Patents

Literature

32results about How to "Accurate weight measurement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

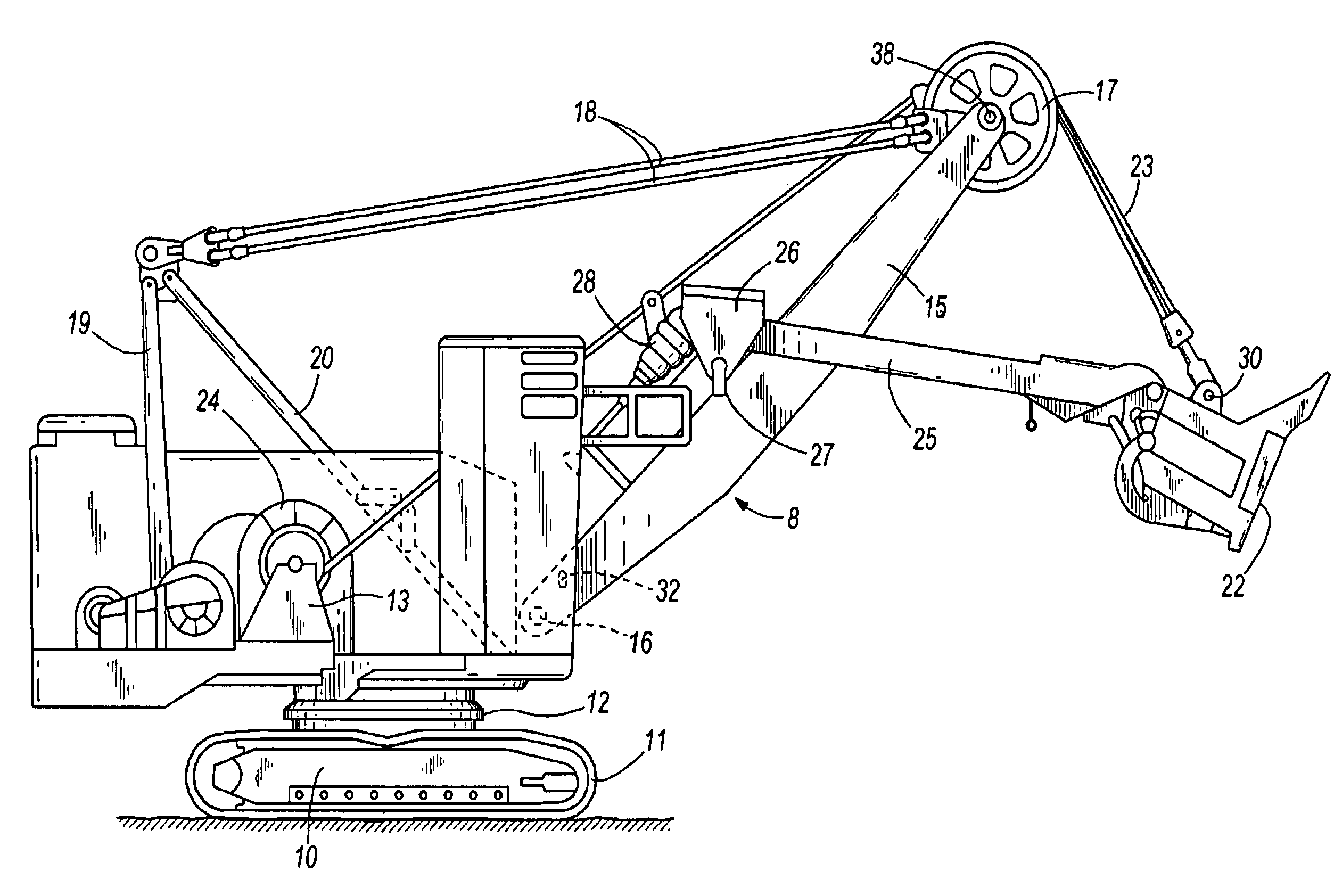

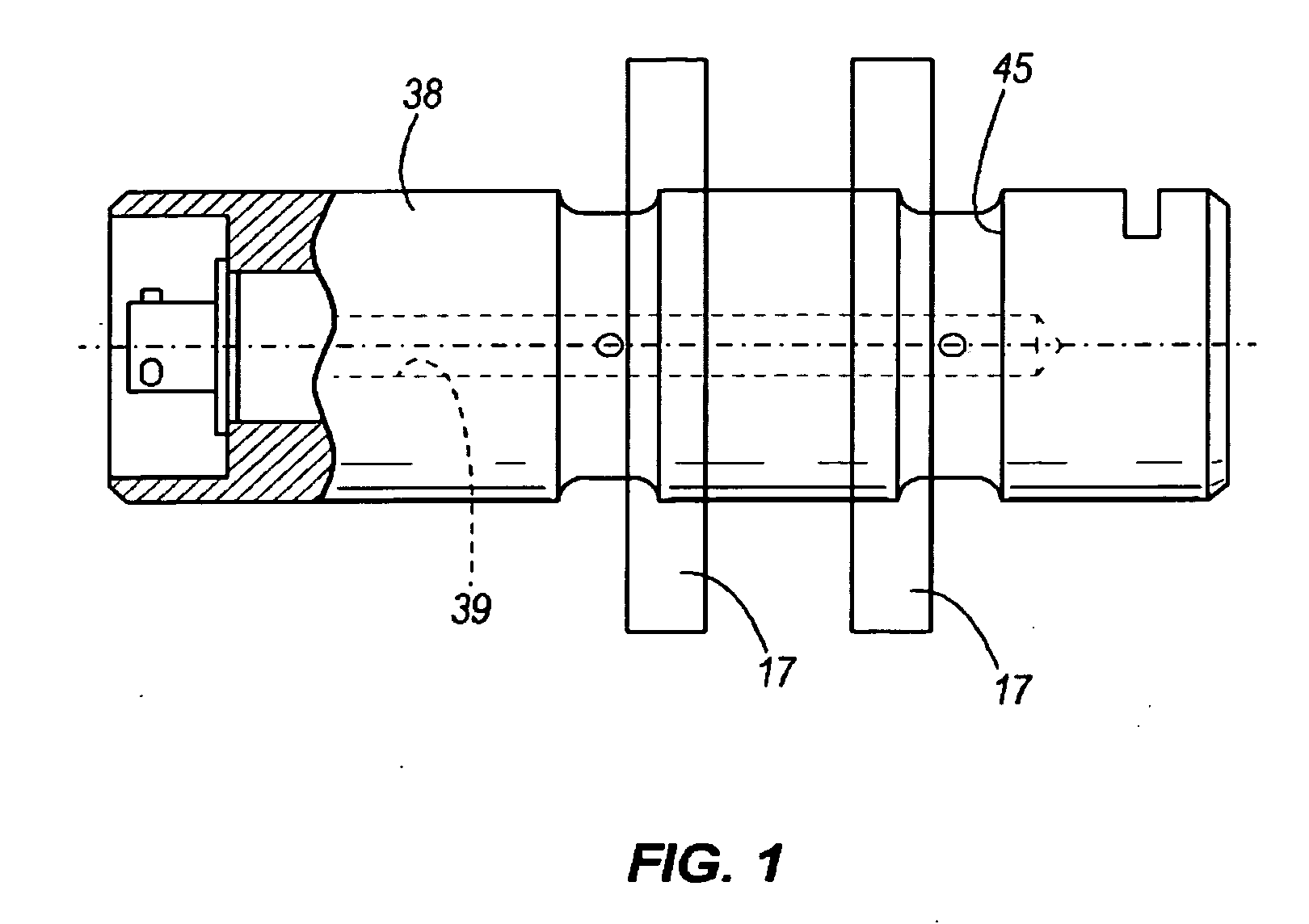

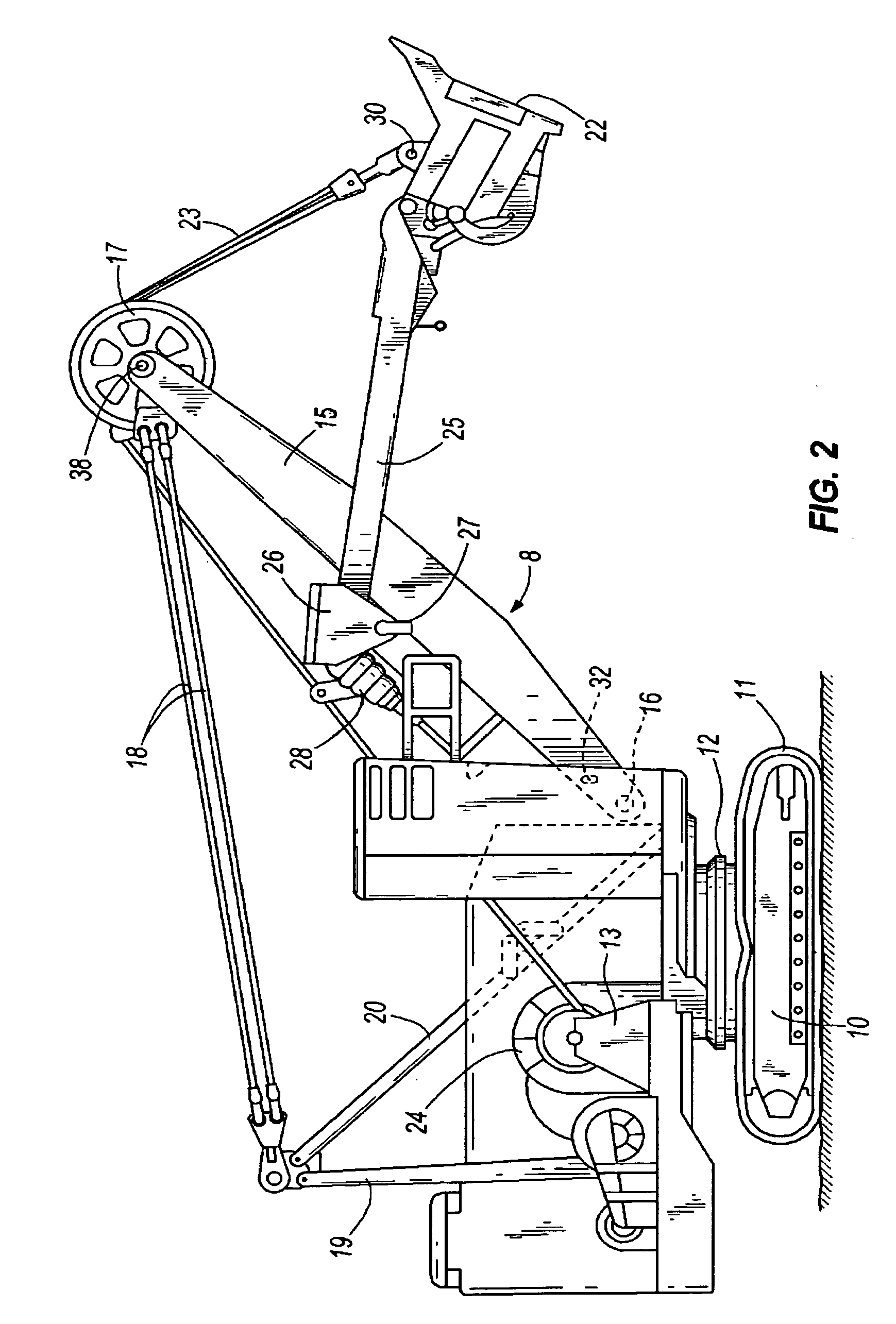

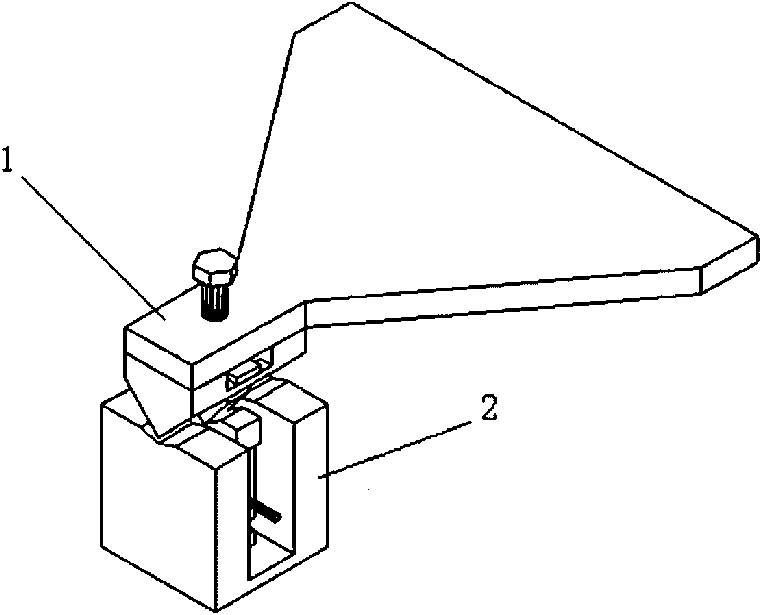

Device for measuring a load at the end of a rope wrapped over a rod

InactiveUS20070266601A1Accurate weight measurementAccurately determine it locationWeighing apparatus using elastically-deformable membersMechanical machines/dredgersStrain gaugePull force

A machine for raising and lowering a load, the machine including a platform, a boom attached at one end to the platform, a rod mounted transverse to the longitudinal axis of the boom on the other end of a boom, the rod having a central bore there through, with at least two strain gauges mounted therein and angled relative to each other, a hoist rope extending over the rod and having an end adapted to be attached to the load, and a mechanism connected to the at least two strain gauges for determining the angle of departure of the hoist rope from the rod and the amount of pull of the load on the hoist rope.

Owner:HARNISCHFEGER TECH

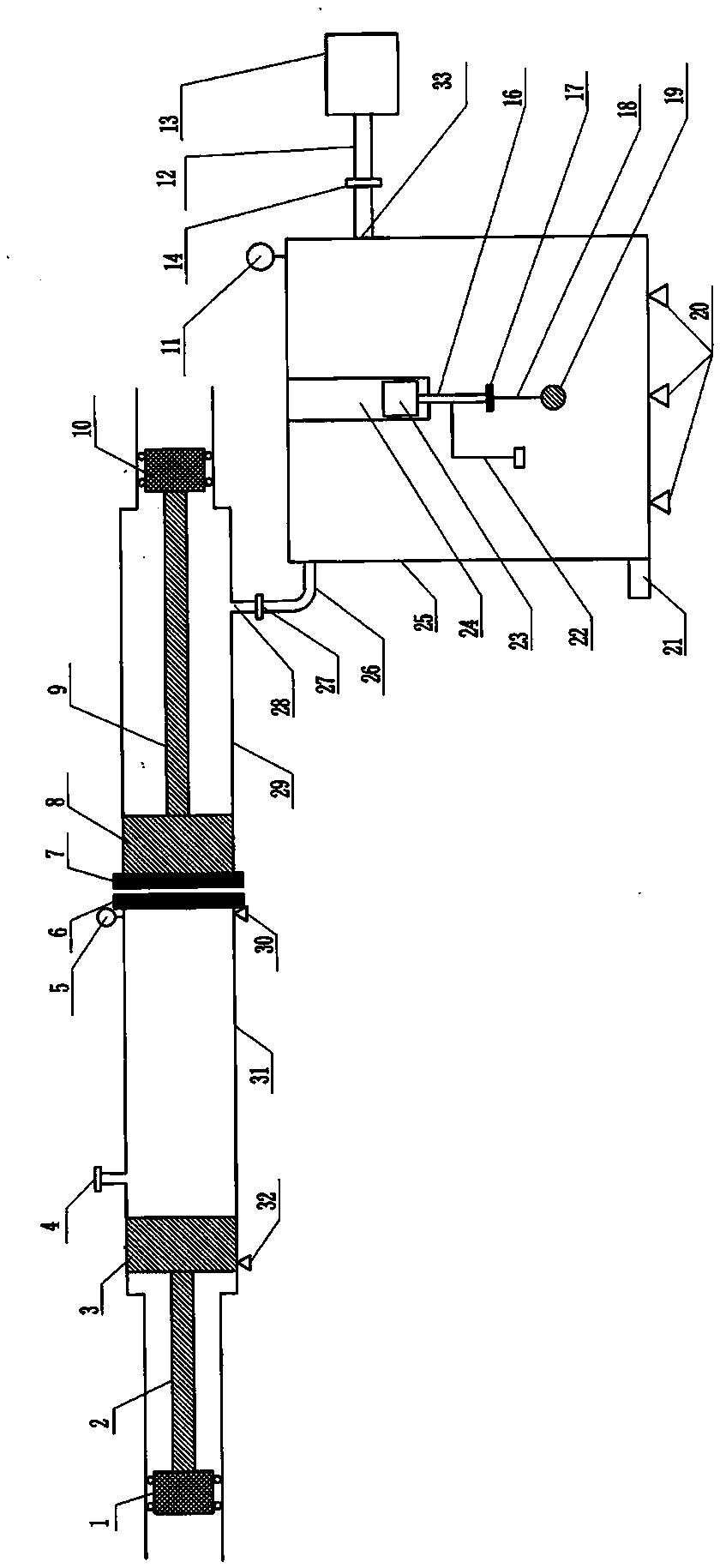

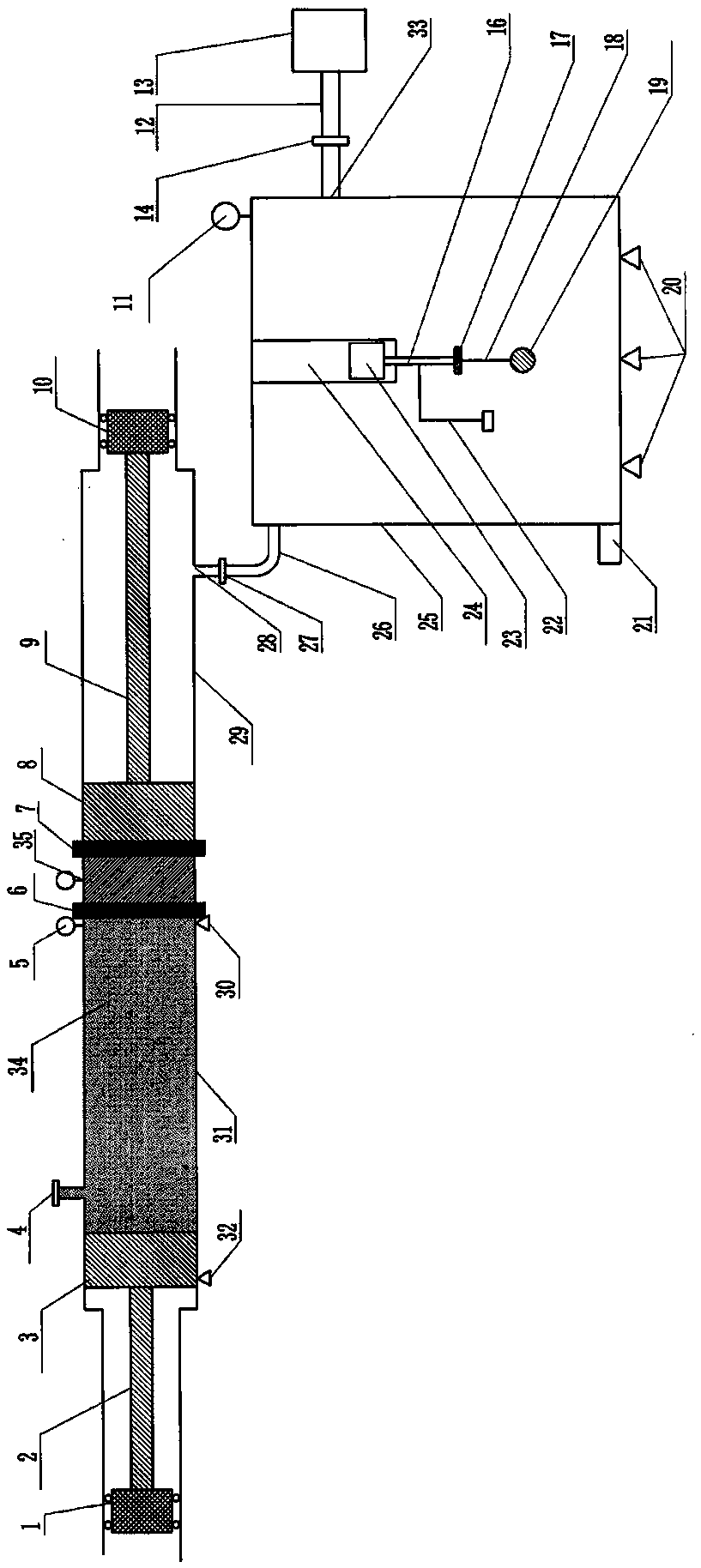

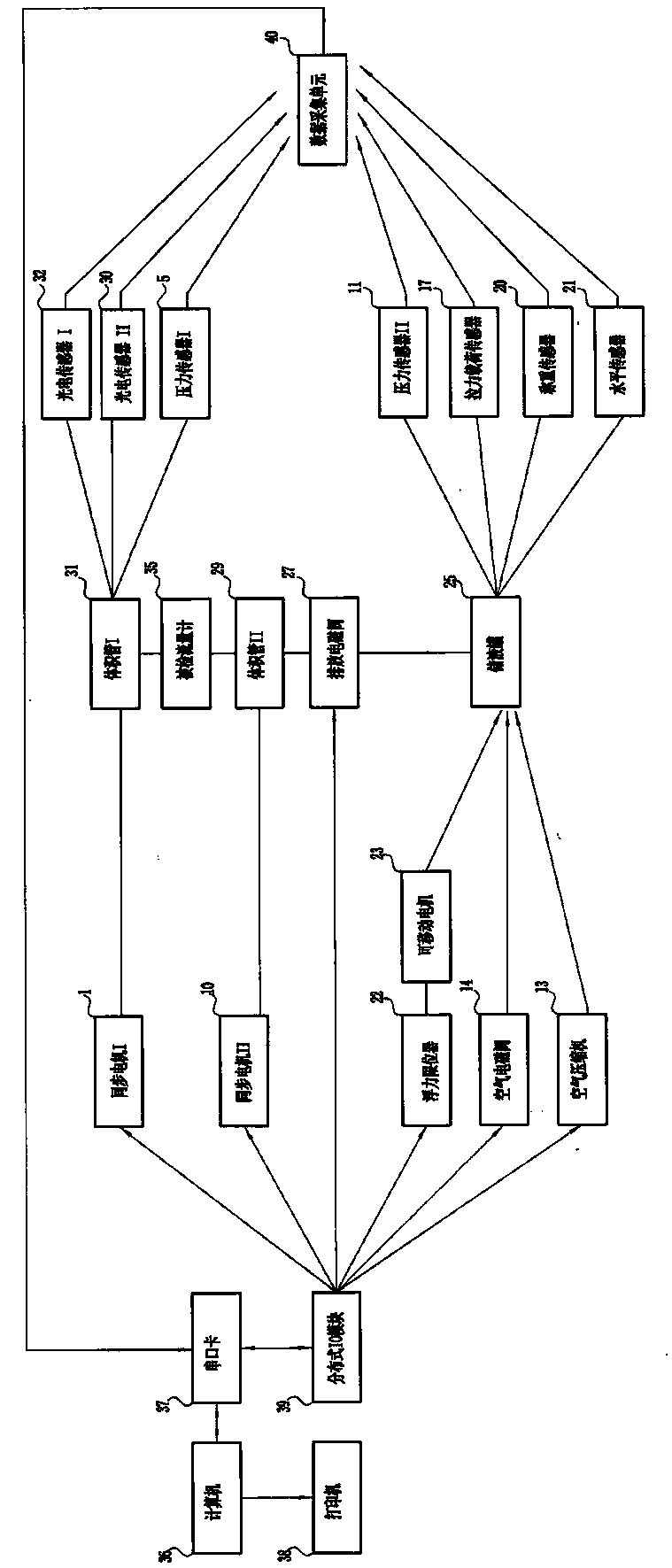

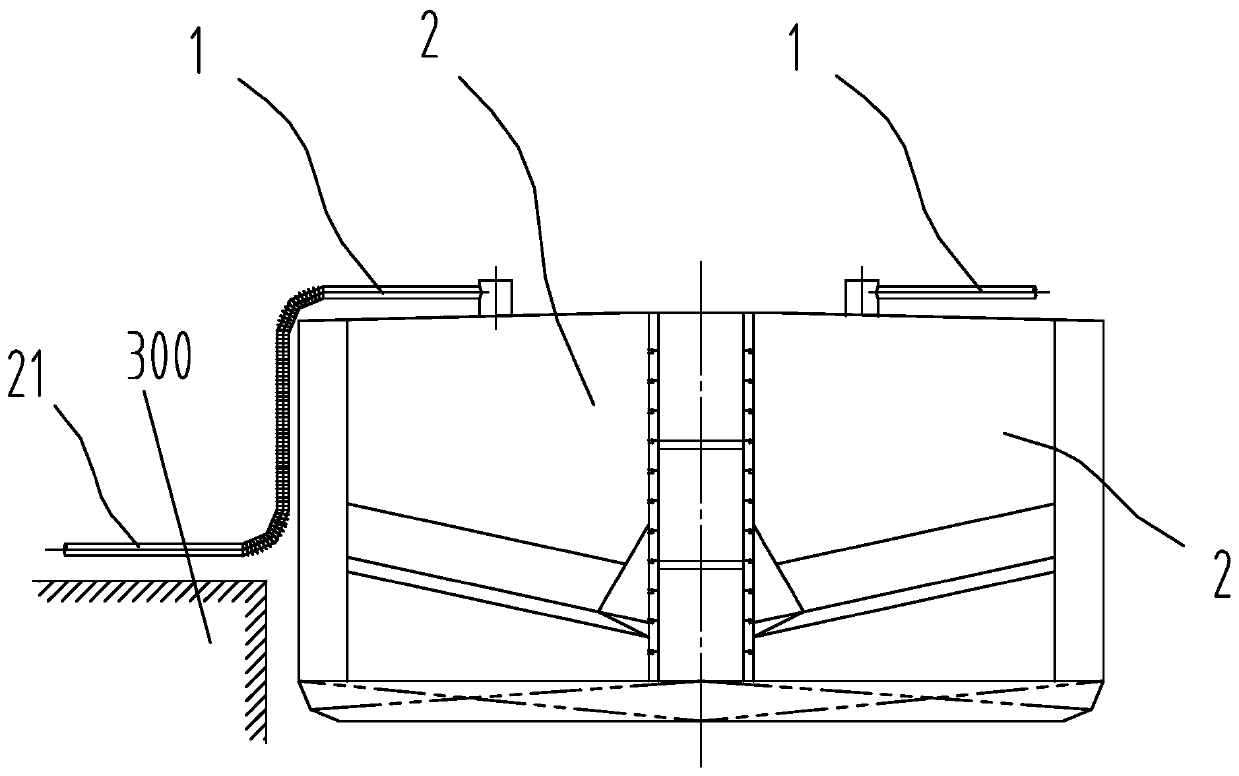

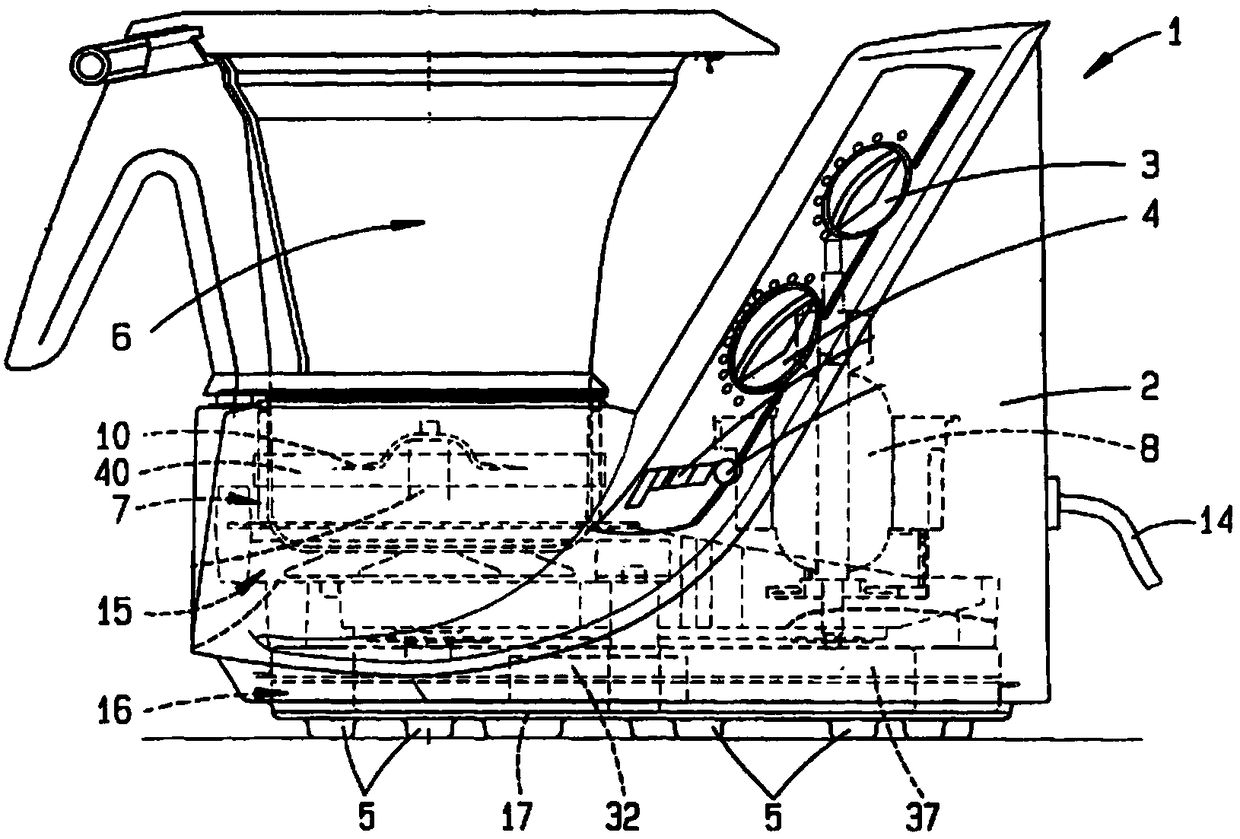

Flowmeter verification device and verification method thereof

InactiveCN107843315AChange won't happenTest results are not affected by temperatureTesting/calibration apparatusSynchronous motorLiquid storage tank

Provided are a flowmeter verification device and a verification method thereof. The device comprises a volume pipe I31, a volume pipe II29, a working piston I and a working piston II which are arranged in the volume pipe I and the volume pipe II, a synchronous motor I and a synchronous motor II which are connected with the working piston I and the working piston II, a photoelectric sensor I and aphotoelectric sensor II which are installed on the volume pipe I, a liquid storage tank 25 connected with the volume pipe II, a data collection unit 40, a computer and the like, a flowmeter to be verified is installed at the two ends of the volume pipe I and the volume pipe II, liquid which is the same as liquid flowing through the flowmeter actually is injected into the volume pipe I, the synchronous motor I and the synchronous motor II drive the working piston I and the working piston II to work to trigger the photoelectric sensor I and the photoelectric sensor II, time for the liquid to flow through the flowmeter to be verified is read, then the liquid is discharged into the liquid storage tank so that the volume of the liquid which flows through the flowmeter to be verified can be measured, the normal flow which flows through the flowmeter to be verified is calculated, according to readout data of the flowmeter to be verified, a readout error is calculated, and according to the error, whether or not the flowmeter is qualified is judged. According to the device and the method, measurement is convenient, and the data is accurate.

Owner:李盛

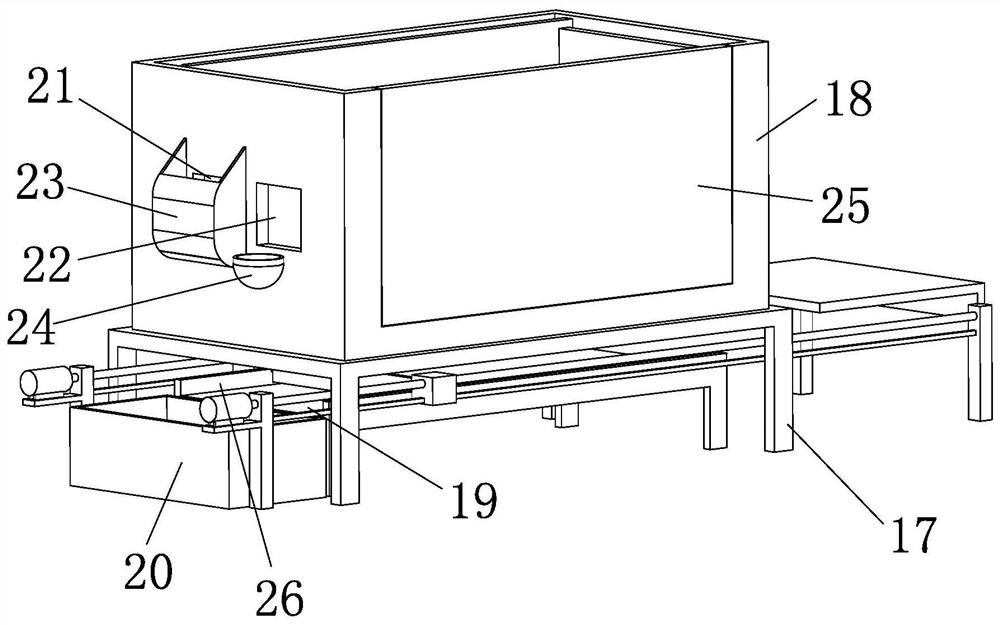

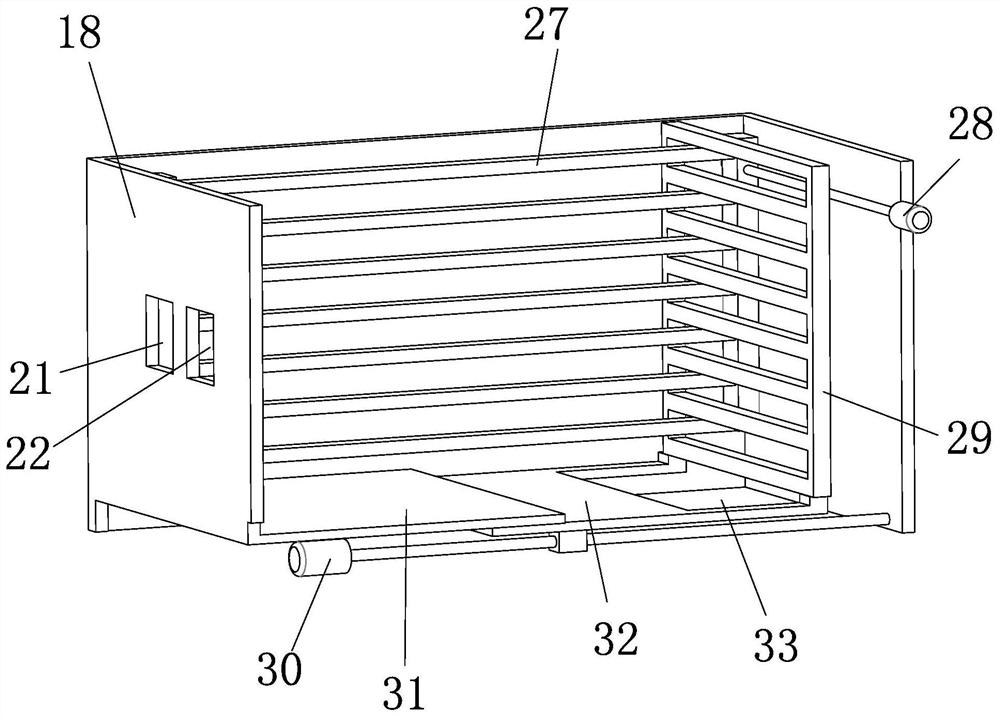

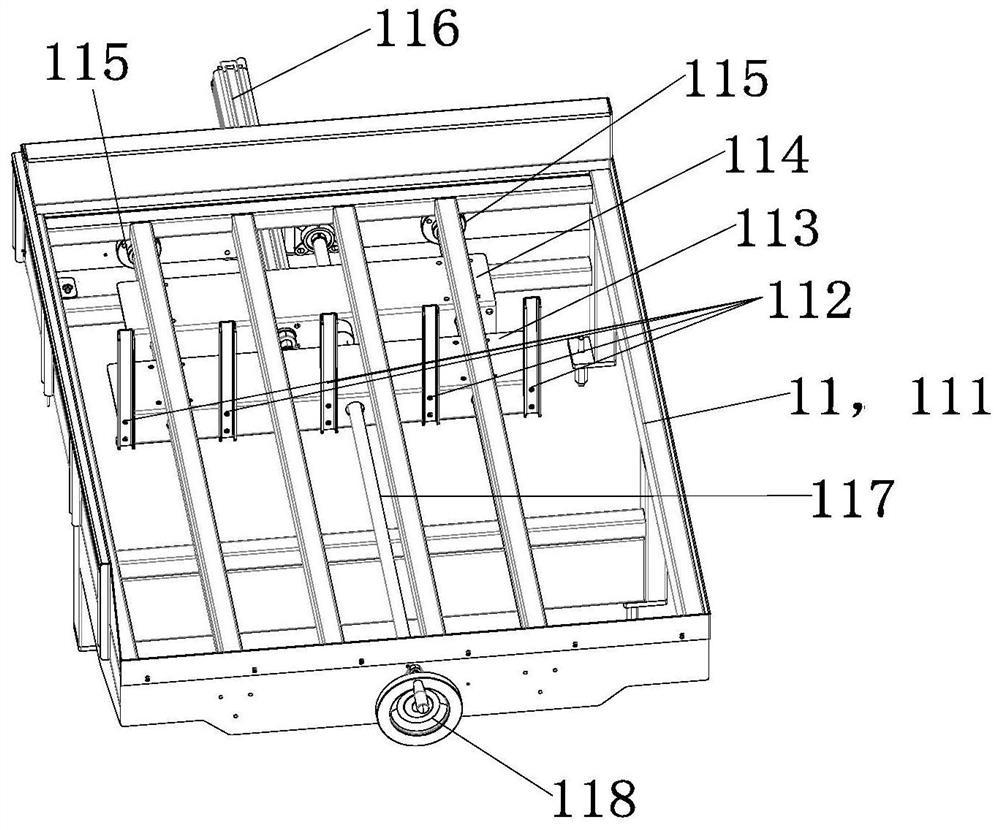

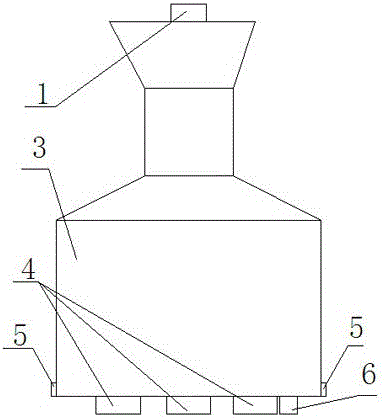

Multifunctional pig raising metabolism cage

ActiveCN113475407AAccurate weight measurementLavatory sanitoryAnimal housingBiotechnologyAnimal science

The invention provides a multifunctional pig raising metabolism cage, and belongs to the technical field of agricultural animal husbandry. The problem that an existing pig raising metabolism cage is not convenient enough in disinfection mode is solved. The multifunctional pig raising metabolism cage comprises a fixedly-arranged support, a cage body fixedly arranged on the support, a metabolism receiving disc fixedly arranged on the support and located below the cage body, a weighing part fixedly arranged and used for weighing the total weight of the support, the cage body and the metabolism receiving disc, a fixedly-arranged material receiving box, a scraping device used for scraping metabolites on the metabolism receiving disc into the material receiving box and a sterilizing device used for sterilizing the interior of the cage body. Compared with the prior art, the multifunctional pig raising metabolism cage has the advantages that the cage body can be automatically disinfected, and meanwhile, it can be guaranteed that the weight of metabolite of pigs can be measured more accurately every time.

Owner:JINHUA ACAD OF AGRI SCI

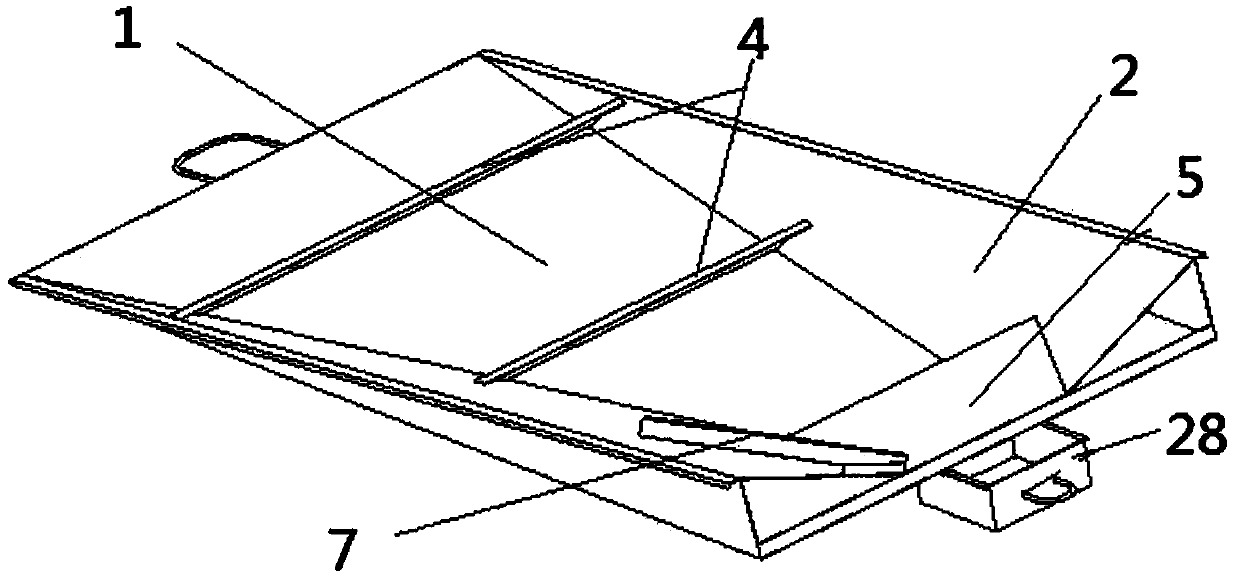

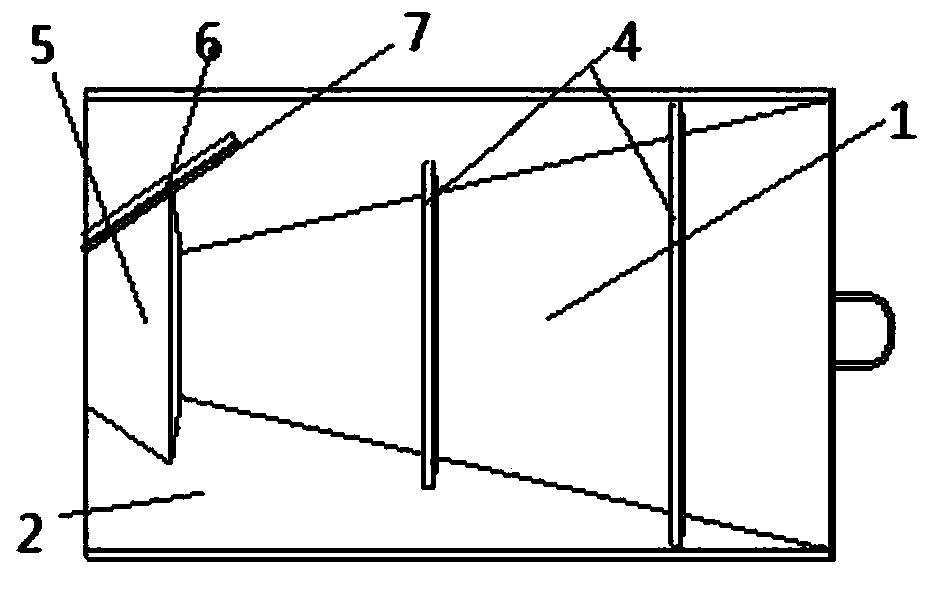

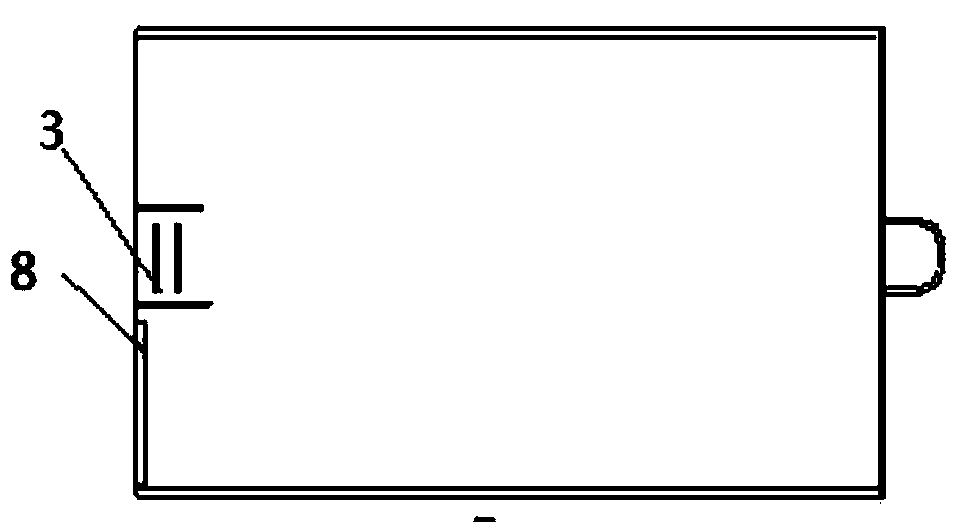

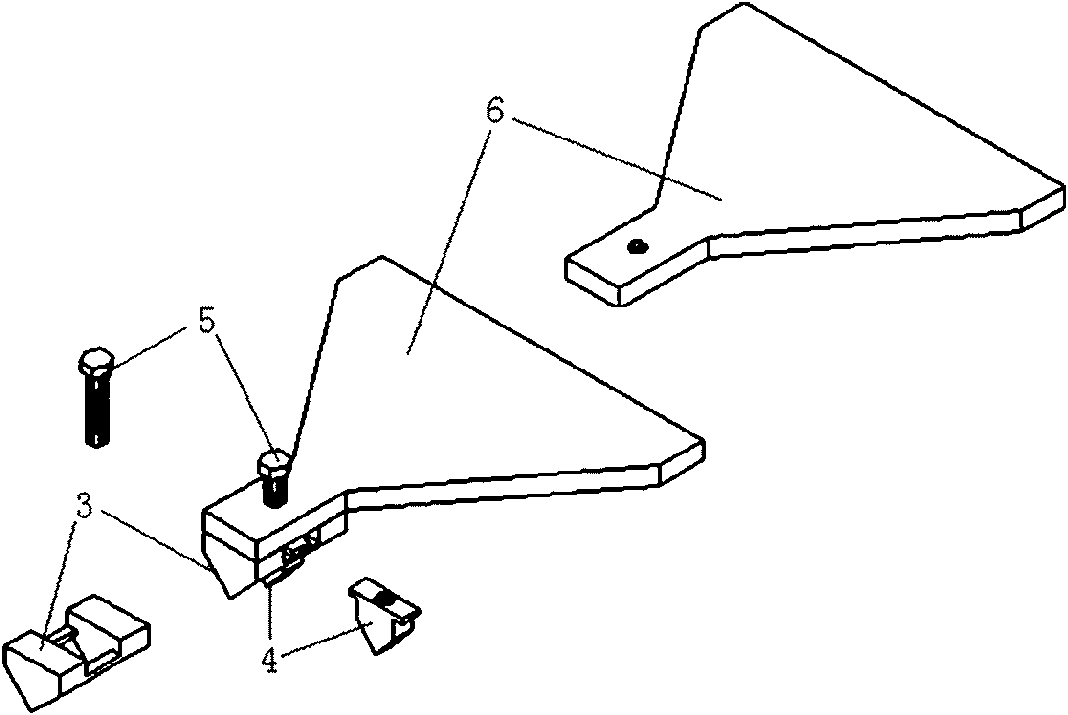

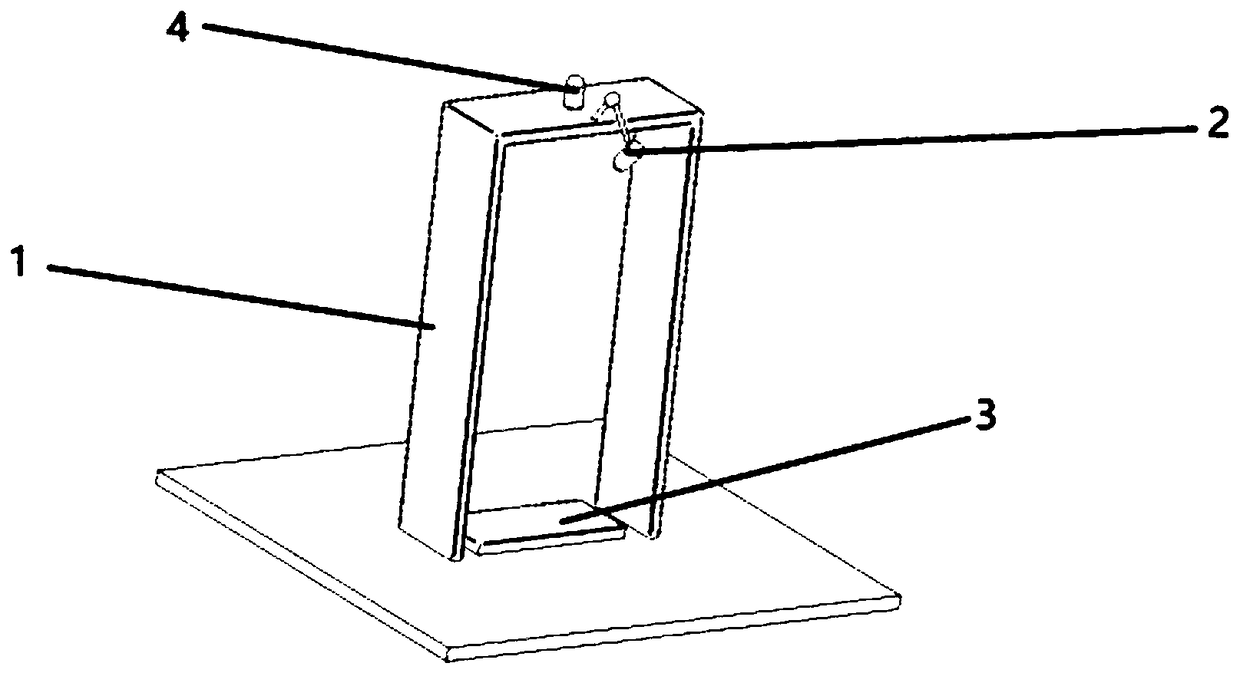

Dung-urine separator and metabolism cage for livestock nutrition research

The invention discloses a dung-urine separator and a metabolism cage for livestock nutrition research; the dung-urine separator comprises a bottom plate and side plates arranged on two sides of the bottom plate; the bottom plate and the side plates form a groove shape; the front portion of the bottom plate is provided with an urine outlet; the height of one end, close to the urine outlet, of the bottom plate inner surface is lower than that of the other end, far away from the urine outlet, of the bottom plate inner surface; the height of one end, close to the urine outlet, of the side plate inner surface is lower than that of the other end, far away from the urine outlet, of the side plate inner surface; the middle portion and rear portion of the bottom plate inner surface are provided with dung baffle plates, and the bottom of the dung baffle plates are provided with holes; a forage baffle plate is arranged above the urine outlet. The dung-urine separator can fully separate the livestock dung from urine, thus solving dung and urine separate collection problems, and providing guarantee for experiment results.

Owner:INST OF SUBTROPICAL AGRI CHINESE ACAD OF SCI +1

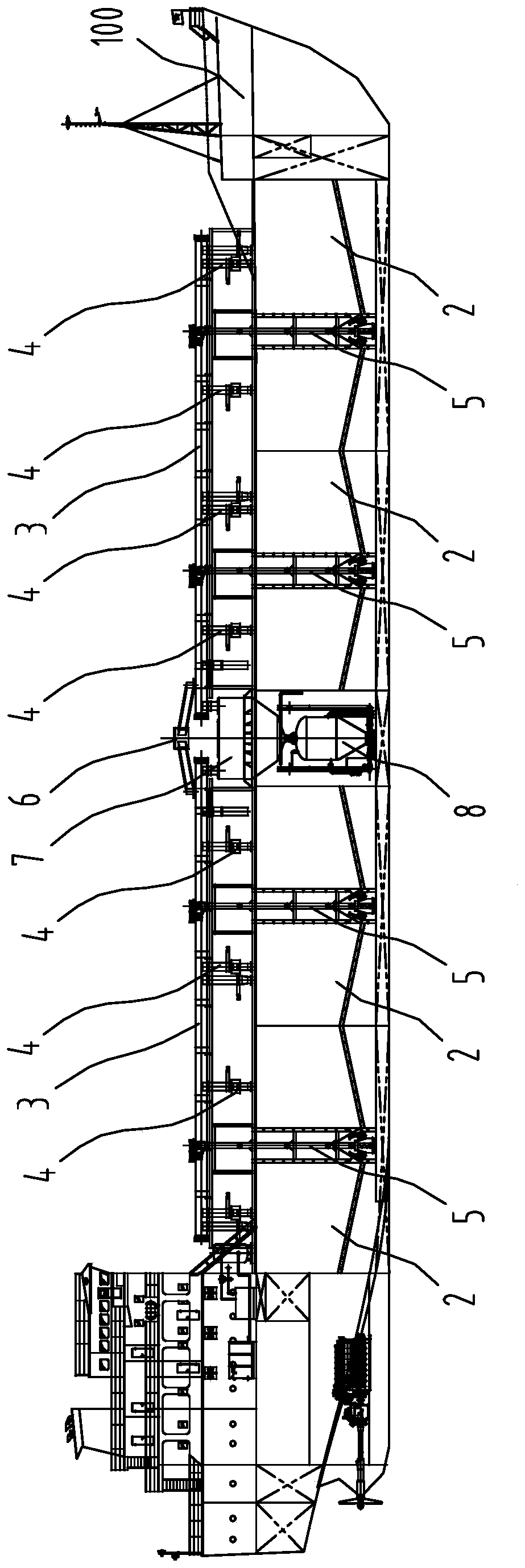

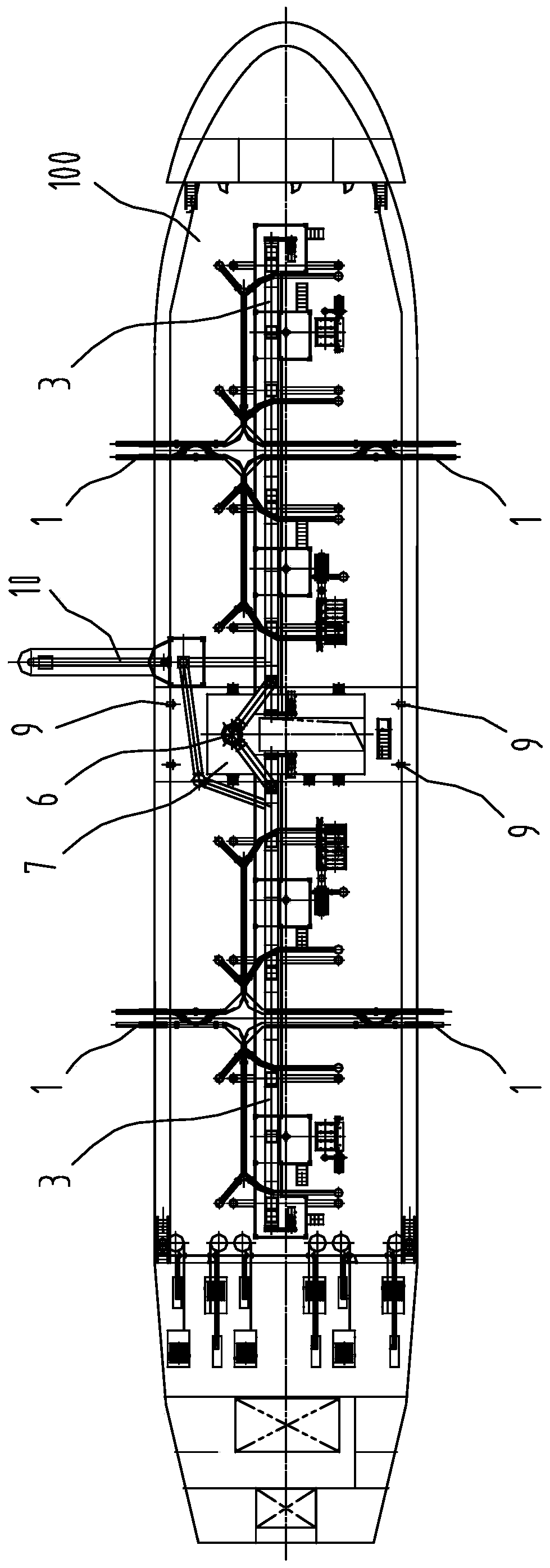

Self-loading self-unloading ship and ship loading and ship unloading method thereof

PendingCN110395359AAccurate weight measurementAccurate dynamic measurementCargo handling apparatusPassenger handling apparatusScrew conveyorMarine engineering

Owner:杭州云天港口机械装备有限公司

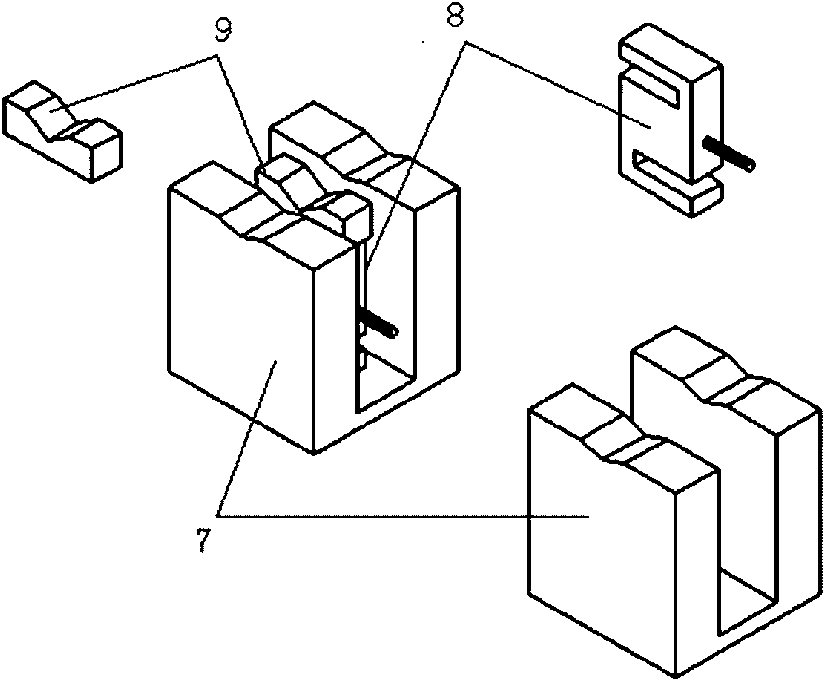

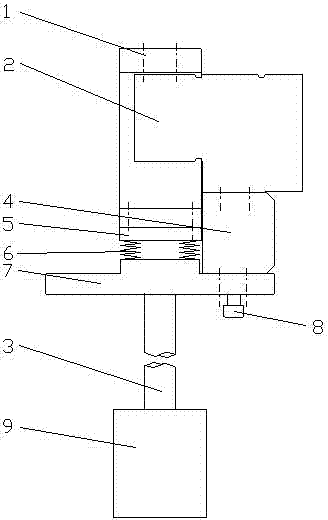

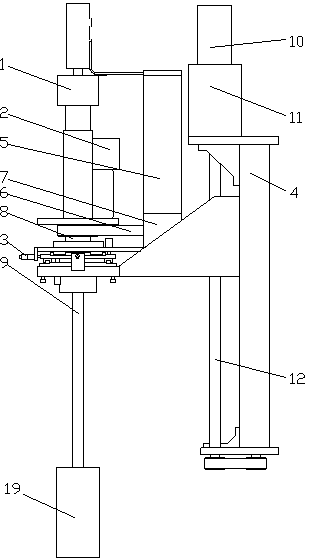

Liftable knife edge and knife rest device for weight adjustment

ActiveCN101666698ANot easy to damageExtended service lifeStatic/dynamic balance measurementVessel partsWeight adjustmentModel parameters

The invention relates to a liftable knife edge and knife rest device for weight adjustment, belonging to the technical field of measurement. The device comprises a combined knife edge and a combined knife rest, wherein the combined knife edge is arranged above the combined knife rest and movably connected with the combined knife rest. The device can carry out position adjustment to the combined knife edge according to the working state adjusted by model parameters, and a weight sensor in the combined knife rest is uneasy to be damaged, and the service life is long.

Owner:SHANGHAI JIAO TONG UNIV

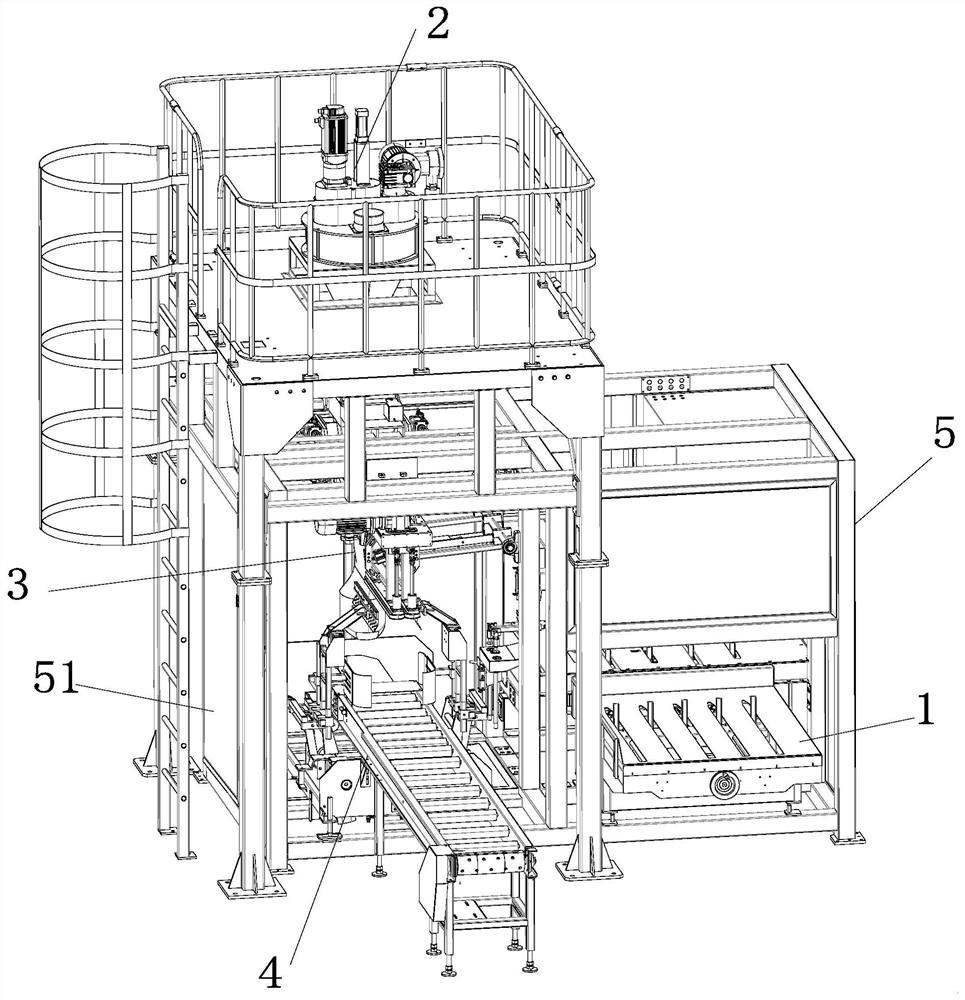

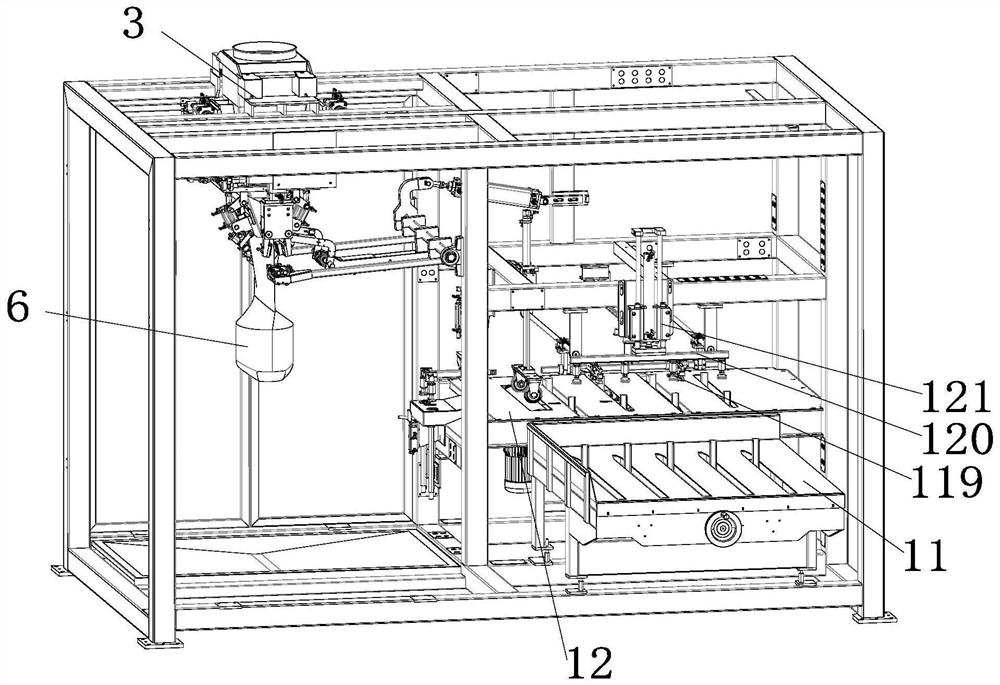

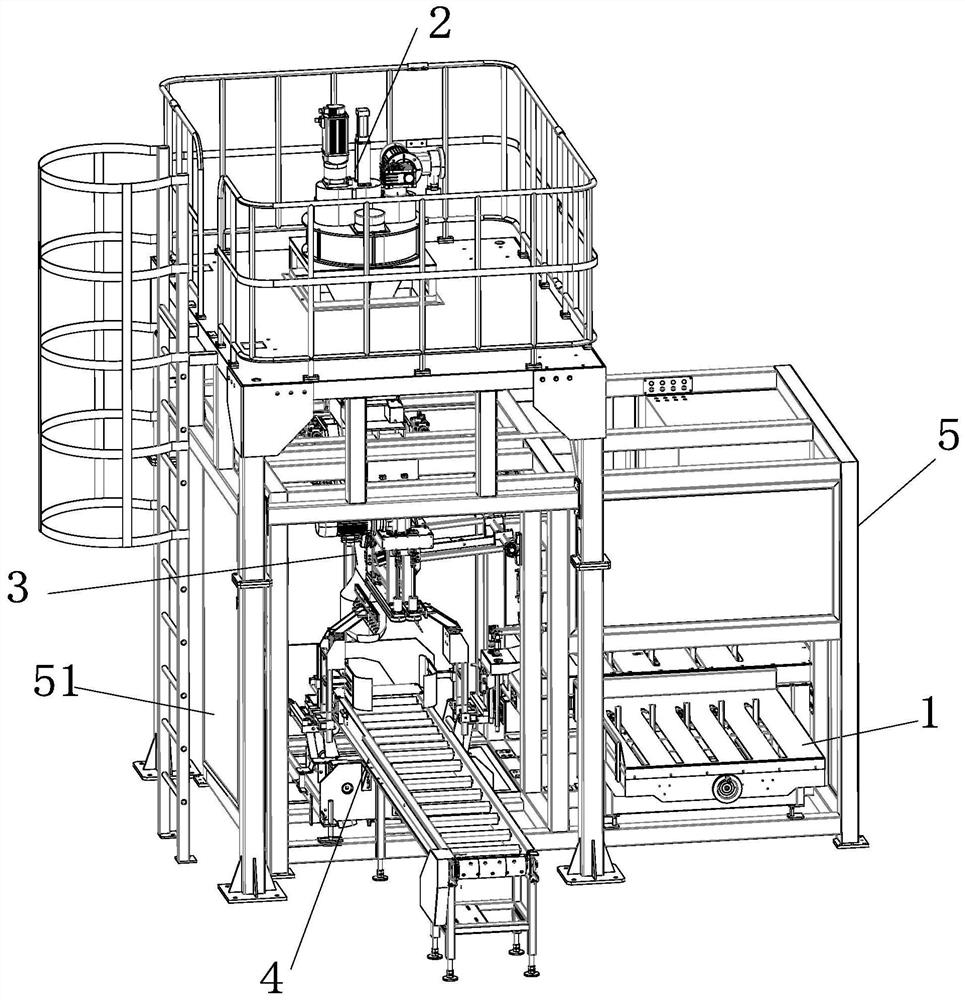

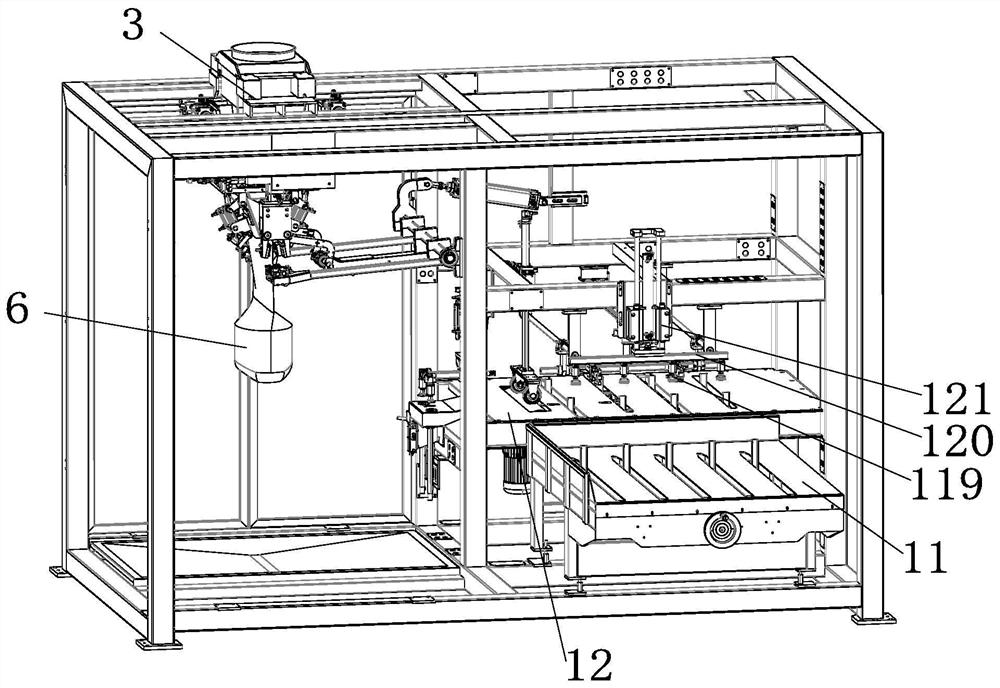

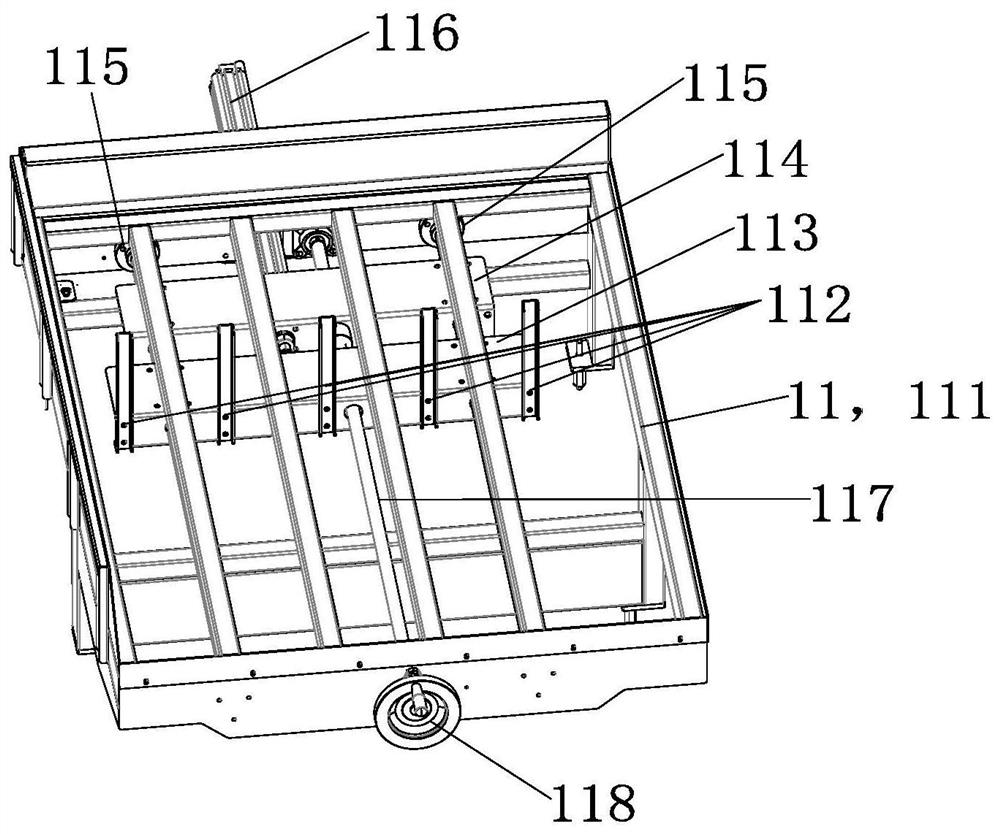

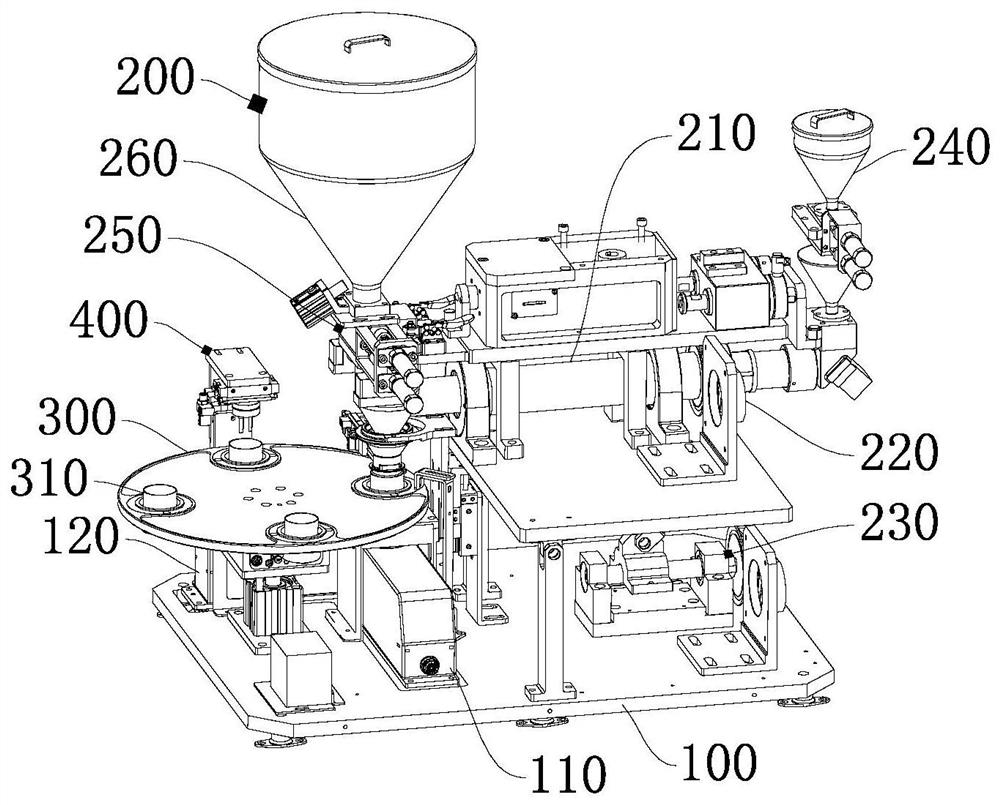

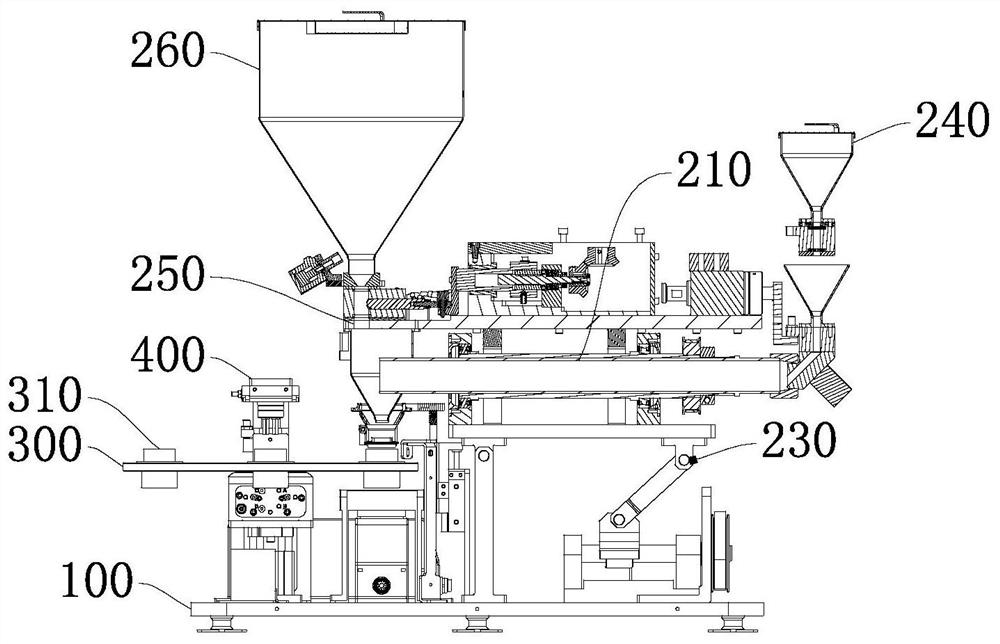

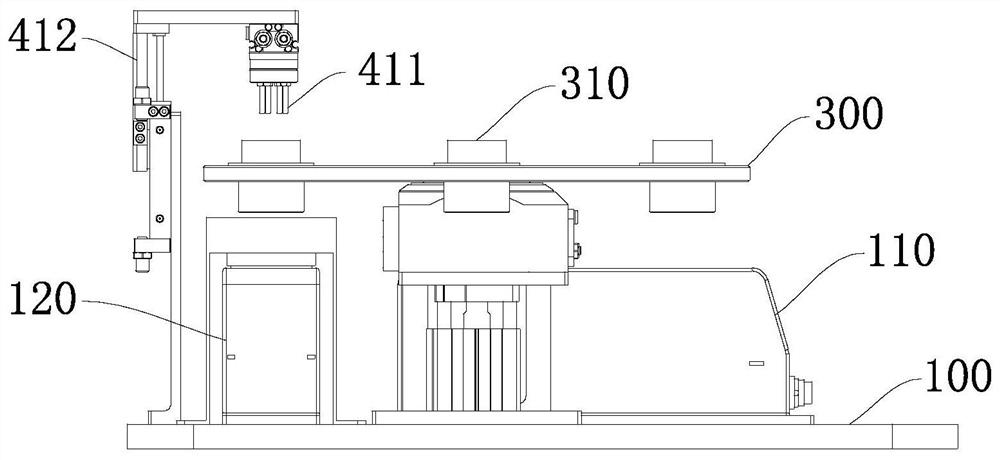

Novel automatic weighing and packaging machine

ActiveCN112109933AHigh precisionImprove packaging qualitySolid materialProcess engineeringElectrical and Electronics engineering

The invention discloses a novel automatic weighing and packaging machine. The novel automatic weighing and packaging machine comprises an automatic bag feeding mechanism, a bag clamping mechanism, a vertical feeding mechanism and a bag pushing mechanism, wherein the automatic bag feeding mechanism installs packaging bags on the bag clamping mechanism, the bag clamping mechanism adds the materialsto the packaging bags on the bag clamping mechanism through the vertical feeding mechanism, the bag clamping mechanism is provided with a weighing device, the weighing device weighs the materials in the packaging bags on the bag clamping mechanism, when the materials in the packaging bags reach the preset weight, the vertical feeding mechanism stops feeding; and the packaging bags filled with thematerials are pushed into the next processing station through the bag pushing mechanism. According to the design of the novel automatic weighing and packaging machine, the materials are conveyed intopackaging bags on the bag clamping mechanism through the vertical feeding mechanism, the weighing device is arranged on the bag clamping mechanism, the weighing accuracy of the materials in the packaging bags can be improved, and the dust raising phenomenon in the feeding process is reduced.

Owner:JIANGSU TOM PACKAGING MACHINERY

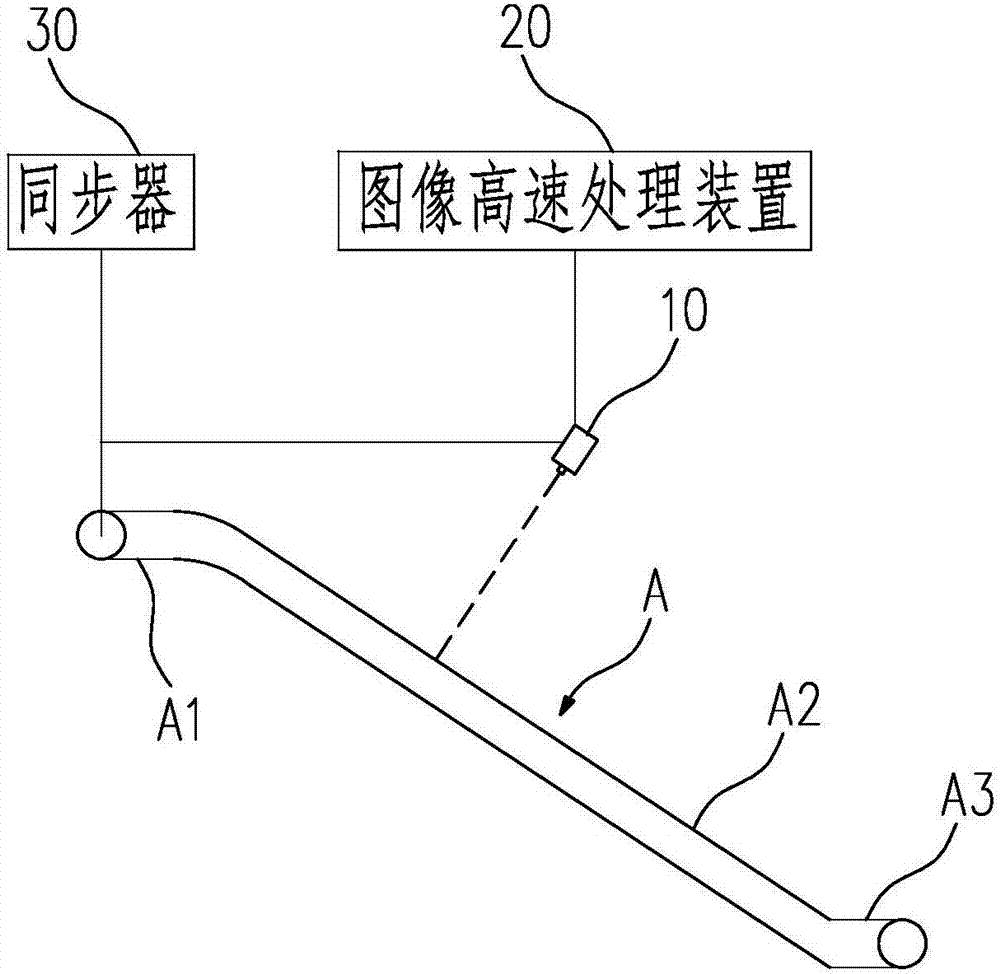

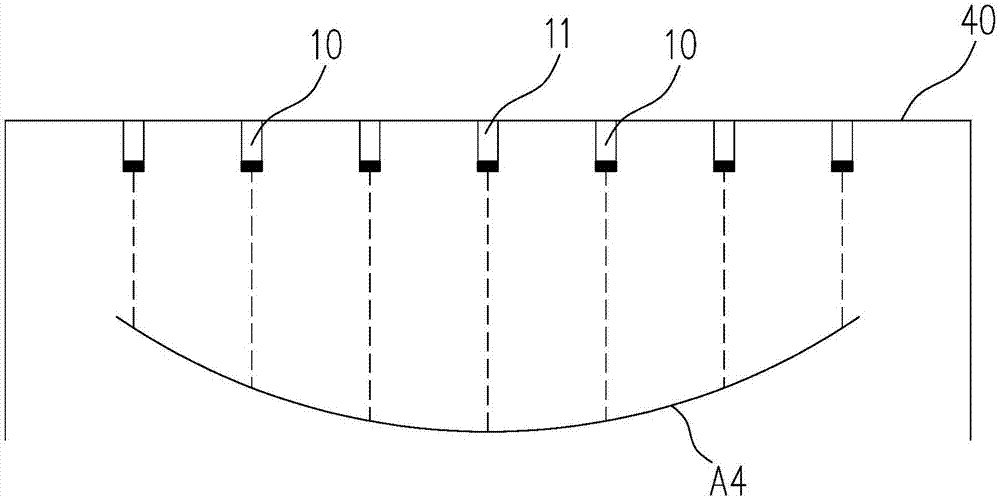

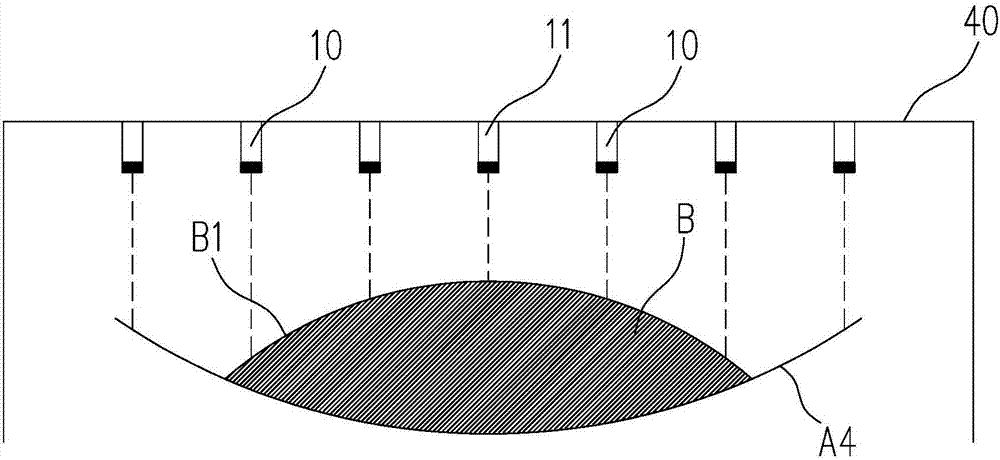

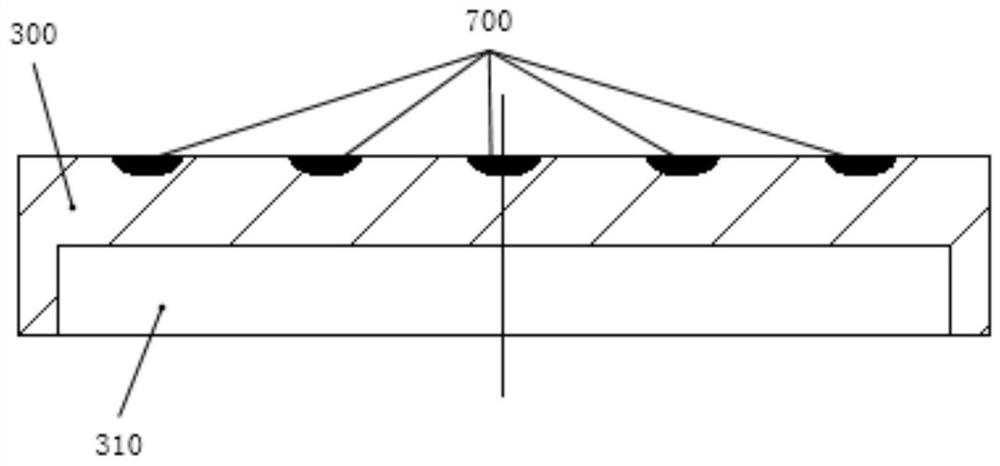

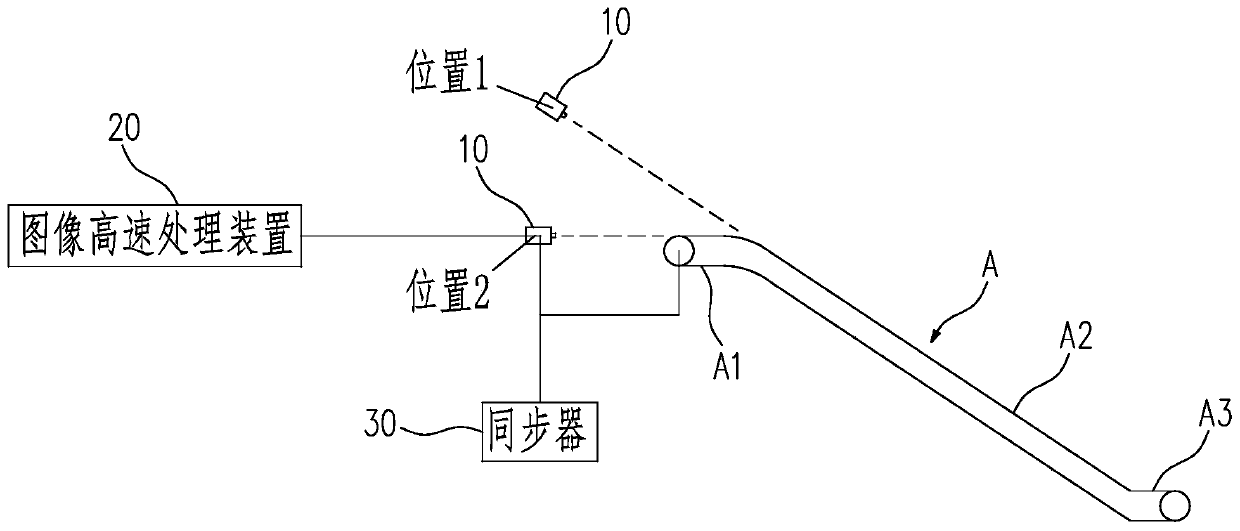

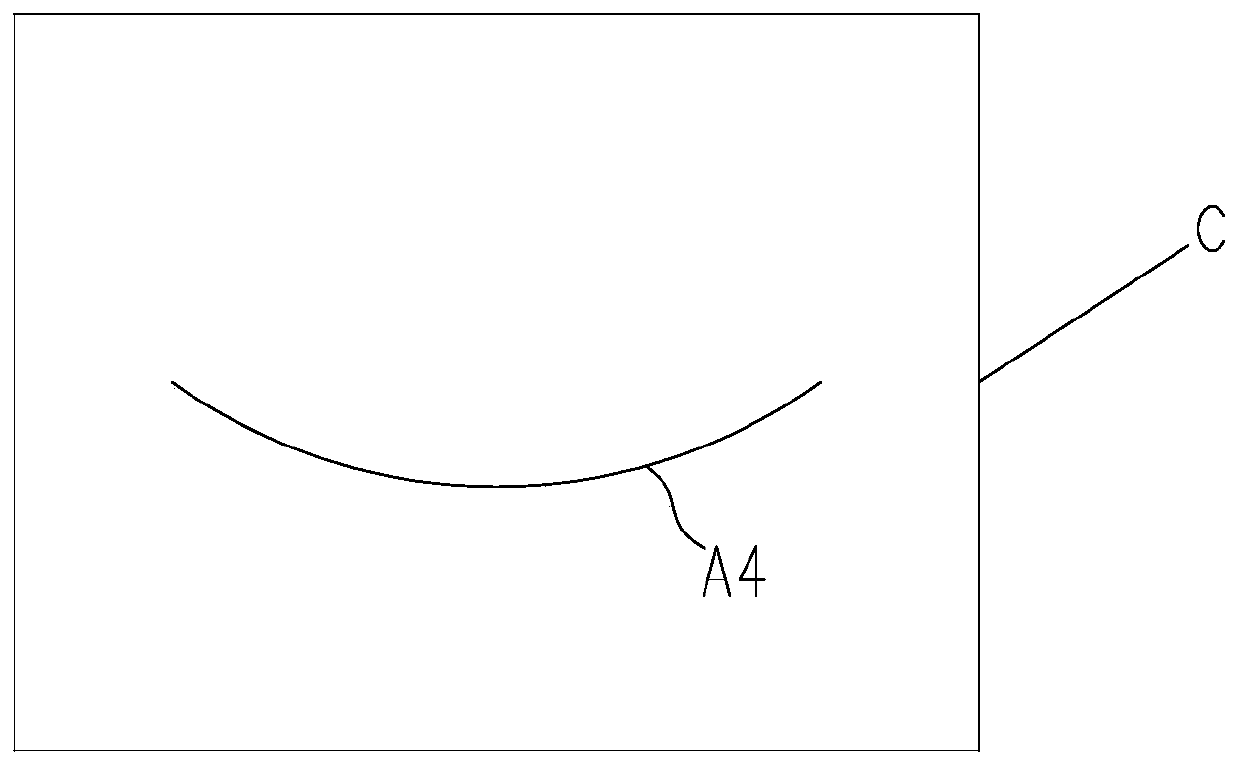

Non-contact weighing and deviation warning device for belt conveyor

ActiveCN106989803ARealize real-time weighingLess componentsControl devices for conveyorsWeighing apparatus for continuous material flowFailure rateEngineering

The invention belongs to the technical field of transmission bands and particularly relates to a non-contact weighing and deviation warning device for a belt conveyor. The device comprises the following components: a sensing device used to obtain contour information data of a belt and a material on the belt in a direction vertical to the belt conveying direction, a data processing device used to obtain the cross section area of the material on the belt according to the contour information data, to obtain the mass of the material conveyed by the belt in the corresponding operation time with combination of the conveying speed and the operation time of the belt and the material density, to compare contours of the belt obtained in different periods, and to send an alarm signal when the difference between the contours of the belt obtained in different periods reaches a set value, and a synchronizer used to enable the sensing device to work with the belt at the same time. The non-contact weighing and deviation warning device is advantaged by few components and low cost, is not contacted with the belt in measurement, and is high in measurement precision and low in failure rate.

Owner:ANHUI UNIV OF SCI & TECH

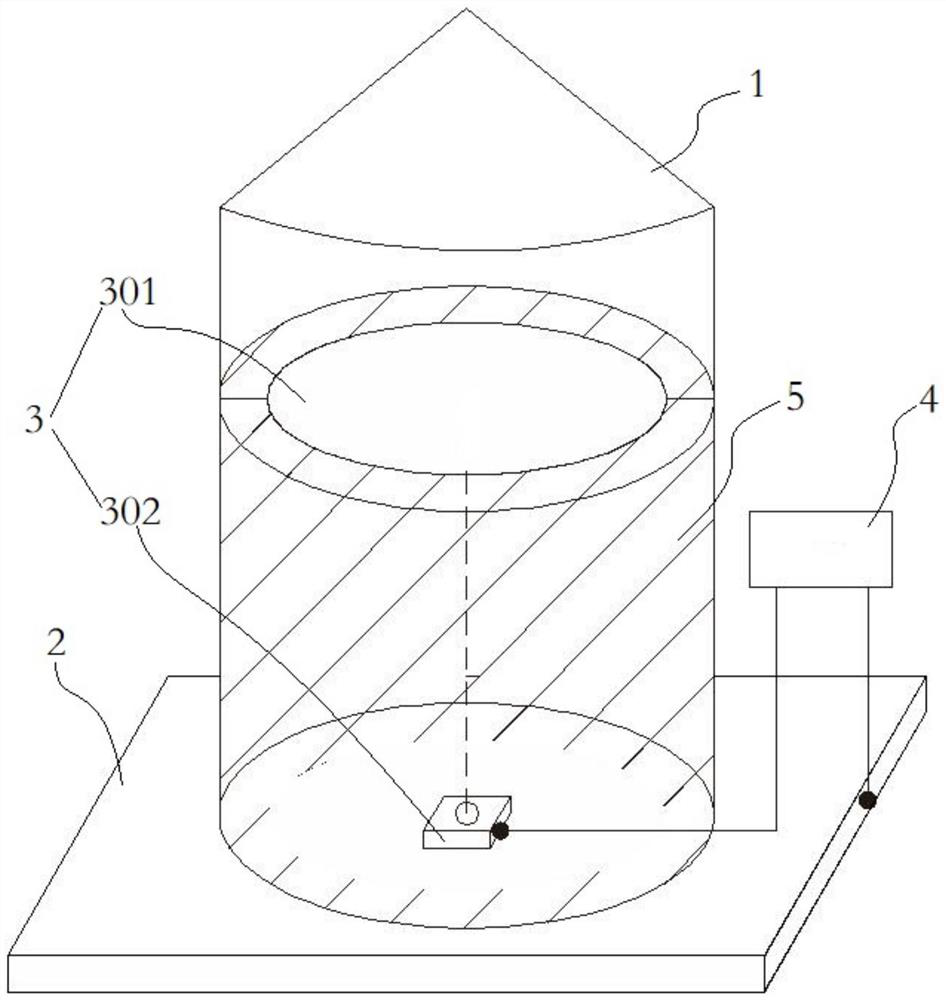

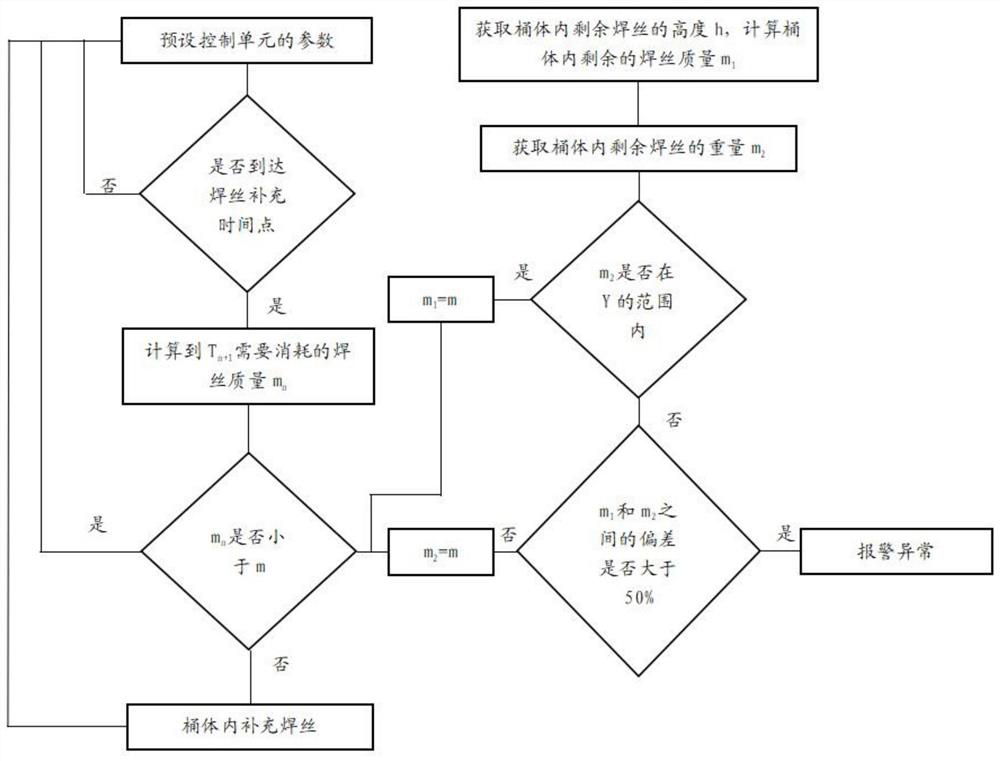

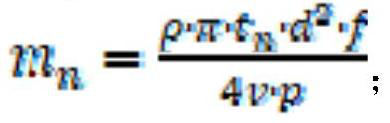

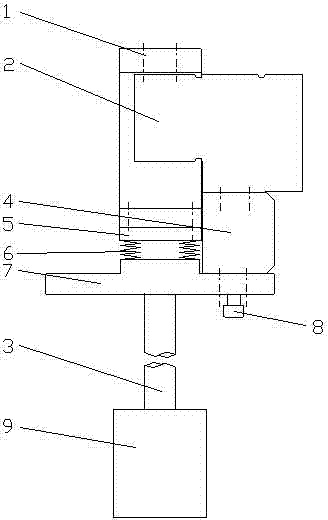

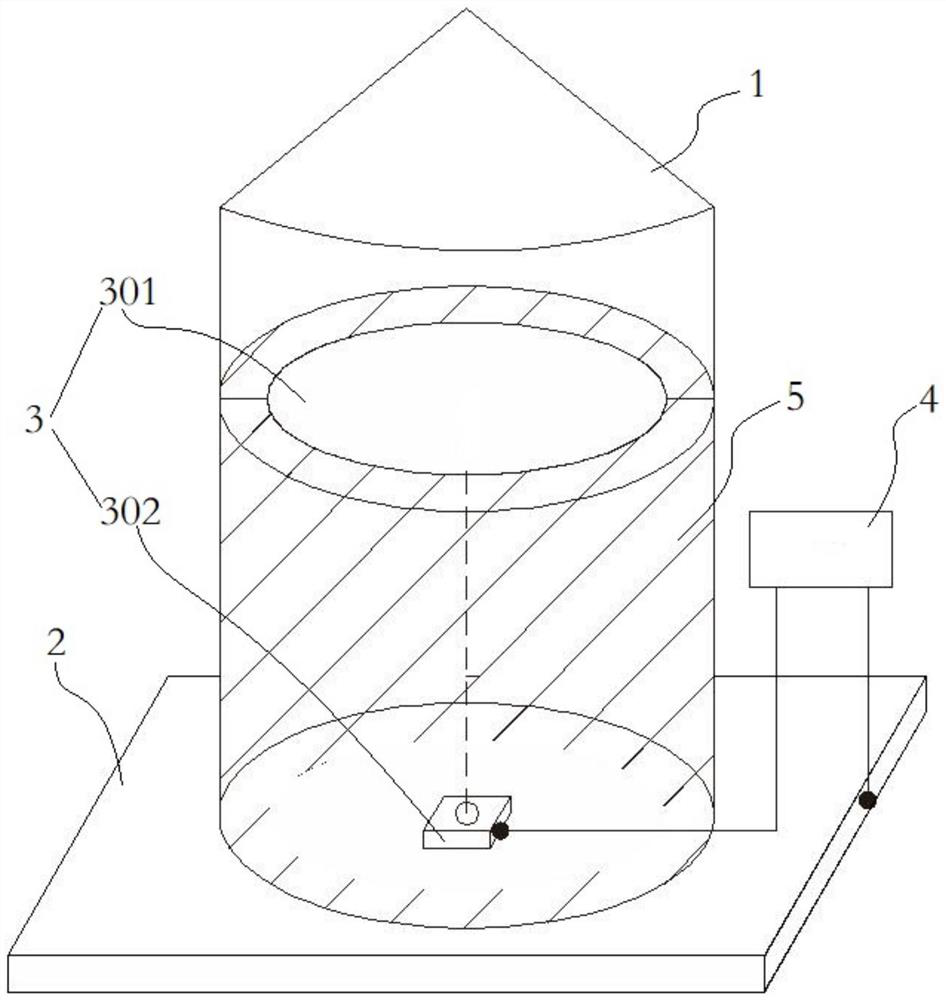

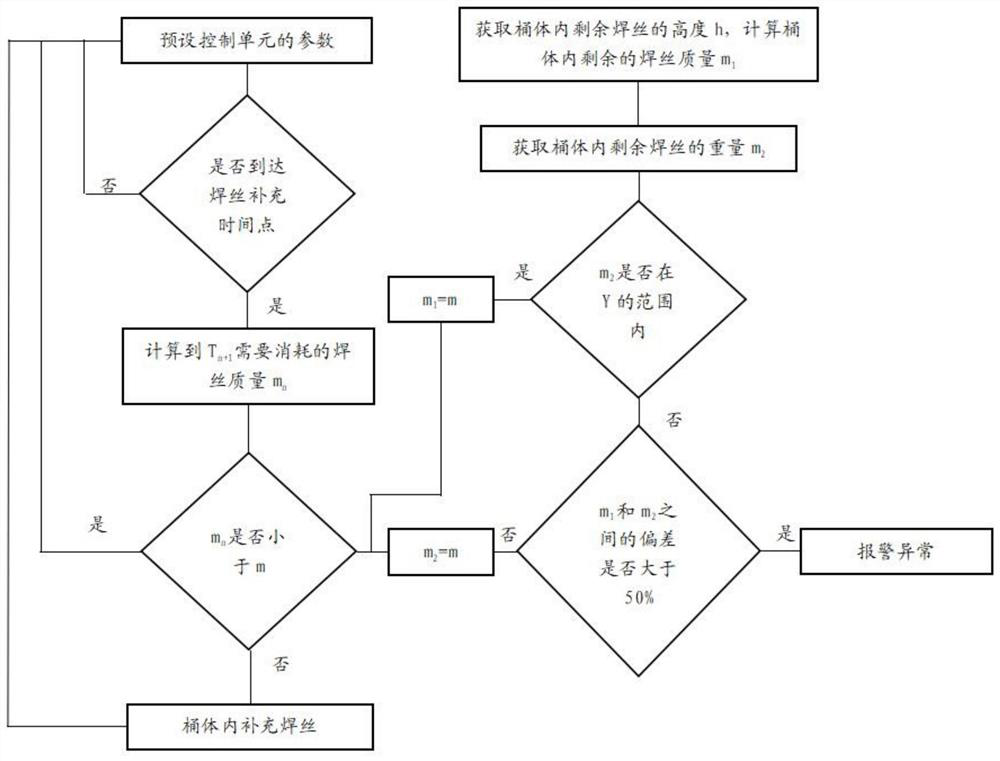

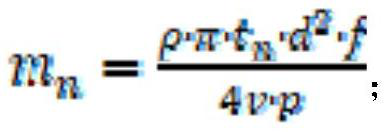

Barreled welding wire allowance monitoring device and monitoring method thereof

ActiveCN113146003AAccurate weight measurementReduce measurement errorTotal factory controlWelding accessoriesProduction lineWeight monitoring

The invention relates to the technical field of monitoring devices, and discloses a barreled welding wire allowance monitoring device and a monitoring method thereof. The monitoring device comprises a barrel body, a weight monitoring unit, a height monitoring unit and a control unit, and welding wires are loaded in the barrel body. The weight monitoring unit is used for monitoring the weight of the welding wires. The barrel body is mounted on the weight monitoring unit. The height monitoring unit is used for monitoring the height of the welding wires. The height monitoring unit is mounted in the barrel body. The control unit is electrically connected with the weight monitoring unit and the height monitoring unit. The weight monitoring unit and the height monitoring unit are used for monitoring the welding wire allowance in a segmented mode, the weight of the remaining welding wires can be accurately measured, measurement errors are reduced, whether the welding wires need to be replaced or not at present is judged in advance, and welding wire waste is reduced as much as possible on the premise that production line stopping is not affected.

Owner:GUANGQI HONDA

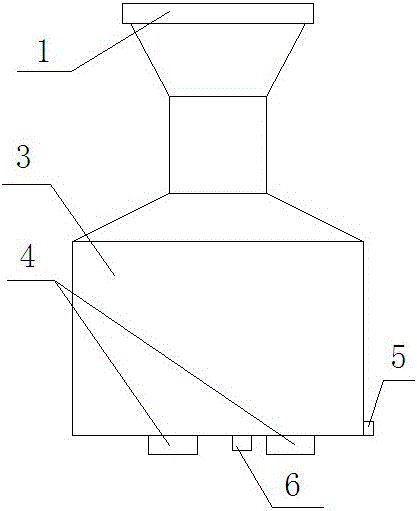

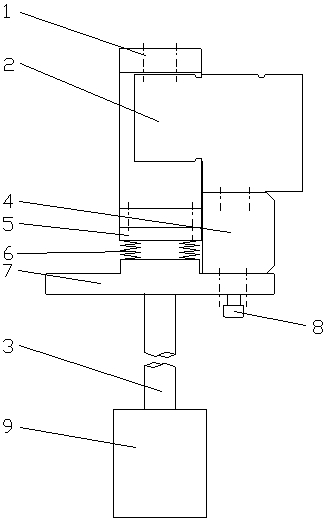

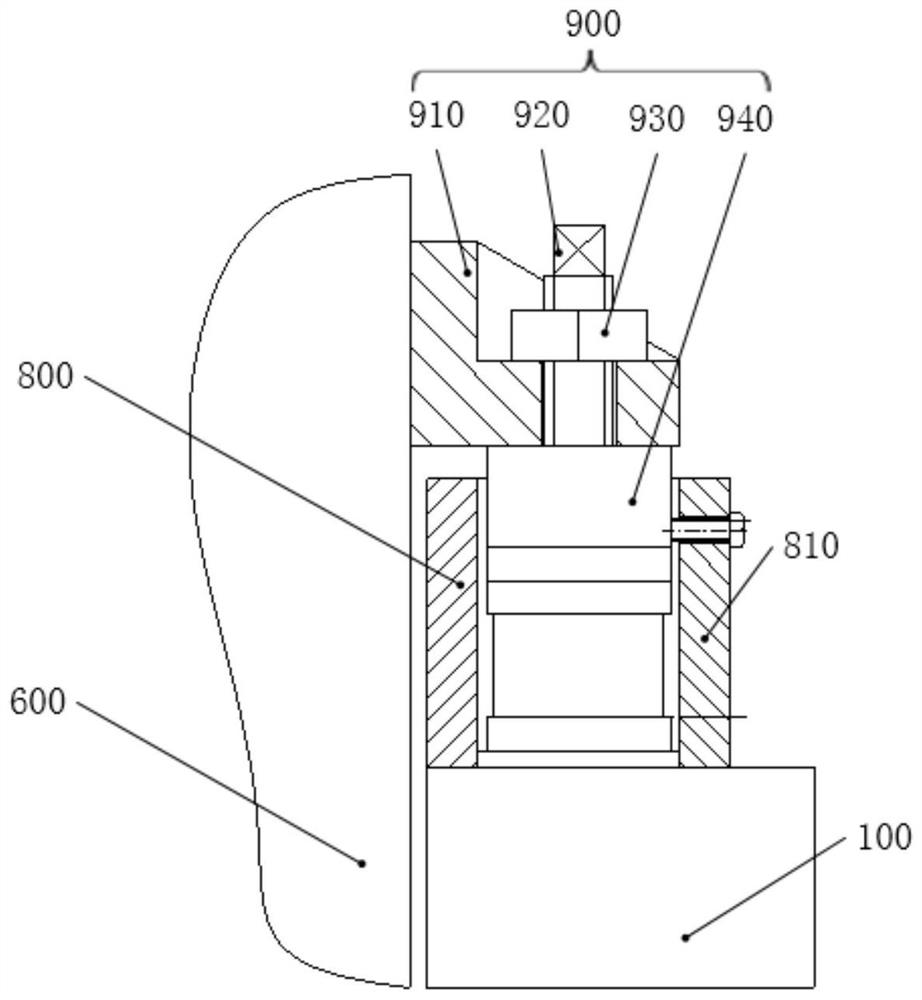

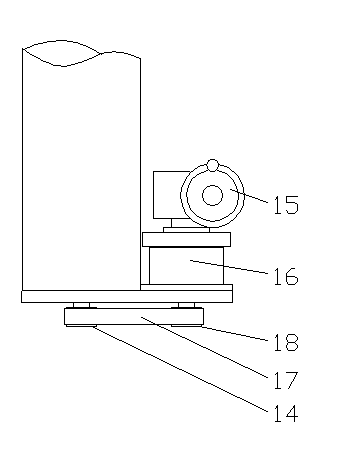

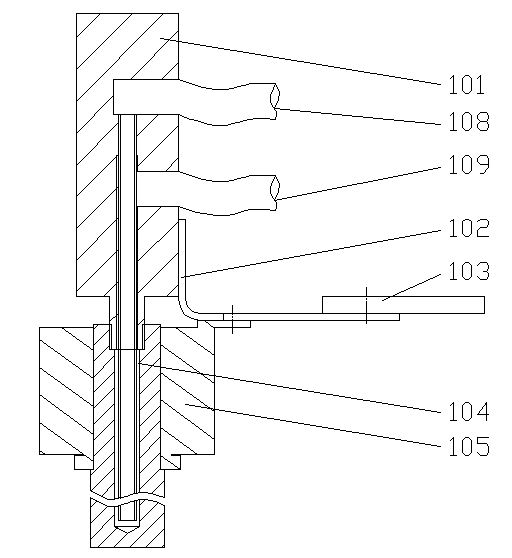

Weighing mechanism used for seed crystal driving device

ActiveCN102478420ASmall rangeAccurate weight measurementSpecial purpose weighing apparatusEngineeringExpansion joint

The invention discloses a weighing mechanism used for a seed crystal driving device and belongs to the technical field of vacuum equipment. The weighing mechanism comprises an outer frame, a weighing sensor, an adjusting support and an expansion joint component. The outer frame is fixed on a top flange of a seed crystal shaft. The expansion joint component is hermetically arranged on the lower end surface of the top flange of the seed crystal shaft. The support is fixed on the lower flange of the expansion joint component and positioned on one side of the seed crystal shaft. Adjusting screws that are mounted on the lower flange of the expansion joint component are in contact with the support, and the weighing sensor is fixed on the outer frame and the support respectively. During operation, a sample is connected at the other end of the seed crystal shaft. By adopting the expansion joint seal structure, the measurement range of the weighing sensor is properly selected according to the actual sample and the measurement range of the weighing sensor is effectively reduced; and besides, the weighing sensor that works in the air can accurately measure the weight of the sample in vacuum.The invention solves the problems that the selectivity of the weighing sensor is limited and the mechanism is heavy. The weighing mechanism is advantageous in simple structure and reasonable overall layout.

Owner:SHENYANG SCI INSTR RES CENT CHINESE ACAD OF SCI

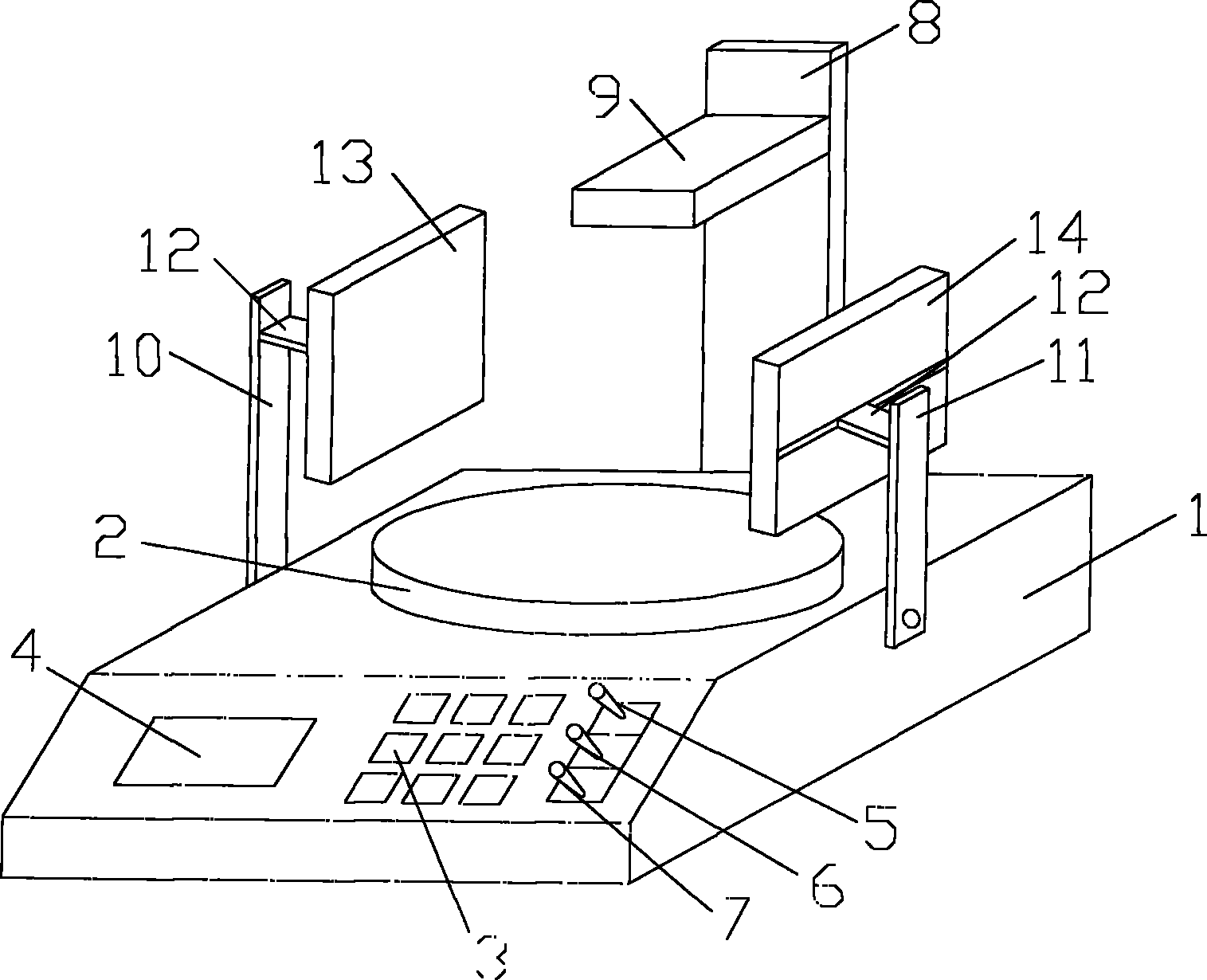

Electronic balance capable of measuring size of object

InactiveCN102466511AAccurate weight measurementRealize the function of one machine with multiple functionsSpecial purpose weighing apparatusEngineeringLoad cell

The invention relates to an electronic balance capable of measuring the size of an object, which comprises a balance body, a balance plate arranged on the balance body, and a weighing sensor fixed below the balance plate. A front panel of the balance body is fixedly provided with a keyboard, a display screen and an operation handle. A rear panel of the balance body is fixedly provided with a rear upright. The rear upright is movably provided with a first measuring plate. The two sides of the balance body are provided with left and right uprights. The two uprights are both movably provided with telescopic rods. The telescopic rods are provided with second and third measuring blocks. The electronic balance can accurately measure not only the weight of the object but also the size of the object, so that the electronic balance is multifunctional and the working efficiency is improved.

Owner:常熟市佳衡天平仪器有限公司

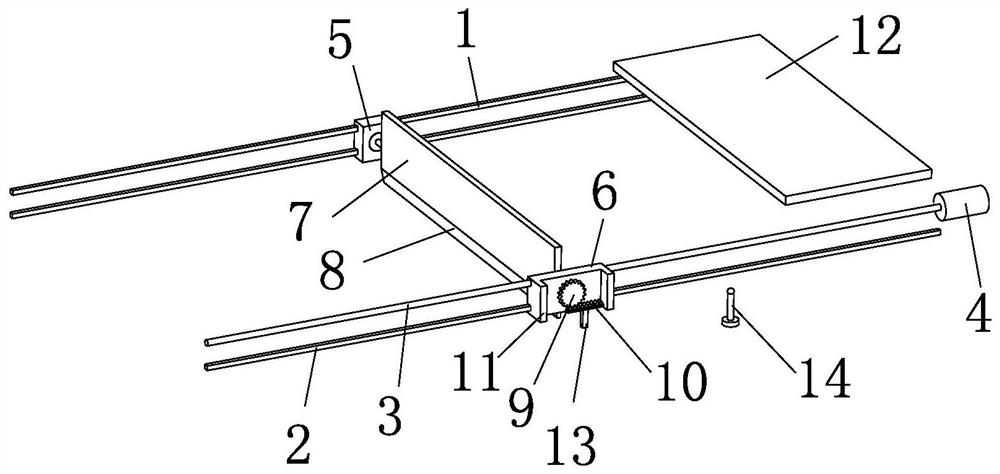

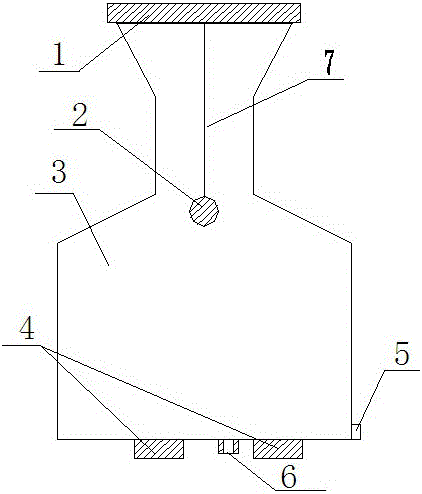

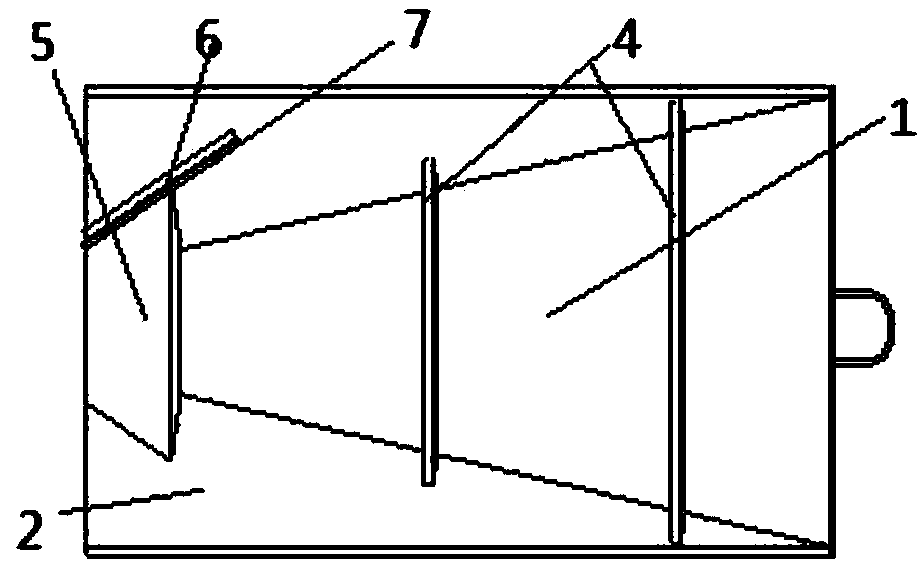

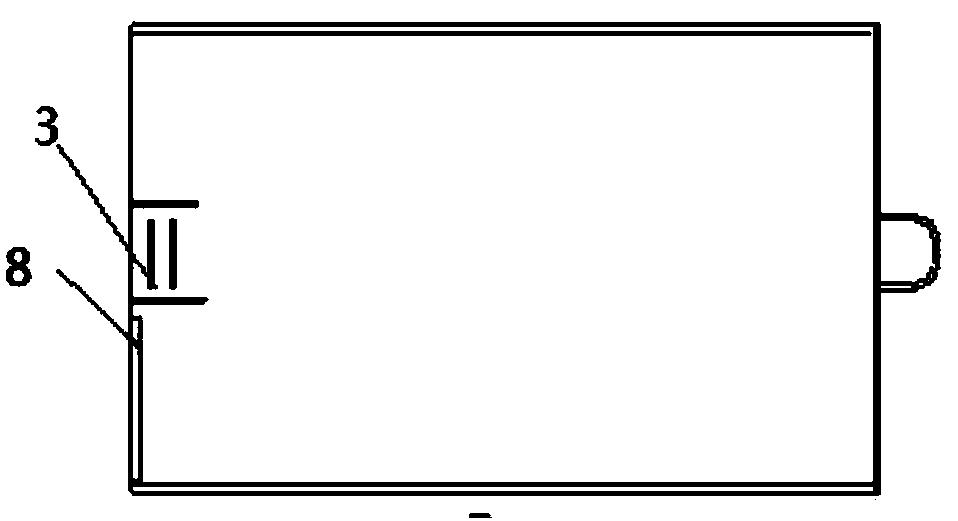

Calibrating device for fuel oil re-fuelling device and use method thereof

PendingCN106643995AEasy to use and flexibleDoes not affect check resultTesting/calibration for volume measurementEngineeringFuel oil

The invention discloses a calibrating device for a fuel oil re-fuelling device and a use method thereof. The calibrating device comprises a tank body (3), a tensile force load sensor (1), a known volume solid standard metal ball (2), a gravity load sensor (4), a level bubble (5) and a liquid draining hole (6), wherein the gravity load sensor and the liquid draining hole are arranged at the bottom of the tank body; the level bubble is formed on the side wall of the tank body; the tensile force load sensor is arranged on an upper cover of the tank body; the solid standard metal ball is located in an inner chamber of the tank body and is suspended on the tensile force load sensor. In a use process, to-be-measured liquid is injected into the tank body, the weight of the to-be-measured liquid is measured by the gravity load sensor, the tensile force is measured through the tensile force load sensor so that the density of the to-be-measured liquid can be calculated, the volume of the to-be-measured liquid is calculated according to a formula, and then a calculated result is compared with a numerical value of the re-fuelling device, so that a measuring result can be acquired. The calibrating device disclosed by the invention has the advantages of simple structure, convenience in use, accurate calibration, small error and high accuracy.

Owner:李盛

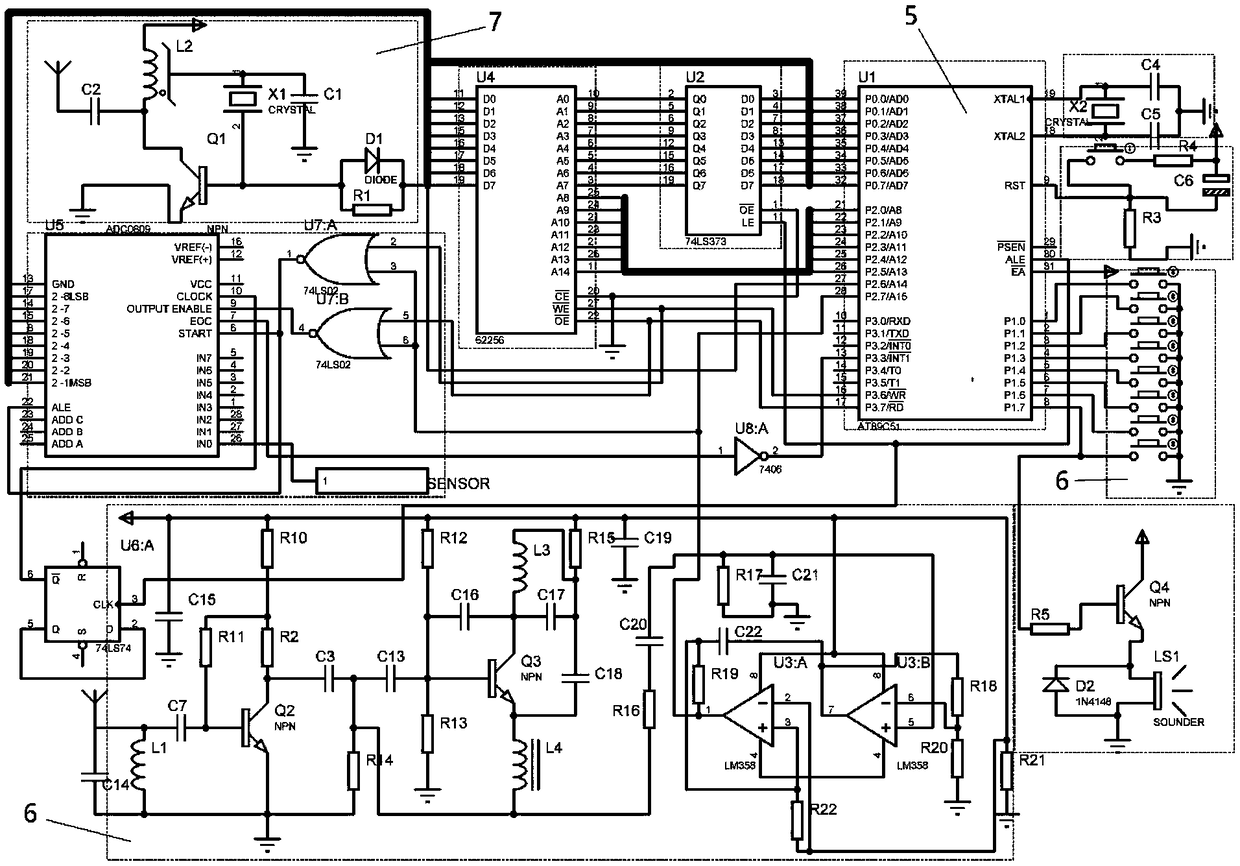

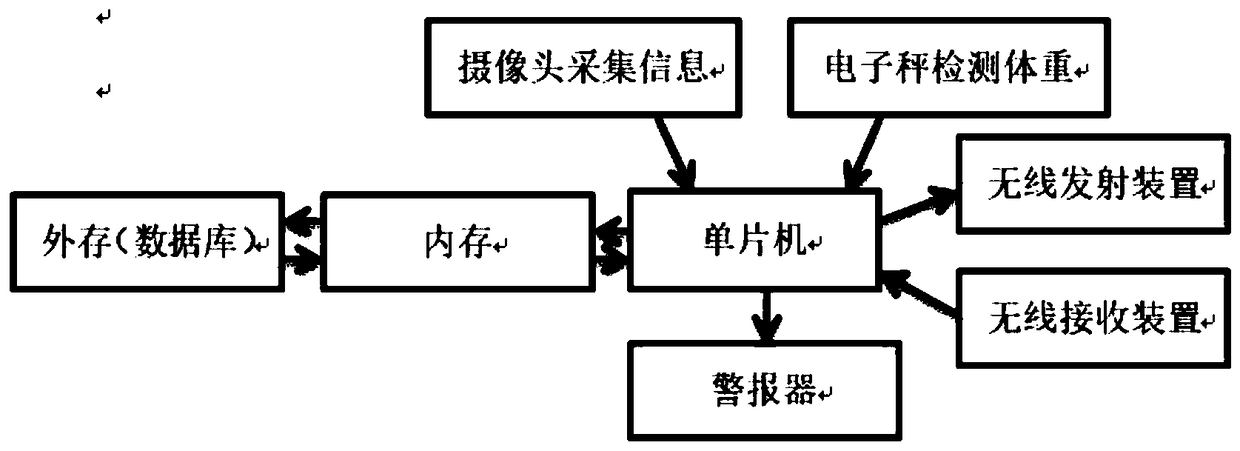

Detection system based on inspection station

InactiveCN108896151AAccurate weight measurementSimple compositionProgramme controlComputer controlSecurity checkSingle chip

The invention discloses a detection system based on an inspection station and belongs to the field of public safety. The detection system is arranged in a to-be-passed security check place at a customs, an airport and a station during outgoing, passengers who go out in a short time are detected and whether a dangerous object is hidden in a passenger is judged according to detection conditions. Anelectronic scale and a camera are arranged at each security check door, the camera is capable of identifying a face and an electronic scale is capable of measuring the weight of the person. If the weight of the same person who goes out or returns back in a short time is greatly changed than the weight measured during the returning back or going out of the person last time, a dangerous object may be hidden in the body, so at this moment, a buzzer at the security check door will ring to prompt that the person is dangerous. A security check worker is capable of further checking the person so as to prevent dangerous conditions from occurring. Information acquired by the electronic scale and the camera can be stored in a database and a single chip microcomputer is used for analysis.

Owner:陈彤云

An automatic weighing packaging machine

ActiveCN112109933BHigh precisionImprove packaging qualitySolid materialProcess engineeringElectrical and Electronics engineering

The invention discloses an automatic weighing and packaging machine, which includes an automatic bag loading mechanism, a bag clamping mechanism, a vertical feeding mechanism and a bag pushing mechanism; the automatic bag loading mechanism installs the packaging bag on the bag clamping mechanism, and the bag clamping mechanism The material is added into the packaging bag on the bag clamping mechanism through the vertical feeding mechanism. The bag clamping mechanism is provided with a weighing device, and the weighing device weighs the materials in the packaging bag on the bag clamping mechanism. The packaging bag When the material in the bag reaches the predetermined weight, the vertical feeding mechanism stops feeding; the packaging bag containing the material is pushed into the next processing station by the bag pushing mechanism. The present invention designs the automatic weighing packaging machine, transports the material to the packaging bag on the bag clamping mechanism through the vertical feeding mechanism, and sets a weighing device on the bag clamping mechanism, which can improve the weighing accuracy of the material in the packaging bag , reducing the occurrence of dust during the feeding process.

Owner:JIANGSU TOM PACKAGING MACHINERY

Weighing mechanism used for seed crystal driving device

ActiveCN102478420BSmall rangeAccurate weight measurementSpecial purpose weighing apparatusEngineeringExpansion joint

Owner:SHENYANG SCI INSTR RES CENT CHINESE ACAD OF SCI

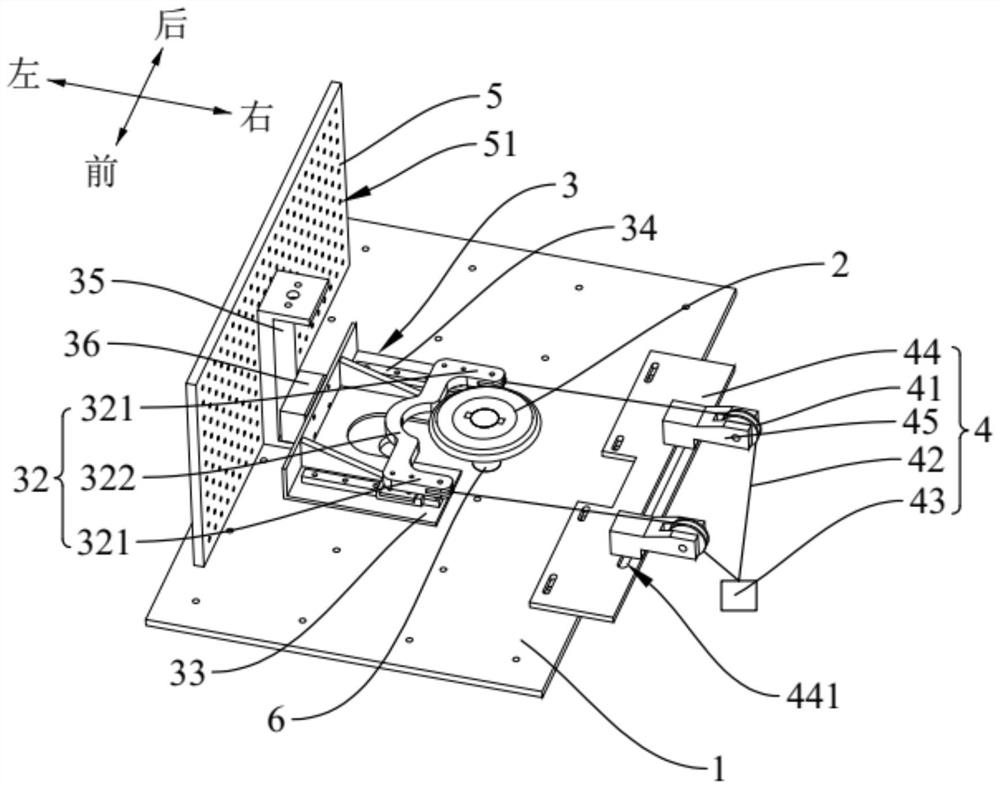

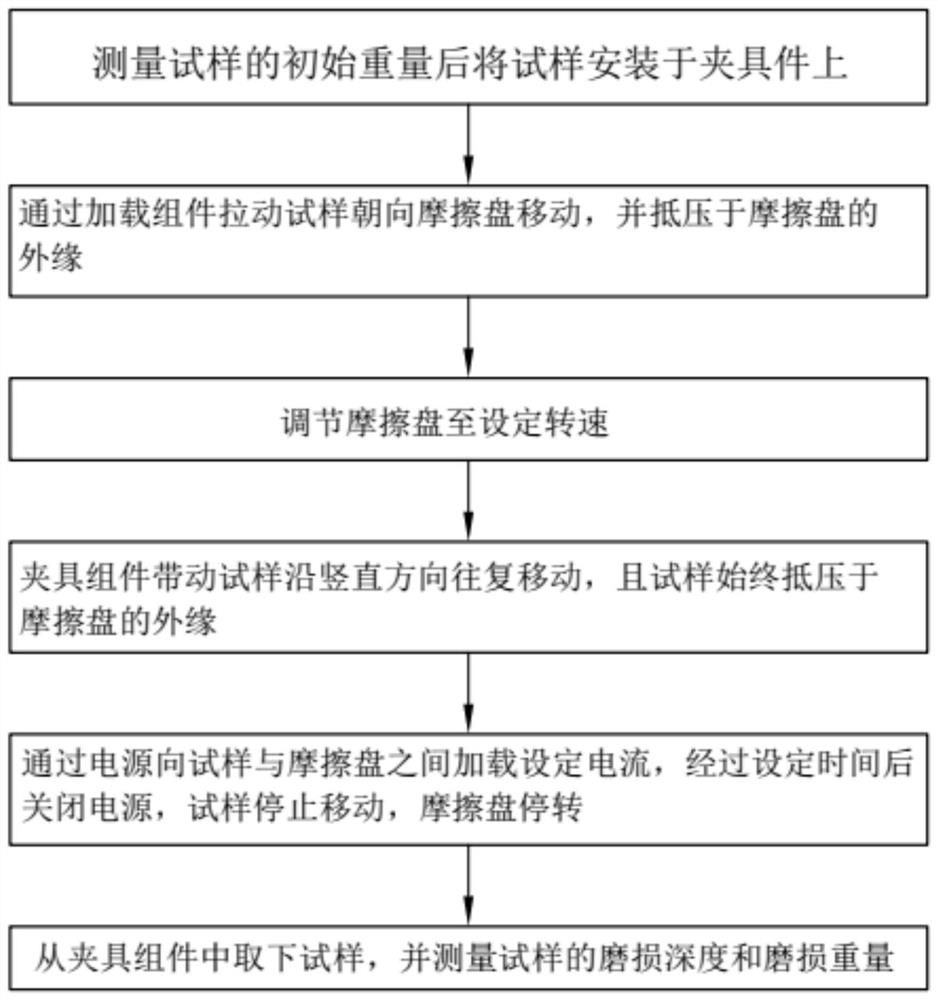

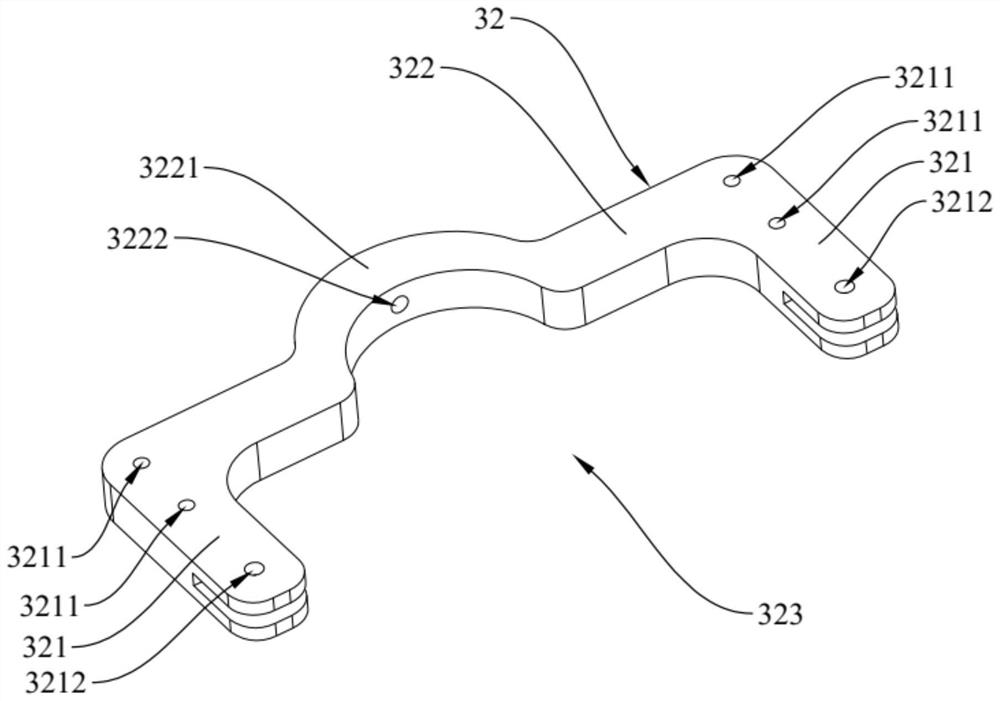

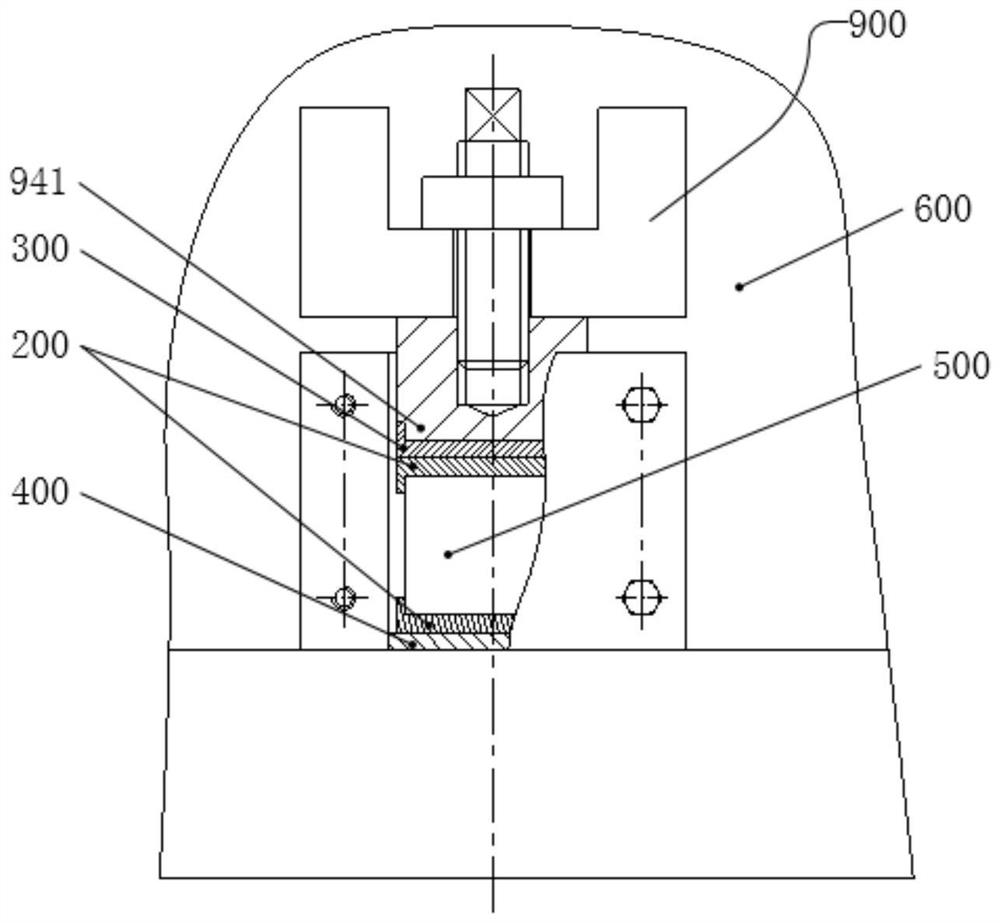

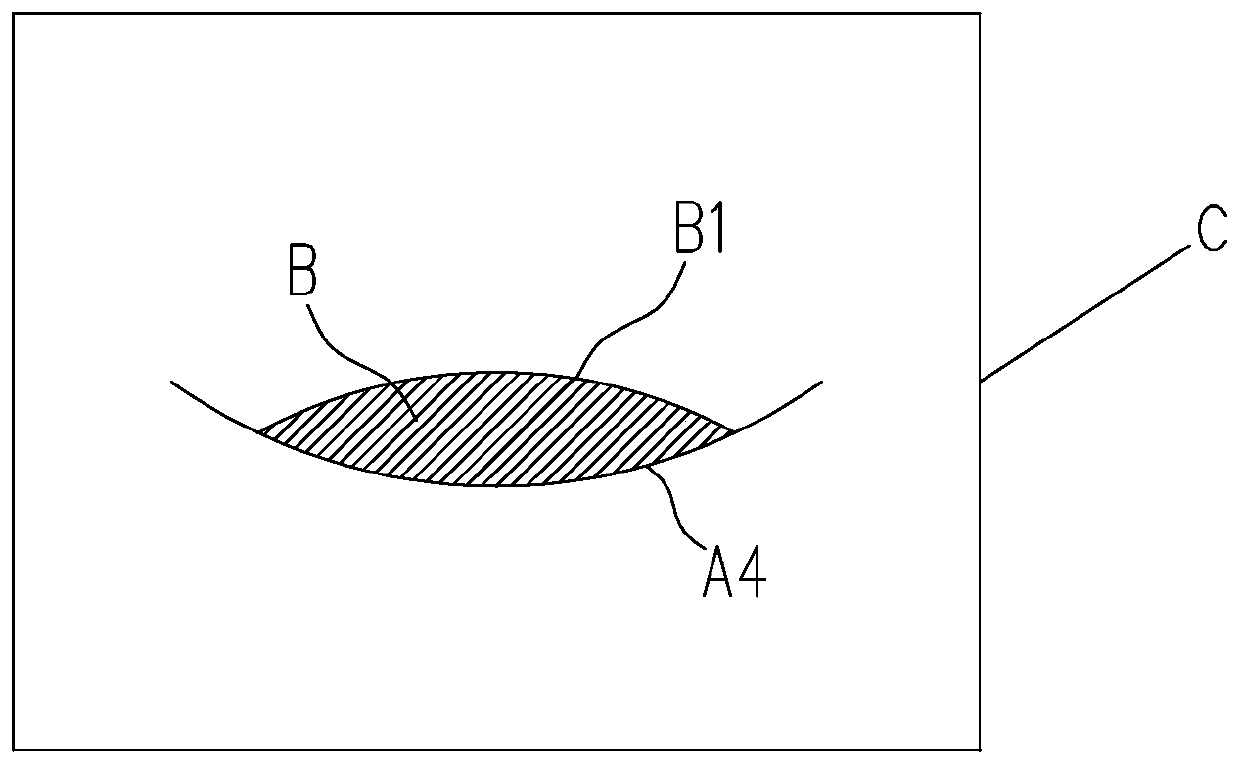

Current-carrying friction wear test method

PendingCN114235615AAccurately measure depthAccurate weight measurementInvestigating abrasion/wear resistanceElectric current flowMechanical engineering

The invention relates to the technical field of friction tests, and discloses a current-carrying friction wear test method. The current-carrying friction wear test method comprises the following steps: measuring the initial weight of a sample, and mounting the sample on the clamp assembly; the loading assembly pulls the sample to move towards the friction disc and abuts against the outer edge of the friction disc. And adjusting the friction disc to a set rotating speed. The clamp assembly drives the sample to reciprocate in the vertical direction, and the sample abuts against the outer edge of the friction disc all the time. A set current is loaded between the sample and the friction disc through a power supply, the power supply is turned off after a set time, the sample stops moving, and the friction disc stops rotating. The sample is taken down from the clamp assembly, and the abrasion depth and the abrasion weight of the sample are measured. According to the current-carrying friction wear test device, the friction condition of the sample and the friction disc under the current-carrying condition can be truly simulated by adopting the current-carrying friction wear test method, the flexible adjustment of the current-carrying friction wear test device is realized, and the measurement efficiency and the accuracy of a test result are improved.

Owner:TIANJIN RES INST FOR ADVANCED EQUIP TSINGHUA UNIV +1

Movable weighing device

ActiveCN112964341AAccurate weight measurementContinuous and orderly productionBio-packagingWeighing apparatus for materials with special property/formDry iceSlide plate

The invention discloses a movable weighing device which comprises a rack, a sliding flat plate, an upper sliding plate, a lower sliding plate, a weighing sensor and a cylinder used for loading dry ice tobacco shreds; a gap is formed between the rack and the cylinder; the lower sliding plate is fixedly arranged on the rack, and the upper sliding plate is fixedly connected with the inner wall of the cylinder; the weighing sensor is arranged between the lower sliding plate and the upper sliding plate, and sliding flat plates are fixedly arranged at the upper end and the lower end of the weighing sensor respectively. In the movable weighing device, a vibration cabinet vibrates on one surface in the production process, the weighing sensor slides between the upper sliding plate and the lower sliding plate, and the sliding direction is parallel to the vibration direction of the vibration cabinet, so that the movement generated by the vibration of the vibration cabinet is counteracted, the weight of the dry ice tobacco shreds in the cylinder is accurately measured, and continuous and orderly production is ensured.

Owner:CHINA TOBACCO HENAN IND

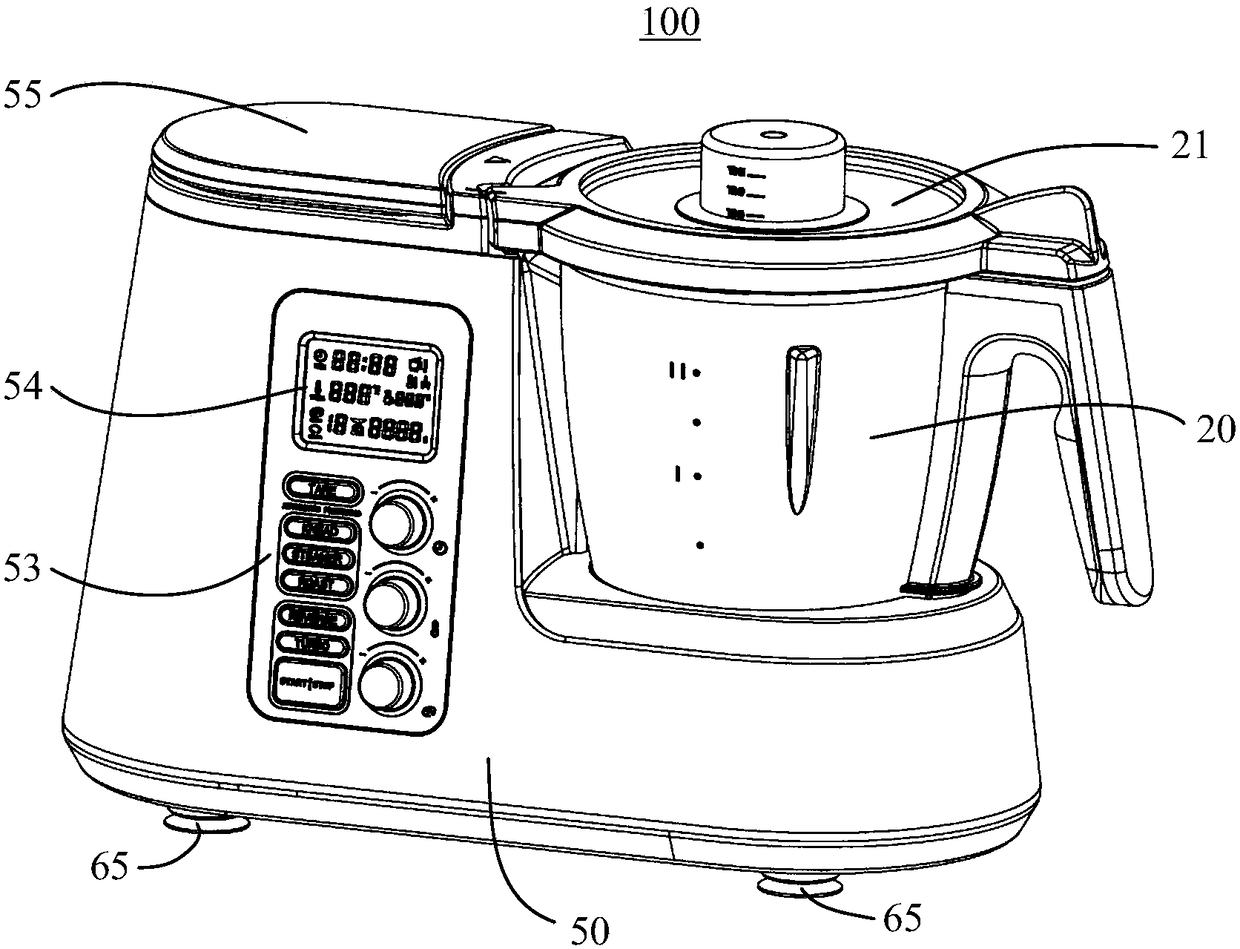

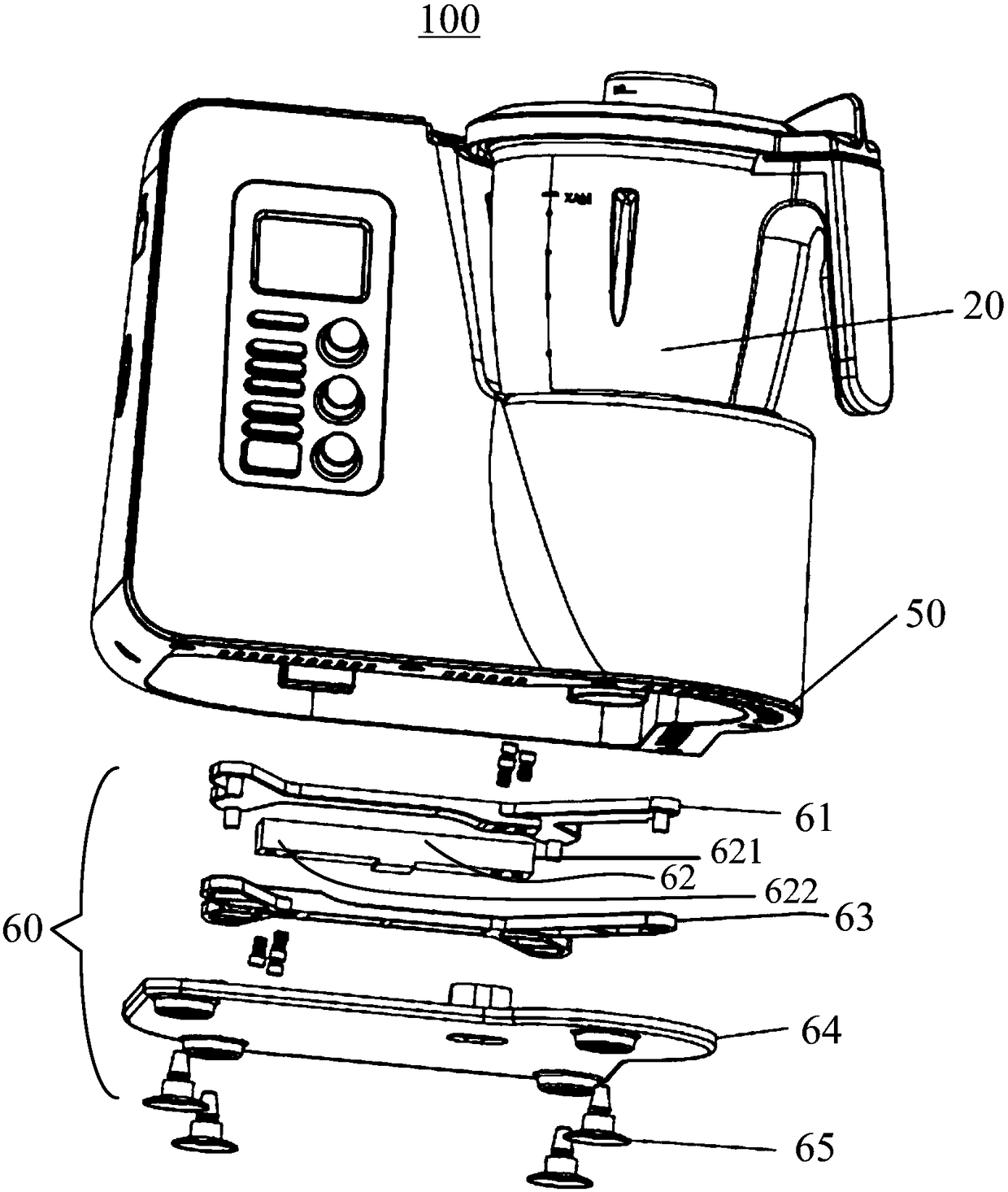

food processor

Owner:GUANGZHOU SHENGWEI ELECTRIC MFG +1

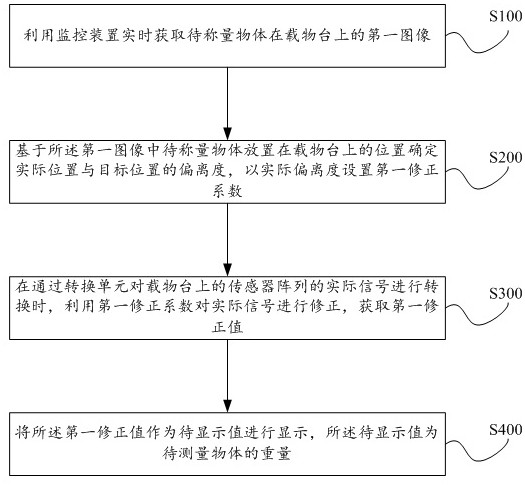

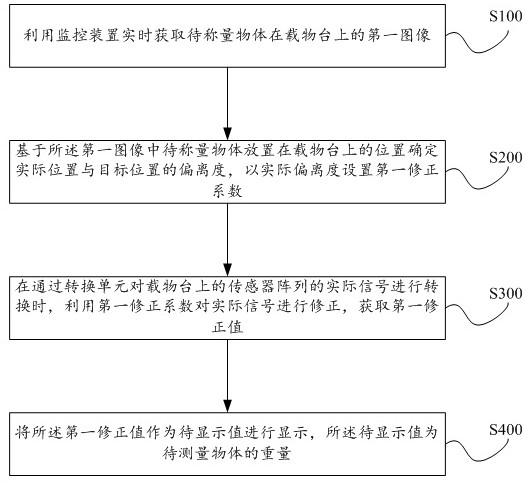

Weight calibration method based on precise weighing

ActiveCN113393525AAccurate measurementCorrection errorImage enhancementImage analysisSensor arrayMedicine

The invention relates to a weight calibration method based on precise weighing. The method comprises the following steps: acquiring a first image of an object to be weighed on an objective table in real time by using a monitoring device; determining the deviation degree of the actual position and the target position based on the position of the to-be-weighed object on the objective table in the first image, and setting a first correction coefficient according to the actual deviation degree; when the actual signal of the sensor array on the objective table is converted through the conversion unit, correcting the actual signal through the first correction coefficient, and obtaining a first correction value; displaying the first correction value as a to-be-displayed value, wherein the to-be-displayed value is the weight of the to-be-measured object; expressing the degree of the to-be-measured object deviating from the center position of the objective table through the first correction coefficient, and then correcting the influence on the reference signal, so that the corrected signal value can be equivalent to the fact that the object to be weighed is placed in the center of the objective table, errors caused by position deviation are effectively corrected, accurate weight measurement is achieved, and the measurement precision is improved.

Owner:深圳市安普测控科技有限公司

Non-contact belt conveyor weighing and deviation warning device

ActiveCN107128661BRealize real-time weighingLess componentsConveyorsControl devices for conveyorsSimulationConveyor belt

The invention belongs to the technical field of conveyor belts and particularly relates to a non-contact type belt conveying weighing and deviating warning device. The device comprises a sensing device, a data processing device and a synchronizer, wherein the sensing device is used for obtaining outline information data of a belt and materials on the belt perpendicular to the conveying direction of the belt, the data processing device is used for obtaining the area of the cross section of the materials on the belt according to the outline information data, the data processing device is combined with conveying speed of the belt, running time and material density to obtain material mass conveyed within the corresponding running time of the belt, the data processing device can compare shape outlines of the belt obtained during different periods, and when deviation values of the belt shape outlines obtained during the different periods reach set values, the data processing device sends out a warning signal; and the synchronizer is used for enabling the sensing device and the belt to work synchronously. The device has few components and is low in cost. Moreover, in the measuring process, the device does not make contact with the belt, measuring precision is high, and the fault rate is low.

Owner:ANHUI UNIV OF SCI & TECH

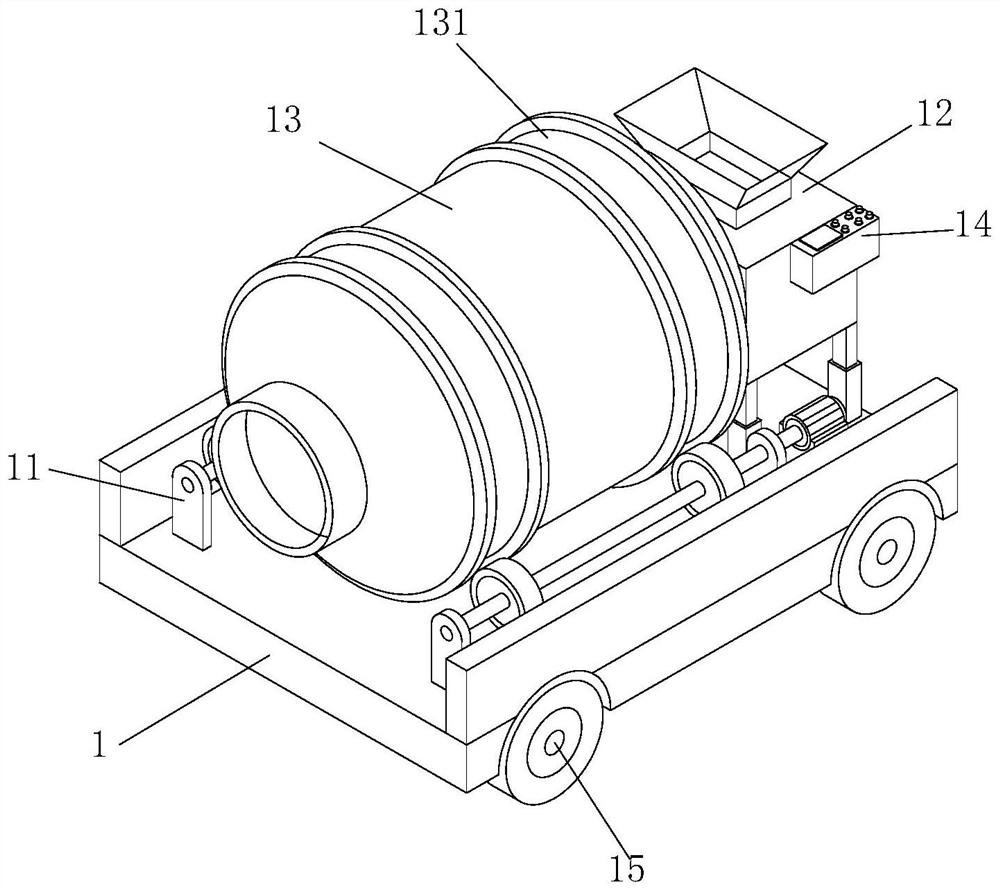

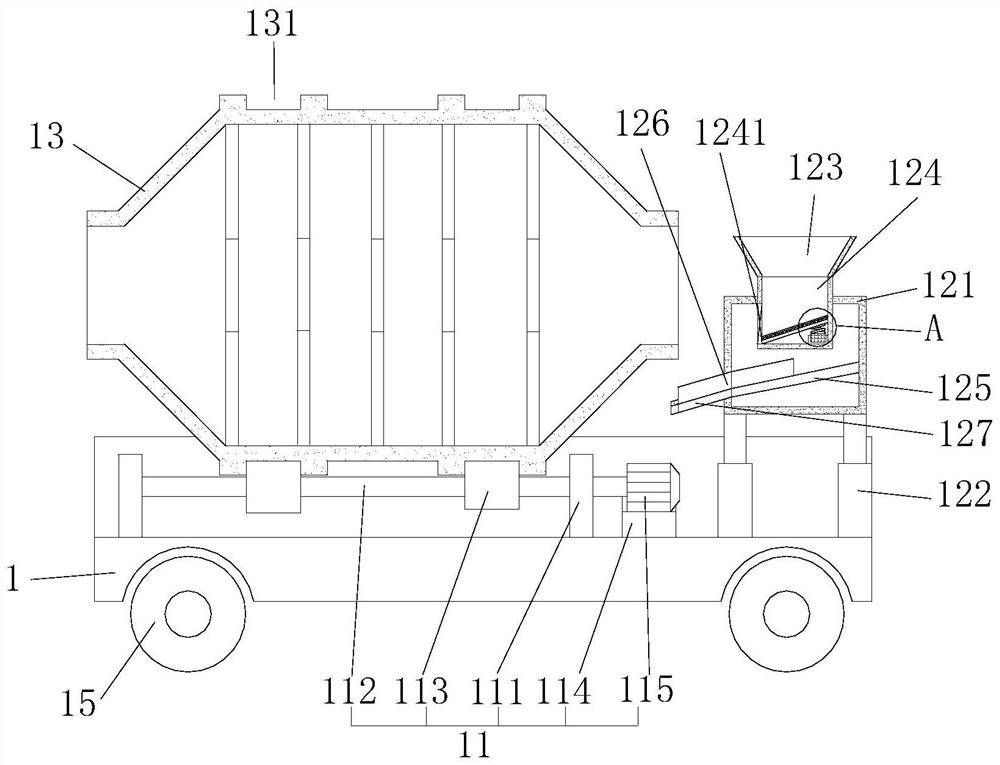

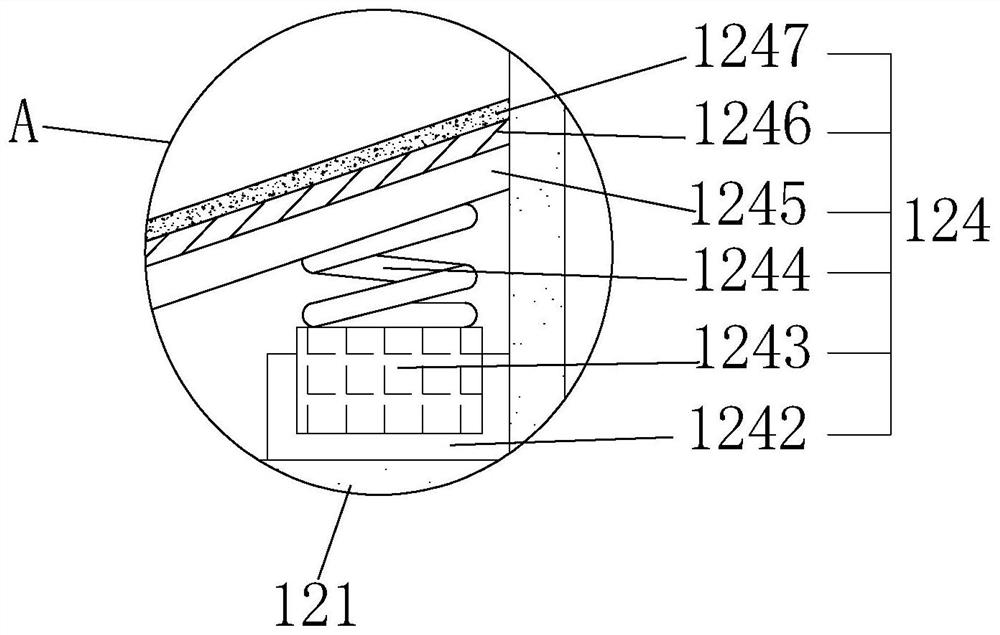

Slurry mixer for road construction

PendingCN114311308AAccurate weight measurementSmooth rotationMixing operation control apparatusCement mixing apparatusStructural engineeringSlurry

The invention provides a slurry stirrer for road construction, which comprises a base, the base comprises a feeding device, a stirring barrel is arranged on the upper surface of the base, the feeding device is arranged on one side of the stirring barrel, the feeding device comprises a shell, a telescopic foot rod is arranged on the upper surface of one side of the base, the shell is arranged at the top end of the telescopic foot rod, and a feeding hopper is arranged on the top surface of the shell. A weighing cavity is formed under the feeding hopper and comprises an electric gate, the electric gate is arranged on the inner wall of one side of the weighing cavity, a fixing base is arranged on the bottom face of the other side of the weighing cavity, a vibration assembly is arranged on the bottom face of the fixing base, the top face of the vibration assembly is connected with an elastic assembly, the upper end of the elastic assembly is connected with a first inclined plate, and a gravity sensing device is arranged on the upper surface of the first inclined plate. A second inclined plate is arranged below the weighing cavity, a square through hole is formed in the outer wall of one side of the shell, the second inclined plate is connected with the square through hole, and a feeding channel is formed in the outer surface of the square through hole.

Owner:浙江万吉建设有限公司

Gunpowder weighing device with re-weighing function

PendingCN113551746AReduce weighing errorsHigh precisionWeighing apparatus detailsWeighing apparatus with automatic feed/dischargeExplosive AgentsProcess engineering

The invention discloses a gunpowder weighing device with a re-weighing function. The device comprises a supporting device which is provided with aprimary weighing area and a secondary weighing area, adischarging device, a conveying device and a static electricity eliminating device, wherein the discharging device is used for adding gunpowder; the conveying device is provided with a gunpowder cup, the gunpowder cup is used for receiving the gunpowder discharged by the discharging device in the primary weighing area, and the conveying device drives the gunpowder cup to be transferred to the secondary weighing area from the primary weighing area so as to weigh the gunpowder cup loaded with the gunpowder for multiple times; and the static electricity eliminating device is used for eliminating static electricity of the gunpowder in the gunpowder cup which is subjected to primary weighing and / or secondary weighing. The influence of static electricity on gunpowder weighing can be reduced, the gunpowder weighing accuracy is improved, and the device is applied to the field of gunpowder and explosive weighing equipment.

Owner:湖南摩铠智能科技有限公司

Weighing and charging platform

InactiveCN112212955AReduce shakingAccurate Weight MeasurementTicket-issuing apparatusWeighing apparatus detailsControl engineeringMachine

The invention discloses a weighing and charging platform, which comprises a toll booth, weighing equipment and a gate passing machine, and the weighing equipment comprises a weighing platform, a weighing meter and an auxiliary weighing platform, the auxiliary weighing platform is arranged at the lower end of the weighing platform, and the auxiliary weighing platform comprises a fixing plate, a supporting pipe and an upper end plate cover; a supporting pipe is arranged between a fixing plate and an upper end plate cover, the supporting pipe is fixedly connected with a plurality of steel plates,and a damping layer is arranged between the weighing platform and the auxiliary weighing platform. The platform has the beneficial effects that through the arrangement of the auxiliary weighing platform, the shaking amplitude of the vehicle is reduced, so that the goods of the vehicle are more accurately weighed and measured, meanwhile, the protection device plays a role in protecting the weighing meter, the service life of precision parts in the device is prolonged, the cost is saved, and the practicability is high.

Owner:常州市路通自动化设备厂

Weight Calibration Method Based on Accurate Weighing

ActiveCN113393525BAccurate measurementCorrection errorImage enhancementImage analysisSensor arrayEngineering

The present invention relates to a weight calibration method based on accurate weighing, the method comprises using a monitoring device to acquire a first image of an object to be weighed on a stage in real time; placing the object to be weighed on the stage based on the first image The position above determines the deviation degree between the actual position and the target position, and the first correction coefficient is set with the actual deviation degree; Make corrections to obtain the first correction value; display the first correction value as the value to be displayed, the value to be displayed is the weight of the object to be measured, and the degree to which the object to be weighed deviates from the center position of the stage is represented by the first correction coefficient , and then correct the influence of the reference signal, so that the corrected signal value can be equivalent to placing the object to be weighed in the center of the stage, effectively correcting the error caused by the position offset, realizing accurate weight measurement and improving measurement accuracy .

Owner:深圳市安普测控科技有限公司

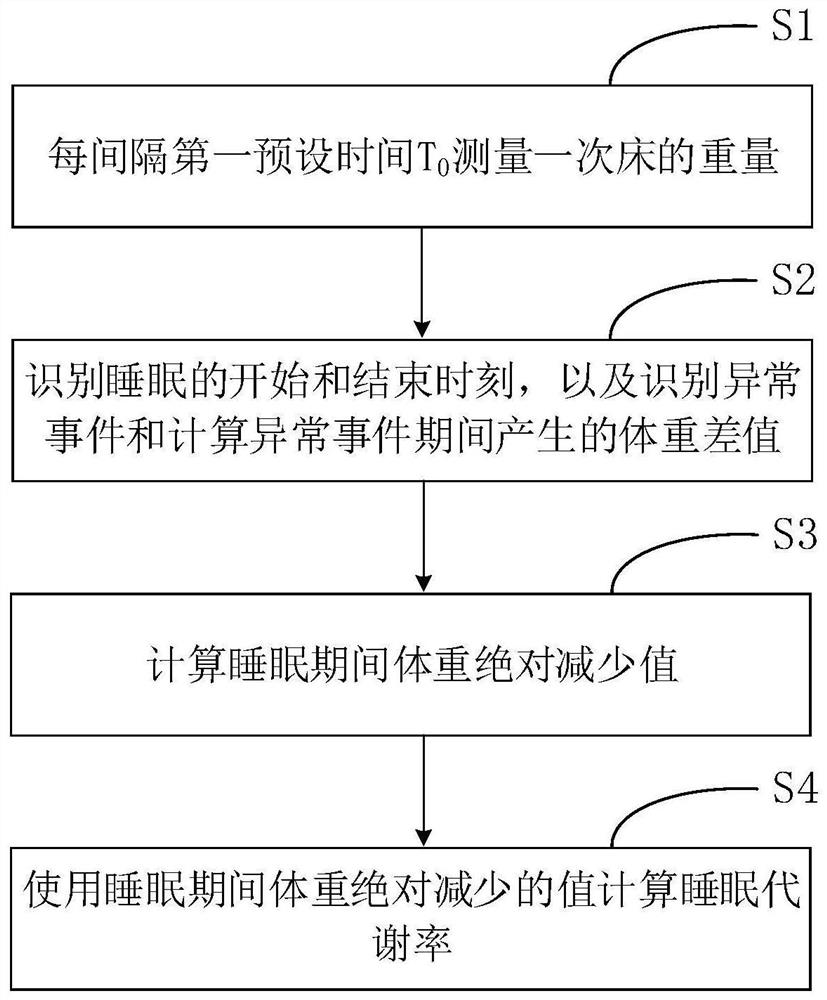

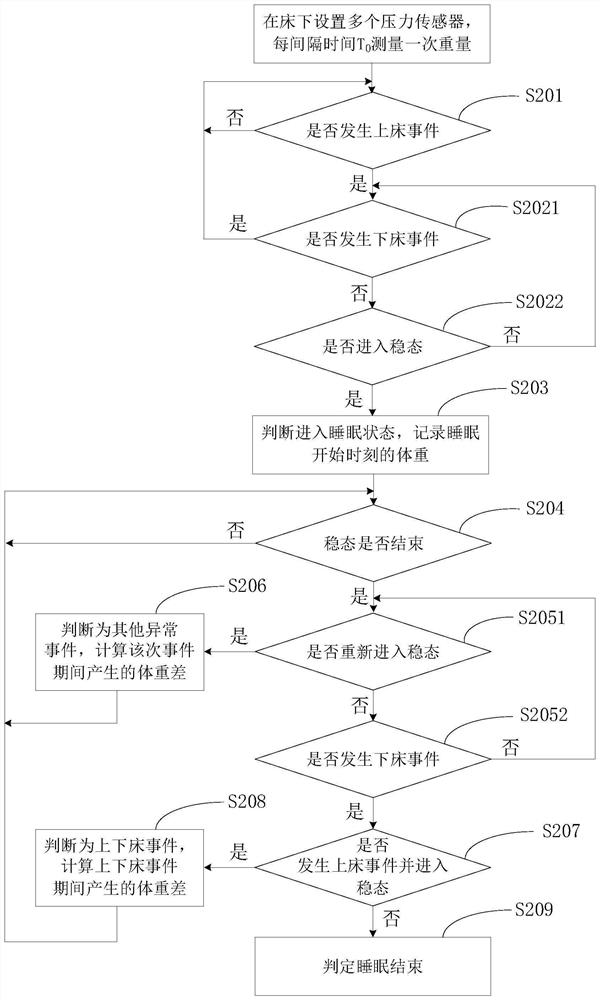

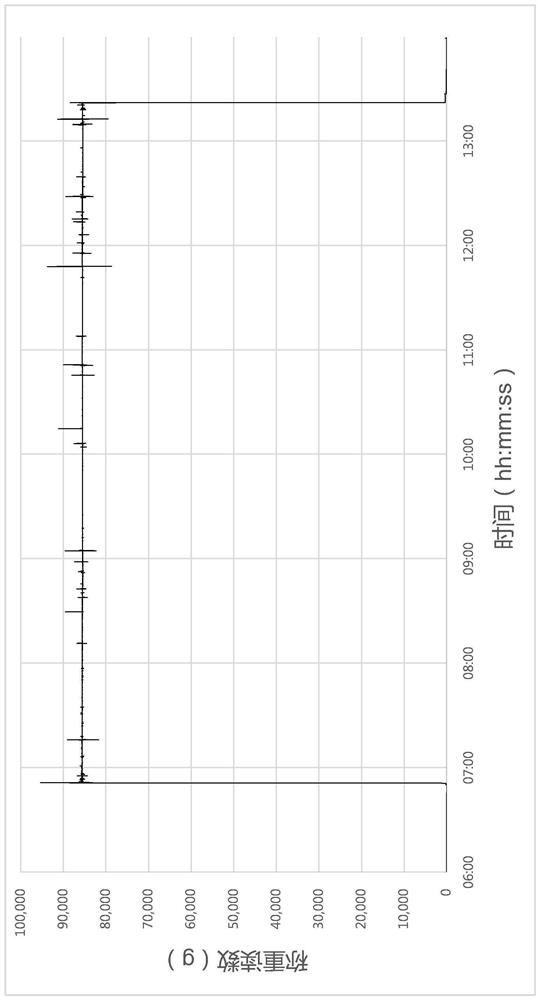

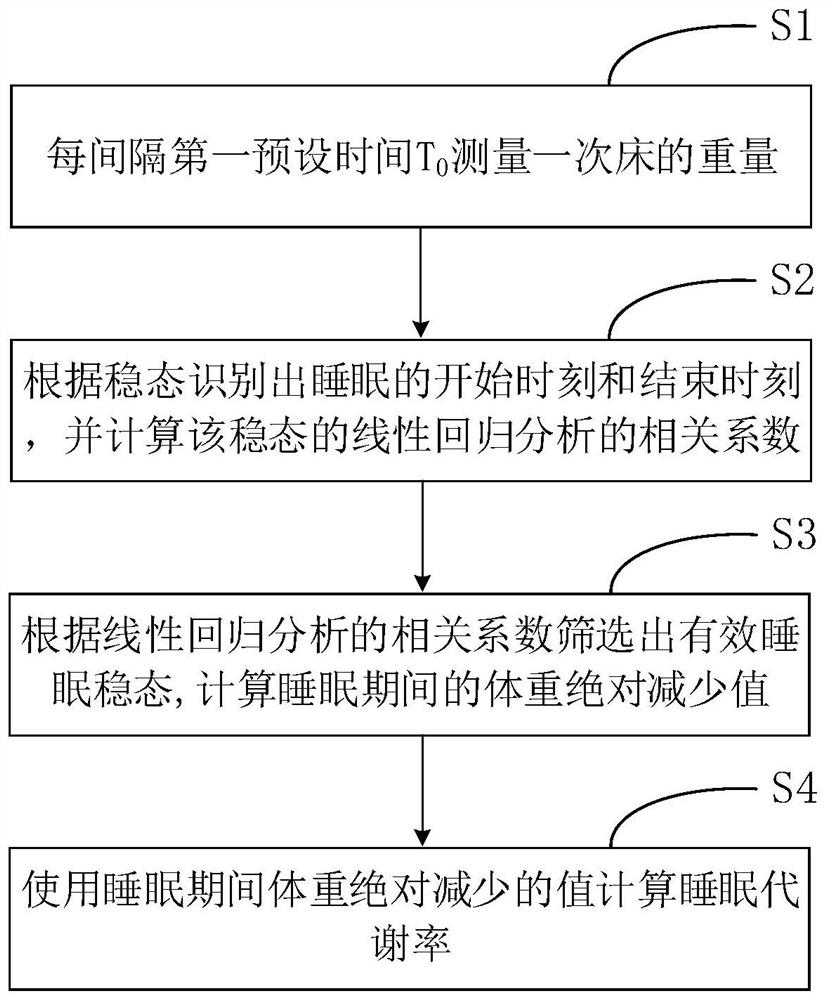

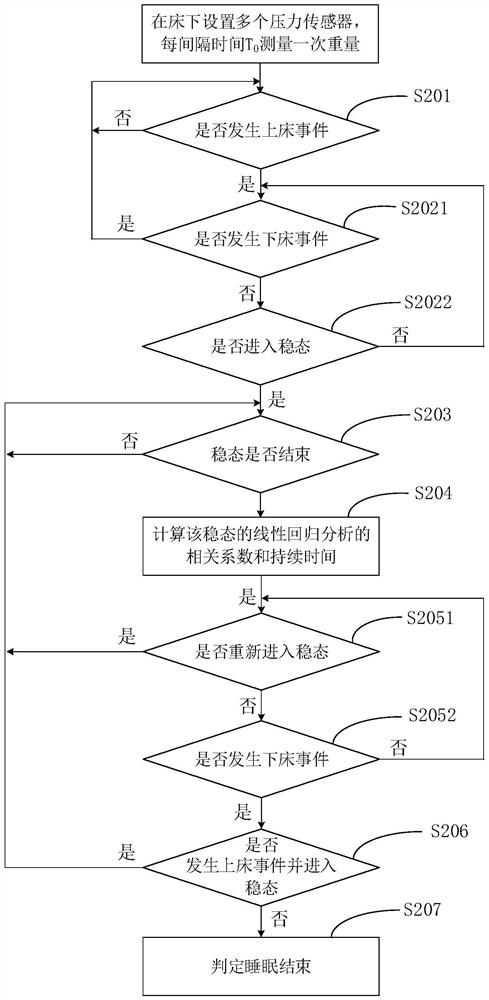

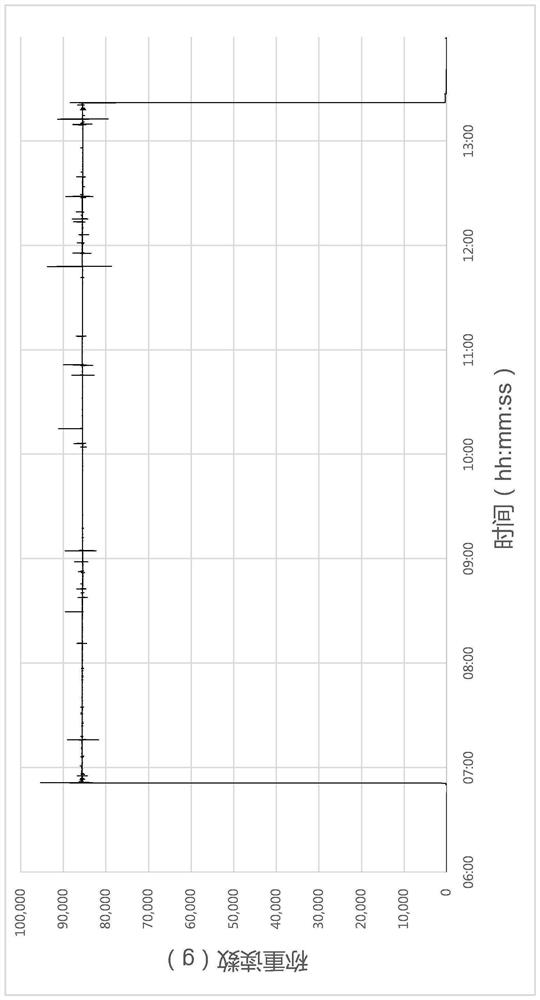

Method for calculating metabolic rate in sleep process

PendingCN113974567AEliminate distracting factorsAccurate weight measurementDiagnostic recording/measuringSensorsSleep StartsStress sensors

The invention relates to a method for calculating a metabolic rate in a sleep process. The method comprises the following steps: measuring the weight of a bed once every first preset time, identifying a steady state according to a measured value, identifying a start moment and an end moment of sleep according to the steady state, identifying an abnormal event and calculating a weight difference value generated during the abnormal event; obtaining a body weight absolute reduction value in the sleep period according to the measured values of the pressure sensor at the sleep starting moment and the sleep ending moment and the body weight difference value generated by the abnormal event; calculating the sleep metabolism rate by using the value of the absolute loss of body weight during sleep. According to the method, the absolute weight loss of the person sleeping on the bed is measured, the metabolic quantity is calculated according to the weight loss in the sleeping process, and due to the fact that weight measurement is more direct than heat measurement, the metabolic condition of the person can be reflected more truly; by introducing abnormal events, various interference factors influencing the body weight in the sleep process can be eliminated, and the body weight measurement is more accurate.

Owner:CHONGQING HUOHOUCAO TECH CO LTD

Feces and urine separation device and metabolic cage for livestock nutrition research

The invention discloses a dung-urine separator and a metabolism cage for livestock nutrition research; the dung-urine separator comprises a bottom plate and side plates arranged on two sides of the bottom plate; the bottom plate and the side plates form a groove shape; the front portion of the bottom plate is provided with an urine outlet; the height of one end, close to the urine outlet, of the bottom plate inner surface is lower than that of the other end, far away from the urine outlet, of the bottom plate inner surface; the height of one end, close to the urine outlet, of the side plate inner surface is lower than that of the other end, far away from the urine outlet, of the side plate inner surface; the middle portion and rear portion of the bottom plate inner surface are provided with dung baffle plates, and the bottom of the dung baffle plates are provided with holes; a forage baffle plate is arranged above the urine outlet. The dung-urine separator can fully separate the livestock dung from urine, thus solving dung and urine separate collection problems, and providing guarantee for experiment results.

Owner:INST OF SUBTROPICAL AGRI CHINESE ACAD OF SCI +1

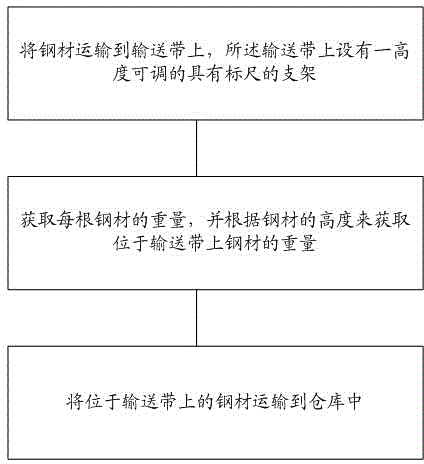

Conveying method for steel

Owner:WUXI BAISHUN MACHINERY PLANT

Sleep process metabolic rate detection method based on linear correlation coefficient interference removal

PendingCN114027792AReflect metabolismEliminate distracting factorsDiagnostic signal processingSensorsMetabolic rateLinear correlation

The invention relates to a sleep process metabolic rate detection method based on linear correlation coefficient interference removal. The method comprises the following steps: measuring the weight of a bed once every first preset time, identifying steady states according to measured values, and screening out effective sleep steady states according to correlation coefficients of linear regression analysis of the steady states; calculating the sum of the weight loss values in the effective sleep steady-state periods as an absolute weight loss value in the sleep period; and calculating the sleep metabolism rate using the absolute weight reduction value during sleep. According to the method, the absolute weight loss of the person sleeping on the bed is measured, the metabolic quantity is calculated according to the weight loss in the sleeping process, and due to the fact that weight measurement is more direct than heat measurement, the metabolic condition of the person can be reflected more truly; various interference factors influencing the body weight in the sleep process can be eliminated by adopting a method for calculating the body weight loss value in the duration of each steady state, and the steady state containing interference can be removed by calculating the correlation coefficient of linear regression analysis.

Owner:CHONGQING HUOHOUCAO TECH CO LTD

Seed-crystal transmission gear

ActiveCN102477587BAchieve connectionAccurate weight measurementAfter-treatment apparatusElectricityMicrometer

The invention relates to a seed-crystal transmission gear, belonging to the technical field of vacuum equipment. The seed-crystal transmission gear comprises a seed shaft, a water-electricity connection mechanism, a weighing mechanism, an adjusting platform and a supporting mechanism, wherein a leadscrew-nut structure connected with a fixed support of the adjusting platform is arranged on the supporting mechanism, and a lead screw is connected with a second output shaft of an electric motor; and the seed-crystal transmission gear further comprises an auxiliary drive mechanism which is connected with the lead screw, and the manual operation is available during the interruption of a power supply. In the invention, a structure with combination of a conducting slip ring and a rotating joint is used in the water-electricity connection mechanism, so that the connection between electricity and water is realized during the autorotation of a seed rod. An expansion-joint seal structure is used in the weighing mechanism, such that a weighing sensor can choose the measuring ranges properly according to actual samples, and the weighing sensor in the atmosphere can measure the weights of the samples in vacuum precisely. Double guide rails and a slider are used in the precision adjustment to ensure flexible movement; the use of a micrometer head not only leads to the more convenient operation, but also realizes the vernier adjustment and the precision adjustment. A structure of aluminum profiles is used in the supporting mechanism, such that the weight is lightened effectively, and the supporting mechanism is beautiful overall.

Owner:SHENYANG SCI INSTR RES CENT CHINESE ACAD OF SCI

A kind of barreled welding wire allowance monitoring method

ActiveCN113146003BAccurate weight measurementReduce measurement errorTotal factory controlWelding accessoriesWeight monitoringElectrical connection

Owner:GAC HONDA AUTOMOBILE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com