Heavy-duty locomotive multistage idling fault detection method

A technology for fault detection and heavy-duty locomotives, applied in instruments, simulators, control/regulation systems, etc., and can solve problems such as single influencing factor and slow calculation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

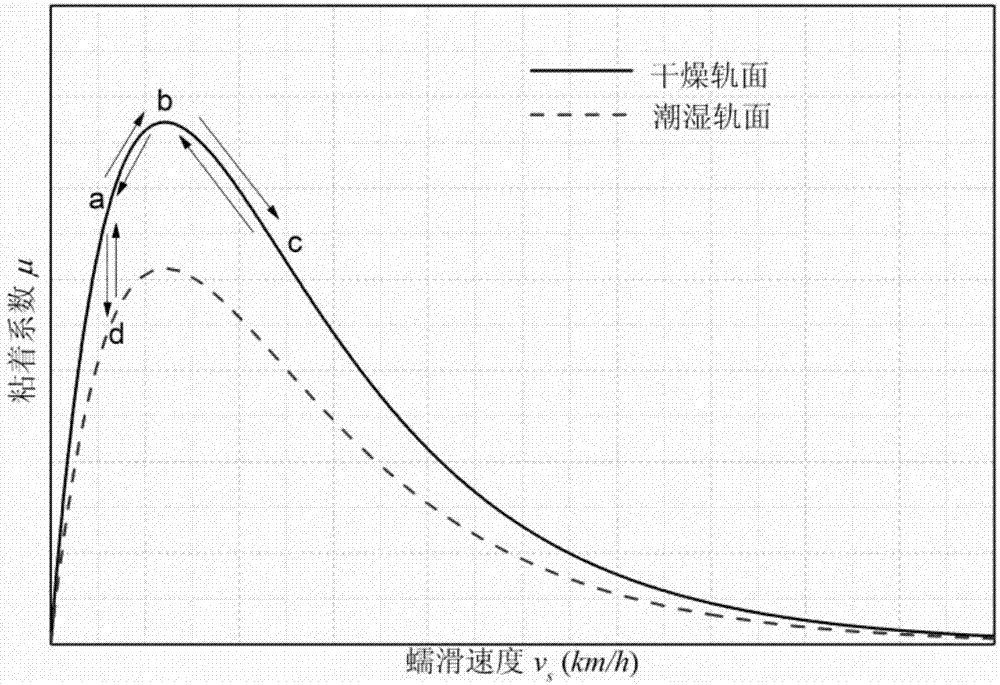

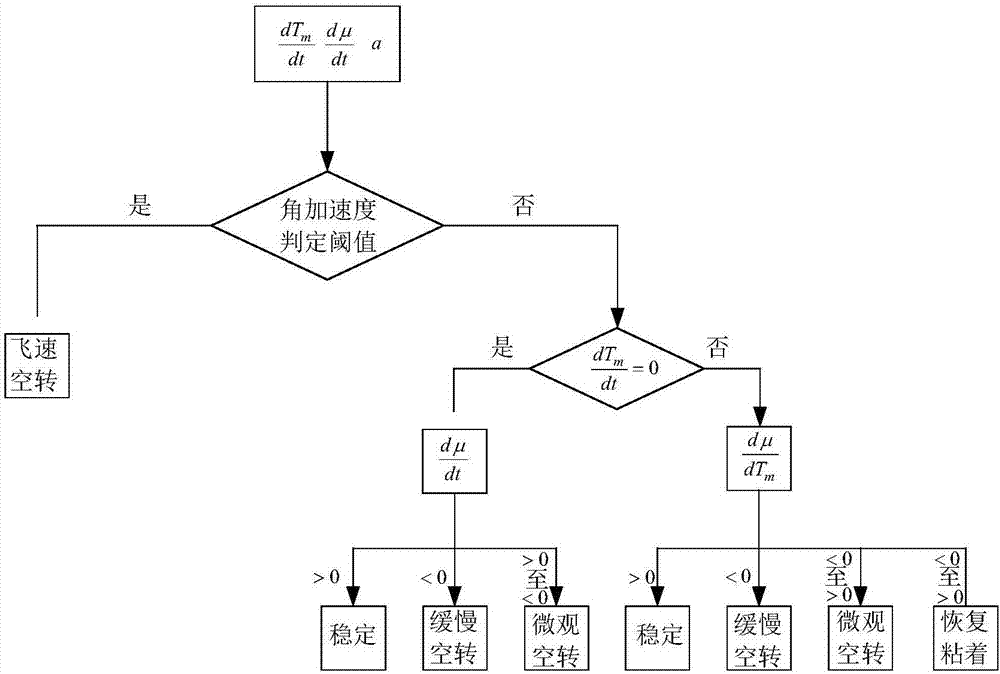

[0088] Such as figure 1 As shown, according to the adhesive characteristic curve, there is dμ / dv on the left side of the peak point, that is, the stable region s >0, on the right side of the peak point, that is, there is dμ / dv in the idle zone s s The symbol of the locomotive makes it difficult to obtain the running status of the locomotive; the following formula, The notation for is not equivalent to Therefore, although μ characterizes the situation of wheel-rail surface adhesion utilization, it cannot utilize To identify the running condition of the wheelset.

[0089]

[0090] According to the change of traction and the speed of locomotive body is unknown, the methods of locomotive idling detection are discussed respectively.

[0091] (1)T m change, the traction force of the locomotive changes at this time,

[0092] a. which is As the output torque of the locomotive increases, the creep speed increases and the adhesion coefficient increases, indicating that t...

Embodiment 2

[0106] Combined with the simulation experiment, the application effect of the present invention is described in detail.

[0107] Aiming at the detection of multi-stage idling faults of wheel sets, a single-axis machine simulation model is established by Matlab / Simulink for verification.

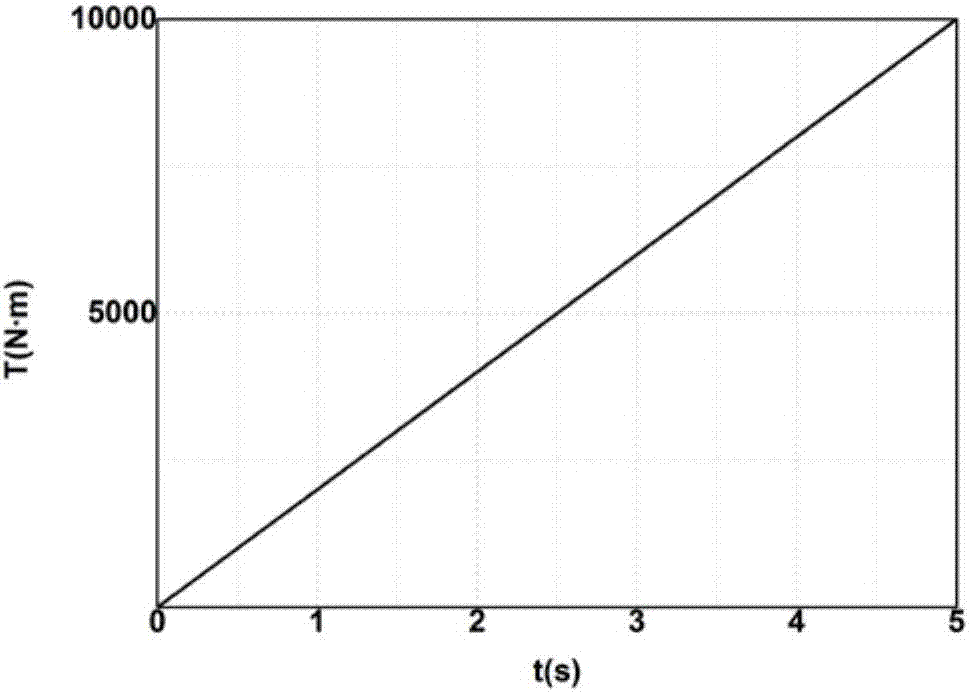

[0108] Simulation 1, such as image 3 As shown, the initial value of the input torque is 0, and then increases in the range of 2000N·m / s, from Figure 4 It can be seen that the coefficient of adhesion increases before 4.2s and decreases after 4.2s. Figure 6 As shown in the judgment diagram, 1 is idling and 0 is stable. At 4.2s, when switching from 0 to 1, the locomotive is idling microscopically, and then the locomotive is idling slowly, and the adhesion coefficient decreases. and Figure 5 The angular acceleration judgment diagram also shows that the car has been idling rapidly at 4.3s.

[0109] Simulation 2, such as Figure 7 The input torque is shown, the initial value is 8000N·m, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com