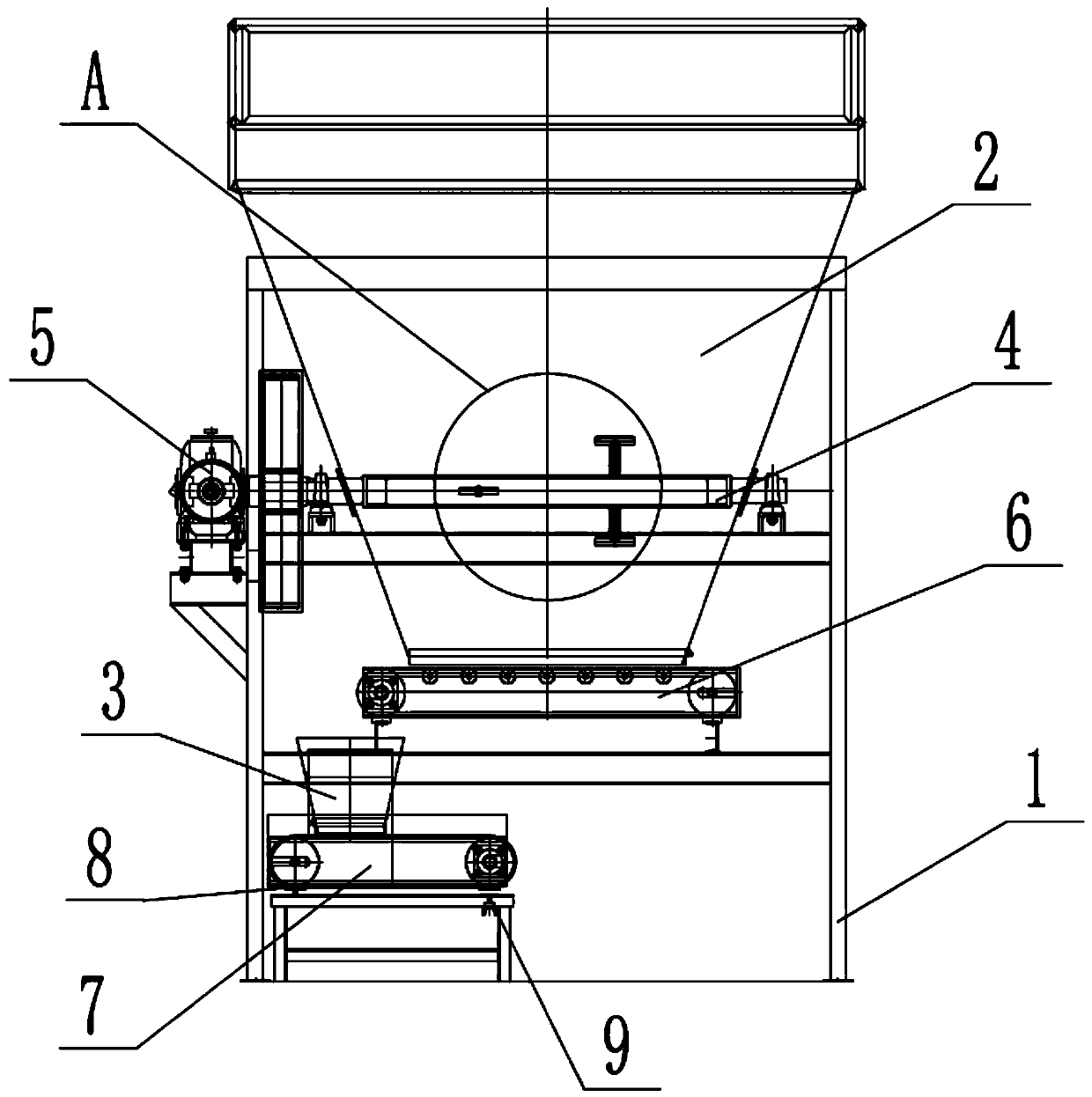

Static metering and feeding system for ceramic raw materials

A feeding system and static metering technology, which is applied in the field of static metering feeding system for ceramic raw materials, can solve the problems of heavy raw material weight, unstable weight of loaded raw materials, affecting production operation, etc., and achieve the effect of reducing weighing errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

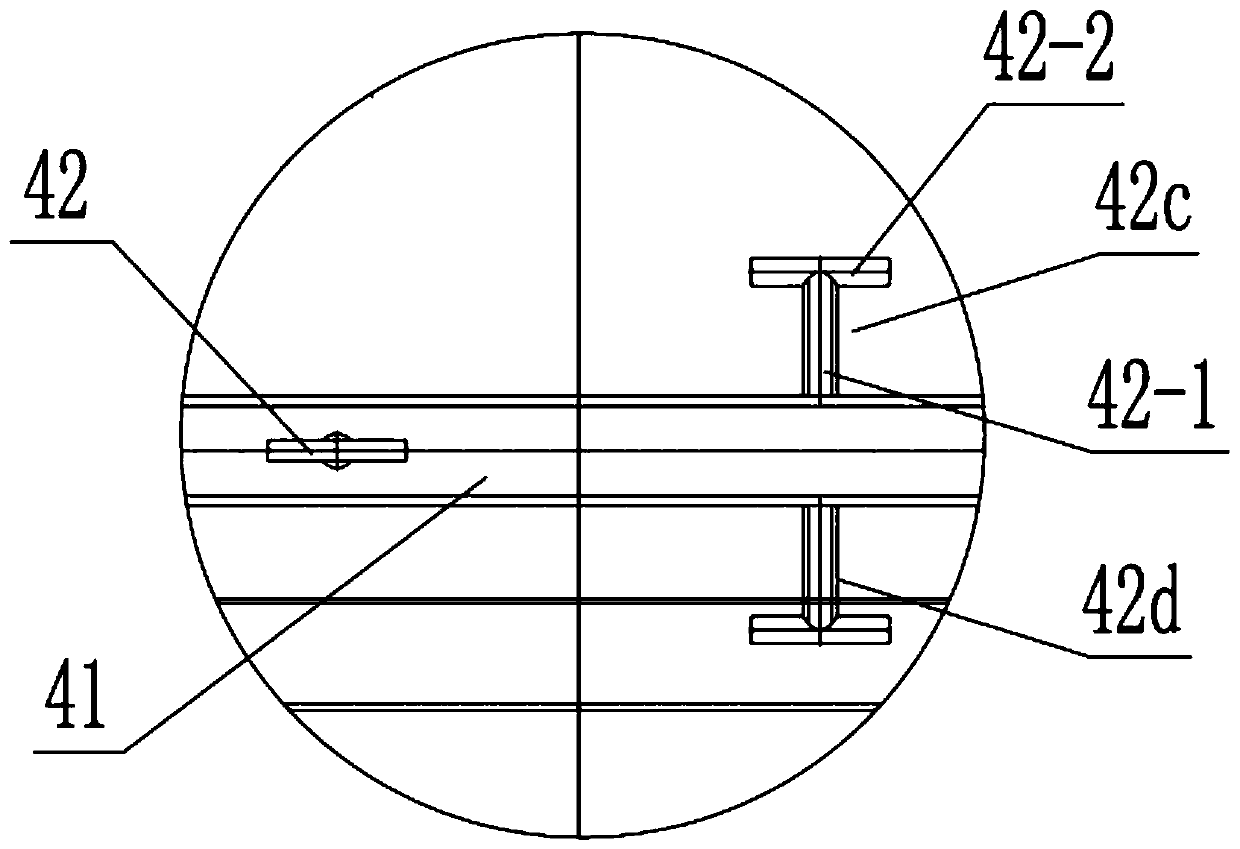

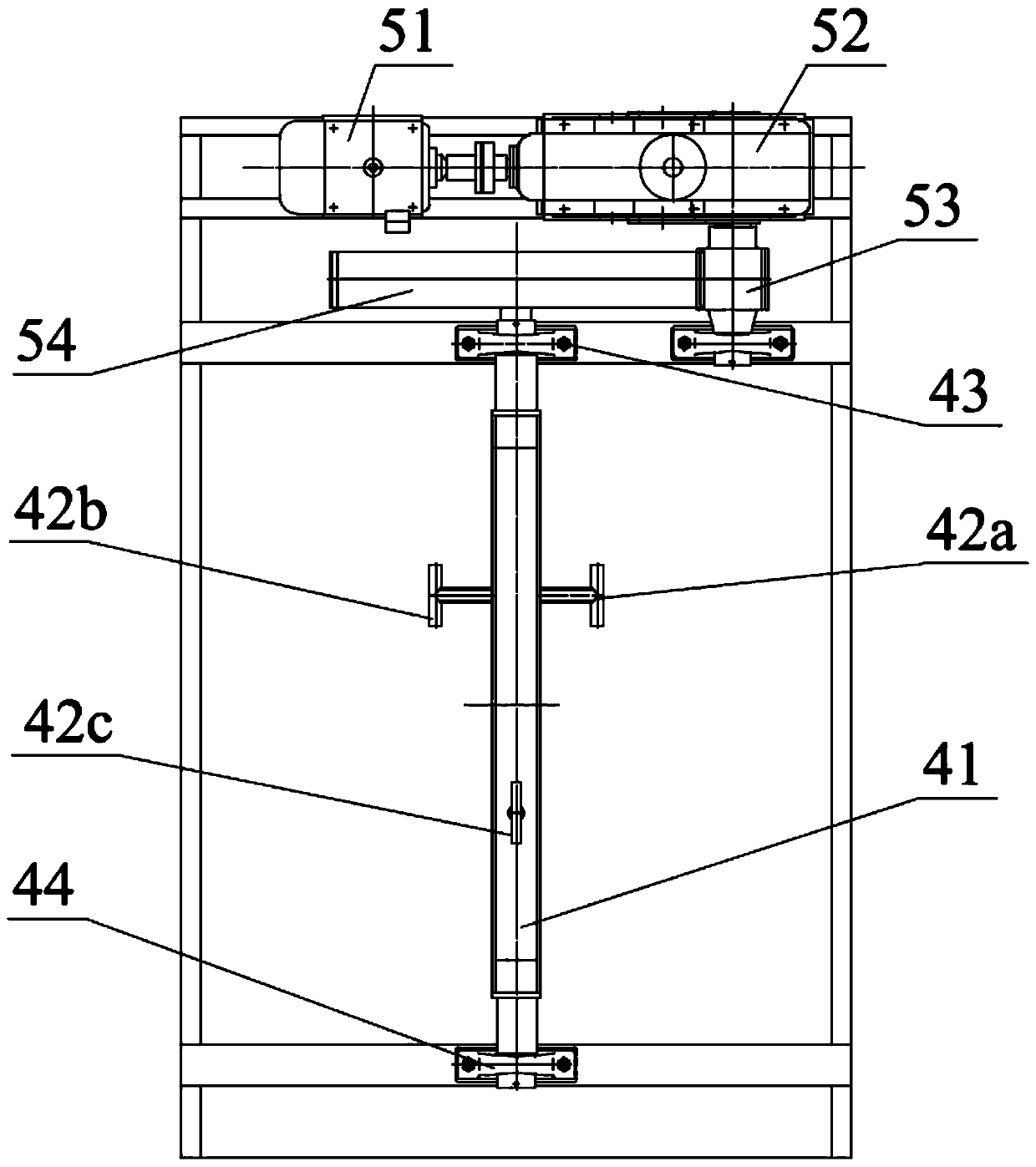

Method used

Image

Examples

Embodiment 1

[0033] When production requires weighing 100kg of raw materials, the unloading weight of the sealing unloading belt 6 per minute is 1.0kg, and the steps are as follows:

[0034] (1) Weighing 50 times by setting the controller, weighing 2.0kg each time;

[0035] (2) The sealing discharge belt 6 runs for 2 minutes, and pours the raw materials in the storage hopper 2 into the weighing hopper 3;

[0036] (3) When the sealing discharge belt 6 stops running, the first load cell 8, the second load cell 9 and the third load cell 10 start to measure the weight of the raw material, and the average value is 1.9kg;

[0037] (4) After the measurement is completed, the weighing belt 7 runs, and the raw materials in the weighing hopper 3 are poured into the conveyor belt, and the raw materials are transported to the next process by the conveyor belt;

[0038](5) The last weighed weight was 1.9kg, compared with the preset weight of 2.0kg, a difference of -0.1kg, when weighing next time, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com