Patents

Literature

37results about How to "Improve sticky utilization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

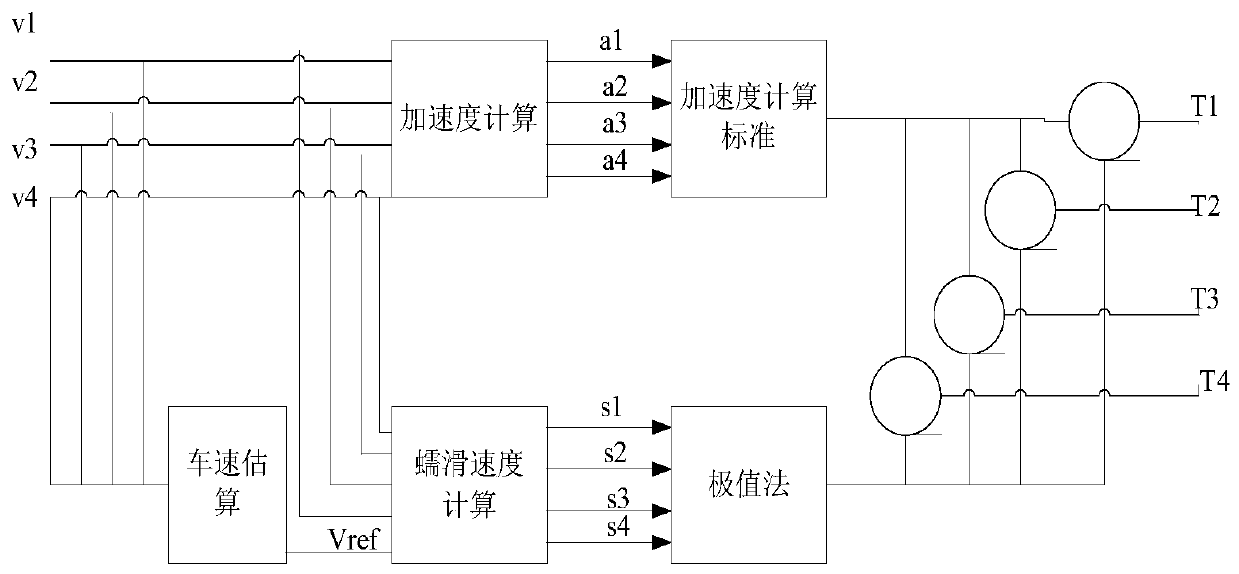

A rail train anti-air rotation anti-skid adhesion optimization control method

ActiveCN108984970AStable output torqueImprove sticky utilizationGeometric CADSpecial data processing applicationsEngineeringSurface conditions

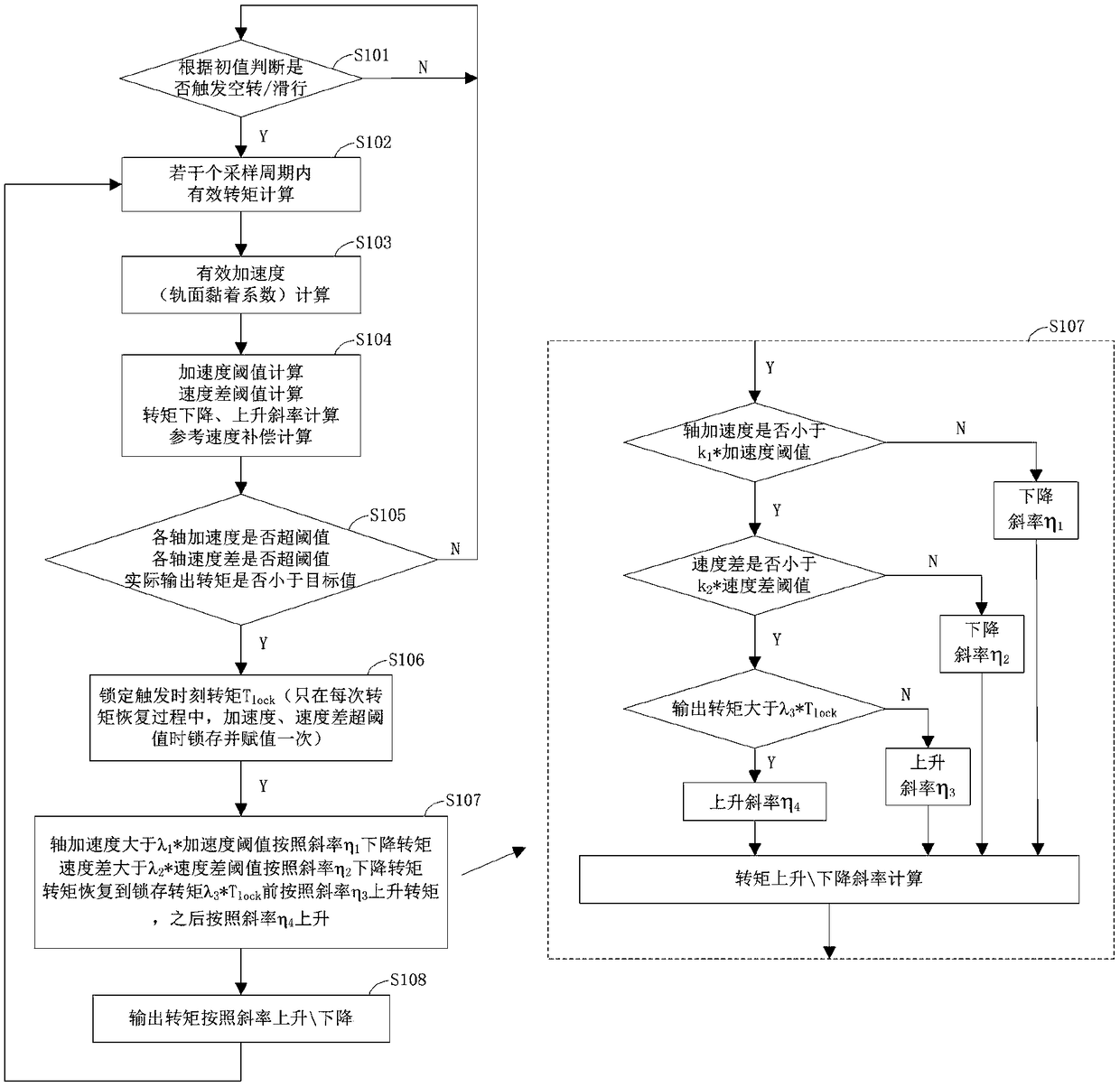

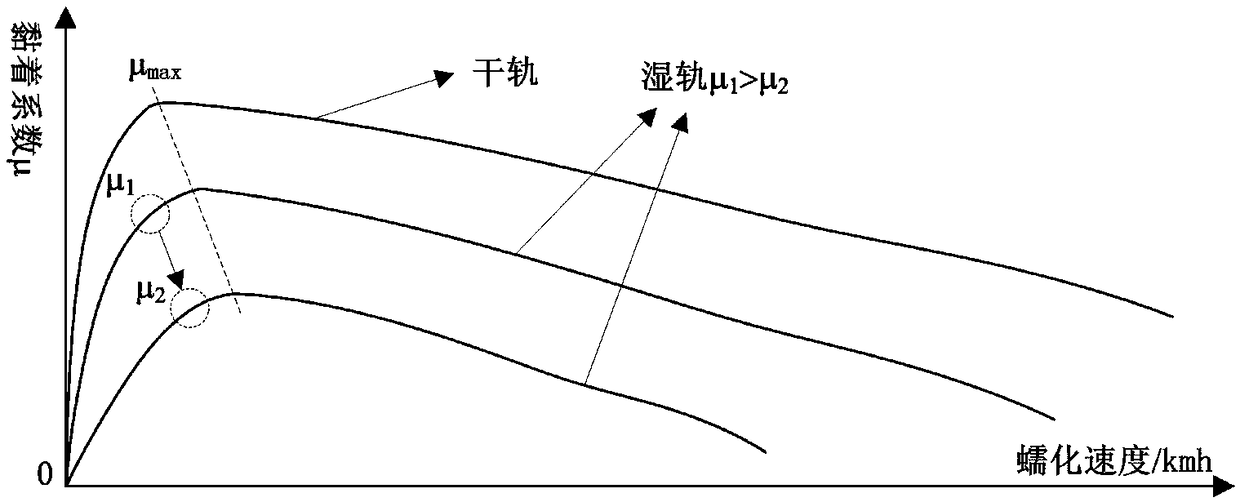

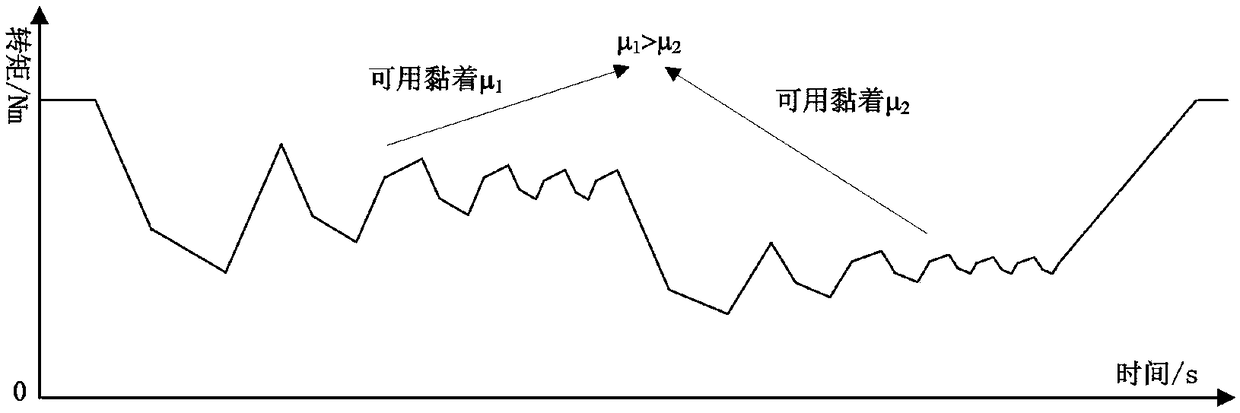

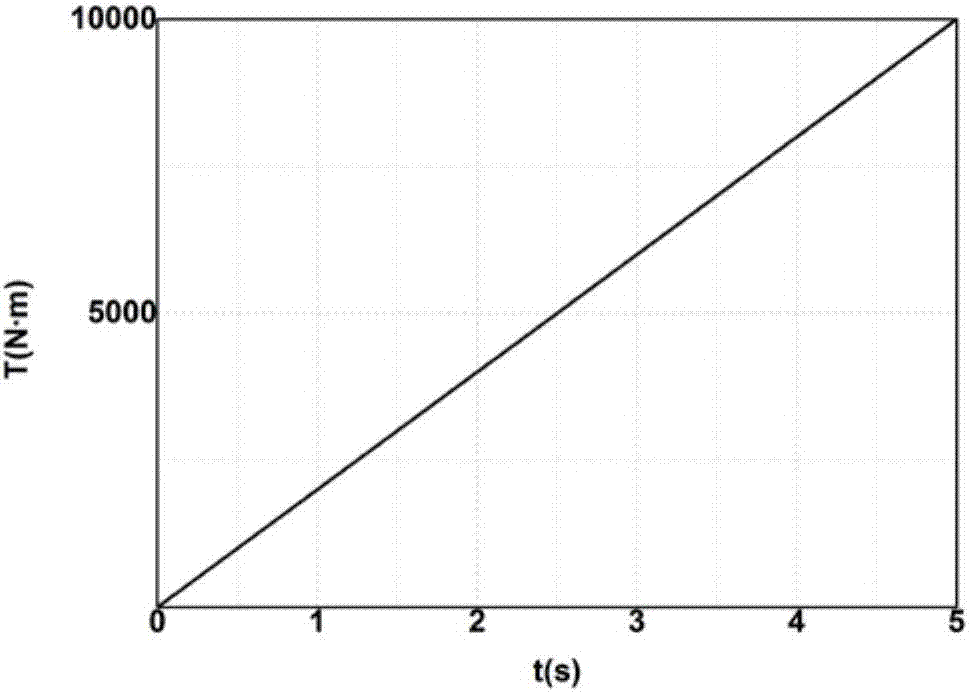

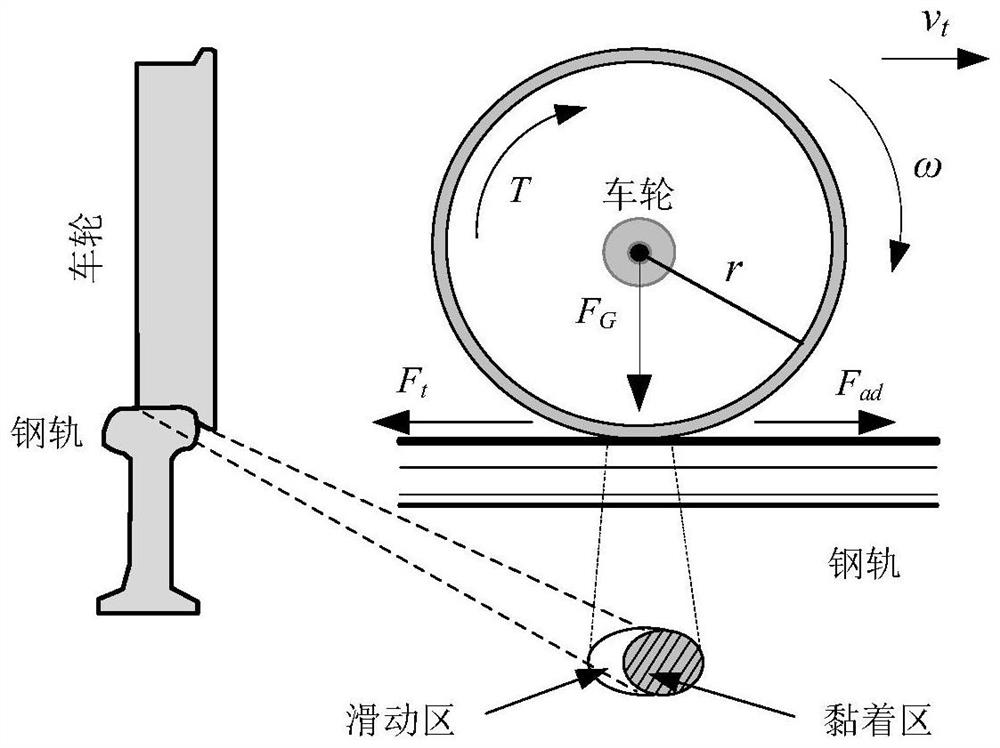

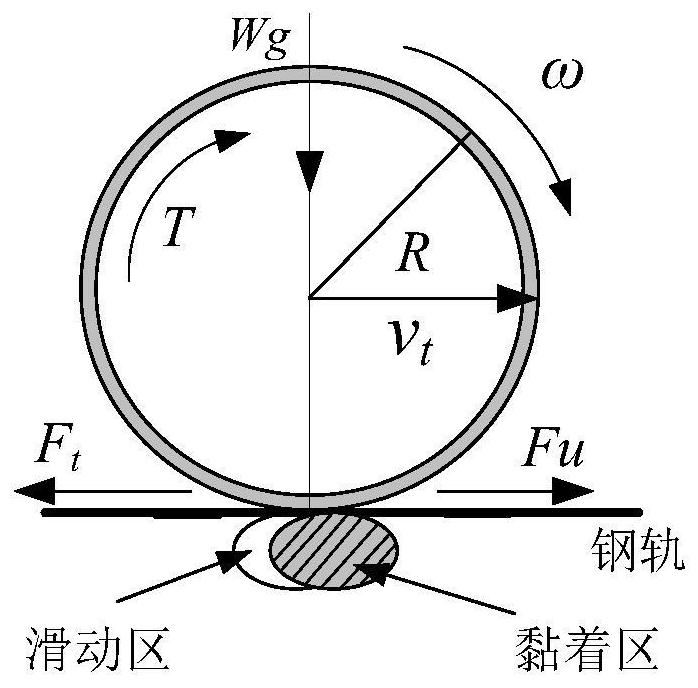

The invention relates to a rail train anti-air rotation anti-skid adhesion optimization control method. According to the current rail surface adhesion condition, the threshold value, the torque decreasing slope and the rising slope are adjusted on-line in real time. Within one anti-air-to-anti-skid regulation cycle, the descent slope is based on the current axis acceleration, and the speed difference is implemented by two steps: fast descent and slow descent. The rising slope is carried out in two steps, fast-rising and slow-rising, according to the latch torque at the time when the thresholdvalue is triggered in the previous regulation cycle. The method takes the easy-to-extract acceleration and the speed difference as the judging conditions, and adjusts the threshold value and the slopeon-line in real time, so that the output torque can be adaptively adjusted according to the rail surface condition, the output torque tends to be stable after 3 to 5 adjustment cycles, the adhesion utilization ratio is effectively improved, and the vehicle stability and the passenger comfort are remarkably improved.

Owner:CRRC QINGDAO SIFANG ROLLING STOCK RES INST

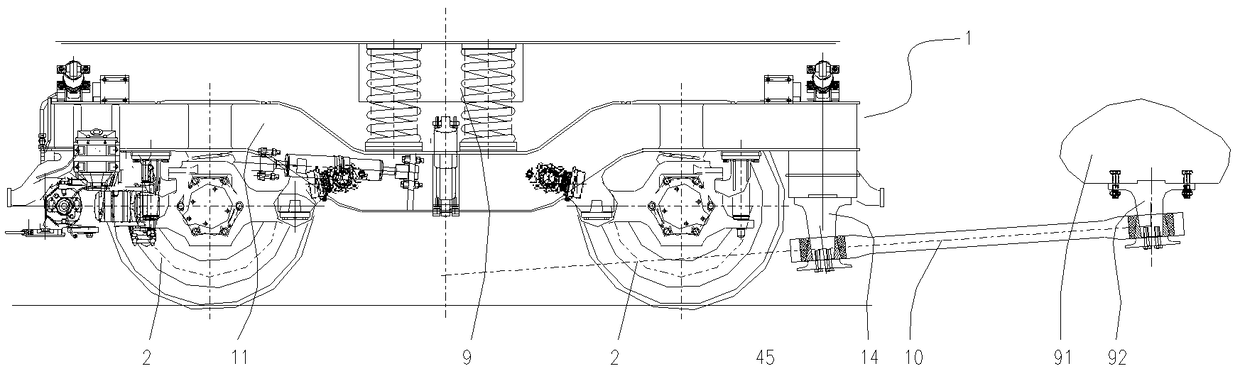

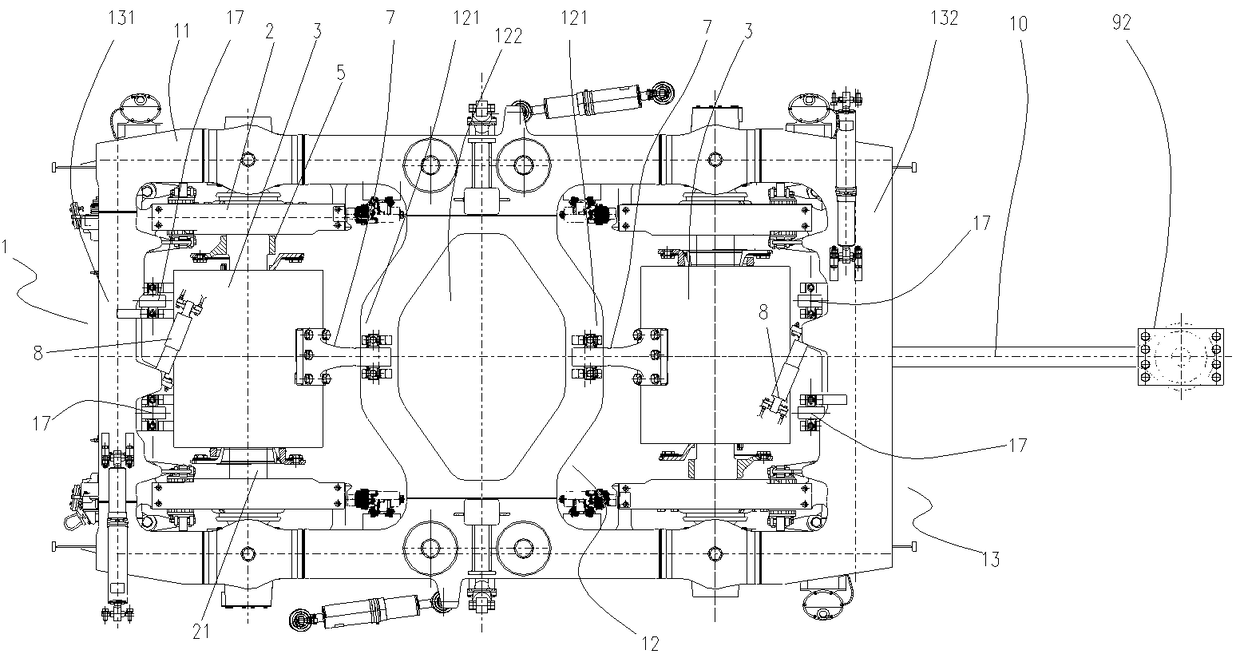

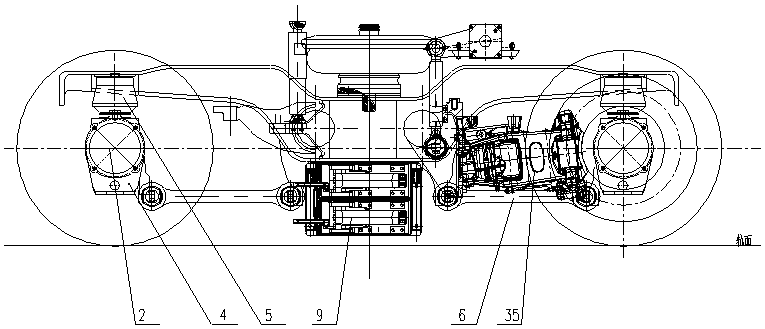

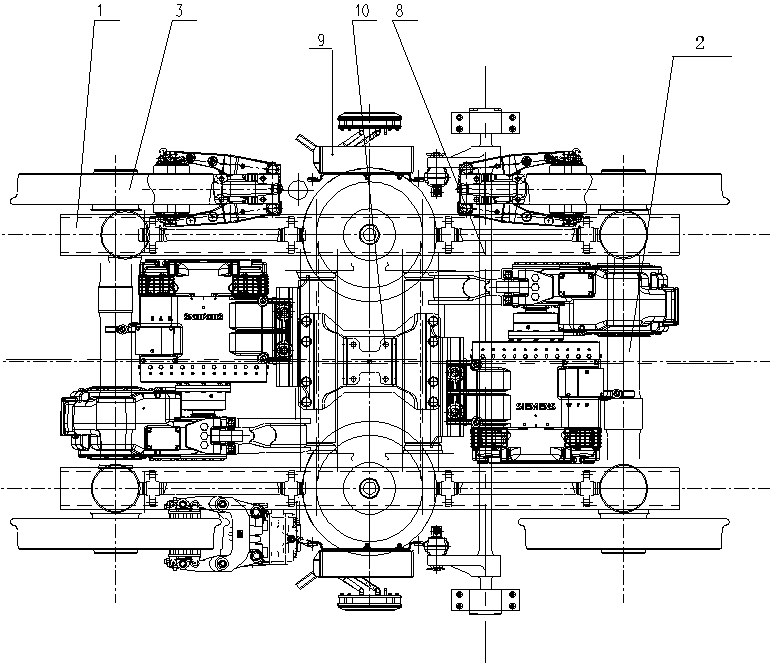

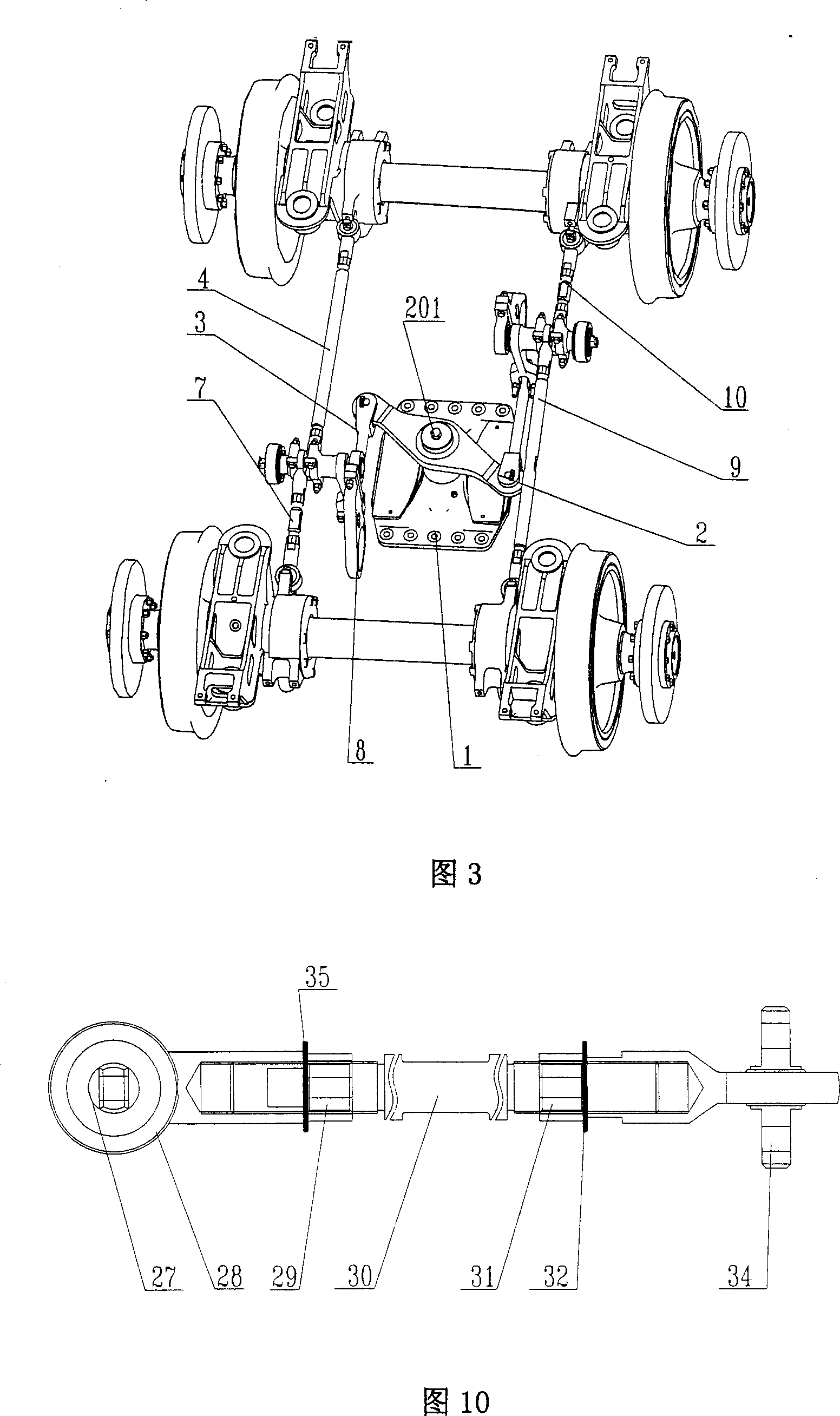

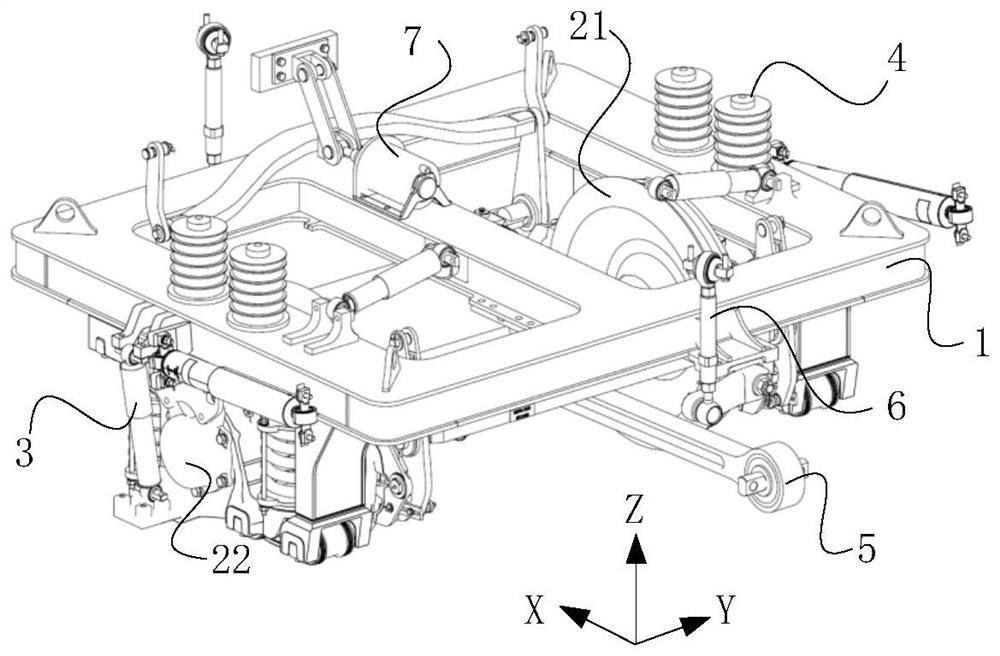

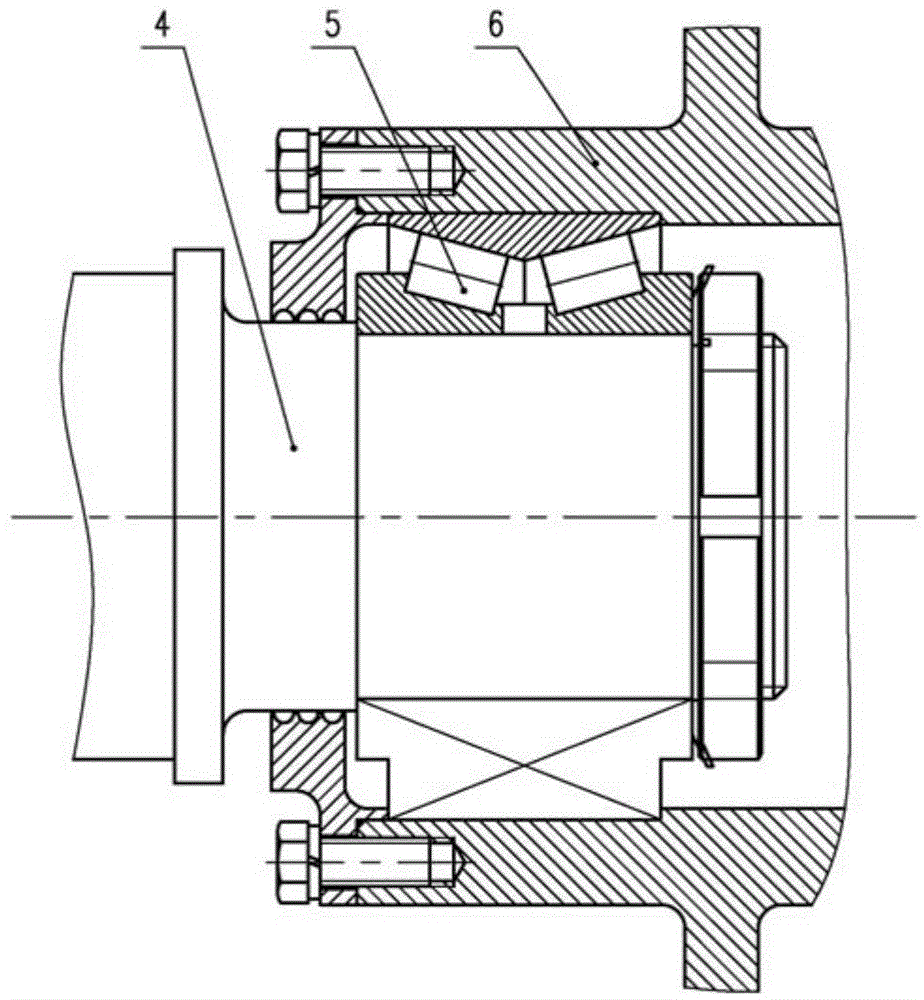

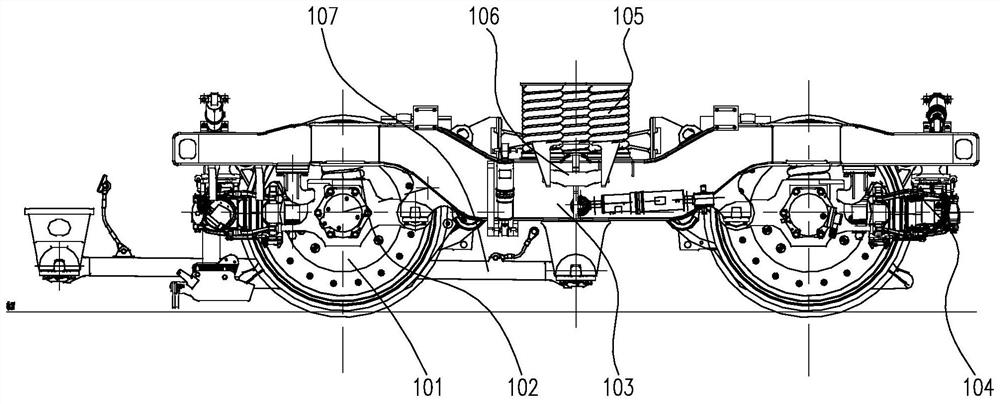

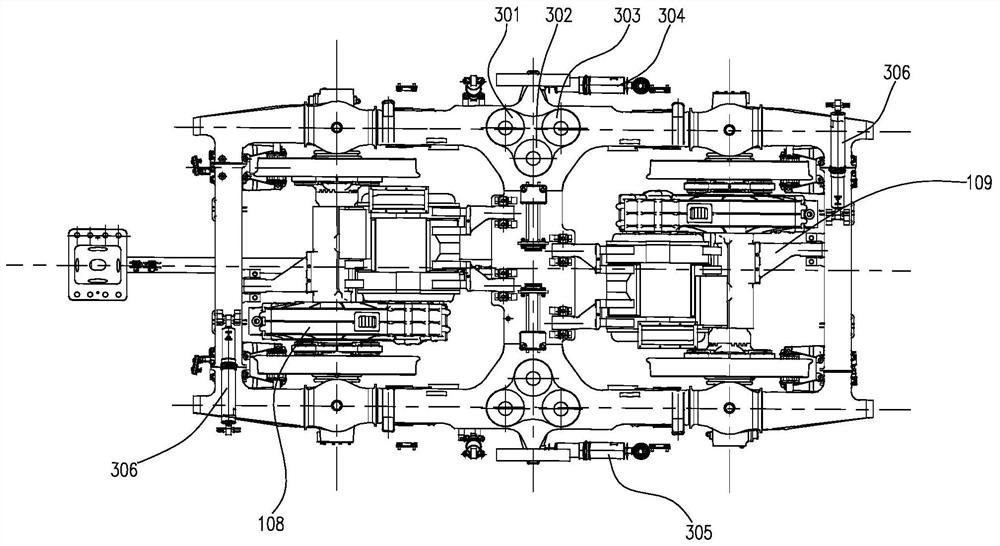

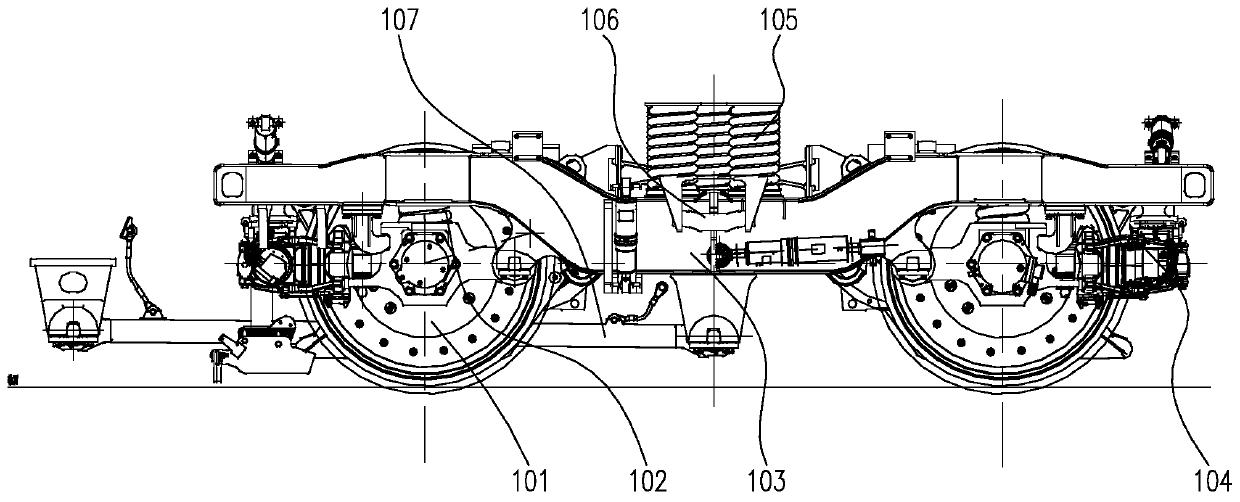

Permanent magnetic direct drive bogie and railway vehicle thereof

ActiveCN108791325AReduce axle load transferImprove sticky utilizationElectric motor propulsion transmissionBogiesBogieCoupling

Owner:ZHUZHOU ELECTRIC LOCOMOTIVE CO LTD

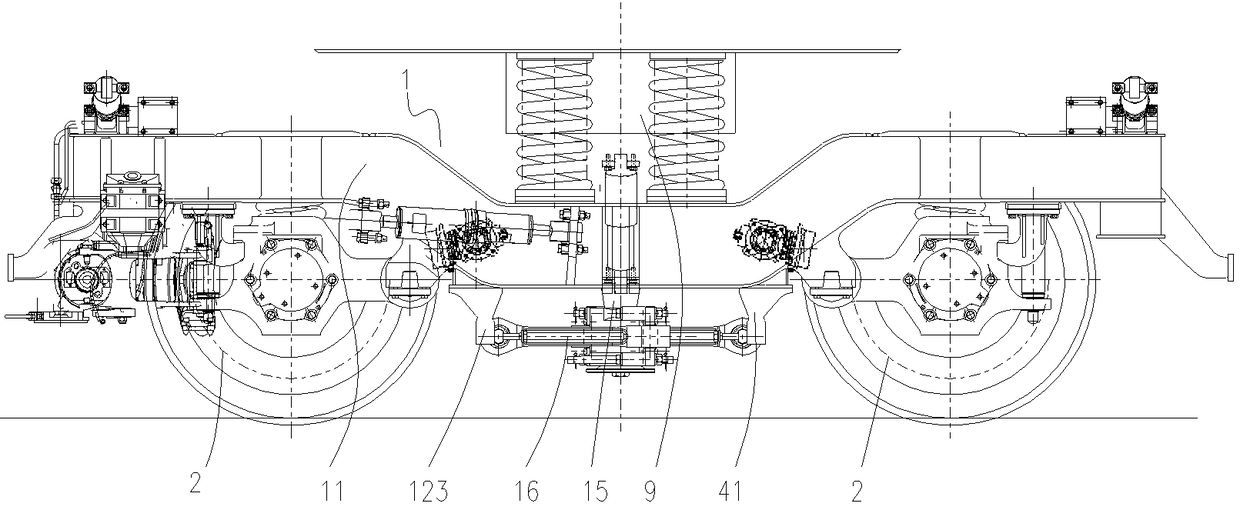

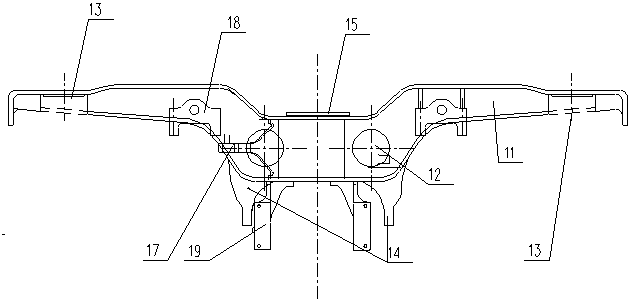

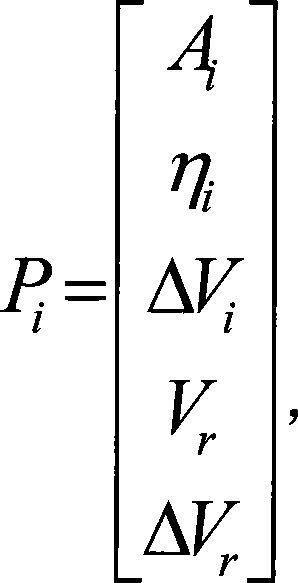

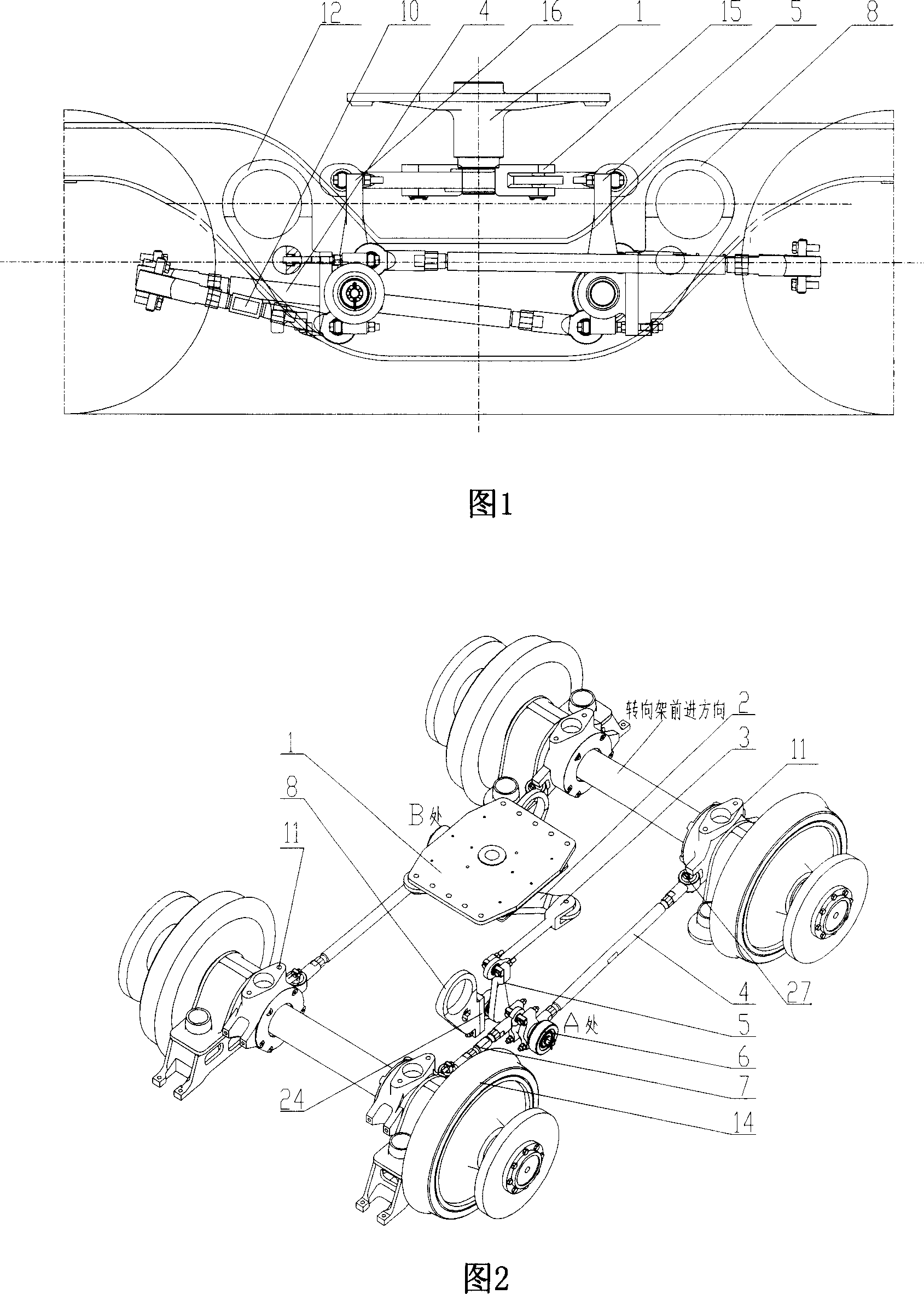

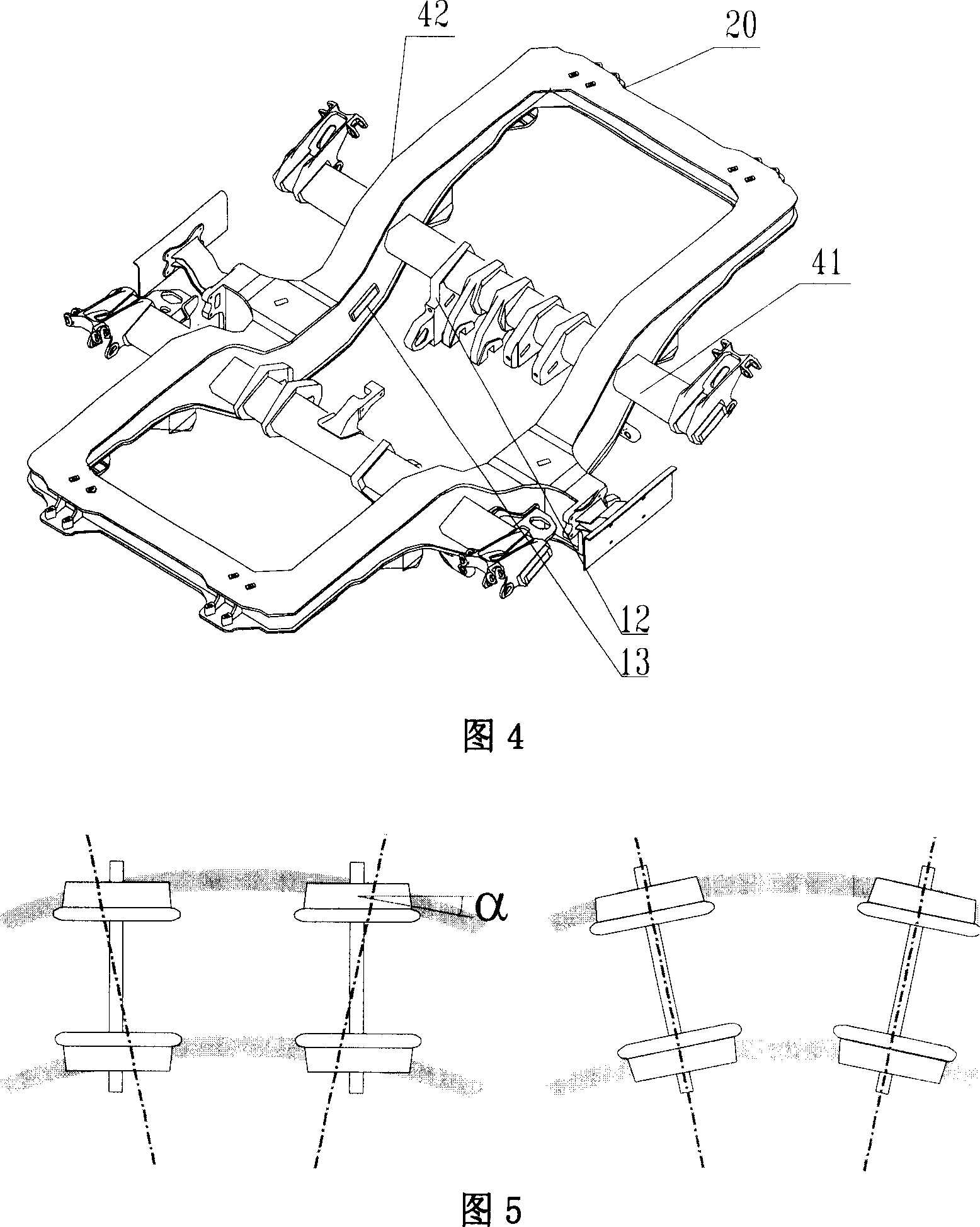

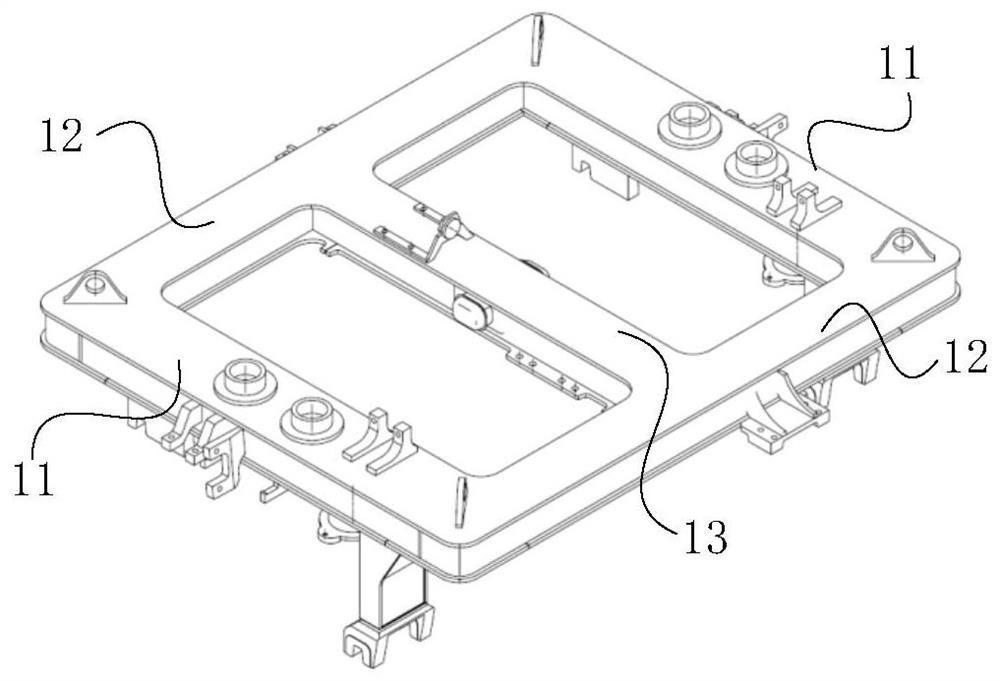

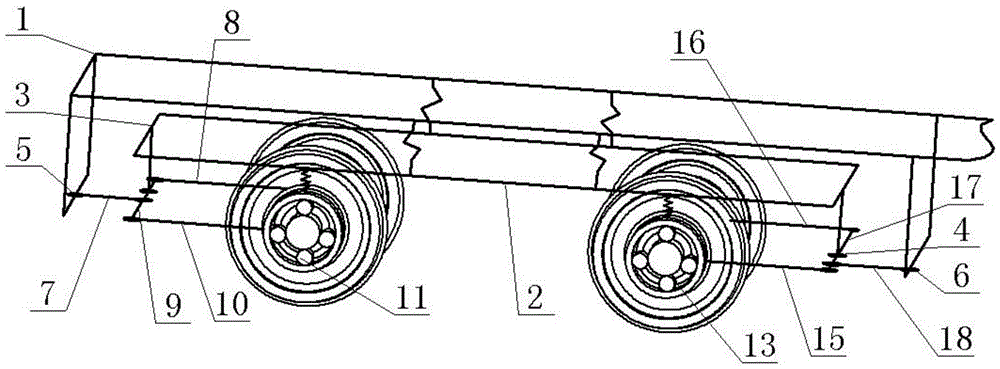

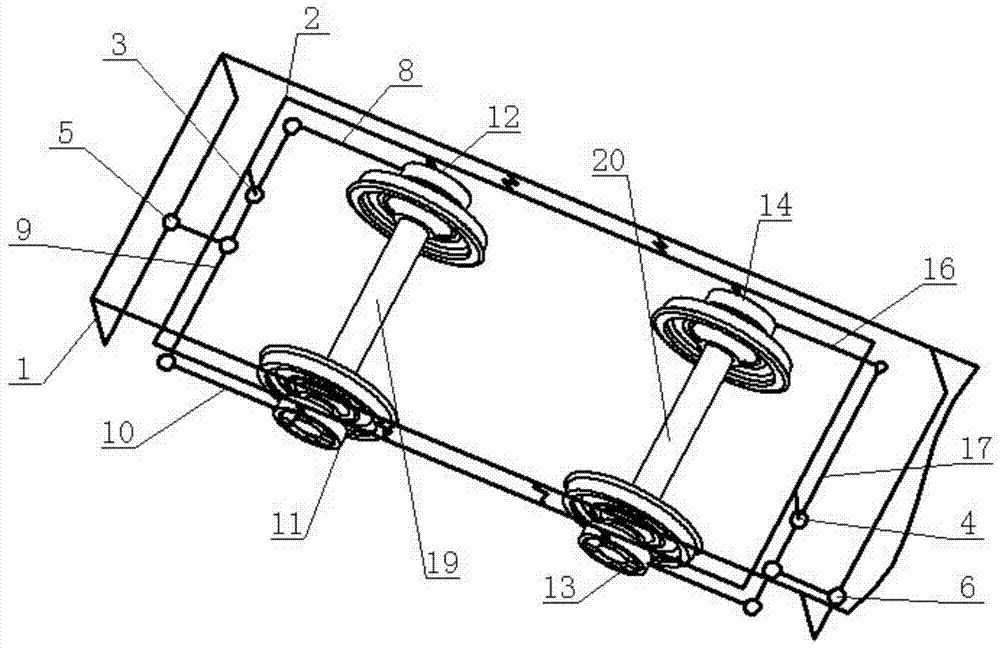

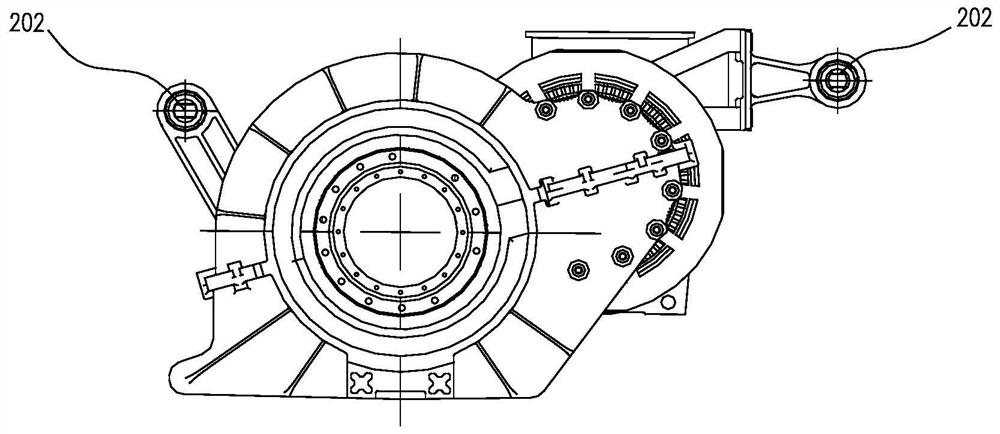

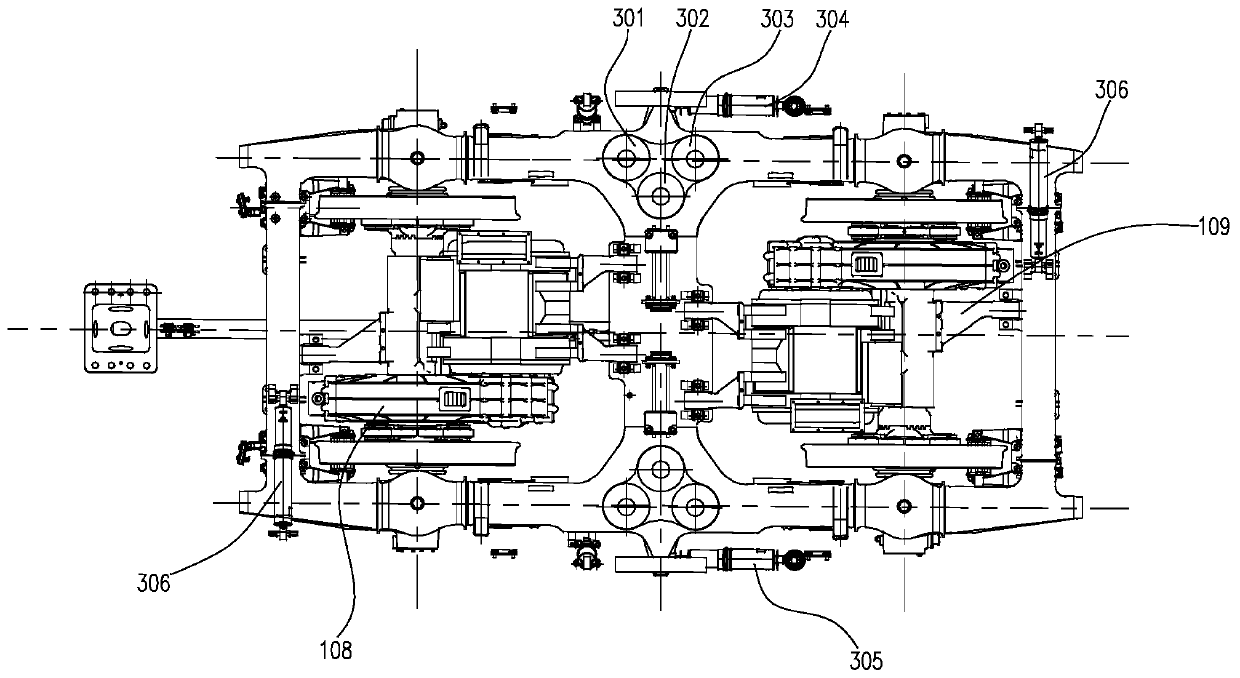

Longitudinal-drive bogie with built-in axle boxes

ActiveCN108032864AReduce in quantityReduce weightElectric motor propulsion transmissionBogiesBogieCoupling

A longitudinal-drive bogie with built-in axle boxes comprises a frame (3) and axle boxes (12); the frame is formed by connecting two side beams (20) and first and second cross beams (23 and 26), boththe frame and the axle boxes are arranged within wheels (1), the two side beams are a traction motor (13) is mounted on each side beam through a motor hanger (21), output shafts of the two traction motors are perpendicular to axles (2), output shafts of the two traction motors are connected with the axles through couplings (16) and gearboxes (17), and the two traction motors are positioned betweenthe first and second cross beams (23 and 26); only one flange brake disc (18) is arranged on one axle and is fitted to a brake caliper (9) on the frame; a traction block (22) is arranged on the firstcross beam, the first cross beam is fixedly connected with one end of a traction pull bar through the traction block (22), and the other end of the traction pull bar is fixed to a vehicle body.

Owner:ZHUZHOU ELECTRIC LOCOMOTIVE CO

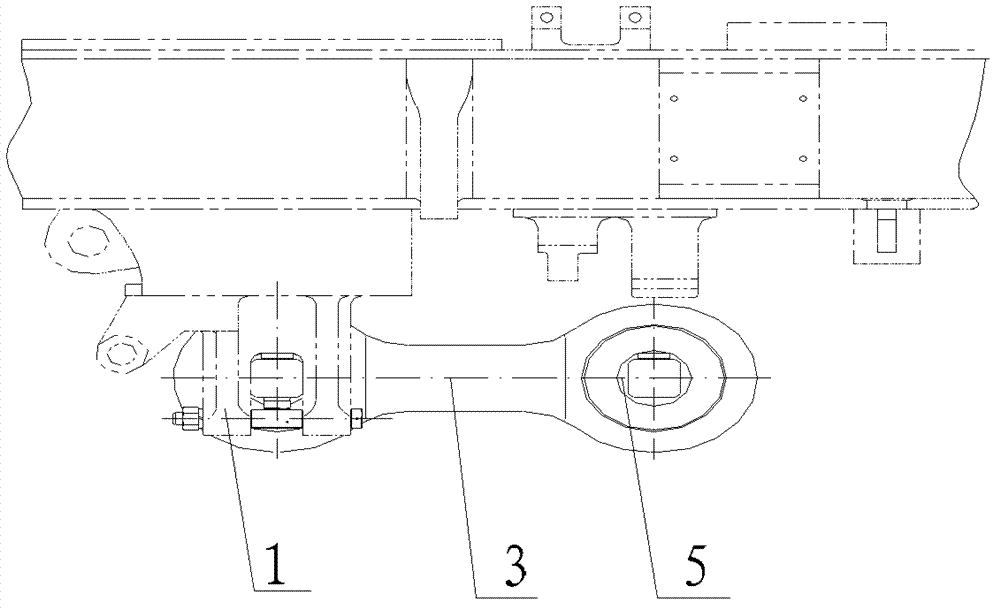

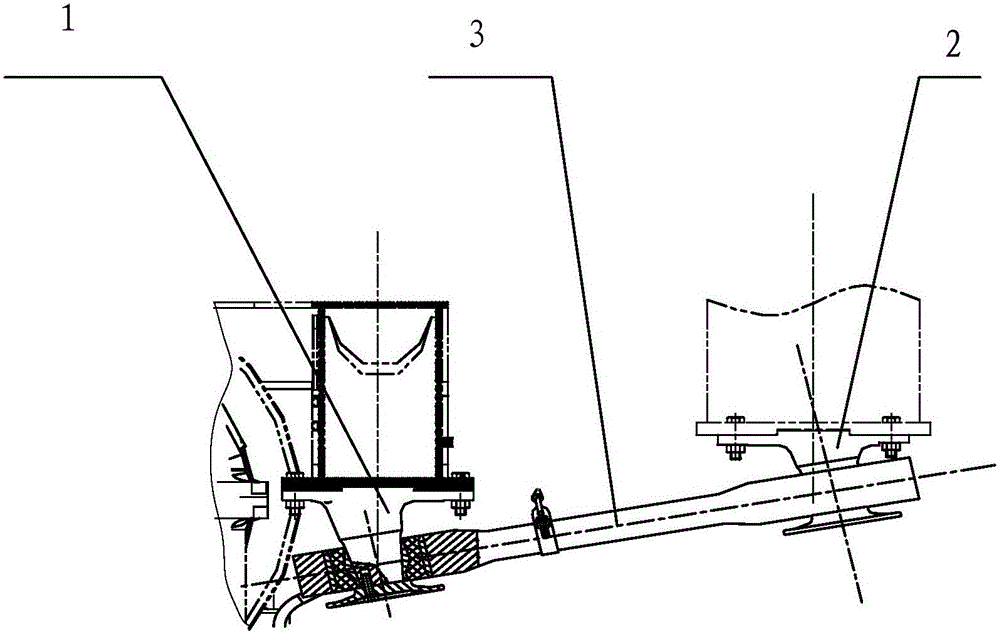

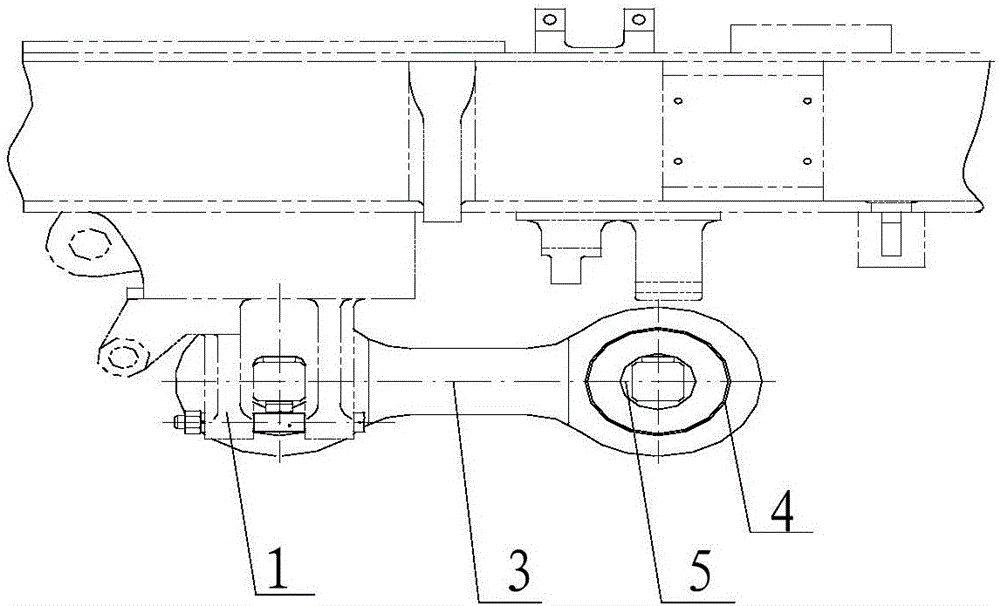

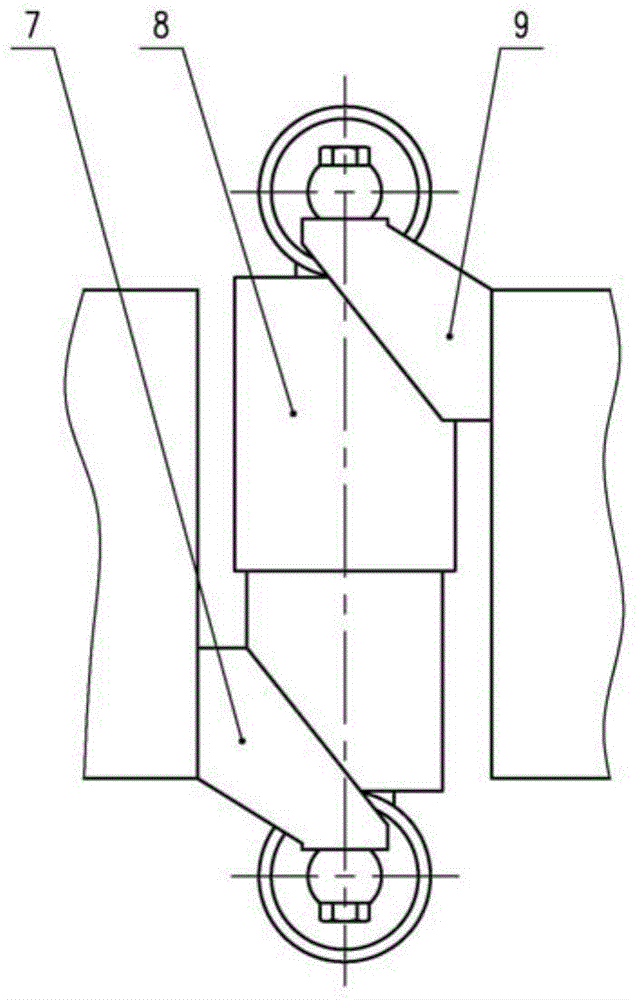

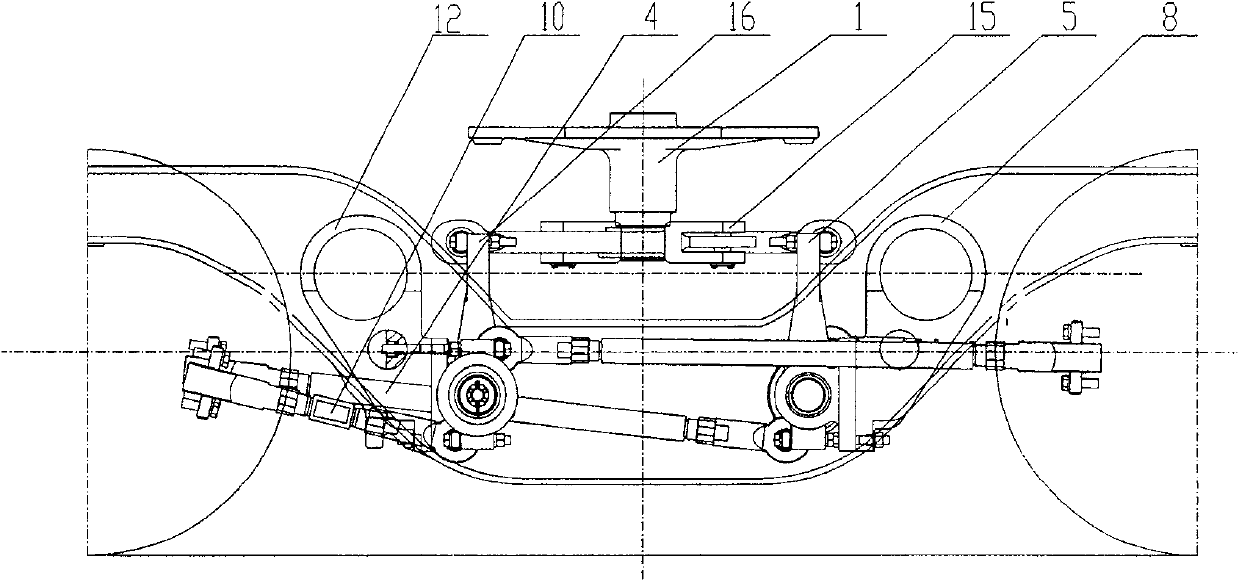

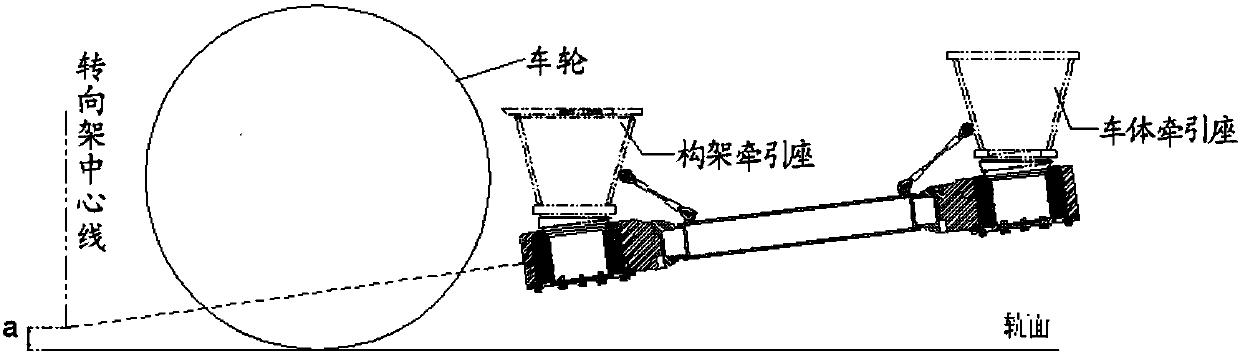

Railway locomotive and railway locomotive traction device

InactiveCN102951171AReduce lateral forceReduce manufacturing costRailway couplingsBogieTransverse force

The invention provides a railway locomotive and a railway locomotive traction device. The traction device comprises a bogie traction seat fixedly mounted on a bogie and a locomotive body traction seat fixedly mounted on a locomotive body, wherein the bogie traction seat is arranged on the upper portion of a lateral end of the bogie and is located on a same horizontal line with the locomotive body traction seat. The traction device further comprises a traction bar which is used for being horizontally arranged between the bogie traction seat and the locomotive body traction seat, two through holes with central lines parallel to each other form at two ends of the traction bar respectively, and the traction bar is used for being fixedly connected with the bogie traction seat and the locomotive body traction seat respectively. Length of the traction bar is designed to be short as far as possible, and accordingly manufacturing cost is saved, the defect that an oblique bar having vertical component force causes axle load transfer in the prior art is overcome and transverse force between wheels and rails is reduced.

Owner:DATONG ELECTRIC LOCOMOTIVE OF NCR

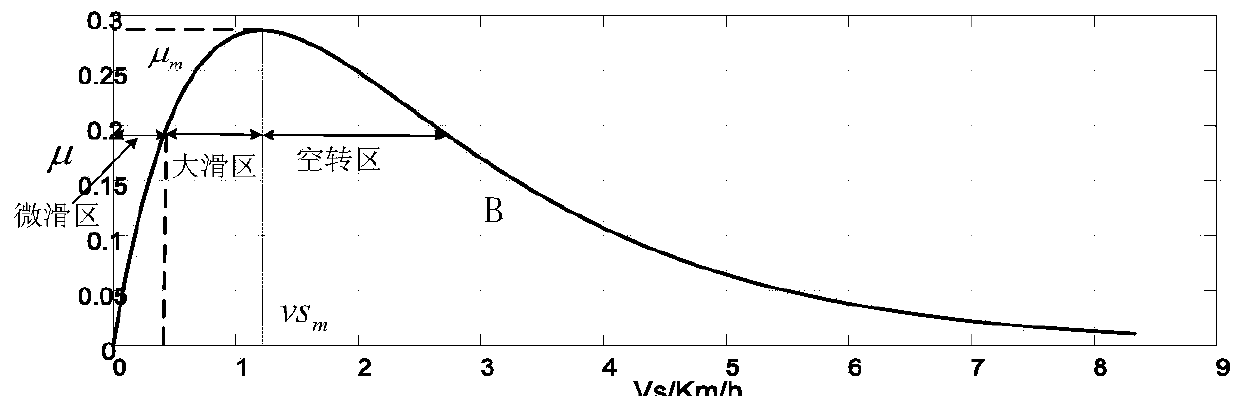

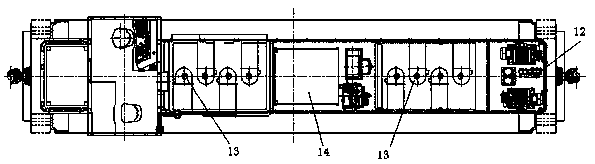

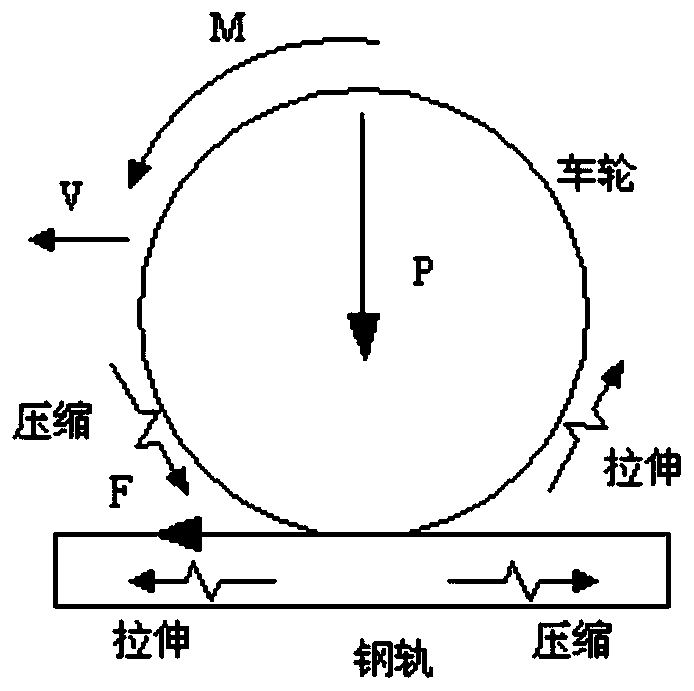

Optimal adhesion control method based on optimal creep speed searching and tracking

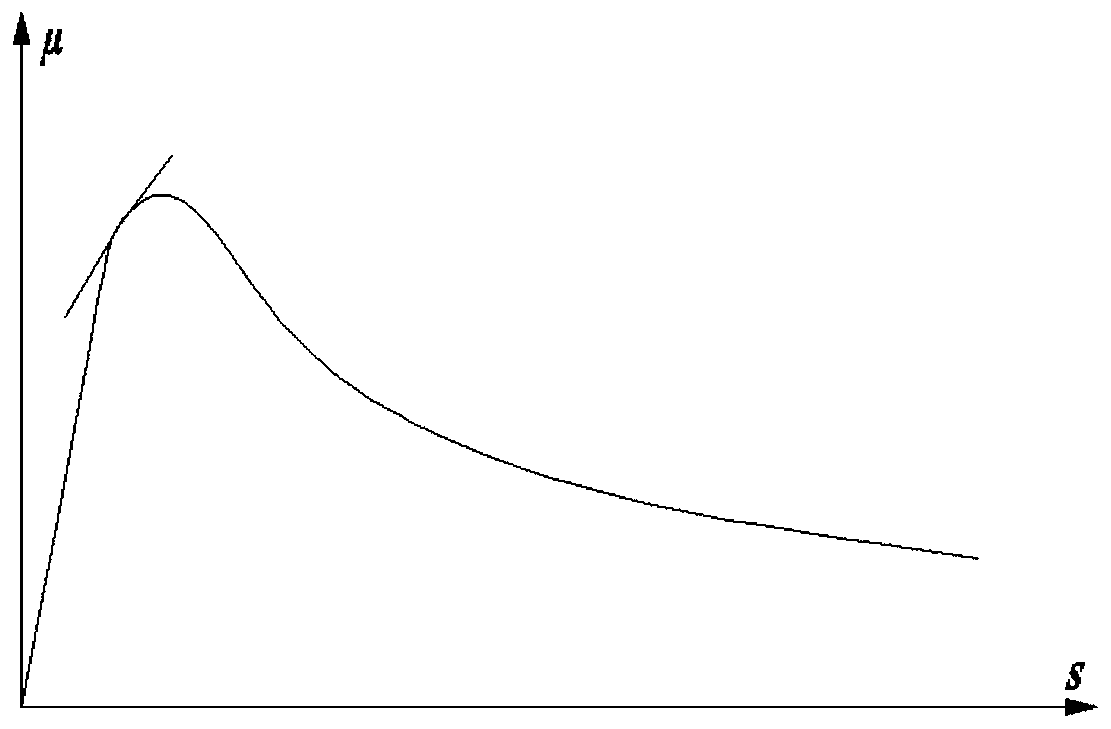

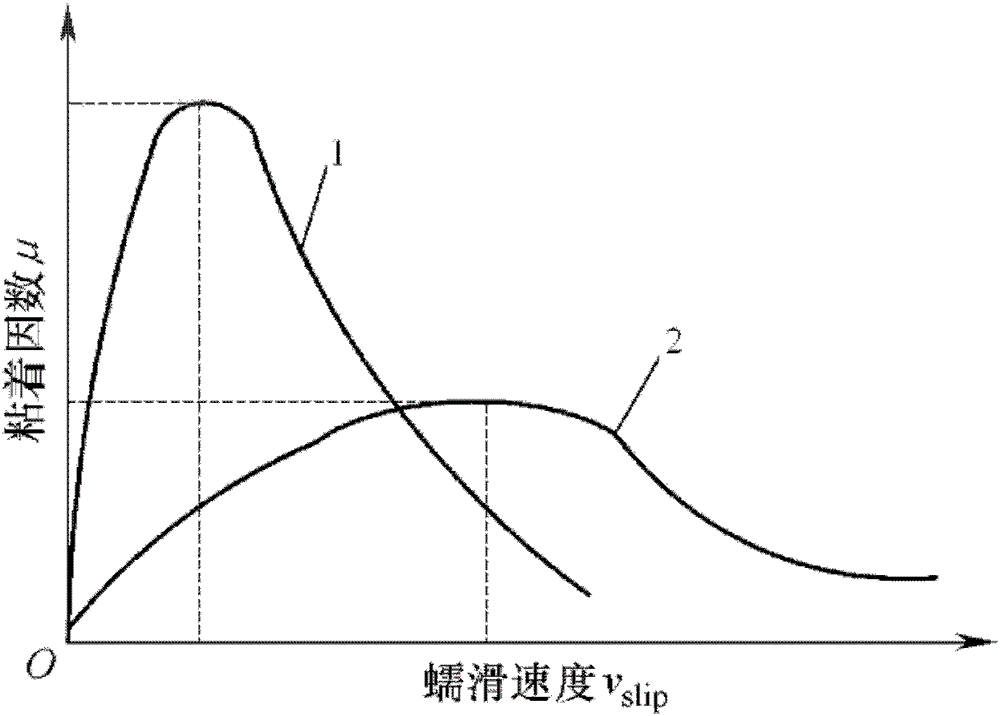

ActiveCN110450794AEffective trackingExcellent adhesionSpeed controllerElectric energy managementAdhesion forceAdhesion coefficient

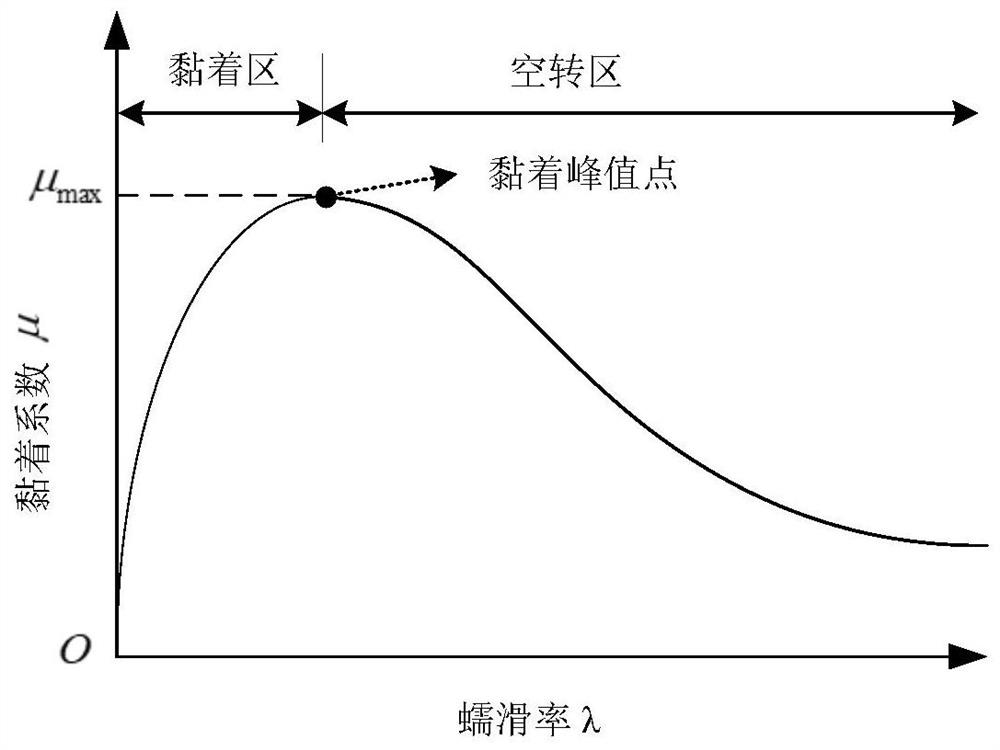

The invention discloses an optimal adhesion control method based on optimal creep speed searching and tracking. The method comprises a full state observer, a reference creep speed searching module andan MPC adhesion controller, wherein the full state observer is used for estimating a locomotive adhesion coefficient by utilizing the traction torque of a motor and the wheel pair rotating speed; thereference creep speed searching module is used for judging a locomotive running condition according to the adhesion coefficient and the creep speed of the locomotive, adjusting the reference creep speed and searching the optimal creep speed of a current track surface, and outputting the searched reference creep speed to the MPC adhesion controller; and the MPC adhesion controller is used for predicting the optimal traction torque in real time under two signal conditions of the given reference creep speed and the actual creep speed in combination with the motor control torque constraints, creep speed constraints and a driving performance index, and outputting the optimal traction torque to the locomotive in order to realize the tracking of the optimal creep speed. According to the method,the maximum adhesion force is obtained, the adhesion utilization rate is improved, and meanwhile, the requirements for a traction system are met.

Owner:SOUTHWEST JIAOTONG UNIV

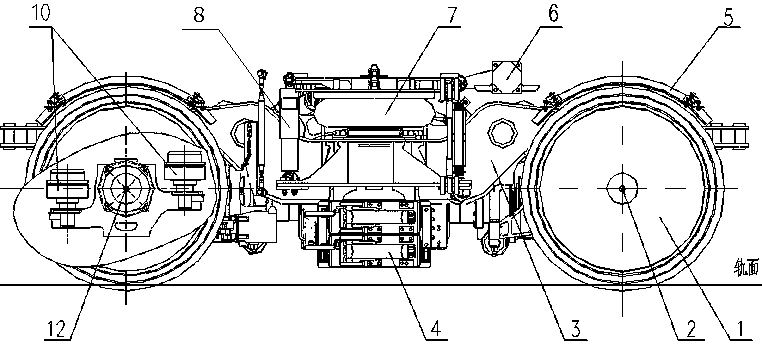

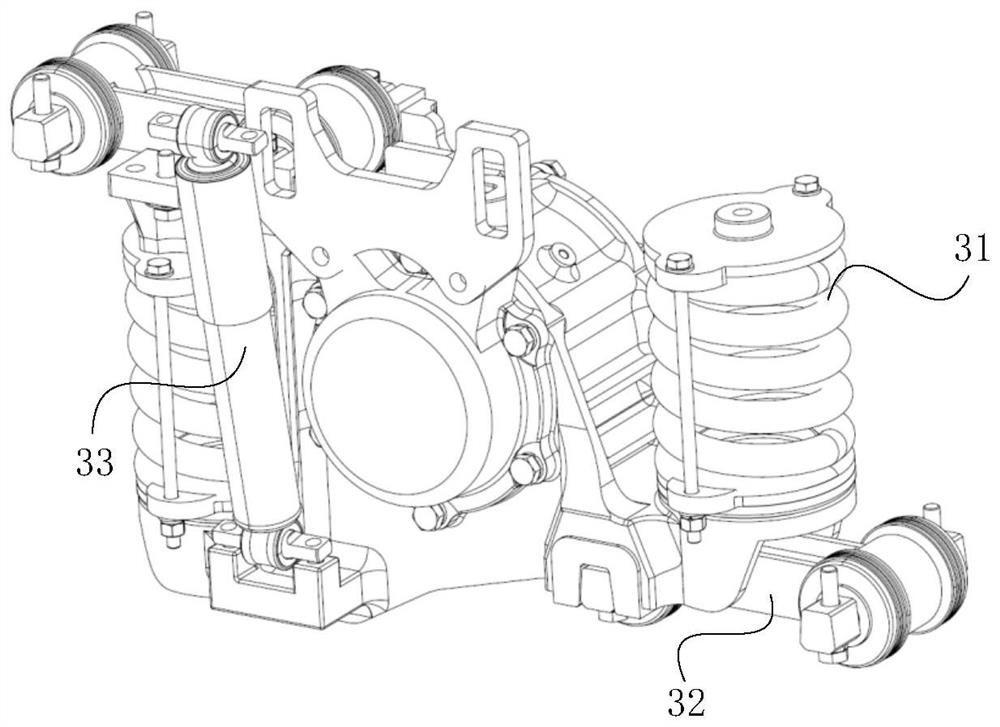

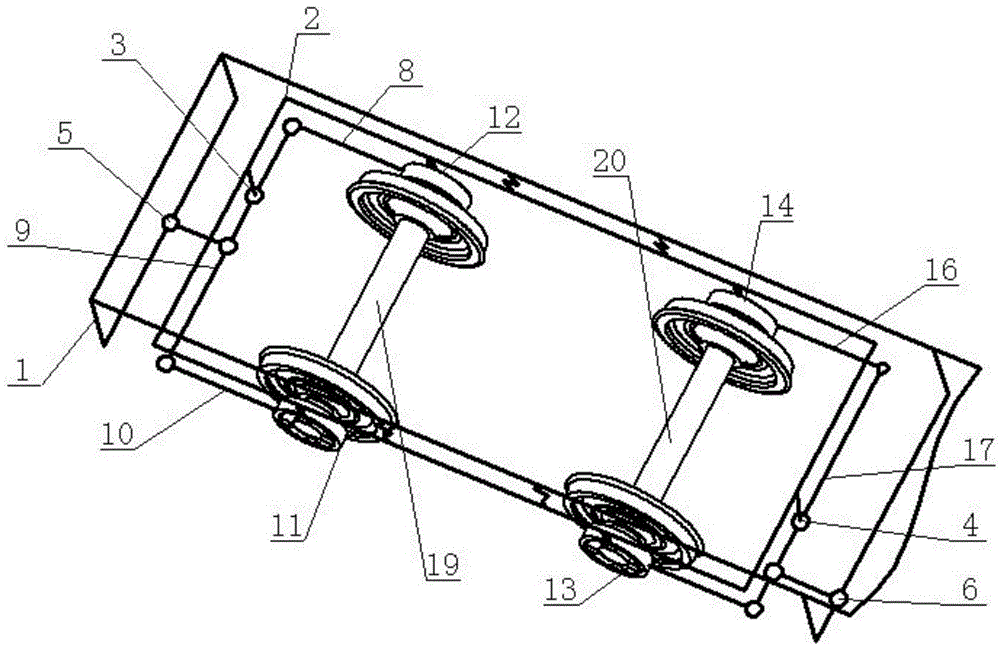

Transverse-drive bogie with built-in axle box

InactiveCN108032865AReduce horizontal sizeSmall lower boundElectric motor propulsion transmissionBogiesBogieLower limit

A transverse-drive bogie with a built-in axle box comprises frames (1) arranged at the front and rear ends of axles (2) respectively, two ends of each axle are fitted with wheels (3) respectively, theframes are mounted on the axles through primary suspension devices (5) and axle boxes (4), each frame comprises two side beams (11), two cross beams (12) are arranged in the middle of the side beamsin parallel, both the frames and the axle boxes are arranged on the inner sides of the wheels (3), four basic brake devices (35) are symmetrically arranged at the bottom of the two side beams of eachframe, two driving motors (33) and two gearboxes (32) are fixedly connected to the two cross beams of each frame, output shafts of the two driving motors are parallel to the corresponding axle, and output shafts of the two driving motors are connected with the axles through the gear boxes respectively. The mature reliable scheme of transversely arranged motors is used herein, so that mounting space is reduced at the premise of meeting the transmission torque requirement; the gearboxes employ two-stage transmission, so that the size of the gearboxes is reduced and the lower limit is guaranteed.

Owner:ZHUZHOU ELECTRIC LOCOMOTIVE CO

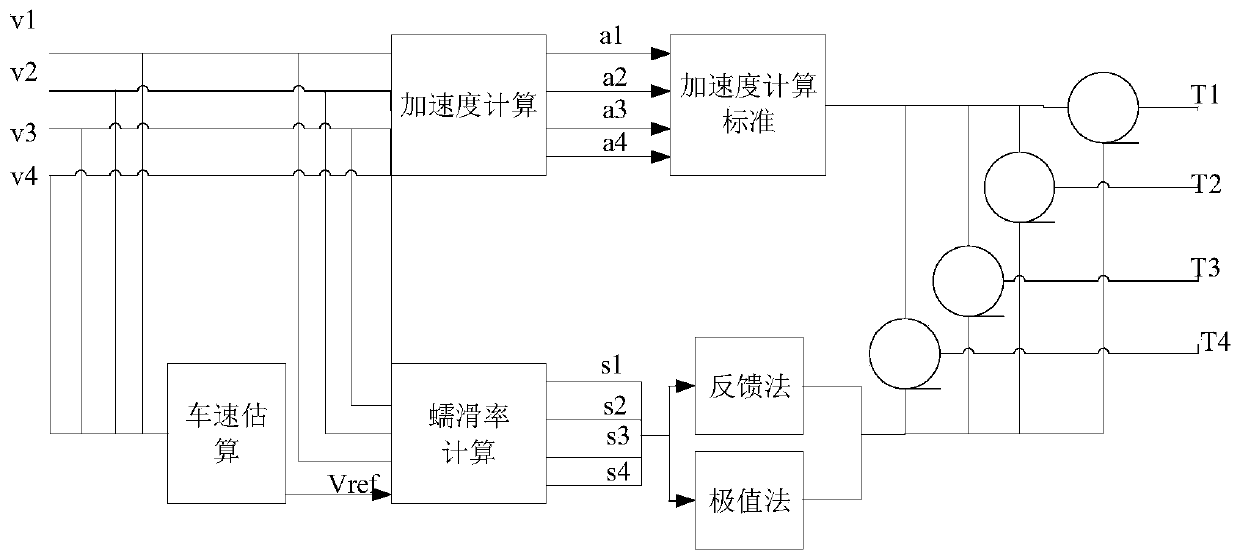

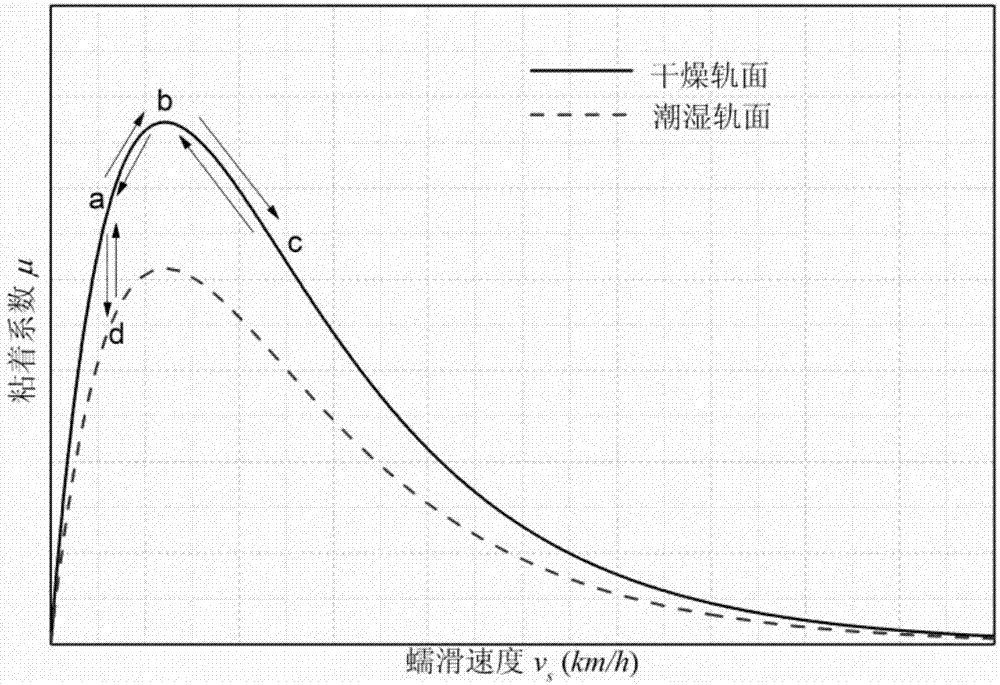

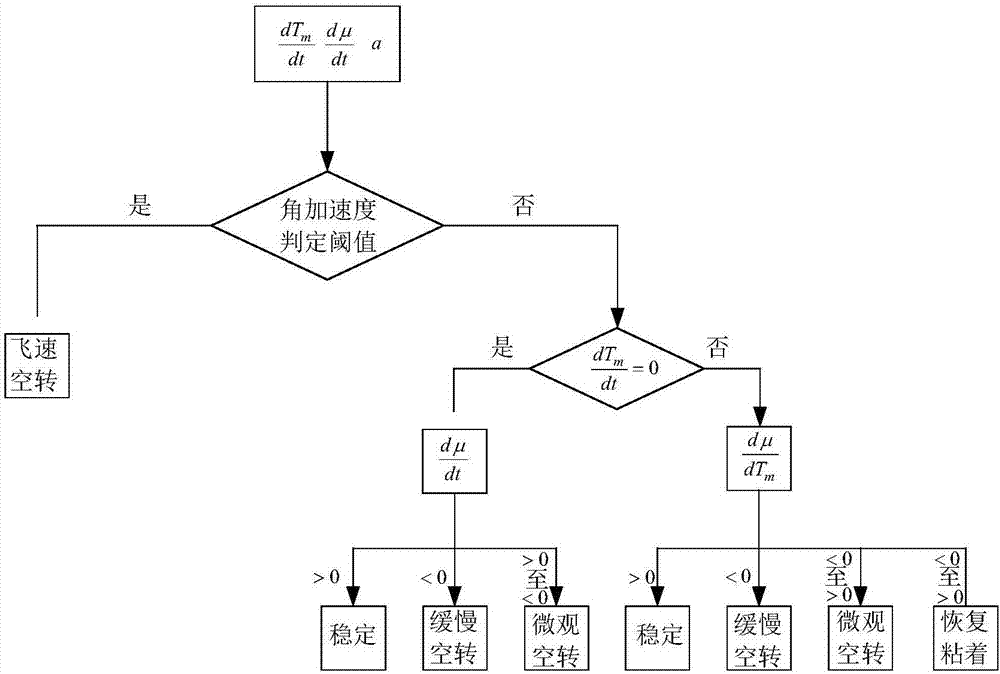

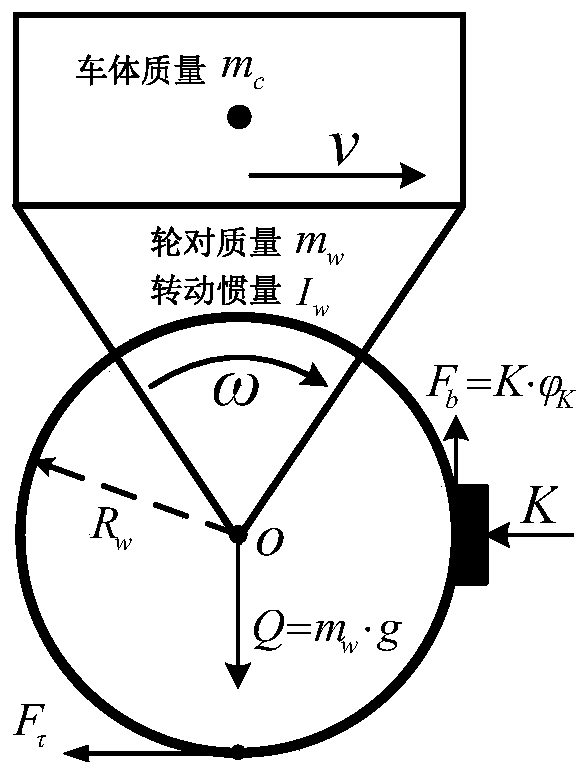

Heavy-duty locomotive multistage idling fault detection method

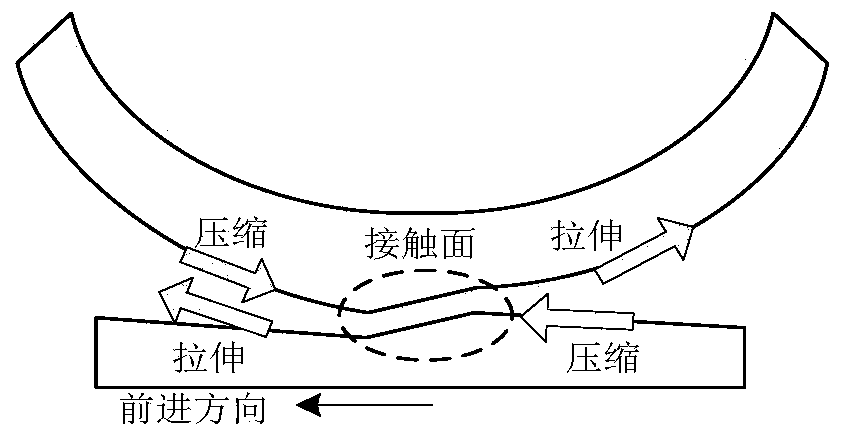

InactiveCN107219775AWith predictive functionImprove reliabilitySimulator controlAdhesion coefficientHeavy duty

The invention discloses a heavy-duty locomotive multistage idling fault detection method comprising the following steps that firstly the idling fault is graded according to different idling phenomena; and then the locomotive idling fault is detected and classified by analyzing a wheel / rail surface adhesion feature curve according to the locomotive operation work state by using the combination method of the wheel diagonal acceleration, the traction moment derivative and the adhesion coefficient derivative. The adhesion coefficient derivative is used as the criterion so as to have the prejudging function for idling operation; multistage fault detection is performed on idling operation of the locomotive wheelset so as to guide multistage adjustment of the locomotive adhesion system for the traction torque; and using the locomotive body speed signal is avoided so that the reliability of the algorithm can be greatly enhanced. Besides, the algorithm is simple in structure and easy to implement, and the effectiveness of the detection method can be verified through simulation.

Owner:HUNAN UNIV OF TECH

Optimal traction torque online search based locomotive adhesion control method

ActiveCN112061177AAvoid severe abrasionsExtended service lifeRailway signalling and safetyComplex mathematical operationsWeight transferControl theory

The invention discloses an optimal traction torque online search based locomotive adhesion control method, comprising the following steps: S1, performing idling detection on locomotive axles, recognizing the axle with idling operation first of a locomotive as a search axle, and the rest axles as receiving axles; S2, obtaining the optimal traction torque, suitable for operating under a current railsurface working condition, of the search axle through an optical traction torque online search algorithm; and S3, quickly responding to changes, caused by an axle weight transfer phenomenon, of adhesion weight to regulate the optimal traction torque of each receiving axle based on the optimal traction torque of the search axle. According to the optimal traction torque online search based locomotive adhesion control method disclosed by the invention, an adhesion control strategy of the whole locomotive is designed, integrity of the locomotive is taken into consideration, and influences, on adhesion weight of each axle, by the axle weight transfer phenomenon of the vehicle body, are analyzed; and the axles are cooperatively matched by virtue of the advantage of independently regulating thetorque by an the axle-control type traction system, so that integral traction force of the locomotive can be effectively improved, and integral traction performance of the locomotive is improved.

Owner:CHENGDU YUNDA TECH CO LTD

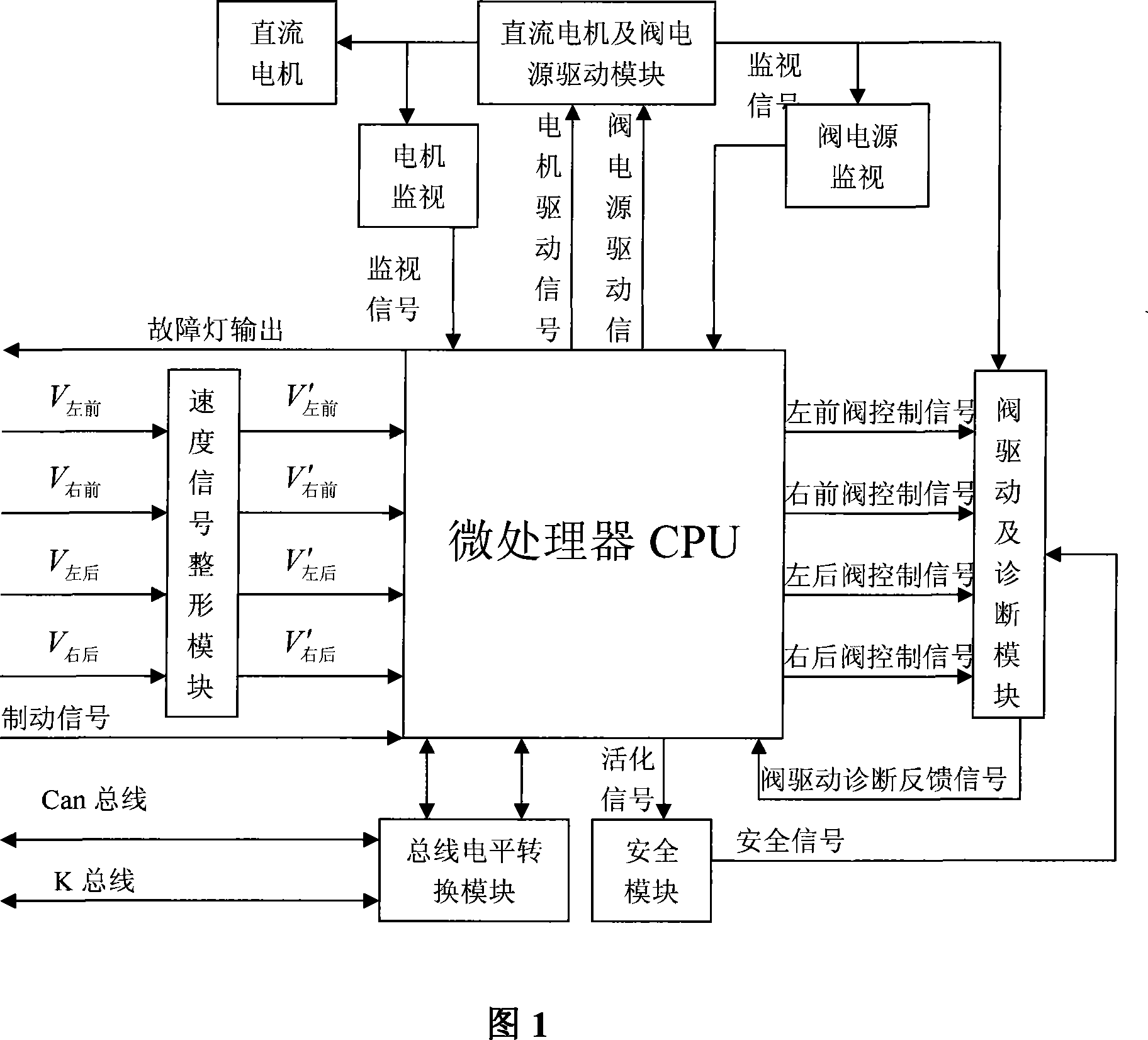

Automobile locking-proof controller with agglutination controlling self-learning function

InactiveCN101138980APrevent side slipAvoid shockAdaptive controlRecording and playback systemsMotor driveControl signal

An anti-locking controller of the automobile with the functions of adhesion control and self study includes a speed signal shaping module, a microprocessor CPU, a direct current motor, a valve electrical source driving module, a valve driving module, a diagnosis module and a bus level conversion module. The automobile speed signal is transformed a sine wave into digital pulse signal and input the microprocessor CPU by the speed signal shaping module, and the microprocessor CPU figures out relevant physical quantity according to the speed signal to confirm whether the vehicle slips or not, and if certain wheel is judged as being slip, the microprocessor CPU can promptly send a motor driving signal and a valve electrical source signal to the direct current motor and the valve electrical source driving module to start the motor and the valve electrical source, then relevant valve control signal is sent to execute the adhesion control towards the slip wheel; the controller uses an adhesion tracing parameter SPf to control the adhesion of the braking vehicle and uses a balance parameter SPb to control the stability of the braking vehicle and uses a anti-impact parameter SPc to control the comfort of the vehicle.

Owner:ZHUZHOU TIMES ELECTRONICS TECH CO LTD +1

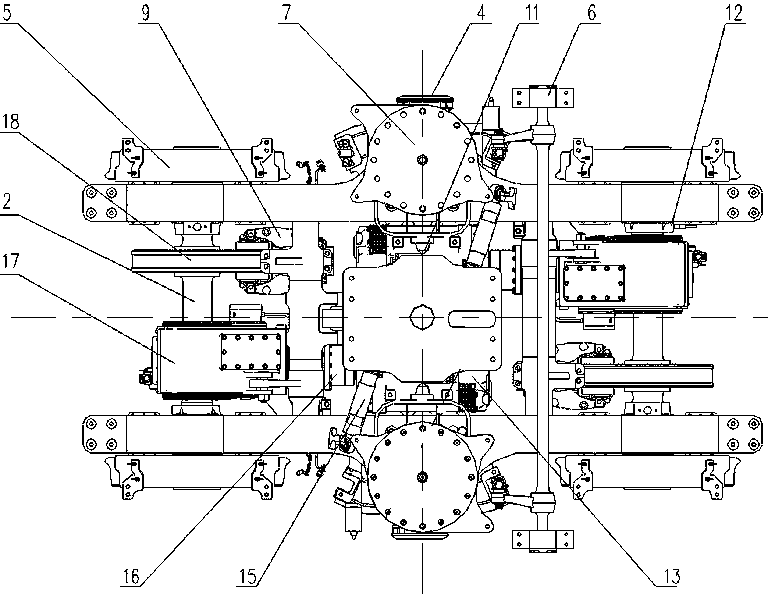

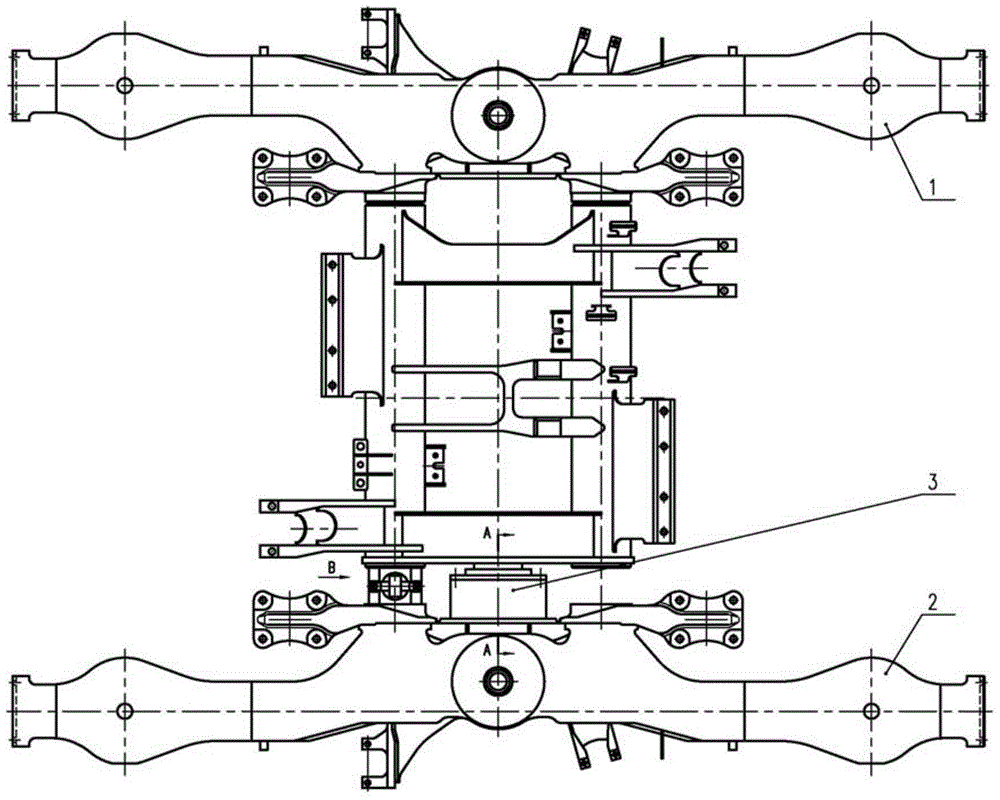

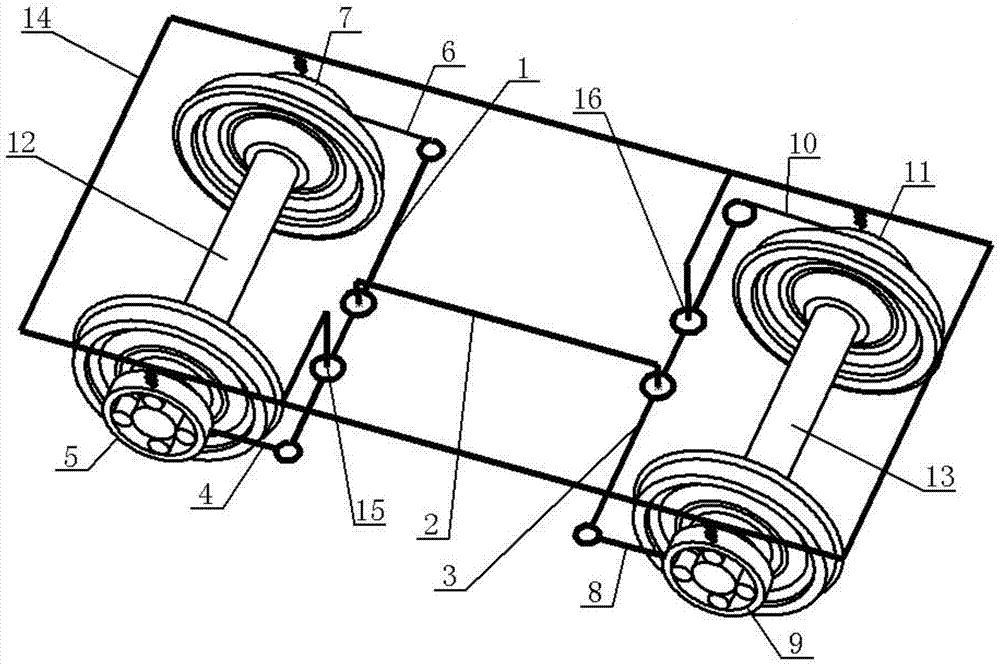

Centre pin type guiding compelling radial direction mechanism

ActiveCN101117125AReduce longitudinal positioning stiffnessFree head movementWheel axle self-adjustmentsBogieEngineering

The central pin type forced steering radial mechanism has a radial truck which has forced steering, self steering and flexible steering performance. A novel radial adjustment mechanism is adopted to reduce the longitudinal positioning rigidity of a wheel pair opposite frame and to enable wheel pairs to approach in the radius direction as much as possible when the truck passes through a curve, thereby reducing noise and abrasion and increasing the adhesive force of the curve. The central pin type forced steering radial mechanism is provided with a frame, the truck is connected with a car body through the central pin and supports the car body upward and elastically, and the central pin type forced steering radial mechanism is also provided with two sets of wheel pairs and the radial adjustment mechanism. The radial adjustment mechanism is provided with a central rotating disc, a group of vertical push rods are respectively connected with the end part of the central rotating disc, and the other end of each vertical push rod is connected with a rotating arm. The rotating arm is connected with a positioning sleeve and forms a first positioning point on the truck side sill through the positioning sleeve, and the rotating arm is connected with the positioning sleeve and forms a second positioning point on the truck transom through the positioning sleeve. Two sets of tie rods are respectively connected with the ratating arm, and the other end of the each tie rod is connected with the axle box of front and rear wheel pairs.

Owner:CRRC QINGDAO SIFANG CO LTD

Railway locomotive traction device and railway locomotive

InactiveCN102951171BImprove sticky utilizationAxle weight offset is smallRailway couplingsBogieTransverse force

The invention provides a railway locomotive and a railway locomotive traction device. The traction device comprises a bogie traction seat fixedly mounted on a bogie and a locomotive body traction seat fixedly mounted on a locomotive body, wherein the bogie traction seat is arranged on the upper portion of a lateral end of the bogie and is located on a same horizontal line with the locomotive body traction seat. The traction device further comprises a traction bar which is used for being horizontally arranged between the bogie traction seat and the locomotive body traction seat, two through holes with central lines parallel to each other form at two ends of the traction bar respectively, and the traction bar is used for being fixedly connected with the bogie traction seat and the locomotive body traction seat respectively. Length of the traction bar is designed to be short as far as possible, and accordingly manufacturing cost is saved, the defect that an oblique bar having vertical component force causes axle load transfer in the prior art is overcome and transverse force between wheels and rails is reduced.

Owner:DATONG ELECTRIC LOCOMOTIVE OF NCR

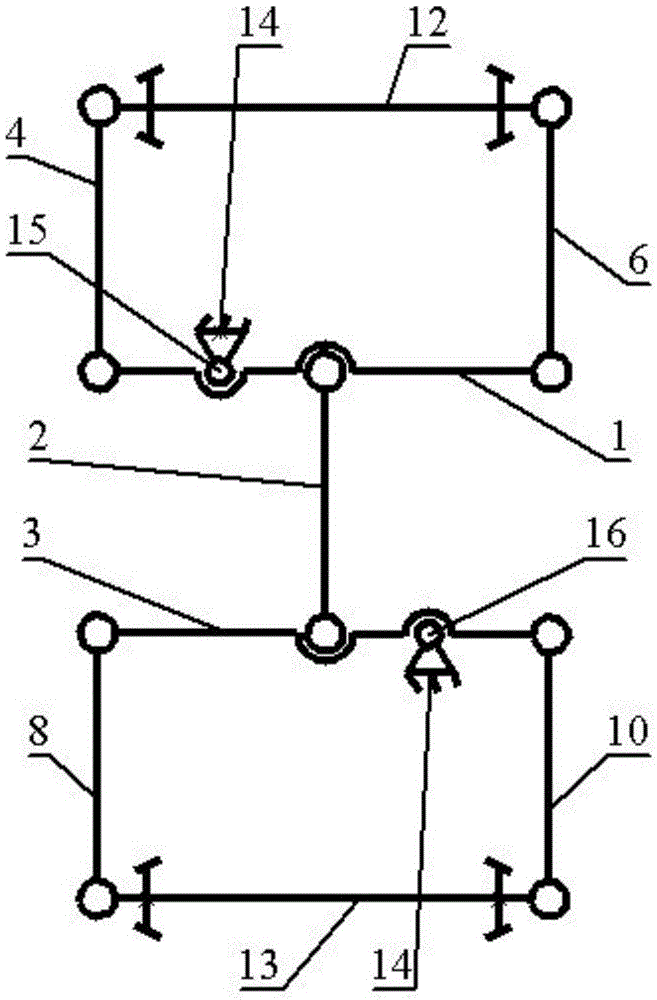

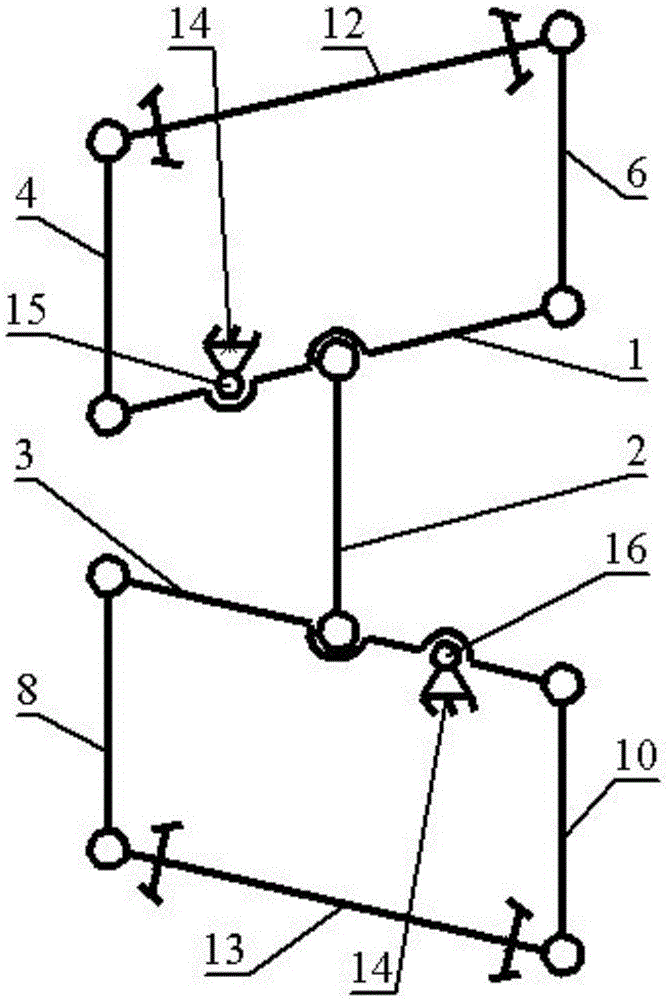

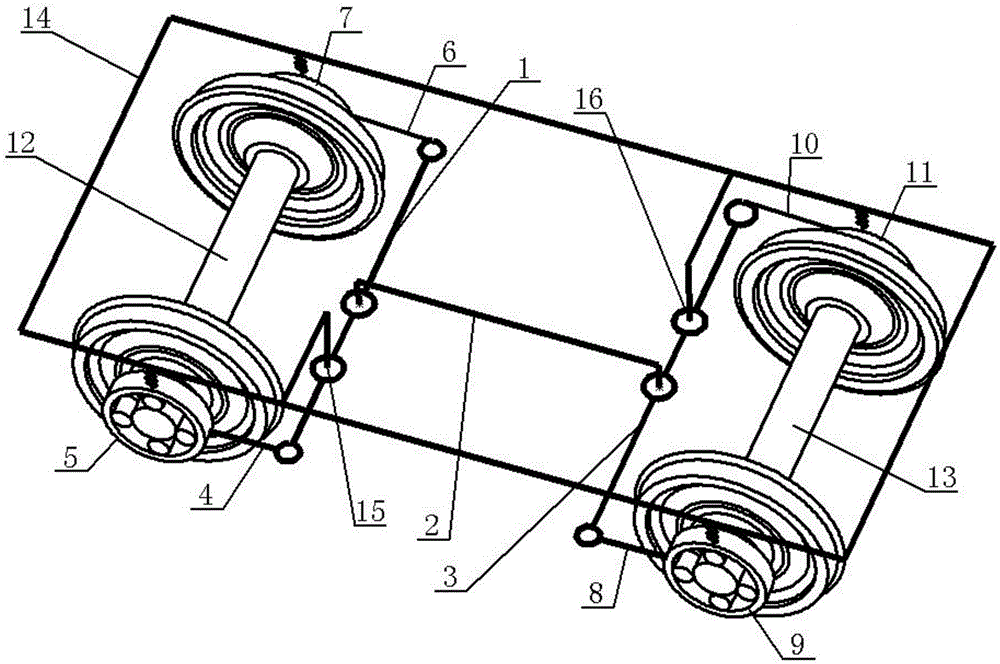

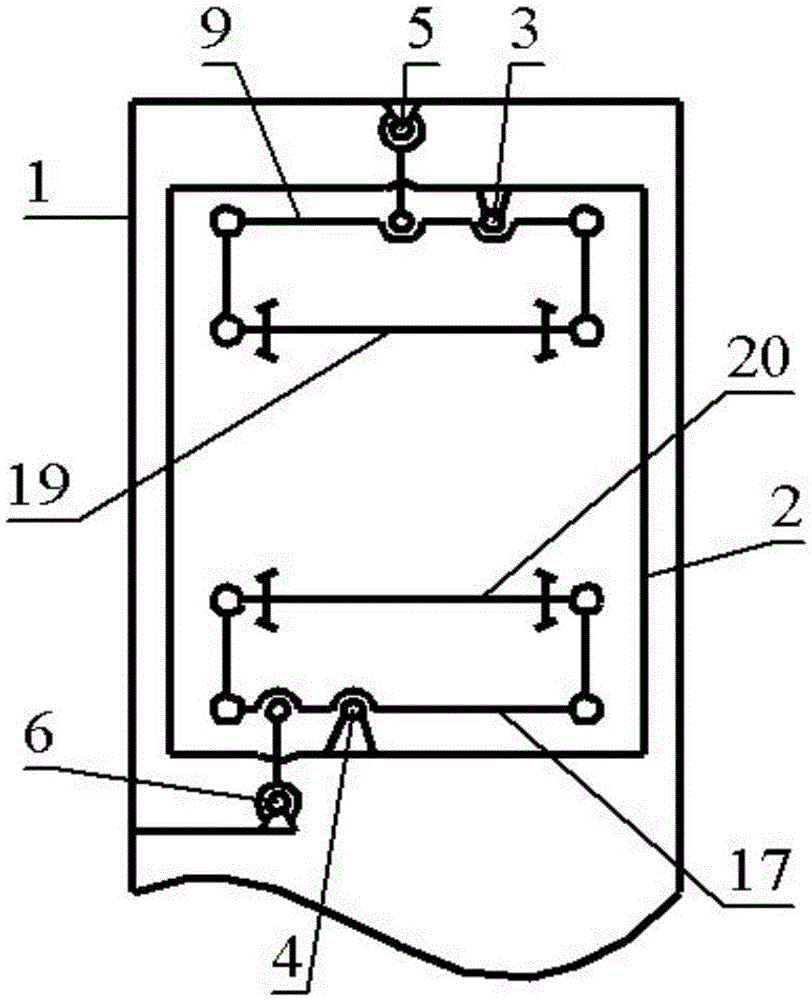

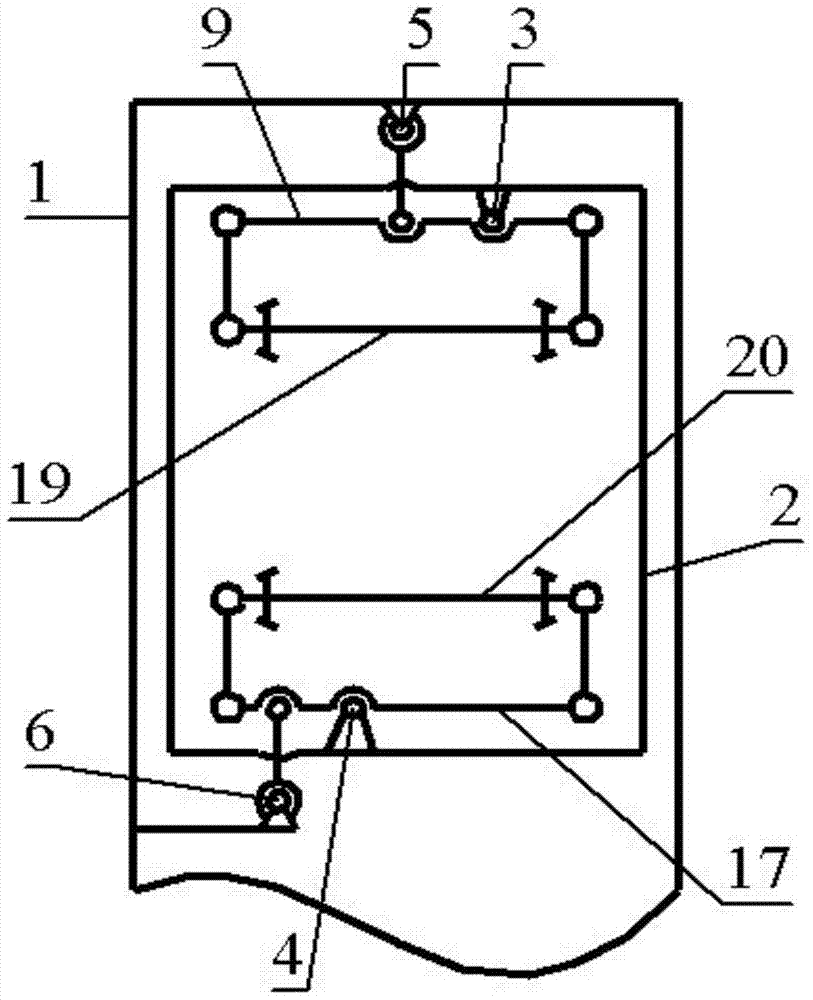

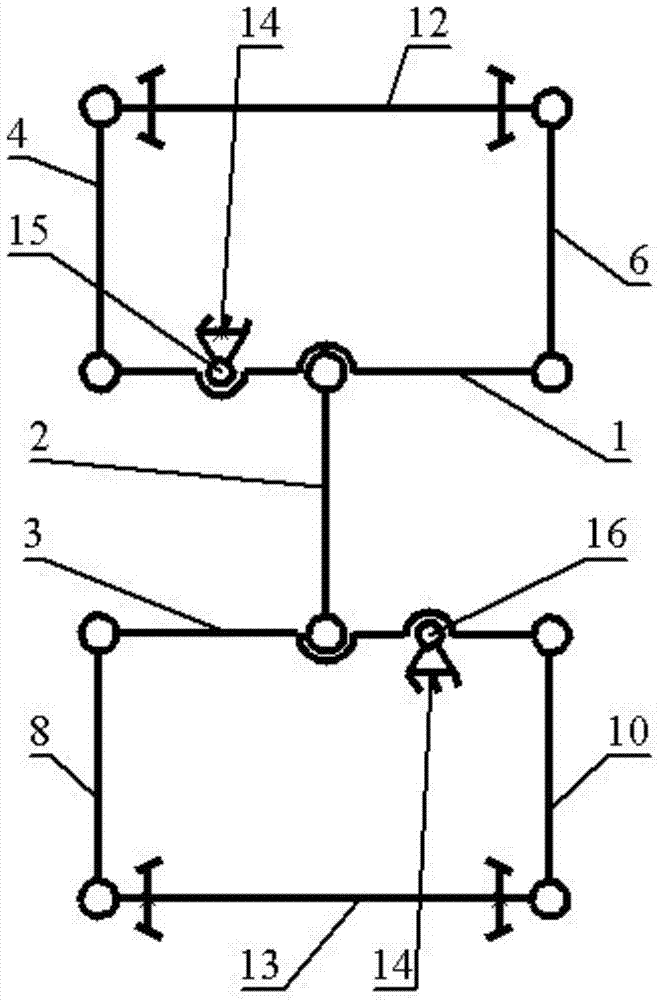

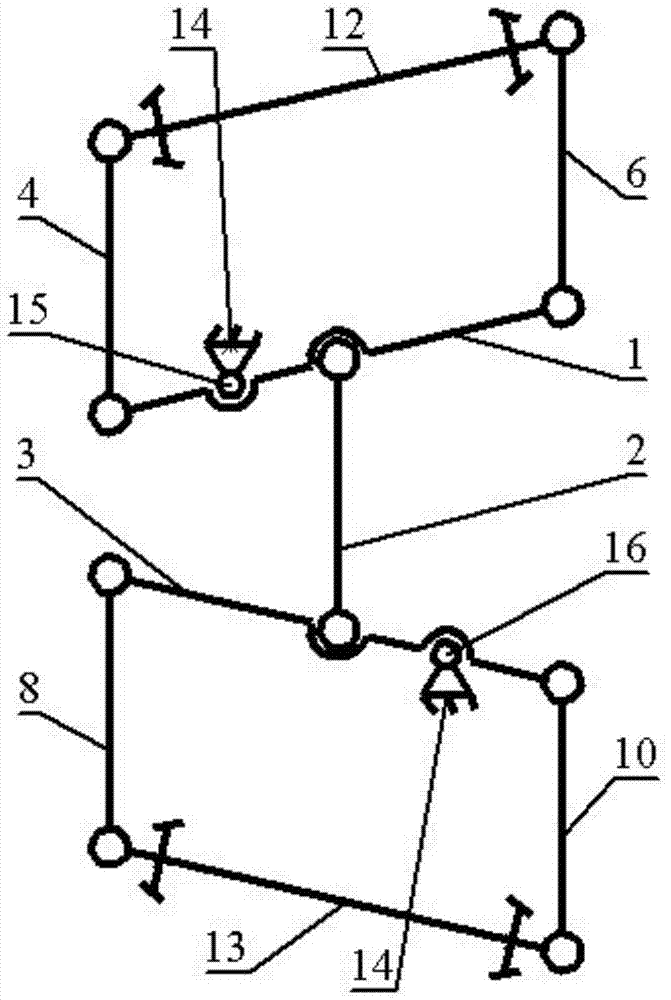

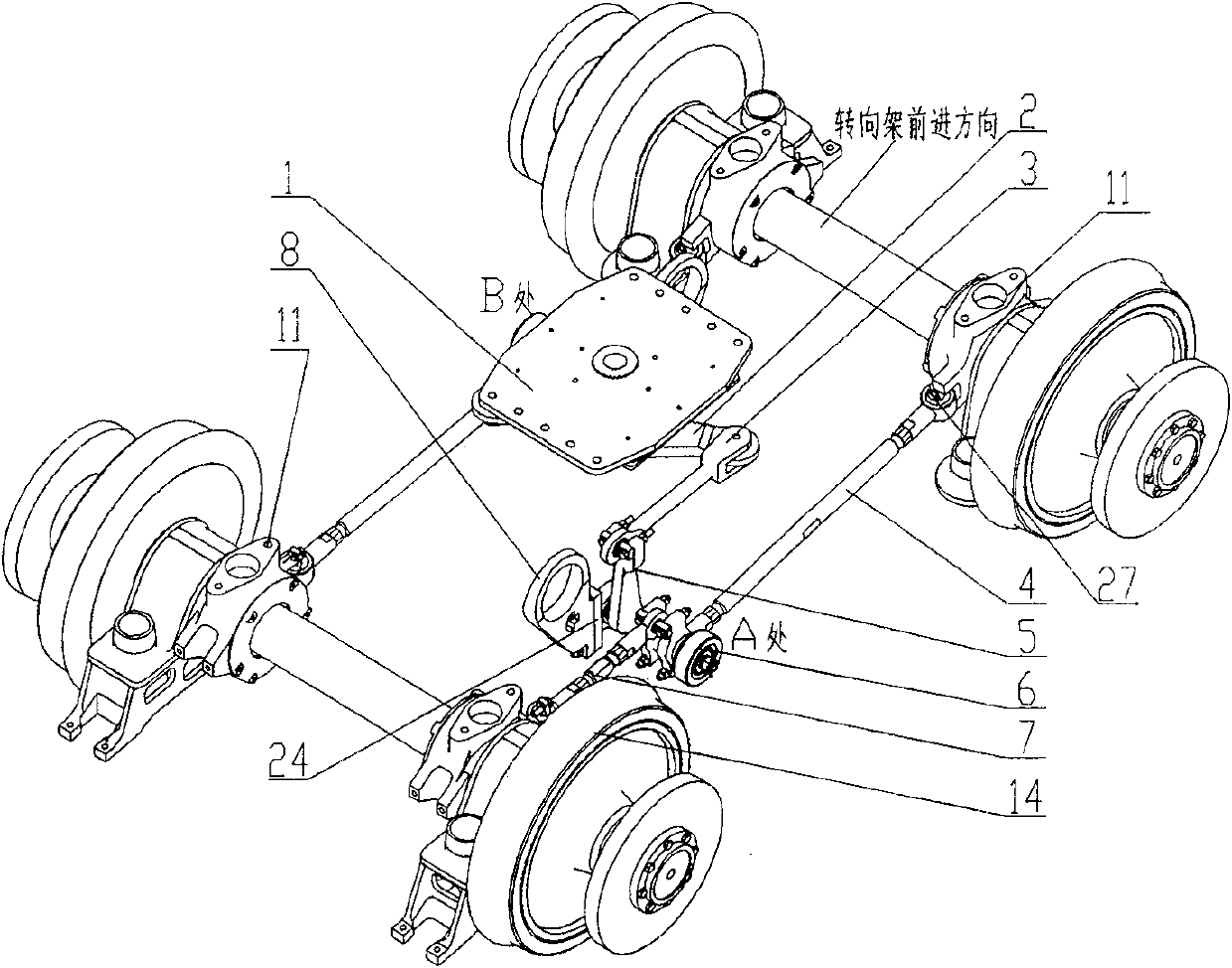

Radial bogie mechanism

InactiveCN105460040AReduce angle of attackReduce wearBogie-underframe connectionsWheel axle self-adjustmentsBogieCoupling

The invention discloses a radial bogie mechanism, which relates to the technical field of motor vehicle structures and can effectively solve problems of the traditional bogie radial mechanism in the form of a deputy frame. One end of a left front pull rod is hinged on a left front axle box; the other end of the left front pull rod is hinged at the left end of a front cross beam; one end of a right front pull rod is hinged on a right front axle box; the other end of the right front pull rod is hinged at the right end of the front cross beam; one end of a left rear pull rod is hinged on a left rear axle box; the other end of the left rear pull rod is hinged at the left end of a rear cross beam; one end of a right rear pull rod is hinged on a right rear axle box; the other end of the right rear pull rod is hinged at the right end of the rear cross beam; the front cross beam is hinged on the left of the center of a frame; the rear cross beam is hinged on the right of the center of the frame; and the front cross beam is connected with the rear cross beam through a coupling rod so as to realize linkage between wheel pairs. As each wheel pair moves towards a radial position when a bogie passes through a curve, the radial bogie mechanism is beneficial for reducing an attack angle between a wheel rim and a steel rail so that the wear of the wheel rim is reduced and the adhesiveness of a motor vehicle on the curve is improved. The radial bogie mechanism is mainly used for bogies of motor vehicles or trucks.

Owner:SOUTHWEST JIAOTONG UNIV

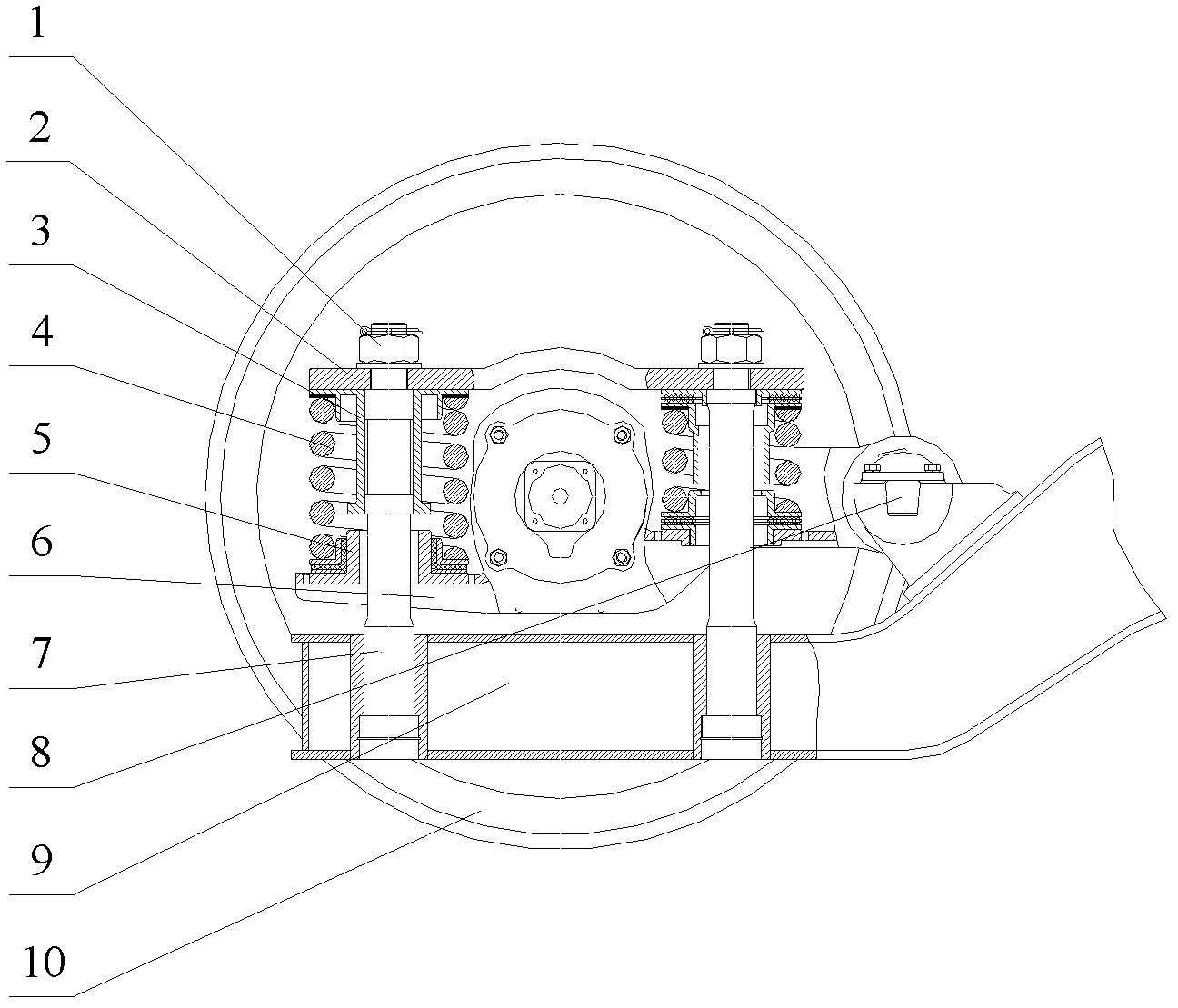

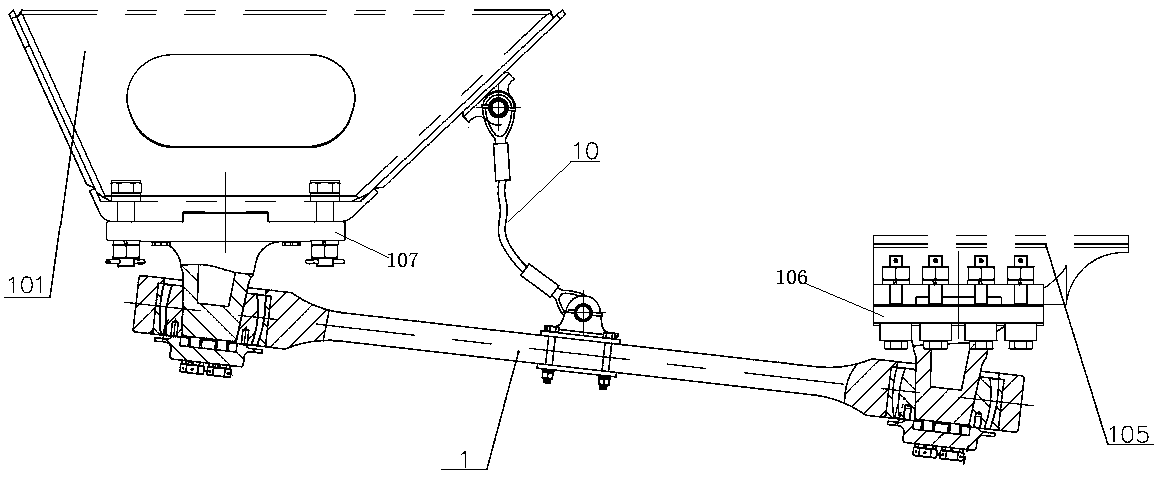

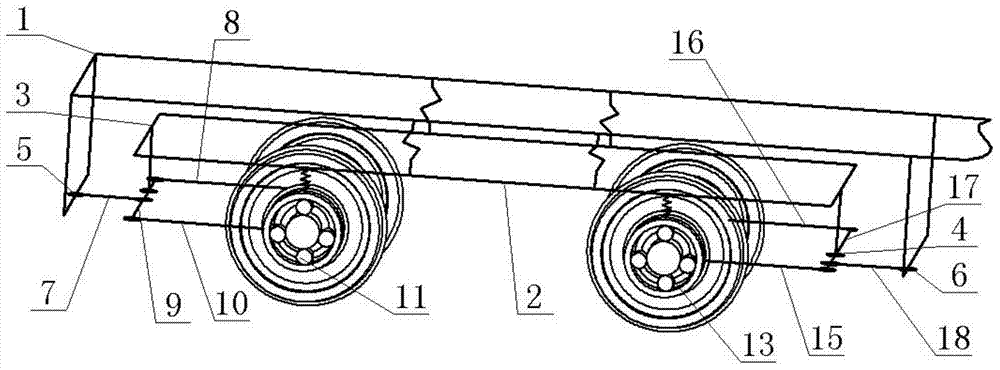

Non-power single-axle bogie and rail engineering vehicle

PendingCN111605577AImprove stabilityReduce noiseBogiesBogie-underframe connectionsBogieMechanical equipment

The embodiment of the invention provides a non-power single-axle bogie and a rail engineering vehicle, which relate to railway maintenance mechanical equipment, and aim to solve the problems that thelayout space of all parts at the lower part of a vehicle body is limited and the manufacturing cost of the whole vehicle is relatively high due to a two-axle or three-axle bogie in related technologies. The non-power single-axle bogie comprises a framework, a wheel set, a primary suspension device, a secondary suspension device, a traction device, balance rod devices and a basic brake device, wherein the wheel set is provided with an axle, wheels mounted to the axle, and an axle box mounted to the axle; the primary suspension device is used for mounting the axle box on the framework; the secondary suspension device is used for connecting the framework with a vehicle body; the traction device is located on the lower side of the framework and used for connecting the framework with a vehiclebody; the balance rod devices are respectively arranged at the front end and the rear end of the framework and are used for connecting the framework with a vehicle body; and the basic brake device isprovided with a brake cylinder, a lever assembly and a brake shoe, and the brake cylinder drives the brake shoe to press the wheel through the lever assembly.

Owner:CRCC HIGH TECH EQUIP CORP LTD

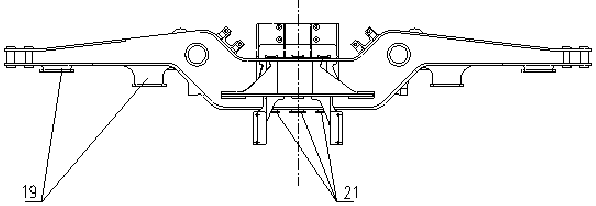

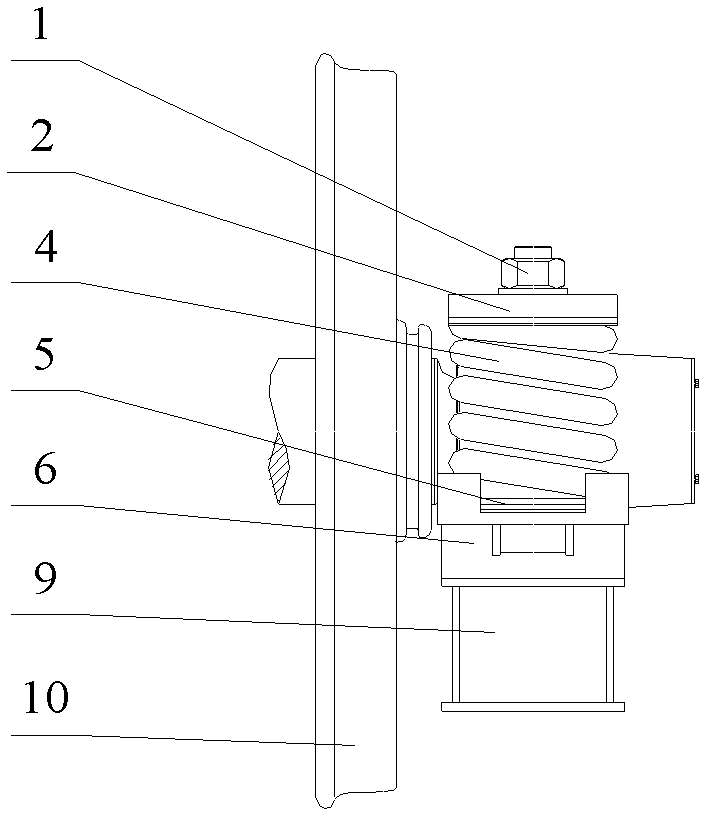

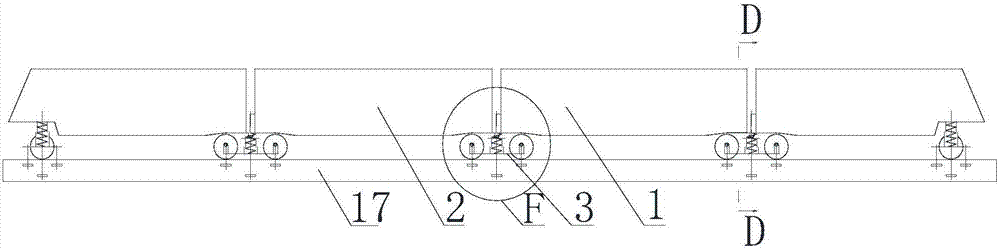

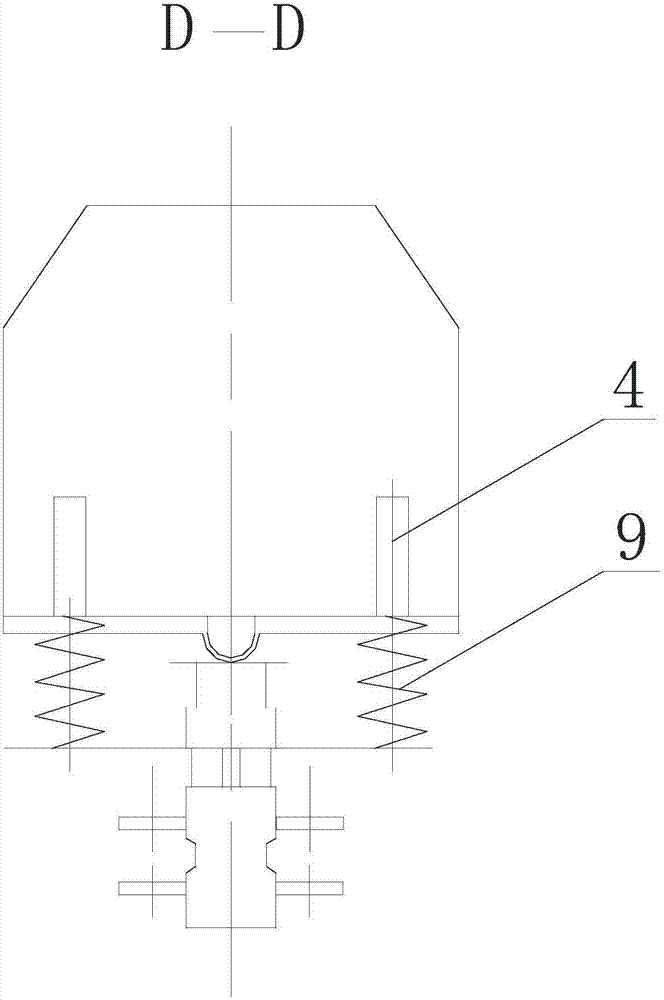

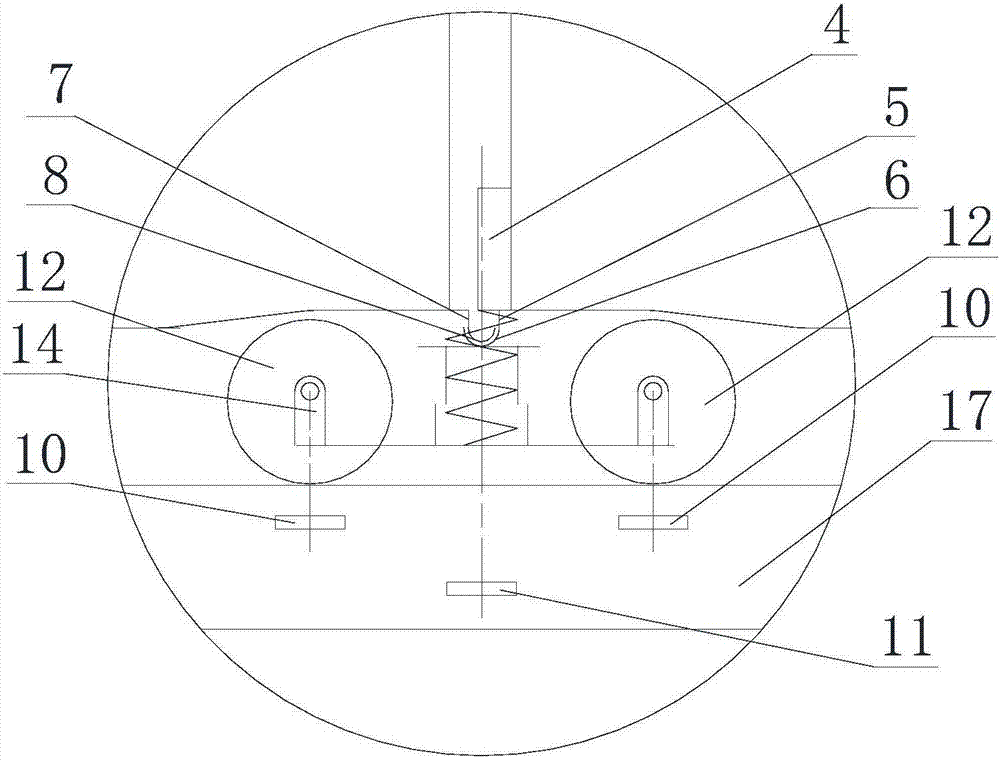

Underneath type primary suspension structure for railway locomotive bogie framework

InactiveCN102717810ALower installation heightImprove sticky utilizationAxle-boxes mountingBogieEngineering

The invention discloses an underneath type primary suspension structure for a railway locomotive bogie framework. The underneath type primary suspension structure mainly comprises a wheel set, a framework and a tumbler journal box, wherein the framework is supported on a journal of the wheel set by primary springs, one end of the tumbler journal box is rotatably arranged on the journal of the wheel set (10), the other end of the tumbler journal box is fixed on the framework (9) by an elastic node (8). The framework (9) is suspended below the tumbler journal box (6) in parallel by two guide pillars (7), a connecting plate (2) and the primary springs (4), the tumbler journal box supports the primary springs by spring lower seats (5), the two primary springs pass through a spring upper seat (3), the connecting plate and the guide pillars and are fixed by a nut (1). According to the invention, the framework is arranged below the journal box, so that the height of the upper plane of the intermediate framework of a bogie is lowered, and a B0B0-B0B0 axle type eight-axle locomotive can be realized in Chinese standard gauge limit.

Owner:SOUTHWEST JIAOTONG UNIV

Connecting device special for straddle type monorail carriages

PendingCN107097805AReduce space consumptionNo longer constrained nodding motionBufferRail derailment preventionBogieEngineering

The invention discloses a connecting device special for straddle type monorail carriages. The connecting device comprises a steering device located between the carriages and track beams, the steering device is connected with the carriages separately and then makes contact with the track beams, one carriage of the adjacent carriages protrudes from the side walls close to each other to form load-bearing platforms which are connected with the top of a corresponding damper, a lower traction table is installed on the side wall of the carriage provided with the load-bearing platforms, a traction pin boss is arranged on the lower traction table, the traction pin boss is connected with a bogie, an upper traction table is installed on the side walls, close to each other, of the other carriage, the upper traction table is arranged on the traction pin boss, and the upper traction table is connected with the traction pin boss. By means of a spherical articulated device, longitudinal connection of the carriages is tight, the integrity of the carriages is improved, longitudinal impulse of the carriages is reduced, ride is comfortable, the number of the bogies is reduced, each axle can reach the maximum allowable axle load, weight lightening of the vehicle is achieved, and the energy-saving effect is achieved.

Owner:运达创新(成都)投资有限公司

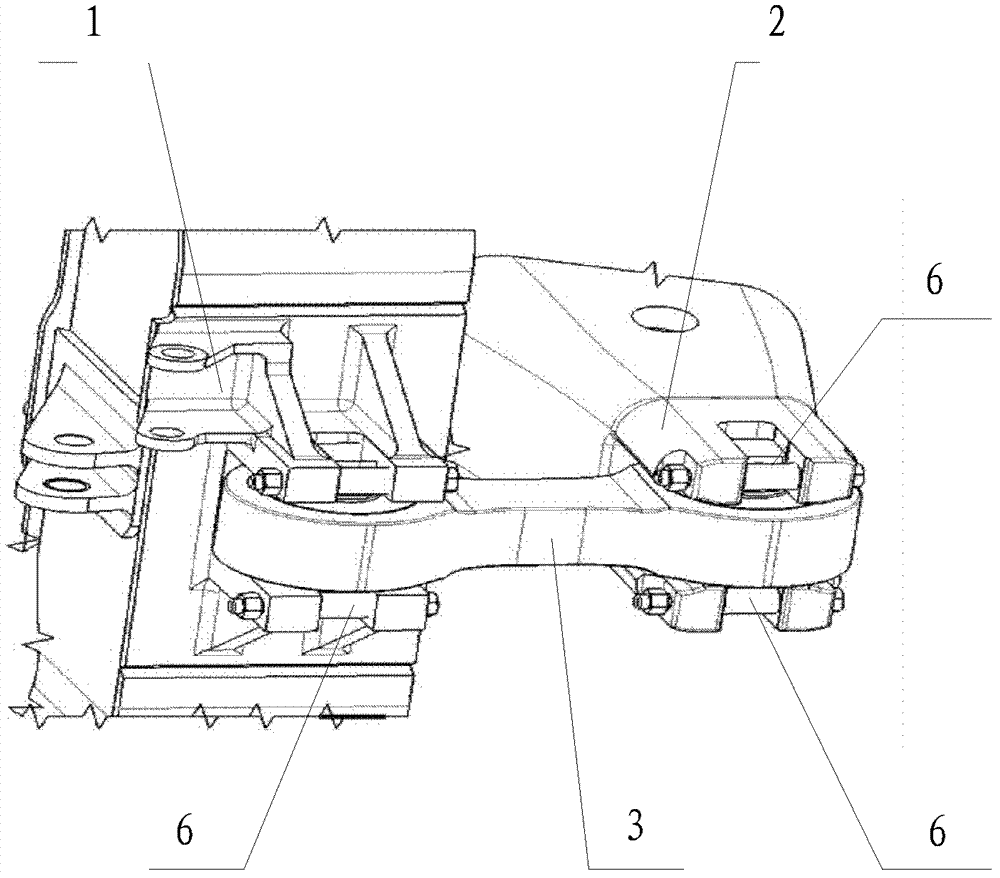

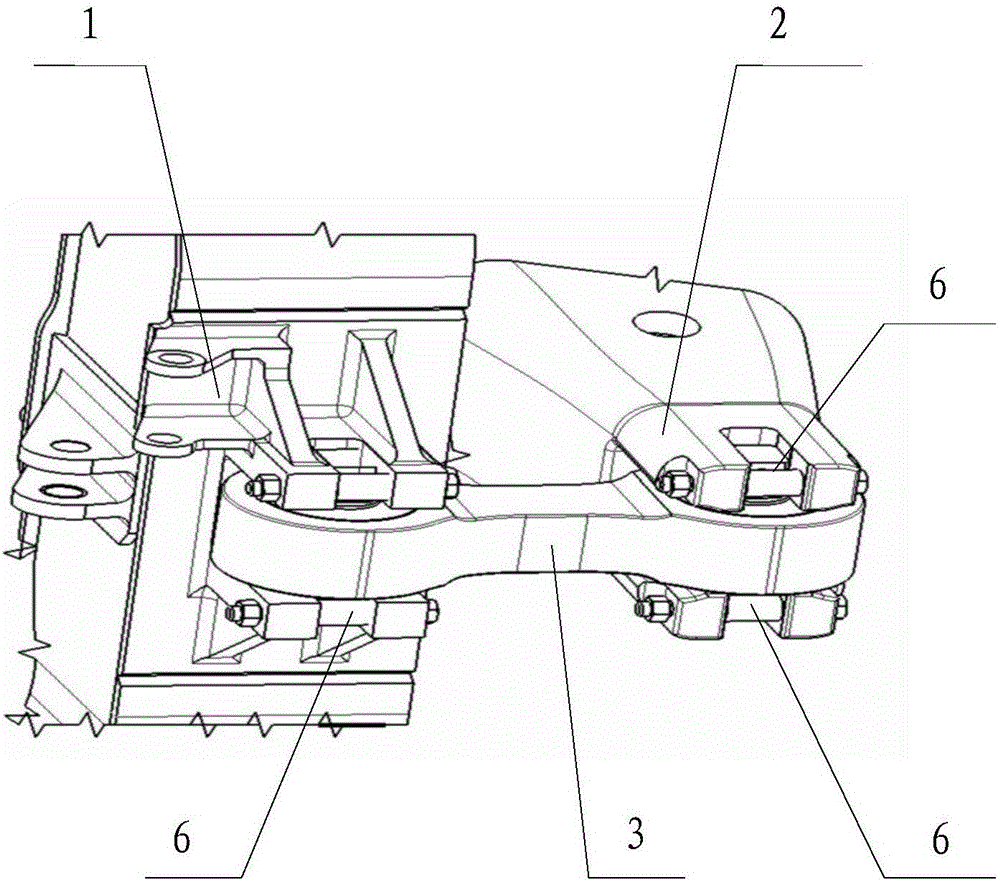

Forced guide mechanism for bogie

InactiveCN105460041AReduce manufacturing costImprove sticky utilizationBogie-underframe connectionsWheel axle self-adjustmentsBogieEngineering

The invention discloses a forced guide mechanism for a bogie, which belongs to the technical field of structural design of locomotive vehicles and can effectively solve the problem of limitation of the distance between axles when a vehicle uses a forced guide frame. The forced guide mechanism comprises a vehicle body, a framework, a front guide rod for connecting a front cross beam and the vehicle body, and a rear guide rod for connecting a rear cross beam and the vehicle body, wherein one end of a left front pull rod is articulated on a left front axle box, and the other end of the left front pull rod is articulated at the left end of the front cross beam; one end of a right front pull rod is articulated on a right front axle box, and the other end of the right front pull rod is articulated at the right end of the front cross beam; one end of a left rear pull rod is articulated on a left rear axle box, and the other end of the left rear pull rod is articulated at the left end of the rear cross beam; one end of a right rear pull rod is articulated on a right rear axle box, and the other end of the right rear pull rod is articulated at the right end of the rear cross beam; the front cross beam is articulated in the position, deviating to the right, at the center of the framework, and the rear cross beam is articulated in the position, deviating to the left, at the center of the framework; one end of the front guide rod is articulated at the front end of the vehicle body, and the other end of the front guide rod is articulated on the front cross beam; and one end of the rear guide rod is articulated at the rear end of the vehicle body, and the other end of the rear guide rod is articulated on the rear cross beam. The forced guide mechanism is mainly used for manufacturing locomotive vehicles.

Owner:SOUTHWEST JIAOTONG UNIV

Rail car and rotatable frame thereof

The invention discloses a rotatable frame. A split rotatable structure is adopted, a T-shaped beam and a straight beam of the frame are connected through a rotating device, when wheel loads of a front axle and a rear axle of a bogie are inconsistent, and additional torque is generated, the straight beam and the T-shaped beam can mutually rotate until the wheel loads are balanced, and therefore the wheel loads are automatically and evenly distributed. The invention further provides a rail car with the rotatable frame, low wheel load transferring can be achieved, the adhesion utilization rate can be improved, wheel abrasion can be reduced, and is homogenized, development of car traction performance can be facilitated, meanwhile, the running performance of the car is improved, and the wheel rail abrasion is reduced.

Owner:ZHUZHOU ELECTRIC LOCOMOTIVE CO

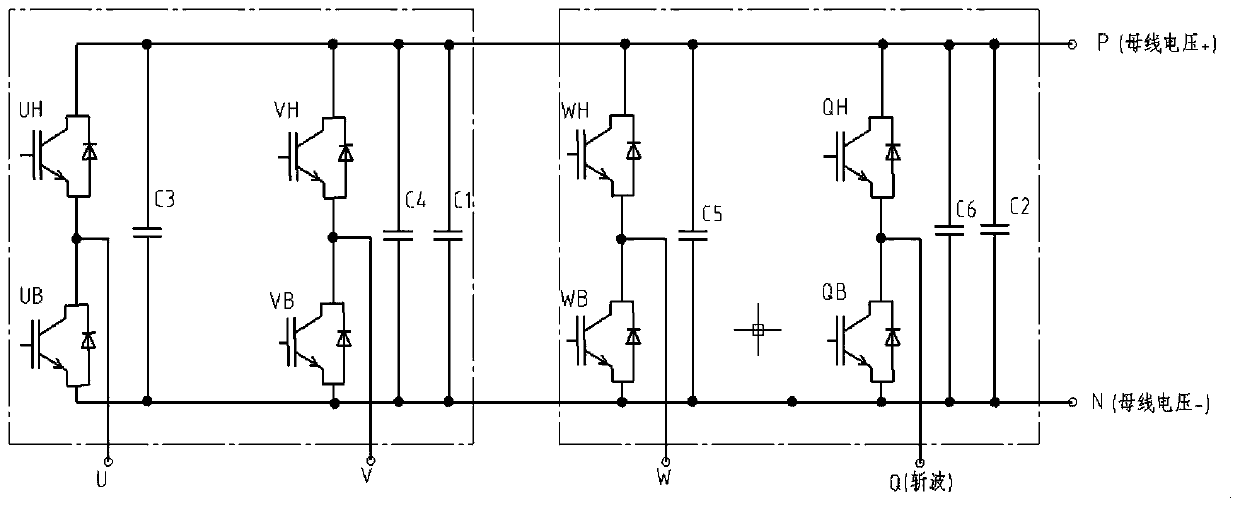

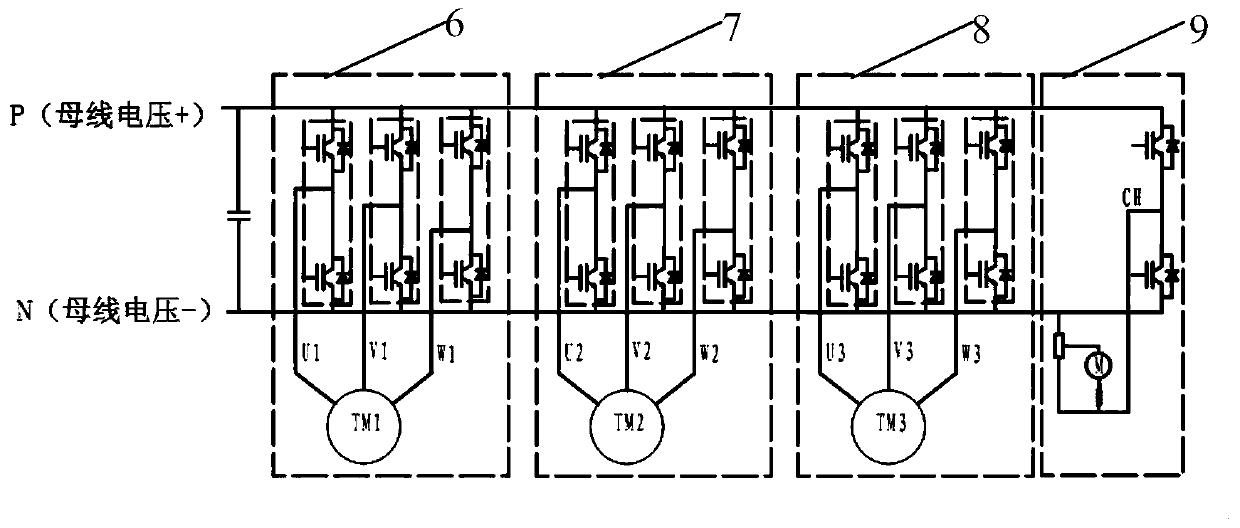

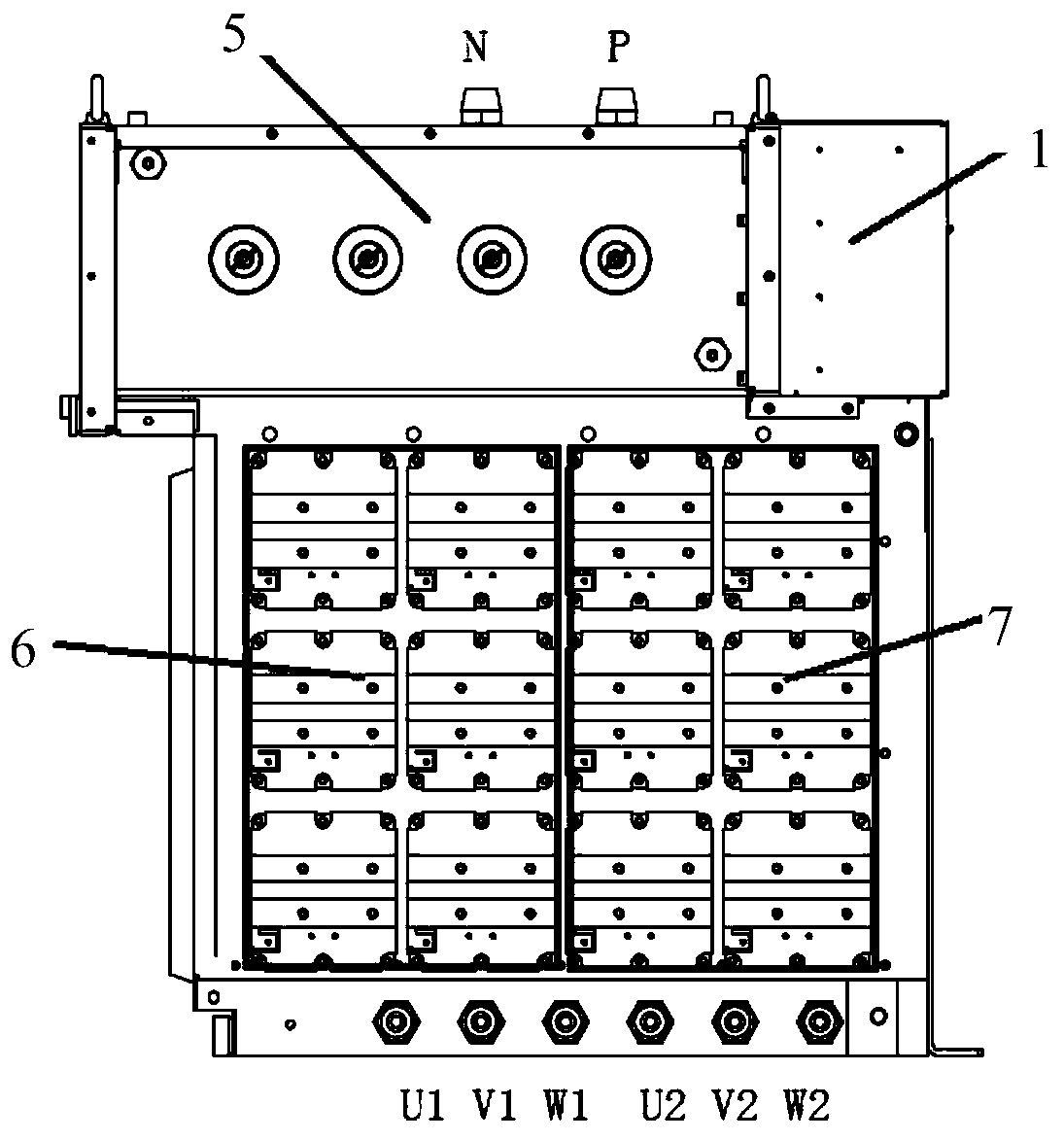

Air-cooled axle-controlled traction inversion power unit with double-sided heat dissipation

PendingCN110957958AEasy to installImprove cooling effectAC motor controlConversion constructional detailsElectric machineryCooling effect

The invention belongs to the technical field of bullet train locomotive traction systems and relates to an air-cooled axle-controlled traction inversion power unit with double-sided heat dissipation.An original mode that a frame control type three-phase inverter circuit is used for pulling three motors is replaced by a mode that a shaft control type three-phase inverter circuit pulls three motors. On the premise that the installation size of an original frame control type traction inversion power unit is met, three three-phase inversion units, a chopping unit and a direct current bus supportcapacitor are integrated on one power module, so that the power conversion function of one three-phase inversion unit and one chopping unit in the original frame control traction inversion power unitis realized, the system redundancy is improved, and the fault resistance is enhanced; and meanwhile, the heat pipe radiators are additionally arranged on the two sides of the main body air duct, so that the double-sided layout mode of the IGBT in one power unit in an air-cooled heat dissipation mode is realized, the heat dissipation of the IGBT is more uniform, the length of the radiators is reduced, the space utilization rate of a locomotive is improved, and finally, the cooling effect of the power unit is improved.

Owner:XIAN YONGDIAN ELECTRIC

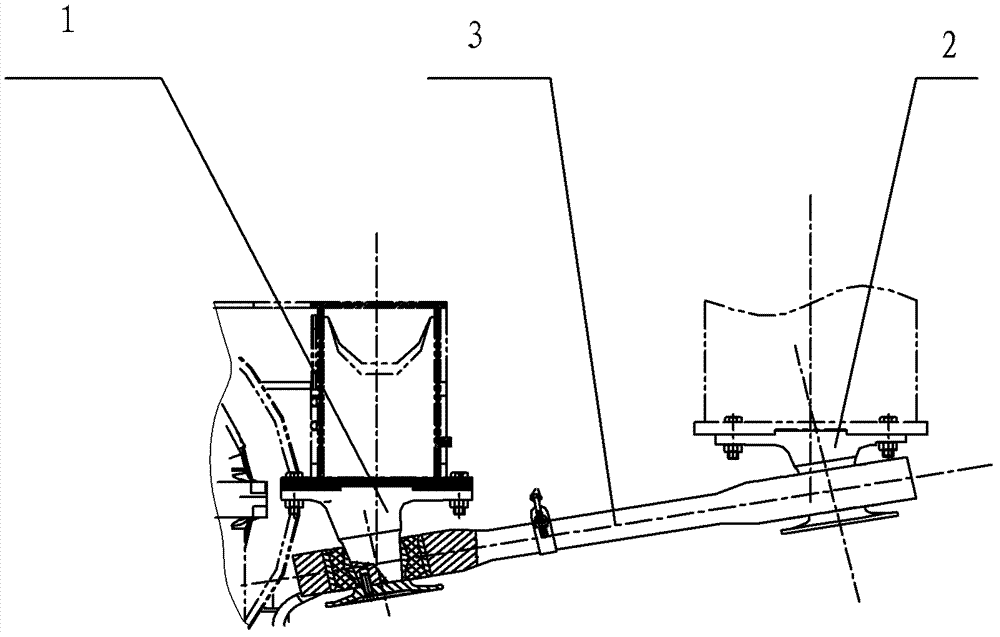

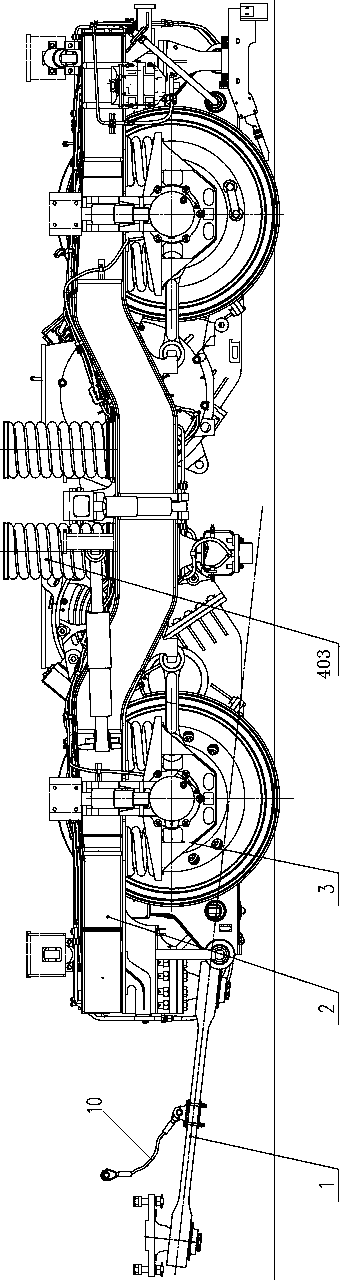

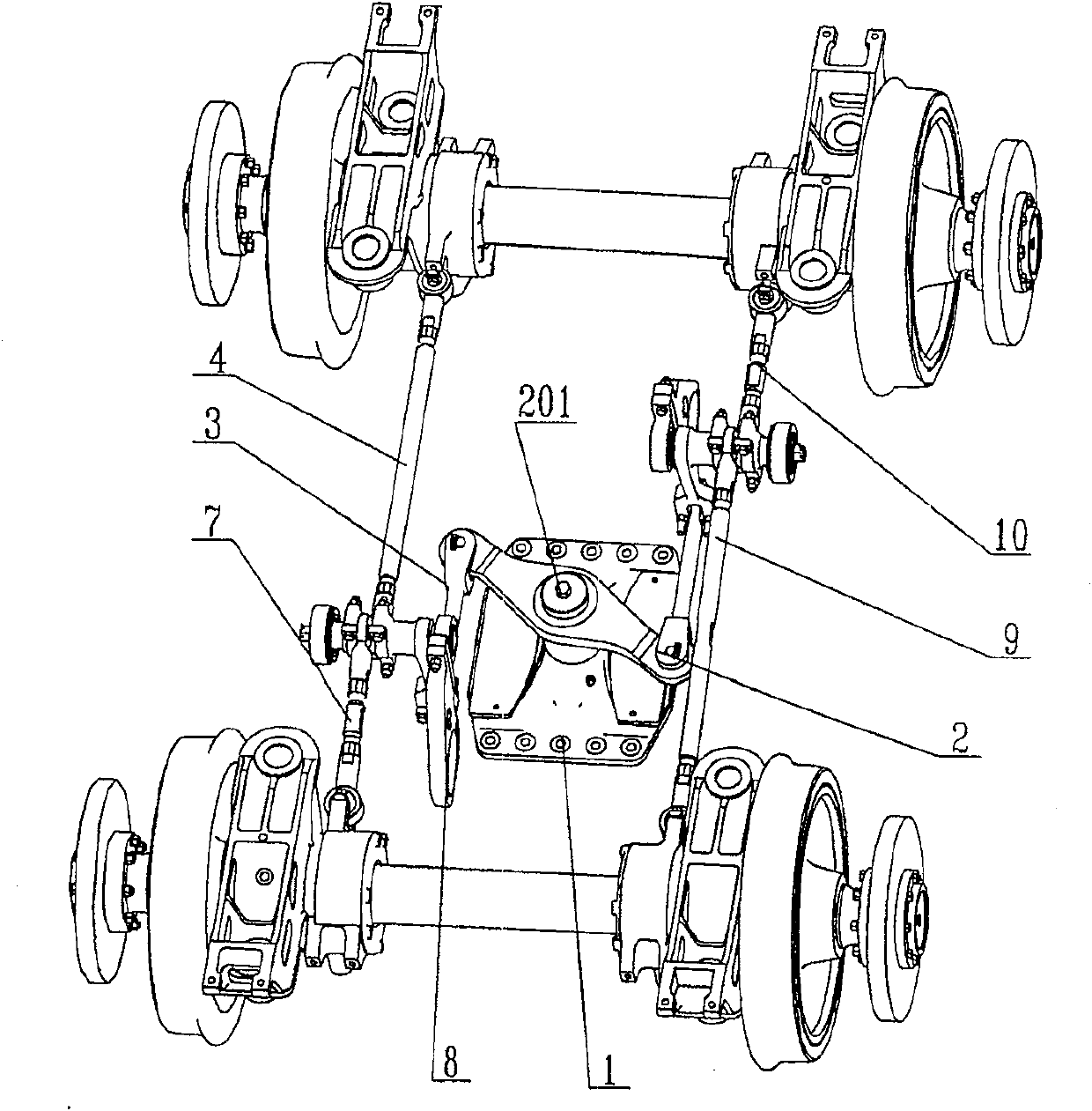

B0 bogie for power-centralized D-series high-speed train

InactiveCN107738660AImprove sticky utilizationReduce axle load transferBogie-underframe connectionsBogieWeight transfer

The invention discloses a B0 bogie for a power-centralized D-series high-speed train. The B0 bogie comprises an 8-shaped framework, a wheel set and a single traction bar, wherein a framework tractionbase is arranged on a framework end beam, one end of the single traction bar is connected to the framework traction base through a first traction base, and the other end of the single traction bar isconnected to a train body chassis through a second traction base; the height of the end, connected with the framework traction base, of the single traction bar is lower than that of the end, connectedwith the train body chassis, of the single traction bar. By means of the B0 bogie for the power-centralized D-series high-speed train, a middle-arranged low-level slant single-pull-rod traction structure is adopted to achieve low-level traction of a small-wheel-diameter bogie, the adhesion utilization rate is greatly increased, and the axial weight transfer is reduced; meanwhile, through the optimization of position relations of parts on the bogie, the D-series high-speed train has excellent comfort, stationarity and safety. The speed level of an existing line of 160 km / h is satisfied, and the requirements for the safety, stationarity, and low wheeltrack motion acting force when a passenger railway line is running at the speed level of 200 km / h are also met.

Owner:ZHUZHOU ELECTRIC LOCOMOTIVE CO

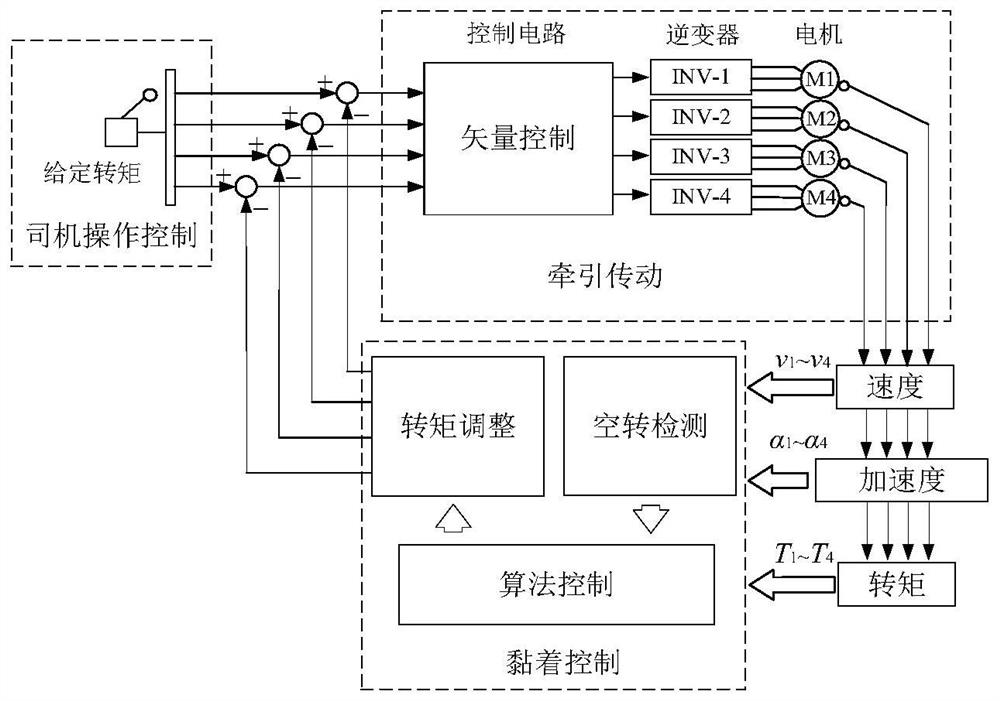

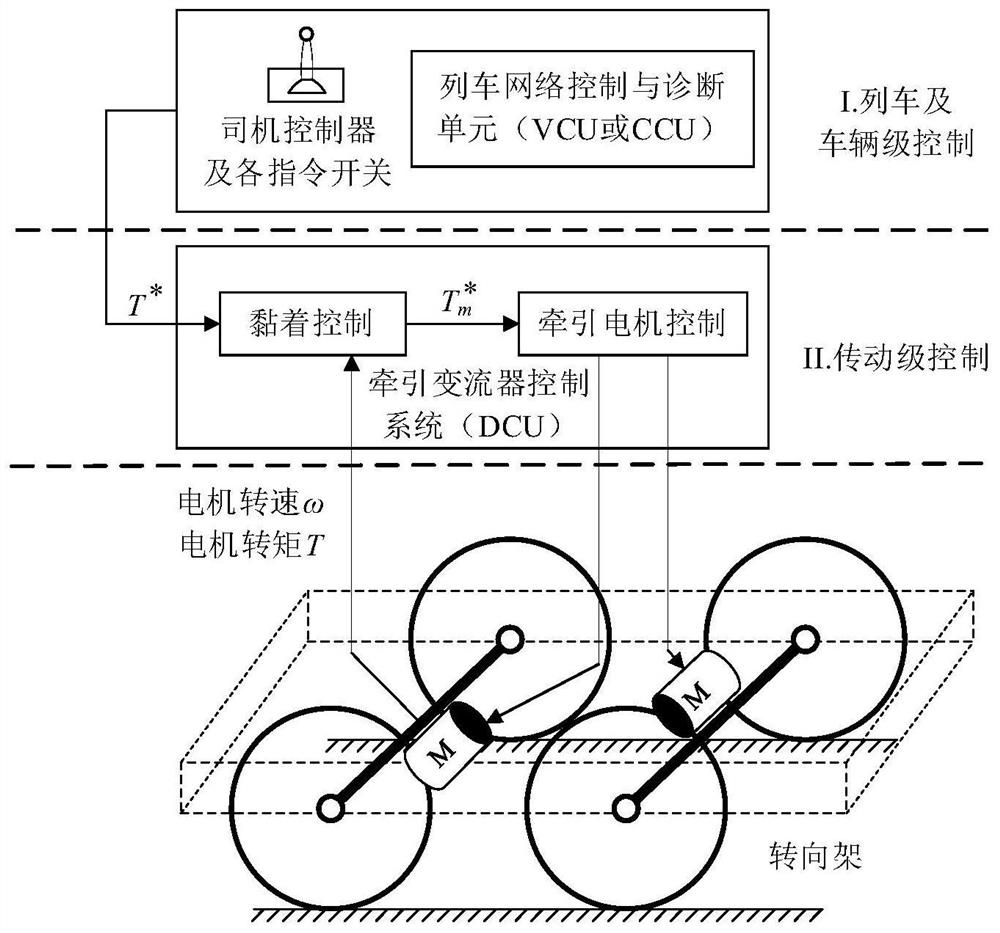

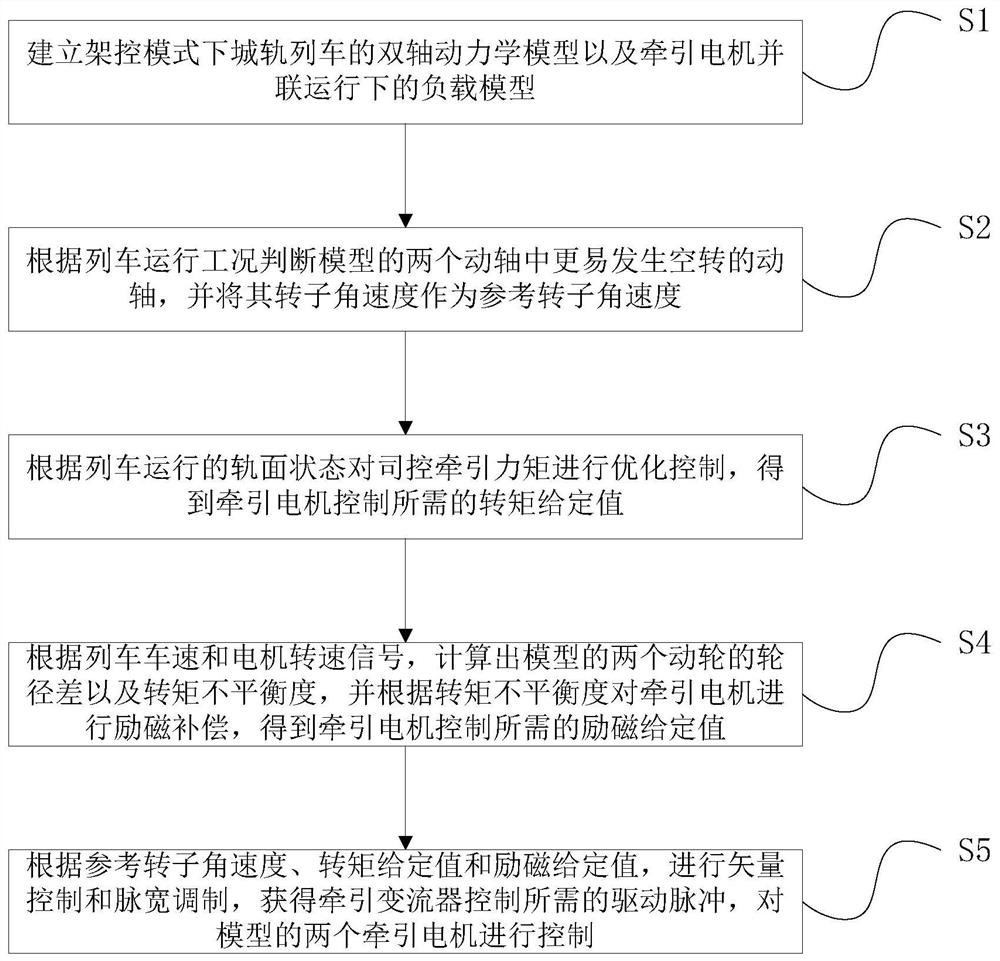

Urban rail train adhesion control method and system based on frame control mode

InactiveCN112104284AVerify correctnessReduce torque imbalanceSpeed controllerElectronic commutation motor controlLoad modelElectric machinery

The invention discloses an urban rail train adhesion control method and system based on a frame control mode. The method comprises the steps:establishing a biaxial dynamic model of an urban rail trainunder the frame control mode and a load model under parallel operation of traction motors; judging the moving shaft which is easier to idle in the two moving shafts of the model according to the train operation condition, and taking the rotor angular speed of the moving shaft as a reference rotor angular speed; performing optimization control on the driver-controlled traction torque according tothe running rail surface state of the train to obtain a torque set value required by traction motor control and obtain an excitation given value required by traction motor control; carrying out vectorcontrol and pulse width modulation according to the reference rotor angular speed to acquire the torque given value and the excitation given value, driving pulses needed by traction converter control, and controlling the two traction motors of the model. According to the invention, the adhesion condition between wheel tracks and the dynamic characteristics of a vehicle body can be truly simulatedto verify the correctness of a traction control strategy.

Owner:CHENGDU YUNDA TECH CO LTD

A bogie forced guiding mechanism

InactiveCN105460041BReduce manufacturing costImprove sticky utilizationBogie-underframe connectionsWheel axle self-adjustmentsBogieEngineering

The invention discloses a bogie forced guide mechanism, which belongs to the technical field of locomotive and vehicle structure design, and can effectively solve the problem that the vehicle is limited by the axle distance when using the forced guide frame. Including the car body and frame, the front guide rod connecting the front cross beam and the car body, the rear guide rod connecting the rear cross beam and the car body; one end of the left front tie rod is hinged on the left front axle box, the other end is hinged on the left end of the front cross beam, and one end of the right front tie rod is hinged On the right front axle box, the other end is hinged on the right end of the front crossbeam. One end of the left rear tie rod is hinged on the left rear axlebox, and the other end is hinged on the left end of the rear crossbeam. Right end of the rear cross member. The front cross beam is hinged at the right position of the frame center, and the rear cross beam is hinged at the left position of the frame center. One end of the front guide rod is hinged at the front end of the vehicle body, and the other end is hinged at the front beam; one end of the rear guide rod is hinged at the rear end of the vehicle body, and the other end is hinged at the rear beam. Mainly used in the manufacture of rolling stock.

Owner:SOUTHWEST JIAOTONG UNIV

A radial bogie mechanism

InactiveCN105460040BReduce angle of attackReduce wearBogie-underframe connectionsWheel axle self-adjustmentsBogieCoupling

The invention discloses a radial bogie mechanism, which relates to the technical field of locomotive vehicle structure design, and can effectively solve the problems existing in the radial bogie mechanism in the form of an existing sub-frame. One end of the left front tie rod is hinged on the left front axle box, and the other end is hinged on the left end of the front crossbeam. One end of the right front tie rod is hinged on the right front axlebox, and the other end is hinged on the right end of the front crossbeam. Hinged to the left end of the rear beam, one end of the right rear tie rod is hinged to the right rear axle box, the other end is hinged to the right end of the rear beam, the front beam is hinged to the left of the center of the frame, the rear beam is hinged to the right of the center of the frame, the front beam It is connected with the coupling rod between the rear beams, so as to realize the linkage between the wheel sets. When the bogie passes through the curve, each wheel set tends to the radial position, which is beneficial to reduce the angle of attack between the wheel rim and the rail, thereby reducing the wear of the wheel rim and improving the adhesion of the rolling stock on the curve. It is mainly used for the bogies of locomotives or freight cars.

Owner:SOUTHWEST JIAOTONG UNIV

Centre pin type guiding compelling radial direction mechanism

ActiveCN100588578CReduce longitudinal positioning stiffnessFree head movementWheel axle self-adjustmentsBogieEngineering

The central pin type forced steering radial mechanism has a radial truck which has forced steering, self steering and flexible steering performance. A novel radial adjustment mechanism is adopted to reduce the longitudinal positioning rigidity of a wheel pair opposite frame and to enable wheel pairs to approach in the radius direction as much as possible when the truck passes through a curve, thereby reducing noise and abrasion and increasing the adhesive force of the curve. The central pin type forced steering radial mechanism is provided with a frame, the truck is connected with a car body through the central pin and supports the car body upward and elastically, and the central pin type forced steering radial mechanism is also provided with two sets of wheel pairs and the radial adjustment mechanism. The radial adjustment mechanism is provided with a central rotating disc, a group of vertical push rods are respectively connected with the end part of the central rotating disc, and theother end of each vertical push rod is connected with a rotating arm. The rotating arm is connected with a positioning sleeve and forms a first positioning point on the truck side sill through the positioning sleeve, and the rotating arm is connected with the positioning sleeve and forms a second positioning point on the truck transom through the positioning sleeve. Two sets of tie rods are respectively connected with the ratating arm, and the other end of the each tie rod is connected with the axle box of front and rear wheel pairs.

Owner:CRRC QINGDAO SIFANG CO LTD

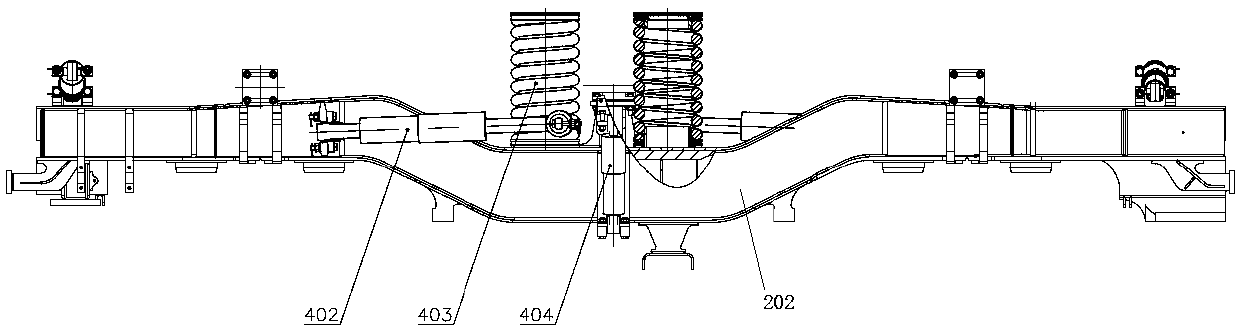

A locomotive bogie

ActiveCN110588700BLow rotational resistanceEasy to adjustBogiesBogie-underframe connectionsBogieControl theory

The invention discloses a locomotive bogie. The locomotive bogie comprises a framework shaped like a Chinese character 'ri', the framework comprises two side beams, one horizontal beam and two end beams, the middle portions of the side beams adopt concave structures, the locomotive bogie is characterized in that the upper surface of the middle portion of each side beam is provided with three steelsprings, the three steel springs are distributed at three vertices of an isosceles triangle, the bottom edge of the isosceles triangle is parallel to the longitudinal direction of the side beams, andan apex angle of the isosceles triangle is closer to the center of the framework than base angles. According to the locomotive bogie, two-series spring group triangle arrangement is adopted, spaces of biaxial bogie side beam middle portion concaving and being connected with the framework middle horizontal beam are utilized sufficiently, triangular arrangement can obtain less bogie head-shaking rotating resistance than longitudinal arrangement and larger vehicle body side rolling resistant stiffness than horizontal arrangement, therefore, by means of the locomotive bogie, good curve passing performance and dynamic limit utilization degree can be obtained.

Owner:ZHUZHOU ELECTRIC LOCOMOTIVE CO LTD

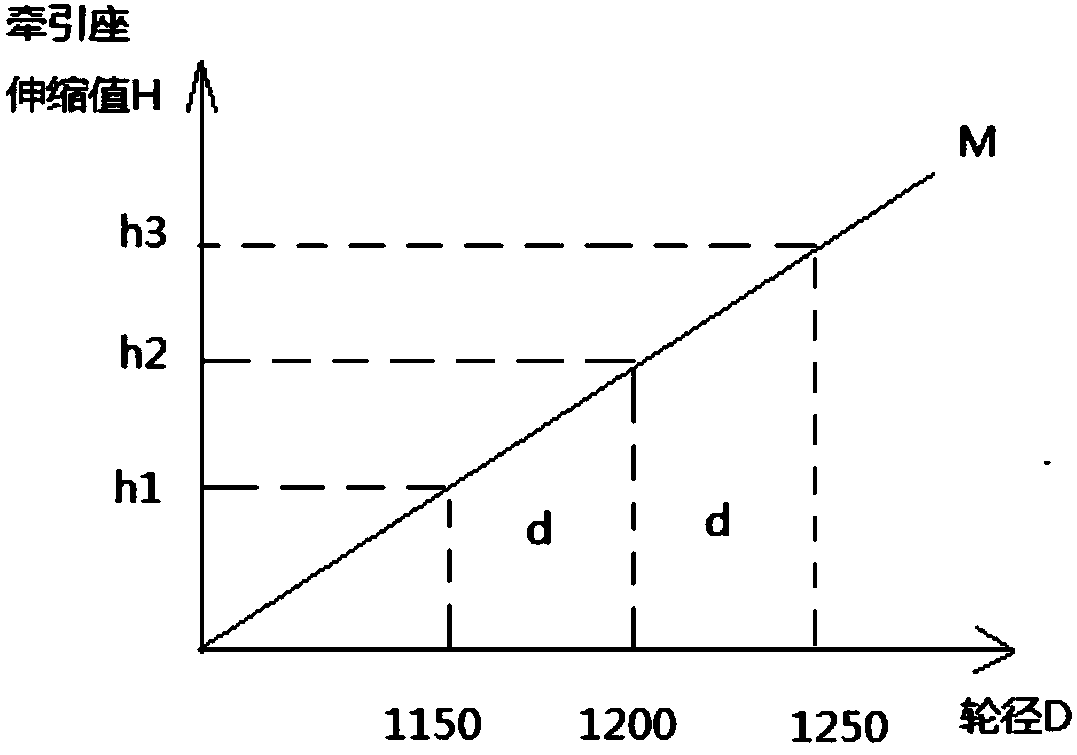

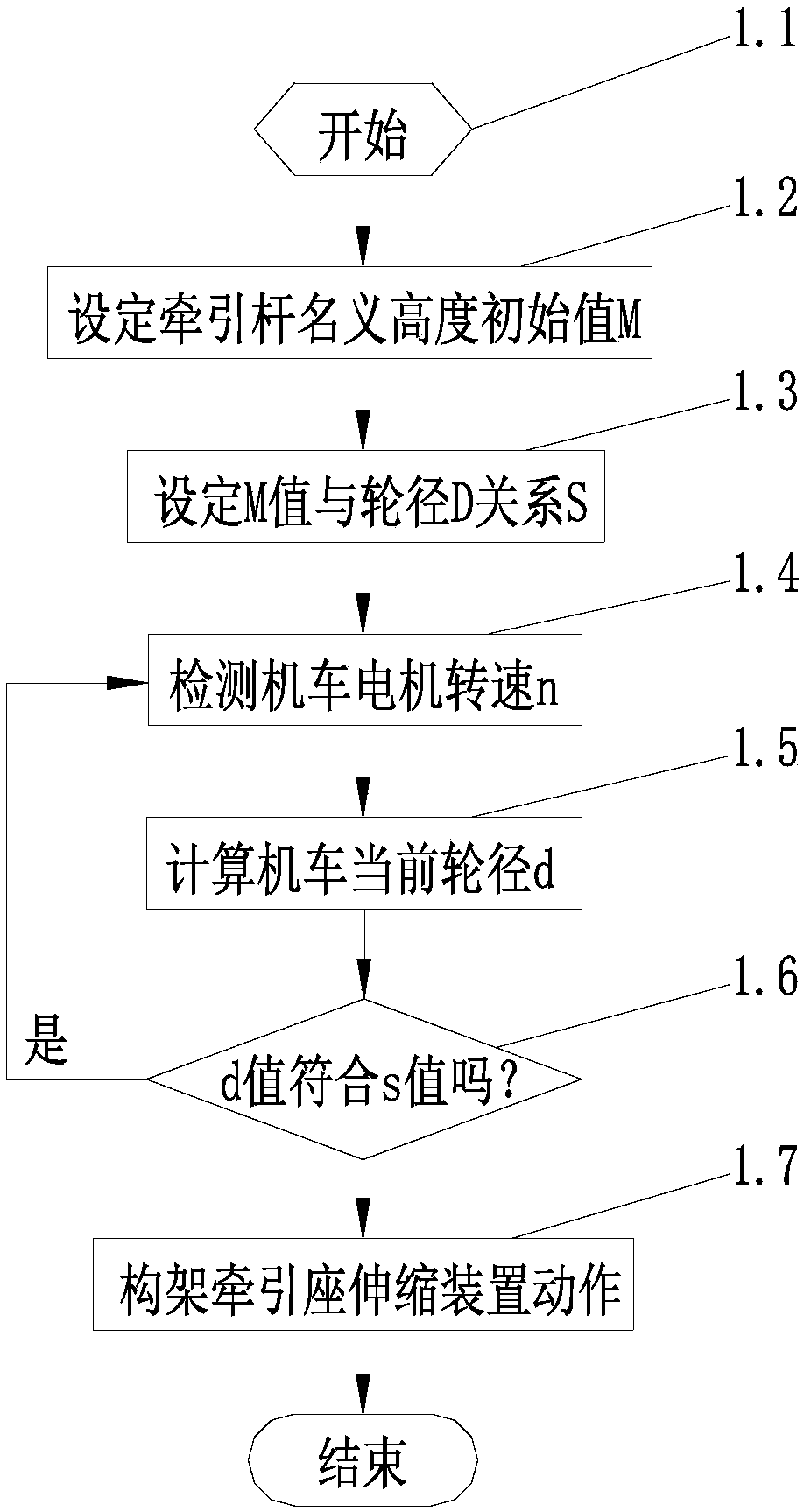

Control method of adjusting height of nominal towing point of locomotive automatically

InactiveCN107650929AReduce idlingImprove sticky utilizationGeometric CADSpecial data processing applicationsTowingAutomatic tuning

The invention discloses a control method of adjusting the height of a nominal towing point of a locomotive automatically. A curve S of the locomotive wheel diameter D, the flexible height H of a traction base and the initial value M of nominal height of a traction bar is set as H=MD. After the current locomotive wheel diameter d is detected, the system is compared to a conditional value curve S toadjust the flexible value h of the traction base automatically, so that the current nominal height of the traction bar and the set curve M value are overlaid, and therefore, the adhesive utilizationratio of the locomotive is increased, and the idling of the locomotive wheel is reduced.

Owner:CRRC DALIAN CO LTD

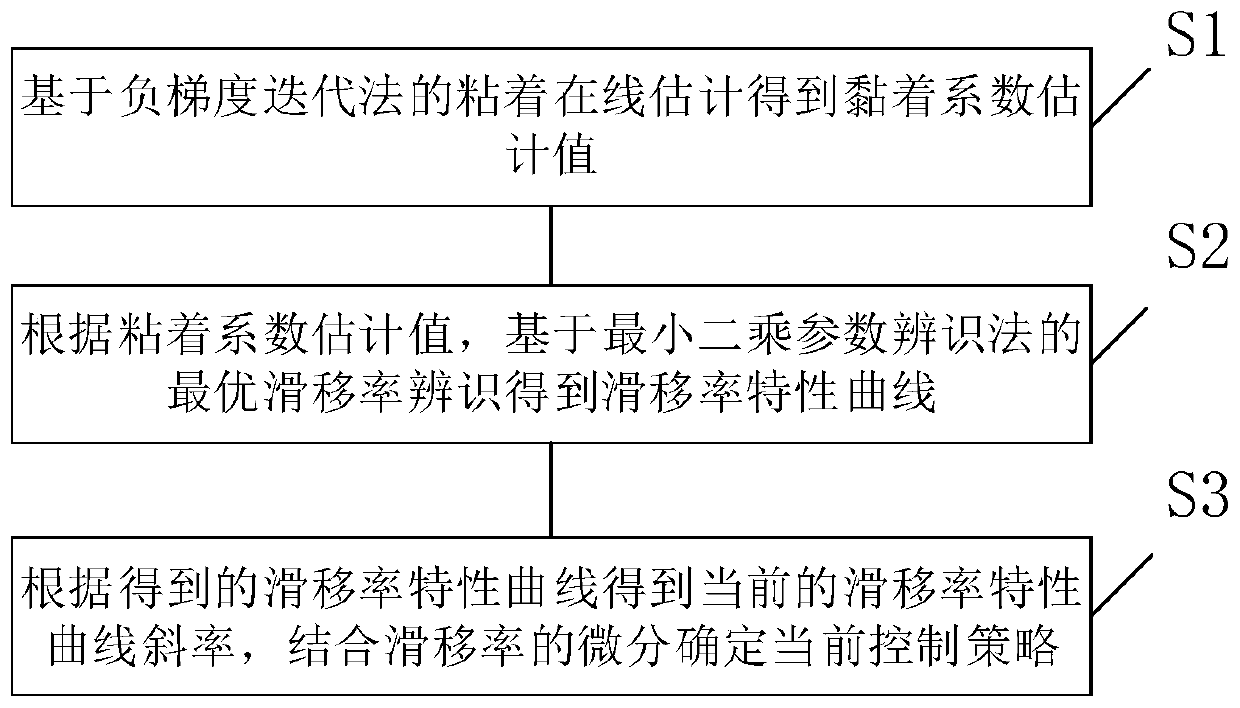

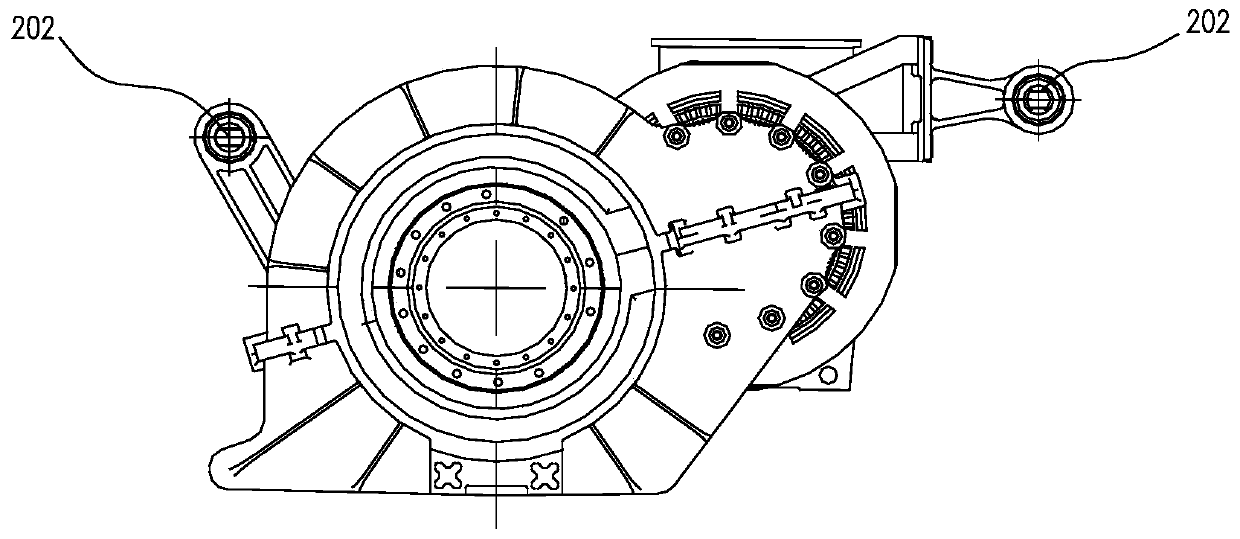

Antiskid control method for rail vehicle braking system

ActiveCN109229082BAvoid taxiingImprove sticky utilizationBraking systemsAdhesion coefficientControl theory

The invention relates to an anti-skid control method for the braking system of a rail vehicle, which comprises the following steps: step S1, on-line estimating adhesion coefficient based on negative gradient iteration method to obtain an estimated value of adhesion coefficient; 2, accord to that estimated value of the adhesion coefficient, identify the optimal slip rate based on the least square parameter identification method to obtain a slip rate characteristic curve; Step S3, obtaining the slope of the current slip rate characteristic curve according to the obtained slip rate characteristiccurve, and determining the current control strategy according to the differential of the slip rate. Compared with the prior art, the invention can effectively prevent the wheelset from coasting in the braking process of the train, improve the adhesion utilization rate and shorten the braking distance.

Owner:TONGJI UNIV

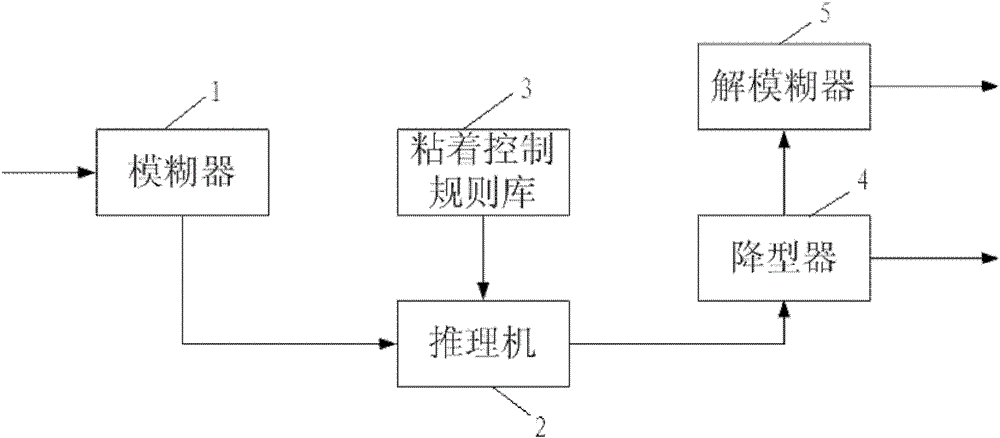

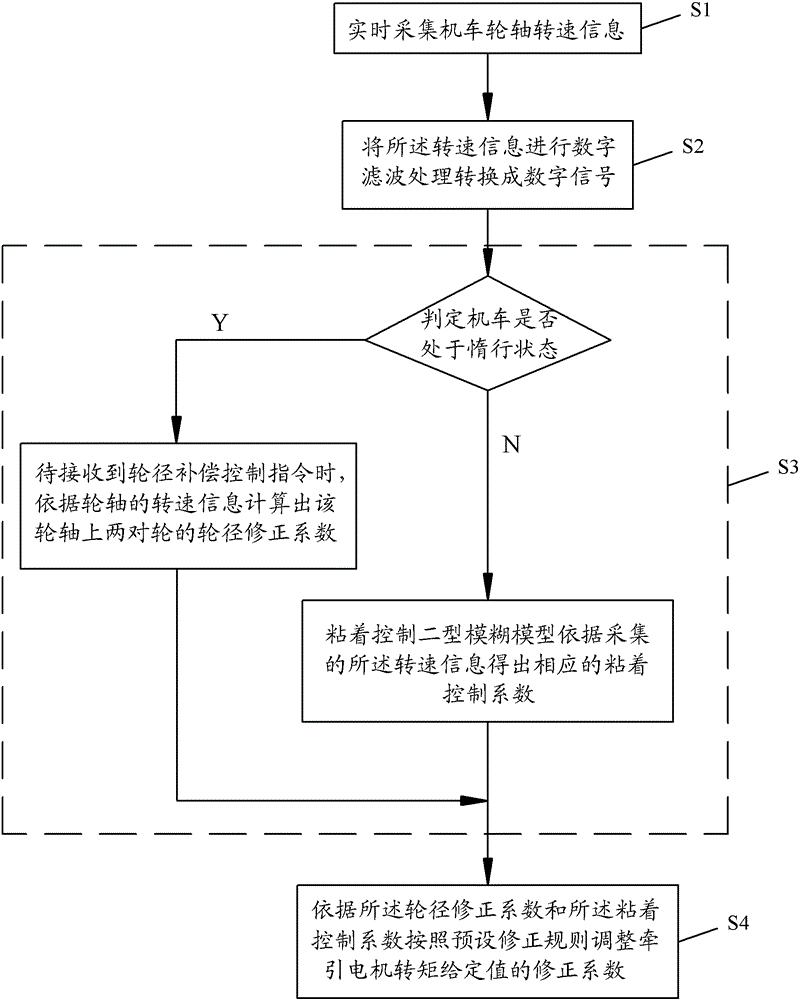

Electric locomotive adhesion control method and device

ActiveCN103183037BAchieving AdaptivenessRealize intelligenceLocomotivesAdaptive controlDrive wheelEngineering

The invention provides an electric locomotive adhesion control method and a device. The method comprises the following steps: collecting rotating speed information of locomotive wheel shafts at real time; performing digital filtering processing of the rotating speed information, then converting into digital signals; determining whether the locomotive is in a coasting state according to the digital signals, if yes, calculating a wheel diameter correction coefficient according to the rotating speed information of two driving wheels when receiving a wheel diameter compensation control instruction, and if no, calculating a corresponding adhesion control coefficient according to the collected rotating speed information based on an established adhesion control type-II fuzzy model; and adjusting a correction coefficient of a traction motor torque given value according to the wheel diameter correction coefficient and the adhesion control coefficient based on a preset correction rule. The invention realizes the intelligentization of adhesion control, effectively improves the adhesion utilization rate between wheel tracks, and realizes optimization utilization of available adhesion strength of electric locomotive.

Owner:CHINA CNR CORPORATION

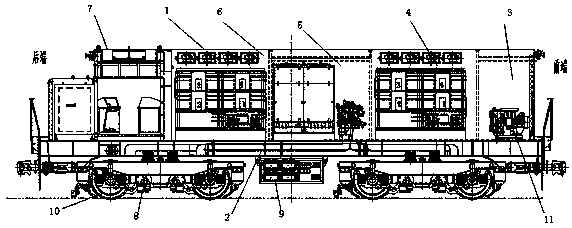

A 1000kw power class pure electric AC drive shunting locomotive

ActiveCN105711606BImprove sticky utilizationImprove traction performanceElectric locomotivesRailway transportBogieHigh energy

Owner:CRRC ZIYANG CO LTD

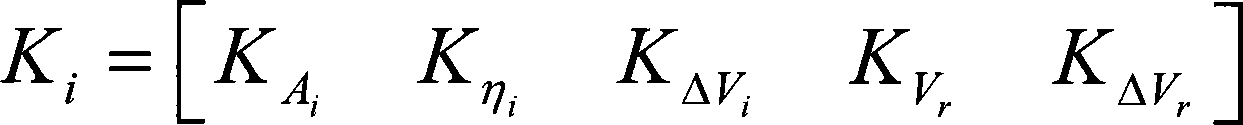

Locomotive Adhesion Control Method Based on Dynamic Axle Load Transfer Compensation and Multi-axis Coordination

ActiveCN108944963BOptimal Control StrategyReduce the number of idlingSpeed controllerElectric energy managementControl systemAxle load

The invention discloses a locomotive adhesion control method based on dynamic axle load transfer compensation and multi-axis coordination. One set of virtual three-layer distributed adhesion control system is established, wherein the first layer is a torque distribution layer used for dynamically adjusting a given torque according to a calculated axle load transfer amount; the second layer is a dynamic inter-axle coordination layer used for selecting the earliest idling axle of a locomotive as a main control axle and selecting other axles as slave control axles; and the third layer is an adhesion control layer used for recognizing rail surface on the basis of a support vector machine; the current rail surface state is recognized by using the support vector machine; and adhesion control strategies of the main control axle and the slave control axles are correspondingly designed for different rail surface states. According to the locomotive adhesion control method based on dynamic axle load transfer compensation and multi-axis coordination, a traction control strategy of a heavy-duty electric locomotive is optimized, and the thought of the support vector machine is integrated into the rail surface recognition. According to the locomotive adhesion control method based on dynamic axle load transfer compensation and multi-axis coordination, as one set of dynamic main and slave adhesion control method is designed, the idling frequency of the locomotive is reduced, and the adhesion utilization of the whole locomotive is enhanced.

Owner:SOUTHWEST JIAOTONG UNIV

Locomotive bogie

ActiveCN110588700ALow rotational resistanceEasy to adjustBogiesBogie-underframe connectionsBogieChinese characters

The invention discloses a locomotive bogie. The locomotive bogie comprises a framework shaped like a Chinese character 'ri', the framework comprises two side beams, one horizontal beam and two end beams, the middle portions of the side beams adopt concave structures, the locomotive bogie is characterized in that the upper surface of the middle portion of each side beam is provided with three steelsprings, the three steel springs are distributed at three vertices of an isosceles triangle, the bottom edge of the isosceles triangle is parallel to the longitudinal direction of the side beams, andan apex angle of the isosceles triangle is closer to the center of the framework than base angles. According to the locomotive bogie, two-series spring group triangle arrangement is adopted, spaces of biaxial bogie side beam middle portion concaving and being connected with the framework middle horizontal beam are utilized sufficiently, triangular arrangement can obtain less bogie head-shaking rotating resistance than longitudinal arrangement and larger vehicle body side rolling resistant stiffness than horizontal arrangement, therefore, by means of the locomotive bogie, good curve passing performance and dynamic limit utilization degree can be obtained.

Owner:ZHUZHOU ELECTRIC LOCOMOTIVE CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com