Focusing and leveling detection device and method

A technology of focusing, leveling, and detecting device, which is applied to exposure devices for photoengraving processes, microlithography exposure devices, etc., can solve the problems of low measurement accuracy and small measurement range, and achieves improved measurement accuracy, convenient operation and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

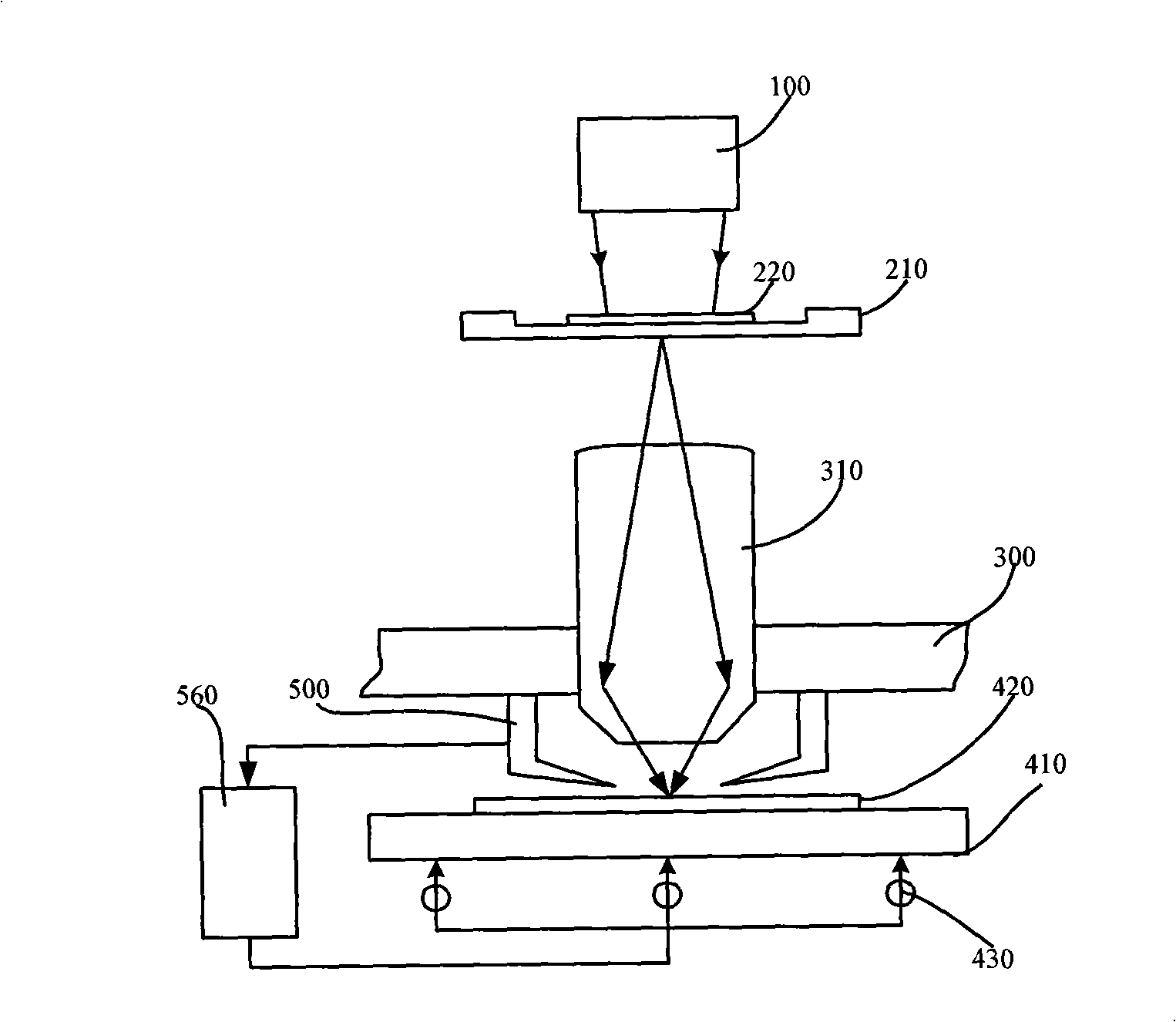

[0042] figure 2 It is a schematic diagram of the plane principle of the optical exposure system. Under the illumination of the illumination system 100 , the light source projects and exposes the image on the mask 220 onto the silicon wafer 420 through the projection objective lens 310 . Mask 220 is supported by mask stage 210 , and silicon wafer 420 is supported by work stage 410 . figure 2Among them, there is a silicon wafer focusing and leveling detection device 500 between the projection objective lens 310 and the silicon wafer 420. This device is rigidly connected with the projection objective lens 310 or the projection objective lens support 300, and is used to perform position information on the surface of the silicon wafer 420. Measurement, the measurement results are sent to the silicon wafer surface position control system 560, after signal processing and calculation of the focusing and leveling amount, the focusing and leveling actuator 430 is driven to adjust the...

Embodiment 2

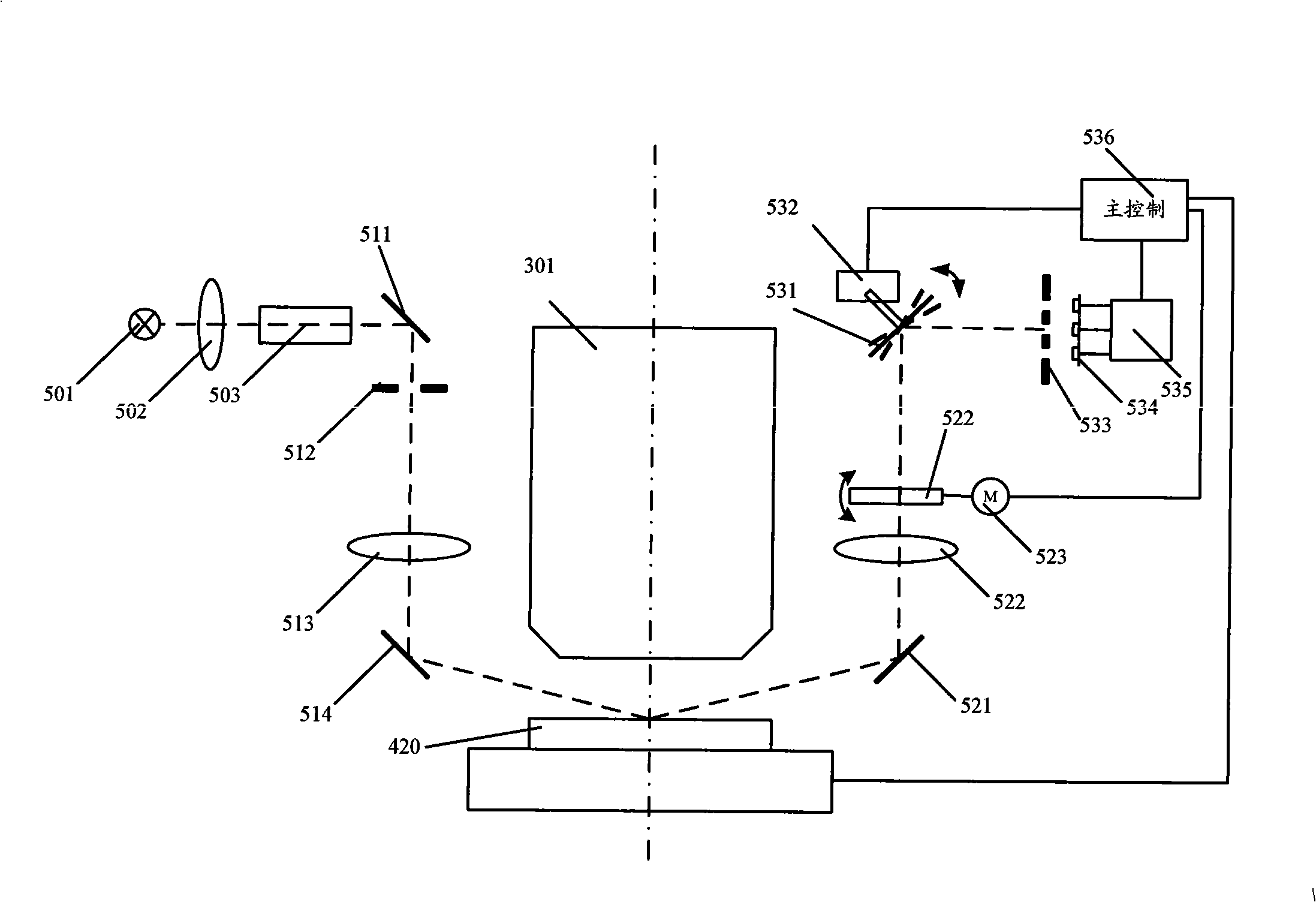

[0054] This embodiment has the same basic principle structure as that of the aforementioned Embodiment 1, except that the slits in the projection unit use a slit array, and the detection slits use a slit array. The details are as follows:

[0055] Figure 12 It is a schematic diagram of the overall structure of this embodiment. The difference from Embodiment 1 is that the slit 512 of the projection unit becomes a slit array of 513; the spot projected by the projection unit on the silicon wafer becomes a spot array 601; Some or all of the light spots have a one-to-many relationship with the detection slit array 537 and the photodetector array 538.

[0056] Figure 13 It is a schematic diagram of signal crosstalk of multiple photodetectors. This embodiment adopts a multi-point arrangement, and if the distance between the light spots is small, signal crosstalk may occur. If the distance between the light spots is small, when the defocus amount of the silicon wafer is large, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com