Sealed pod propeller

A propeller and pod technology, applied in the field of energy conversion construction machinery, can solve the problems of low energy conversion rate of motors, insufficient water sealing performance, and reduced friction coefficient, etc., achieve strong self-regulation ability, provide energy conversion efficiency, eliminate Effects of Seal Failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

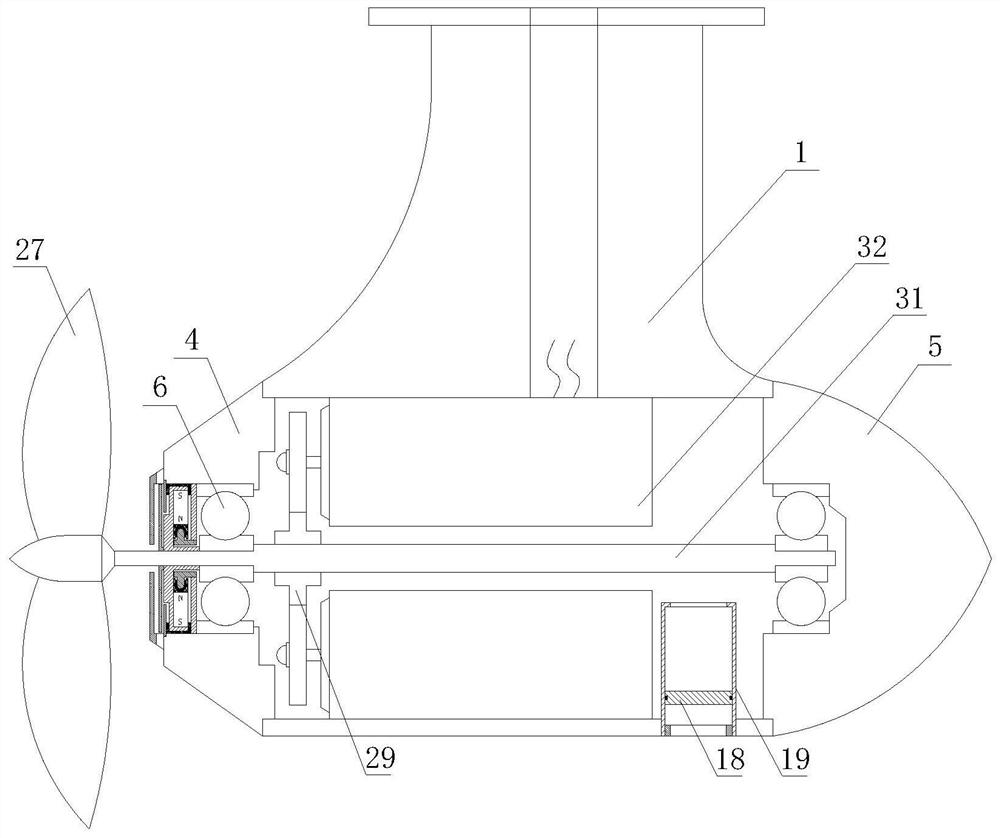

[0038] Such as Figure 1~6 As shown, a sealed pod propeller includes a housing 1 and a rotating shaft 31, the rotating shaft 31 is movably connected to the front end head 5 and the tail end cover 4 at both ends of the housing through a bearing 6, and is provided by a motor 32 through a transmission gear 29. Power rotation, the motor 32 is the driving device; the output end of the rotating shaft 31 is provided with a propeller 27; the housing 1 is also provided with an air pressure adjustment device, the air pressure adjustment device includes a cylinder 19 and a piston 18, and the cylinder Both ends of the body 19 are provided with openings to communicate the inside of the propeller with the outside atmosphere. The piston 18 is placed in the cylinder body 19 and slides under the action of the internal and external pressure difference to balance the internal and external pressure difference; the outer side of the bearing 6 is provided with a seal Assembly, the sealing assembly ...

Embodiment 2

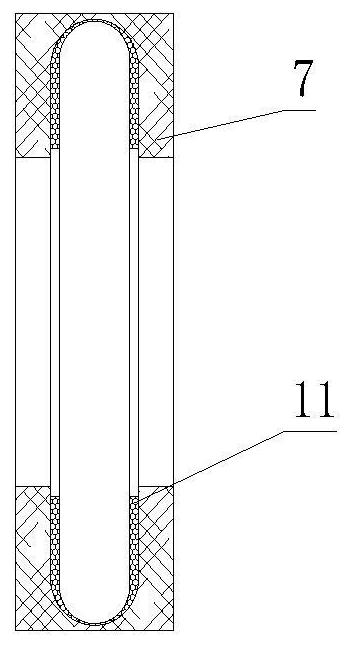

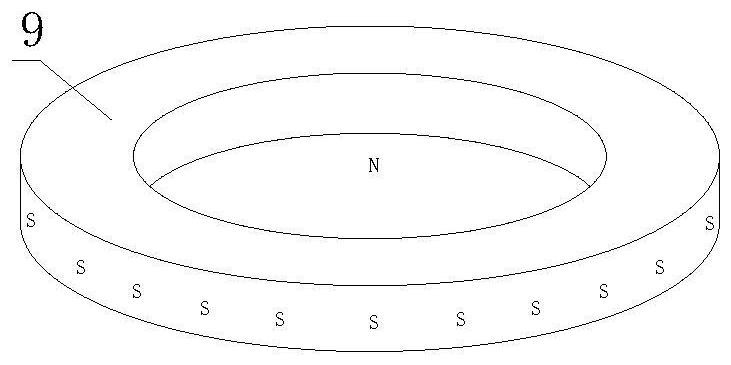

[0042] Such as Figure 7-8 As shown, a sealed pod propeller includes a housing 1 and a rotating shaft 31, the rotating shaft 31 is movably connected to the front end head 5 and the tail end cover 4 at both ends of the housing through a bearing 6, and the motor rotor 3 and the motor stator 2 Power rotation is provided, the rotor 3 is fixed on the rotating shaft 31, the stator 2 provides a radially rotating magnetic field for the rotor 3, and the driving device is a combination of the rotor 3 and the stator 2; the output end of the rotating shaft 31 is provided with a propeller 27; the bearing 6 A sealing assembly is provided on the outside, and the sealing assembly includes a concave pole 7 and a salient pole 8. The concave pole 7 is connected with the permanent magnet 9 and fixed in the end cover; the concave pole 7 is provided with a "U" shape Groove, the concave pole 7 is poured from flexible materials, such as silica gel, polytetrafluoroethylene, etc.; the salient pole 8 is...

Embodiment 3

[0045] Such as Figures 9 to 12As shown, a sealed pod propeller includes a housing 1 and a rotating shaft 31, the rotating shaft 31 is movably connected to the front end head 5 and the tail end cover 4 at both ends of the housing through a bearing 6, and the driving device is an original in the cabin. The motor drives the rotating shaft 31 to rotate through the transmission shaft 30 and the rotating gear; the tail end cover 4 is fixedly connected with the shroud 28; the outer side of the bearing 6 is provided with a sealing assembly, and the sealing assembly includes a concave pole 7 and The salient pole 8, the concave pole 7, the permanent magnet 9 and the exciter 23 are sequentially connected from the inside to the outside and fixed in the cage 20, and the cage 20 is fixedly installed in the installation groove of the end cover; the concave pole 7 is provided with a "U"-shaped groove, and the concave pole 7 is cast from a flexible material, such as silica gel, polytetrafluor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com