Loader and high-precision weighing method of loader

A loader, high-precision technology, applied to the detailed information of weighing equipment, weighing, measuring devices, etc., can solve the problems that the impact of the loader's body bumps cannot be ruled out, and the horizontal inclination of the bushing has not been collected, etc., to achieve precision High and reduce the effect of weighing error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make those skilled in the art better understand the present invention, the present invention will be further described below in conjunction with specific embodiment:

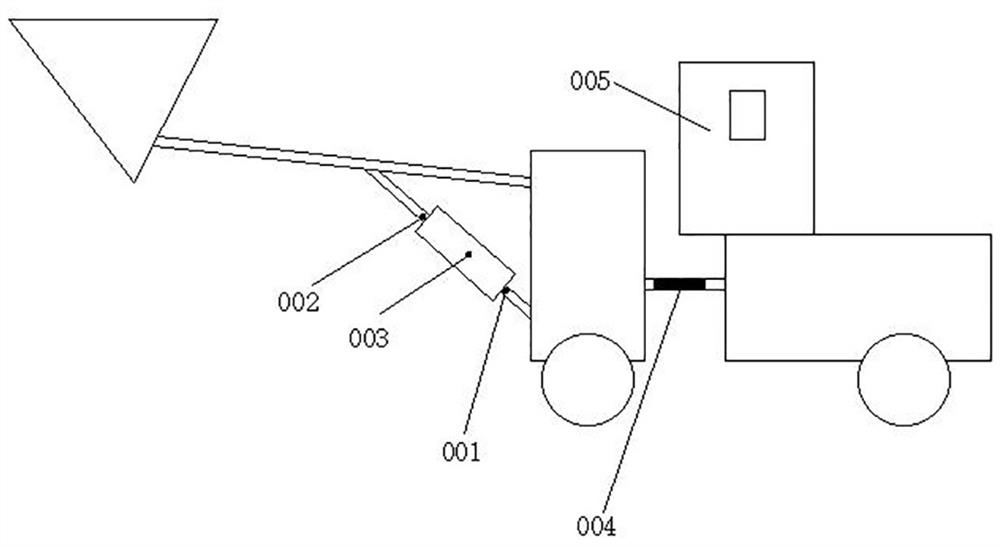

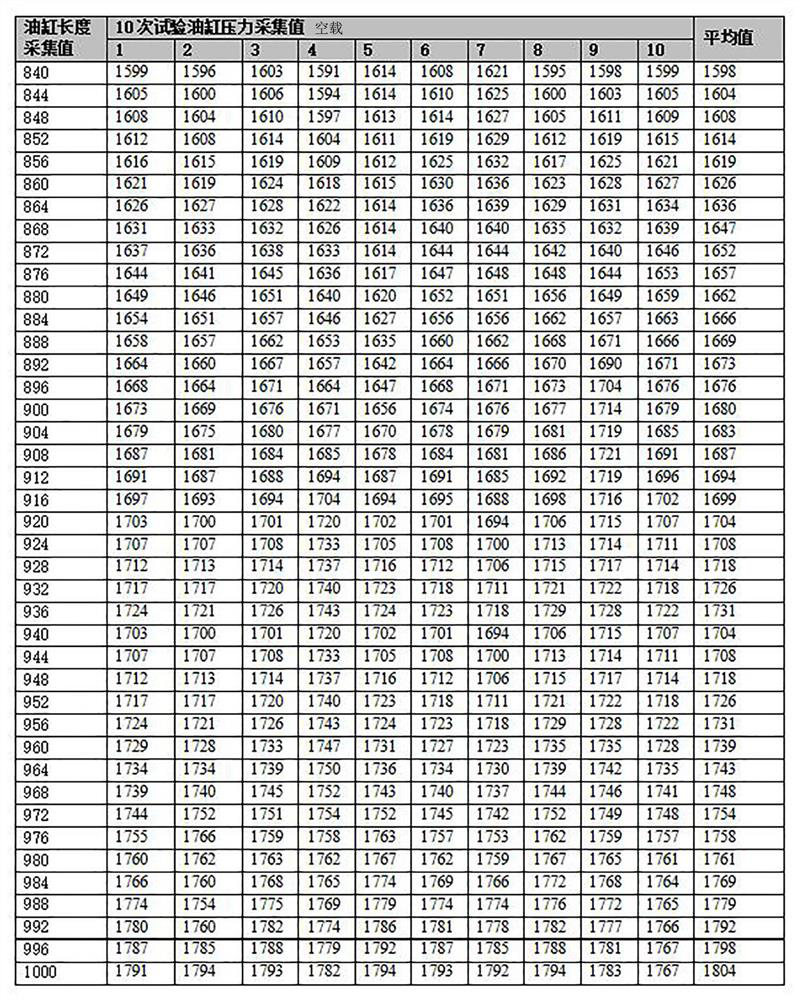

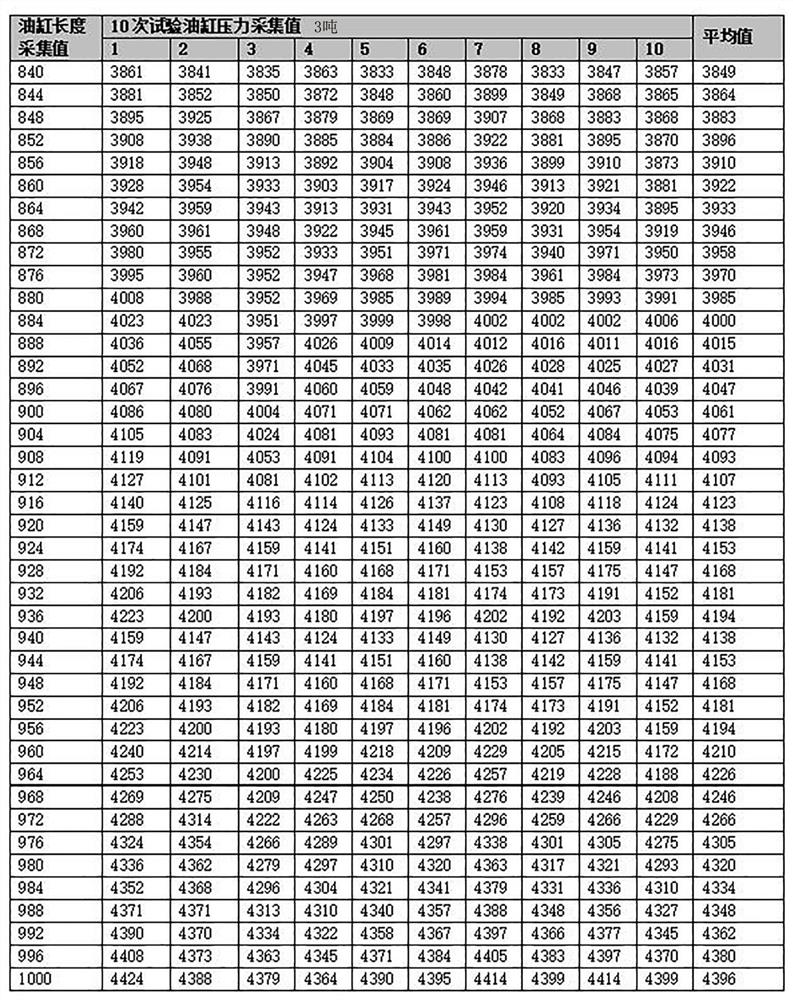

[0031] Such as Figure 1-4As shown, the loader and the high-precision weighing method of the loader include a loader body and a weighing system installed on the loader body, and the weighing system includes a host, a first pressure sensor 001, a second pressure sensor 002, displacement detection sensor 003 and car body attitude detection sensor 004; the host is installed in the control room of the loader body, and the signal output end of the host is connected to a display screen; the first pressure sensor 001 is installed in the boom distribution of the hydraulic system of the loader body The flange of the oil inlet pipeline at the rear end of the valve is used to detect the oil pressure signal; the second pressure sensor 002 is installed at the flange of the oil return pipeline at the rear e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com