Turbine disk tenon and groove drilling device and turbine disk tenon and groove drilling method

A technology for drilling devices and turbine discs, which is applied in the direction of drilling/drilling equipment, turbines, and drilling molds for workpieces, etc., which can solve the problem of high surface symmetry and cannot guarantee the technology of mortise and groove bottom holes to be processed Requirements and other issues to achieve high-precision positioning and eliminate positioning errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

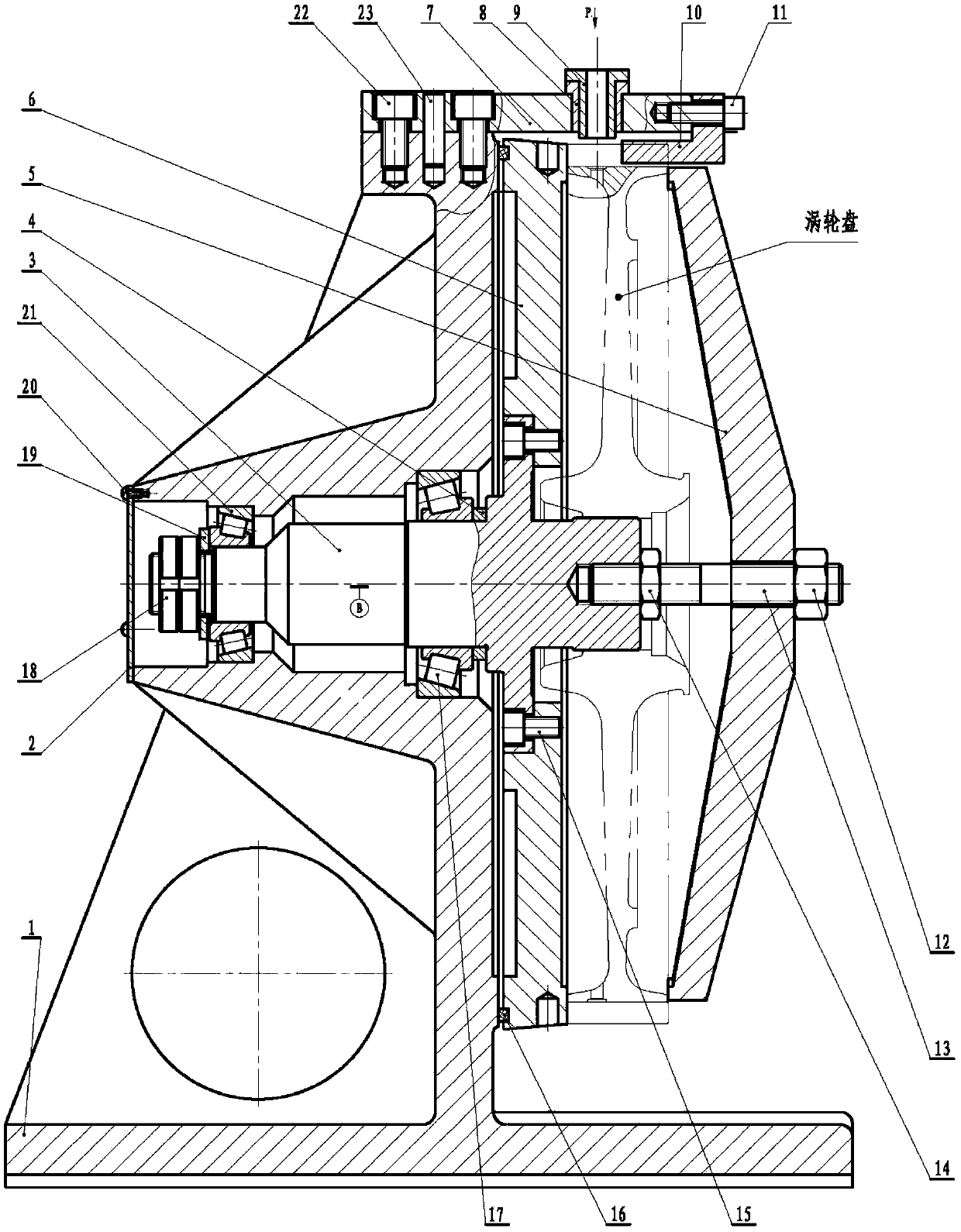

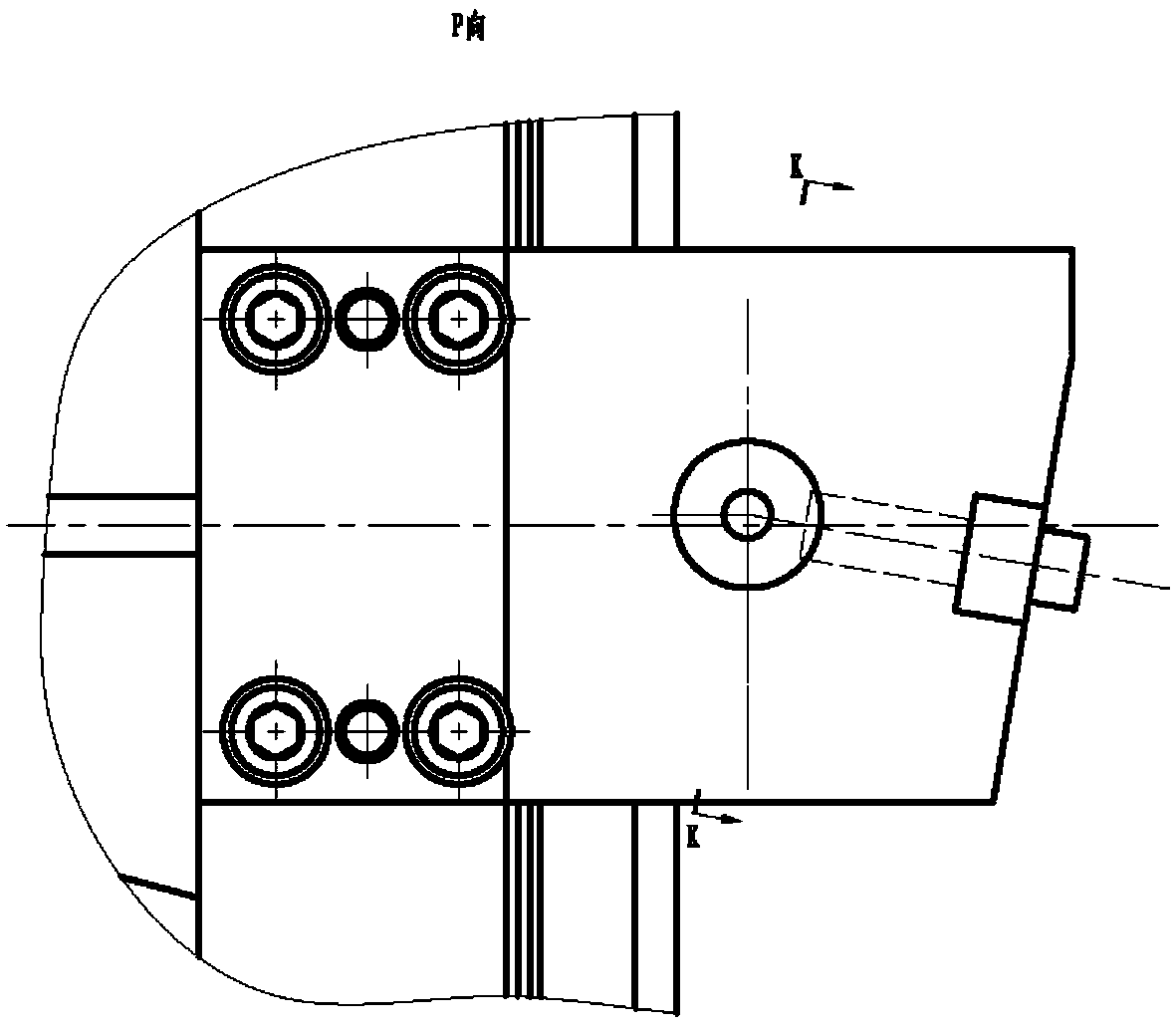

[0031] Attached below Figure 4 ~ Figure 12 The present invention is described in further detail to the specific embodiment of the present invention:

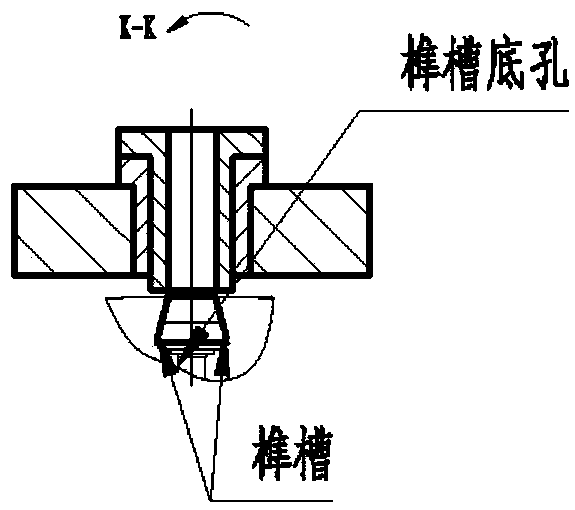

[0032] A turbine disk tongue and groove drilling device, base 1, cover plate 2, mandrel 3, adjustment pad 4, pressure plate 5, disk 6 for supporting the turbine disk, drilling template 7, bushing 8, drill sleeve 9, First nut 12, stud 13, second nut 14, first screw 15, sealing ring 16 for sealing between disc 6 and base 1, first bearing 17, third nut 18, washer 19, second Screw 20, second bearing 21, third screw 22, cylindrical pin 23, locking nut 24, tightening nut 25. Screw in tightening nut 25, locking nut 24 on bushing 8; Drill bushing 9 inserts in the bottom hole 7b of drilling template 7 from below drill template 7, also can directly put into directly from the straight groove 7a of drill template 7; After the groove 8b of the bushing 8 corresponds to the platform 9b of the drill bushing 9, insert the bushing 8 between th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com