A V-cone flowmeter vertical installation structure

A technology for installing structures and flowmeters, used in measuring devices, volume measurement, liquid/fluid solids measurement, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with accompanying drawing and embodiment the present invention is described in detail:

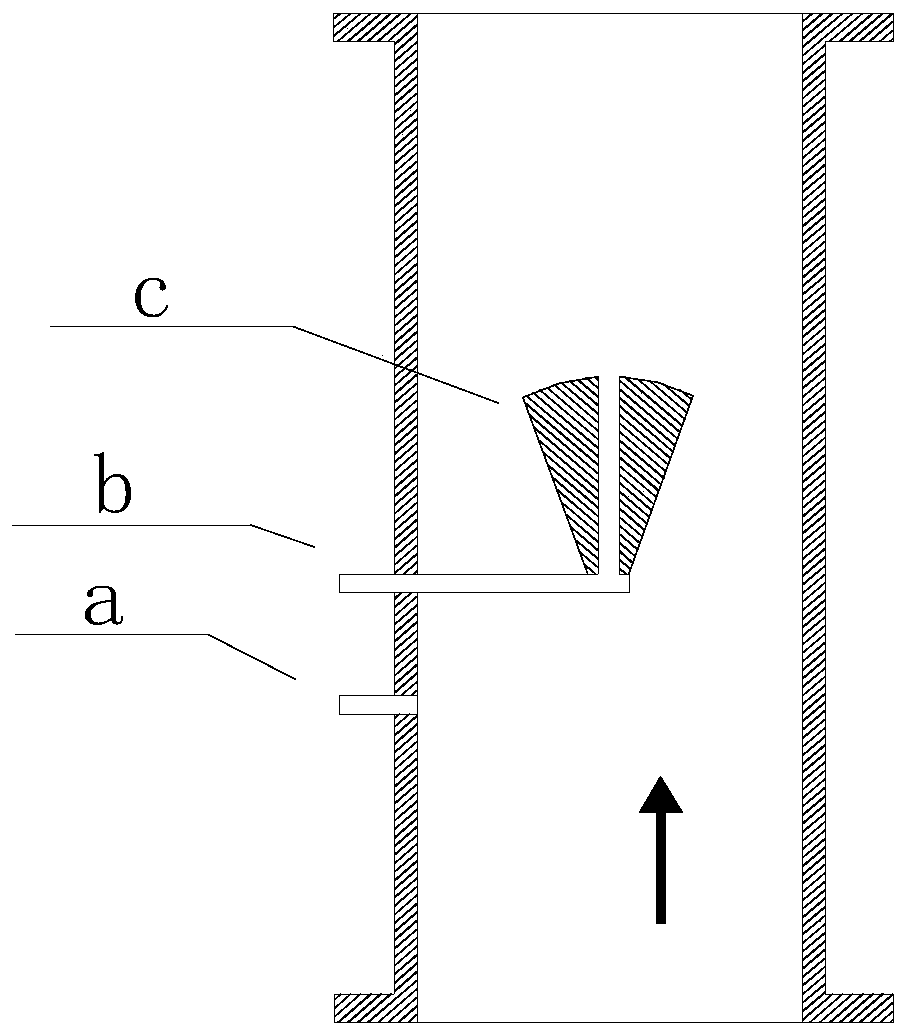

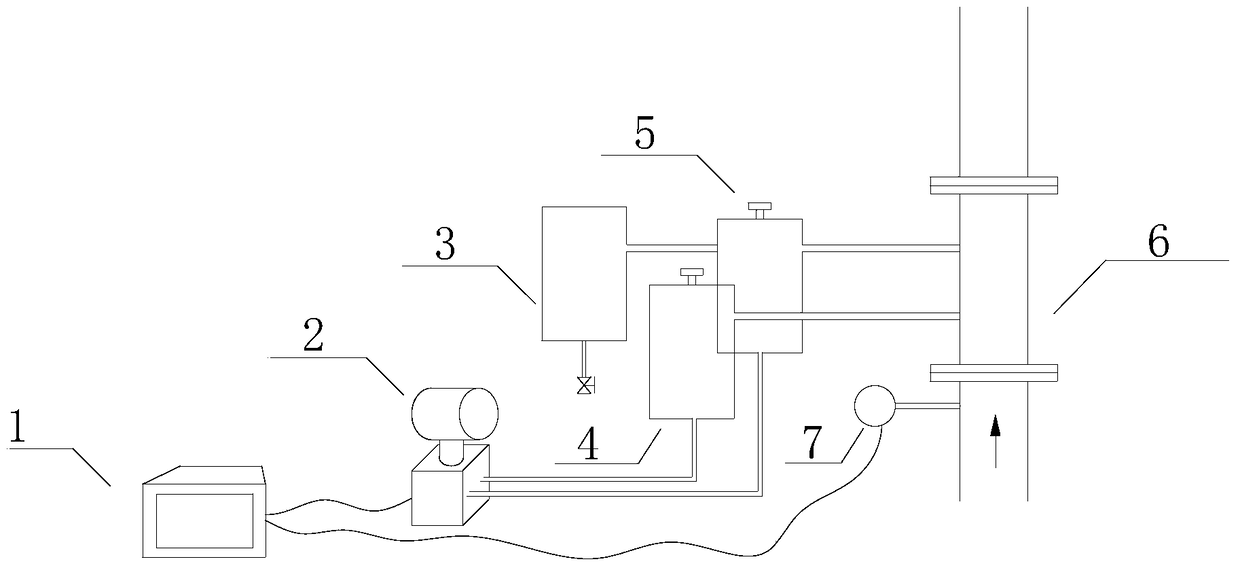

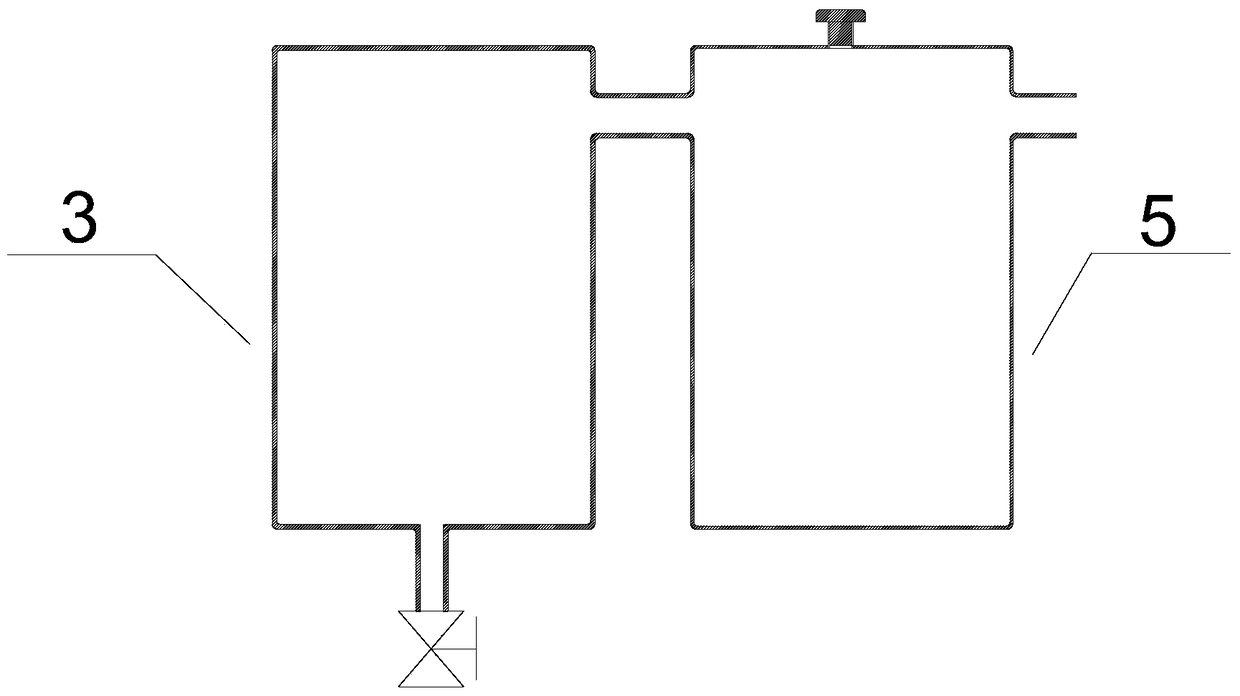

[0027] Such as figure 2 and image 3 As shown, the vertical installation structure of a V-cone flowmeter of the present invention includes a high-pressure end condensation tank 4 and a low-pressure end condensation tank 5 respectively welded and installed on the high-pressure end interface and the low-pressure end interface of the V-cone flowmeter 6 through stainless steel pipes. The inlets of the high-pressure end condensing tank 4 and the low-pressure end condensing tank 5 are arranged above the sides and are respectively flush with the high-pressure end interface and the low-pressure end interface of the V-cone flowmeter; the other side of the inlet of the low-pressure end condensing tank 5 is the same The outlet of the height is welded with a water storage tank 3, and the bottom of the water storage tank 3 has a hole and is connected with a valve; the bott...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com