Antiskid control method for rail vehicle braking system

A technology for braking systems and rail vehicles, applied in the field of anti-skid control of rail vehicle braking systems, can solve problems such as quantitative calculation or perception of non-stick conditions, and achieve the effects of online parameter identification, skid prevention, and shortened braking distances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments. This embodiment is carried out on the premise of the technical solution of the present invention, and detailed implementation and specific operation process are given, but the protection scope of the present invention is not limited to the following embodiments.

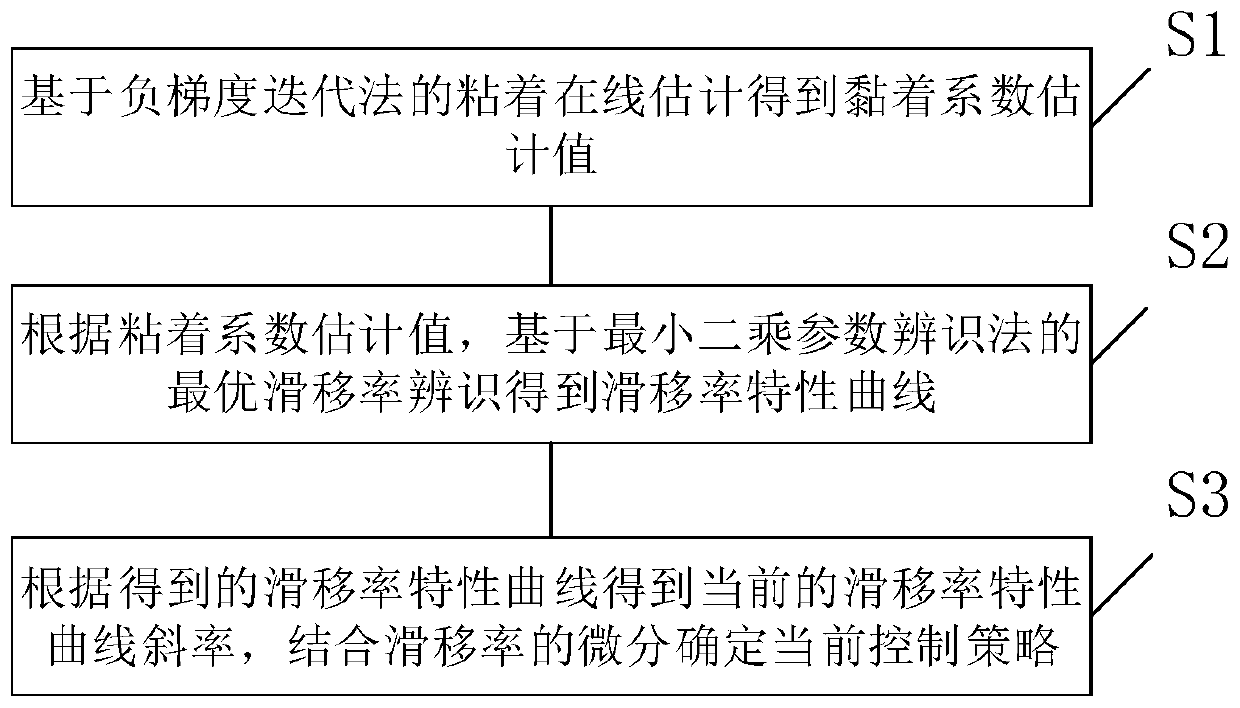

[0048] A method for anti-skid control of a rail vehicle braking system, such as figure 1 shown, including:

[0049] Step S1: Obtain the estimated value of the adhesion coefficient through online estimation of the adhesion based on the negative gradient iterative method, including:

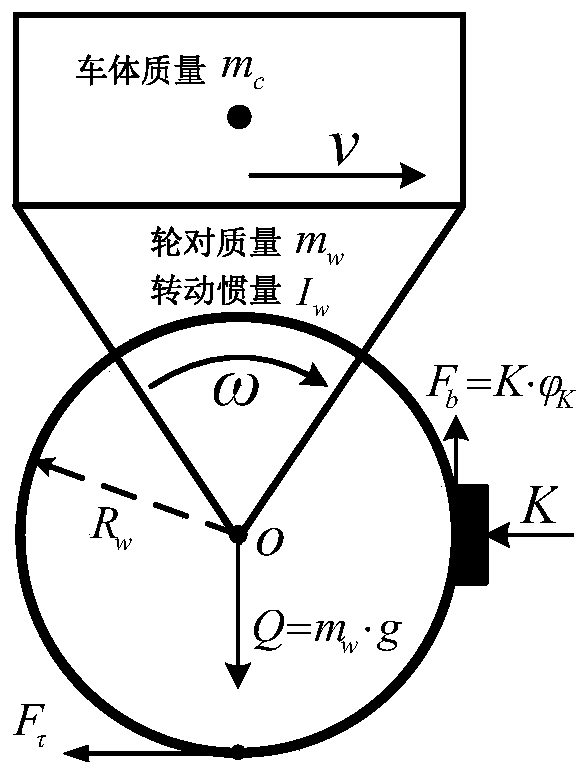

[0050] Step S11: Obtain the braking force K and wheel pair angular velocity ω applied by the braking system at the current moment in real time;

[0051] Step S12: Obtain the estimated value of the adhesion force between the wheel and rail, and continuously update the estimated value of the adhesion force...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com