A rail train anti-air rotation anti-skid adhesion optimization control method

A rail train and optimization control technology, applied in the direction of instrumentation, geometric CAD, calculation, etc., can solve problems such as low adhesion utilization, poor passenger comfort, large torque fluctuations, etc., to achieve increased adhesion utilization and speed difference threshold setting Reasonable, volatility-reducing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In the following, the present invention will be specifically described through exemplary embodiments. It should be understood, however, that elements, structures and characteristics of one embodiment may be beneficially incorporated in other embodiments without further recitation.

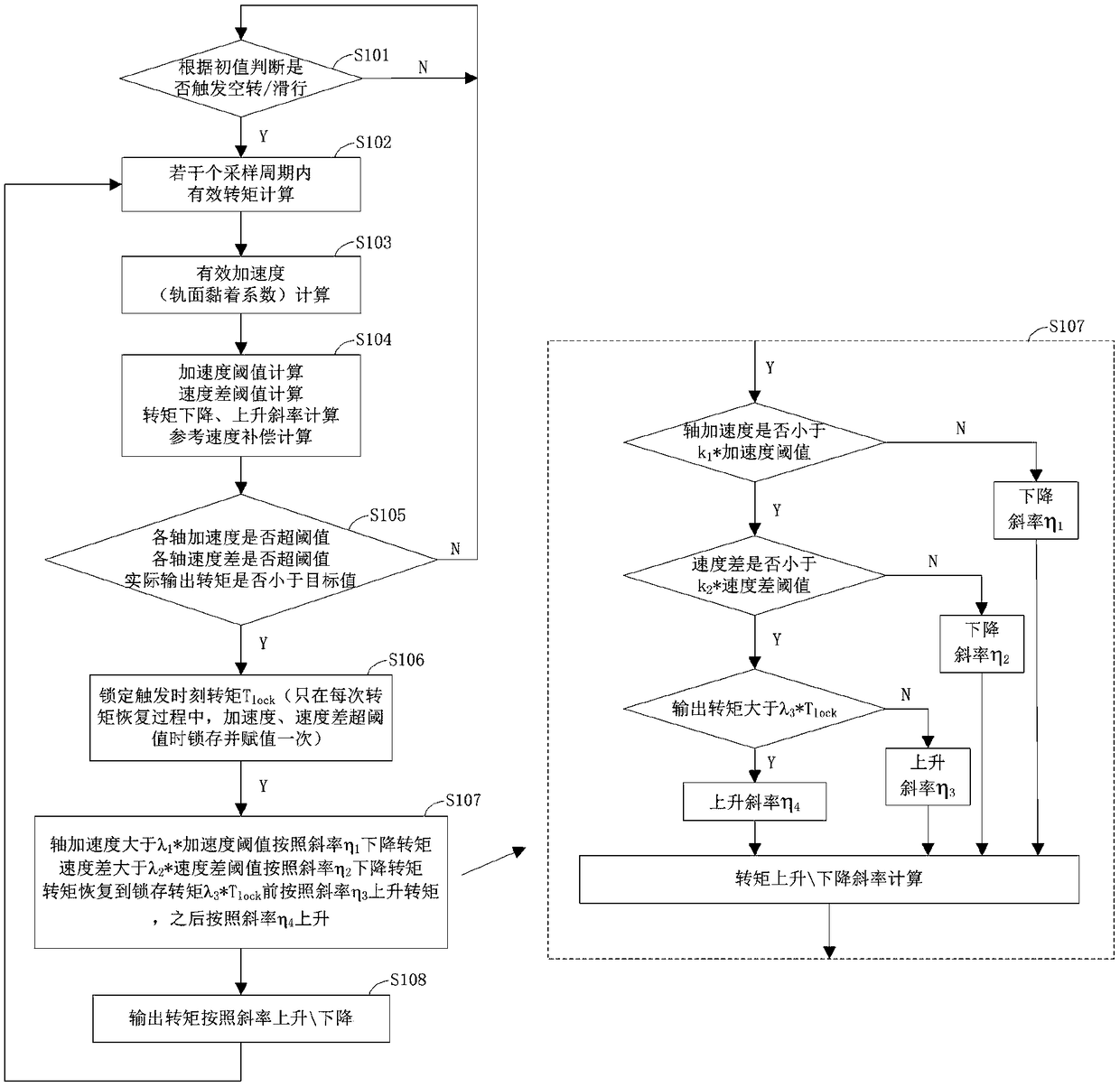

[0041] see figure 1 , the present invention discloses a rail train anti-idling anti-slip sticking optimal control method, the specific steps of which are:

[0042] S101. Judging whether idling or coasting is triggered according to the initial value of the acceleration and speed difference thresholds. If so, perform anti-idling anti-adjustment and execute step S102. Otherwise, execute step S101 to continue judging at the next moment.

[0043] S102. Calculate the effective value of the output torque in several sampling periods by formula (1), the formula (1) is expressed as:

[0044]

[0045] In the formula, T e is the output effective torque, T i is the output torque at the sampling mome...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com