Precision positioning method for rotating mould cutting roller

A technology of precise positioning and cutter roll, applied in rigid/semi-rigid container manufacturing, paper/cardboard containers, container manufacturing machinery, etc., to achieve the effect of convenience and error avoidance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

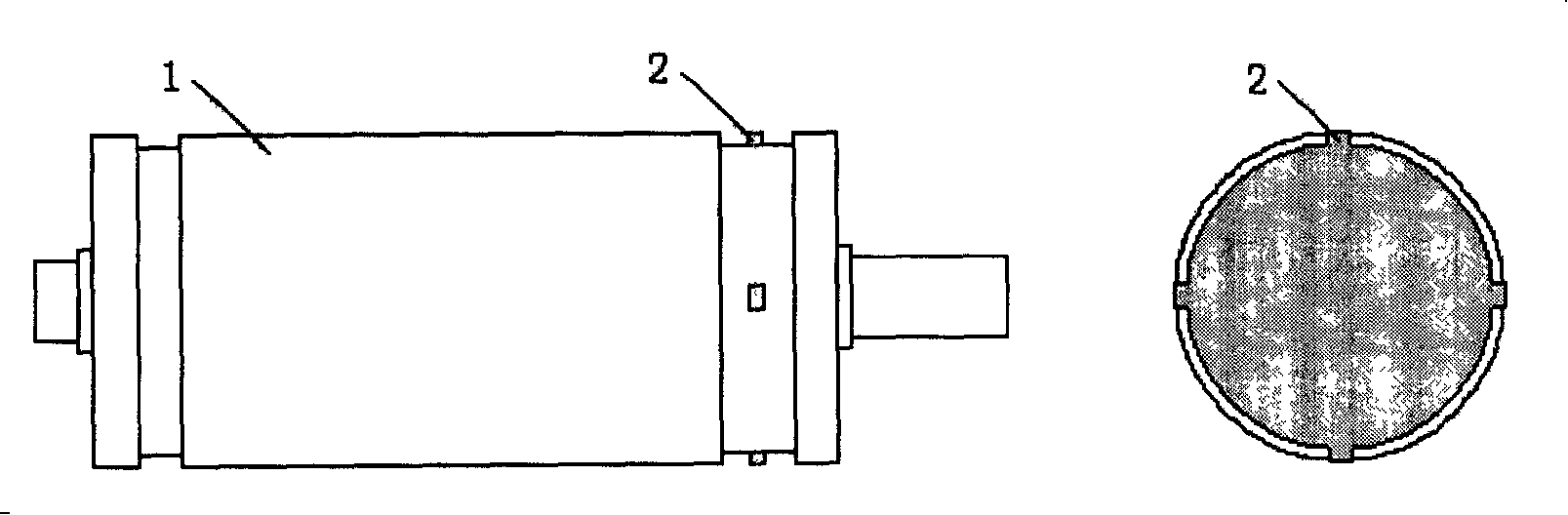

[0011] exist figure 1 Among them, there is a row of bosses (2) evenly distributed along the circumference on the die-cutting knife roller (1), and the number of bosses (2) is four in total. Using the inductive proximity switch to detect the arrival time of the bosses, it can be directly obtained The current position of the die cutter roll (1).

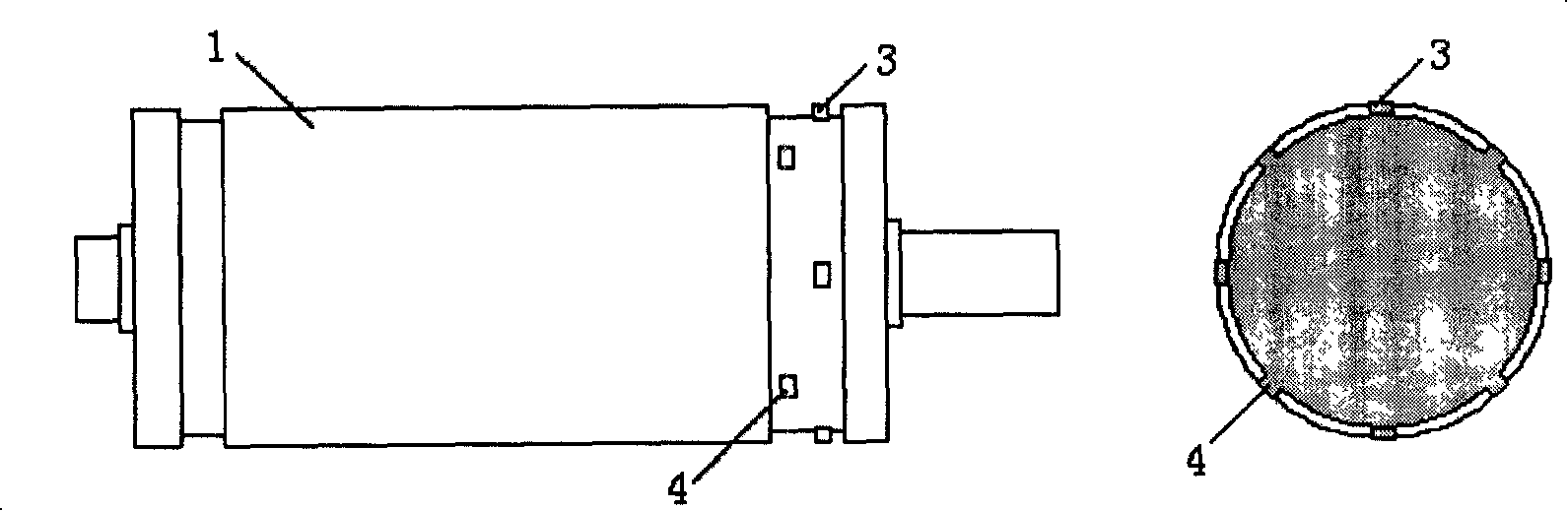

[0012] exist figure 2 Among them, there are two rows of evenly distributed bosses on the die cutter roller (1), one row is bosses (3), and the other row is bosses (4). The number of bosses in each row is four, and the die cutter There are eight bosses on the roller (1), and there is a certain distance between the two rows of bosses, and the bosses (3) and bosses (4) are staggered at a phase angle of 45° from each other, and the inductive proximity switch is used to detect them. The arrival time of a row of bosses can directly obtain the current position of the die-cutting knife roller (1). When the phase relationship between the ind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com