Device for measuring a load at the end of a rope wrapped over a rod

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

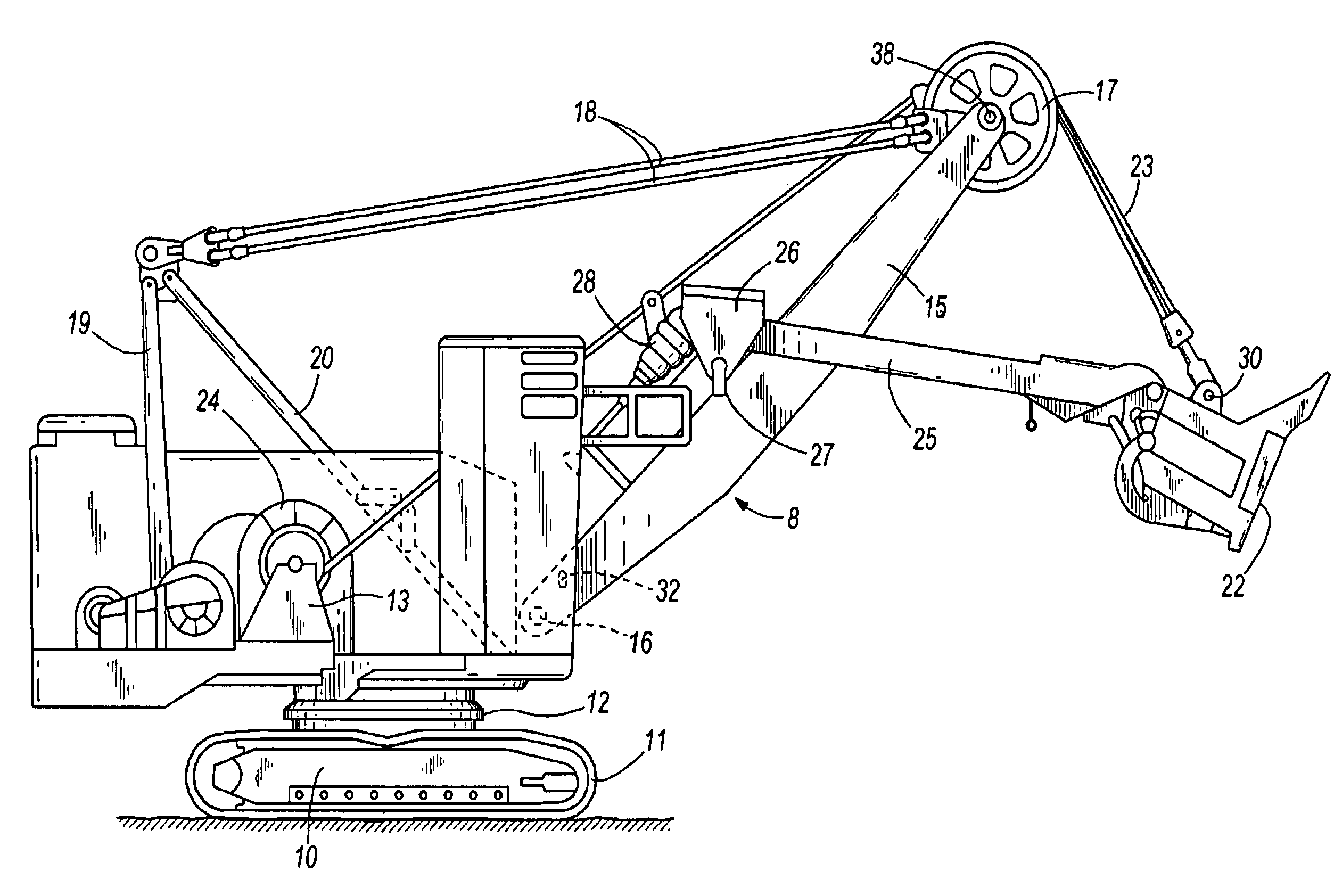

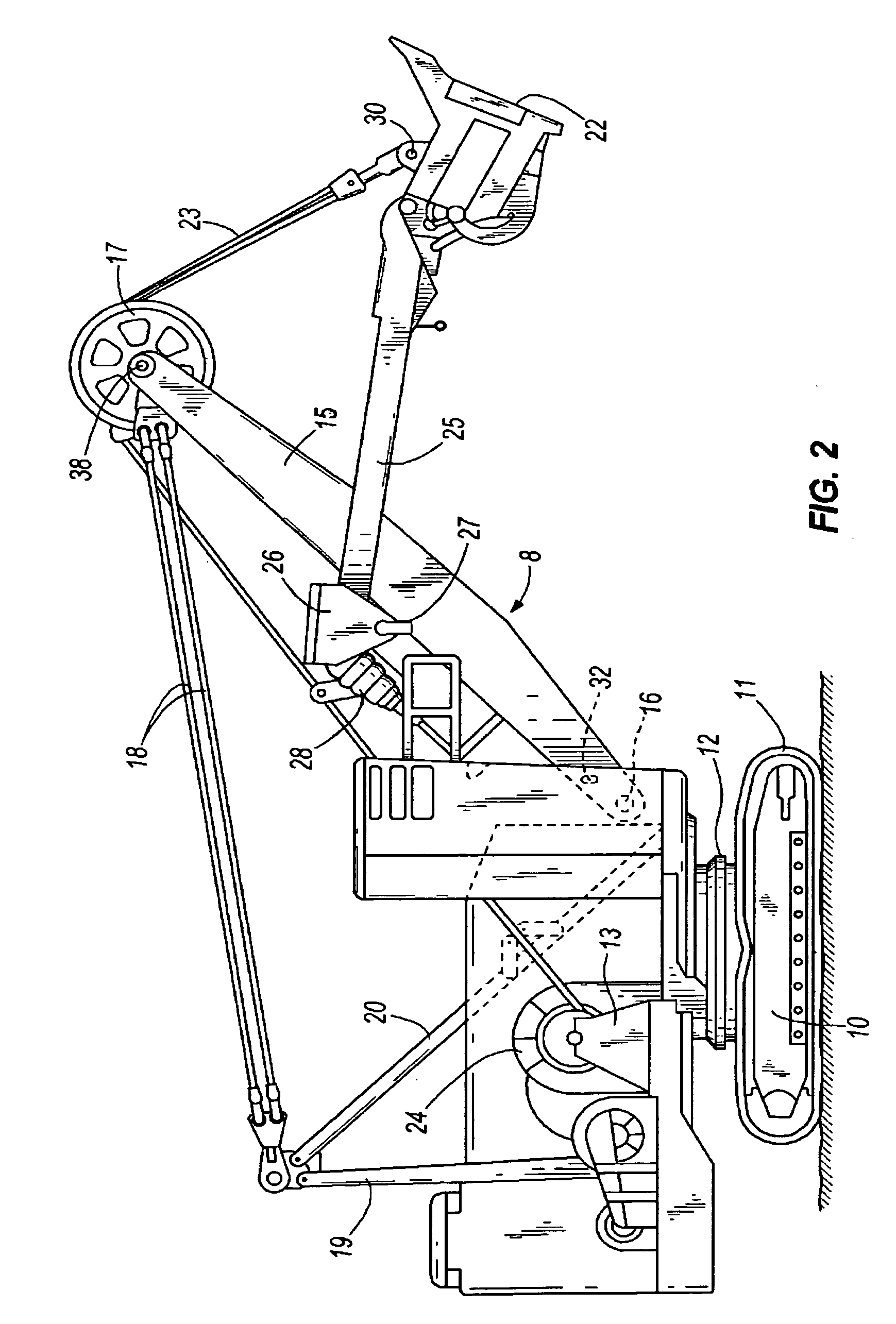

[0024]As described below and as illustrated in the drawings, the invention is a machine for raising and lowering a load, such as a hoisting machine 8 including a device 22 supported from a structure. More particularly, the machine can be a piece of large mining machine or an industrial crane, or any device for lifting a load. In this detailed description, a power shovel is described, and the device 22 for holding the material to be lifted is a dipper.

[0025]The power shovel 8 of FIG. 2 is of a well-known construction commonly referred to as an electric rope shovel. The shovel 8 comprises a mobile base 10 supported on drive tracks 11, and having supported thereon through a turntable 12, a platform in the form of a machinery deck 13. The turntable 12 permits full 360 degrees of rotation of the machinery deck relative to the base. A boom 15 is pivotally connected at a lower end 16 to the machinery deck 13. The boom 15 is held in a upwardly and outwardly extending relation to the deck by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com