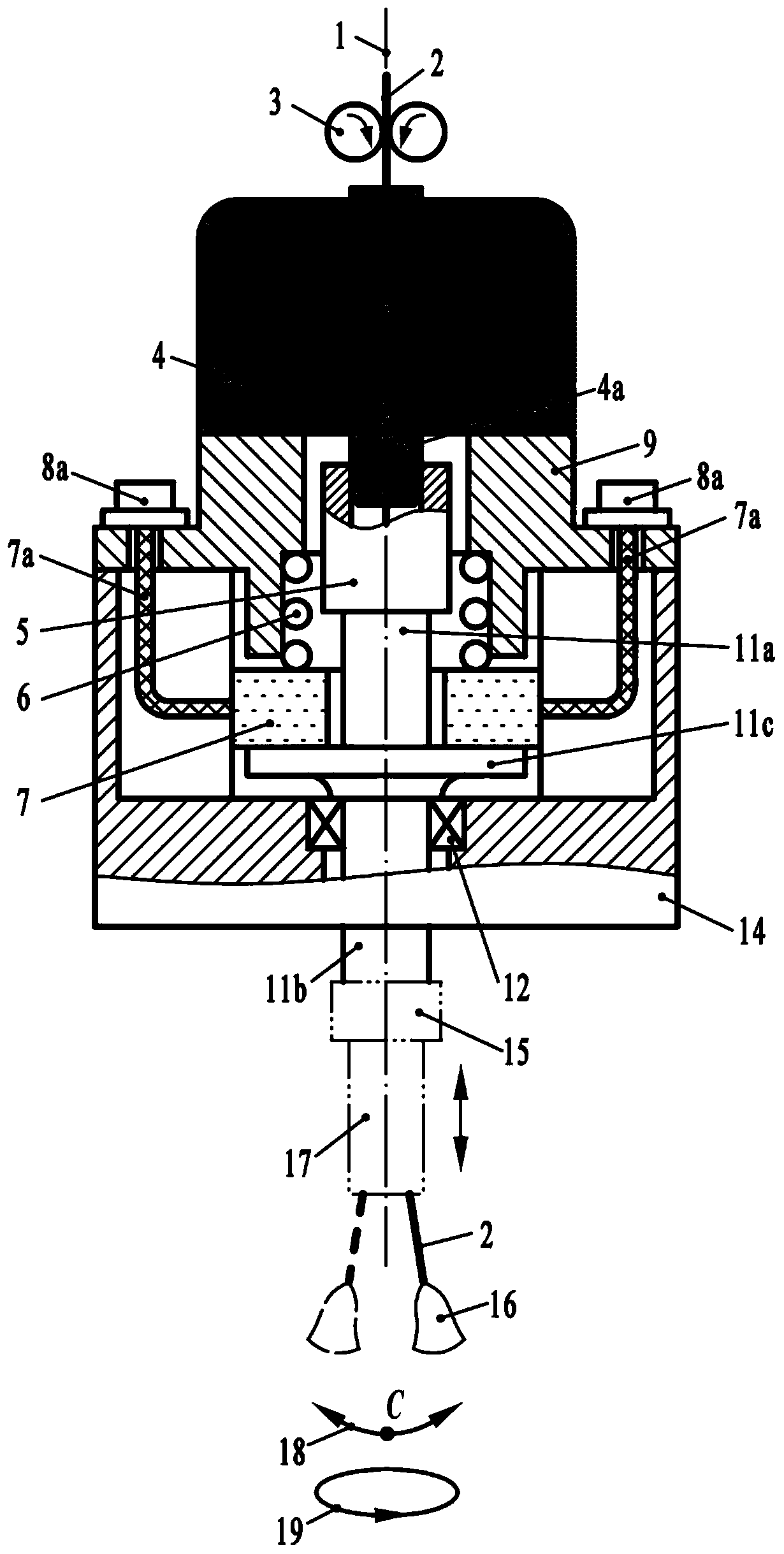

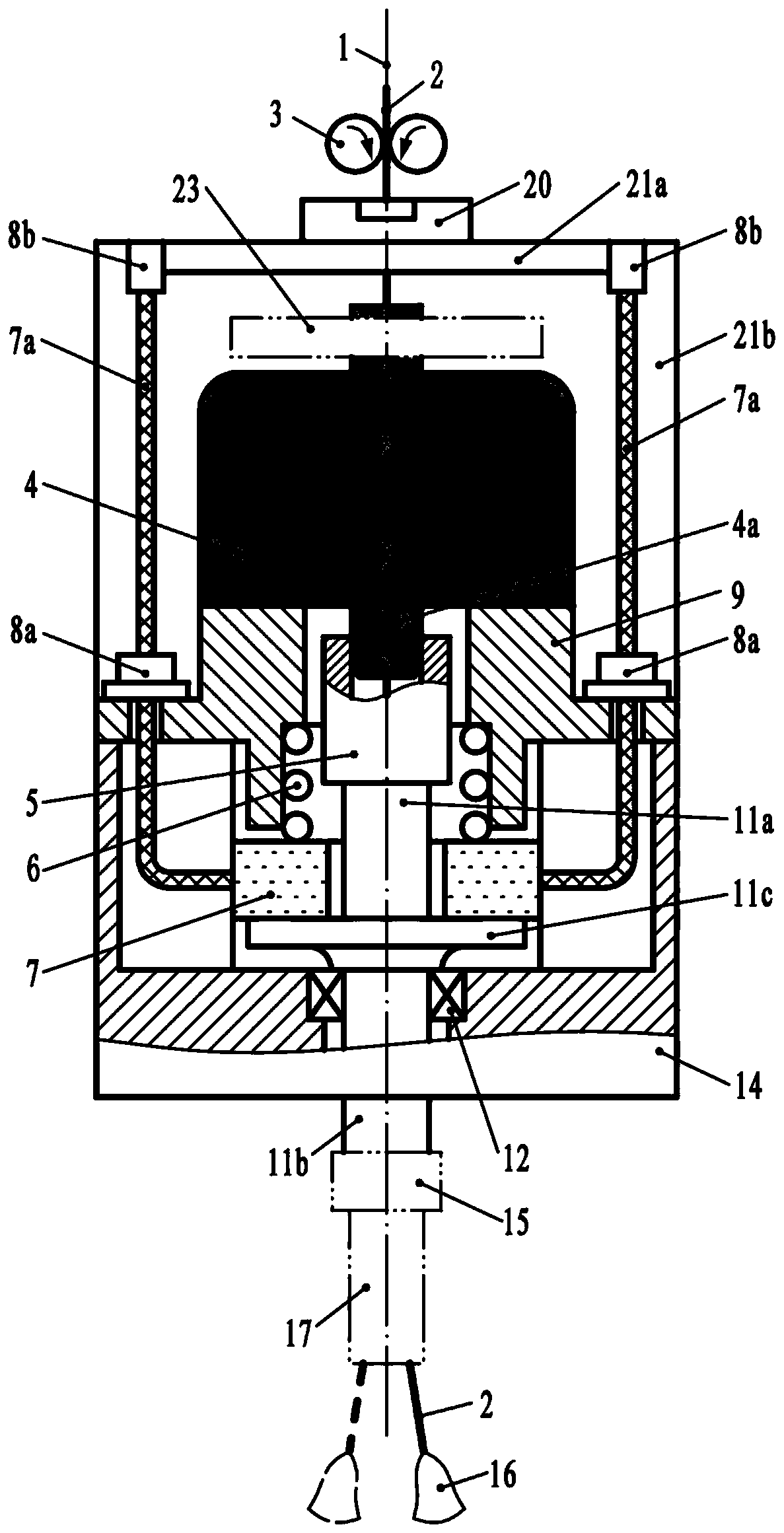

Rocking/rotating arc gas metal arc welding torch and a using method thereof

A technology of melting electrode gas and rotating arc, which is applied in arc welding equipment, electrode accessories, electrode support devices, etc., and can solve problems such as poor adjustability and adjustability, poor process adaptability, and low transmission positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

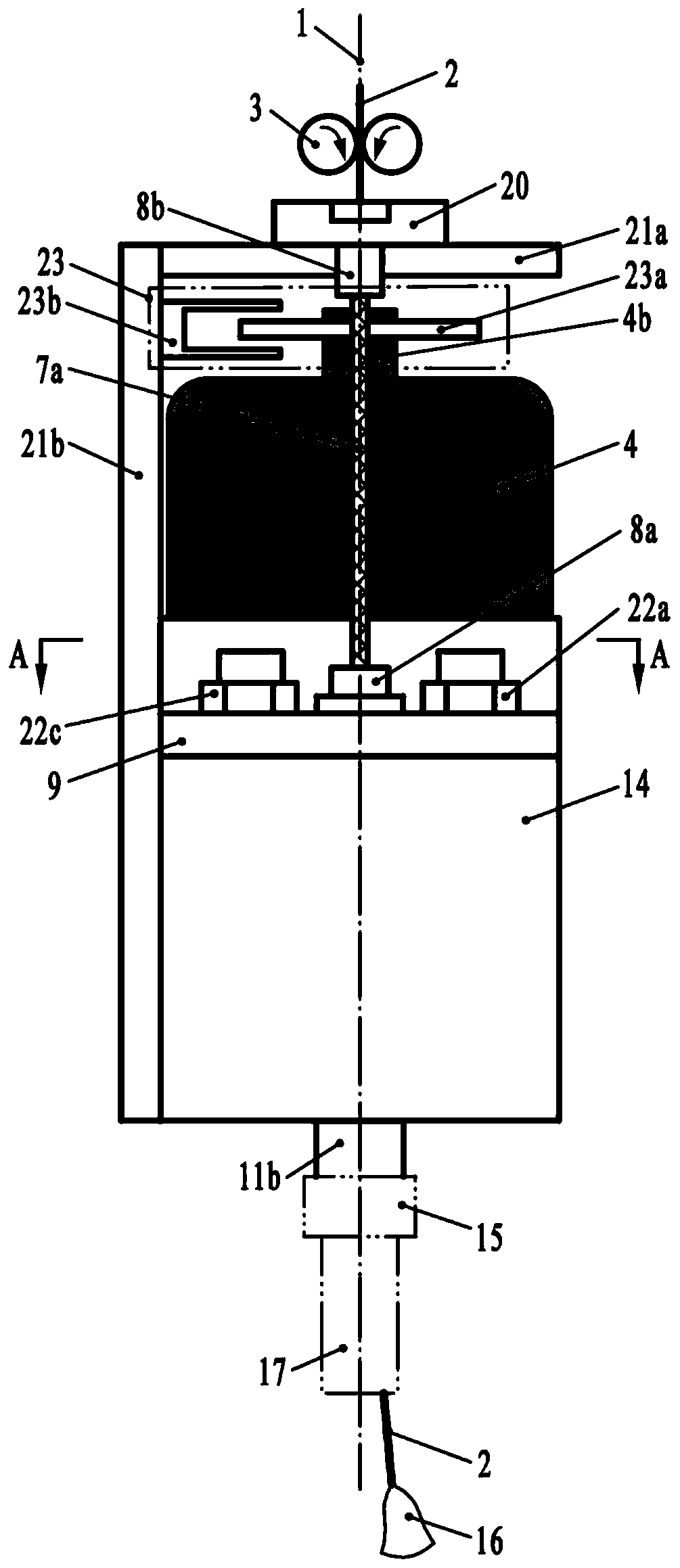

Embodiment 3

[0064] Welding torch embodiment 3: On the basis of welding torch embodiment 2, a hollow-shaft motor 4 with double-shaft extensions is used, and a shaft 4b protruding from the motor is provided for detecting arc shaking / rotation frequency and arc shaking The photoelectric switch device 23 of midpoint C, as shown in Fig. 2 (a) and Fig. 2 (b), its device is made of external grating disc 23a and optocoupler 23b, can also cover a dustproof cover (not drawn); The optical coupler 23b and the dust cover are fixedly connected to the support frame. At this time, the hollow shaft motor 4 is preferably a stepping motor or a DC motor.

[0065] In the welding torch embodiment 1 and embodiment 2, the sensing device for detecting the arc shaking / rotation frequency and the arc shaking midpoint is not specially provided, or in the welding torch embodiment 3, the photoelectric switch device 23 is set at On the upper extension shaft 4b of the double shaft extension hollow shaft motor 4, the moto...

Embodiment 1

[0086] Embodiment 1 of the telescopic adjustment method of the conductive rod mechanism: a telescopic adjustment method of the conductive rod mechanism for shaking / rotating the arc melting electrode gas shielded torch, see Fig. 4(a), including the following steps:

[0087] ① Loosen the first lock nut 15a that is threadedly connected with the first retractable conductive rod or the first retractable conductive tip in the retractable conductive rod mechanism 17, so that the upper end surface of the first lock nut 15a Out of contact with the lower end surface of the arc movement output shaft 11d of the welding torch, it is in an unlocked state; ② Rotate the first retractable conductive rod or the first retractable conductive tip to make the first retractable conductive tip screwed in by threaded connection The upper end of the conductive rod or the first retractable conductive tip shrinks up or down in the central hole of the arc movement output shaft 11d; ③ reversely rotates the ...

Embodiment 2

[0089] Embodiment 2 of the telescopic adjustment method of the conductive rod mechanism: a telescopic adjustment method of the conductive rod mechanism for shaking / rotating the arc melting electrode gas-shielded torch, see Fig. 4(b) and Fig. 4(c), including the following steps :

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com