Centre pin type guiding compelling radial direction mechanism

A force-guided, pin-type technology, applied in the self-adjustment direction of the wheel shaft, can solve the problems of large wheel flange wear, poor guiding performance, and affecting the speed and stability of rail vehicles, and achieves the reduction of longitudinal positioning stiffness and wide application range. The effect of reducing noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

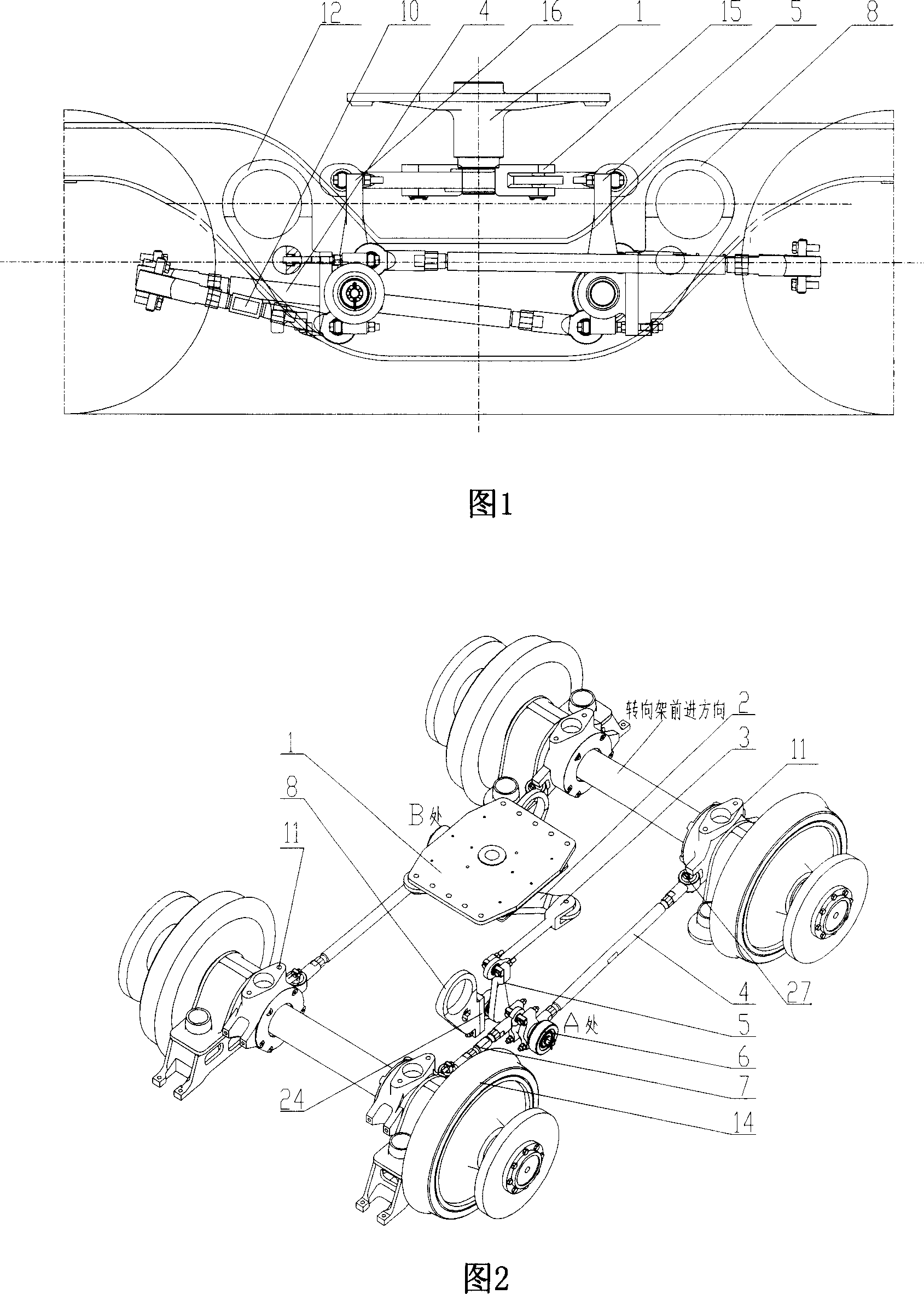

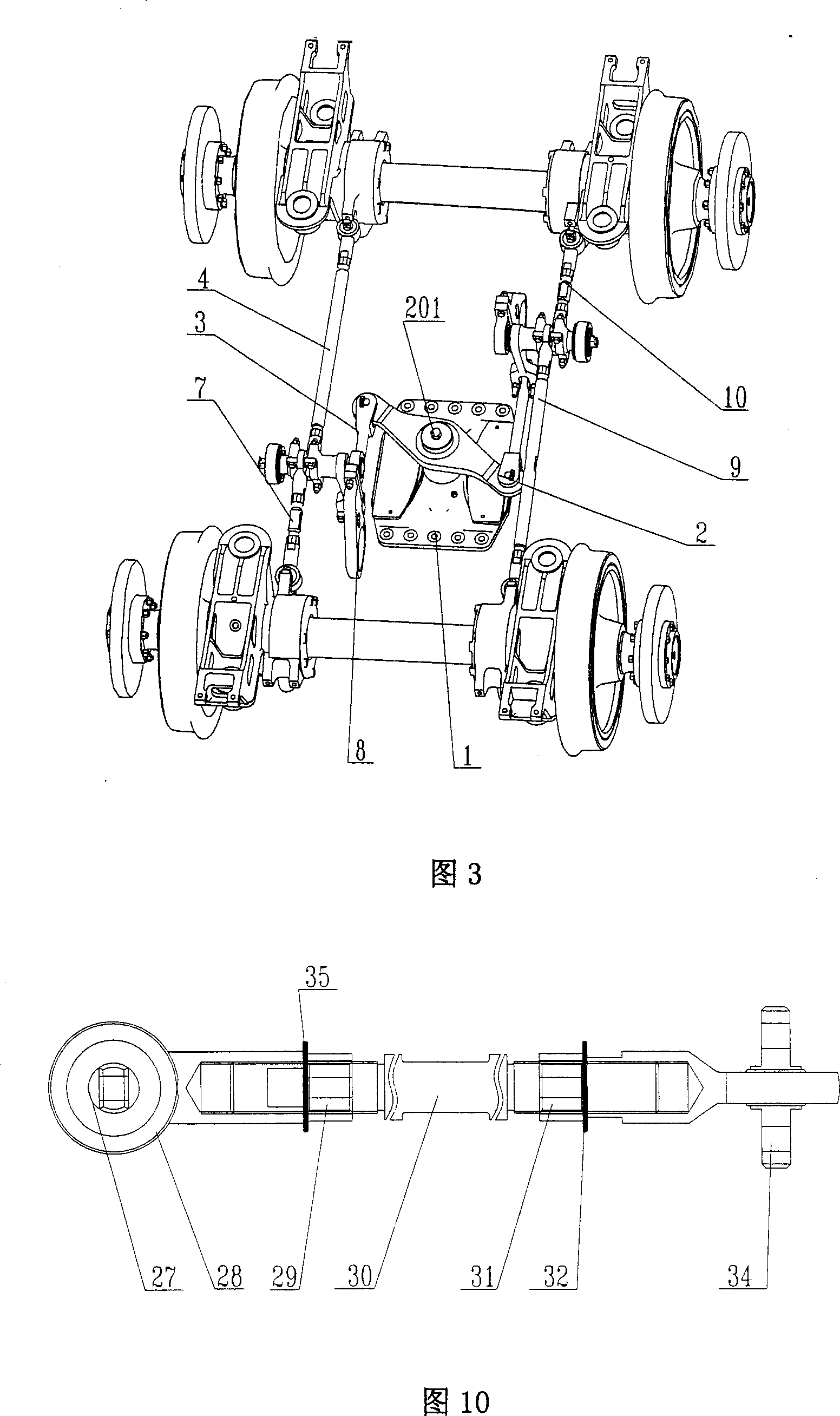

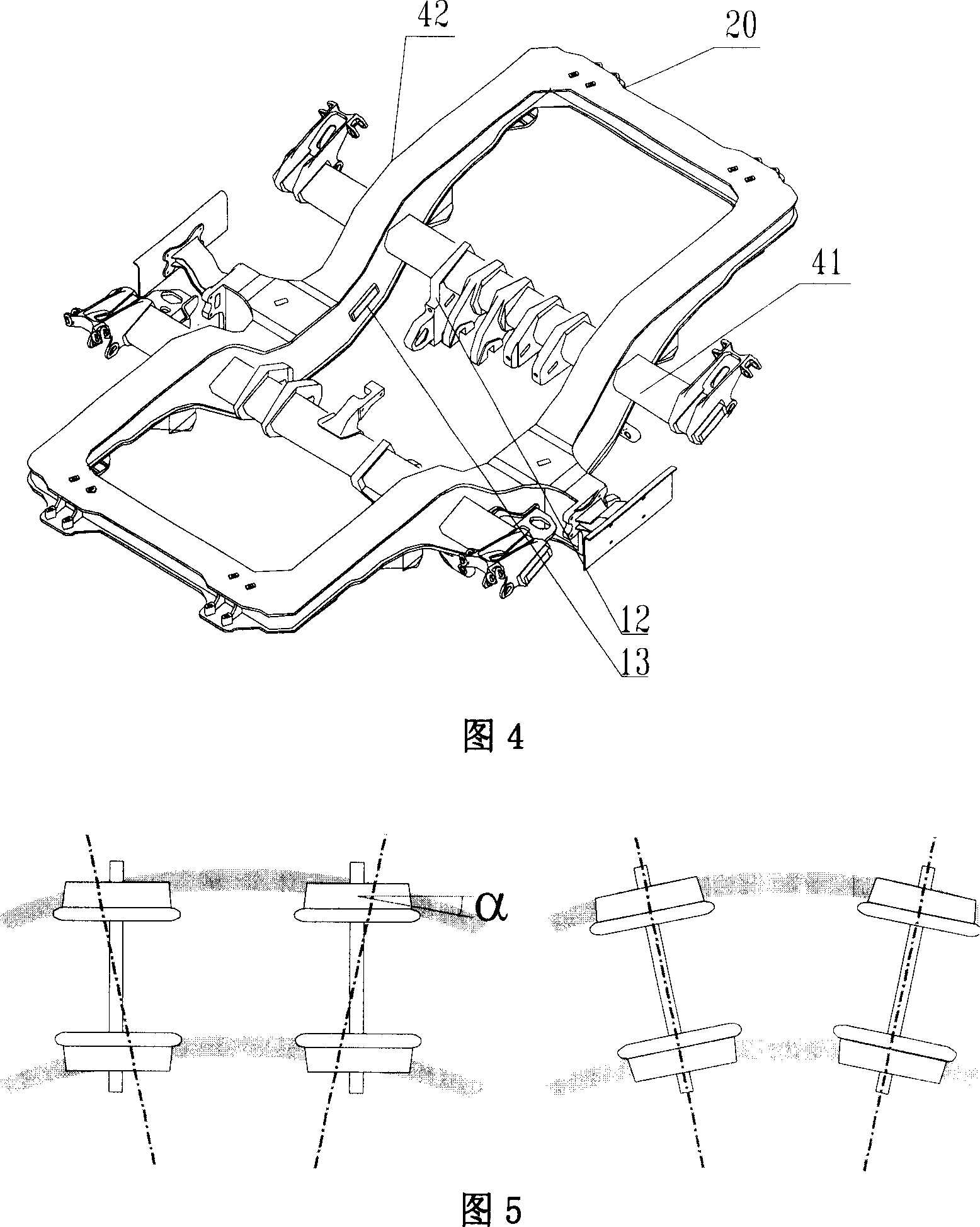

[0046] Embodiment 1, as shown in Figures 1 to 10, the central pin type forced radial mechanism of the present invention is applied to a power bogie 20 with two shafts and the traction mode is center pin traction, and the bogie 20 has two groups wheelset 14, and elastically supports a body 18 of a railway vehicle assembly 19. In this embodiment, the railway vehicle 19 is an urban rail vehicle with its own power.

[0047] The central pin type is forced to a radial mechanism, and passes through the central pin 1 and the vehicle body 18 .

[0048] The radial adjustment mechanism has a central turntable 2, which is connected to the bottom of the center pin 1 through a spline 201 and moves together with the center pin 1 .

[0049] A group of longitudinal push rods 3 and 15 are respectively connected to the end of the central turntable 2, and the other ends are connected to the rotating arms 5 and 16 respectively.

[0050] The pivoting arms 5 and 16 are connected respectively and f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com