Seed-crystal transmission gear

A transmission device and seed crystal technology, applied in post-processing devices, crystal growth, post-processing, etc., can solve the problems of inconvenient maintenance, bulky structure, increased weight, etc., and achieve the effects of convenient operation, flexible movement, and weight reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

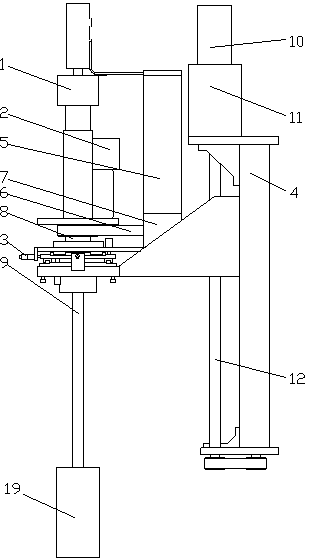

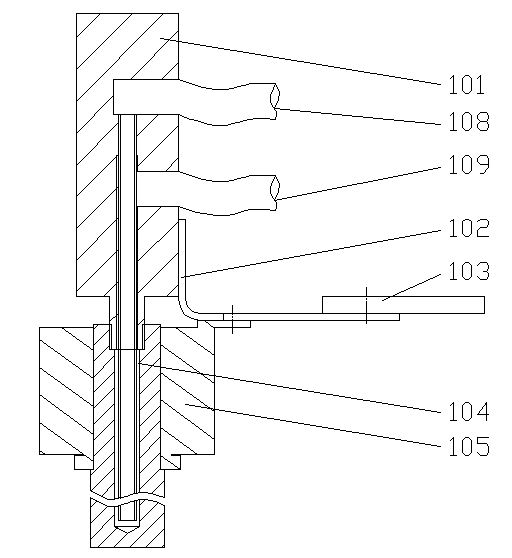

[0034] Embodiment 1: as figure 1 , figure 2 As shown, the present invention includes a seed crystal shaft 9, a water and electricity connection mechanism 1, a weighing mechanism 2, an adjustment platform 3 and a support mechanism 4, the weighing mechanism 2 is fixed on the adjustment platform 3, and the first motor 5 passes through the first transmission The device is connected to the seed crystal shaft 9 between the weighing mechanism 2 and the adjustment platform 3, the screw assembly connected to the fixed bracket 309 of the adjustment platform 3 is arranged on the support mechanism 4, the screw 12 is connected to the output shaft of the second motor 10 The connection also includes an auxiliary drive mechanism connected to the lead screw 12, and the first and second motors and the auxiliary drive device are respectively connected to the power supply.

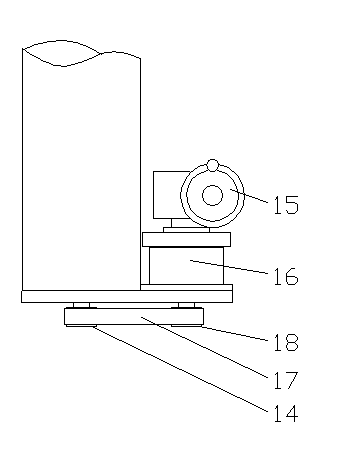

[0035] Described auxiliary driving mechanism comprises electromagnetic clutch 11, electromagnetic power loss clutch 16, h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com