Noise reduction control method and system for switched reluctance motor

A technology of switched reluctance motor and control method, which is applied in control system, AC motor control, torque ripple control, etc., and can solve problems such as incomplete establishment of turn-on phase torque, large air and mechanical noise, large torque ripple, etc. , to achieve the effect of continuously adjustable speed, strong versatility, and good load adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

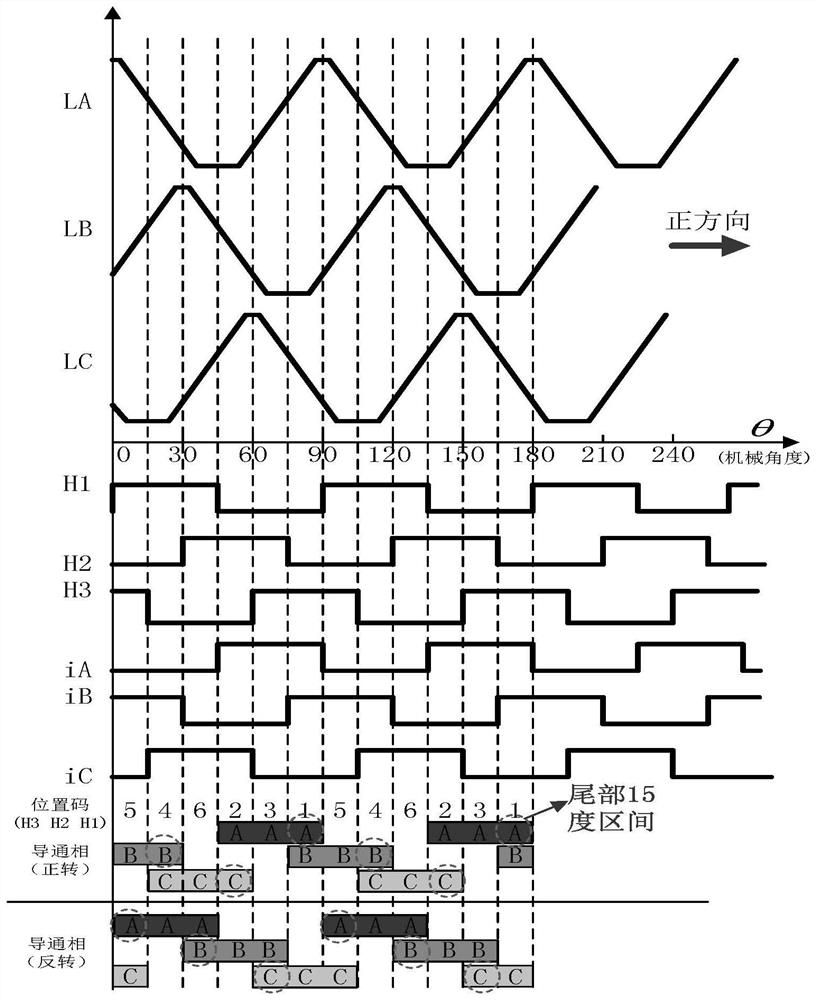

[0078] Embodiment 1 of the present invention selects a switched reluctance motor with 6 slots in the stator and 4 teeth in the rotor as the test object, hereinafter referred to as a switched reluctance motor or a test motor.

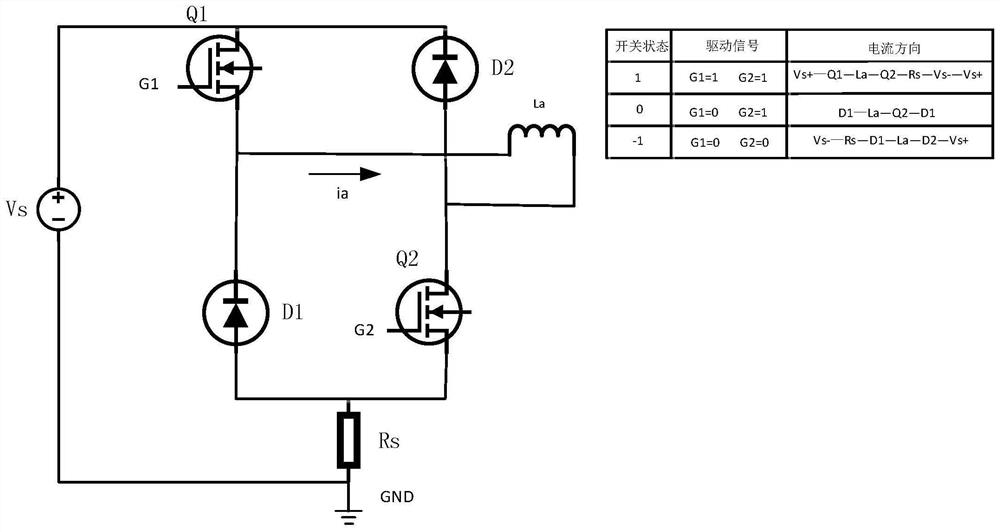

[0079] 1. If figure 1 Shown is the schematic diagram of the power switch tube applied to the one-phase winding drive control of the switched reluctance motor of this patent, which is defined as a power asymmetric H-bridge. In the figure, Q1 and Q2 are power MOS tubes, which are used to pass the power supply V s To the switched reluctance motor winding L a power supply, D1 and D2 are switched reluctance motor winding freewheeling diodes, R s is the sampling resistance of the switched reluctance motor winding. Defining the switched reluctance motor winding L a three working states: 1, 0, -1, other windings are equivalent, as follows:

[0080] ① "1" state: switched reluctance motor winding L a Power is supplied, Q1 and Q2 are turned on, and the curren...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com