Calibrating device for fuel oil re-fuelling device and use method thereof

A technology for verification devices and fuel dispensers, applied in measuring devices, testing/calibration devices, instruments, etc., can solve the problems of large fuel dispenser error influence, fuel dispenser error influence, slow temperature response speed, etc., and achieve actual measurement accuracy High, less error factors, simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to illustrate the present invention in detail, the present invention will be further described in detail below in conjunction with specific implementation examples, but the described examples should not be interpreted in a limiting manner.

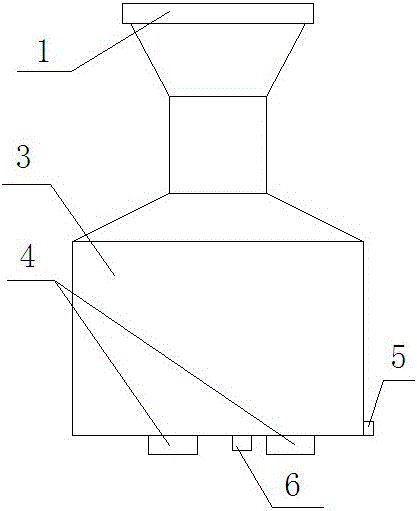

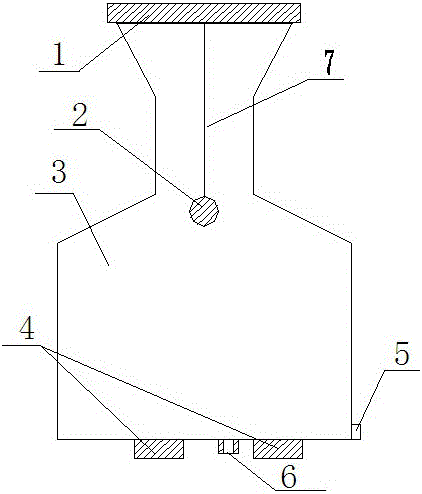

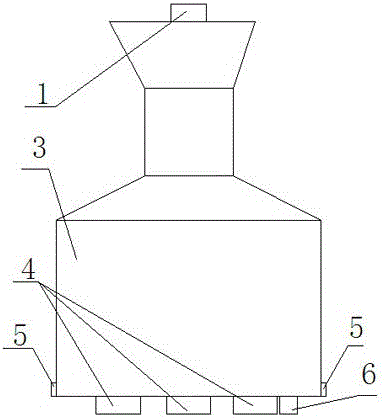

[0035] From Figure 1-Figure 4 It can be seen that the present invention contains a tank body 3, a tensile load sensor 1, a solid standard metal ball 2 of known volume, a gravity load sensor 4, a horizontal bubble 5, a drain hole 6, a gravity load sensor 4 and a drain hole 6 It is arranged at the bottom of the tank body 3, the horizontal bubble 5 is arranged on the lower side wall of the tank body 3, the tensile load sensor 1 is installed on the upper cover of the tank body 3, and the solid standard metal ball 2 is located in the inner cavity of the tank body 3, and passes through Thin nylon wire 7 is suspended on the tensile load sensor 1 .

[0036] There are three gravity load sensors 4, which are evenly distributed on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com