Unbalance loading error correction method and system

A technology of eccentric load error and correction coefficient, applied in the field of eccentric load error correction and system, can solve problems such as inaccurate eccentric load error correction, achieve small weighing error, accurate eccentric load error correction, improve accuracy and correction efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention is further illustrated below by means of examples, but the present invention is not limited to the scope of the examples.

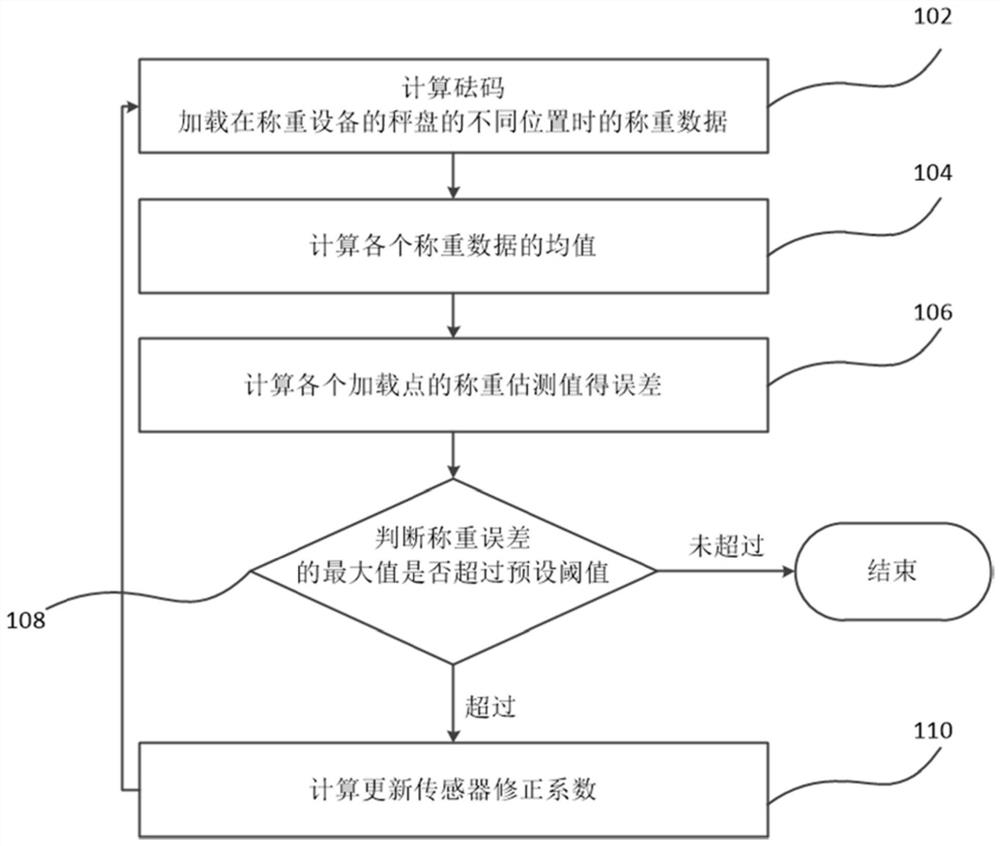

[0039] In the method for correcting the eccentric load error of the weighing equipment in one embodiment, the following steps are included:

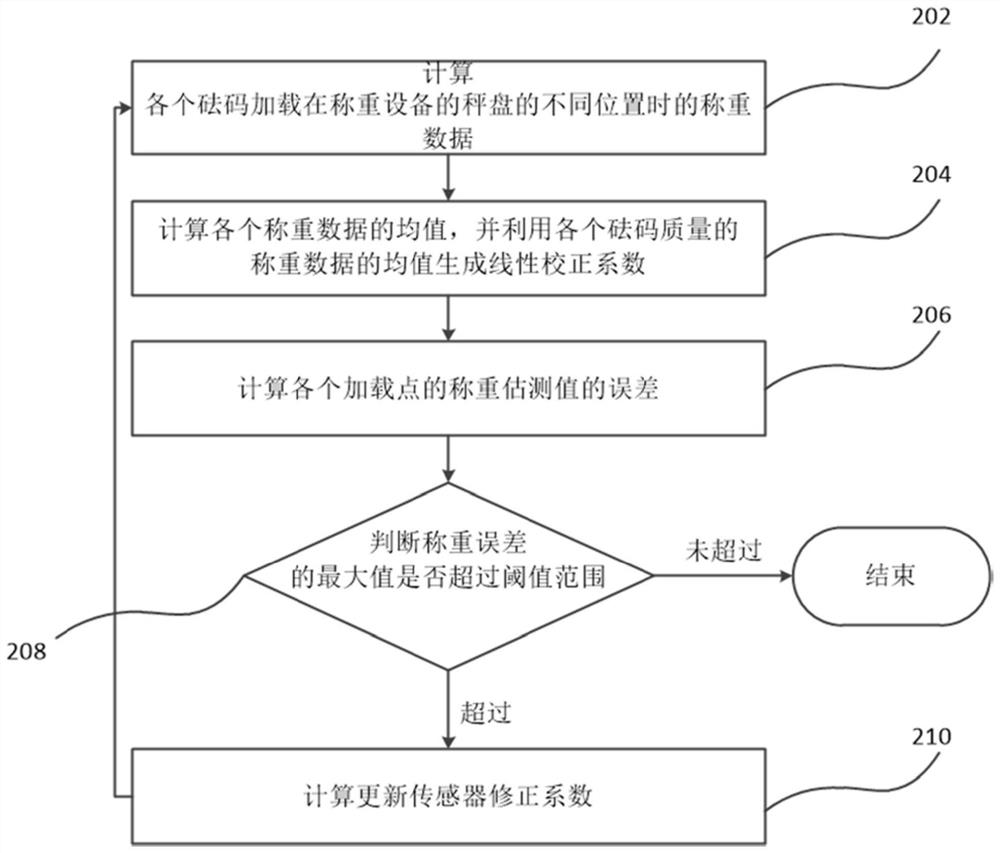

[0040] The weighing data when weights of different masses are loaded on different positions of the weighing platform of the weighing device are respectively obtained.

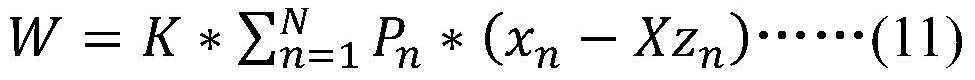

[0041] The difference between each weighing data of each mass weight and the mean value of the weighing data is calculated respectively, and the linear parameter is calculated by using the mean value of each mass weight.

[0042] When the maximum value of the absolute value of the difference exceeds the threshold, use linear parameters to calculate and update the sensor correction coefficient, and update the weighing data of the weighing device; until all the differences are less than the threshold.

[0043] In this embo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com