Three-dimensional point coordinate measuring method and measuring apparatus thereof

A coordinate measurement and three-dimensional coordinate technology, applied in the field of precision measurement, can solve the problems of inability to detect shading parts, low flexibility, and high cost, and achieve the effects of expanding the measurement range, small size, and flexible and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

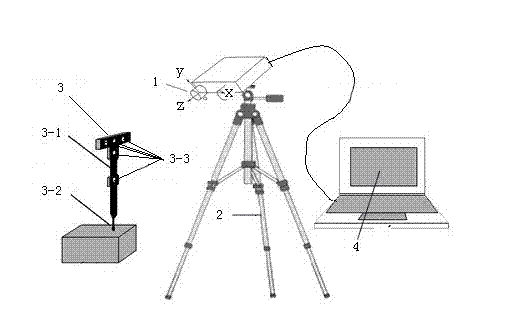

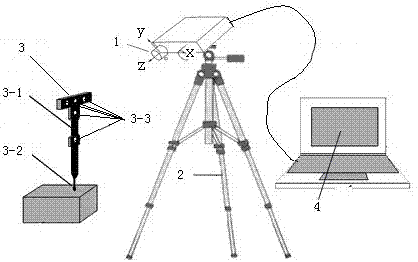

[0024] A method for measuring three-dimensional point coordinates, the method is to contact the measured point with the measuring probe, two CCD cameras collect the image information of the measuring probe, and determine the three-dimensional point coordinates of the measured point through the supporting computer software, the method is realized through the following steps :

[0025] (1) Establish a camera coordinate system. For two fixed CCD cameras, use the camera self-calibration algorithm to calculate the internal parameters of the camera and the relative orientation of the two cameras, thereby establishing the camera coordinate system.

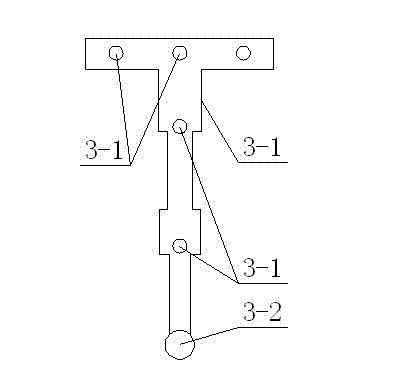

[0026] ⑵. According to the binocular stereo vision matching algorithm, calculate the three-dimensional coordinates of a set of marker points Pg1-PgN fixedly set on the measuring probe at the time of measurement in the camera coordinate system coordinate system, and use the principle of beam adjustment to calibrate the measuring probe. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com