Control method of adjusting height of nominal towing point of locomotive automatically

An automatic adjustment and control method technology, applied to locomotives, special data processing applications, instruments, etc., can solve the problems of wheel diameter changes, locomotive nominal traction point height cannot always be at the best position, etc., to reduce idling and improve utilization Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

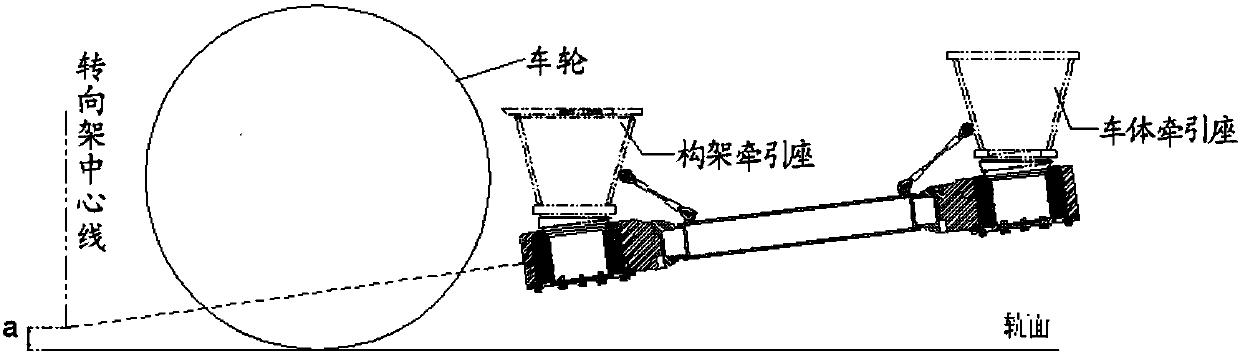

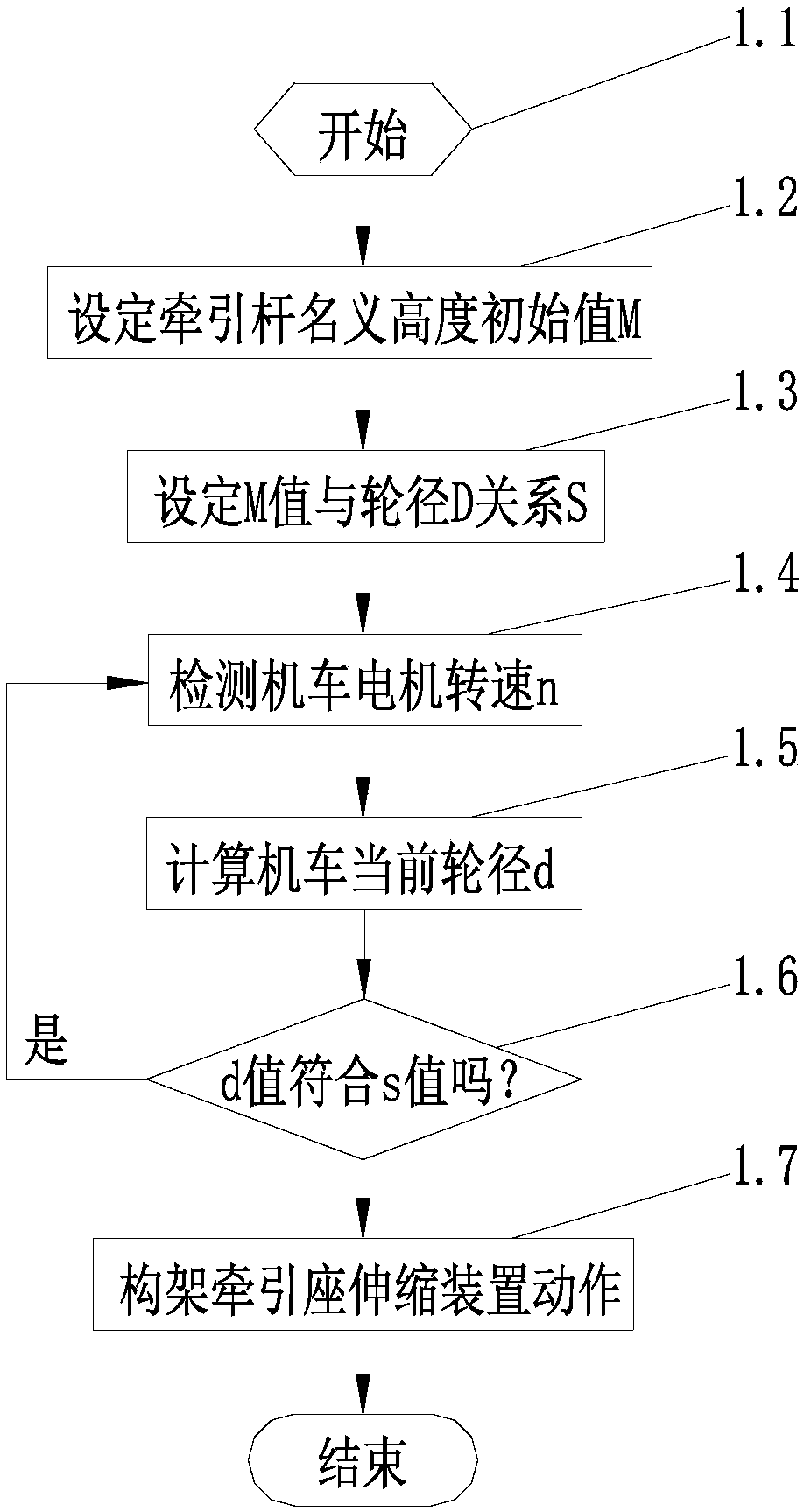

[0017] now attached figure 1 To attach image 3 To further explain the invention, the locomotive control system of the present invention detects parameters such as the running speed of the locomotive and the rotational speed of the traction motor to calculate the current wheel diameter of the locomotive, judges the value of the nominal height of the drawbar, and raises or lowers the drawbar by adjusting the telescopic device of the frame fifth wheel , so that the nominal height of the locomotive drawbar is matched with the wheel-rail adhesion in real time.

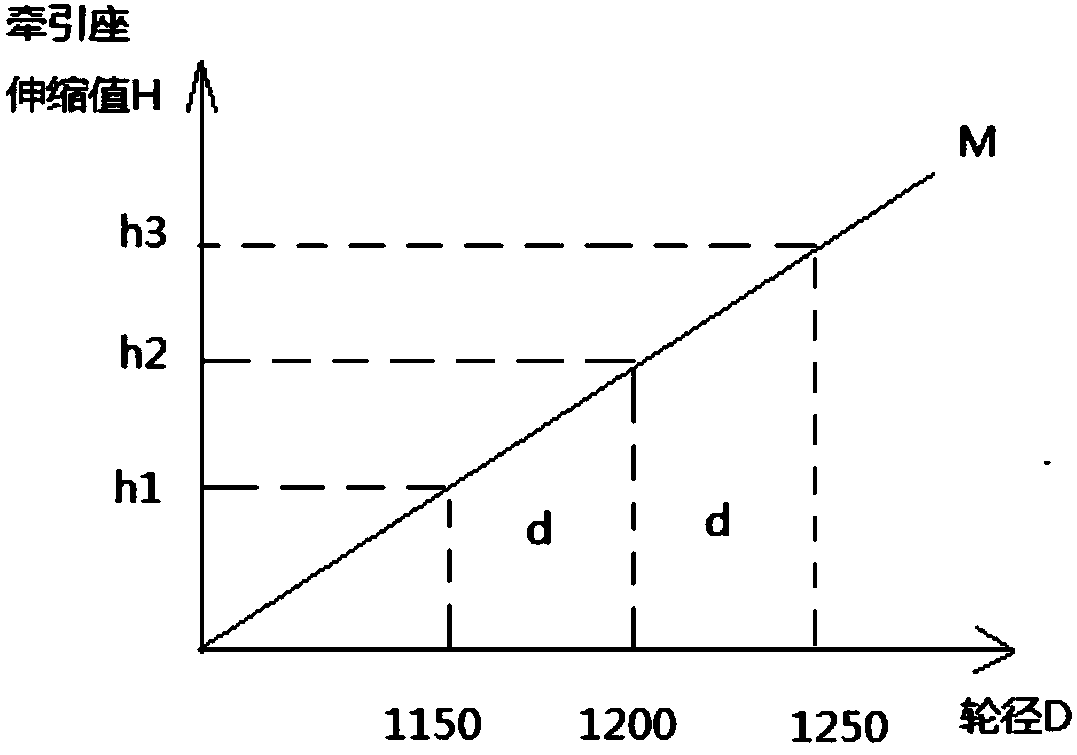

[0018] Set the locomotive wheel diameter D, the retractable height H of the fifth wheel, and the initial value M of the nominal height of the drawbar. The relationship value curve S is as follows: figure 2 As shown, after detecting the current wheel diameter d of the locomotive, the system compares it with the relational value curve S, and automatically adjusts the telescopic value h of the fifth wheel so that the nomina...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com