Damper bearing

A technology of damping bearings and damping rings, which is applied in the field of damping bearings, can solve the problems of abnormal wear of moving rings and damping rings, reduce the service life of bearings, and easy entry of impurities, so as to achieve smooth operation, reduced rotational resistance and long service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

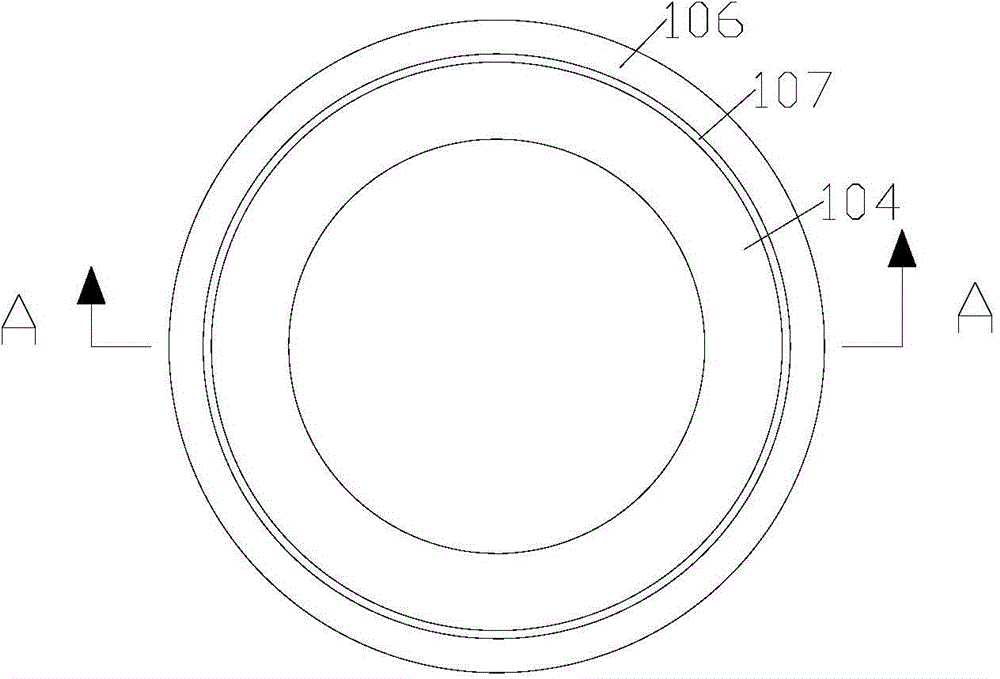

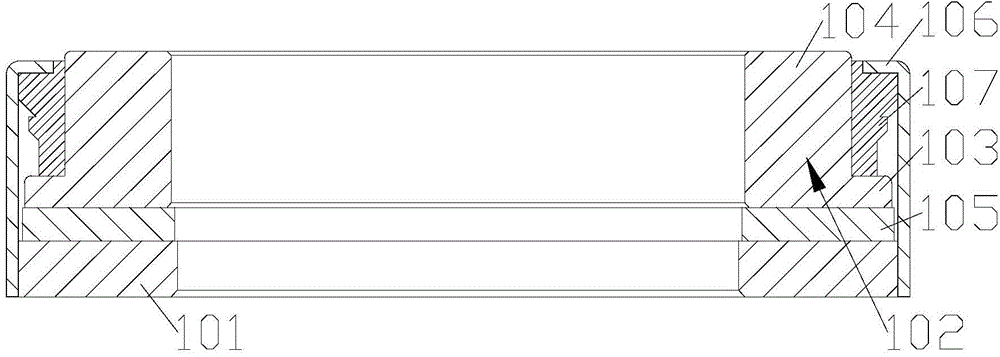

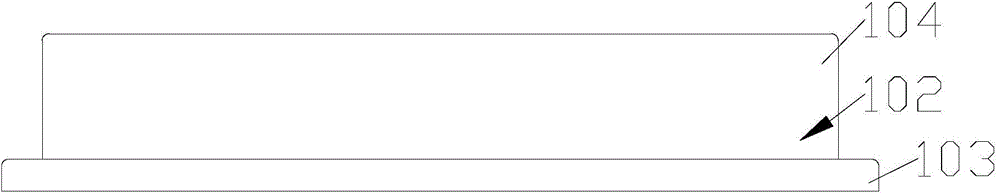

[0036] Figure 1-Figure 17 It shows the damping bearing provided by Embodiment 1 of the present invention, including: fixed ring 101; The moving ring 104 is integrally formed, the first moving ring 103 is closer to the fixed ring 101 than the second moving ring 104, the outer diameter of the first moving ring 103 is larger than the outer diameter of the second moving ring 104; the damping ring 105, the damping ring 105 is set Between the first moving ring 103 and the fixed ring 101; the casing 106, the fixed ring 101, the moving ring 102 and the damping ring 105 are all arranged inside the casing 106, the casing 106 is fixed to the fixed ring 101, and the casing 106 is far away from the fixed ring 101 The inner diameter of one end is less than the outer diameter of the first moving ring 103, and the second moving ring 104 passes through the casing 106; the sealing ring 107, the sealing ring 107 is arranged on the outer diameter of the casing 106, the first moving ring 103 and ...

Embodiment 2

[0039] Figure 18-Figure 25 It shows the damping bearing provided by Embodiment 2 of the present invention. Compared with Embodiment 1, the improvement of this embodiment is that four drag-reducing oil grooves 108 are arranged on the damping ring 105, and the drag-reducing oil grooves 108 are arranged on the damping ring 105 The side close to the first moving ring 103. The side of the damping ring 105 close to the first moving ring 103 is provided with a drag reducing oil groove 108, and a special grease can be injected into the drag reducing oil groove 108, so that the first moving ring 103 and the damping ring 105 can be lubricated to reduce the rotational resistance In addition, the drag reducing oil groove 108 reduces the contact area between the damping ring 105 and the first moving ring 103, which can also reduce the rotational resistance, and the damping bearing runs more smoothly.

[0040] Further, the thickness of the damping ring 105 is 4cm. The damping ring 105 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com