A locomotive bogie

A locomotive bogie and frame technology, which is applied in the direction of the bogie, the device for lateral relative movement between the underframe and the bogie, the parts of the railway car body, etc. Large, inconvenient to carry with the vehicle, etc., to achieve the effect of good safety and stability of the locomotive, simple and reliable structure, and good dynamic limit utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in further detail below in conjunction with the accompanying drawings.

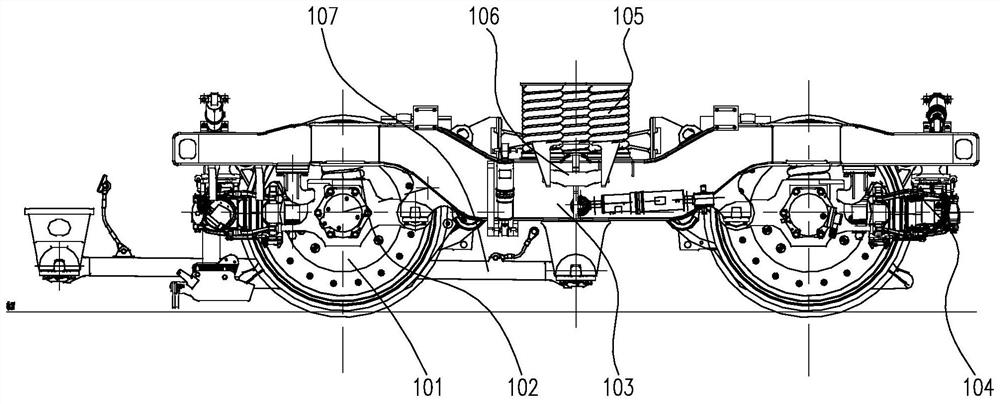

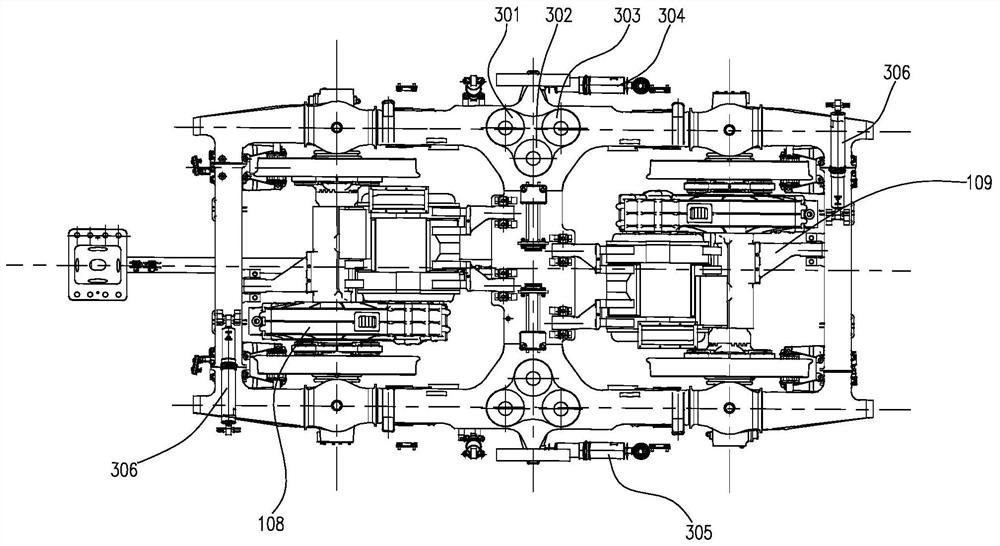

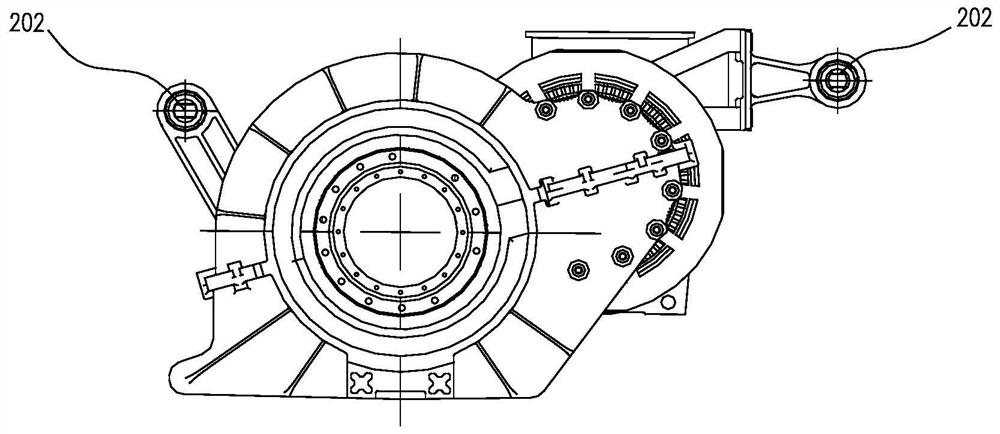

[0029] Such as Figure 1-2 As shown, the B0 bogie of the present invention includes wheel set assembly 101, primary suspension 102, frame 103, foundation braking device 104, secondary suspension 105, integral lifting device 106, traction device 107, driving device 108, driving unit suspension device 109.

[0030] Wheelset assembly 101 adopts integral rolled steel wheels and hollow axles. The integral rolled steel wheels have good integrity and can effectively avoid jumping wheels caused by high-speed operating loads; hollow axles can significantly reduce the axle mass while ensuring strength, so it is also The unsprung mass of the first series is reduced, which is very beneficial to reduce the wheel-rail force during high-speed operation.

[0031] The driving device 108 adopts a non-load-bearing gearbox; the driving torque is transmitted from the pinion to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com