Patents

Literature

54results about How to "Reduce weighing errors" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

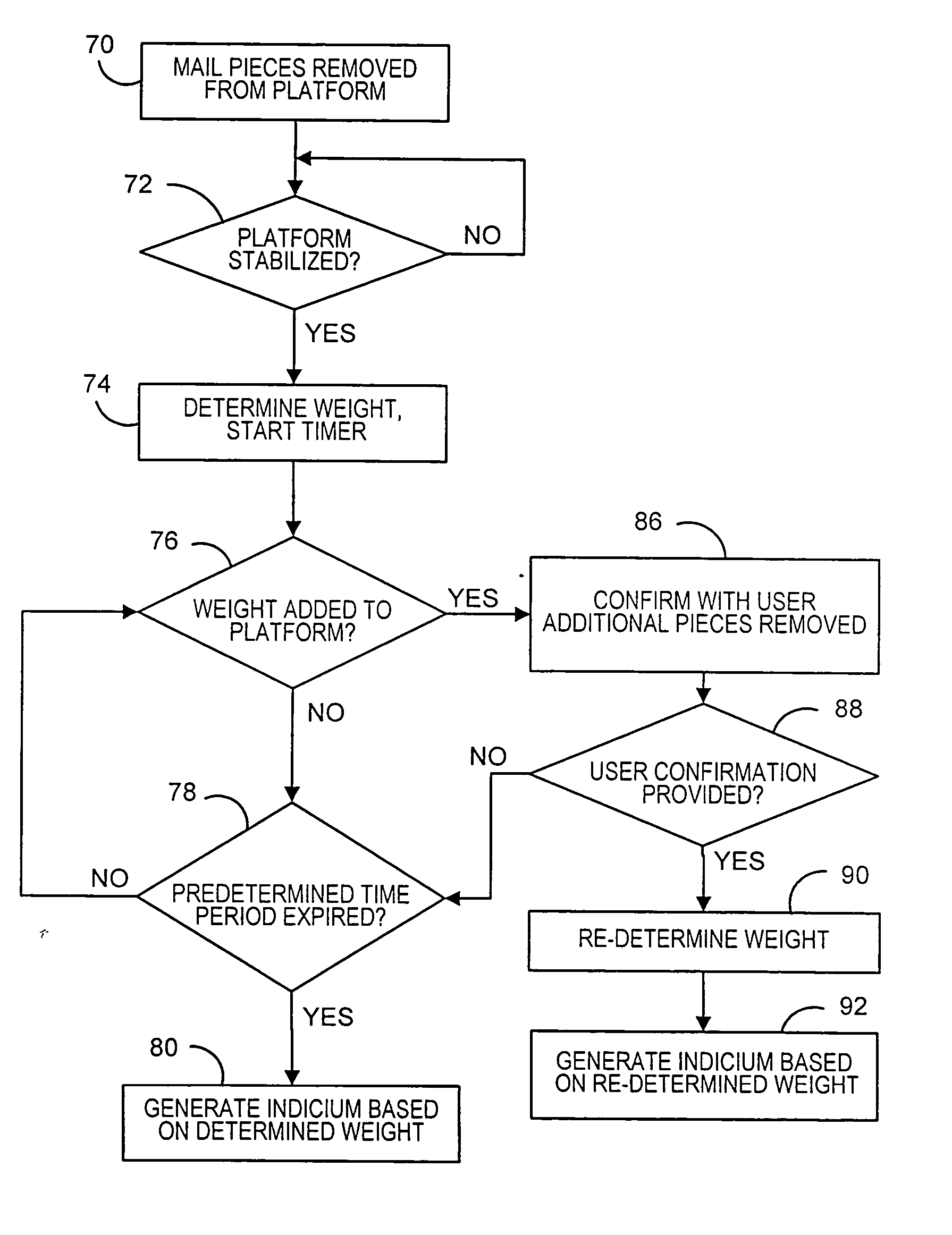

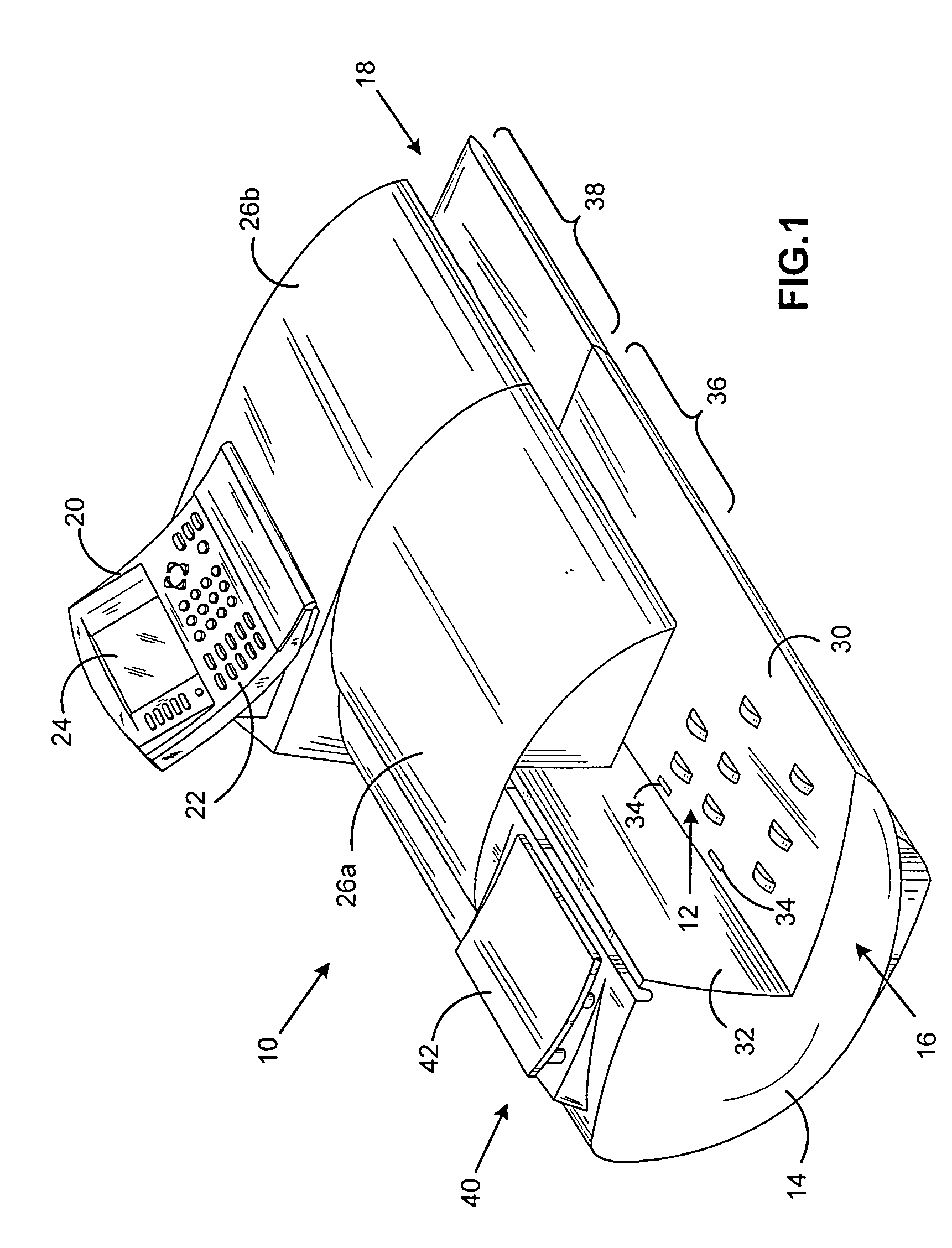

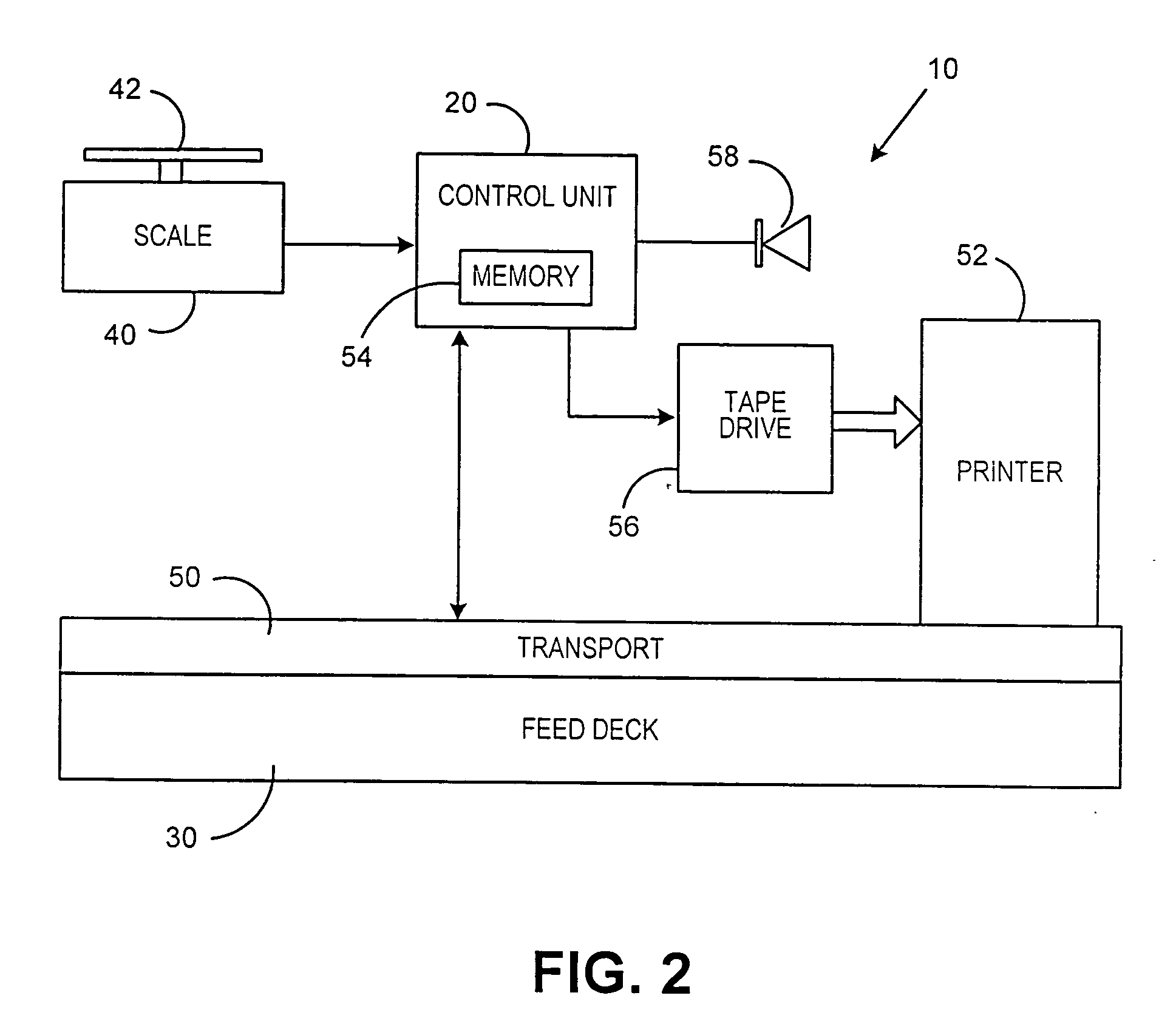

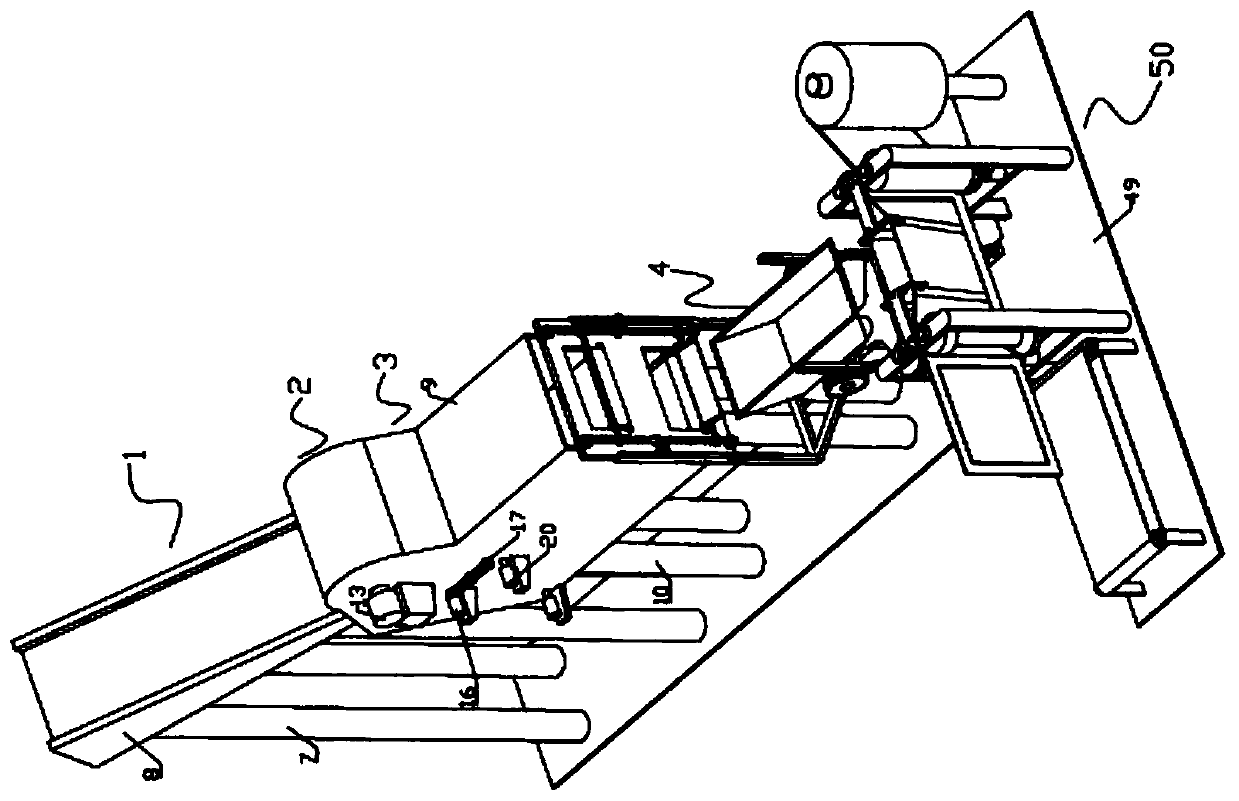

Mailing machine including methods and systems to reduce weighing errors when operating in a differential weighing mode

ActiveUS20050278264A1Reduce feedingReduce weighing errorsFranking apparatusSpecial data processing applicationsEngineeringDevice Sensor

A mailing machine is provided, that when operating in a differential weighing mode, can detect if a user has replaced one or more mail pieces that may have been inadvertently removed at the same time back onto the scale. If the mailing machine detects such replacement within a predetermined time period after the scale has stabilized, the weight calculated for the mail piece can be reduced by the amount added back to the scale, or alternatively the user could be requested to confirm that multiple pieces were inadvertently removed from the scale at the same time and the user is trying to correct that error and a new weight determined.

Owner:PITNEY BOWES INC

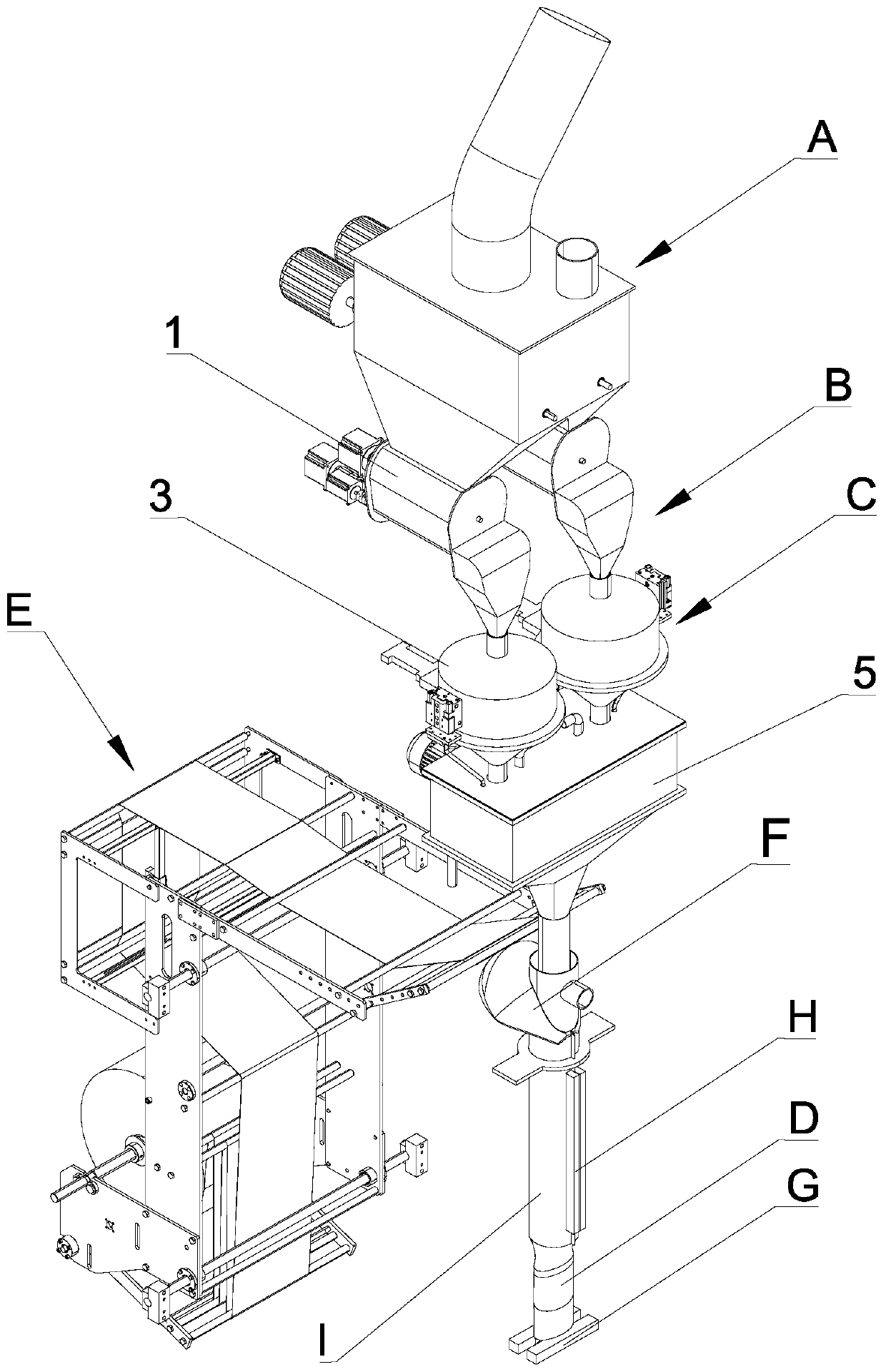

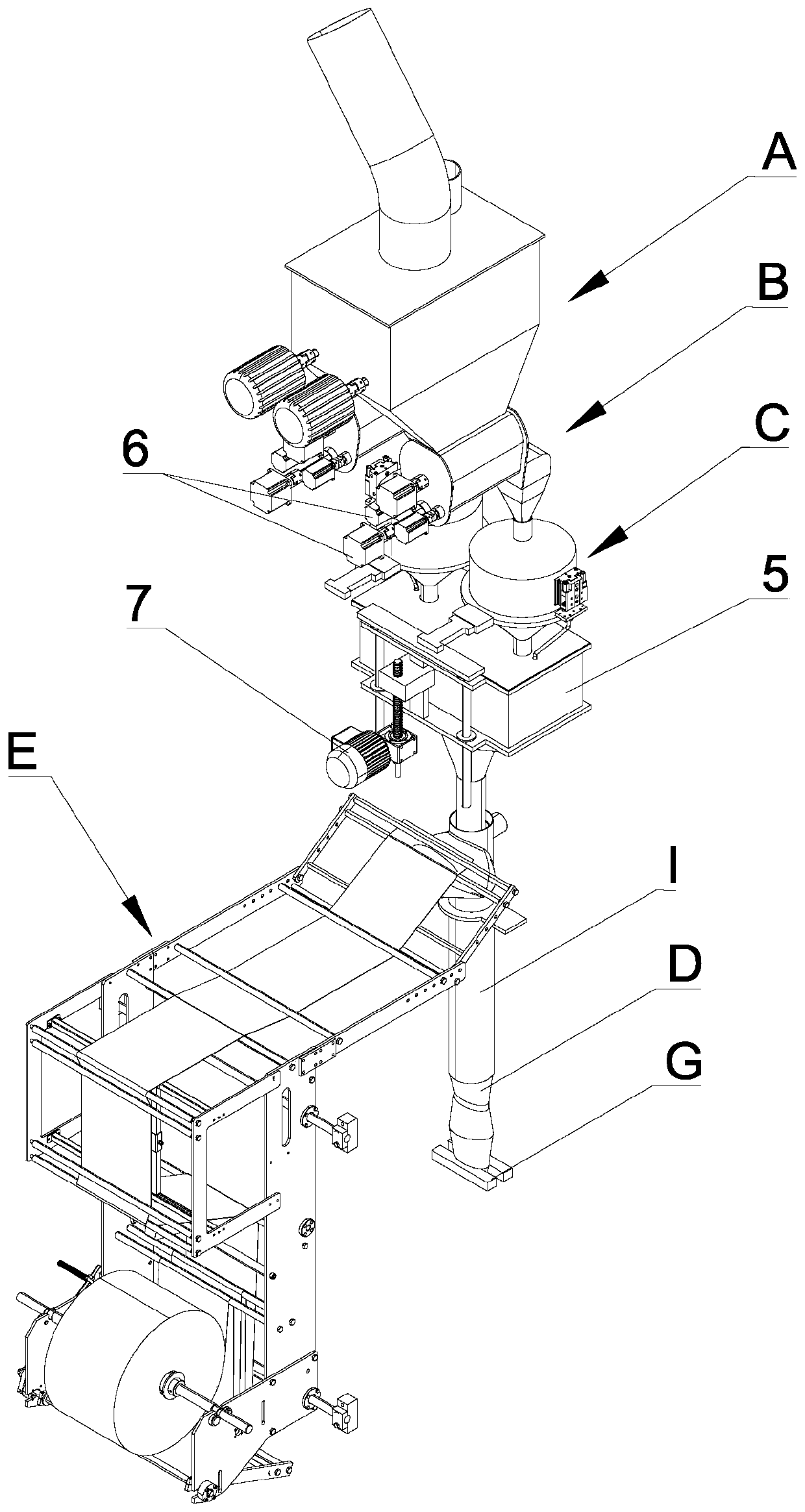

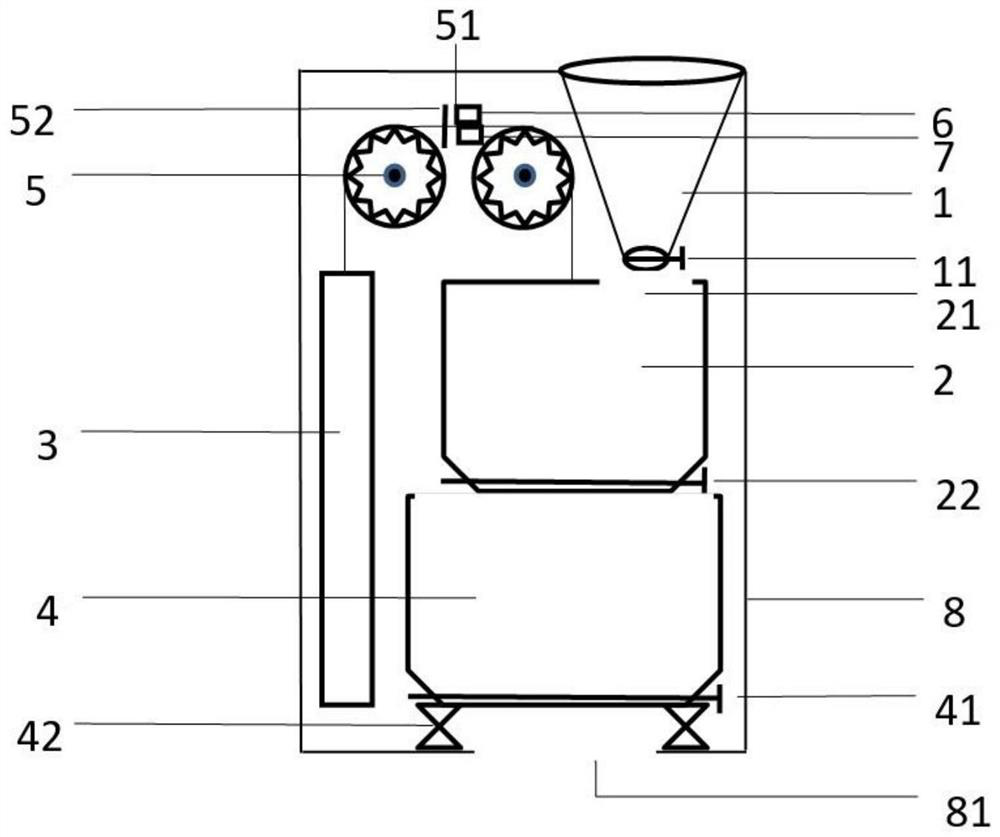

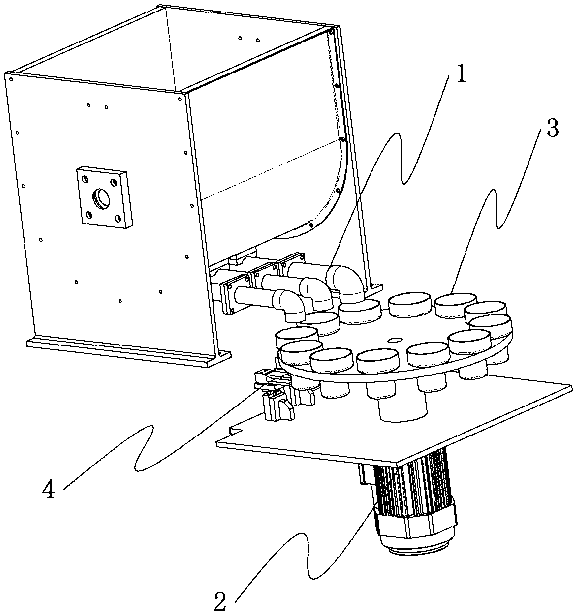

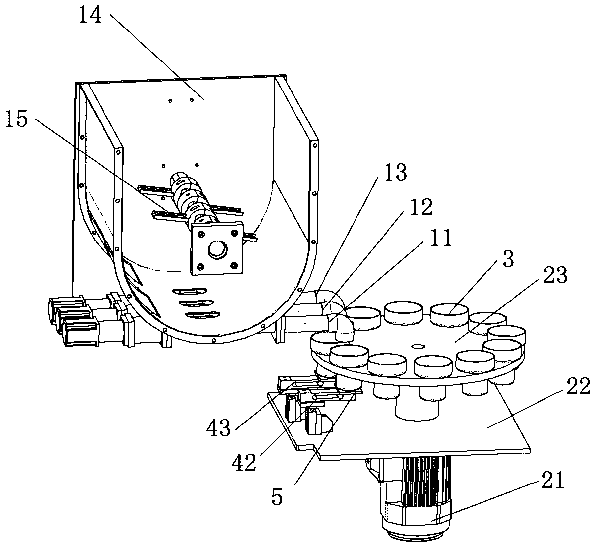

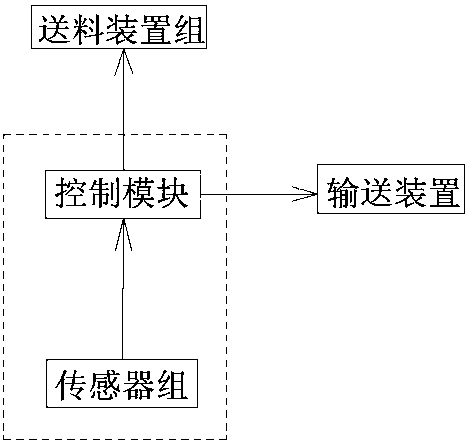

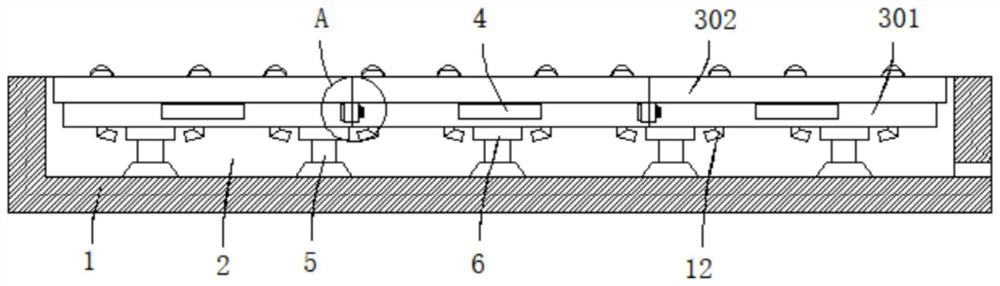

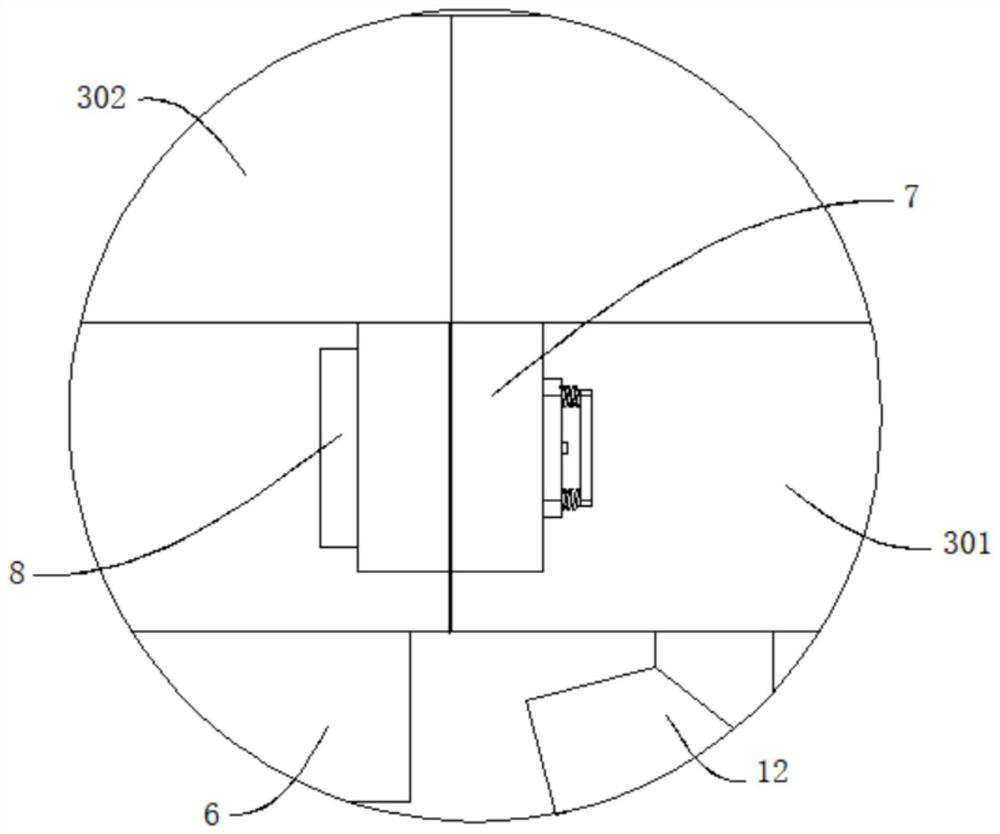

Food precise quantifying and packing production line

ActiveCN110920967AReduce weighing errorsWrapper twisting/gatheringSolid materialBiotechnologyProduction line

Owner:芜湖市智行天下工业设计有限公司

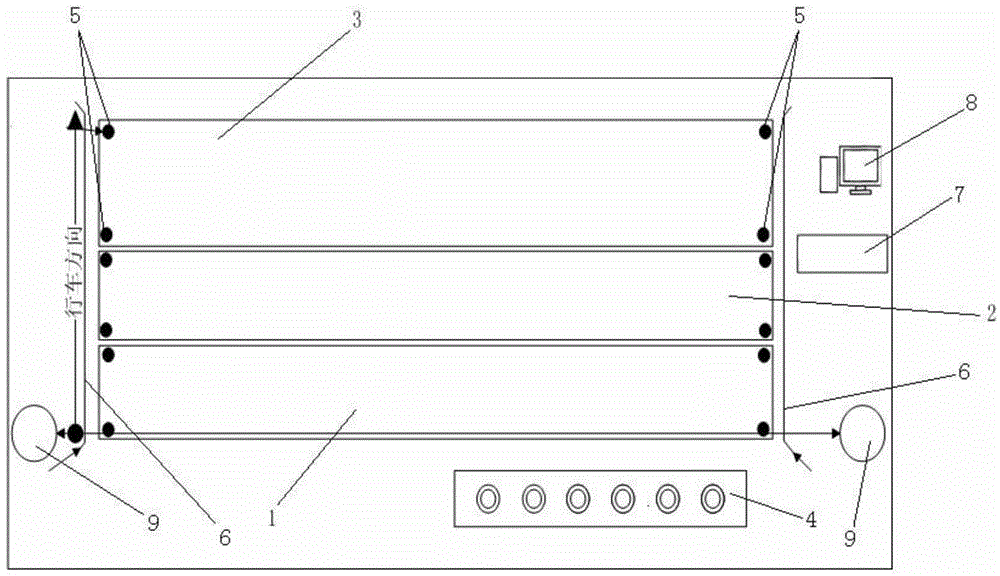

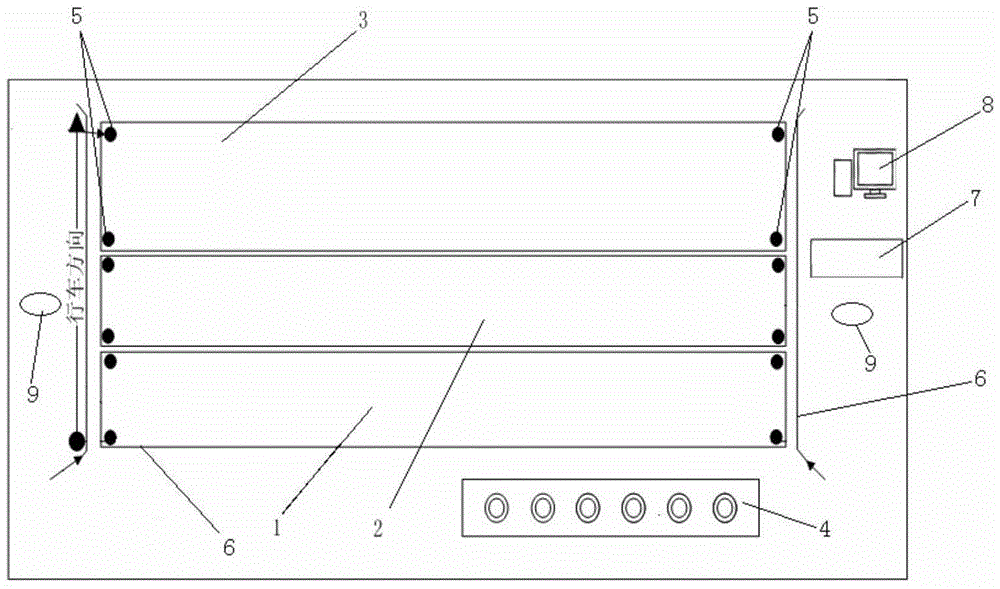

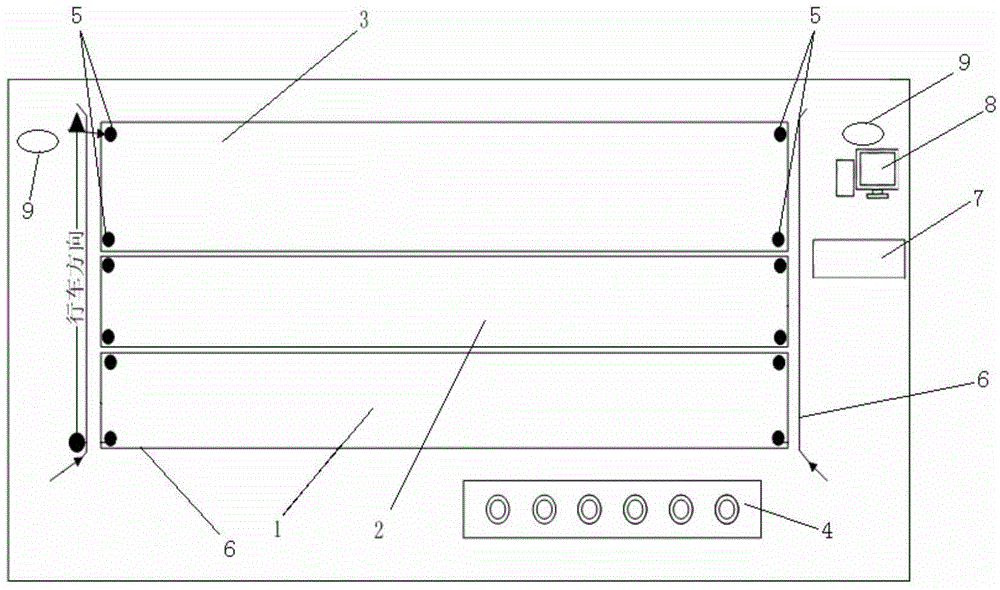

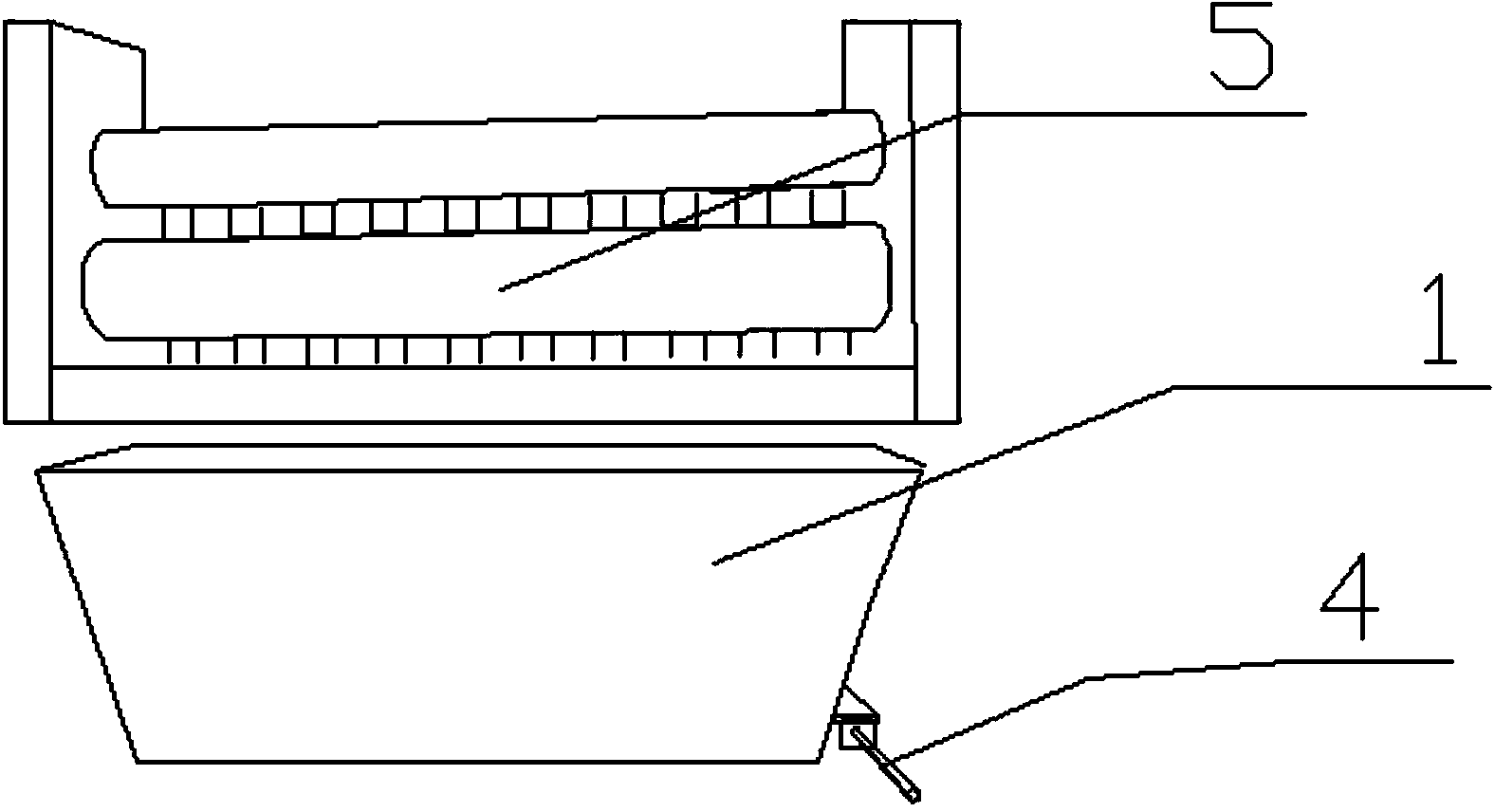

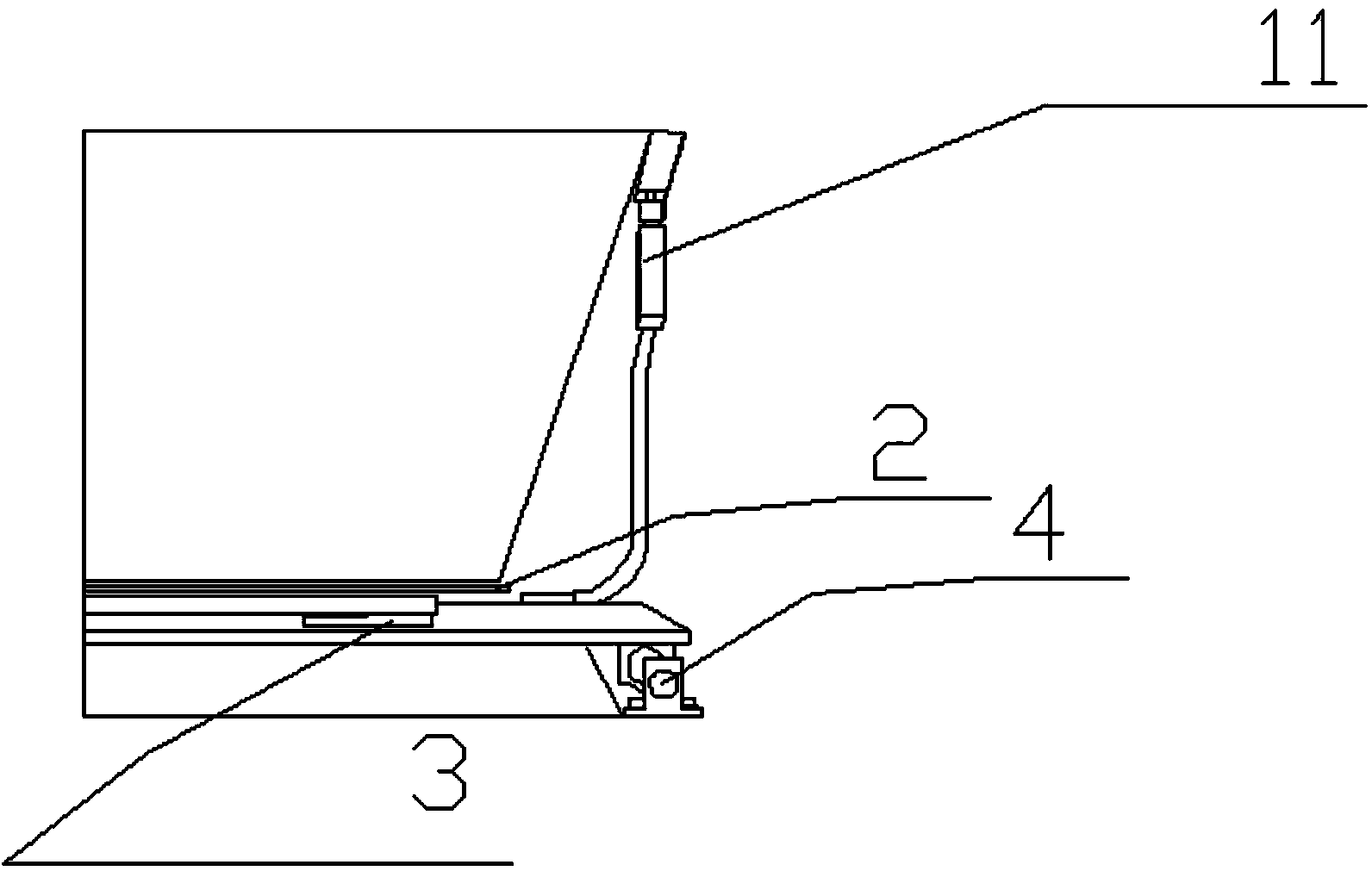

Novel multi-platform-surface dynamic weighing system

InactiveCN104359540AGuaranteed measurementIncrease widthSpecial purpose weighing apparatusMulti platformHigh velocity

The invention discloses a novel multi-platform-surface dynamic weighing system. The novel multi-platform-surface dynamic weighing system comprises a vehicle separator, a tire identifier, a scale body, signal acquisition equipment, signal processing equipment, a first scale platform, a second scale platform and a third scale platform, wherein the first scale platform, the second scale platform and the third scale platform are sequentially arranged abreast along the driving direction; the vehicle separator is used for separating vehicles; the tire identifier is arranged in front of the first scale platform or behind the third scale platform, and the vehicles pass through the tire identifier and the vehicle separator. Due to the adoption of the structure in which the three scale platforms are arranged abreast, the length of the three-scale-platform weighing system is increased compared with a single-scale-platform weighing system and a double-scale-platform weighing system, the staying time of the vehicles on the scale platforms is prolonged, and the influence on weighing errors caused by non-standard vehicle passing behaviors such as S-type passing of the vehicles, jumping of the vehicles over the scale platforms and high-speed passing of the vehicles through the scale platforms can be eliminated.

Owner:重庆市华驰交通科技有限公司

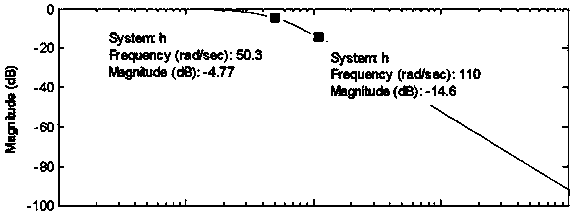

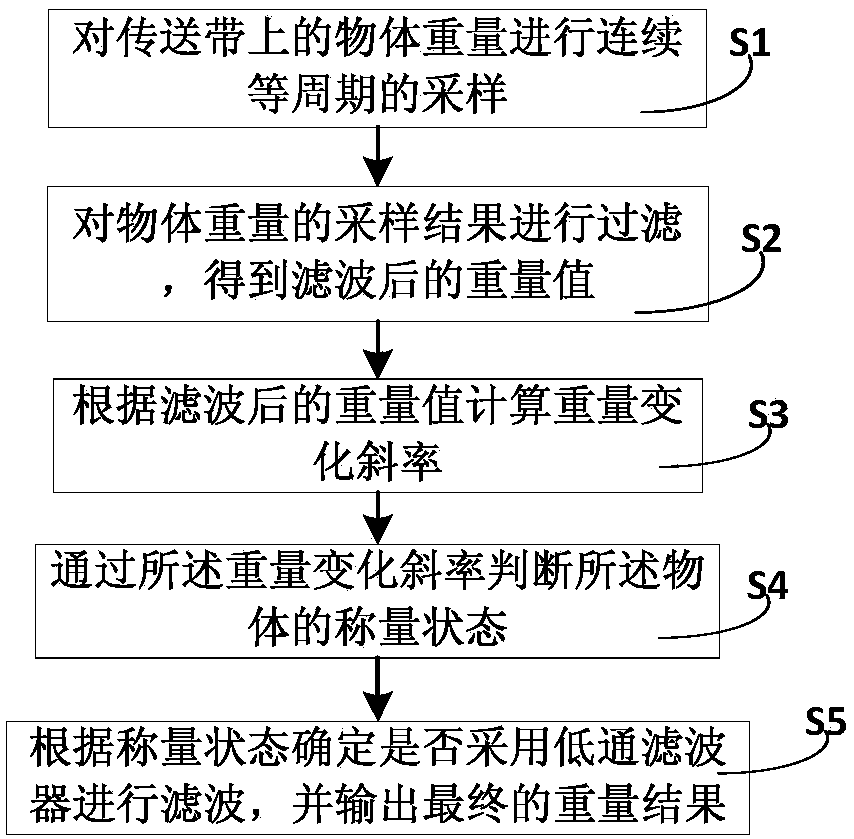

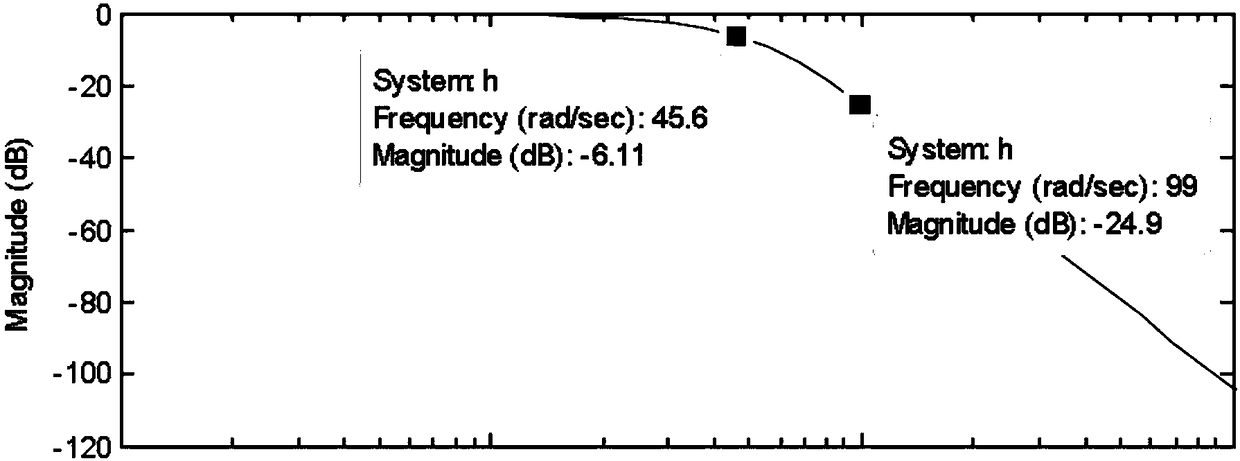

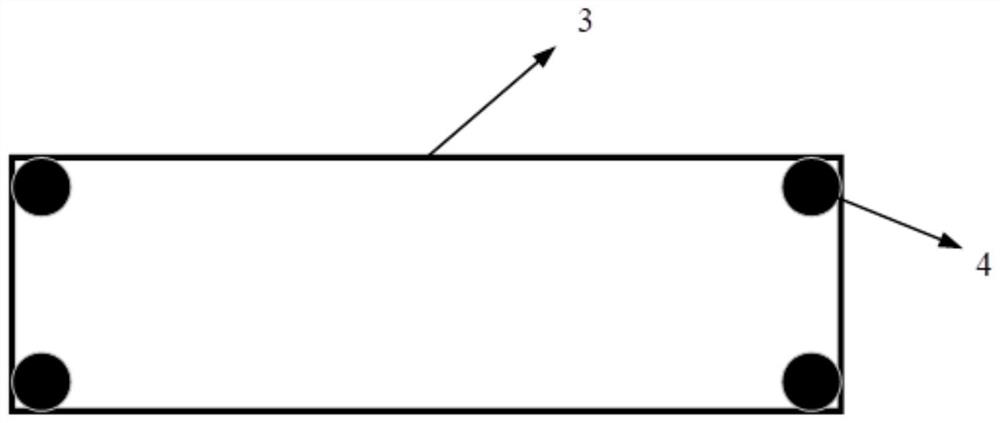

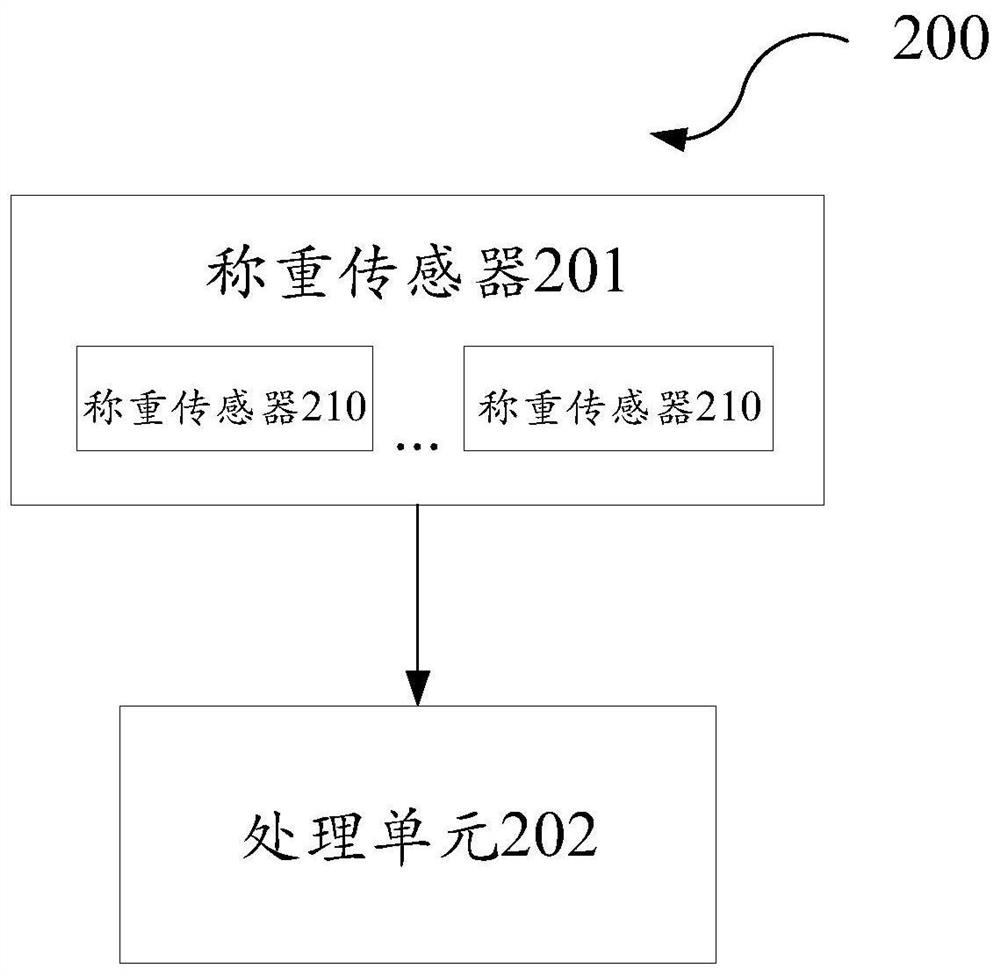

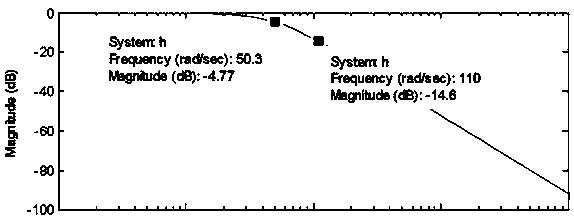

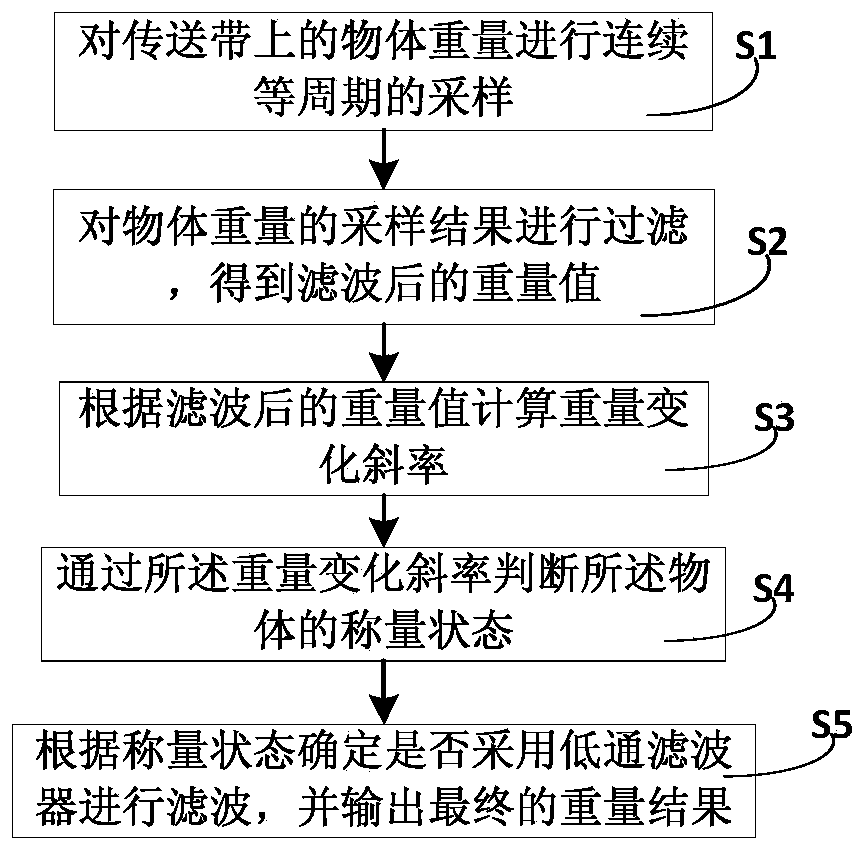

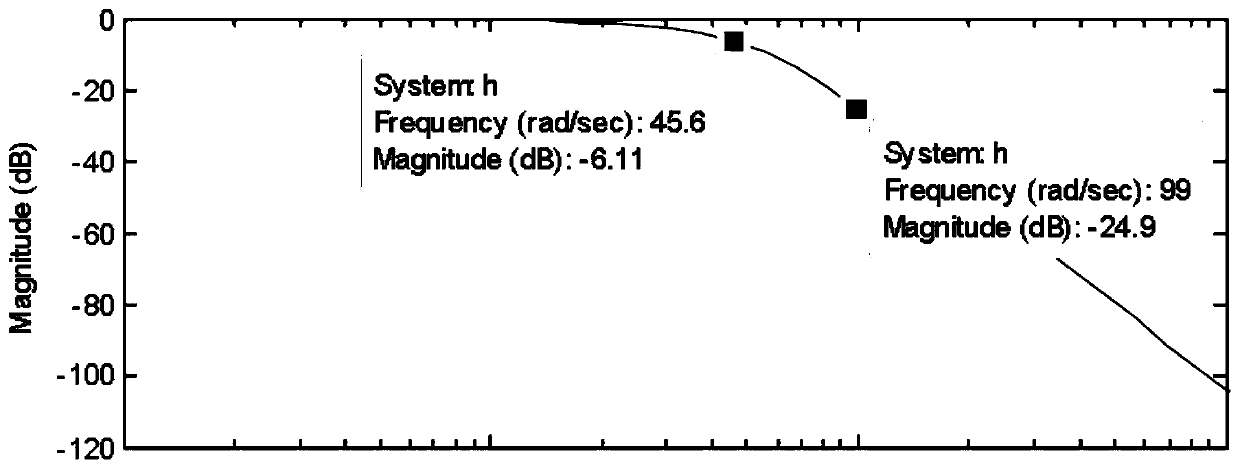

Dynamic weighing filtering method and system thereof

ActiveCN108168680AReduce vibration and noiseReduce weighing errorsWeighing apparatus testing/calibrationLow-pass filterWeight change

The invention provides a dynamic weighing filtering method and system thereof. The dynamic weighing filtering method comprises the following steps that step S1, continuous and equal-period sampling isperformed on the object weight on a conveying belt; step S2, the sampling result of the object weight is filtered so as to obtain the filtered weight value; step S3, the weight change slope is calculated according to the filtered weight value; step S4, the weighing state of the object is judged by the weight change slope; and step S5, whether a low-pass filter is applied to perform filtering is determined according to the weighing state and the final weight result is outputted. The movement characteristics of the object on the conveying belt can be met and the vibration noise and the weighingerror caused by movement of the object on the conveying belt can be effectively reduced; and the filtering process is fast in speed and high in accuracy, filtering is smooth and transition is stableso that the dynamic weighing process is enabled to be more stable and reliable and the accuracy and the working efficiency of dynamic weighing can be greatly enhanced.

Owner:深圳市美新特智能装备有限公司

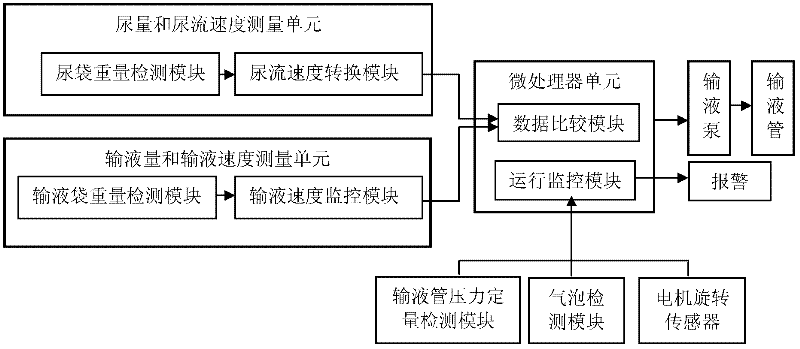

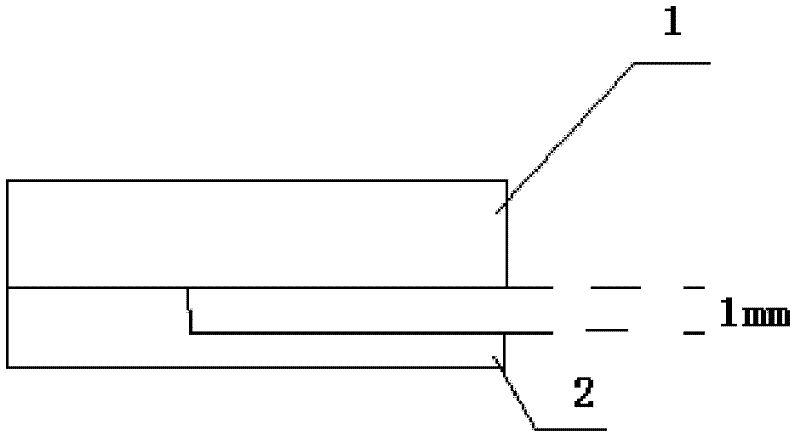

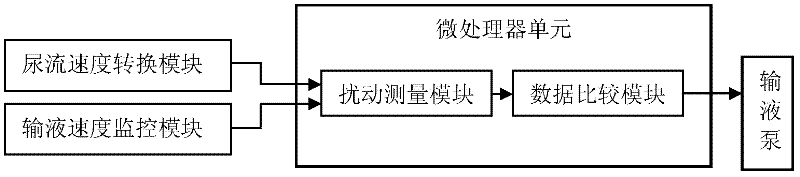

Infusion control system and method for adjusting infusion amount based on urine output

InactiveCN102366645AAvoid the problem of not being able to detect the flow rate of urineAvoid permanent damageFlow monitorsHuman–machine interfaceControl system

Owner:冯新庆

Dynamic weighing and sorting integrated device for logistics

Owner:XUZHOU UNIV OF TECH +1

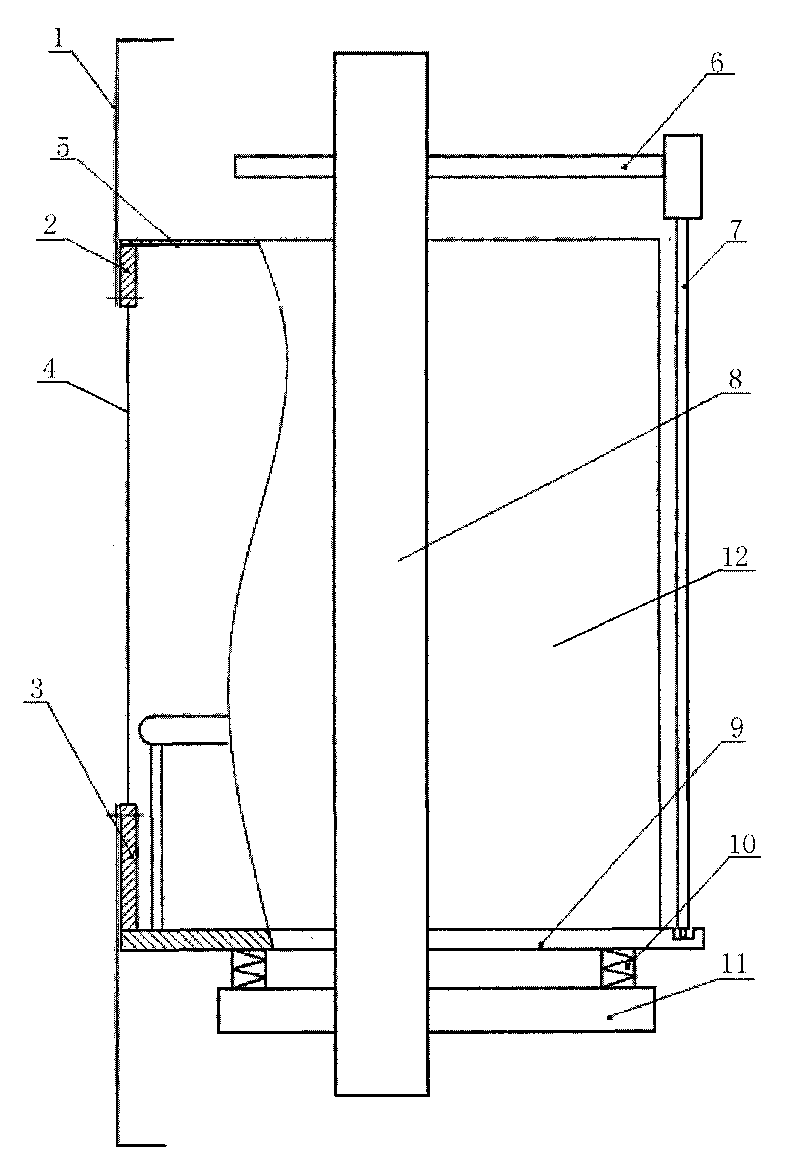

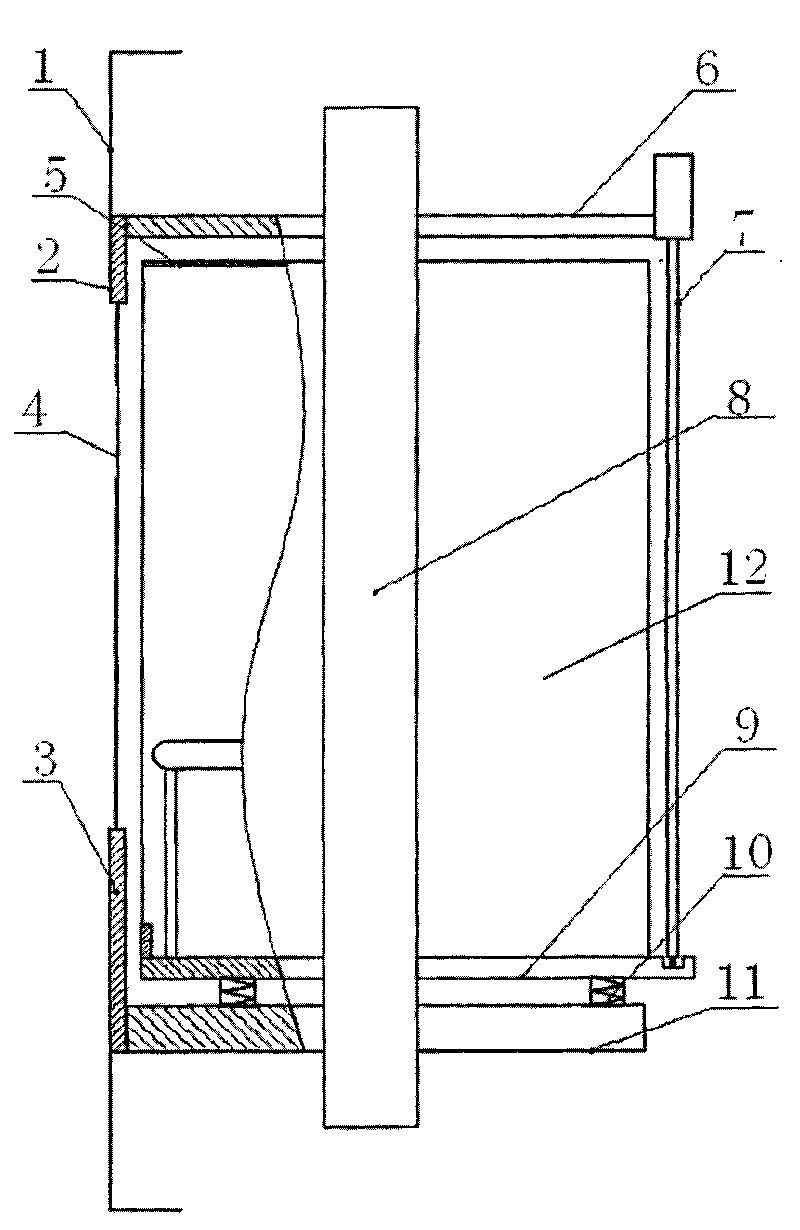

Sightseeing elevator cage

InactiveCN101717031AEasy to installMeet the installationBuilding liftsAgricultural engineeringEngineering

A sightseeing elevator cage comprises a cage and a frame, wherein the cage is arranged on the bottom frame of the frame, an elastic weighing device is arranged between the cage and the bottom frame, and an outer cover is arranged on the frame at the rear wall of the cage; the frame comprises the bottom frame, an upright post and a mounting frame, wherein the bottom frame and the mounting frame are rigidly connected through the upright post; the outer cover is fixed on the mounting frame and the bottom frame; and the outer cover is connected with the mounting frame and the bottom frame through connecting pieces. Compared with the prior art, the sightseeing elevator cage has the advantages of simple and convenient mounting, field mounting quality improvement, high mounting strength, good stability, capability of meeting the requirements on installation of the complex outer cover, reduction in weight of the sightseeing side of the cage, capability of balancing the compression amount of weighing rubber, weighing error reduction and good weighing effect.

Owner:HITACHI ELEVATOR CHENGDU

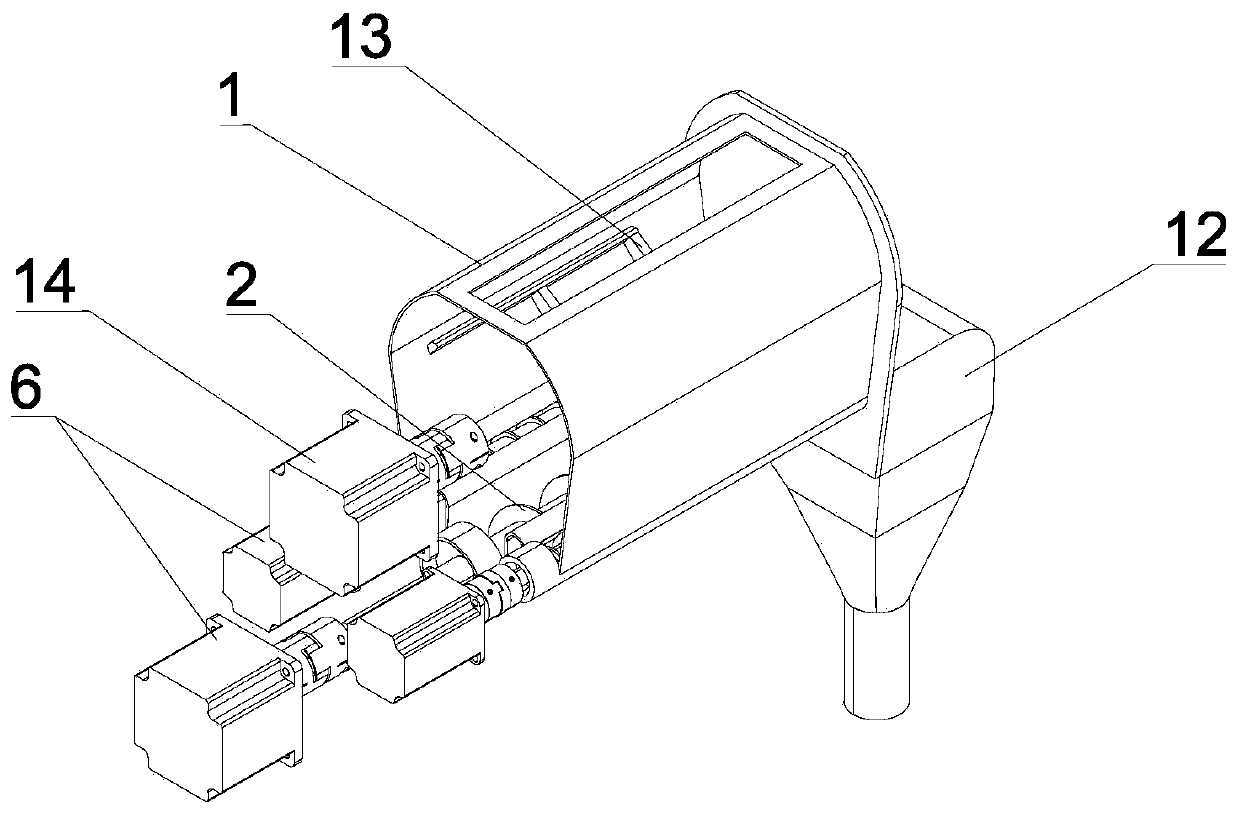

High-speed and precise packaging machine

PendingCN110356636AImprove pass rateGuaranteed accuracySolid materialEnvironmental resistanceSocial benefits

The invention discloses a high-speed and precise packaging machine. The machine comprises weighing units and a packaging unit, wherein the weighing units are multiple; each weighing unit comprises a feeding mechanism and a weighing mechanism, the feeding mechanism comprises a packaging hopper and a plurality of spiral feeding rods with different sizes, the weighing mechanism comprises weighing hoppers and a weighing module, and the weighing hoppers are arranged below a feeding opening of the feeding mechanism; the packaging unit is positioned below the weighing units and comprises material bags used for packaging materials; and middle transition hoppers are arranged between the weighing hoppers and the material bags, discharging openings of the multiple weighing hoppers extend into upper openings of the middle transition hoppers, and discharging controlling mechanisms for controlling opening and closing of the discharging openings are arranged on the weighing hoppers. According to themachine, the precision, the accuracy, the stability and the production efficiency of material packaging are greatly improved, so that huge social benefits are brought to multiple aspects such as energy conservation and consumption reduction, manpower and material resource saving, environmental protection and safety.

Owner:李宝婕

Catalytic complex for preparing isocyanurate foam from bagasse ployol

The invention relates to a catalytic complex for preparing isocyanurate foam from bagasse ployol comprising the constituents (by mass ratio) of solvent 100 parts, foaming catalyst 0-20 parts, chain growth catalyst 1-15 parts and foam stabilizer 15-60 parts. The catalytic compound is suitable for the water foaming system of cane trash polyhydric alcohols, the reaction speed can be regulated well.

Owner:GUANGZHOU INST OF GEOCHEMISTRY - CHINESE ACAD OF SCI

Vacuum packing machine with interior scale

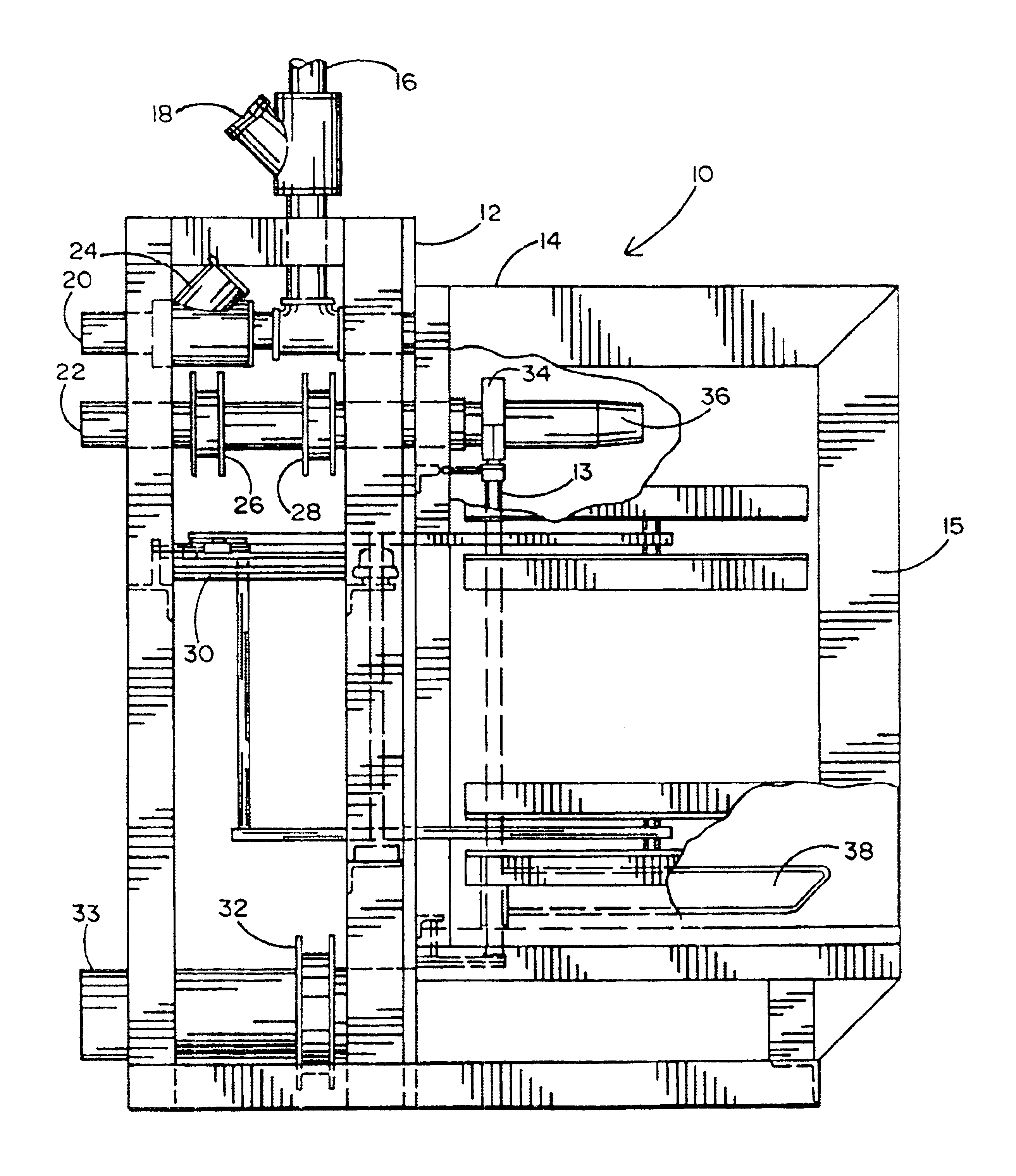

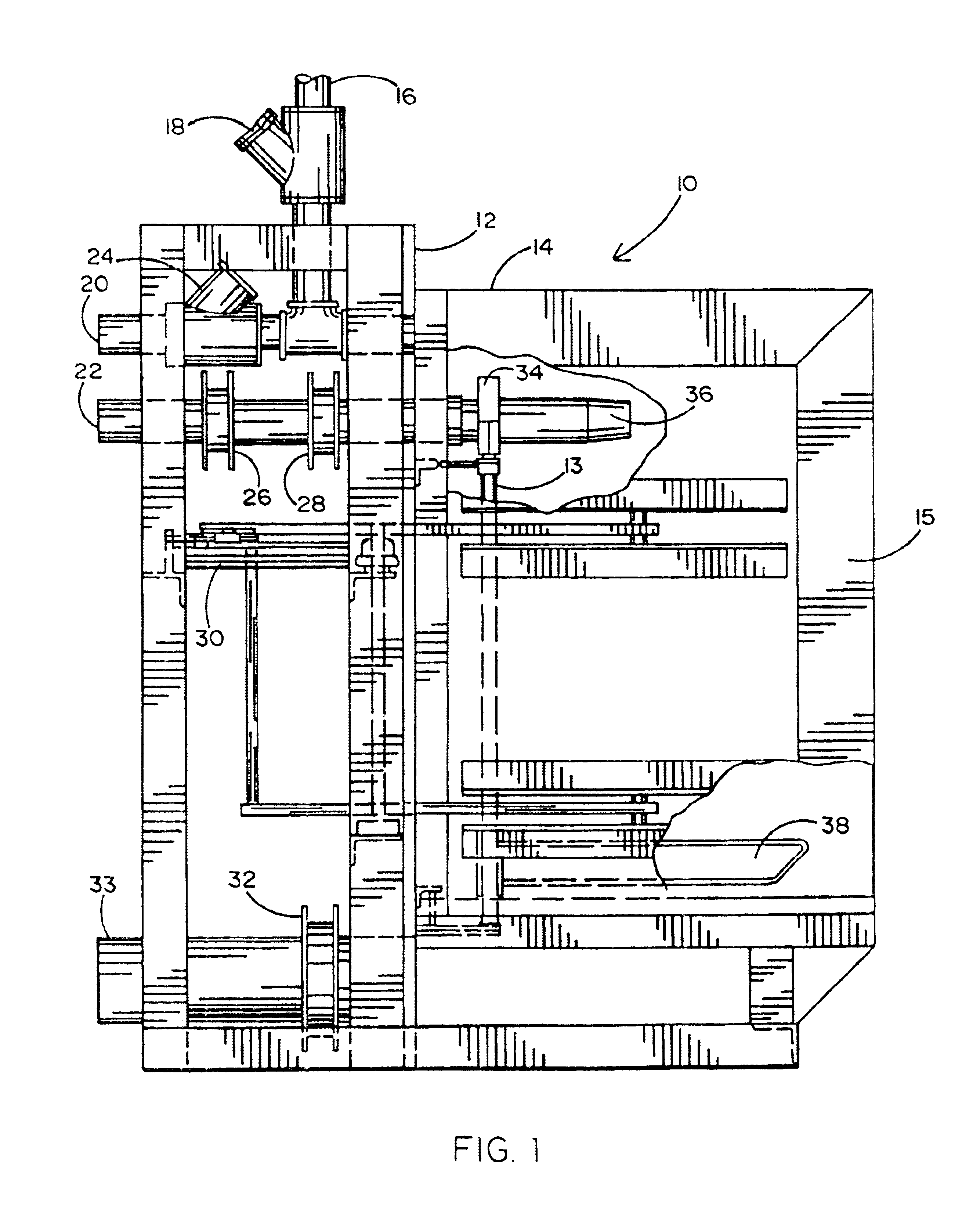

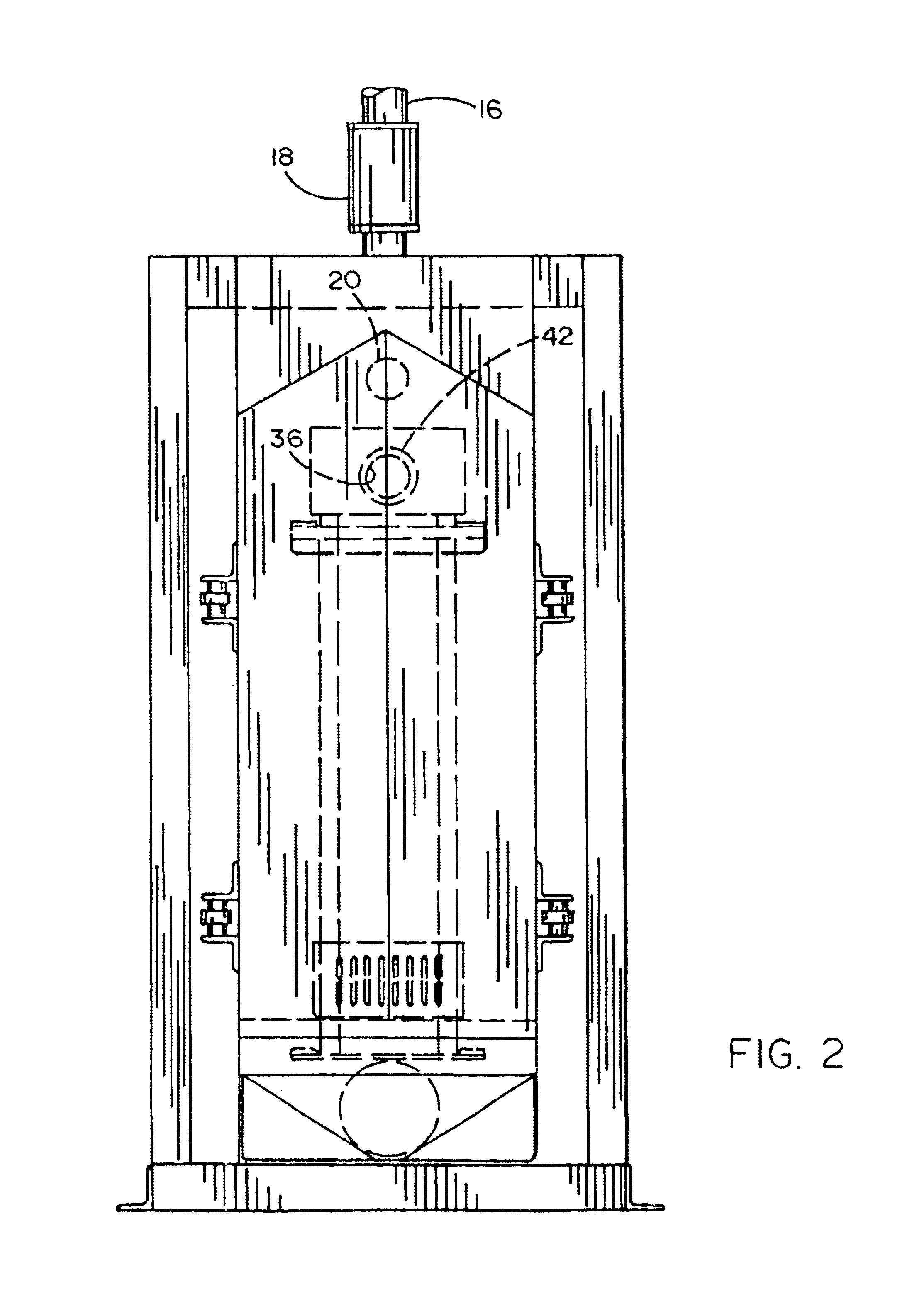

InactiveUS6874548B1Exclude influenceReduce weighing errorsPackaging under vacuum/special atmosphereSolid materialEngineeringLoad cell

A vacuum packer for filling valve bags employs a load cell-based scale mechanism located within the vacuum chamber. An interior packer front plate is supported from the back, inner wall of the chamber on four flexure spring check straps. The front plate is supported from a single load cell mounted on the back, interior wall of the vacuum chamber. Side bag retention plates, end retention plates and the lower bag support saddle are mounted to the packer front plate. A flexible connection is furnished between the back of the filling spout and the interior back wall of the vacuum chamber. All other required piping is made directly to the back wall of the chamber, thus removing them from the scale mechanism entirely.

Owner:DURANT WILL G

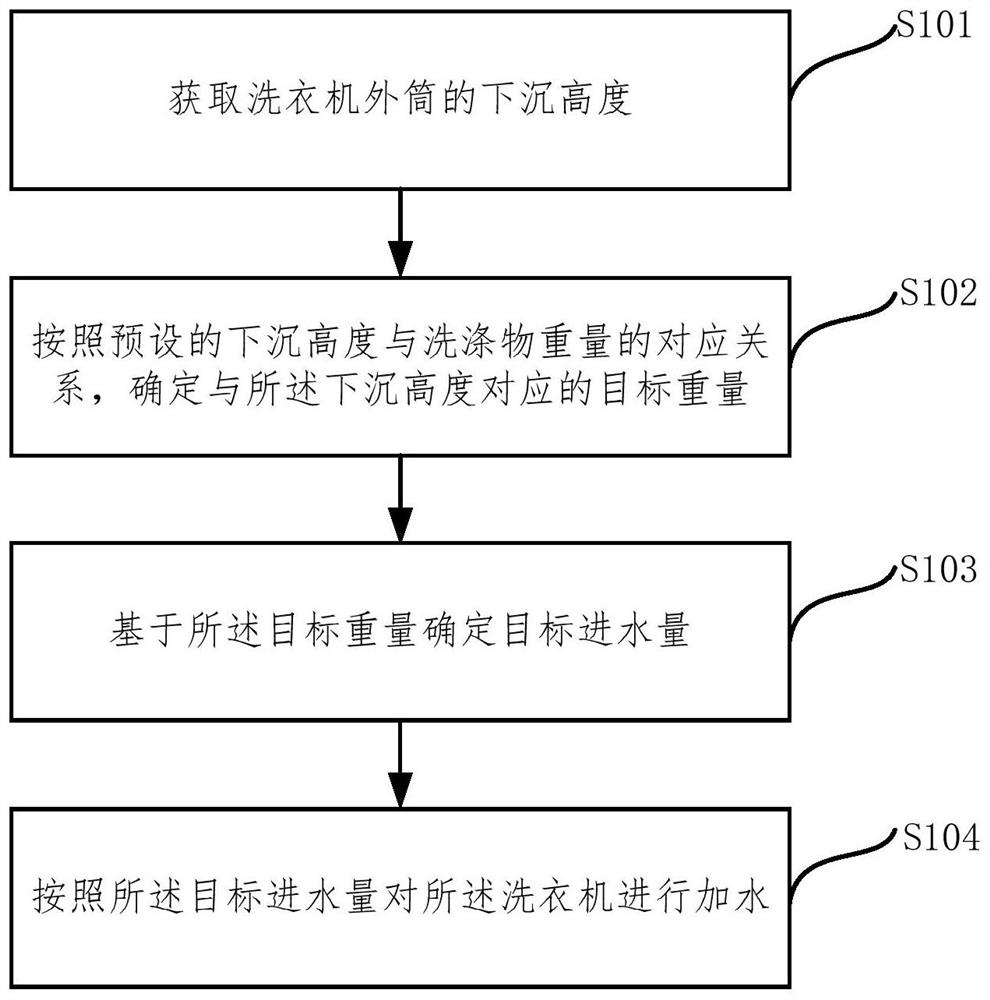

Washing machine control method and device, electronic equipment and storage medium

InactiveCN112899975AReduce weighing errorsAccurate weighing resultsControl devices for washing apparatusTextiles and paperLaundry washing machineElectric machinery

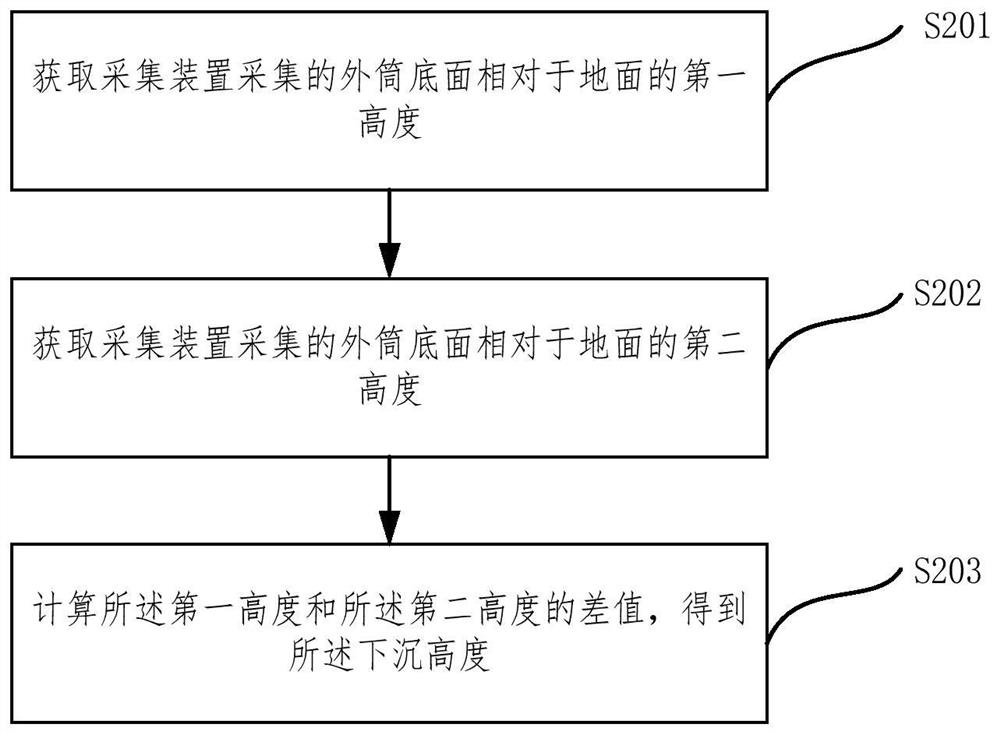

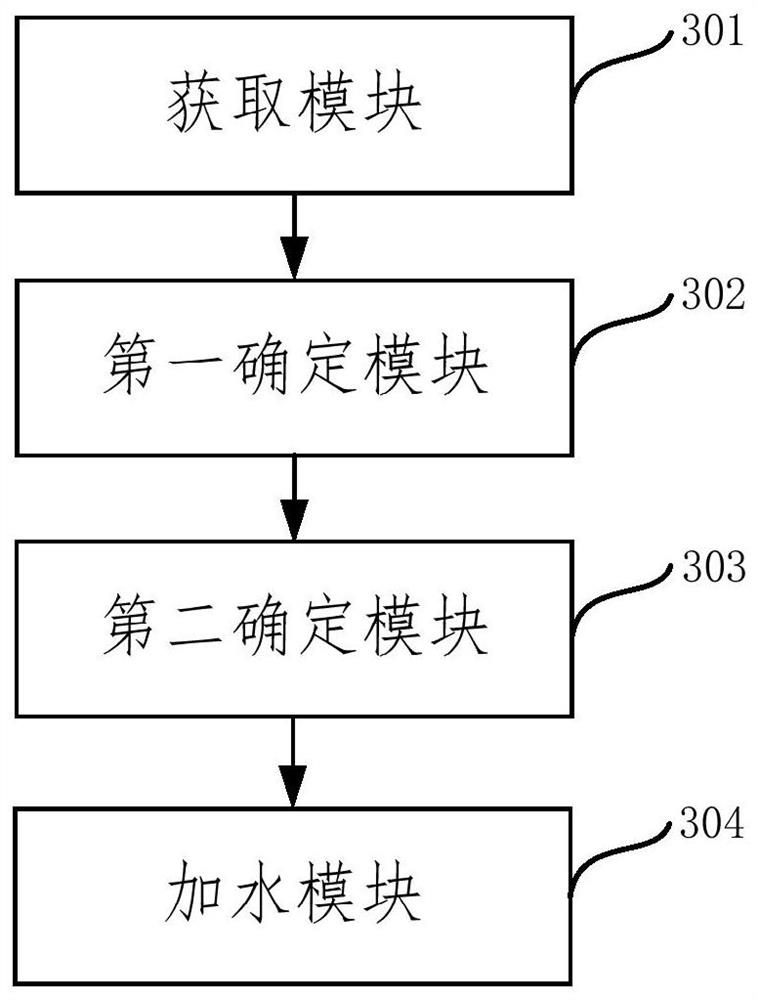

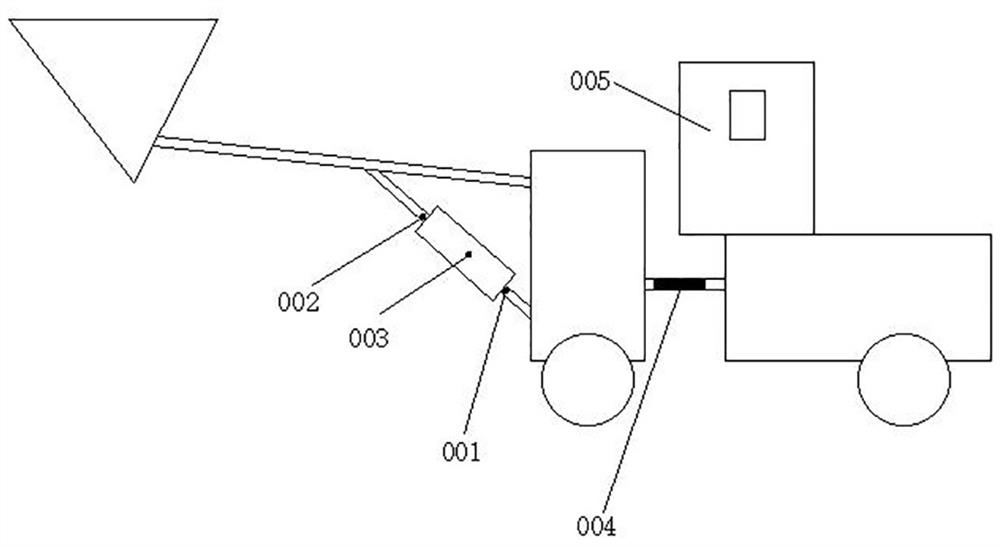

The invention provides a washing machine control method and device, electronic equipment and a storage medium, and belongs to the technical field of household appliances. The control method includes the following steps: obtaining a sinking height of an outer drum of a washing machine, wherein the sinking height is collected after washing is placed in the outer drum of the washing machine; determining a target weight corresponding to the sinking height according to a preset corresponding relation between the sinking height and the weight of the washing; determining target water inflow based on the target weight; and adding water to the washing machine according to the target water inflow. Namely, the weight of the washing is determined according to the sinking height of the outer drum of the washing machine after the washing is placed, and then the water inflow is determined according to the weight of the washing, so that a weighing result of the washing is not affected by the material of the washing, motor assembly and the like, the weighing error is reduced, and the weighing result is more accurate.

Owner:GREE ELECTRIC APPLIANCES INC

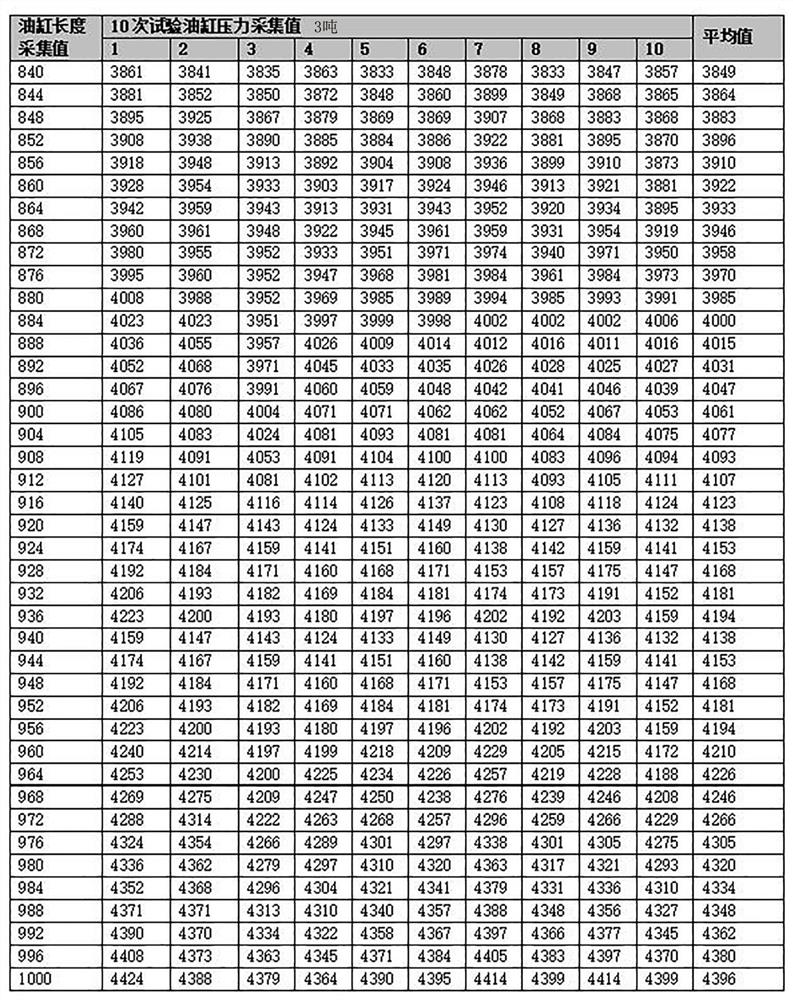

Loader and high-precision weighing method of loader

PendingCN112097886AReduce weighing errorsHigh precisionWeighing auxillary devicesSpecial purpose weighing apparatusControl theoryMechanical engineering

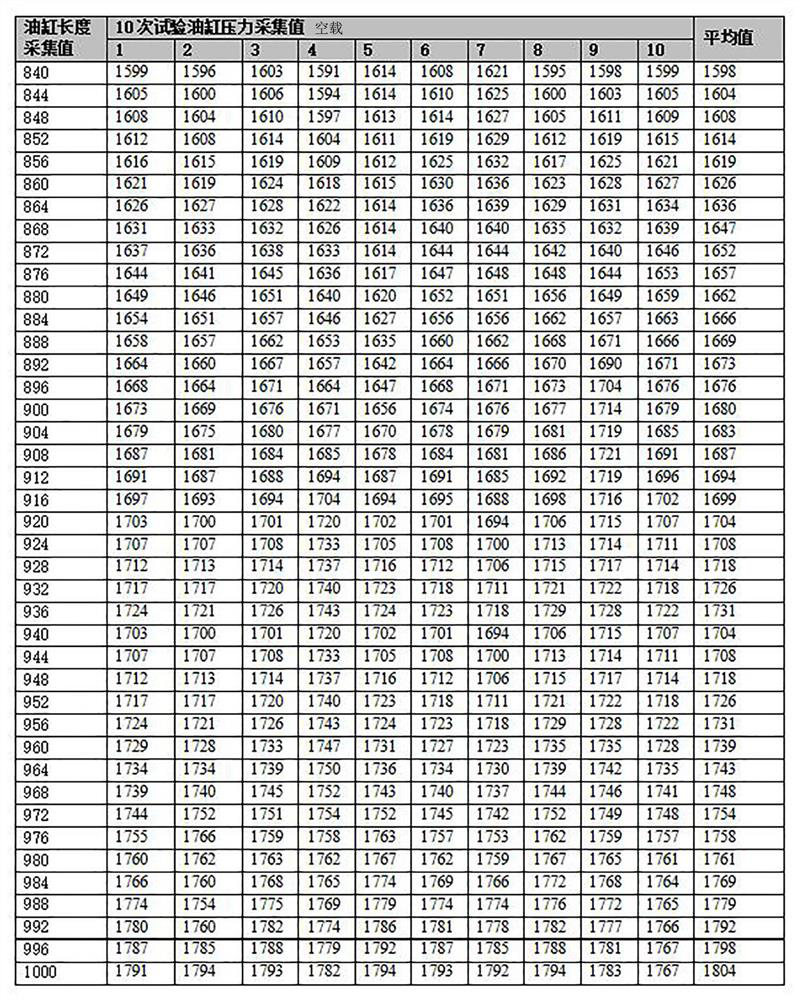

The invention discloses a loader and a high-precision weighing method of the loader, and belongs to the technical field of electronic scales of loaders. A displacement detection sensor used for detecting the extension length of a piston rod of a lifting oil cylinder and a vehicle body posture sensor used for detecting the inclination angle of a vehicle body relative to the horizontal bottom surface are installed on the lifting oil cylinder; primary weighing calculation is carried out through the extension length of the piston rod of the oil cylinder, the relative angle of the vehicle body andthe pressure of the oil cylinder, then the primary weighing structure is corrected in combination with the current vehicle body inclination angle posture, the influence of the vehicle body inclinationangle on weighing is eliminated, and the weighing error is effectively reduced.

Owner:河南达正然智能科技有限公司

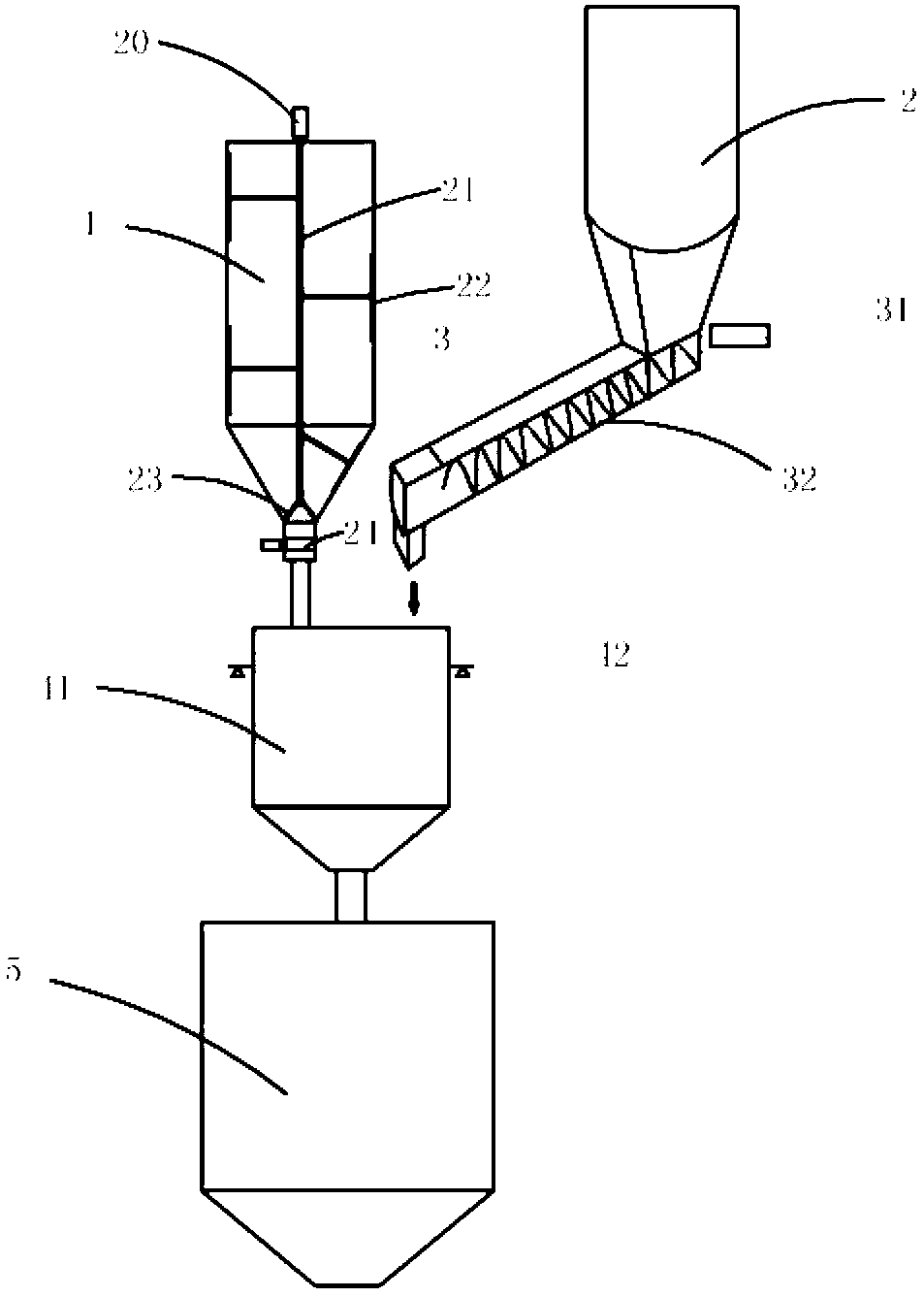

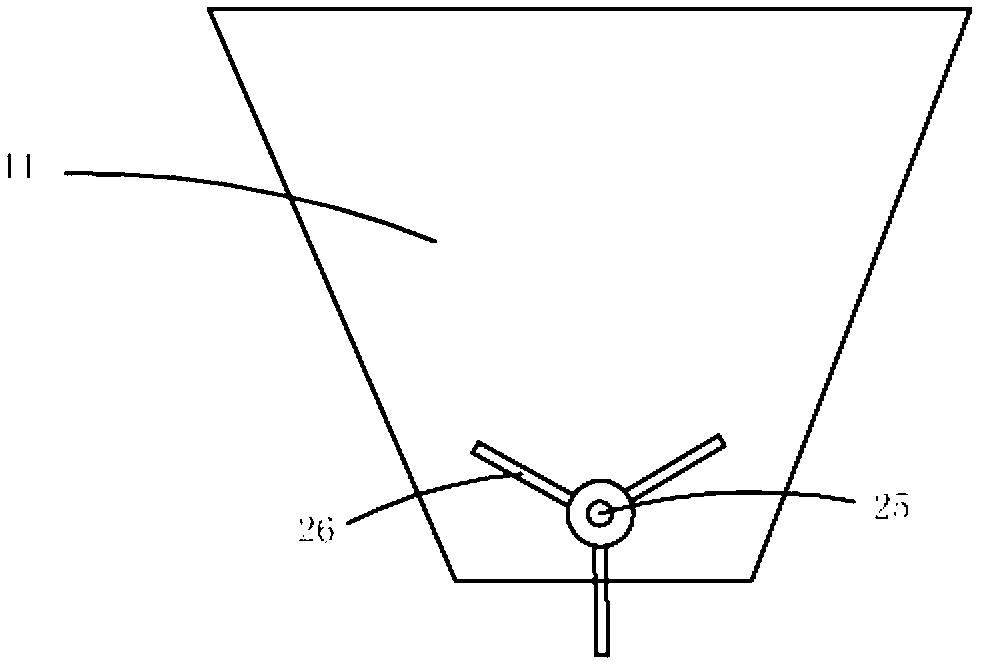

Secondary dosing and mixing system applied to processing rice noodles

ActiveCN103229935AReduce batch-to-batch variationQuality improvementFood shapingFood preparationControl systemProcess engineering

The invention discloses a secondary dosing and mixing system applied to processing rice noodles. The secondary dosing and mixing system comprises each control system in the mixing system. The secondary dosing and mixing system is characterized by comprising a rice noodle temporary storage cabin, a dosing cabin, a spiral conveyer, an automatic weighing device and a mixer, wherein a material outlet of the rice noodle temporary storage cabin is communicated with a material inlet of the automatic weighing device; a material outlet of the dosing cabin is connected with the material inlet of the automatic weighing device via the transversely-arranged spiral conveyer; the automatic weighing device comprises a weighing cabin and a weighing sensor; the weighing cabin is supported by the weighing sensor; and a material outlet of the weighing cabin is communicated with a mixer via a pipeline. The system disclosed by the invention can realize automatic weighing and dosing via a control device, so that errors caused by artificial weighing and dosing are reduced, the difference among different batches in the mass production of rice noodles is reduced, the overall quality of the produced rice noodles is improved, and the production efficiency of rice noodles is increased.

Owner:安徽王仁和米线食品有限公司

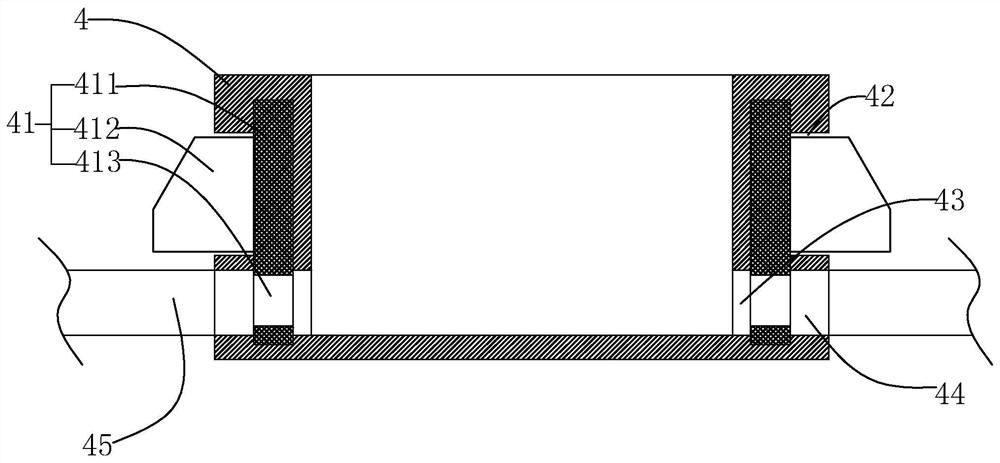

Polar plate weighing device

ActiveCN102359809BSimple structureEasy to useWeighing apparatus for materials with special property/formEngineeringLoad cell

The invention relates to a polar plate weighing device which comprises a weighing frame; a base plate is arranged in the weighing frame; a weighing sensor is arranged above the base plate along the transverse direction; one end of the weighing sensor is connected with the base plate by a cushion block; the other end of the weighting sensor is connected with a supporting bar; a tray is arranged atthe upper end of the supporting bar; and the weighing sensor is connected with a signal analysis display system in a communication way. The polar plate weighing device is suitable for weighing polar plates of storage batteries in the storage battery production process; and the weighing accuracy of the polar plate weighing device is higher relative to the common metering.

Owner:ZHANGJIAGANG SHUNCHEN MACHINERY CO LTD

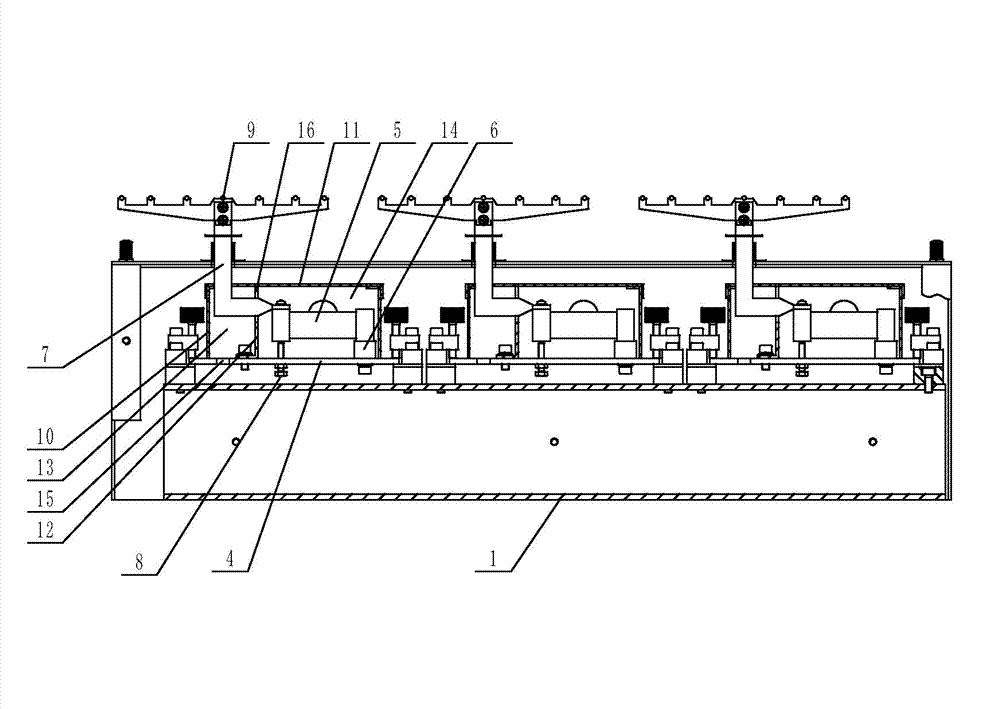

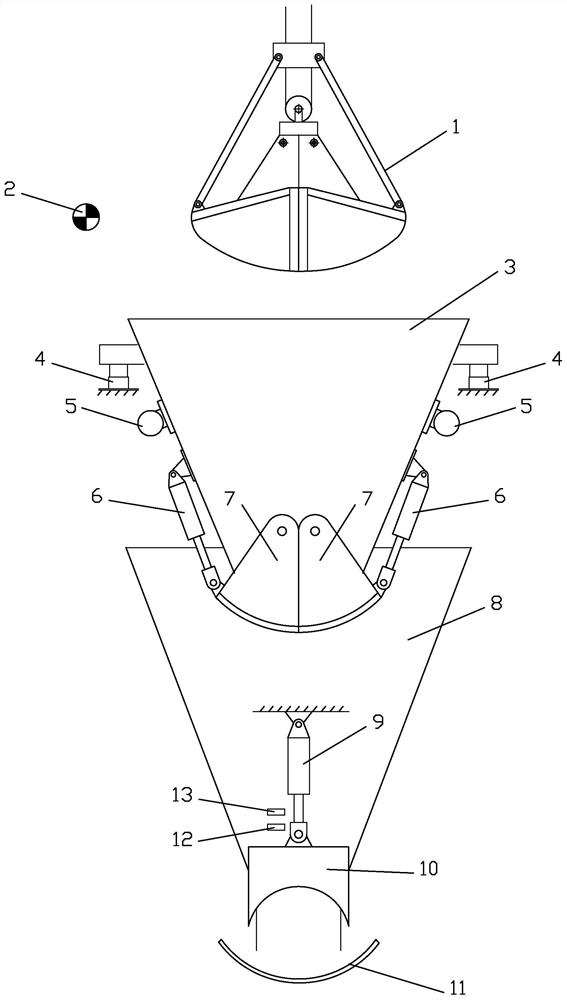

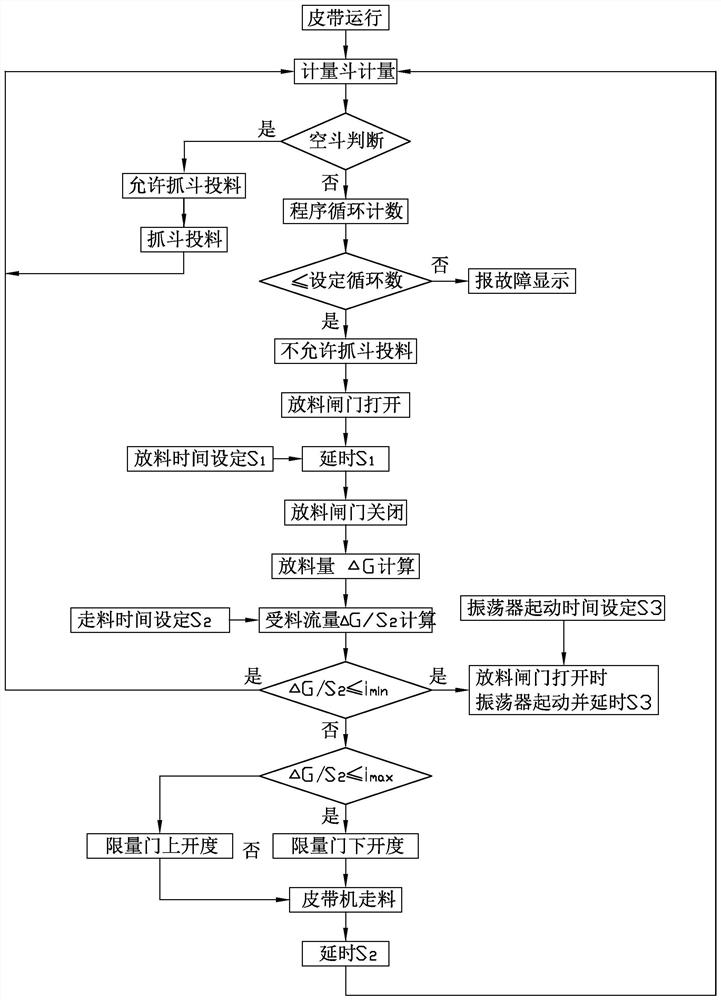

Timing control material receiving system and method

The invention relates to a timing control material receiving system and method. The system comprises a grab bucket and a measuring bucket located below an outlet of the grab bucket, wherein a buffer bin is arranged below an outlet of the measuring bucket, a belt conveyor is arranged below an outlet of the buffer bin, and at least one weight sensor is arranged on the outer side of the wall of the measuring bucket. A gate that is opened and closed in fixed times is arranged at the outlet of the measuring bucket, and is driven by means of a first driving cylinder arranged on the outer side of thewall of the measuring bucket; a quantity limiting door driven by a second driving cylinder is arranged at an outlet of the buffering bin, the gate is opened and closed at least twice in a using process, materials in the measuring bucket are fed into the buffering bin for several times according to the opening and closing times of the gate, and the materials in the buffering bin are continuously conveyed to the belt conveyor through the quantity limiting door. The gate capable of being timed is used, so that the whole material receiving system uniformly receives materials in a time-sharing andsectioning manner, so that the load of the belt conveyor is uniform, and the flow control of the belt conveyor is easy to realize.

Owner:NANJING MEISHAN METALLURGY DEV +1

Grain yield measuring device and method

ActiveCN114097409AReduce weighing errorsSimple structure and principleMowersAgricultural scienceGear wheel

The invention relates to a grain yield measuring device and method. The grain yield measuring device comprises a weight and a measuring hopper which are slidably connected to the two sides of a gear set through a chain. A grain inlet is formed in the top of the measuring hopper, and a second electromagnetic valve is arranged at a grain outlet in the bottom of the measuring hopper; the gear set comprises two gears, a counter and a signal receiver are arranged between the two gears, and a firing pin is arranged on the chain and located between the two gears. When the total weight of grains entering the measuring hopper and the measuring hopper is larger than the weight, the chain drives the firing pin to strike the counter and the signal receiver, meanwhile, grain feeding is stopped, and the second electromagnetic valve is opened. The grain yield measuring device provided by the invention has the characteristics of simple structure principle, low technical cost, simplicity in calibration, stability, reliability, no influence of crop species and the like, reduces the influence of grain moisture, variety and crop species, and reduces the influence of machine vibration and gradient.

Owner:中联智慧农业股份有限公司

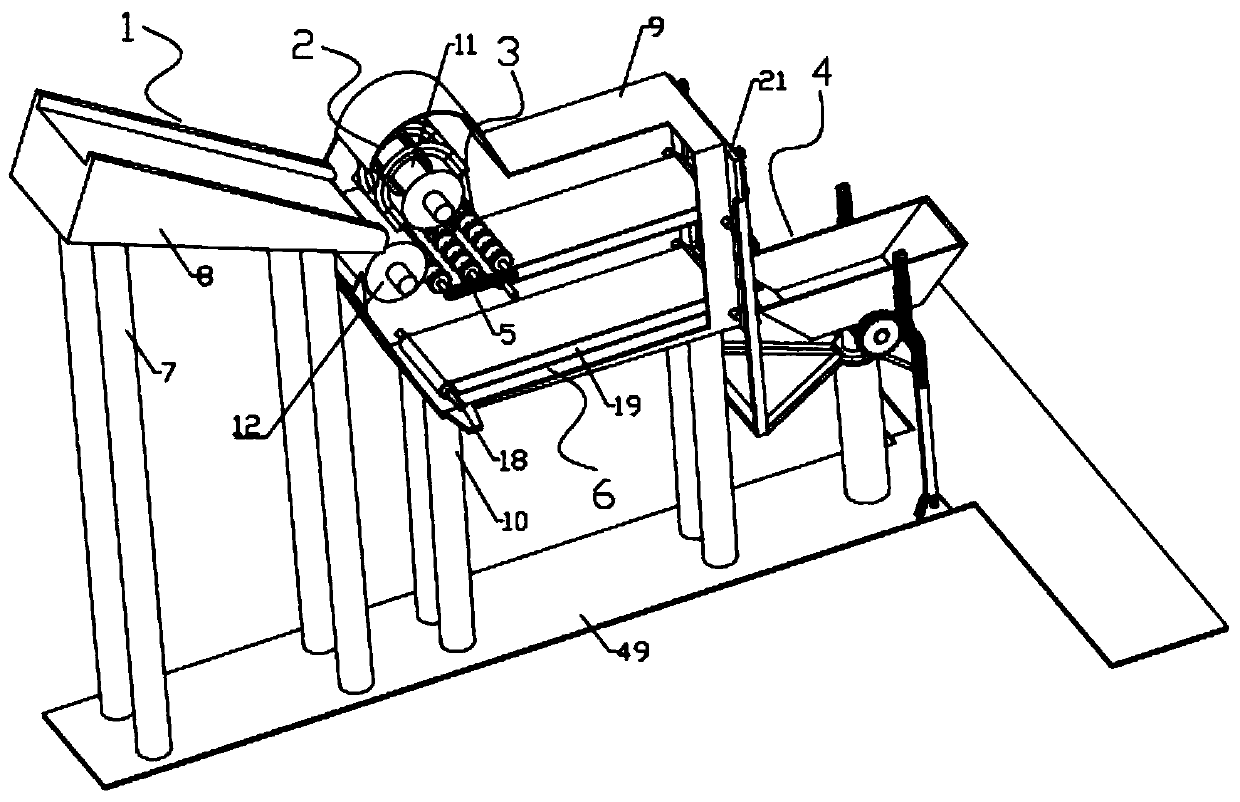

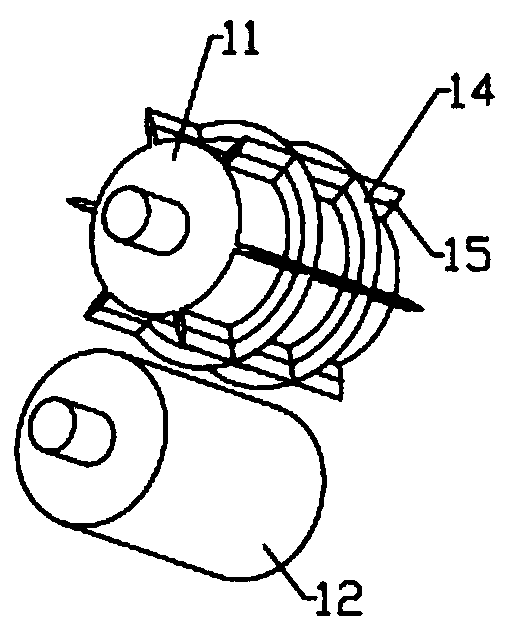

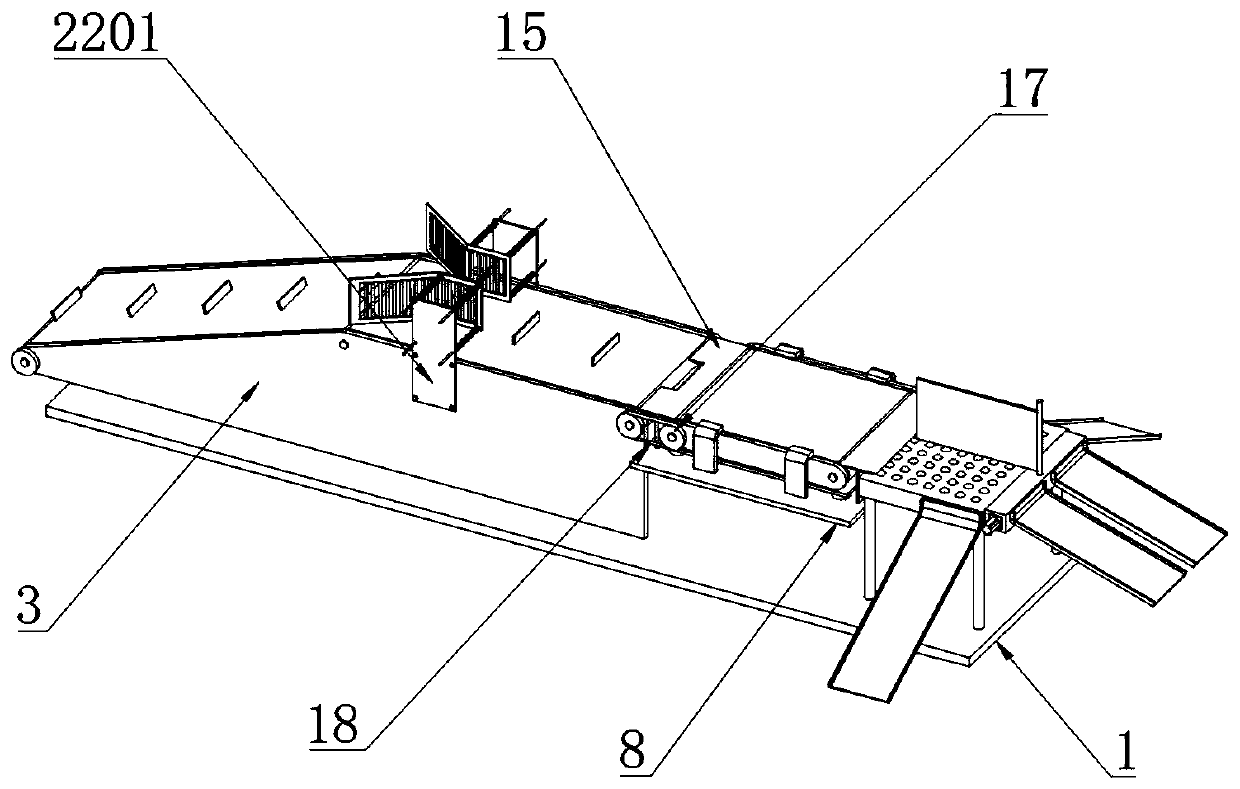

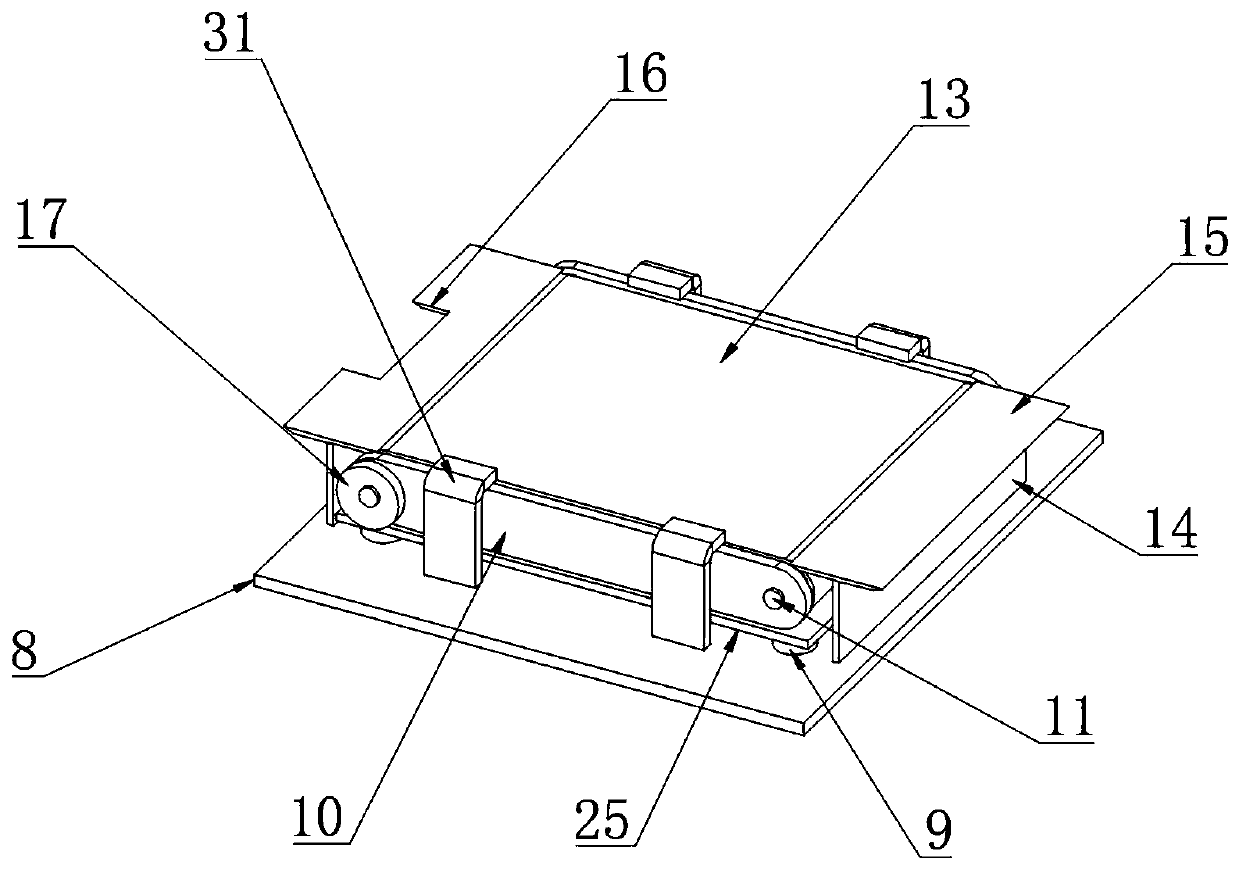

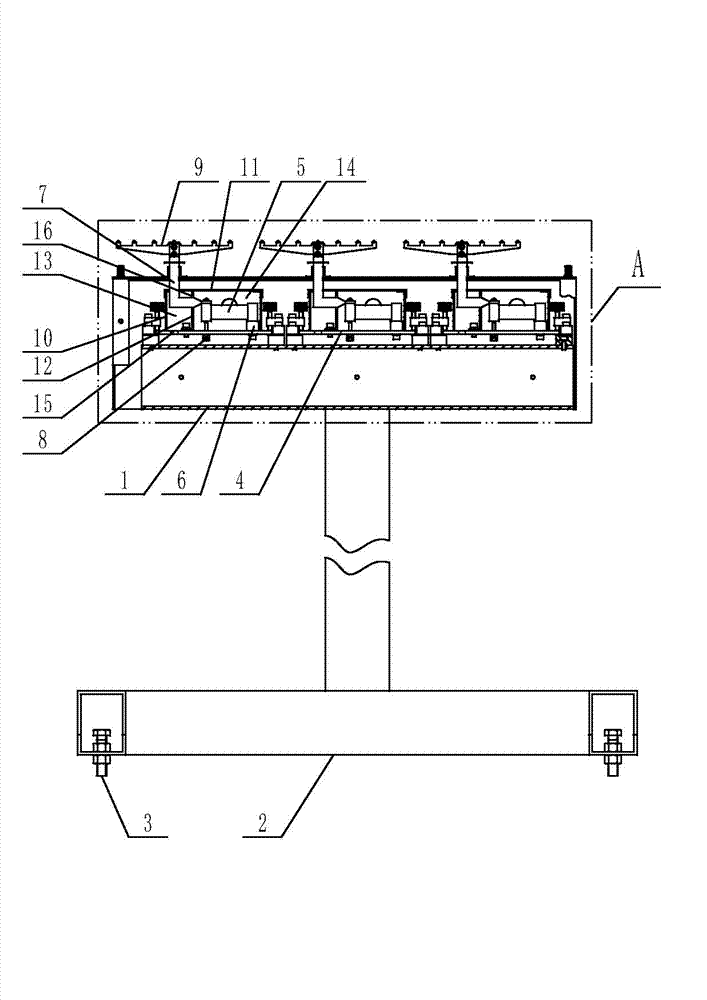

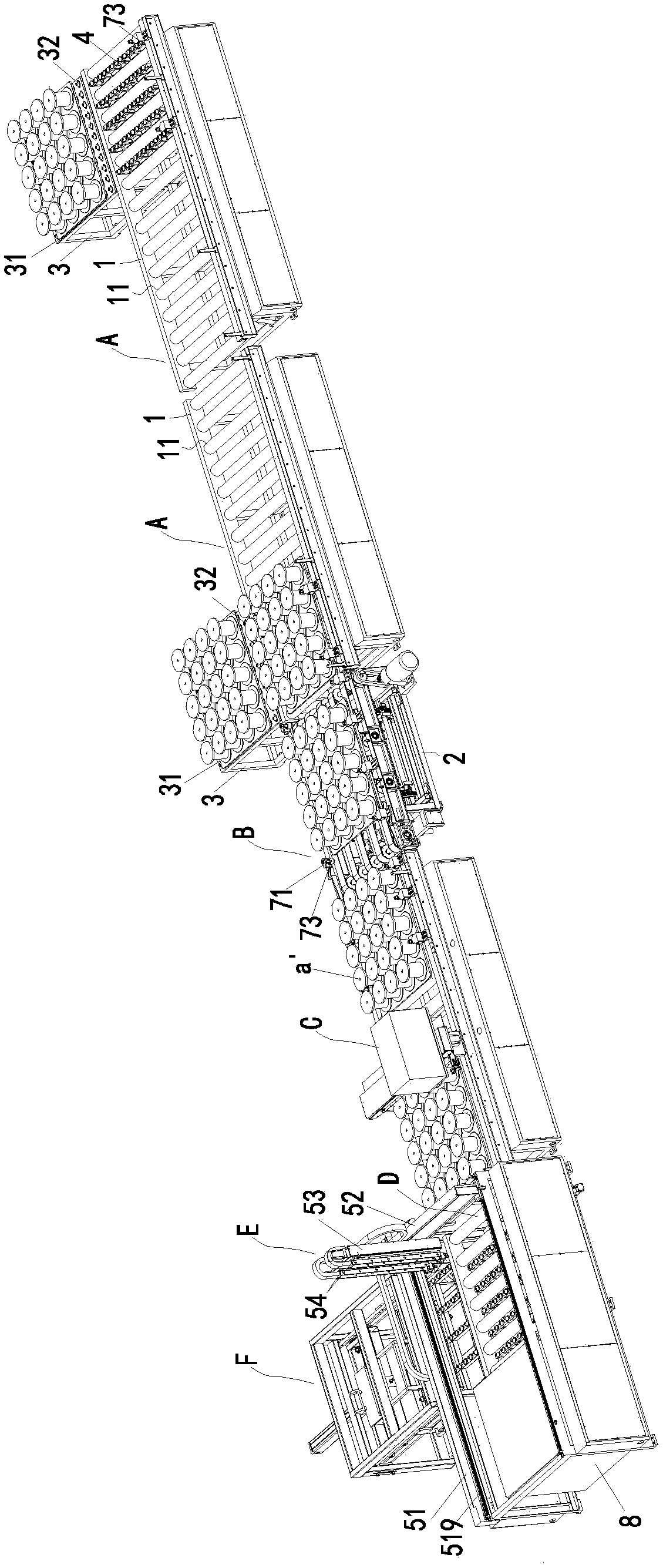

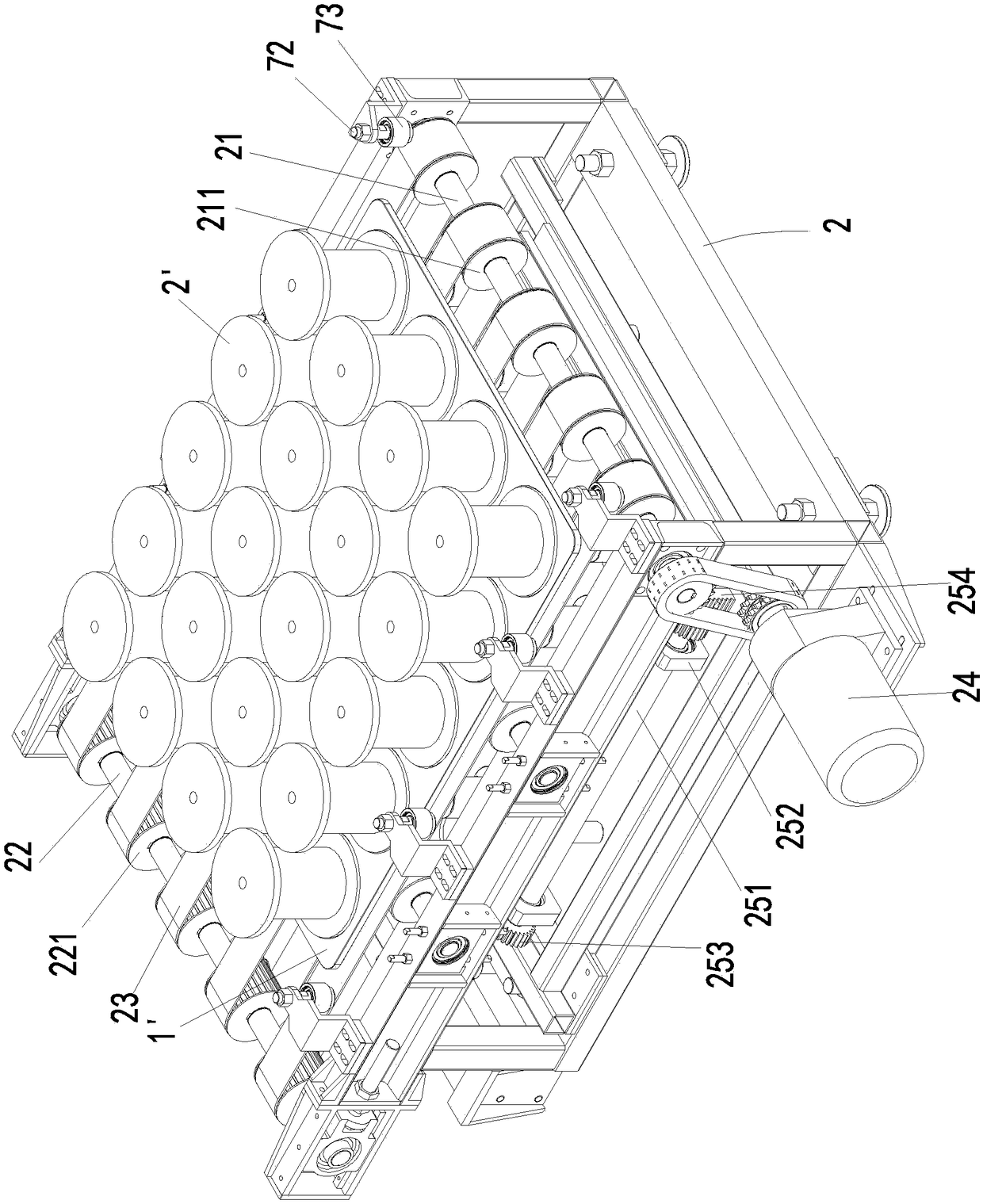

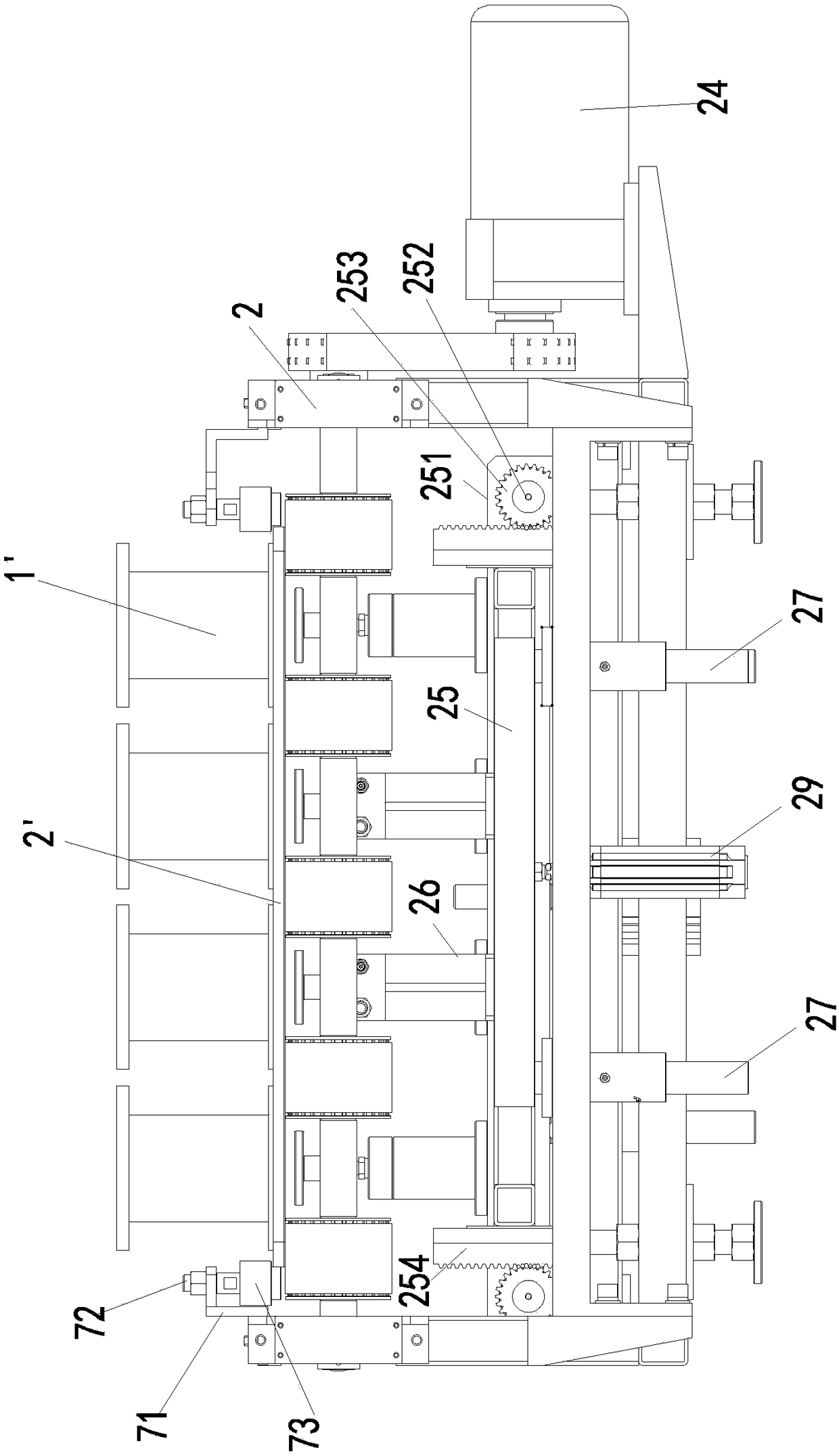

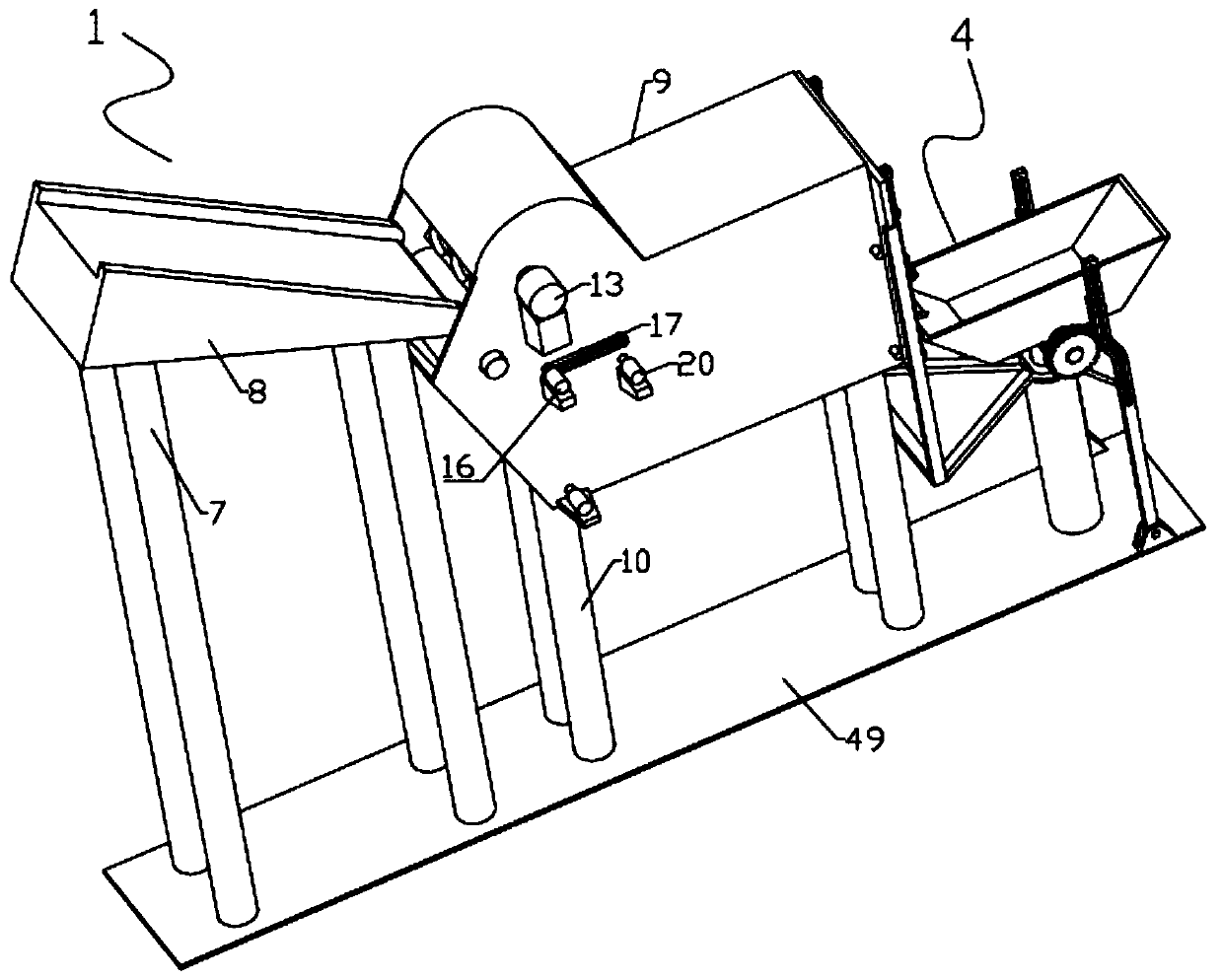

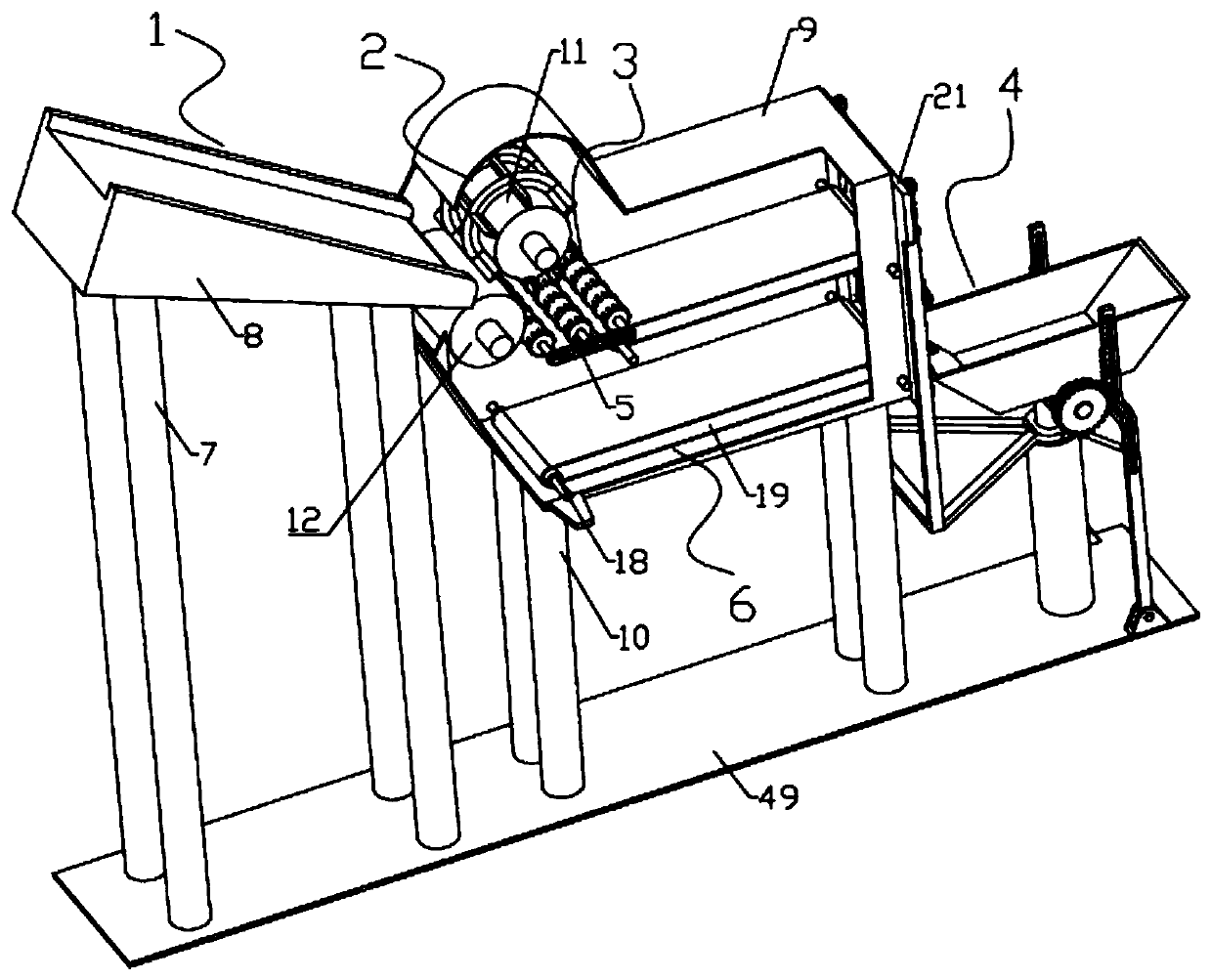

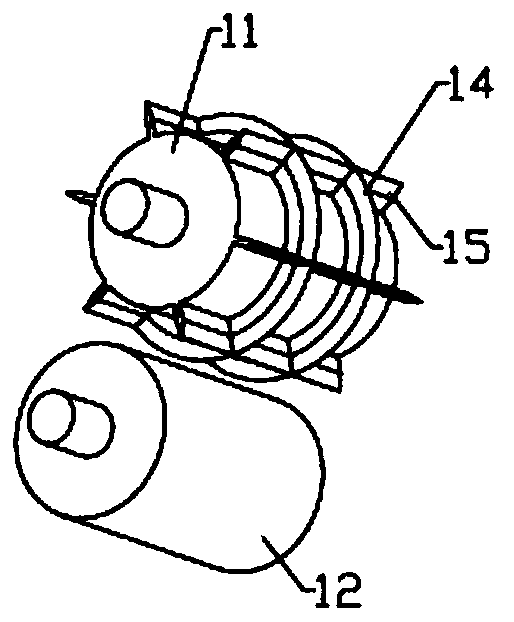

Automatic weighing and labeling device for steel wire roll

PendingCN108284993AEliminate the error-prone problems of manual weighingReduce weighing errorsConveyorsConveyor partsOutput deviceAssembly line

The invention discloses an automatic weighing and labeling device for a steel wire roll. The automatic weighing and labeling device for the steel wire roll comprises a conveying device, a weighing device, a label printing machine and an output device which are all sequentially arranged along an assembly line, wherein the weighing device is used for weighing the conveyed product, the label printingmachine pastes a weight label onto the weighed product, and the output device outputs and stores the labeled product. The weighing device comprises a weighing rack, main transmission rollers erectedon the two sides of the input end of a weighing rack and auxiliary transmission rollers erected on the two sides of the output end of the weighing rack. The main transmission rollers are provided withmain transmission wheels at intervals, the auxiliary transmission rollers are provided with auxiliary transmission wheels at intervals. The main transmission wheels and the auxiliary transmission wheels are correspondingly provided with and wound by belts or chains. The main transmission rollers are in transmission connection with a transmission device. A weighing lifting device is arranged belowthe weighing rack. The weighing lifting device comprises lifting bases which are arranged below the belts through lifting drive device in an ascending or descending manner, and the lifting bases areprovided with weighing sensors.

Owner:东来不锈钢丝(厦门)有限公司

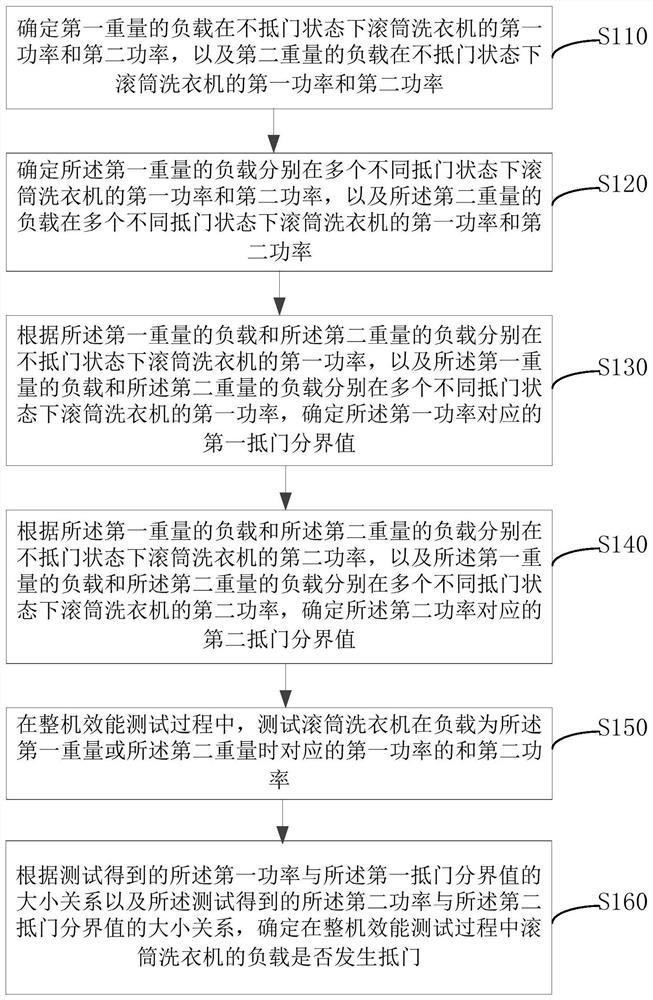

Method and device for judging whether clothes abut against door of roller washing machine

ActiveCN113481694AImprove accuracyReduce weighing errorsControl devices for washing apparatusTextiles and paperLaundry washing machinePower efficient

The embodiments of the invention provide a method and device for judging whether clothes abut against a door of a roller washing machine. The method comprises the steps of determining first power and second power of a load with first weight and a load with second weight in a non-door-abutting state, and determining first power and second power of the load with the first weight and the load with the second weight in a plurality of different door abutting states; determining a first door abutting boundary value and a second door abutting boundary value; in the whole machine efficiency testing process, testing the first power and the second power; and determining whether the loads of the roller washing machine abut against the door or not in the whole machine efficiency testing process according to the relationship between the first power obtained by testing and the first abutting boundary value and the relationship between the second power obtained by testing and the second abutting boundary value. According to the method, the two door abutting boundary values are set firstly, and whether the clothes abut against the door or not is judged according to the two door abutting boundary values. If door abutting occurs, a test can be adopted to reduce weighing errors caused by door abutting, so that the accuracy of whole machine efficiency testing is improved.

Owner:SICHUAN HONGMEI INTELLIGENT TECH CO LTD

Automatic cotton core weighing device

ActiveCN103966707AHigh densityReduce volumeFibre feedersAgricultural engineeringMechanical engineering

Owner:SHENZHEN FUANNA BEDDING & FURNISHING

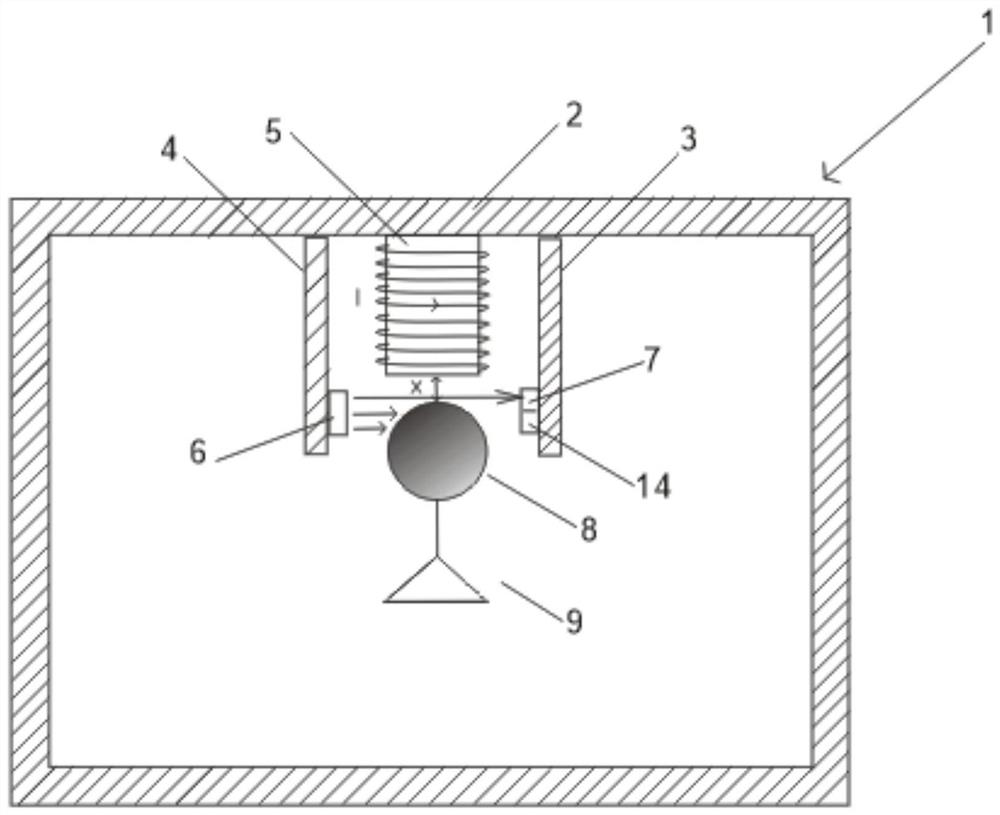

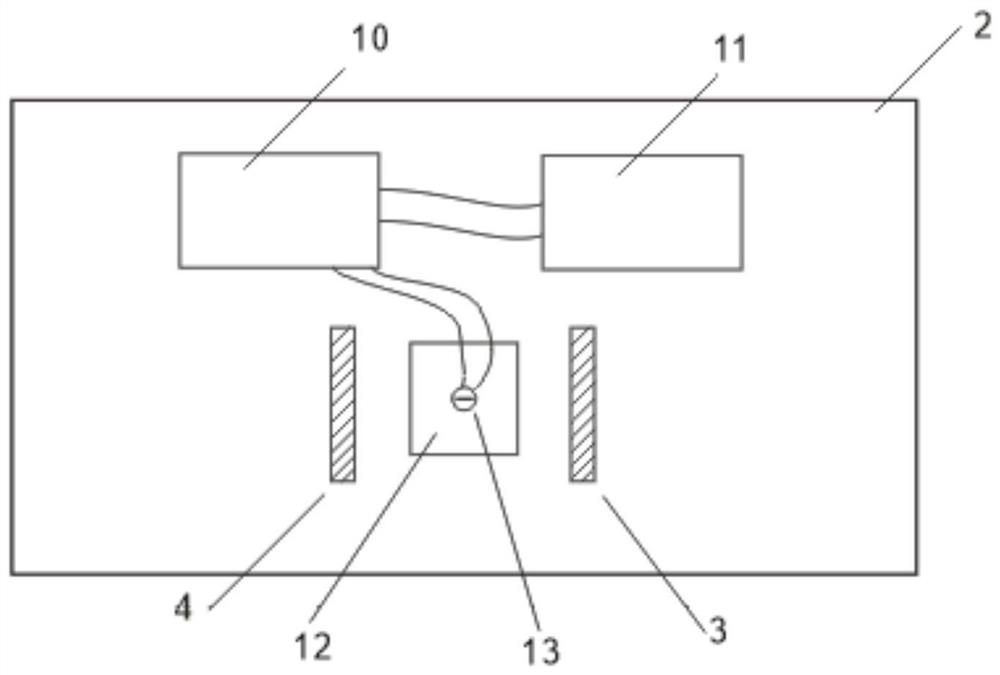

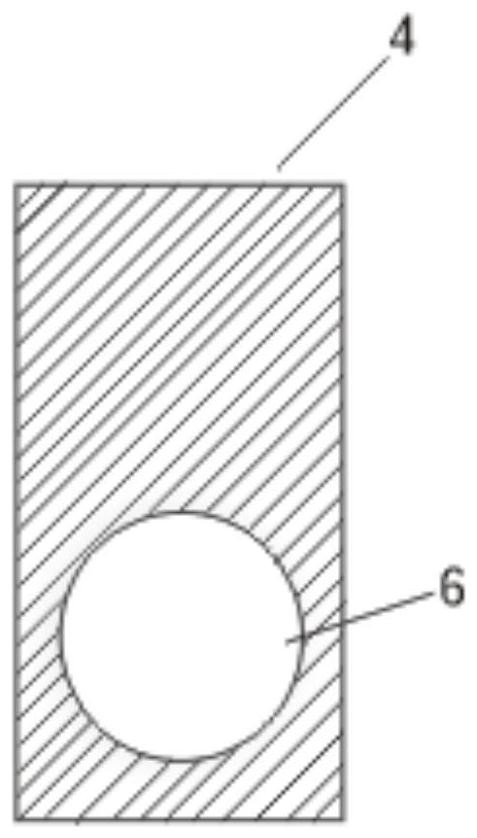

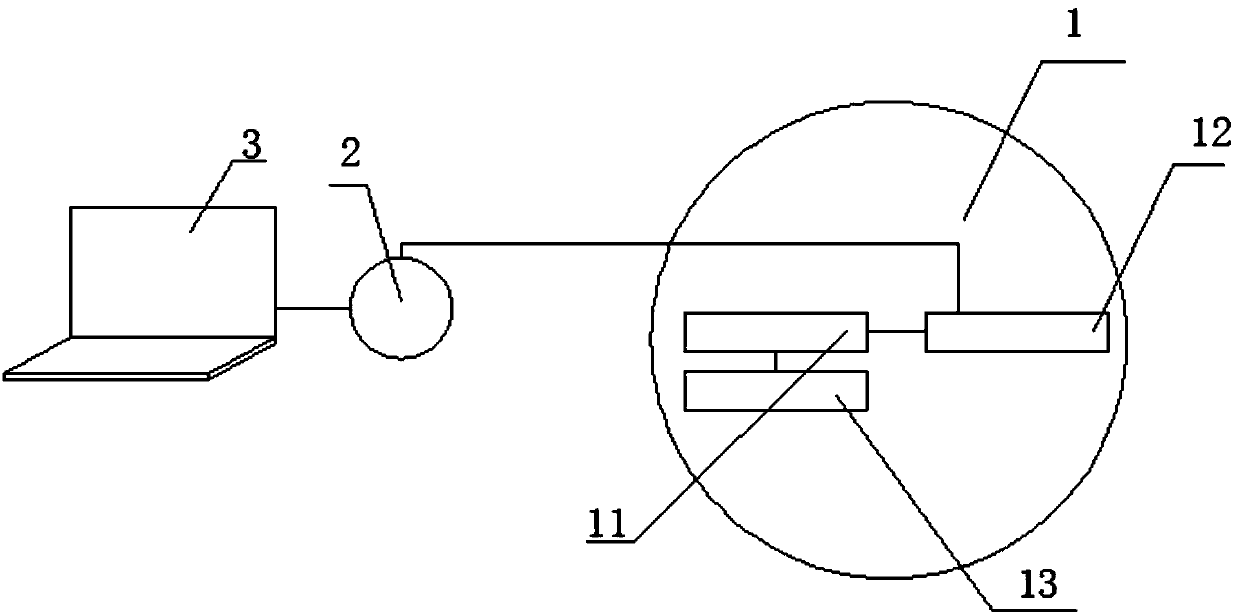

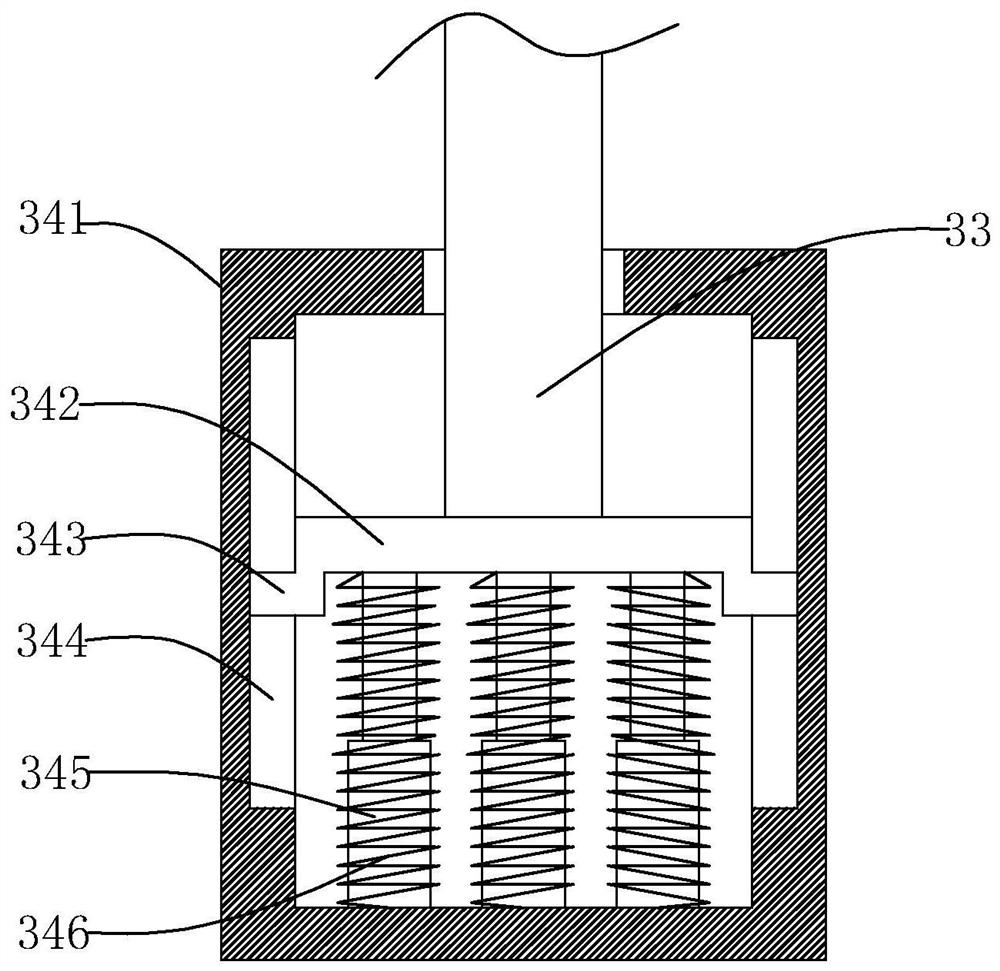

Magnetic suspension weighing system and control method thereof

PendingCN113624309AChange the mechanical structureReduce weighing errorsWeighing apparatus using electromagnetic balancingEngineeringMechanical engineering

The invention provides a magnetic suspension weighing system and a control method thereof. The magnetic suspension weighing system comprises a box body; a weighing mechanism is mounted at the top of the box body, the weighing mechanism comprises a magnetic suspension assembly, a suspended object and an object containing disc, and the object containing disc is connected to the lower portion of the suspended object; the magnetic suspension assembly comprises a photoelectric displacement sensor, a circuit board, an electromagnetic coil and a display screen; the suspended matter is located under the electromagnetic coil. The photoelectric displacement sensor is used for measuring the distance between the suspended matter and the electromagnetic coil; and the circuit board is respectively connected with the photoelectric displacement sensor and the electromagnetic coil. According to the invention, the current on the electromagnetic coil can be automatically adjusted according to objects with different masses added in the containing tray, and the changing current accurately corresponds to the mass of the object, so that the purpose of indirect weight measurement is achieved; according to the weighing system, the gravity of an object is balanced through magnetic force, mechanical friction of a scale body of a traditional electronic scale is eliminated, and the measurement precision is improved.

Owner:JIANGSU UNIV

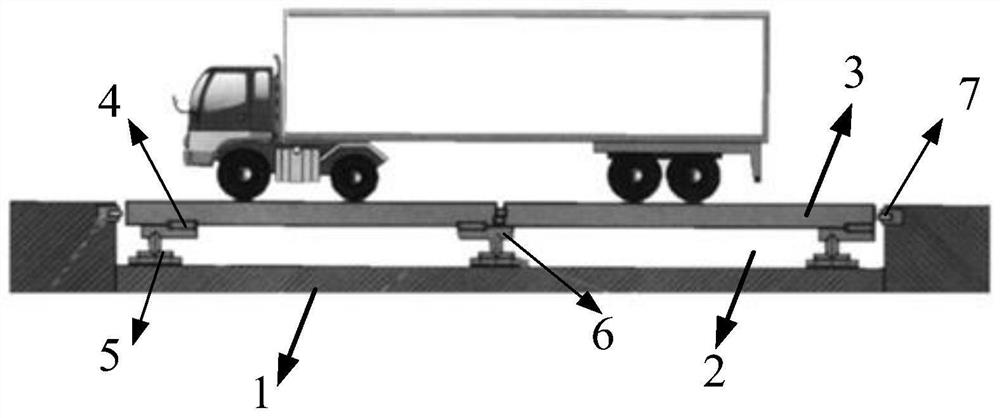

Dynamic weighing device and weighing method thereof

PendingCN112781700AReduce vibrationExtended service lifeWeighing apparatus detailsSpecial purpose weighing apparatusLoad cellSignal processing

The invention relates to a dynamic vehicle weighing device and a weighing method thereof. The dynamic vehicle weighing device includes a weighing sensor and a processing unit. The weighing sensor is used for obtaining a deformation signal generated when a vehicle acts on the top road structure of the weighing sensor in the advancing process. The processing unit is used for determining the weight of the vehicle according to the deformation signal. According to the invention, the deformation signal of the top road structure of the weighing sensor is sensed by using the weighing sensor, and the weight of the vehicle can be determined by directly using the deformation signal. In addition, the weighing sensor is embedded in the road foundation, compared with traditional weighing equipment, the service life of the weighing sensor is prolonged, and meanwhile the weighing precision is improved.

Owner:BEIJING WANJI TECH

A dynamic weighing filtering method and system thereof

ActiveCN108168680BReduce vibration and noiseReduce weighing errorsWeighing apparatus testing/calibrationLow-pass filterControl engineering

The invention provides a dynamic weighing filtering method and system thereof. The dynamic weighing filtering method comprises the following steps that step S1, continuous and equal-period sampling isperformed on the object weight on a conveying belt; step S2, the sampling result of the object weight is filtered so as to obtain the filtered weight value; step S3, the weight change slope is calculated according to the filtered weight value; step S4, the weighing state of the object is judged by the weight change slope; and step S5, whether a low-pass filter is applied to perform filtering is determined according to the weighing state and the final weight result is outputted. The movement characteristics of the object on the conveying belt can be met and the vibration noise and the weighingerror caused by movement of the object on the conveying belt can be effectively reduced; and the filtering process is fast in speed and high in accuracy, filtering is smooth and transition is stableso that the dynamic weighing process is enabled to be more stable and reliable and the accuracy and the working efficiency of dynamic weighing can be greatly enhanced.

Owner:深圳市美新特智能装备有限公司

Silo material weighting system and method based on distributed weighing nodes

ActiveCN109612562AReduce weighing errorsAvoid the problem of needing to set up large weighing equipmentSpecial purpose weighing apparatusWired communicationTransceiver

The invention discloses a silo material weighting system and a method based on the distributed weighing nodes, belongs to the technical field of weighting, and is characterized in that: a plurality ofweighing nodes mutually separated are provided at the bottom of the silo; each of the weighing nodes comprises a weighing sensor, a communication transceiver, and a power supply; the communication transceiver is connected with the data transceiving center; the data transceiving center is connected with the data processing center; and the communication mode between the weighing nodes and the datatransceiving center is wireless communication or wired communication. The existing technical problem that the weight of the silo material cannot be effectively weighted is solved, and the system and the method are mainly applied to the technical field of the silo material.

Owner:江苏海宏信息科技有限公司

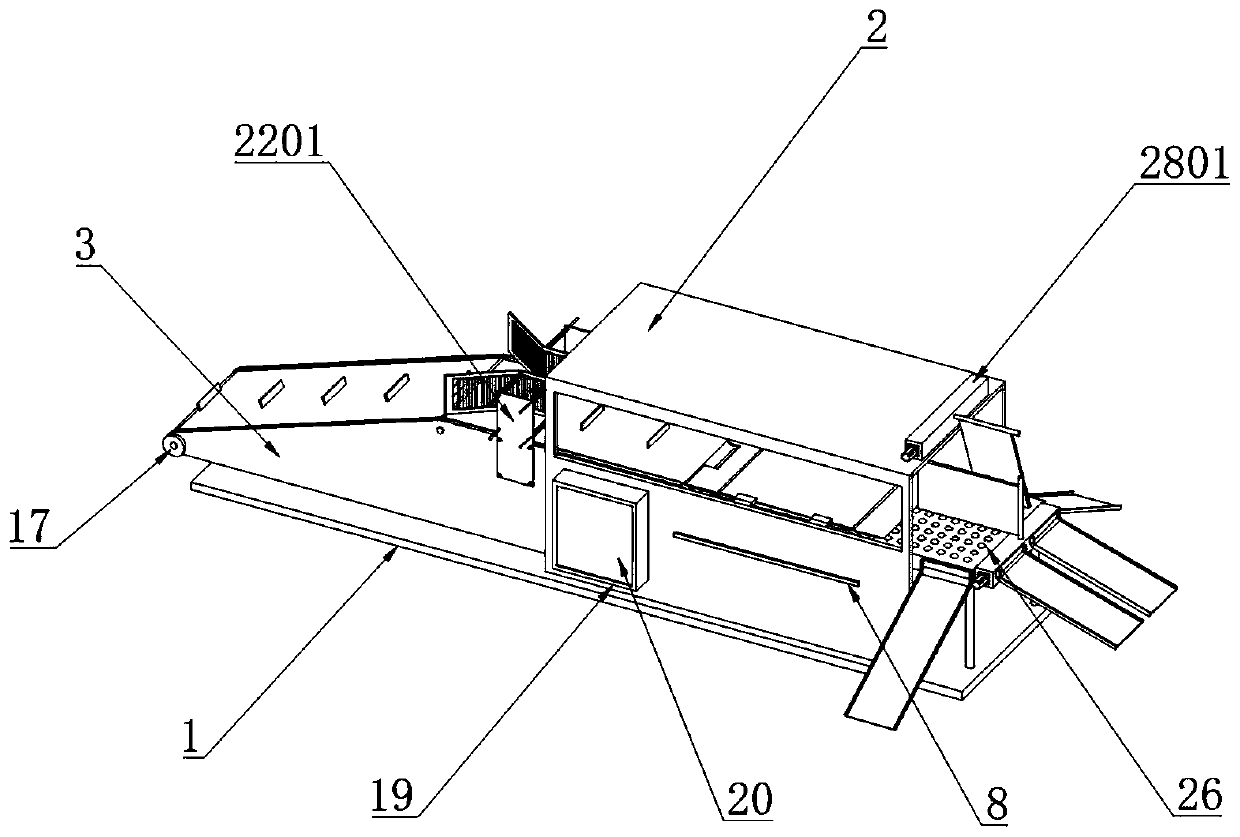

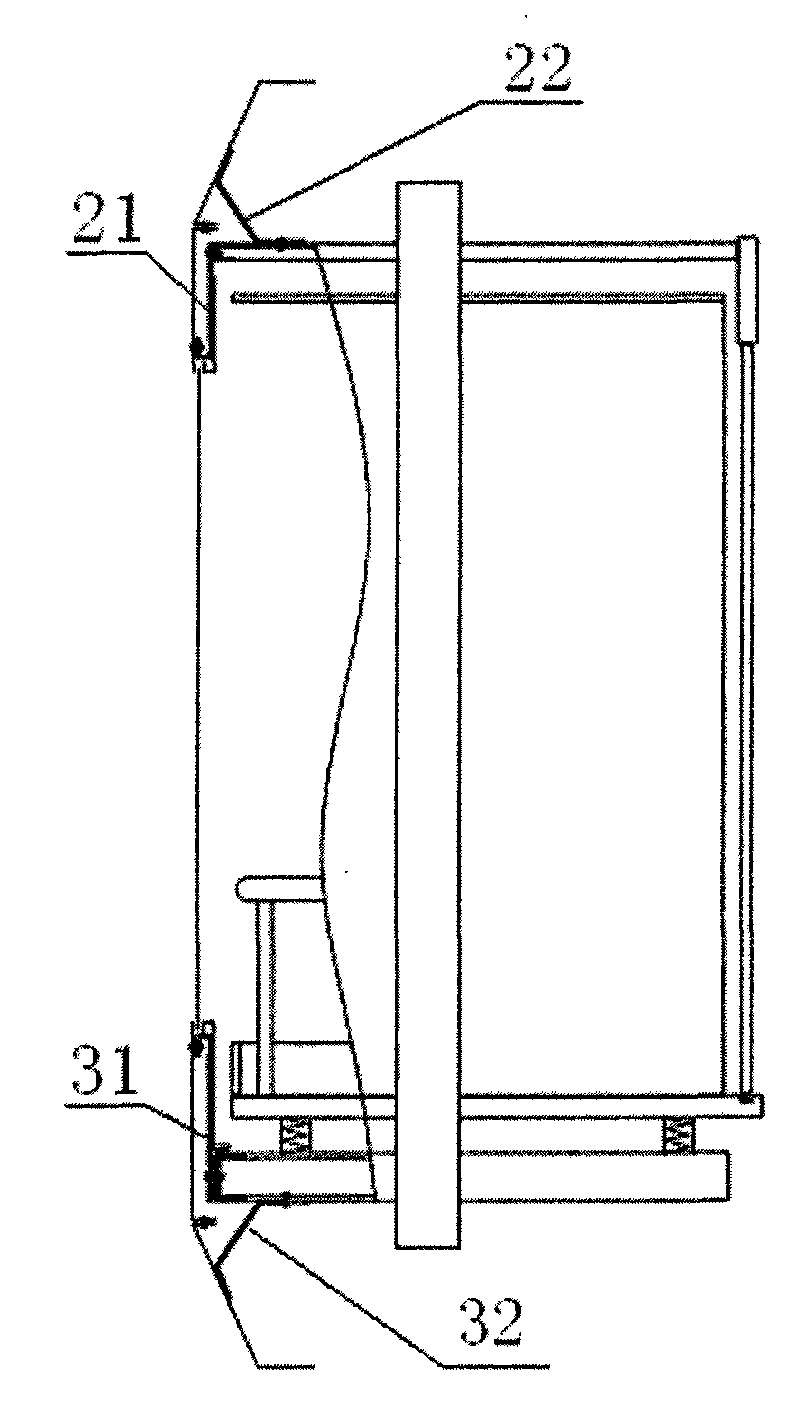

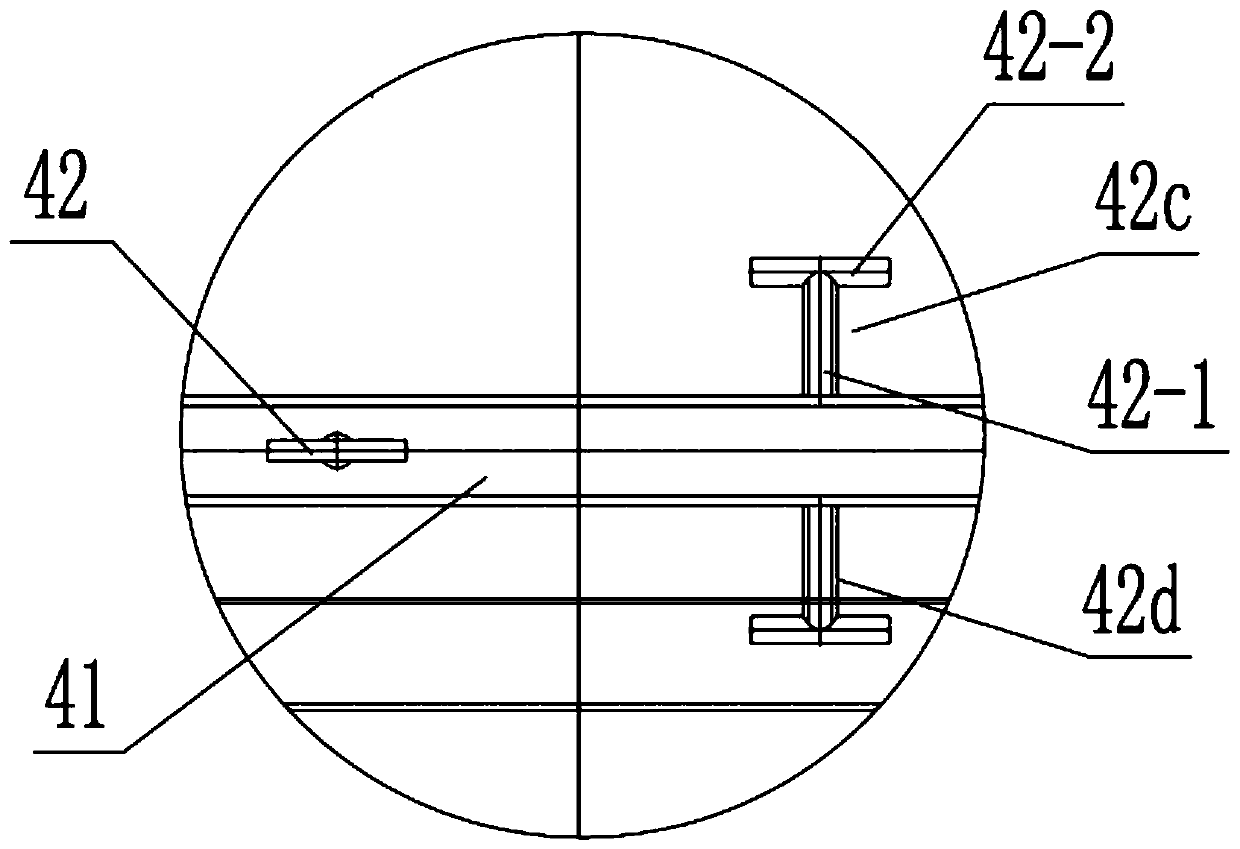

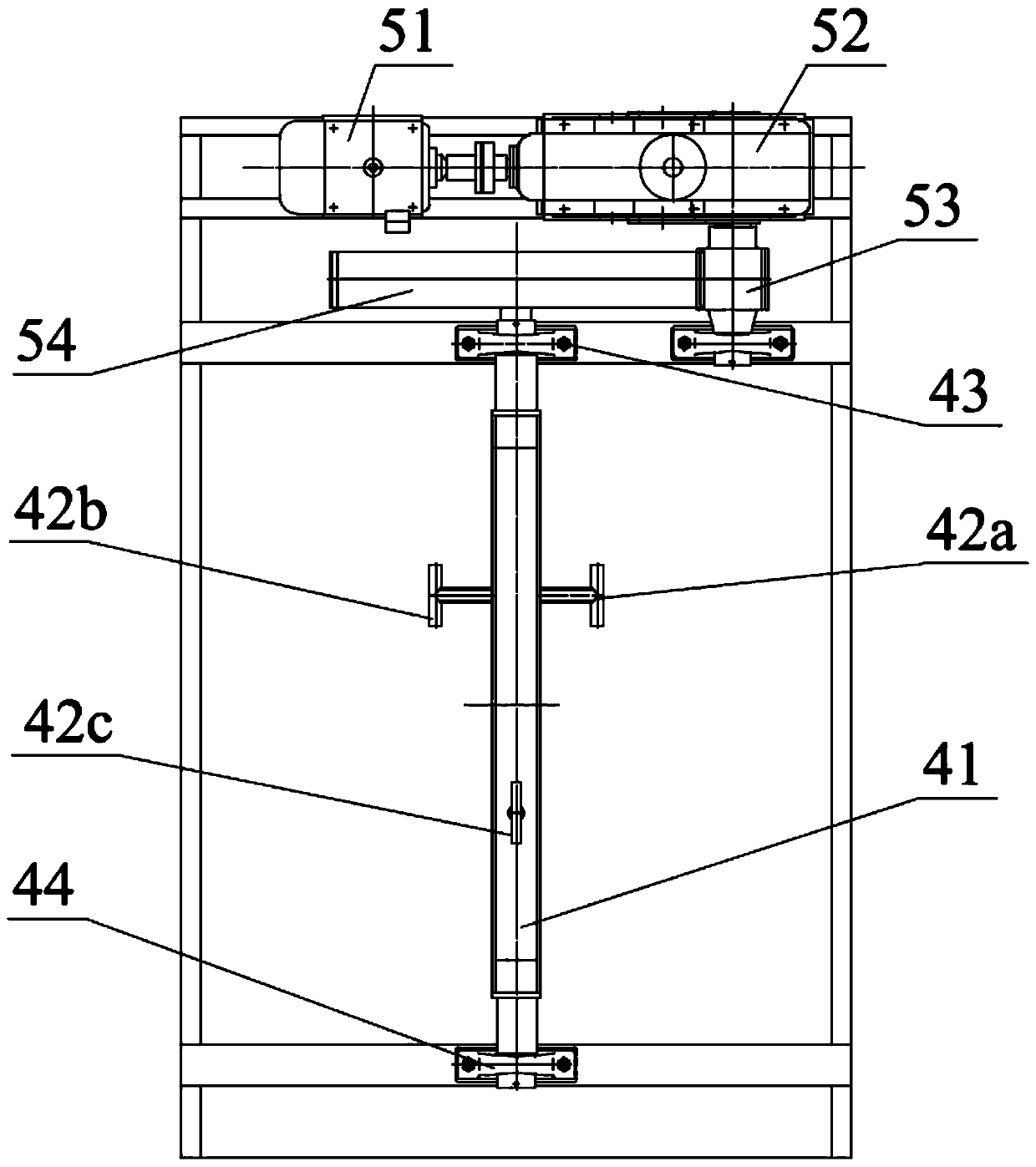

Device for food accurate quantitative weighing and packaging

ActiveCN110937151AReduce weighing errorsPackaging foodstuffsMetal working apparatusAgricultural engineeringStructural engineering

The invention discloses a device for food accurate quantitative weighing and packaging, and relates to the field of packaging equipment. The device comprises a material guide assembly, a cutting assembly, a material conveying assembly and a quantitative weighing assembly. The material guide assembly, the cutting assembly, the material conveying assembly and the quantitative weighing assembly are arranged on a base plate in sequence from left to right. According to the device, due to the fact that the material guide assembly, the cutting assembly, the material conveying assembly and the quantitative weighing assembly are arranged, the material guide operation, the cutting operation, the material conveying operation and the quantitative weighing operation of the food are achieved. Material conveying mechanisms on the upper layer and the lower layer and a driving mechanism are arranged, the ascent and the descent of a first gear rod and a second gear rod are simultaneously controlled, theopening and closing operation of a massive food baffle in a massive food discharging outlet is controlled, the closing and opening operation of a crushed food baffle in a crushed food discharging outlet is controlled at the same time, and therefore the accurate weighing operation can be conducted according to the requirement that the weight ratio of the massive food to the crushed food is 9:1, the food can be poured into a mechanism for the next packaging working procedure, and the weighing error is reduced.

Owner:芜湖市智行天下工业设计有限公司

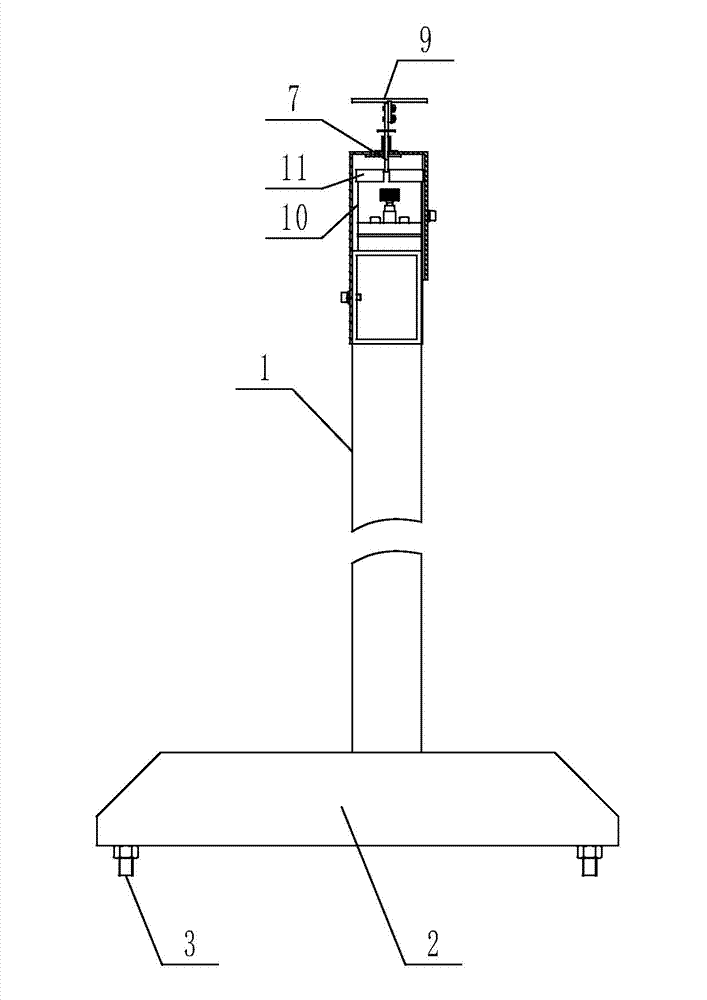

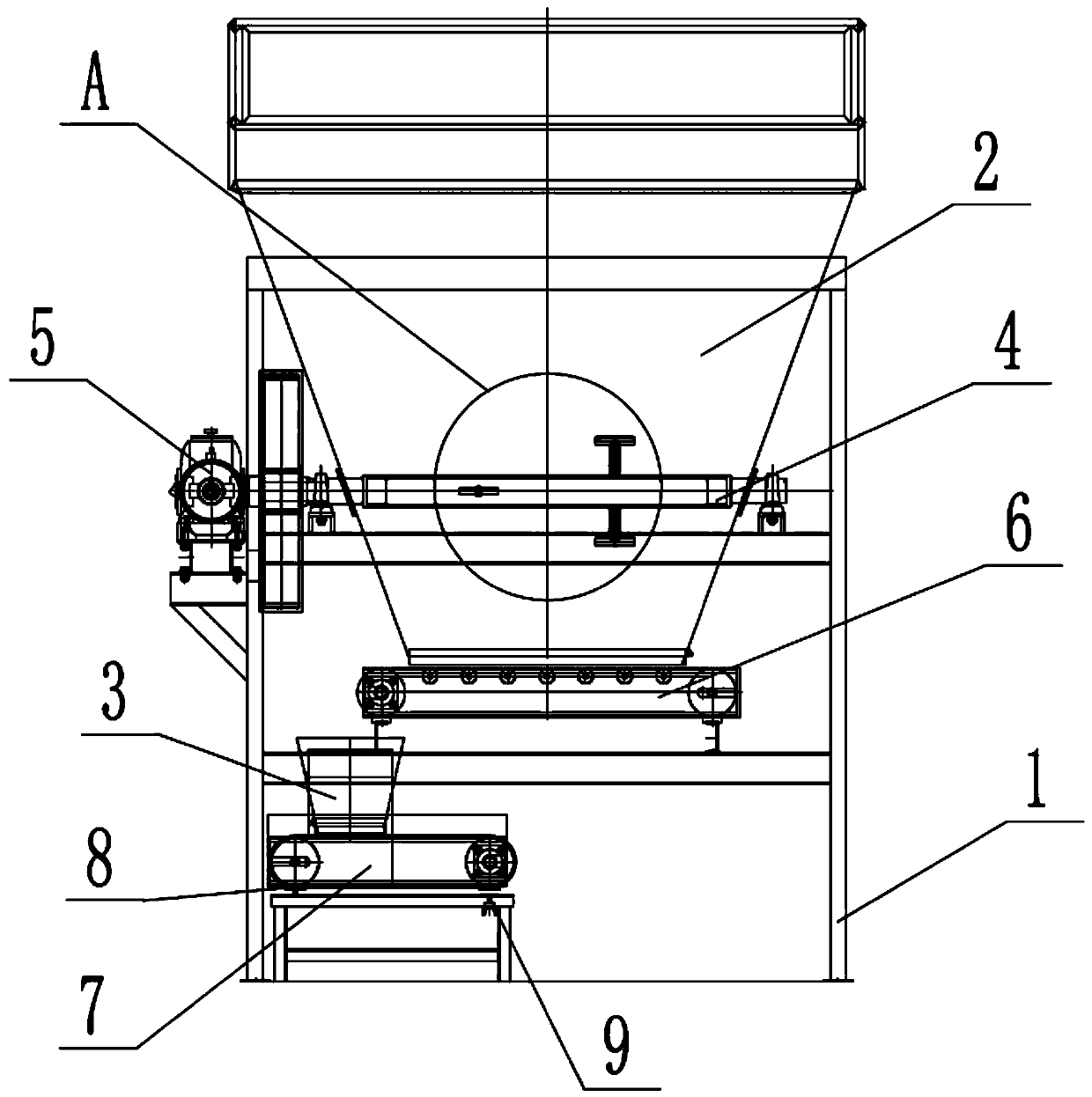

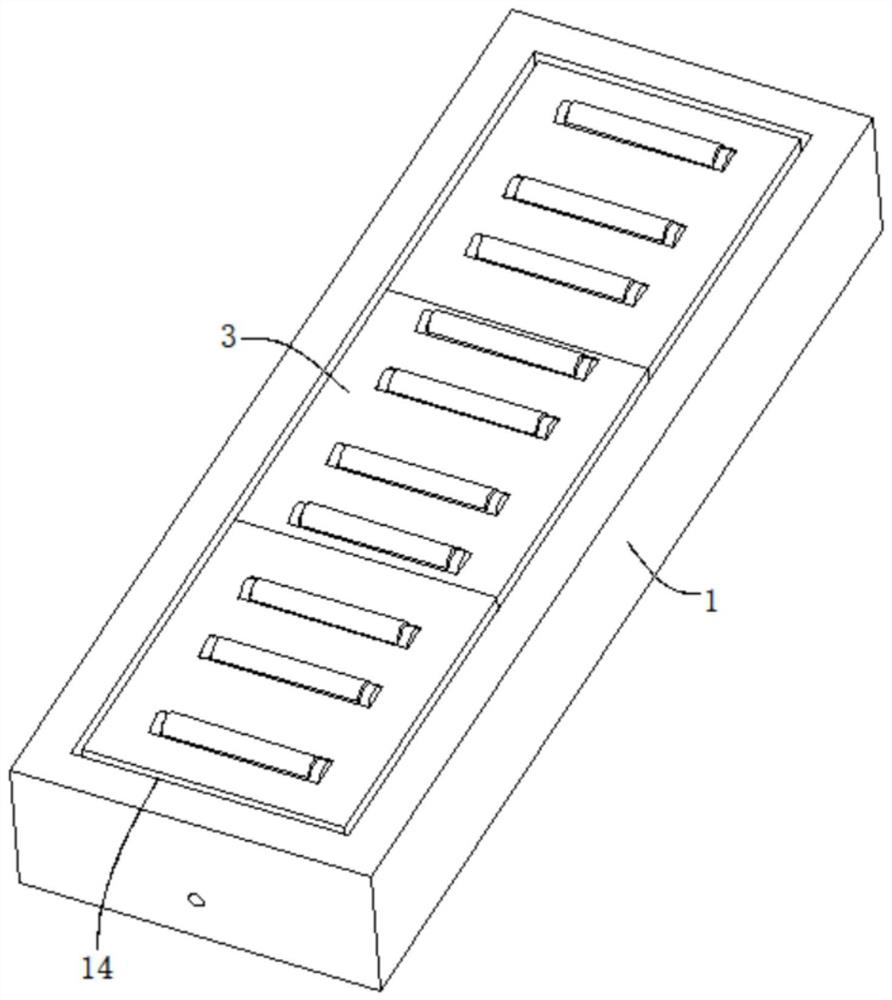

Static metering and feeding system for ceramic raw materials

InactiveCN109879074AAdjust running timeReduce weighing errorsWeighing apparatus with automatic feed/dischargeLoading/unloadingEngineeringMaterial supply

The invention relates to the technical field of ceramic raw material machining, and particularly discloses a static metering and feeding system for ceramic raw materials. The static metering and feeding system comprises a supporting frame and further comprises a storage hopper and a weighing hopper which are arranged on the supporting frame. The storage hopper is located above the weighing hopper,a conveying belt is arranged below the weighing hopper, and an arch breaking assembly is arranged in the storage hopper. One end of the arch breaking assembly is exposed out of the storage hopper andis connected with a drive assembly. A seal unloading belt is arranged below the storage hopper. The weighing hopper and a weighing belt are arranged below the seal unloading belt. A weighing sensingassembly composed of three weighing sensors is arranged below the weighing belt, the seal unloading belt is used for weighing the weight of raw materials, and when the seal unloading belt stops material supply, weighing starts. According to the weight value preset by a controller and the weight of last weighing, the running time of the seal unloading belt is adjusted, the weight, weighed by the seal unloading belt, of raw materials next time is adjusted, more-returning and few-supplementing metering is achieved, and weighing errors are reduced.

Owner:广东鼎汇能科技股份有限公司

Aqueous film-forming foam fire extinguishing agent and preparation method thereof

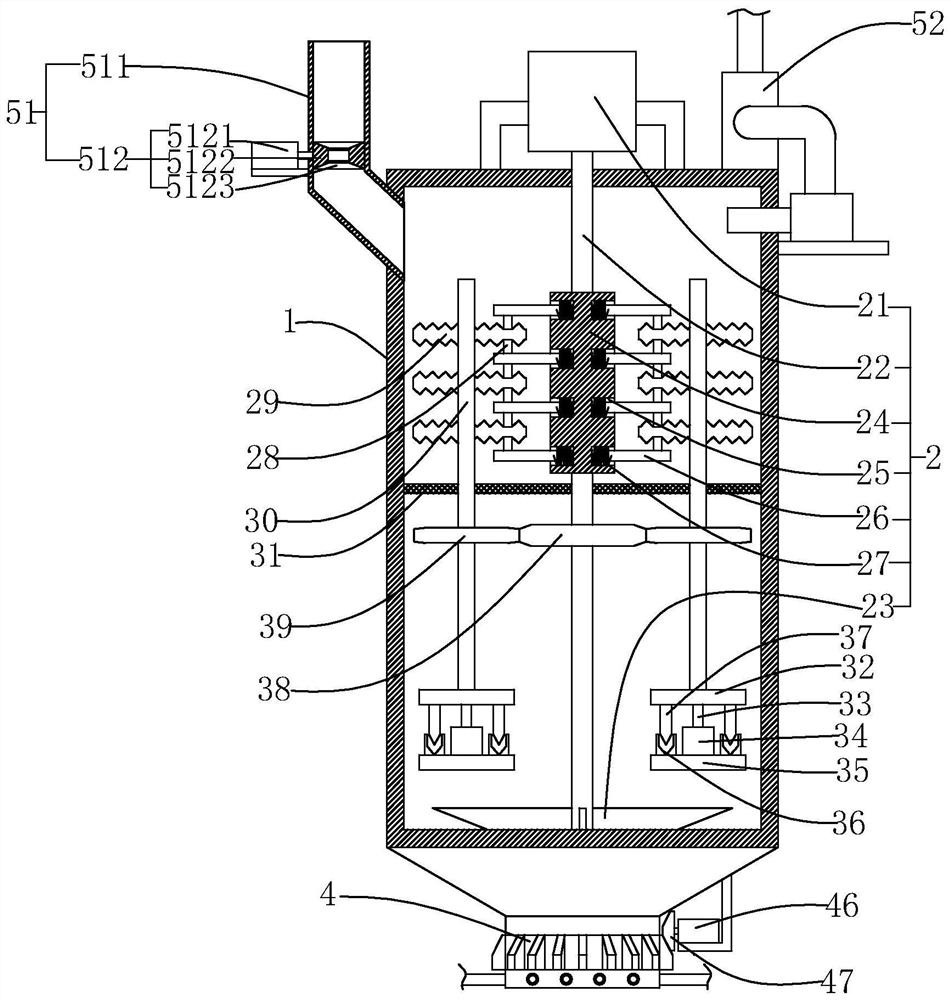

ActiveCN113559452APromote environmental protectionReduce pollutionShaking/oscillating/vibrating mixersRotary stirring mixersFoaming agentActive agent

The invention relates to the technical field of fire extinguishing agent preparation, in particular to an aqueous film-forming foam fire extinguishing agent and a preparation method thereof, and is characterized in that the aqueous film-forming foam fire extinguishing agent comprises the following components in percentage by weight: 5-15% of a combined hydrocarbon surfactant, 5-20% of a PFOS(Perfluorooctane sulfonates)-free hydrocarbon surfactant, 15-25% of a foaming agent, 0.3-0.9% of protection colloid, 5-70% of urea, 5%-8% of a foam stabilizer, 5%-15% of an anti-freezing agent, 3%-5% of a solubilizer, 3%-10% of a flame retardant and 20%-40% of water. According to the present invention, the PFOS(Perfluorooctane sulfonates)-free fluorocarbon surfactant is used, and the fire extinguishing agent can be self-degraded in a certain period, such that the high environmental protection property is provided, the environmental pollution is significantly reduced, and the excellent performance is provided, and the product obtained through the preparation method has characteristics of uniform mixing. The raw material proportioning accuracy is high, and the phenomenon of aggregation and caking is avoided during mixing and stirring.

Owner:京开消防科技(浙江)有限公司

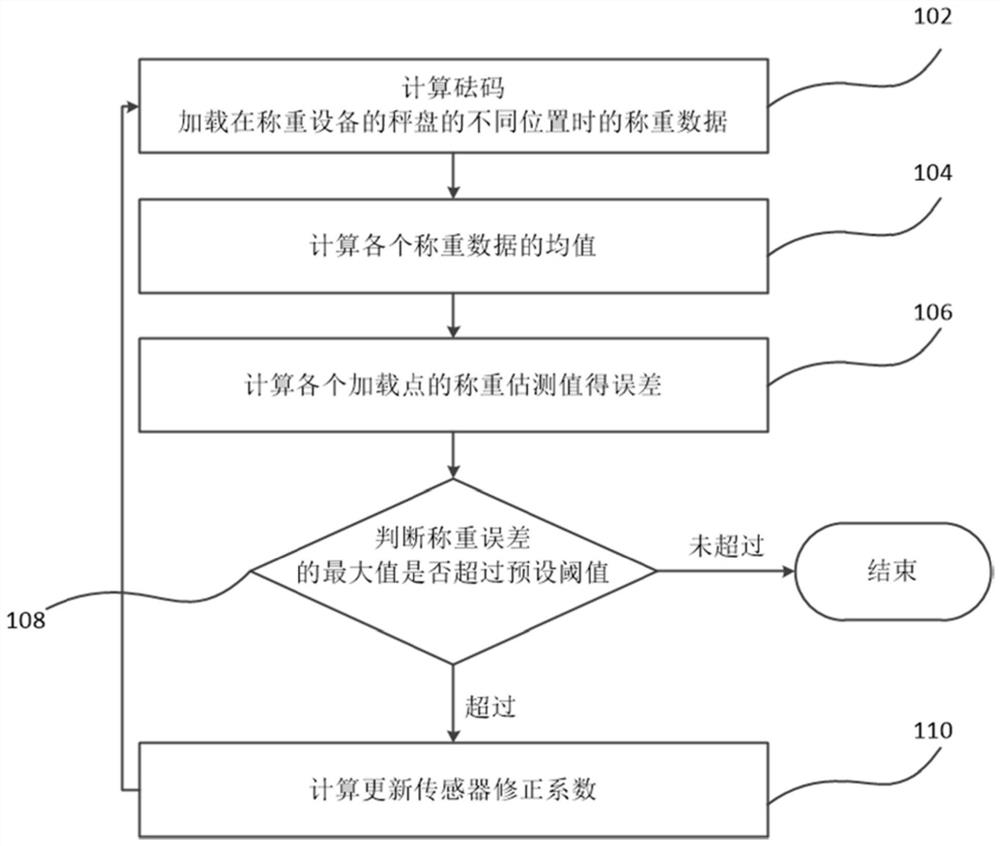

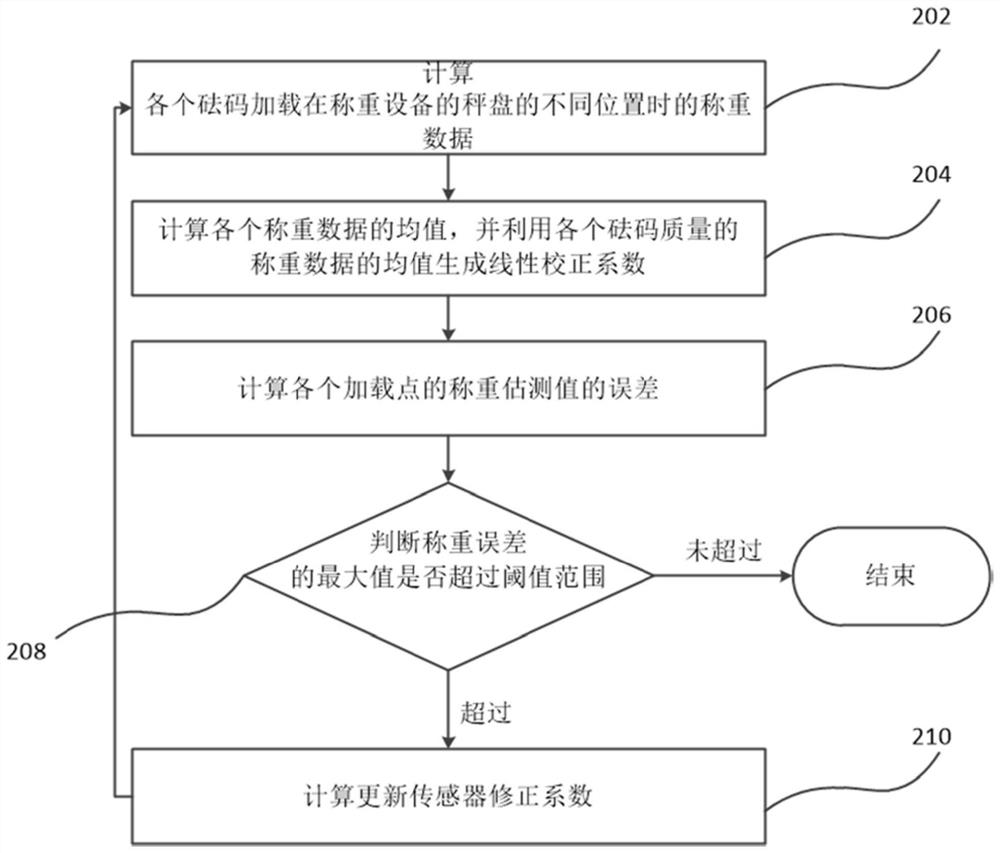

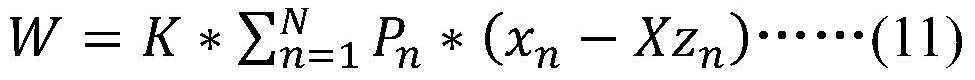

Unbalance loading error correction method and system

ActiveCN113945262AReduce weighing errorsAccurate correction of eccentric load errorWeighing apparatus testing/calibrationAlgorithmIndustrial engineering

The invention discloses an unbalance loading error correction method and system. The correction method comprises the following steps of obtaining weighing data when a weight is loaded at different positions of a weighing platform of weighing equipment, calculating each piece of weighing data and the average value of the weighing data or the difference value of the weights, when the maximum value in the absolute values of the difference values exceeds a preset threshold value, calculating and updating a sensor correction coefficient, and updating the weighing data, and repeating the steps until the absolute values of all the difference values are smaller than the threshold value. The correction system comprises processing equipment and communication equipment, and the processing equipment and the communication equipment execute the correction method. According to the unbalance loading error correction method, the weighing unbalance loading error is directly processed, so that the correction coefficient of the sensor in the weighing equipment is obtained through calculation and is substituted into the weighing data subjected to unbalance loading correction, the minimum weighing error of the weighing data is ensured, and more accurate unbalance loading error correction is realized.

Owner:METTLER TOLEDO (CHANGZHOU) MEASUREMENT TECH CO LTD +2

Method for detecting floating hair amount of knitwear

PendingCN114813444AEasy to separateReduce mistakesWeighing by removing componentPreparing sample for investigationEngineeringMechanical engineering

The invention provides a method for detecting the floating hair amount of knitwear, which comprises the following steps: step 1, taking the knitwear with a preset specification and flawless surface, carrying out overlock treatment on the edge of the knitwear, folding the knitwear in half along the length direction of the knitwear and sewing the knitwear into a trouser leg shape to obtain a sample; 2, the dried single-layer organza gauze is taken, the single-layer organza gauze is weighed through an electronic balance, the weight of the single-layer organza gauze is recorded, and through cooperation of the steps, floating hair can be separated from the sample, the surface of the sample cannot be damaged, damage to the surface of the sample cannot be caused, and waste of the sample cannot be caused; the floating hair on the surface of the sample does not need to be ground and separated on the sample through a friction head, the floating hair can be separated from the sample, substances of the sample cannot be carried, the weight of the floating hair separated from the sample can be truly reflected, errors are greatly reduced, and the accuracy is high; the process of grinding the sample through a friction head is not needed, and the pressure of the friction head does not need to be strictly required.

Owner:FUJIAN SEPTWOLVES IND +1

Multi-station weighing machine and method

ActiveCN105466533BEven by forceAchieve ultra-precise weighingSpecial purpose weighing apparatusControl systemComputer module

Owner:ZHUHAI HUALI FRICTION MATERIAL

Reinforcing device for dynamic weighing of vehicle and using method

ActiveCN113790788AAvoid shaking situationsQuick connectionInternal combustion piston enginesWeighing apparatus detailsSpeed bumpBolt connection

The invention discloses a reinforcing device for dynamic weighing of a vehicle and a using method, and belongs to the technical field of weighing. The reinforcing device for dynamic weighing of a vehicle comprises a cement base, a containing groove is formed in the cement base, a weighing assembly is arranged in the containing groove, a gap is formed between the weighing assembly and the inner wall of the containing groove in the driving direction, the weighing assembly comprises a plurality of weighing bodies, the outer walls of the weighing bodies are connected with junction boxes, and the tops of the weighing bodies are connected with weighing plates. A connection reinforcing mechanism is connected between every two adjacent weighing plates, the bottom wall of the containing groove is fixedly connected with a supporting seat, and a pressure sensor is connected between the supporting seat and the weighing body. The multiple weighing plates are effectively, rapidly and fixedly connected through the connection reinforcing mechanisms, the situations that disassembly and assembly are inconvenient due to bolt connection and the weighing plates shake due to looseness in the later period are avoided, a weighed vehicle is decelerated through the deceleration strip, the accuracy of dynamic weighing is improved, and the practical effect is improved.

Owner:浙江东鼎电子股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com