Multi-station weighing machine and method

A weighing machine and multi-station technology, applied in the direction of weighing, measuring devices, instruments, etc., can solve the problems of no feeding speed, no weighing accuracy, overflow and leakage of the screw nozzle, and achieve reduction The effect of weighing error, improving weighing accuracy and increasing weighing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

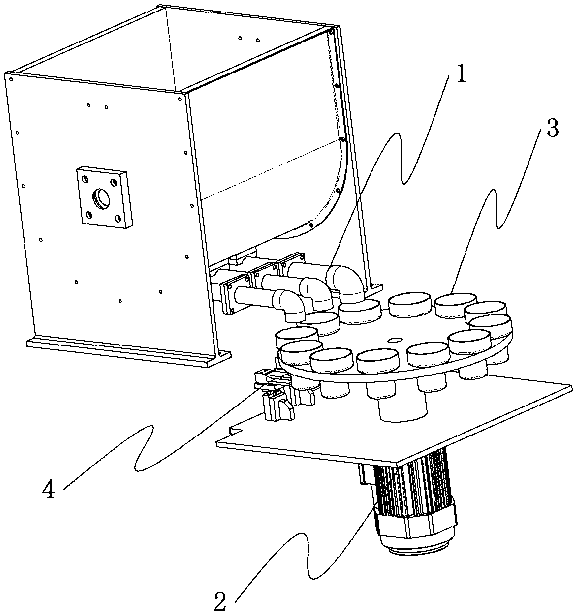

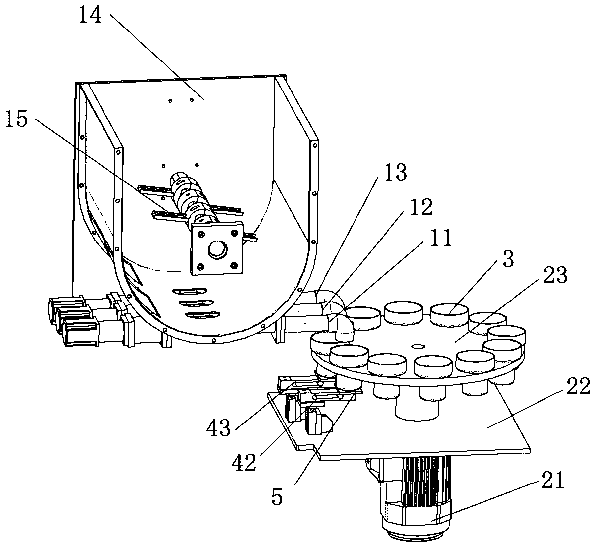

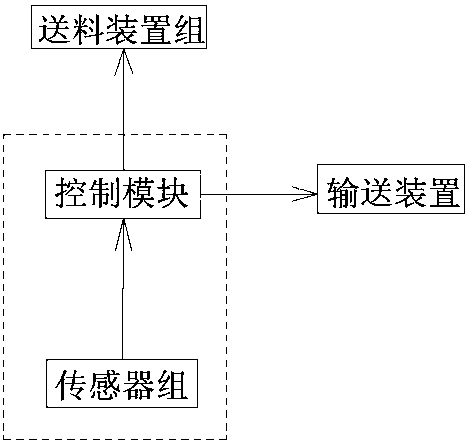

[0051] The feeding device group 1 is composed of two feeding devices, the conveying device is set under the feeding device, the sensor group 4 is composed of two load cells, each load cell is set under a corresponding feeding device, and each load cell is installed On the fixed plate 22 of the conveying device 2 . When the conveying device 2 steps a station distance, there will be a material weighing container 3 set on a load cell, and the supporting pallet 5 will evenly transmit the gravity of the material weighing container 3 to the load cell; The control system can analyze whether there is a material weighing container 3 above and whether the added weight reaches the preset value by monitoring the weight on the load cell; when the first material weighing container 3 is transported to the first feeding device 11 When it is below the discharge port, the control system controls the first feeding device 11 to rotate forward to discharge the material. When the control system det...

Embodiment 2

[0053] The feeding device group is composed of three feeding devices, namely the first feeding device 11, the second feeding device 12 and the third feeding device 13, the conveying device 2 is arranged below the feeding device, and the sensor group 4 is composed of two load cells. Respectively the second load cell 42 and the third load cell 43, the second load cell 42 is located below the corresponding second feeding device 12, the third load cell 43 is located below the corresponding third feeding device 13, each The load cells are all installed on the fixed plate 22 of the conveying device 2 . When the conveying device 2 steps a station distance, there will be a material weighing container 3 set on a load cell, and the supporting pallet 5 will evenly transmit the gravity of the material weighing container 3 to the load cell; The control system can analyze whether there is a material weighing container 3 above and whether the increased weight reaches the preset value by moni...

Embodiment 3

[0055] The feeding device group 1 is composed of three feeding devices, which are respectively the first feeding device 11, the second feeding device 12 and the third feeding device 13; the sensor group 4 is composed of three sensors, which are respectively The first load cell corresponding to the position of the first feeding device 11 , the second load cell 42 corresponding to the position of the second feeding device 12 and the third load cell 43 corresponding to the position of the third feeding device 13 . The control system controls the conveying device 2 to step by one station distance in intervals. When the material weighing container 3 is conveyed to the position below the outlet of the first feeding device 11, the control system controls the first feeding device 11 to rotate forward and discharge the material, and the control system The system detects the increased weight of the material weighing container 3 through the first load cell. When the increased weight of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com