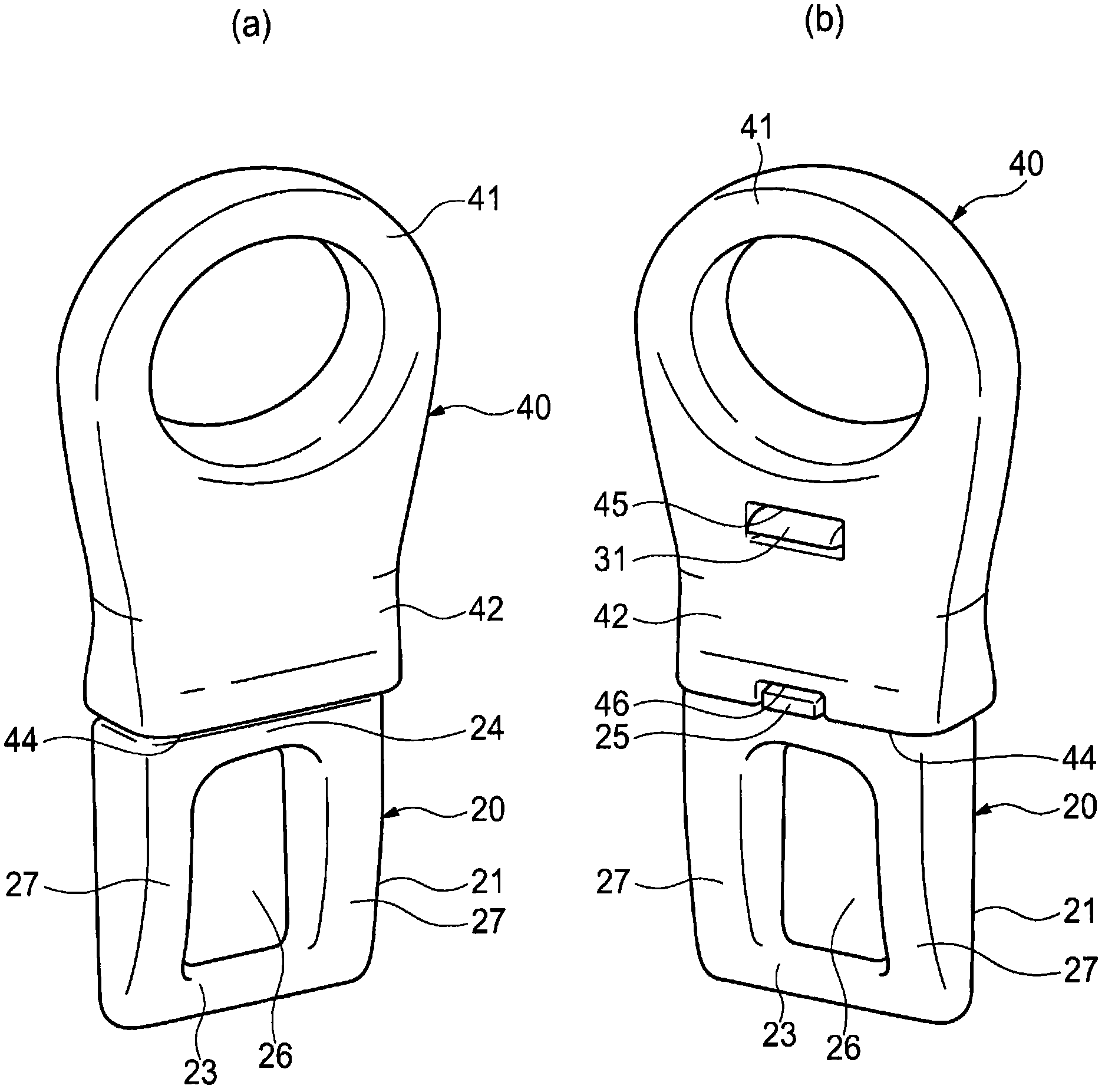

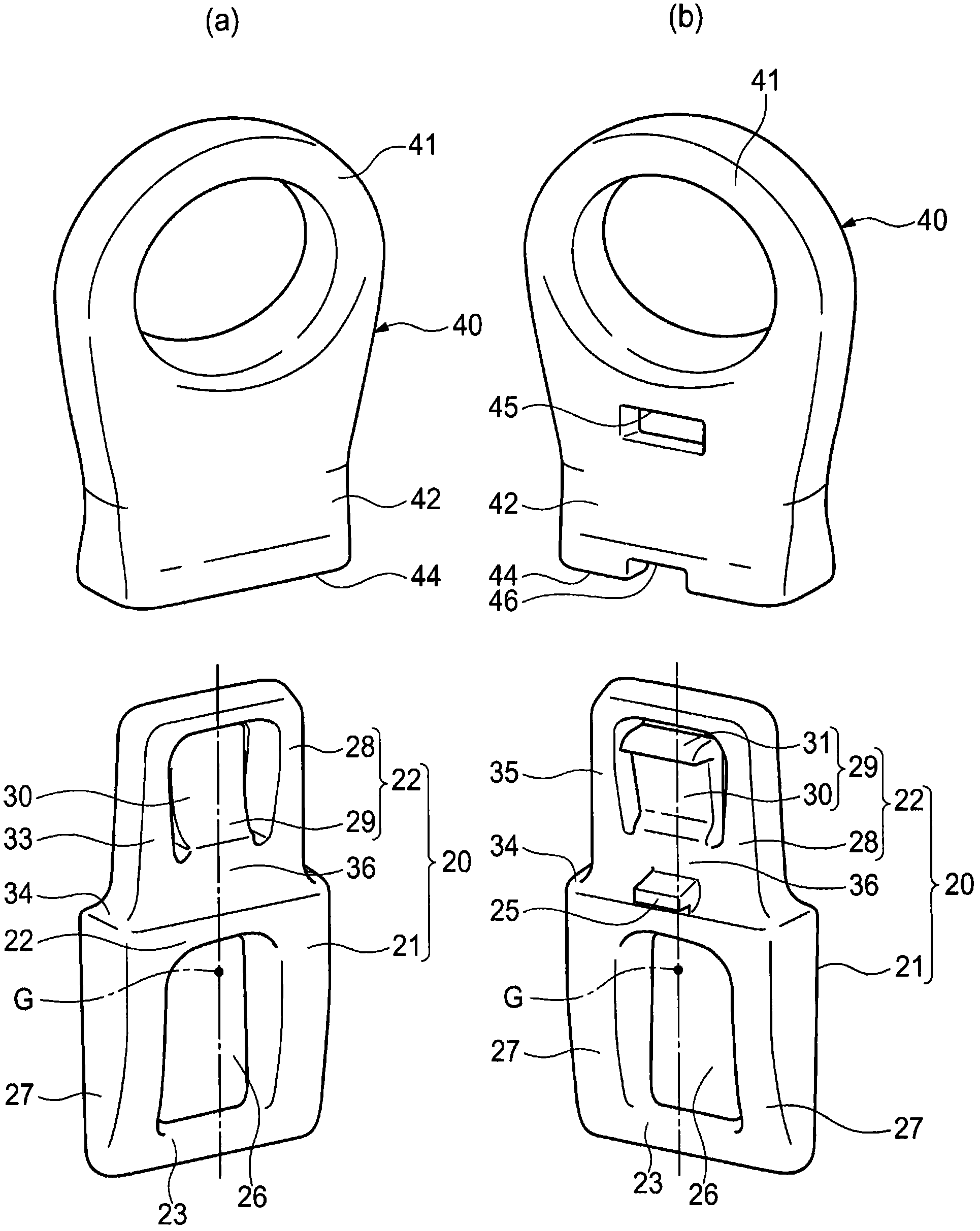

Slider for slide fastener

ActiveCN102469857AWill not affect the installationDoes not affect turning motionSlide fastenersEngineeringFastener

A slider for a slide fastener, provided with a slider body, a clamper, a lock pin, and a cover. The slider is configured so as to be able to be assembled automatically in order that the slider can be mass produced, and the slider is configured in such a manner that a pull tab can be removably mounted to the slider. A slider (10) for a slide fastener is provided mainly with a slider body (11), a clamper (20), and a pull tab (40). A link section (21) of the clamper (20) is mounted to the slider body (11), and the pull tab (40) is mounted to a mounting section (22) of the clamper (20). A projection (25) projecting in the plate thickness direction is formed between the link section (21) and the mounting section (22). When the pull tab (40) is mounted to the clamper (20), the projection (25) is contained in a projection containing section (46) of the pull tab (40).

Owner:YKK CORP

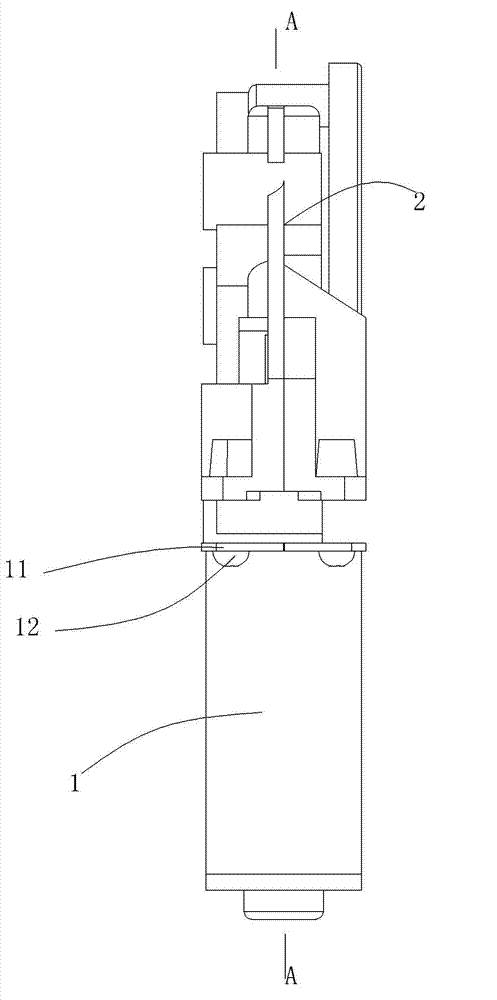

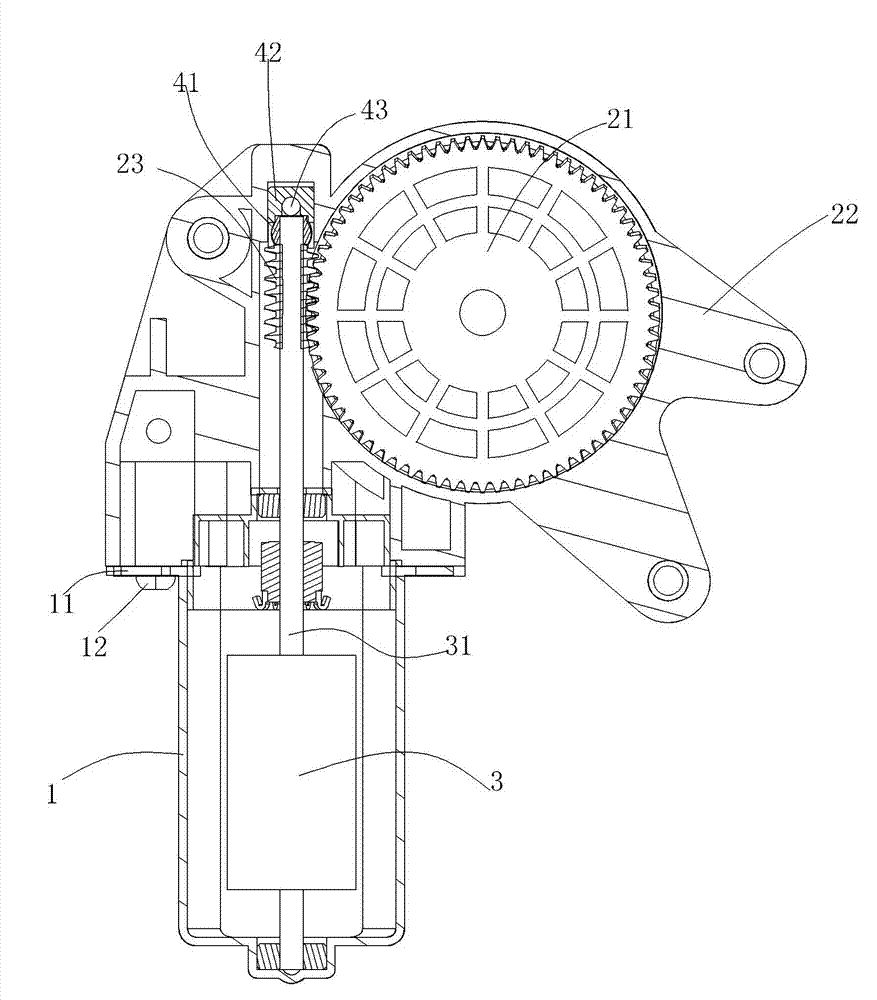

Motor and play detection device of output shaft thereof

ActiveCN102832741AWill not affect the installationMechanical energy handlingMechanical measuring arrangementsReduction driveEngineering

The invention discloses a motor and a play detection device of an output shaft thereof, which comprise a casing and a speed reducer, wherein a rotor is arranged in the casing, an output shaft of the rotor extends out of the casing, the speed reducer comprises a worm wheel, a casing body and a worm, the worm is arranged at the end part of the output shaft, the worm wheel is connected to the casing body in a rotating way, the casing is fixed on the casing body, the output shaft extends into the casing body, the worm and the worm wheel are matched, the end part of the output shaft is provided with a sleeve of which the outer surface is a spherical face, a positioning component is arranged in the casing body, a hole is arranged on the positioning component, the sleeve is connected to the hole in a rotating way, grooves communicated with the inner wall of the hole are arranged on the positioning component, and a clamping arm is formed between the grooves. When the deviation of the installation position of a body occurs, the installation of the body still can not be influenced even if a certain angular offset exists between the output shaft and the positioning component because the outer surface of the sleeve is the spherical face.

Owner:宁波世通汽车零部件有限公司

Clothing processing device

ActiveCN107964759AImprove maintenance efficiencyEasy maintenance and operationOther washing machinesTextiles and paperComputer moduleMechanical engineering

The invention discloses a clothes processing device. The clothing processing device comprises a connecting assembly for connecting a control disc holder module and a box; the connecting assembly comprises an overturning connection assembly disposed at the connection position between the control disc holder module and the rear side of the box; the connection between the control disc holder module and the overturning connection assembly enables the control disc holder module to have an action of sliding back and forth at the upper end of the box body, and when the control disc holder module is slid to a preset position, the control disc holder module can be turned back. According to the clothes processing device, through the cooperation of a slide connection assembly, when the control disc holder module is started, the control disc holder module is slid forward relative to the box body by a certain distance, a fixed connection assembly is separated, and at this time, the control disc holder module can be lifted up relative to a rotary connection assembly; the installation operation of the control disc holder module is the reverse sequence of the process; after the control disc holdermodule is put in place, the connection of the control disc holder module to the box body is further achieved through an auxiliary connection module. The clothes processing device can greatly facilitate maintenance operations, save labor costs and improve worker maintenance efficiency.

Owner:QINGDAO HAIER WASHING MASCH CO LTD +1

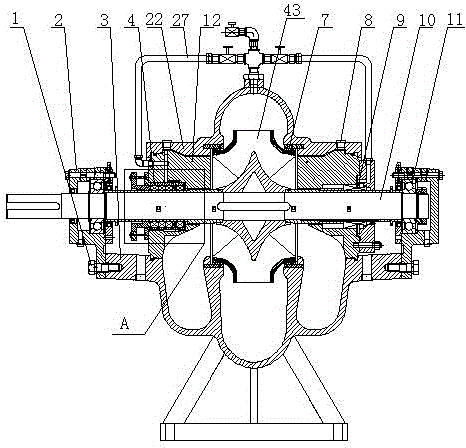

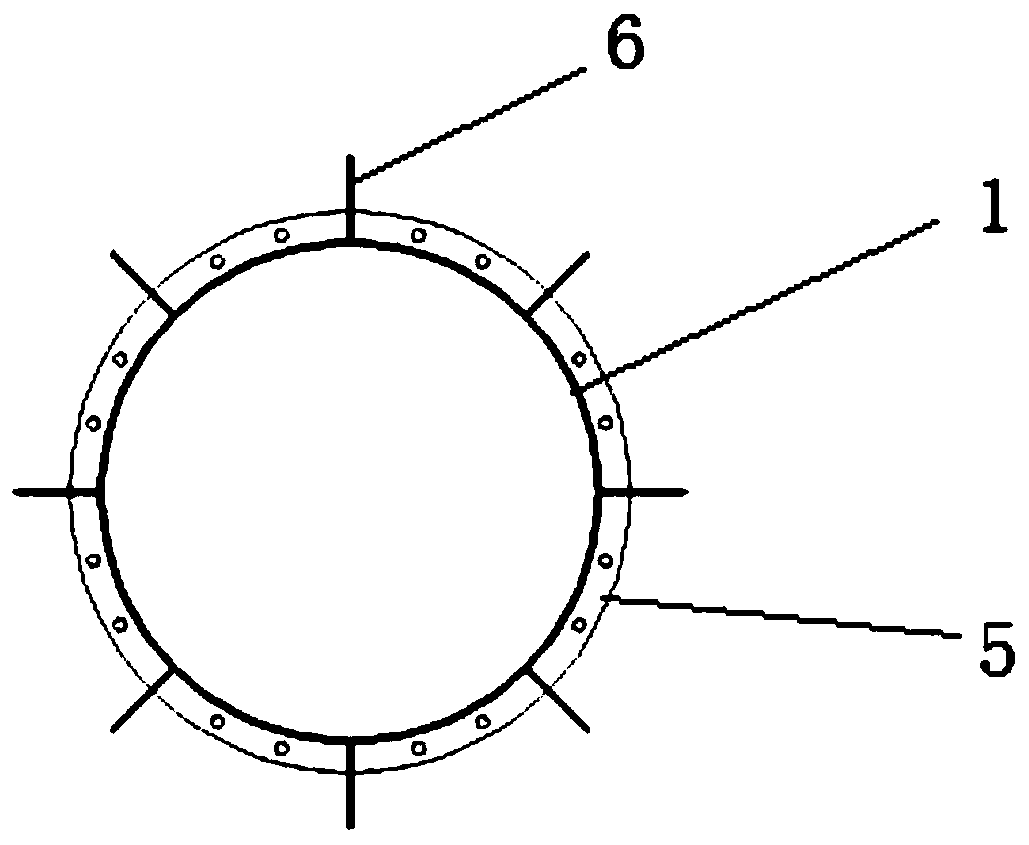

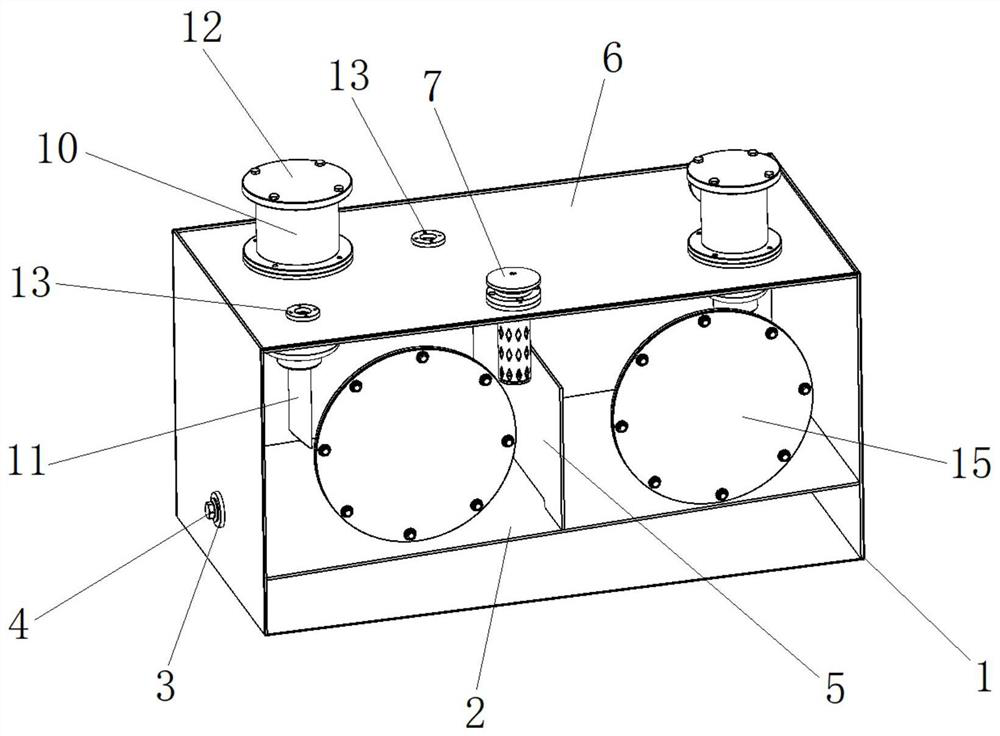

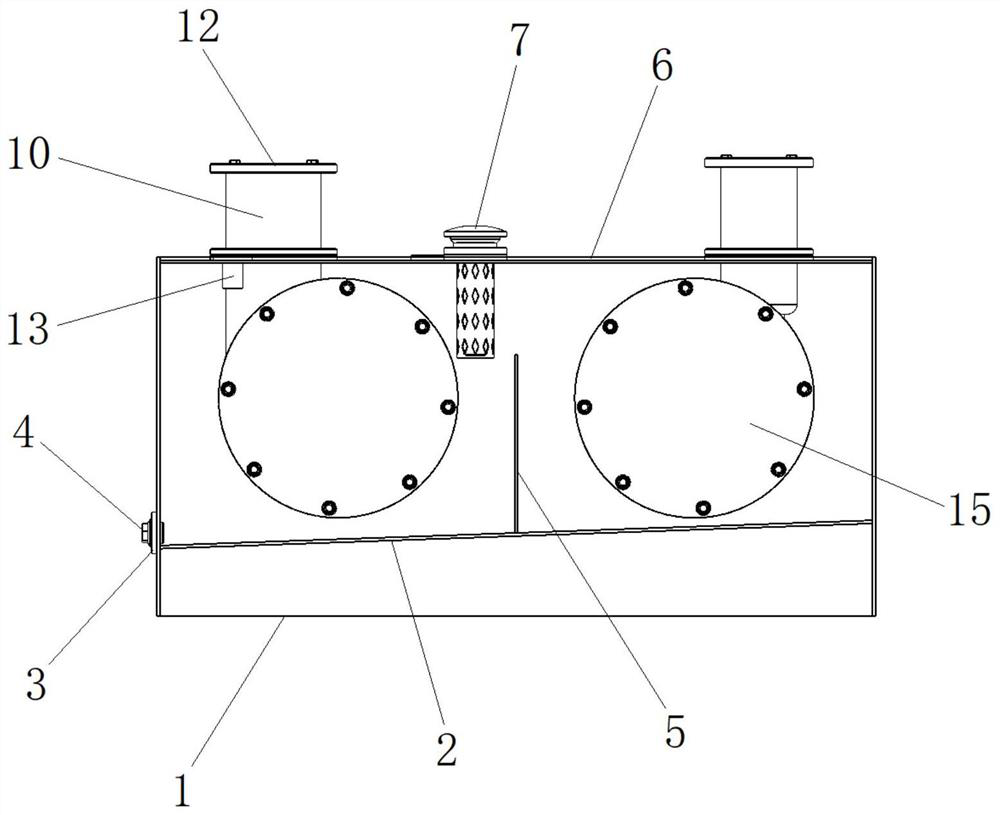

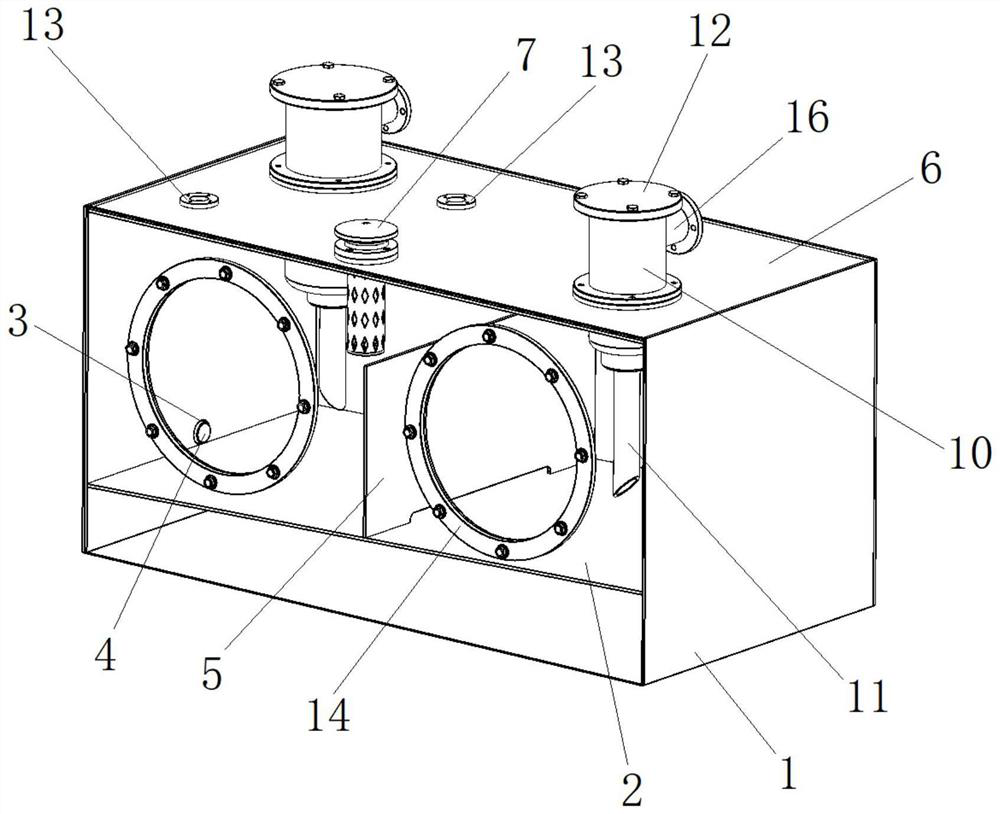

Singe-stage double-suction split case pump with good sealing performance

The invention relates to the field of split case pumps, in particular to a single-stage double-suction split case pump with the good sealing performance. The single-stage double-suction split case pump comprises a front bearing seat, a rear bearing seat and a pump shaft penetrating the front bearing seat and the rear bearing seat. The pump shaft is sleeved with a shaft sleeve. The middle portion of the pump shaft is sleeved with an impeller and a pump body matched with the impeller. The pump body is connected with the front bearing seat and the rear bearing seat through fastening pieces. A sealing component is arranged between the pump body and the impeller. Pump covers are arranged on the two sides of the pump body. The pump covers on the two sides are matched with a padding sealing device and a mechanical sealing device correspondingly. The invention aims at providing the single-stage double-suction split case pump with the good sealing performance, through the specific padding sealing device and the impeller sealing component, the good sealing effect is achieved, meanwhile the bearing span can be lowered, an impeller sealing ring is prevented from falling off, and normal operation of the pump is guaranteed.

Owner:浙江南方泵业有限公司

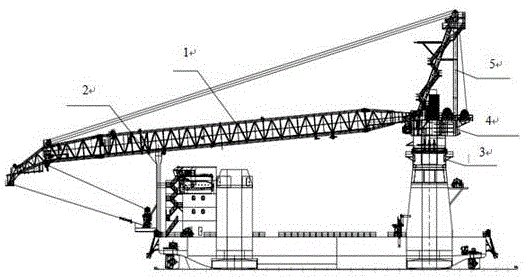

Hoisting process of full-circle slewing crane

InactiveCN105152041AReduced installation effortSpeed up the installation processCranesPropellerSlewing bearing

The invention relates to a hoisting process of a full-circle slewing crane. The hoisting process mainly comprises the following steps: component lifting: double hooks of a 1600T floating crane are utilized to hang a slewing chassis and a final-assembled lifting lug at the top of a propeller strut so as to hoist the slewing chassis and a propeller strut component; hoisting in place: the floating crane is utilized to shift the component to the position above a spud leg, and the component is adjusted in place; the component is slowly laid down onto a cylinder body, and all double-end studs can penetrate in place; after some of bolt pairs are pre-tightened, the floating crane can release the hooks, and all the bolt pairs are pre-tightened subsequently; mounting of remaining parts. The hoisting process has the advantages that a slewing bearing and all the slewing parts are mounted in place, integrally hoisted in place on site and connected with the cylinder body, so that the workload of site mounting is greatly reduced, and the mounting progress is accelerated.

Owner:NANTONG ZHENHUA HEAVY EQUIP MFG

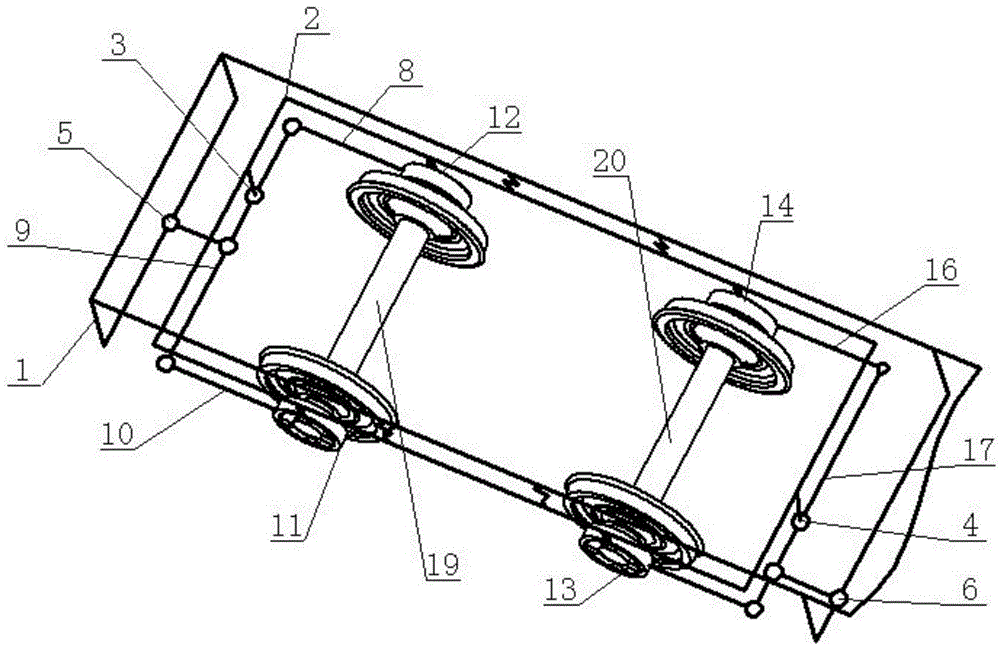

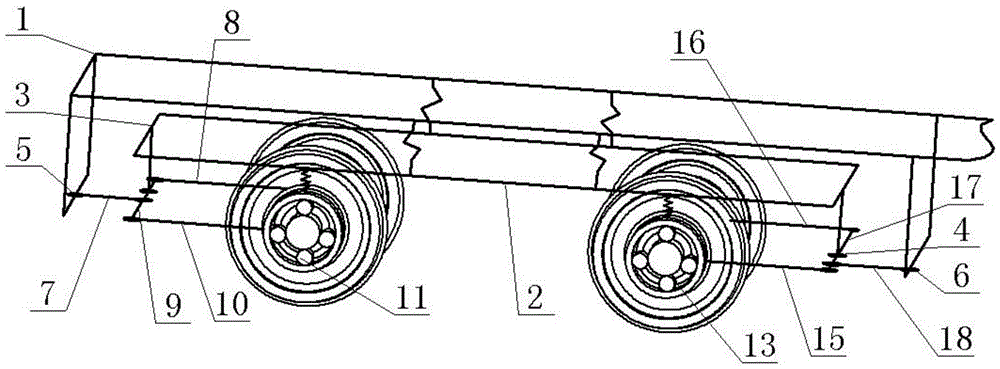

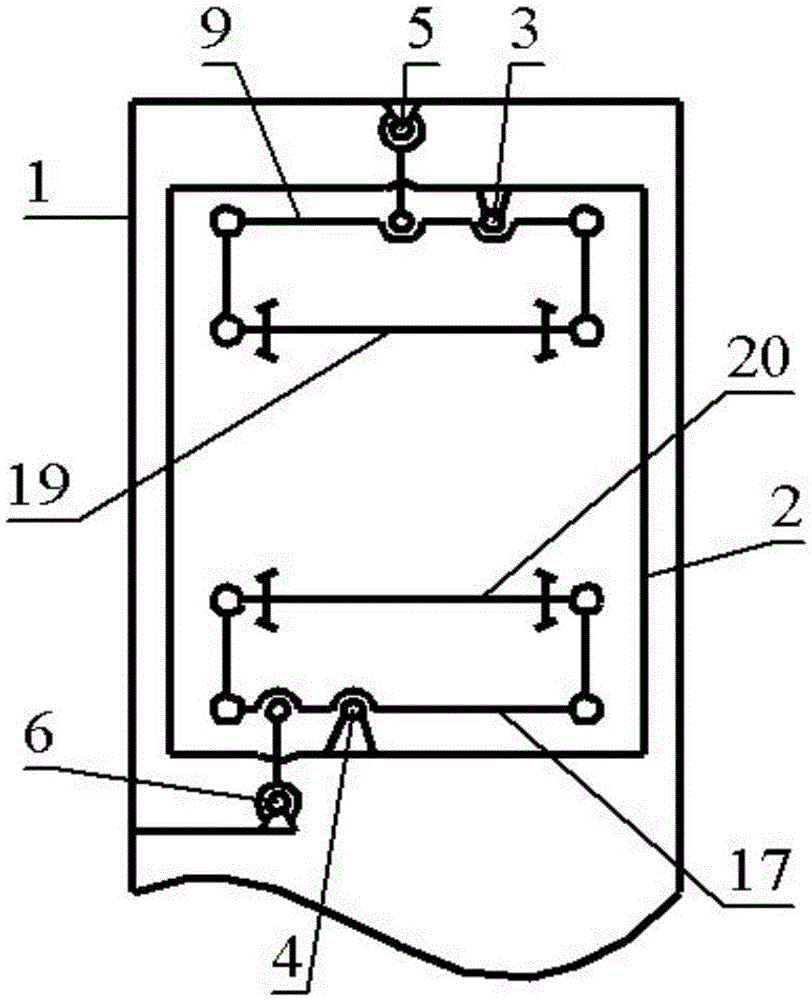

Forced guide mechanism for bogie

InactiveCN105460041AReduce manufacturing costImprove sticky utilizationBogie-underframe connectionsWheel axle self-adjustmentsBogieEngineering

The invention discloses a forced guide mechanism for a bogie, which belongs to the technical field of structural design of locomotive vehicles and can effectively solve the problem of limitation of the distance between axles when a vehicle uses a forced guide frame. The forced guide mechanism comprises a vehicle body, a framework, a front guide rod for connecting a front cross beam and the vehicle body, and a rear guide rod for connecting a rear cross beam and the vehicle body, wherein one end of a left front pull rod is articulated on a left front axle box, and the other end of the left front pull rod is articulated at the left end of the front cross beam; one end of a right front pull rod is articulated on a right front axle box, and the other end of the right front pull rod is articulated at the right end of the front cross beam; one end of a left rear pull rod is articulated on a left rear axle box, and the other end of the left rear pull rod is articulated at the left end of the rear cross beam; one end of a right rear pull rod is articulated on a right rear axle box, and the other end of the right rear pull rod is articulated at the right end of the rear cross beam; the front cross beam is articulated in the position, deviating to the right, at the center of the framework, and the rear cross beam is articulated in the position, deviating to the left, at the center of the framework; one end of the front guide rod is articulated at the front end of the vehicle body, and the other end of the front guide rod is articulated on the front cross beam; and one end of the rear guide rod is articulated at the rear end of the vehicle body, and the other end of the rear guide rod is articulated on the rear cross beam. The forced guide mechanism is mainly used for manufacturing locomotive vehicles.

Owner:SOUTHWEST JIAOTONG UNIV

Watertight isolation structure used for pipeline to penetrating through watertight bulkheads

InactiveCN109720513AWatertight isolation guaranteeSolve the problem of destroying the watertightness of bulkheads in watertight compartmentsFloating buildingsEngineering

Owner:CHINA NATIONAL OFFSHORE OIL (CHINA) CO LTD +1

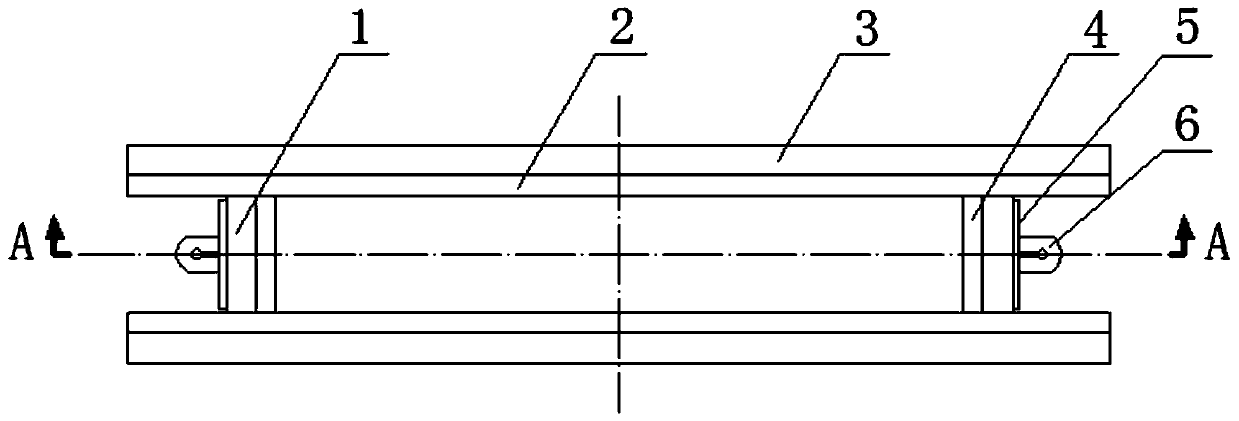

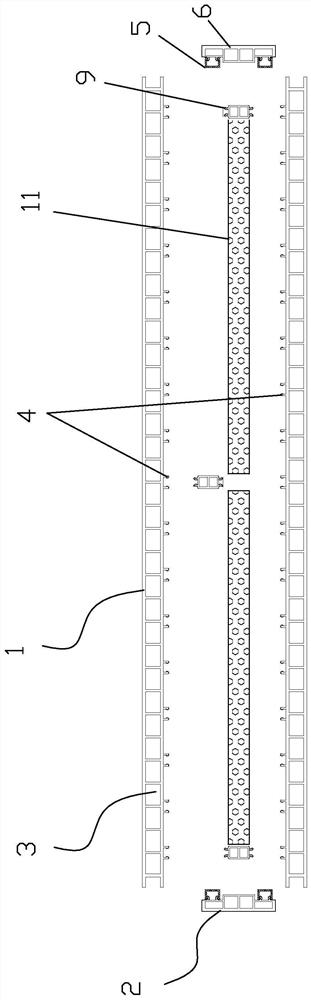

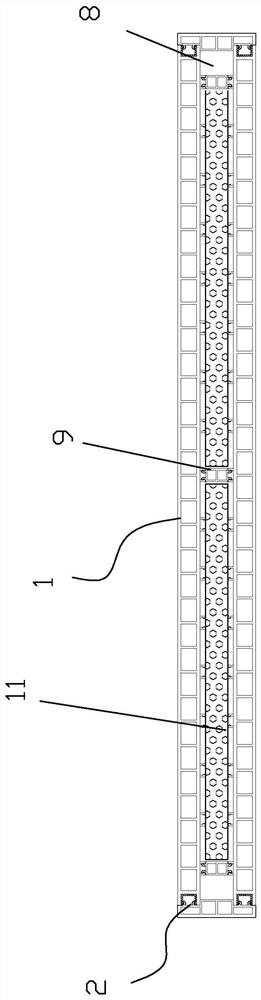

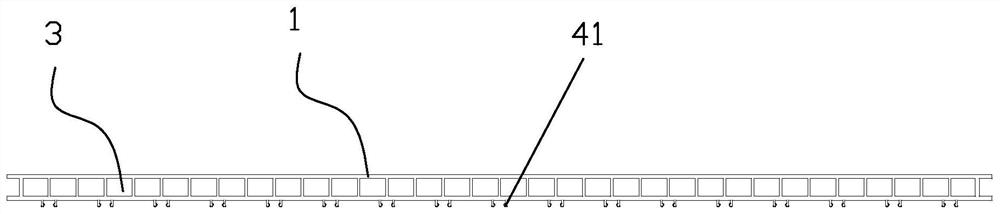

Heat dissipation structure of preheating chamber roller bed

InactiveCN108608340AWill not affect the installationPrevent thermal deformationAbrasive machine appurtenancesRoller-waysEngineeringMechanical engineering

The invention discloses a heat dissipation structure of a preheating chamber roller bed. The heat dissipation structure comprises a roller bed body located in a preheating chamber, wherein the rollerbed body comprises a roller and two sealing end covers arranged on the left and right sides of the roller, each sealing end cover comprises a rotating shaft and two mounting plates arranged on the corresponding rotating shaft, each pair of mounting plates are arranged side by side on the corresponding rotating shaft, each sealing plate located at the outer side is fixedly welded to the side end face of the roller, the center of one of the rotating shaft is provided with a through hole, one side of the preheating chamber is provided with a condensing device, and a condensing tube of the condensing device is connected to the through hole of the corresponding rotating shaft. The heat dissipation structure of the preheating chamber roller bed has the advantages that the roller can be filled with a condensing gas through a ventilation hole to reduce the temperature of the roller; a connecting sleeve arranged at the through hole can make the condensing tube cooperate with the corresponding rotating shaft well, the rotation of the rotating shaft cannot influence the installation of the condensing tube, the structure is designed simply and skillfully, the roller bed is prevented from beingthermally deformed, and the long-term use of the roller bed in the preheating chamber is ensured.

Owner:ZHENJIANG SUBAIXIN CONSTR MACHINERY CO LTD

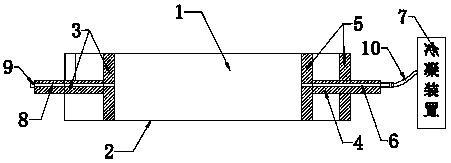

Double-acting-force blow-down valve

Provided is a double-acting-force blow-down valve. The double-acting-force blow-down valve comprises a valve body, a valve deck and a support which are connected in a matched mode, a valve rod is movably connected in the valve body, the valve deck and the support, a bevel gear is connected to the end, arranged on the support, of the valve rod, two gate plates are connected to the end, arranged on the valve body, of the valve rod, and the valve body is internally provided with an inlet end valve seat and an outlet end valve seat which are matched with the two gate plates for use; a limiting part which penetrates into the valve body is arranged outside the valve body. The double-acting-force blow-down valve is reasonable in structure and convenient to use, the integral type valve body is adopted to replace the split-type design, the valve is more compact in structure and light in weight, leakage points outside the valve are reduced, the semi-circular design is adopted by the outlet end valve seat of the valve body, the contact area of the first gate plate and the outlet end valve seat when the first gate plate is closed is decreased, and the goodness of fit of the inlet sealing face can be better guaranteed; meanwhile, the friction force of a medium acting on the gate plates when the gate plates are opened and closed is reduced, the matching requirements between the valve body and the valve seats and between the valve seats and the gate plates are met, it is guaranteed that an inner cavity of the valve body is smooth, free of dead angle and smooth in slagging, and the double-acting-force blow-down valve is worthy of popularization.

Owner:特尔阀门高科技有限公司

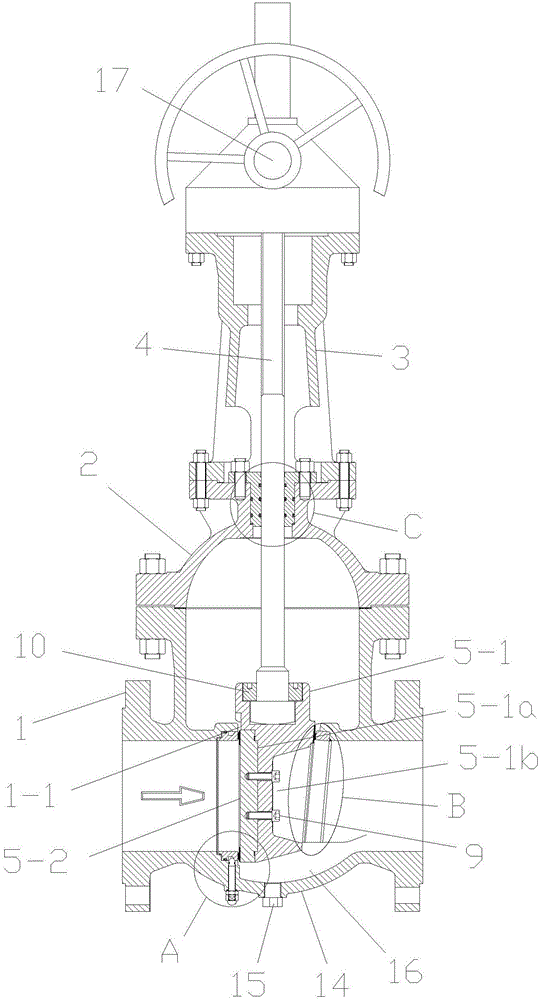

High strength concave type ceiling keel

This invention discloses a high-intensity concave ceiling keel, comprising a reinforcement plate (1), last edge (2) and under edge (3). There are two ends (4) at the end of the reinforcement plate (1), and multiple points occlusion (5)on the reinforcement plate (1) , lap board (6) at the ends of the reinforcement plate (1) and under edge (3) used for joint with the keel, lap board (6) was L-shaped with one side located in the top surface (7) within lower side of edge (3), another side on the reinforcement plate (1) between end (4) and under edge(3). When the main keel and furring connects, the L-shaped plate set up on furring connected to the main keel, enhance their connectivity, so that enhance the strength of whole skeleton keel; the lap plate makes the main keel and furring bonding tightly, without light on the connect place, with good decorative effect of the ceiling.

Owner:大连舒心宏业建材有限公司

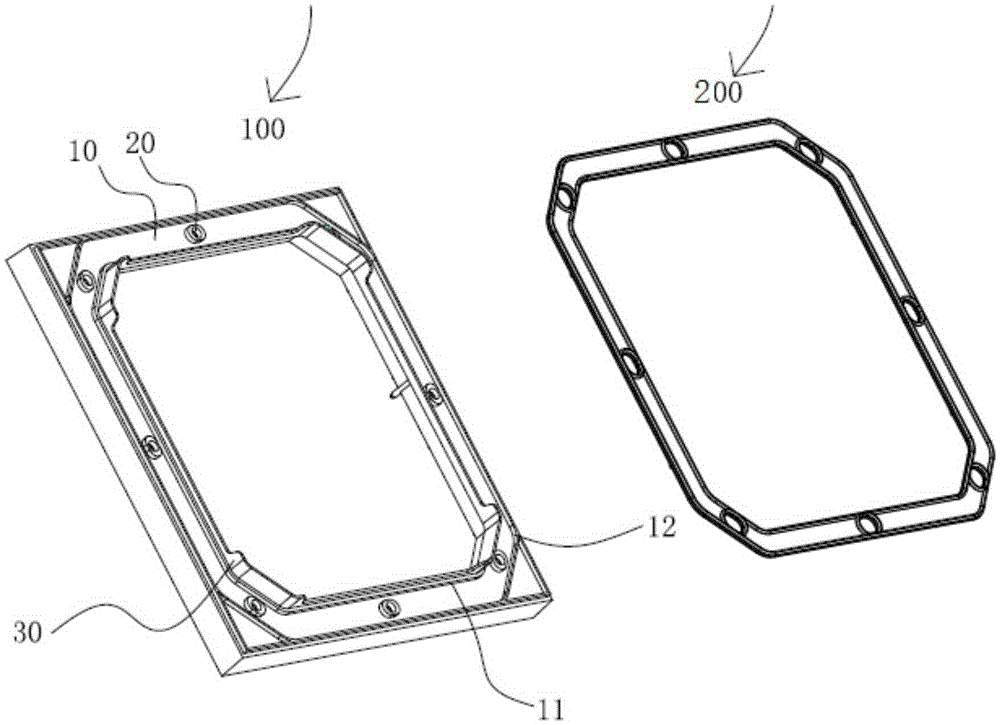

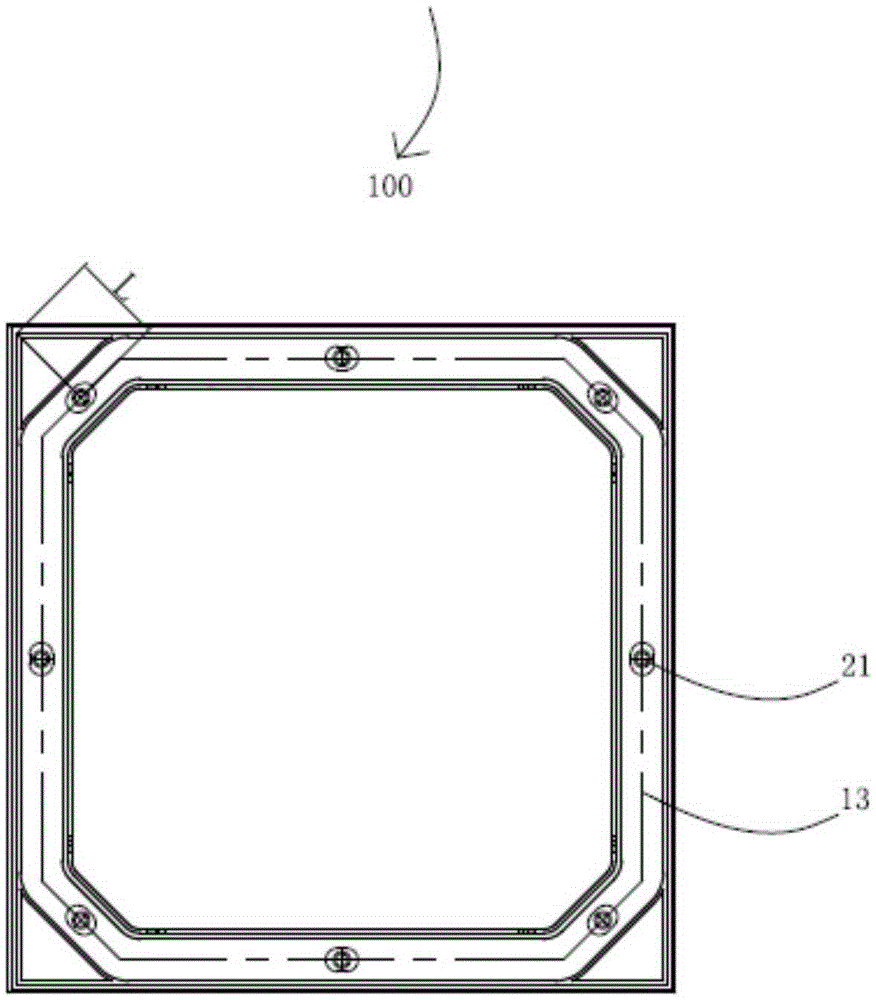

Fixing bottom case of LED display screen module

InactiveCN105913770AEven distribution of nutsGood waterproof effectIdentification meansEngineeringLED display

The invention provides a fixing bottom case of a LED display screen module. The fixing bottom case comprises a sealing groove on the surface edge of the fixing bottom case, and a fixing portion in the sealing groove. The fixing portion is used for fixation of a LED display screen module and a cabinet. The sealing groove is used to place a waterproof seal ring. The fixing portion comprises a plurality of nuts, wherein a part of the nuts are respectively arranged near middle positions of four edges of a square, and the other part of the nuts are respectively arranged on positions of four corners of the square, the positions being moved by a safe distance toward the center of the square. The centers of the nuts are connected with each other to form a polygon. The sealing groove comprises an inner side edge and an outer side edge. The shapes of the inner side edge and the outer side edge are polygons. The center line between the inner side edge and the outer side edge is overlapped with the central connecting line of the nuts. The fixing bottom case makes the nuts uniformly distributed, and waterproof effect of the LED display screen module is good, and installation is stable. The fixing bottom case uses few nuts, and reduces cost.

Owner:SHENZHEN LIANTRONICS +1

A novel cable protection device

PendingCN109087733AEasy to useSo as not to damageClimate change adaptationInsulated cablesEngineeringTemperature difference

The invention discloses a novel cable protection device and aims at providing a cable protection device for reducing temperature difference. The advantages of that technical scheme are as follows: thecable includes an inner core, a protective layer is wrapped around the inner core, a loss prevention device is also arranged outside that protective layer, the loss prevention device comprises a protective sleeve arranged outside the protective layer, a groove on the surface of the protective layer, a bearing nested in the groove and connected with the groove through a sliding device, an externally threaded connecting ring located outside the bearing, a connecting port threadably connected with the connecting ring at the top of the protective sleeve, a sponge ball arranged in the protective sleeve, a plurality of through holes arranged on the surface of the protective sleeve and a water-proof permeable membrane arranged in the through holes. The sliding device comprises a sliding path arranged on the inner walls of the grooves and a sliding block arranged on inner ring of the bearing and clamped to the sliding path.

Owner:无锡胜维电气有限公司

Door body decorative strip and refrigerator

InactiveCN102564020AEasy to disassemble and replaceEasy to change directionsDomestic cooling apparatusLighting and heating apparatusEngineeringRefrigerated temperature

Owner:HAIER GRP CORP +1

Signal remote transmission gas relay

PendingCN112435888AExternal structure improvementThe external structure ensuresHigh-tension/heavy-dress switchesAir-break switchesOil canControl theory

The invention provides a signal remote transmission gas relay. According to the technical scheme, the external structure of the gas relay is improved, and meanwhile, the image acquisition module is introduced. Specifically, the bottom face of the containing cavity is designed to be the inclined face so that one-way movement of oil can be guaranteed, and meanwhile the middle partition plate is additionally arranged so that large fluctuation can be avoided in the oil flowing process. On the basis, the camera is additionally arranged at the top of the device, a liquid level image can be transmitted to a background in real time and remotely monitored by a worker, and frequent on-site checking actions are omitted. In addition, the sleeve is used for protecting the binding post, and a circuit can enter and exit from the side end; and during maintenance, the flange cover at the upper end can be opened, so that the installation and maintenance of the equipment are not influenced. According tothe invention, the oil level monitoring efficiency of the gas relay is improved, and a more perfect protection structure is provided.

Owner:XIAN YA NENG ELECTRIC CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com