Flowmeter verification device and verification method thereof

A verification device and flowmeter technology, which is applied to measurement devices, test/calibration devices, liquid/fluid solid measurement, etc., can solve the problems of inaccurate measurement density, slow temperature changes, and large measurement errors, and achieves the effect of errors. The effect of few factors, accurate verification data, and accurate volume measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] In order to illustrate the present invention in detail, the present invention will be further described in detail below in conjunction with specific implementation examples, but the described examples should not be interpreted in a limiting manner.

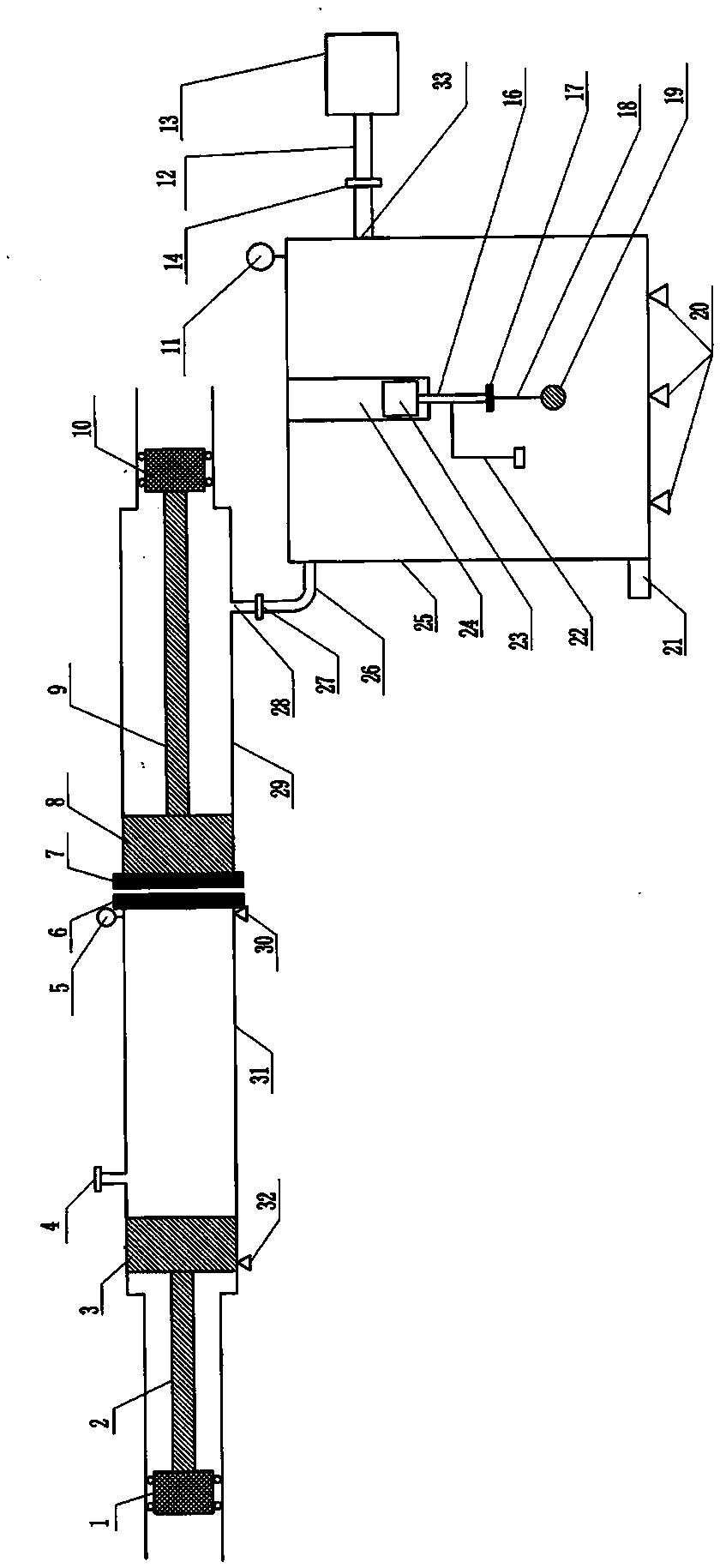

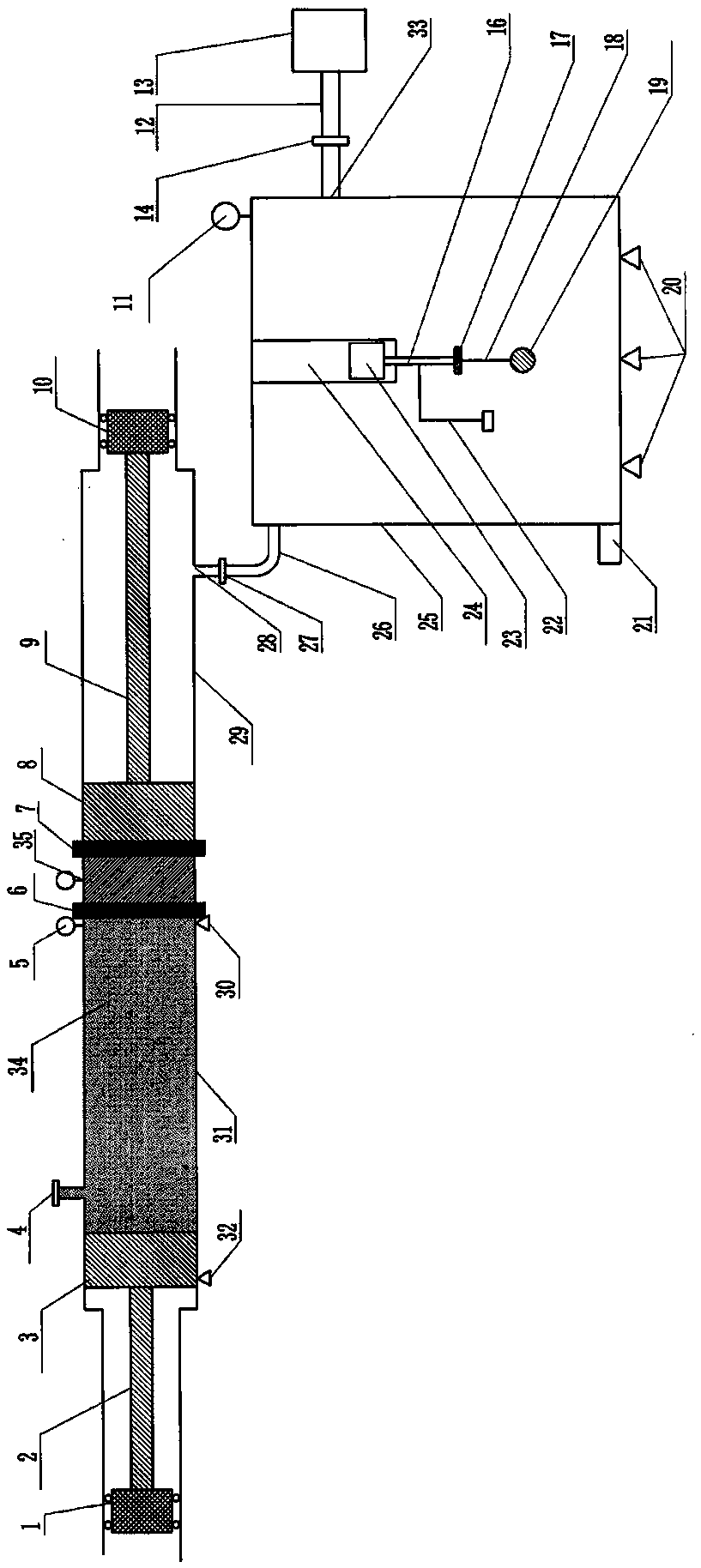

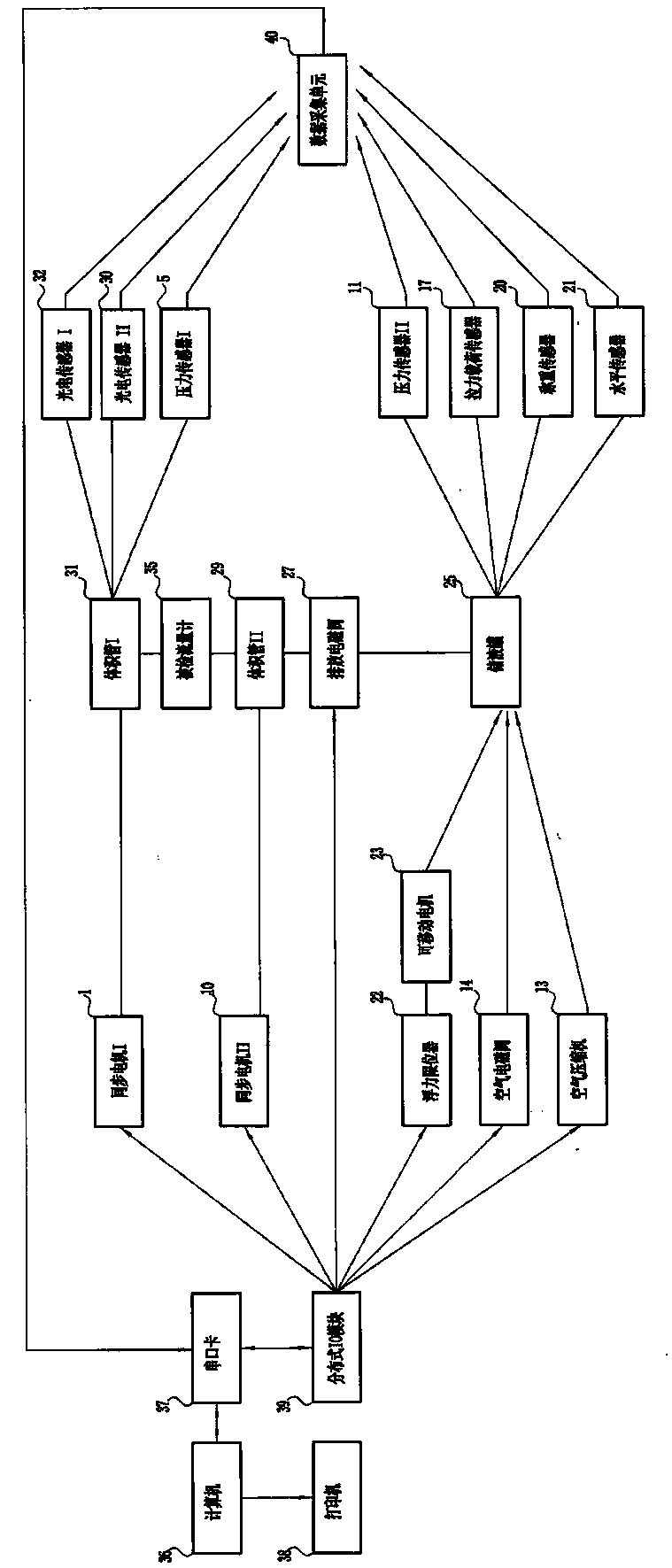

[0050] from figure 1 , image 3 It can be seen from the figure that the flowmeter verification device of the present invention includes volume tube I31, volume tube II29, working piston I3, working piston II8, synchronous motor I1, synchronous motor II10, pressure sensor I5, pressure sensor II11, photoelectric sensor I32, photoelectric Sensor II 30, discharge solenoid valve 27, level sensor 21, liquid storage tank 25, air solenoid valve 14, air compressor 13, buoyancy limiter 22, movable motor 23, tensile load sensor 17, weighing sensor 20, standard metal Sphere 19, data acquisition unit 40, distributed IO module 39, computer 36, serial port card 37, printer 38, wherein, the volume tube I31, volume tube II29 and the measur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com