Patents

Literature

46results about How to "Uniform feeding speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

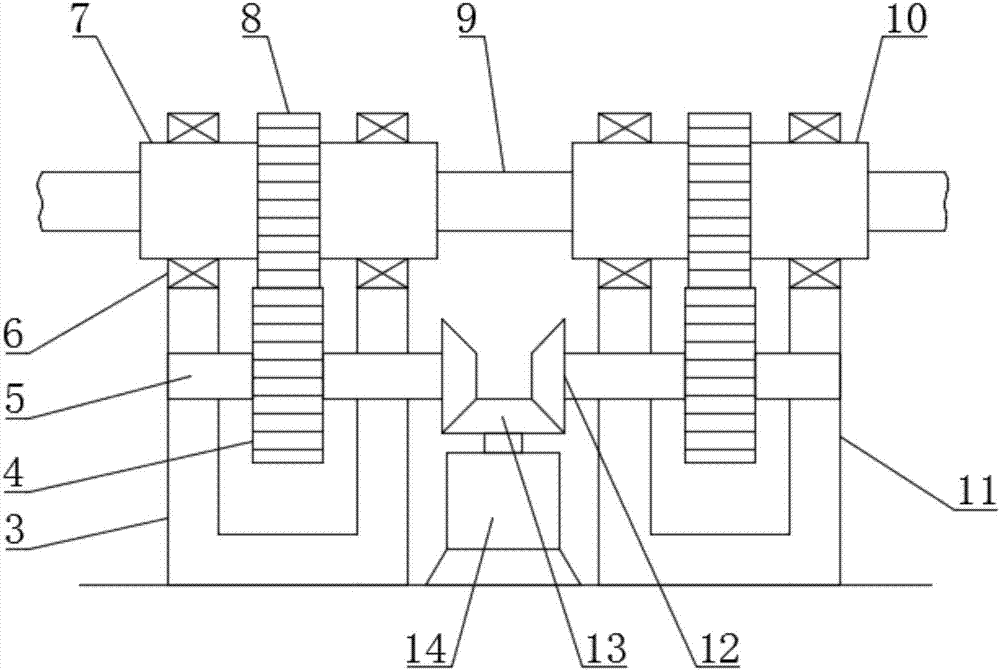

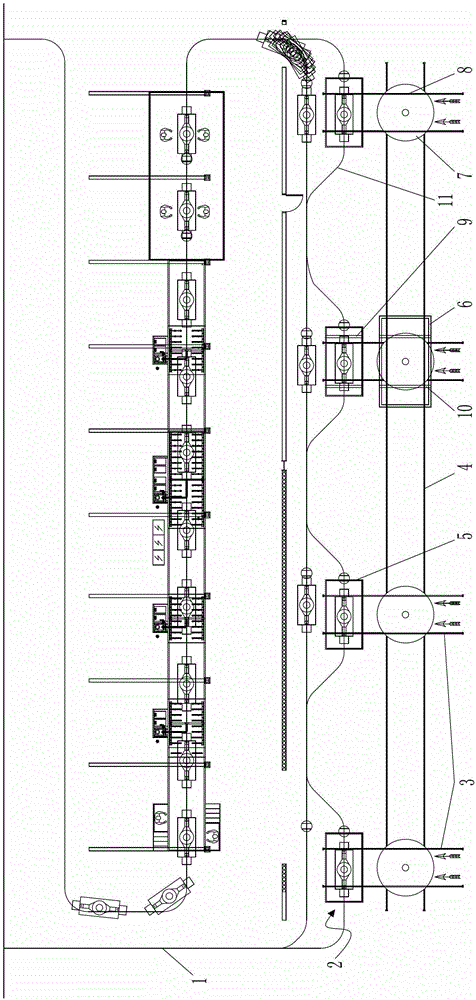

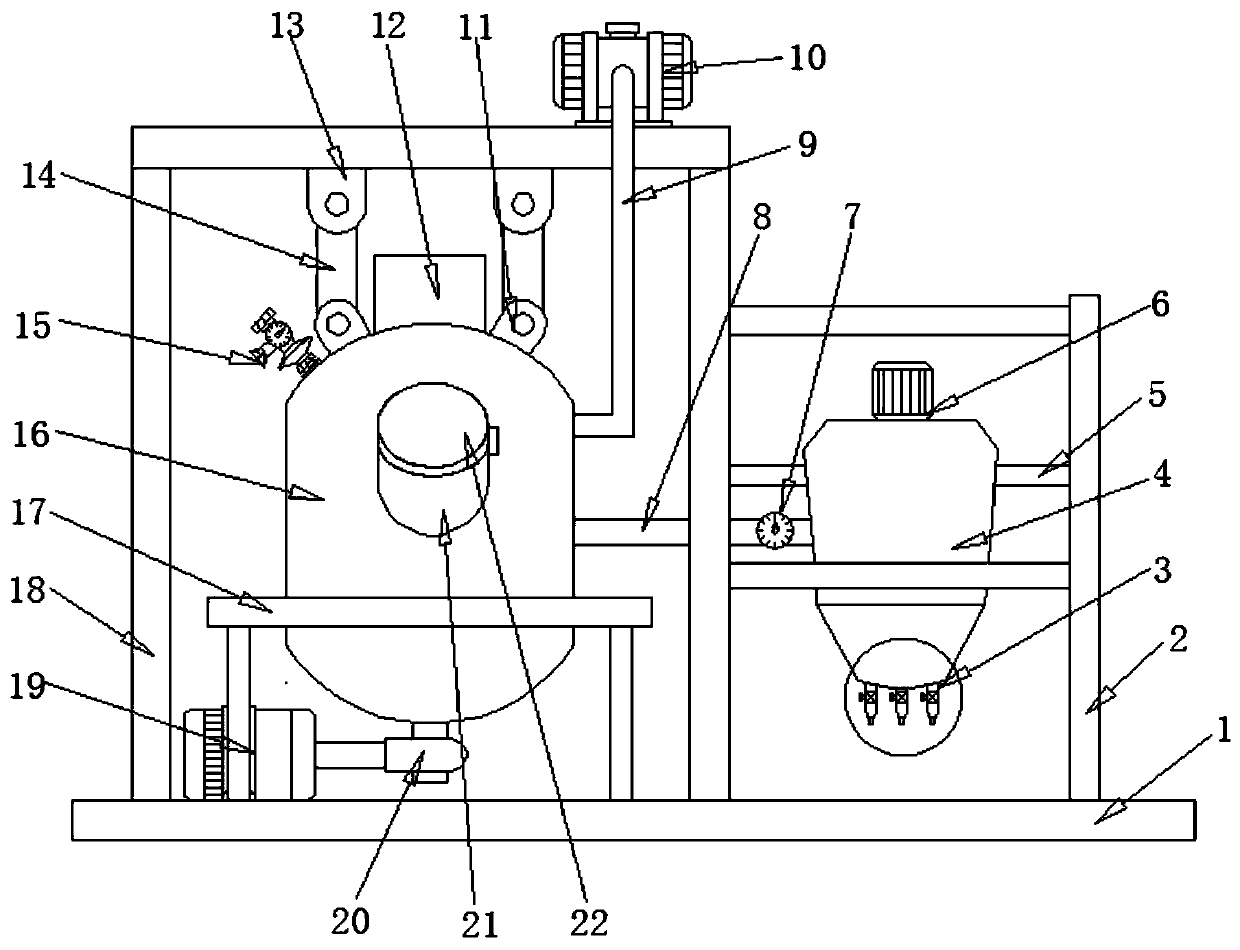

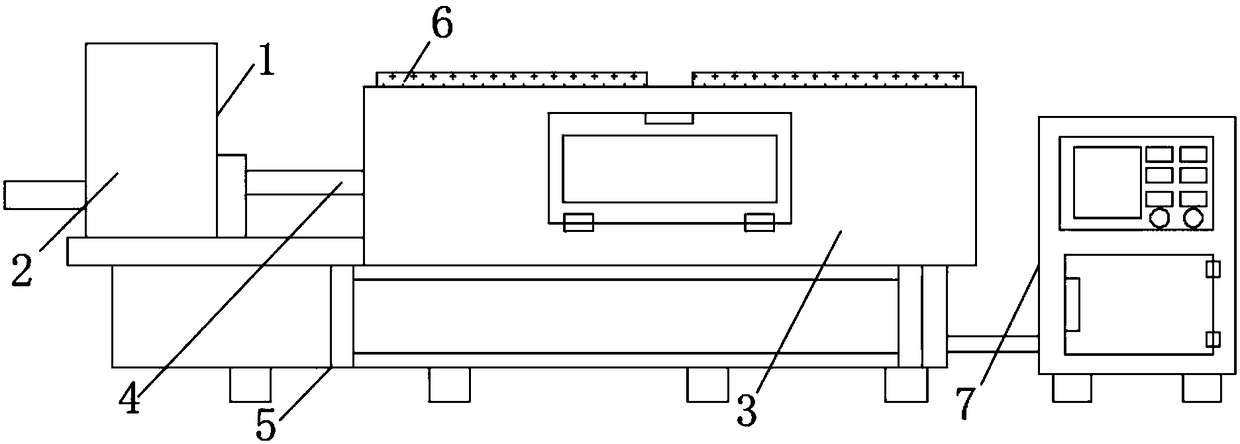

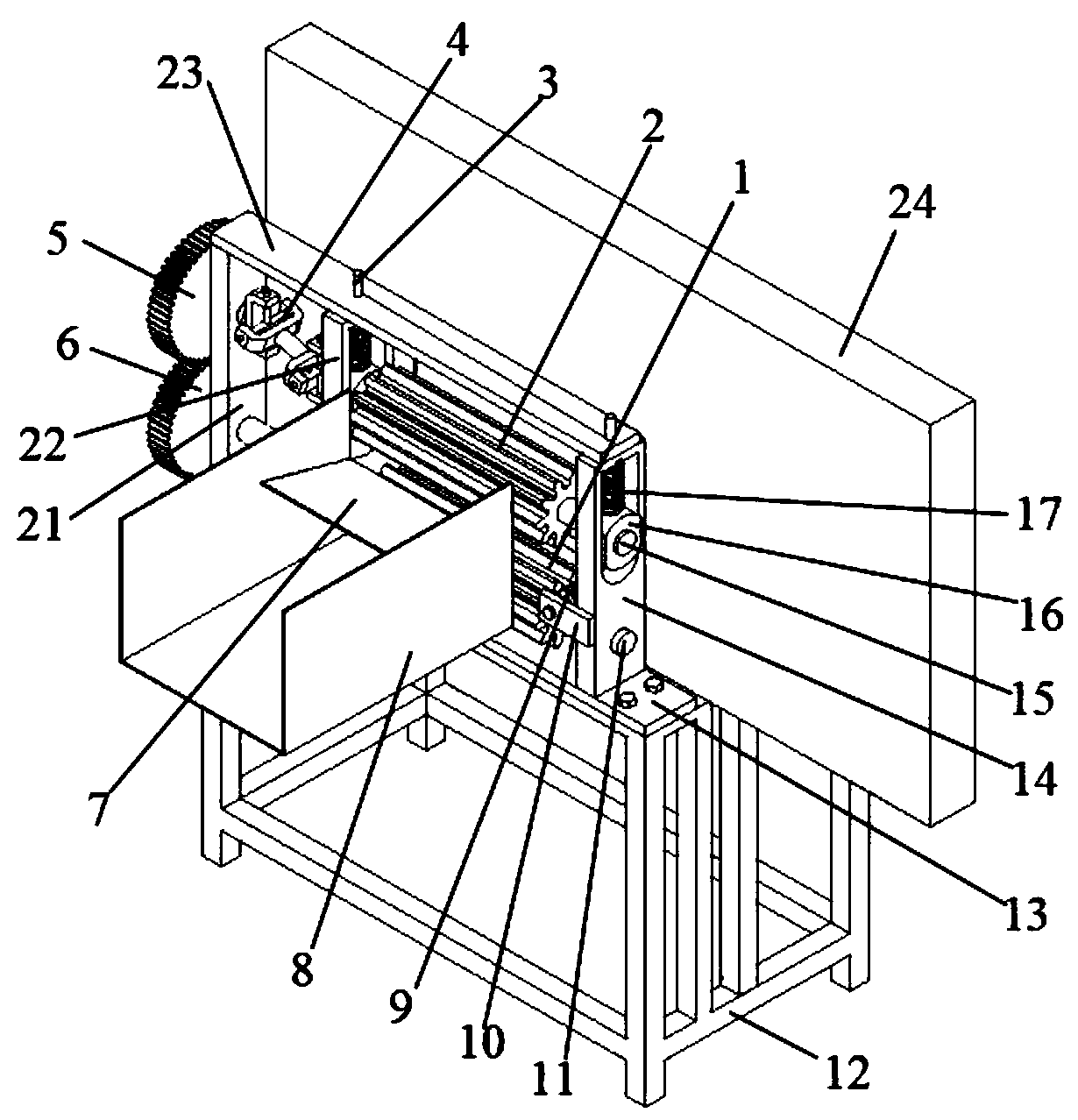

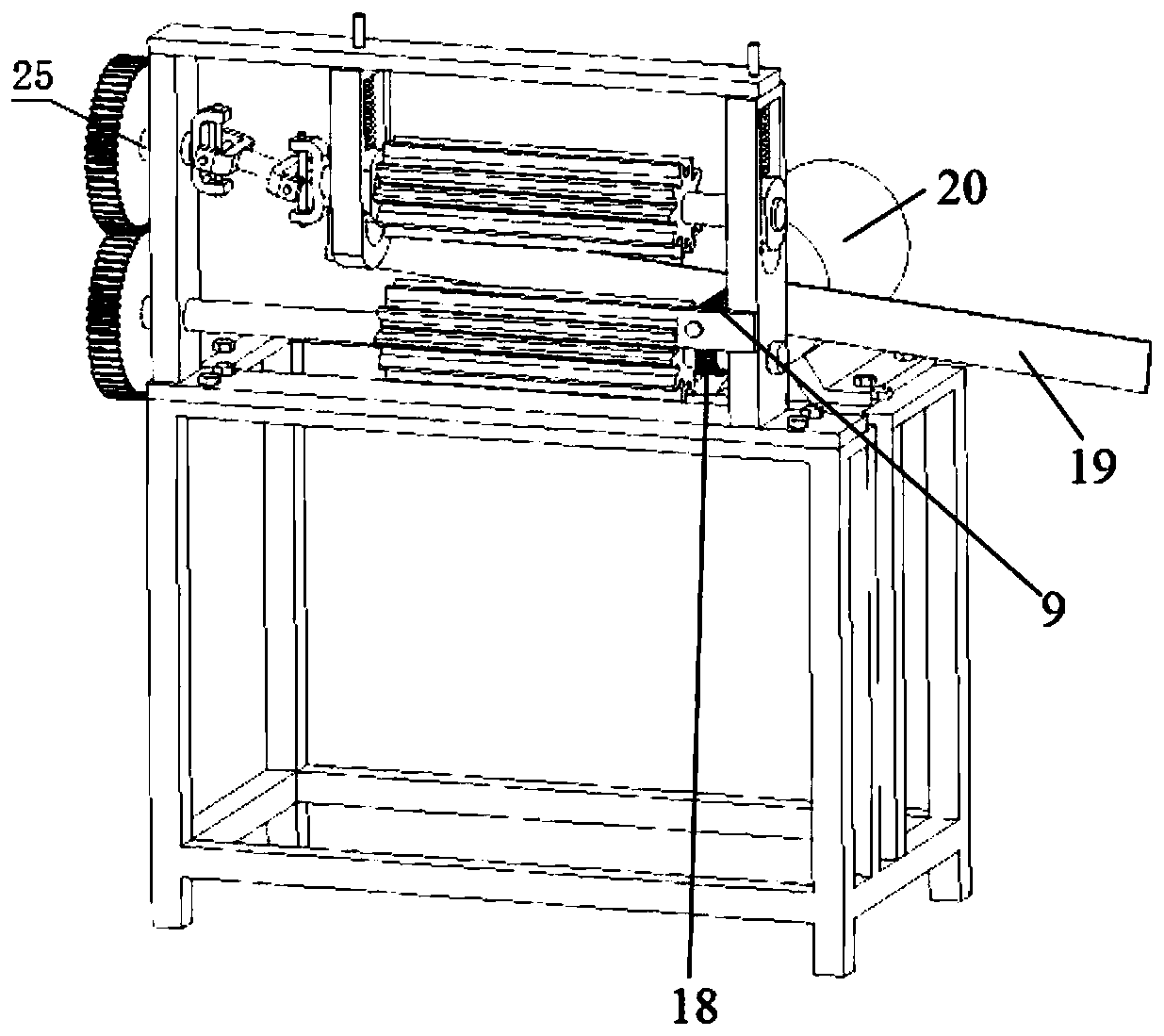

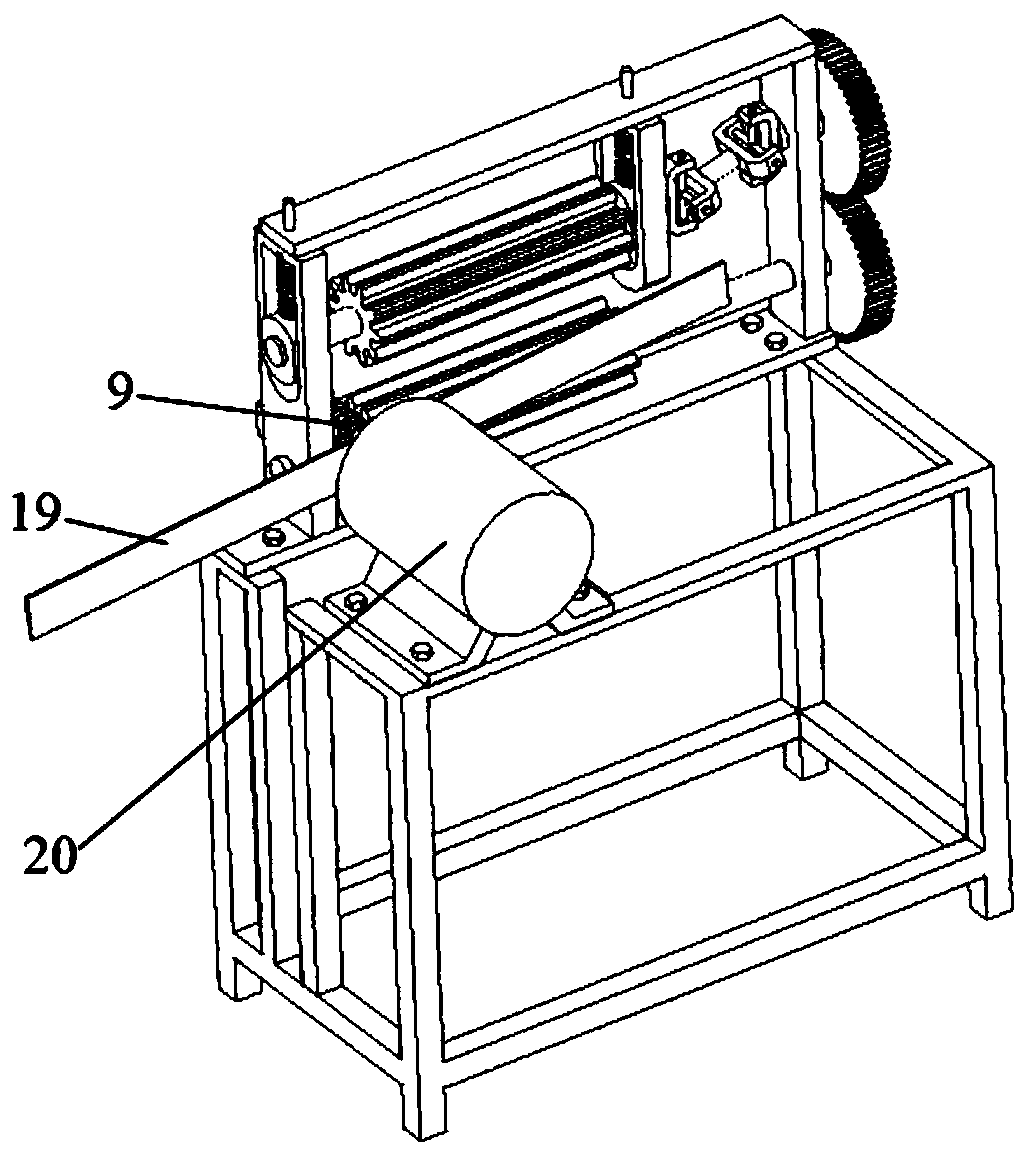

Steel pipe rust removing and cutting integrated machine for building

InactiveCN107234293AImprove processing efficiencyGuaranteed smoothGrinding machinesTube shearing machinesGear wheelArchitectural engineering

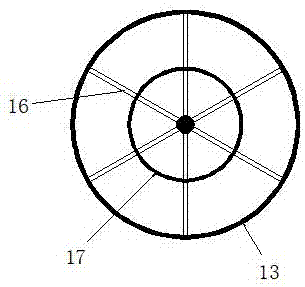

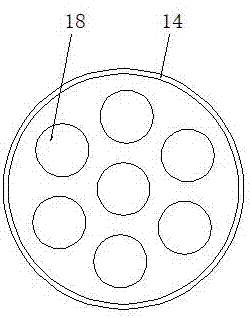

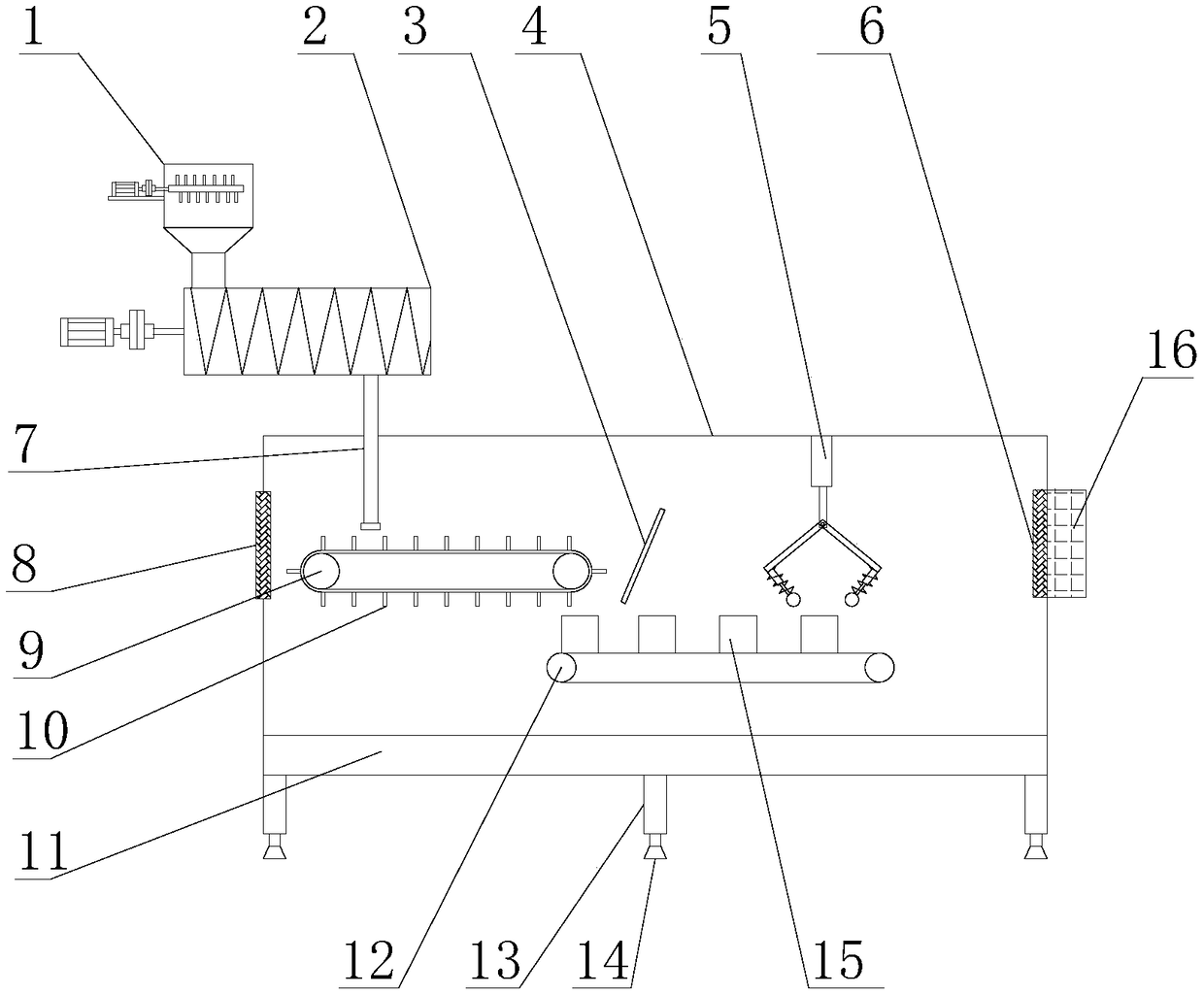

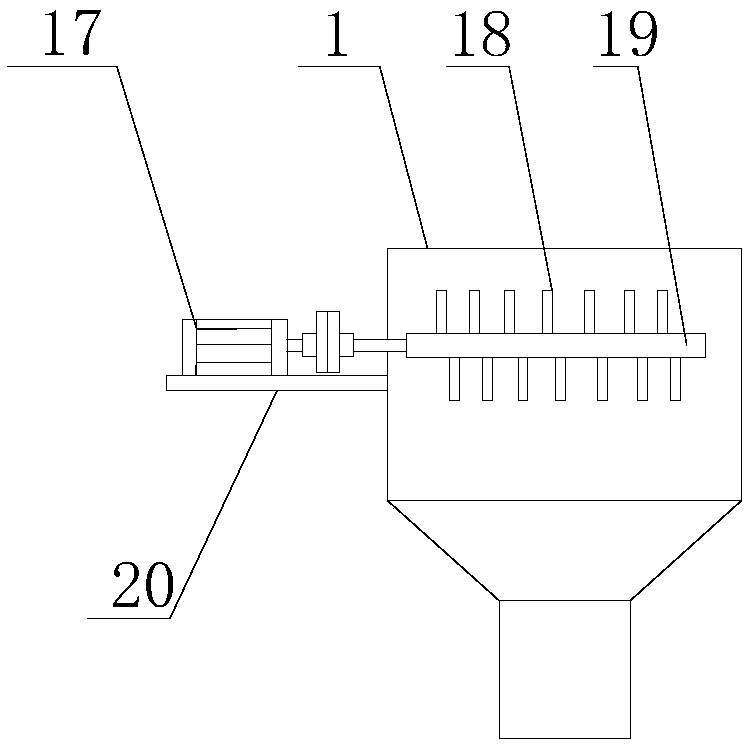

The invention discloses an integrated machine for derusting and cutting steel pipes for construction, which comprises a base and a steel pipe. The base is provided with a first U-shaped seat and a second U-shaped seat, and the tops of the first U-shaped seat and the second U-shaped seat respectively pass through the The bearing with seat is rotatably connected with a first derusting cylinder and a second derusting cylinder, and second gears are fixedly installed on the first derusting cylinder and the second derusting cylinder; the first U-shaped seat and the second U-shaped seat also have Rotationally connected with a rotating shaft, the first gear is installed on the rotating shaft, the first gear meshes with the second gear, the right end of the rotating shaft connected with the first U-shaped seat and the left end of the rotating shaft connected with the second U-shaped seat are equipped with the second bevel gear , the base is also provided with a first motor, the motor shaft at the top of the first motor is connected with a first bevel gear, and the first bevel gear meshes with the second bevel gear. The invention rotates the derusting cylinder, and a derusting brush is arranged on the inner wall of the derusting cylinder to derust the steel pipe, and the scope of derusting is wide; there are two derusting cylinders with opposite rotation directions, so that the derusting is more thorough.

Owner:肖进兴

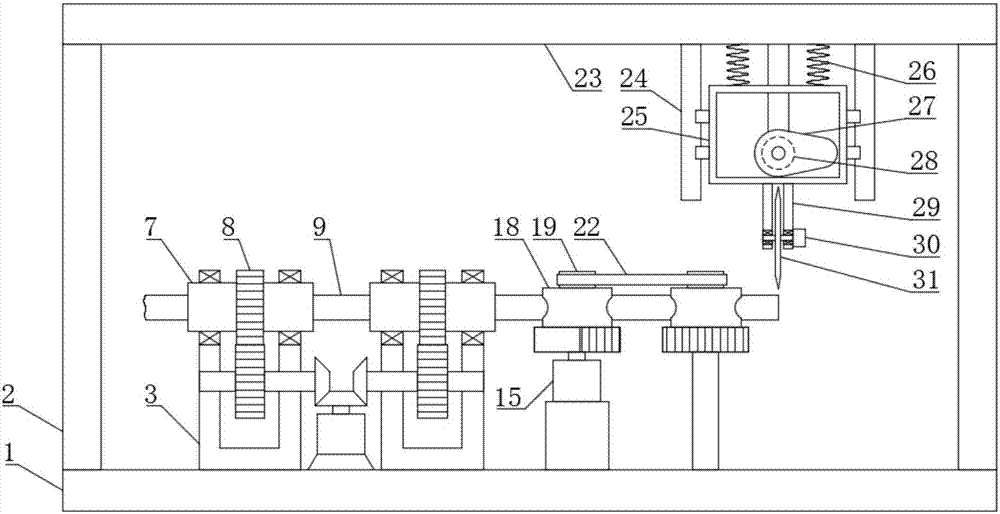

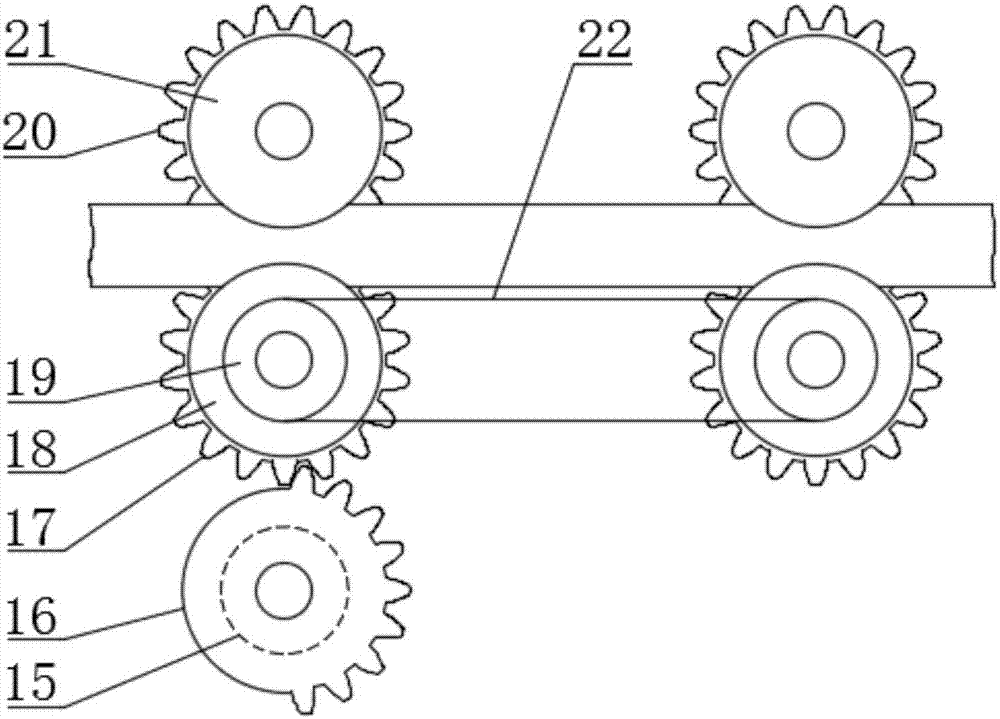

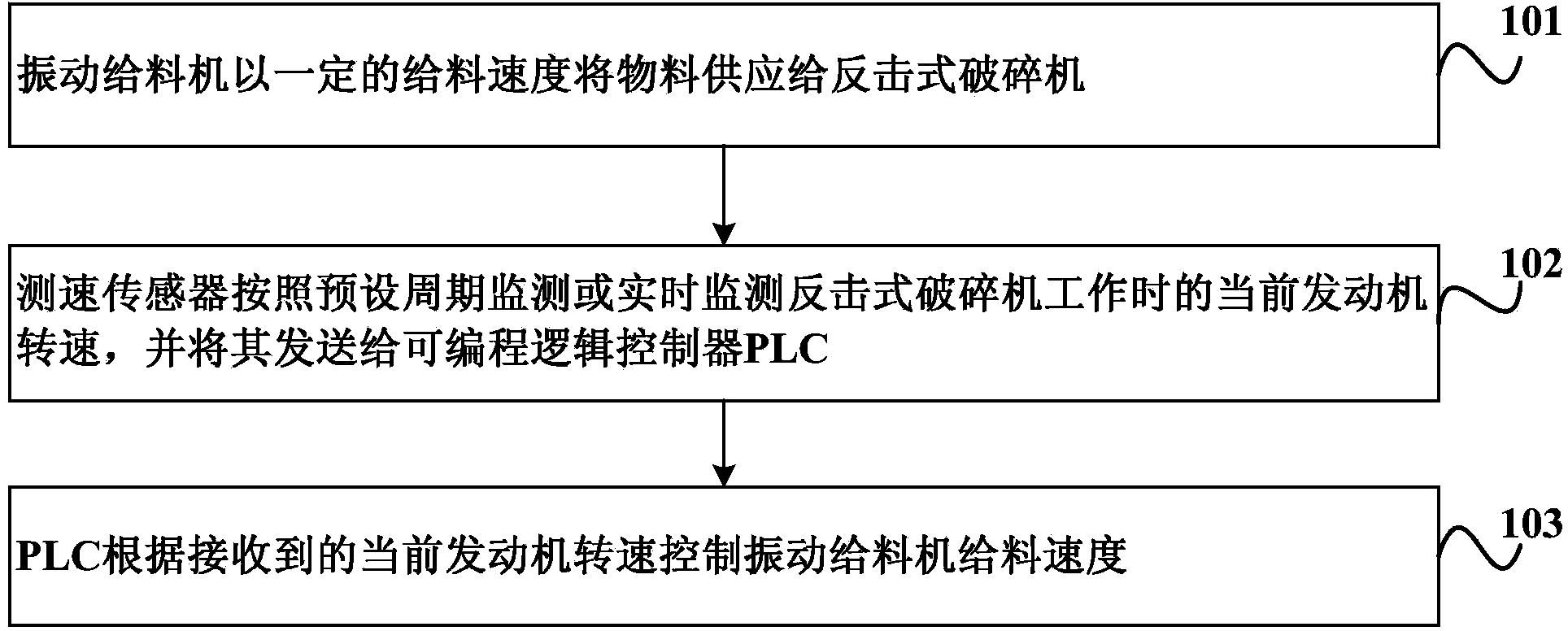

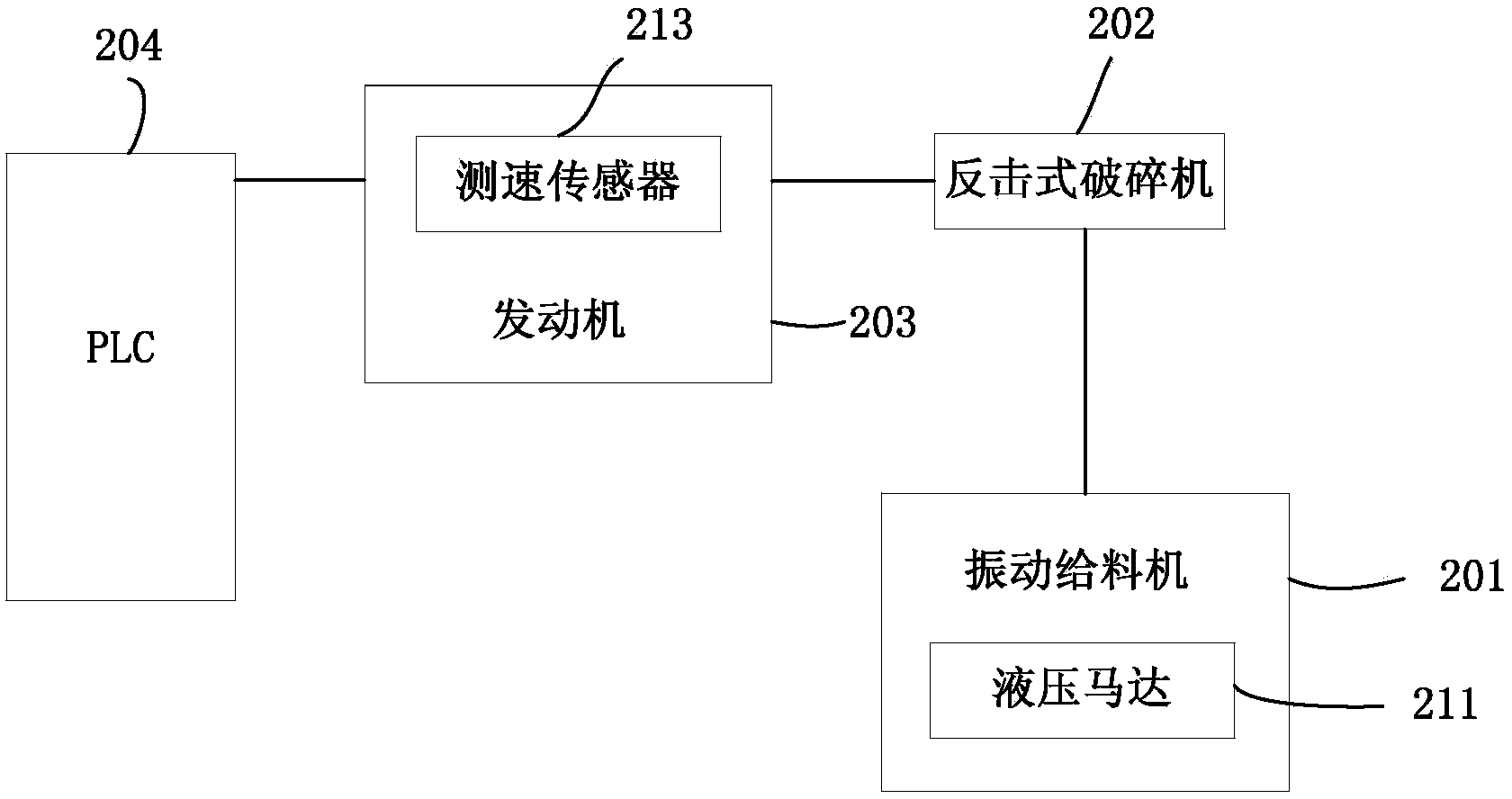

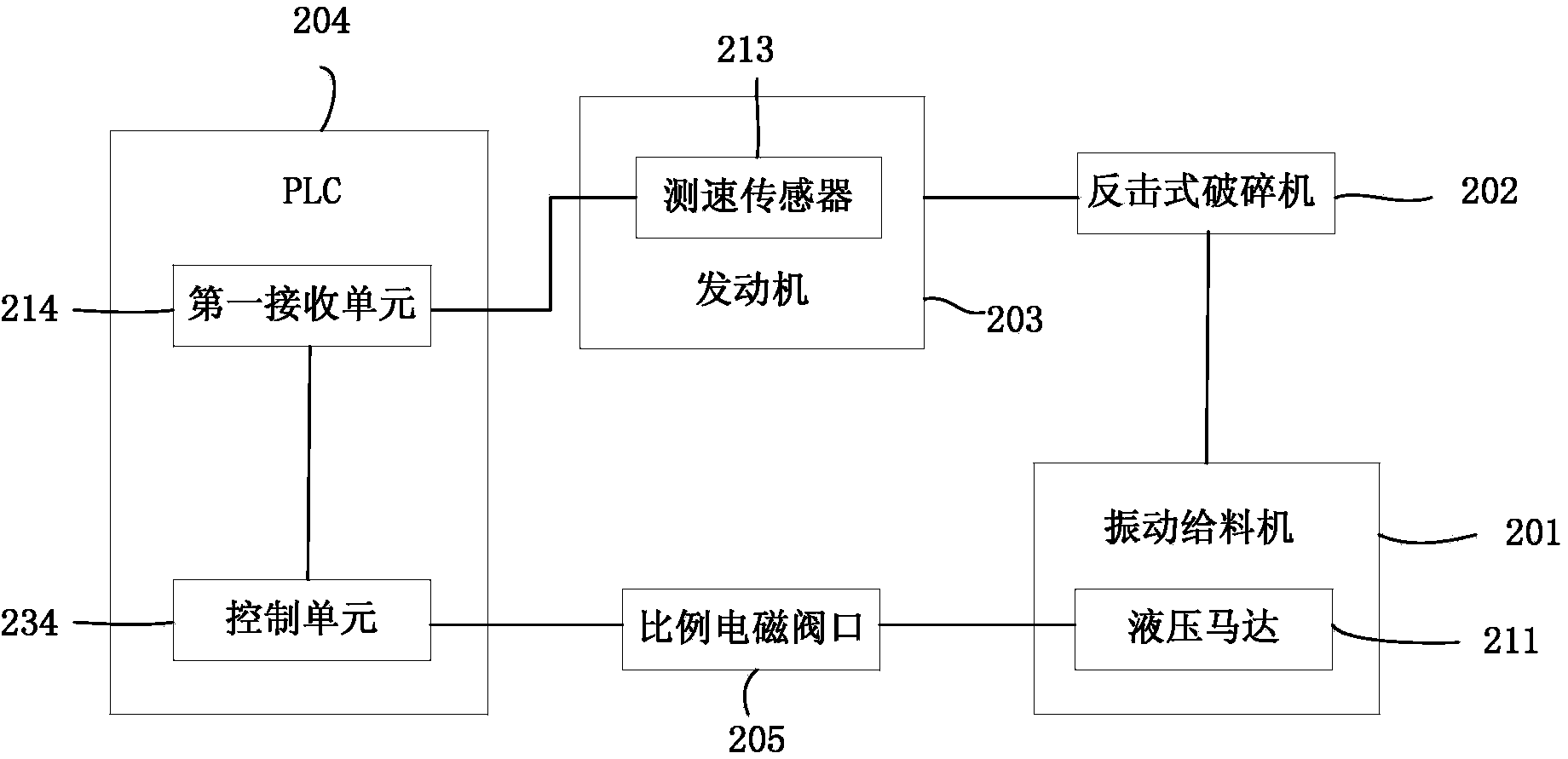

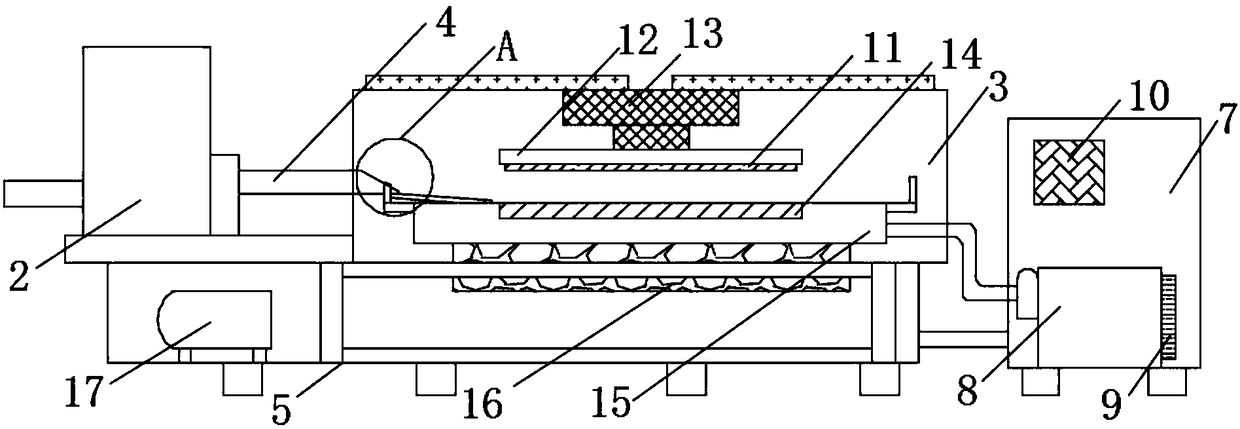

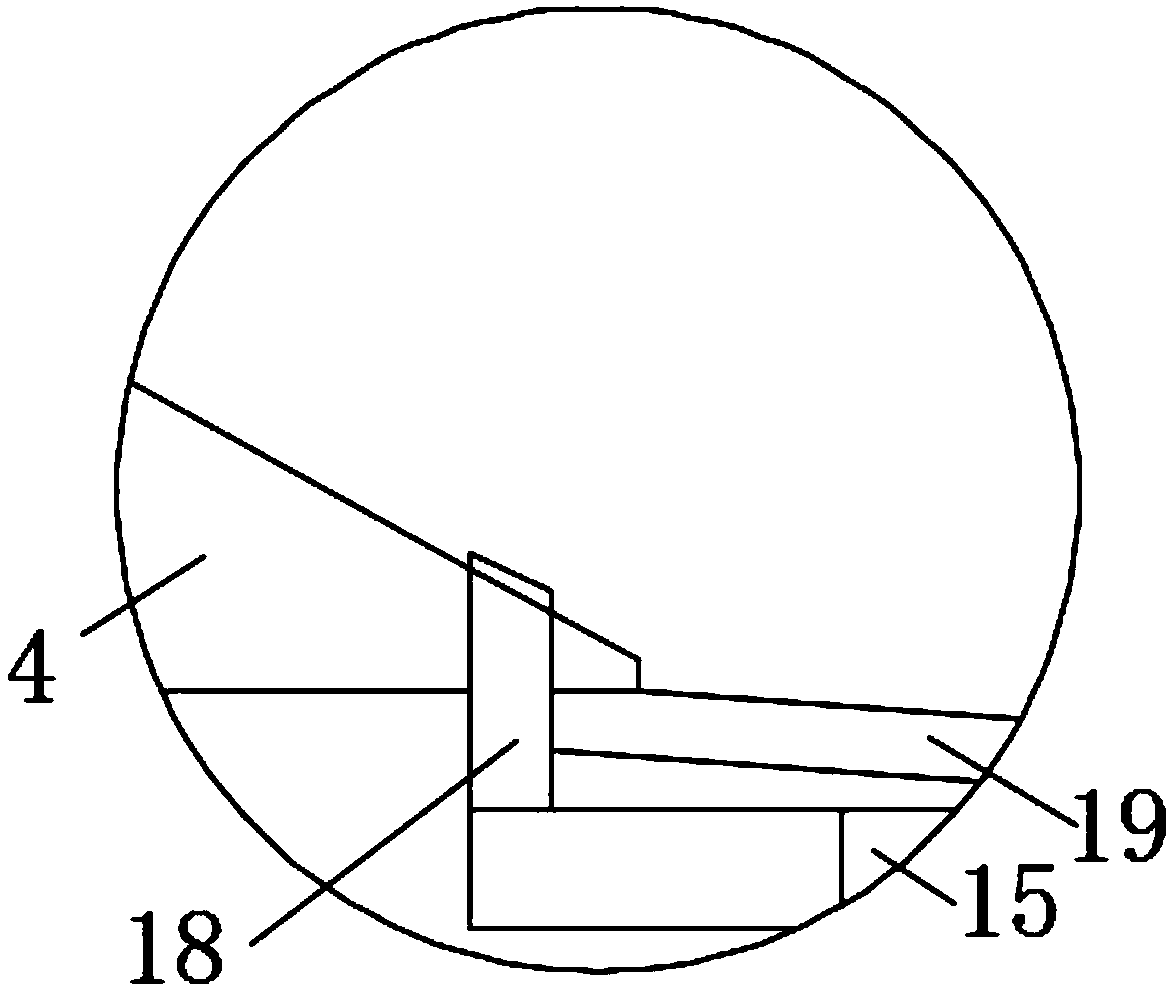

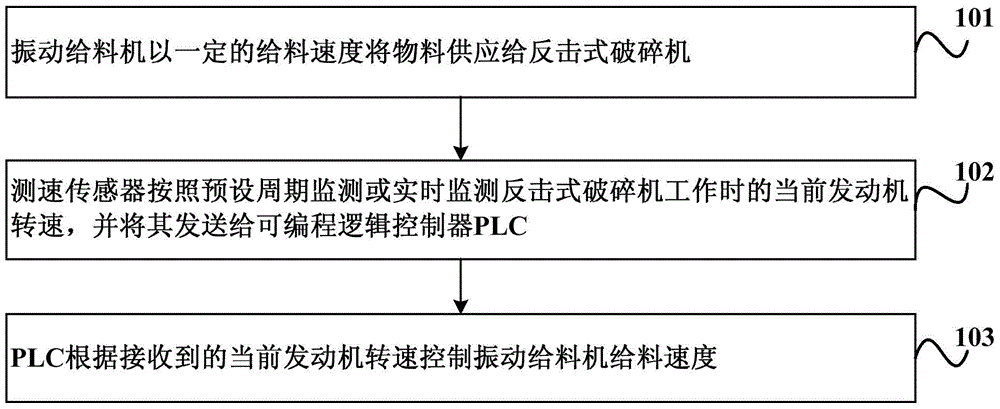

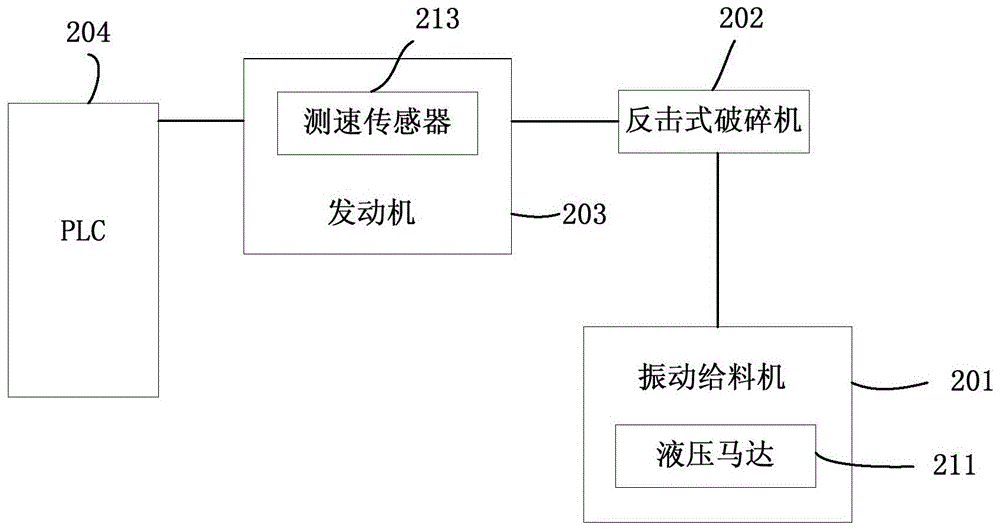

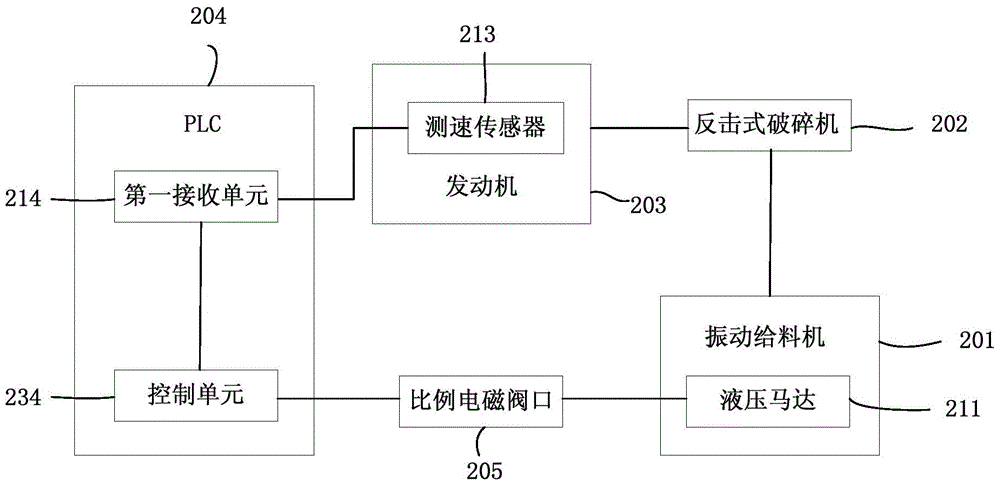

Method and system for controlling feeding speed of vibrating feeder

ActiveCN103949330AAvoid cloggingUniform feeding speedGrain treatmentsProgrammable logic controllerCrusher

The embodiment of the invention discloses a method and a system for controlling the feeding speed of a vibrating feeder. The method comprises the following steps: feeding materials to an impact crusher at a certain feeding speed by virtue of the vibrating feeder, wherein the larger the particle sizes of the materials are, the larger the load of an engine connected with the impact crusher is and the lower the rotating speed of the engine is under the condition that the feeding speed is constant; monitoring the current rotating speed of the engine during the working of the impact crusher according to a preset period or in real time by virtue of a speed measurement sensor, and sending the current rotating speed to a programmable logic controller (PLC); and controlling the feeding speed of the vibrating feeder according to the received current rotating speed of the engine by virtue of the PLC. According to the embodiment of the invention, the feeding speed of the vibrating feeder can be effectively controlled according to the intensity of the load of the engine, so that the automatic regulation of the feeding speed of the vibrating feeder is realized.

Owner:XUZHOU XCMG MINING MACHINERY CO LTD

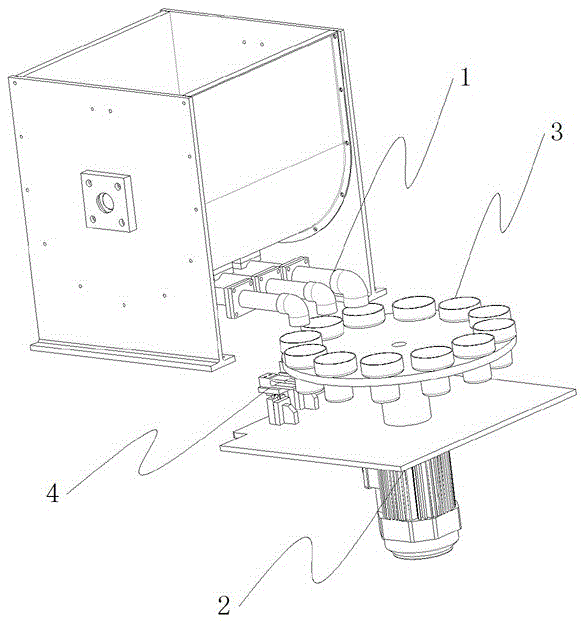

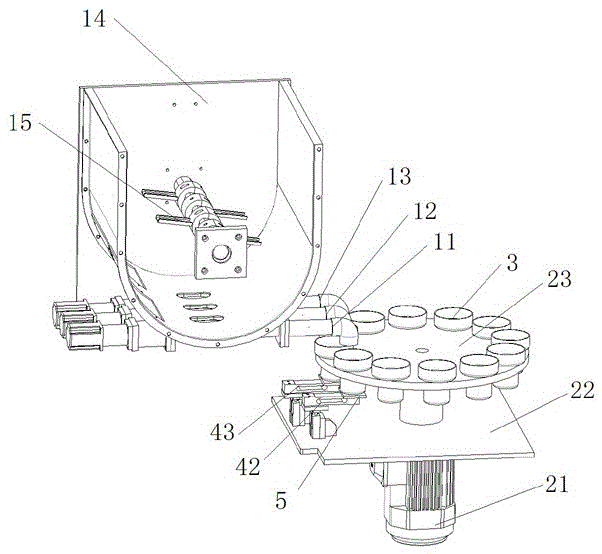

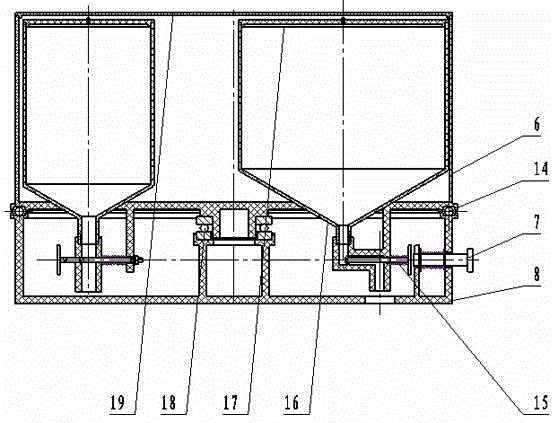

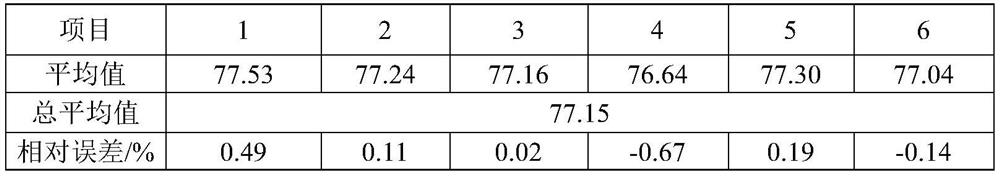

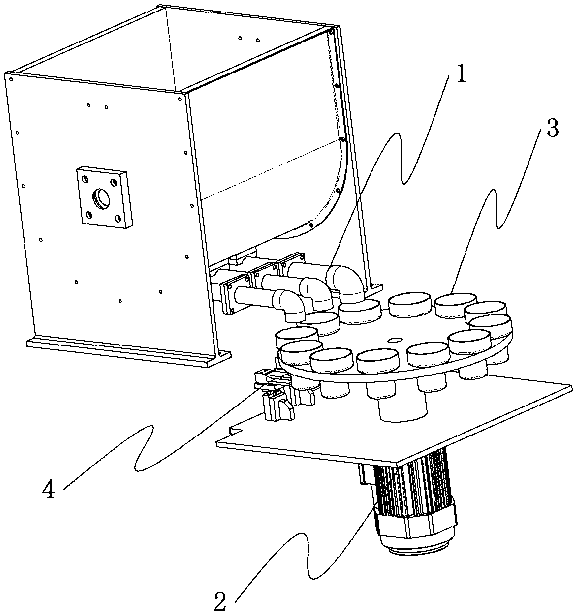

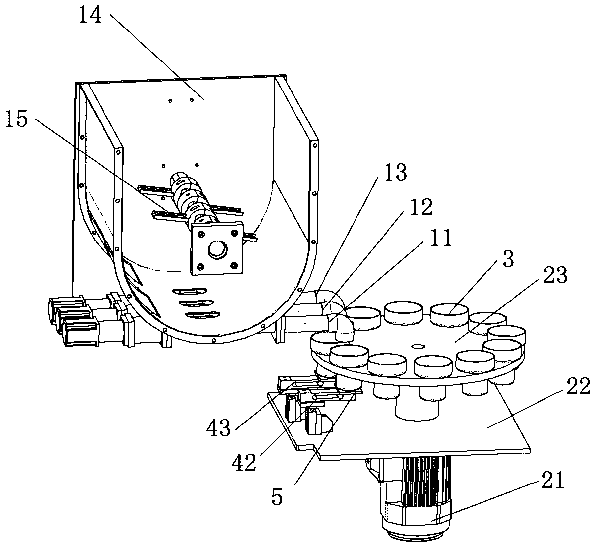

Multi-station weighing machine and method

ActiveCN105466533AShorten weighing timeFast weighingSpecial purpose weighing apparatusEngineeringMechanical engineering

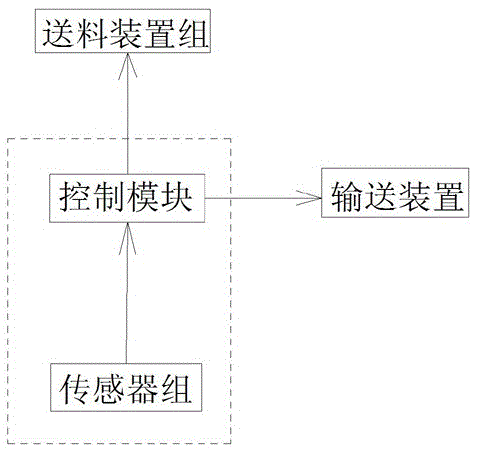

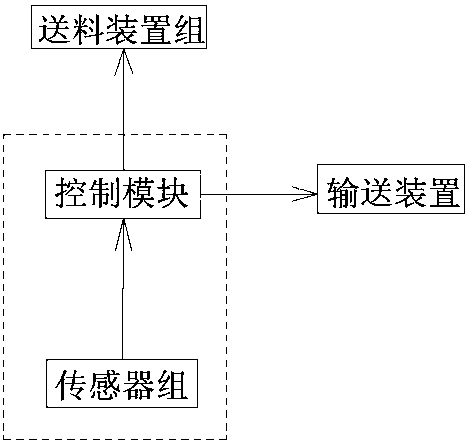

The invention discloses a multi-station weighing machine and method. The multi-station weighing machine is provided with a feeding device group, a conveying device, a material weighing container group and a control system. The feeding device group is provided with at least two feeding devices, and each feeding device is provided with a material inlet and a material outlet. The conveying device is provided with a plurality of conveying stations which are successively arranged in the arranging direction of the material outlet. The material weighing container group is composed of a plurality of material weighing containers, and each material weighing container is correspondingly installed on one conveying station. The control system is provided with a control module and a sensor group electrically connected with the control module, and the control module is electrically connected with the feeding device group and the conveying device. The multi-station weighing machine has the advantages that the weighing speed is high, the weighing precision is high, material overflow is prevented, the size is small, the cost is low, the operation is easy, the structure is simple, the maintenance is simple, etc.

Owner:ZHUHAI HUALI FRICTION MATERIAL

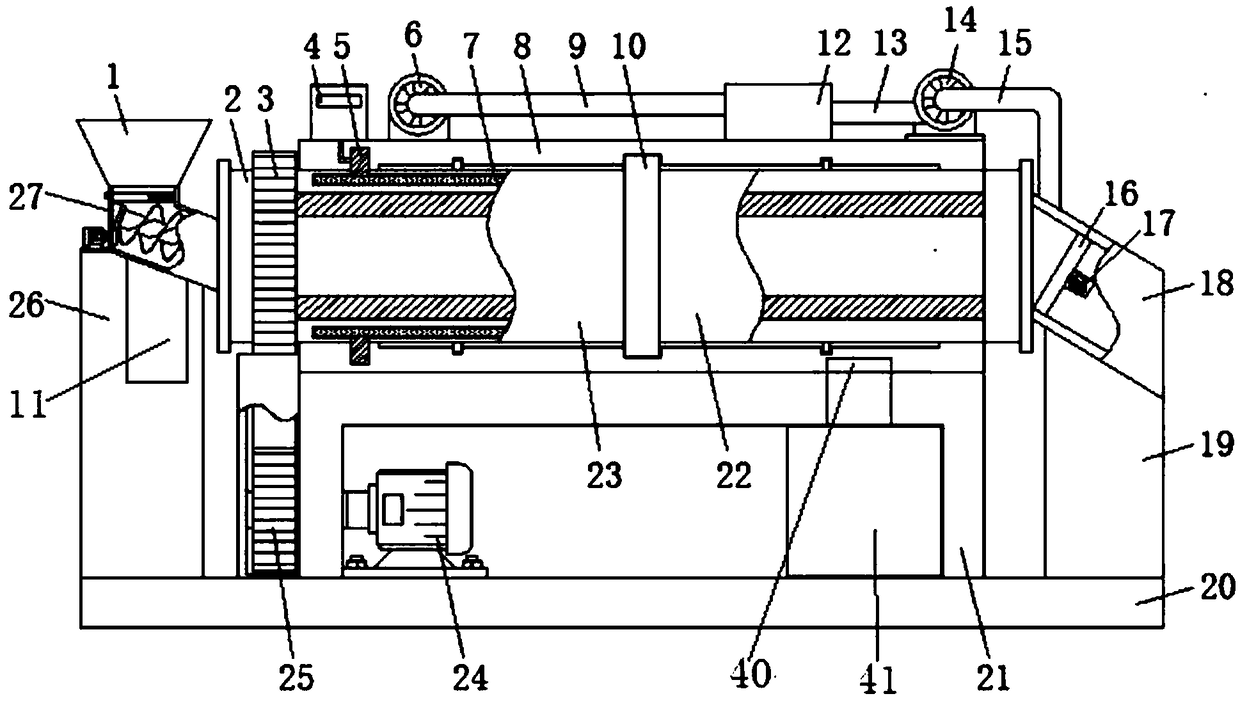

Drum fixation machine with impurity removing and screening functions

InactiveCN108850209AAvoid accumulationUniform feeding speedSievingPre-extraction tea treatmentPulp and paper industryTea leaf

The invention discloses a drum fixation machine with impurity removing and screening functions. The drum fixation machine comprises a fixation machine body, wherein the fixation machine body comprisesa blanking hopper; the blanking hopper is provided with a material guiding assembly; a first support is arranged under the material guiding assembly; an inner drum is arranged at one side of the material guiding assembly; the inner drum is provided with a controller; the inner drum is connected with a discharging pipe; the inner drum comprises a sealed connecting sleeve, a low-temperature heatingbarrel and a high-temperature heating barrel; the material guiding assembly comprises a blanking pipe; a first impurity opening is formed in the lower end of the blanking pipe; a first screen net isarranged on the first impurity opening; the first screen net is provided with a first vibrator and a first pressure sensor; a first impurity tank is arranged under the first impurity opening. According to the drum fixation machine disclosed by the invention, tea leaf raw materials can be effectively prevented from being accumulated in the blanking pipe, the uniformity of a blanking speed can be effectively ensured, dust impurities in tea leaves can be cleaned, simple separation treatment on the quality of the tea leaves can be carried out, and the fixation efficiency of the drum fixation machine can be increased.

Owner:史海艳

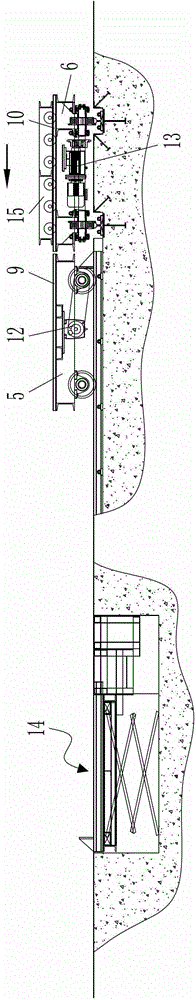

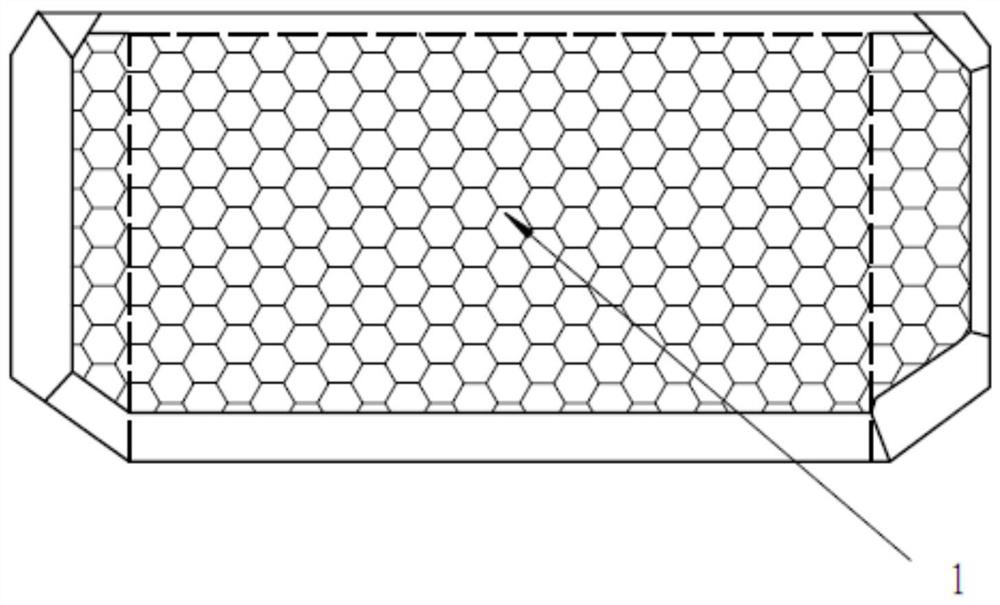

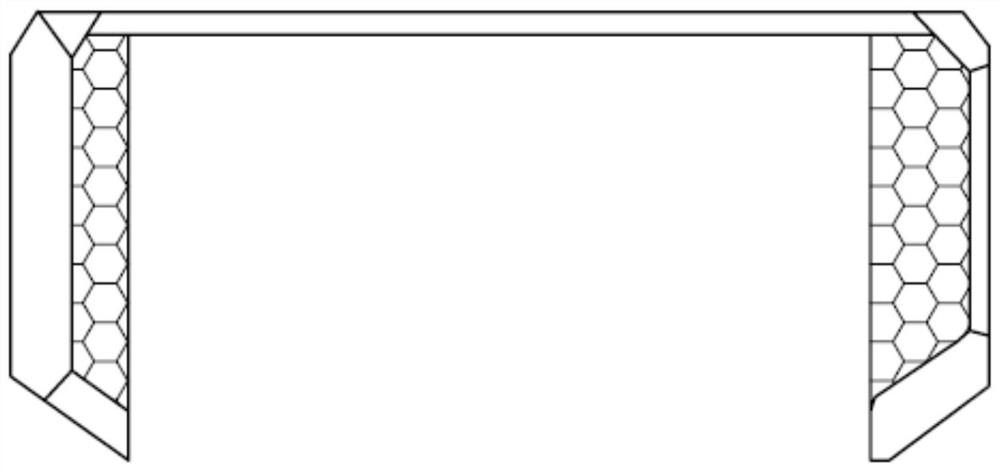

Upper piece equalizing system

ActiveCN102745484AEvenly distributedUniform feeding speedConveyor partsManufacturing lineHanging position

The invention discloses an upper piece equalizing system. The upper piece equalizing system comprises a circular chain 1, wherein the circular chain 1 for transmitting a workpiece is provided with an upper piece area, and is provided with a plurality of workpiece hanging positions which are distributed in the equal distance; and the workpiece output ends of the upper piece area corresponding to a plurality of preorder stations are provided with a plurality of upper piece positions 2. The upper piece equalizing system is characterized in that a longitudinal rail 3 is arranged between each of the upper piece positions and each of the workpiece output ends corresponding to the plurality of the preorder stations; transverse rails 4 are crossed with the longitudinal rails; a first trolley 5 which can slide along the longitudinal rails is arranged on the longitudinal rails; and a second trolley 6 which can slide along the transverse rails is arranged on the transverse rails. When the output speed difference of workpieces at each of preorder stations is large, the workpiece is distributed by the second trolley on the transverse rails in an equalizing mode to control that the speed of the upper pieces at each upper piece position is basically same, and the workpieces on the circular chain are uniformly distributed, so that the subsequent procedures are conveniently carried out; and therefore, the working efficiency can be effectively improved, and the upper piece equalizing system is suitable for popularization and application of the large-scale workpieces on the production line.

Owner:SUZHOU LIUSH MACHINERY EQUIP

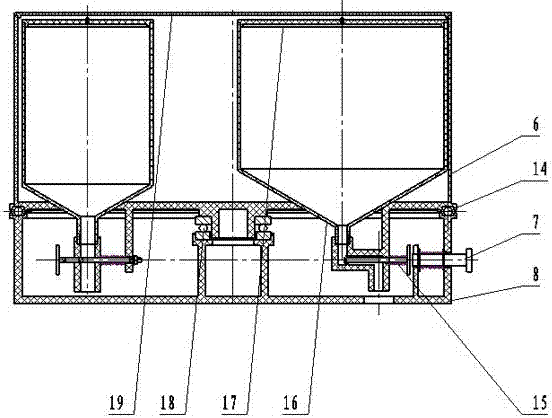

Favoring storing and adding combination instrument

InactiveCN104000522ASolve the clutterAvoid pollutionKitchen equipmentEngineeringMechanical engineering

The invention discloses a favoring storing and adding combination instrument and relates to the technical field of cook kits. A plurality of flavoring boxes (16) are arranged in an upper box (6) provided with a top cap (19) at the upper end. Feeding inlets are respectively formed in the tops of the flavoring boxes (16), and discharging outlets are respectively formed in the bottoms of the flavoring boxes (16) and respectively connected with discharging valves which are formed at the bottom of the upper box (6). A lower box (8) is arranged under the upper box (6) through a rotary shaft and connected with a mounting element. A feeding button (7) is arranged on the box wall of the lower box (8). Along track of the upper box (6) rotating around the lower box (8), switch control ends (15) of the discharging valves respectively pass through a stroke space, at one end in the lower box (8), of the feeding button (7). By the favoring storing and adding combination instrument, the problem of inconvenience in using and cleaning the conventional flavoring containers is solved.

Owner:GUANGXI UNIVERSITY OF TECHNOLOGY

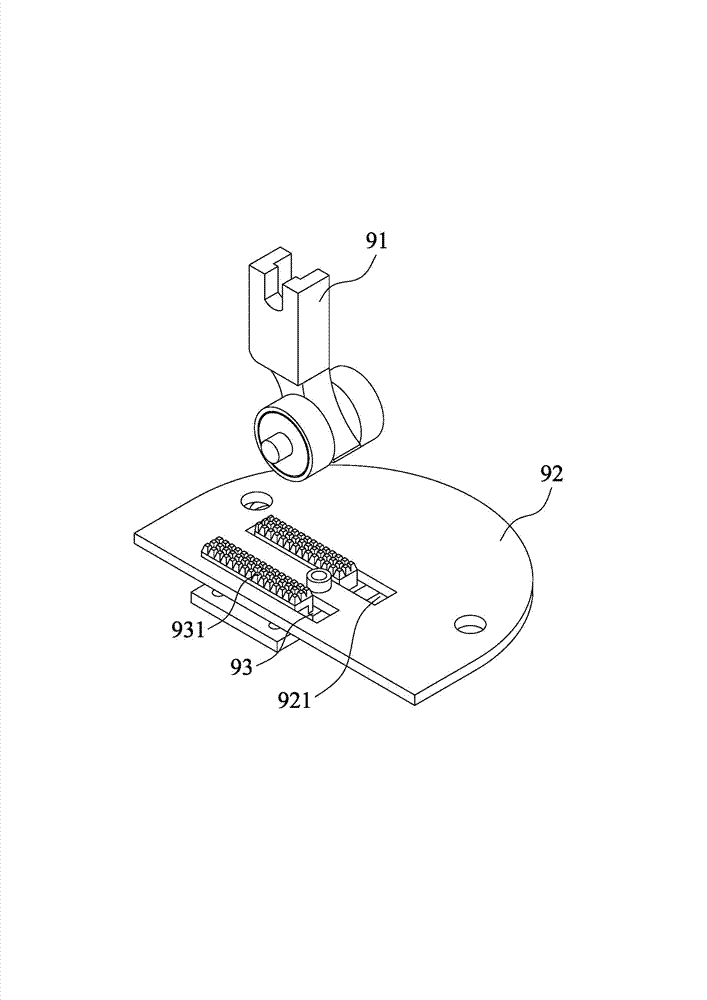

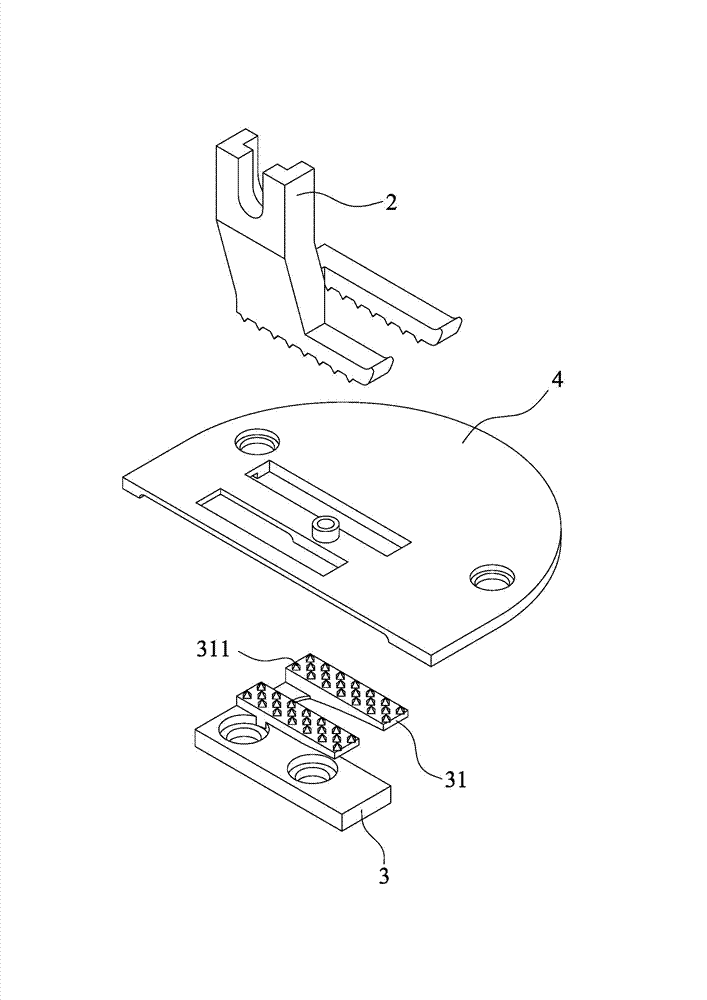

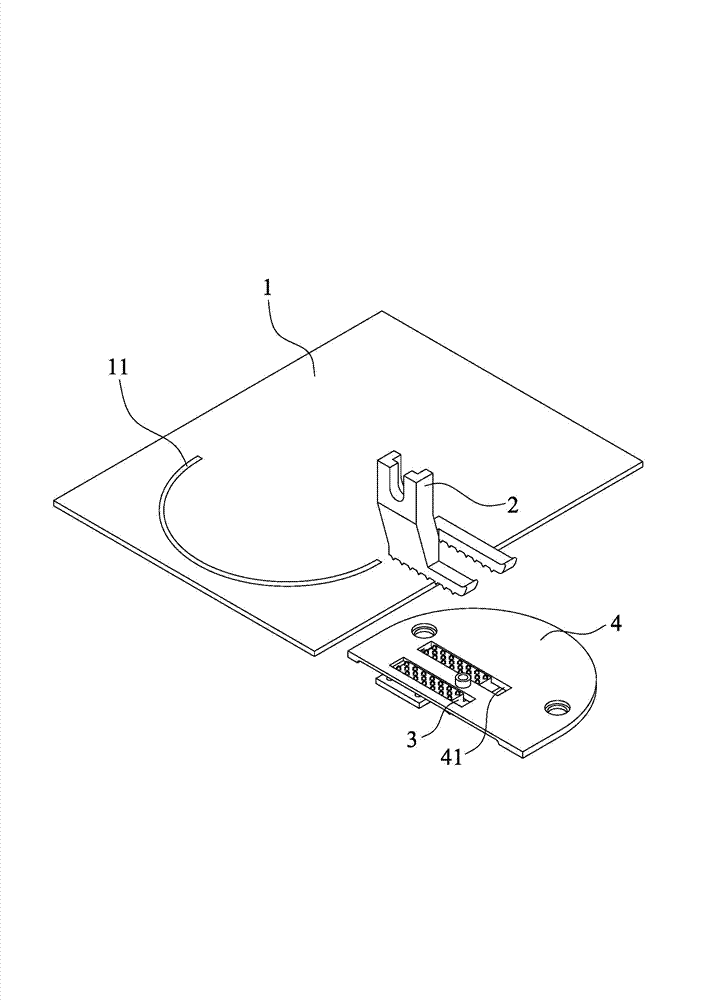

Cloth conveying method and cloth conveying device for sewing machine

The invention discloses a cloth conveying method and a cloth conveying device for a sewing machine. The cloth conveying device comprises a pressing foot, a feed dog, a needle plate and a template, wherein multiple feed teeth are arranged on the top surface of a dog plate of the feed dog, upwards penetrate out of a groove in the needle plate and are opposite to the pressing foot above the needle plate; the feed teeth on the top surface of the dog plate of the feed dog adopt sharp corners; the template is pressed on the top surface of the dog plate of the feed dog; and the tooth tips of the feed teeth on the top surface of the dog plate are inserted into the bottom surface of the template to drive the template to move forwards. The feed teeth on the top surface of the dog plate of the feed dog are made to have the sharp corners which are sharper, the template which is softer in material, can enable the feed teeth to insert and is made of an acrylic plate is adopted, and the feed teeth on the top surface of the dog plate of the feed dog are inserted into the bottom surface of the template to drive the template to move forwards or rearwards, so that the cloth conveying operation is finished, and the automatic cloth conveying process during sewing is realized.

Owner:林鹭峰 +1

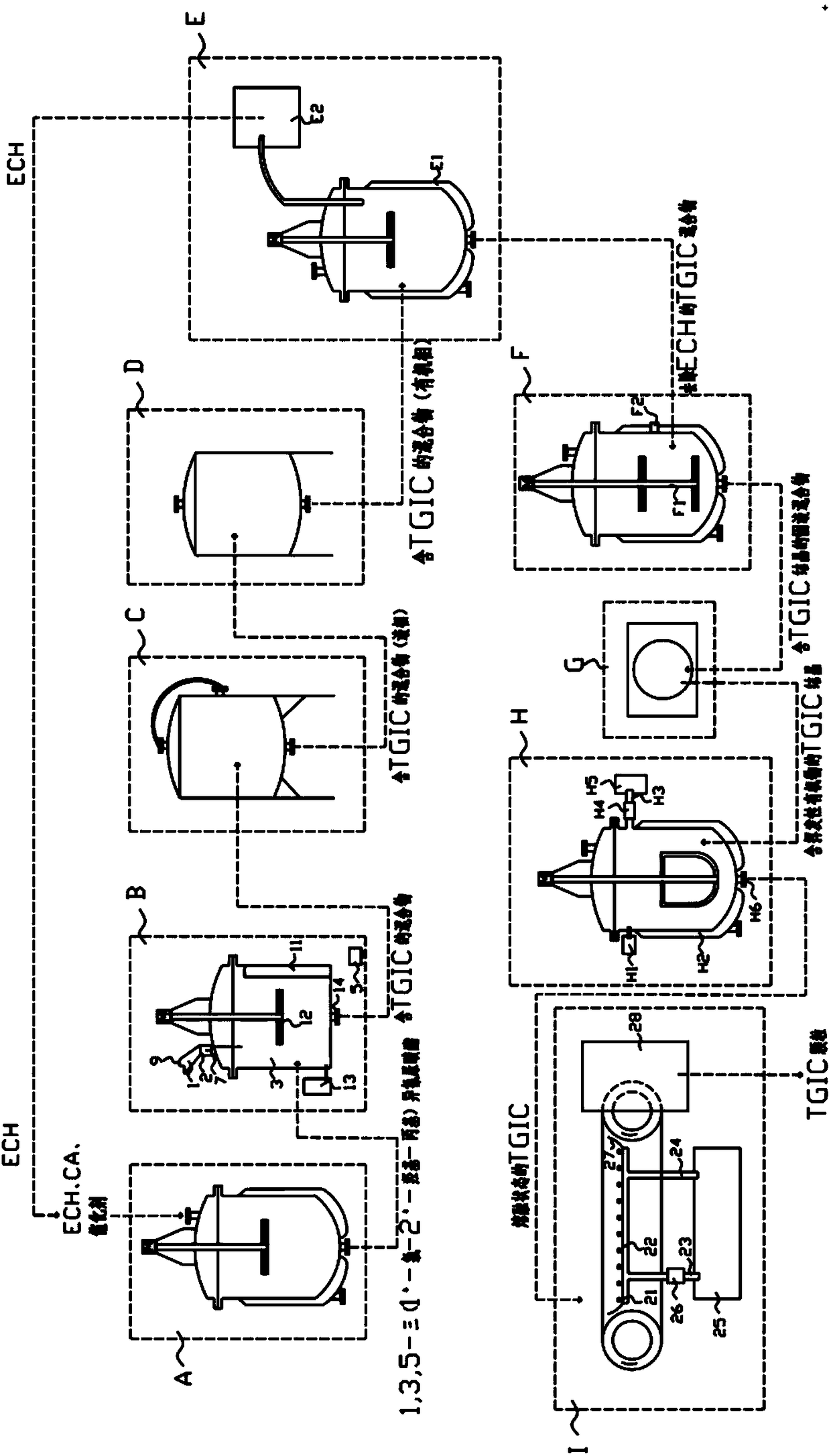

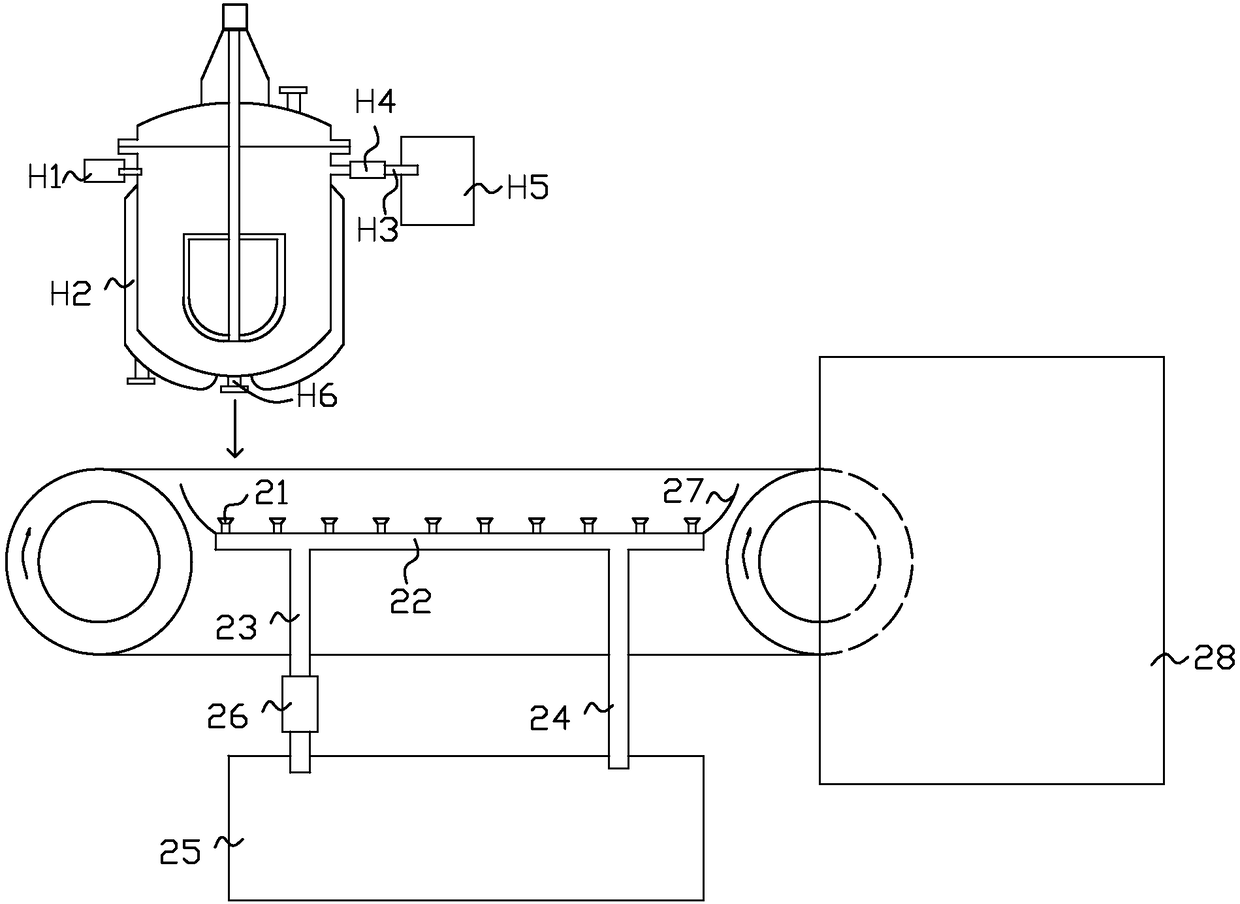

TGIC (Triglycidyl Isocyanurate) production method based on fused steel belt granulation

The invention belongs to the field of production and processing of TGIC, and in particular relates to a TGIC (Triglycidyl Isocyanurate) production method based on fused steel belt granulation. The TGIC production method comprises the specific steps: adding epichlorohydrin, cyanuric acid and a tetramethylammonium chloride catalyst into a reaction container; heating and carrying out synthetic reaction under normal pressure obtain an intermediate product; then adding solid alkali and carrying out cyclization reaction; filtering, standing and layering a cyclization reaction product; heating an organic phase of a lower layer and carrying out depressurization and distillation; crystallizing and centrifuging a distilled material to obtain a TGIC crystal containing volatile organic compounds; putting the TGIC crystal containing the volatile organic compounds into a vacuum environment and heating to obtain fused-state TGIC; dropping the fused-state TGIC on a pre-cooled steel belt granulation machine, and rapidly cooling the TGIC to from TGIC grains which have a firm texture and does not easily generate dust. The method provided by the invention is simple, and achieves a high byproduct repeated utilization rate and a high recycling rate; the prepared TGIC grains have the firm texture and a smooth surface, and are convenient to use.

Owner:HUANGSHAN JINFENG INDAL

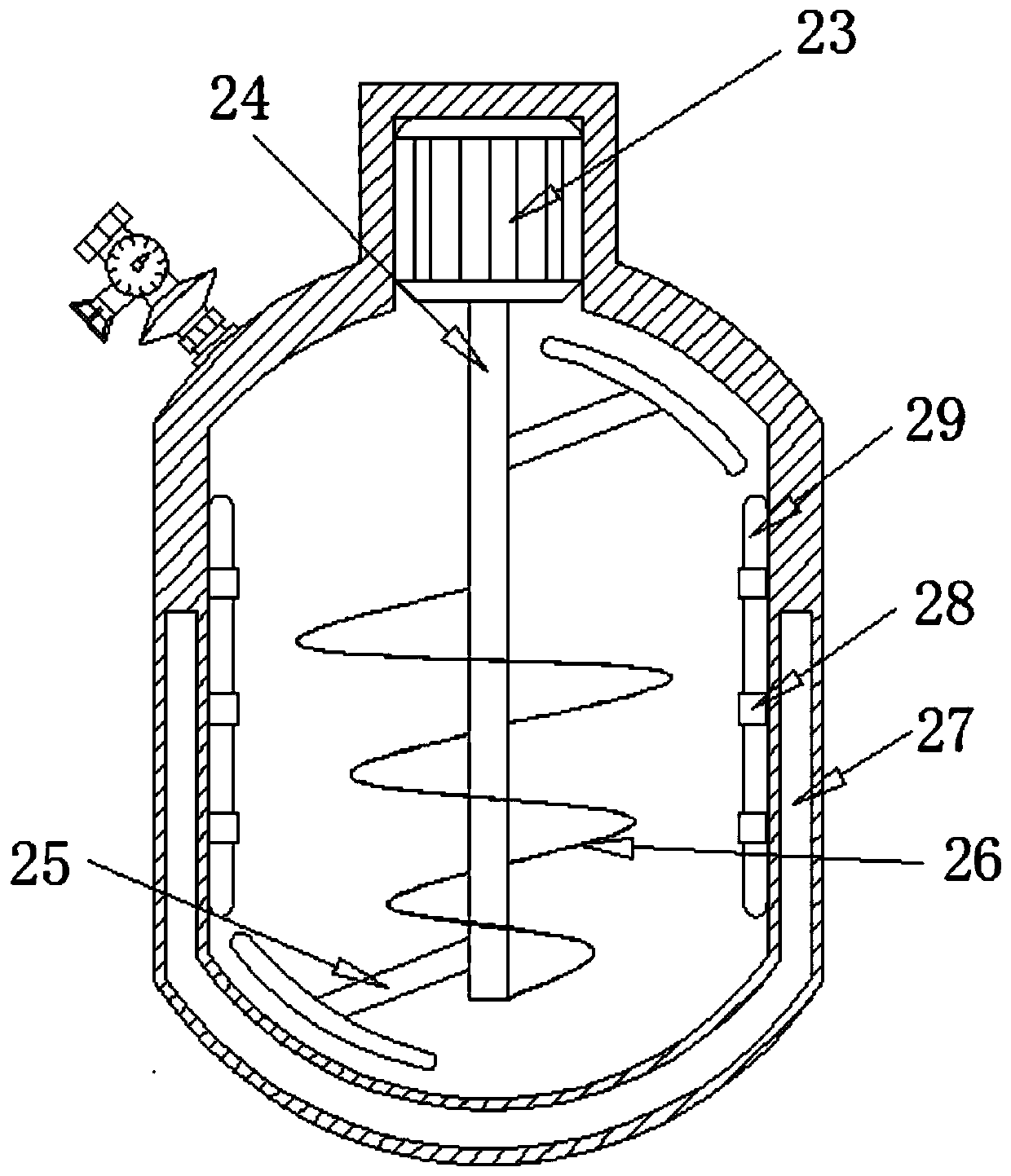

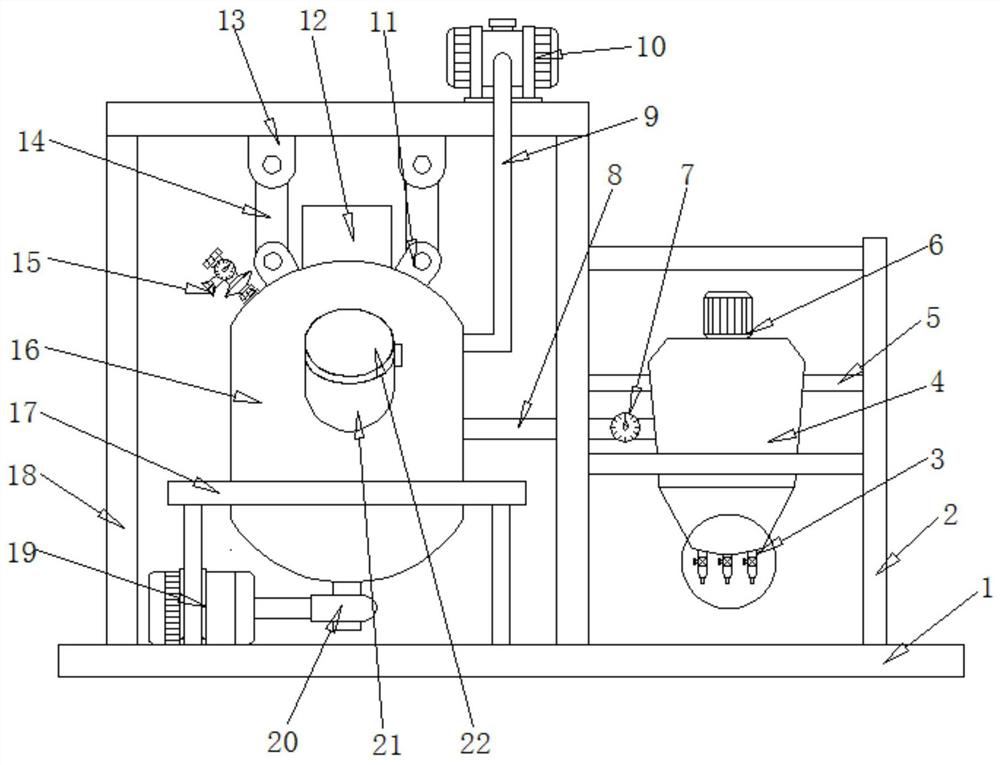

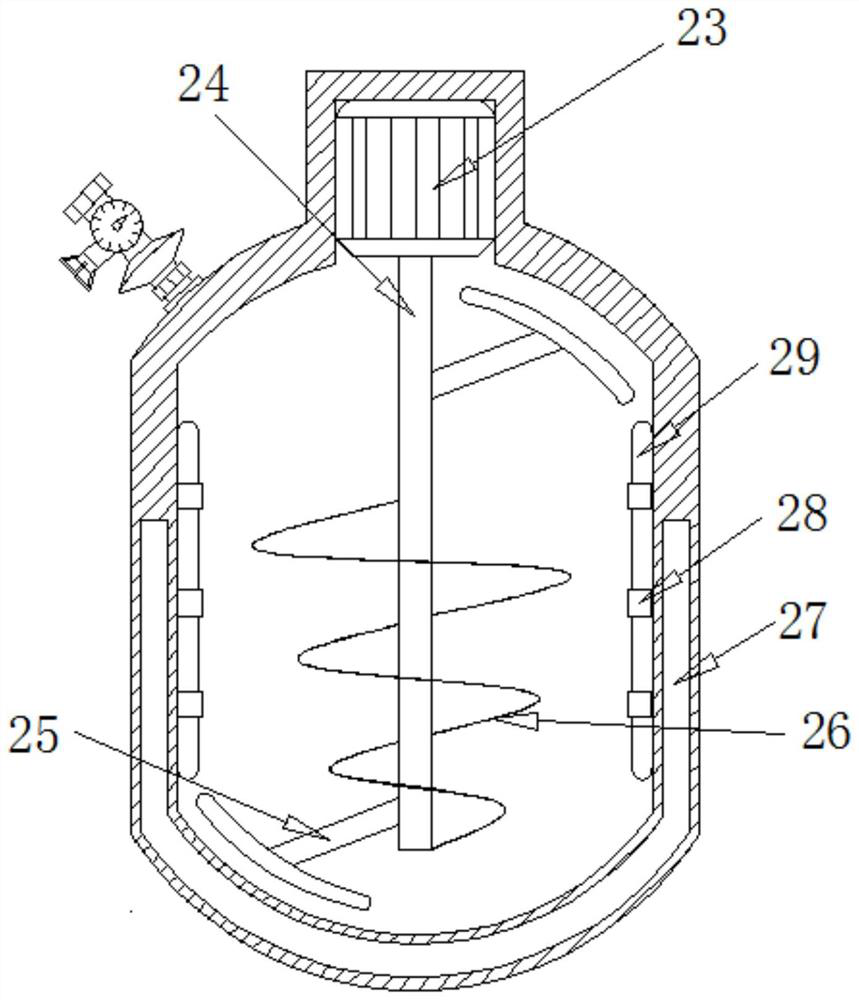

Solid material dissolution extraction device for industrial design

ActiveCN109954293AEasy to separateImprove scraping performanceSolid solvent extractionDissolutionEngineering

The invention discloses a solid material dissolution extraction device for industrial design. The device comprises a base plate and a first extraction tank. The top outer wall of the base plate is fixed with a first mounting rack and a second mounting rack through bolts. A second extraction tank is fixed through bolts on the outer wall of one side of the second mounting rack. The outer wall of twosides of the second extraction tank are both welded with stabilizer bars, and the outer wall of one side of the stabilizer bar is welded with the outer wall of one side of the second mounting rack. The outer wall of one side of the first mounting rack is welded with two equally-spaced fixed blocks. The two fixed blocks are movably fixed with connecting sleeve rods through bolts. The curved structure of an arc-shaped bar can scrape materials which are not on a same straight line. The scraping ability of the device is enhanced, and residue separating capacity of the device is also improved. A sawtooth groove can break and separate stubborn residues. The volume of an interlayer between shunting blades and a shunt tube is definite such that the melt blanking speed becomes uniform.

Owner:北京华诺信得科技有限公司

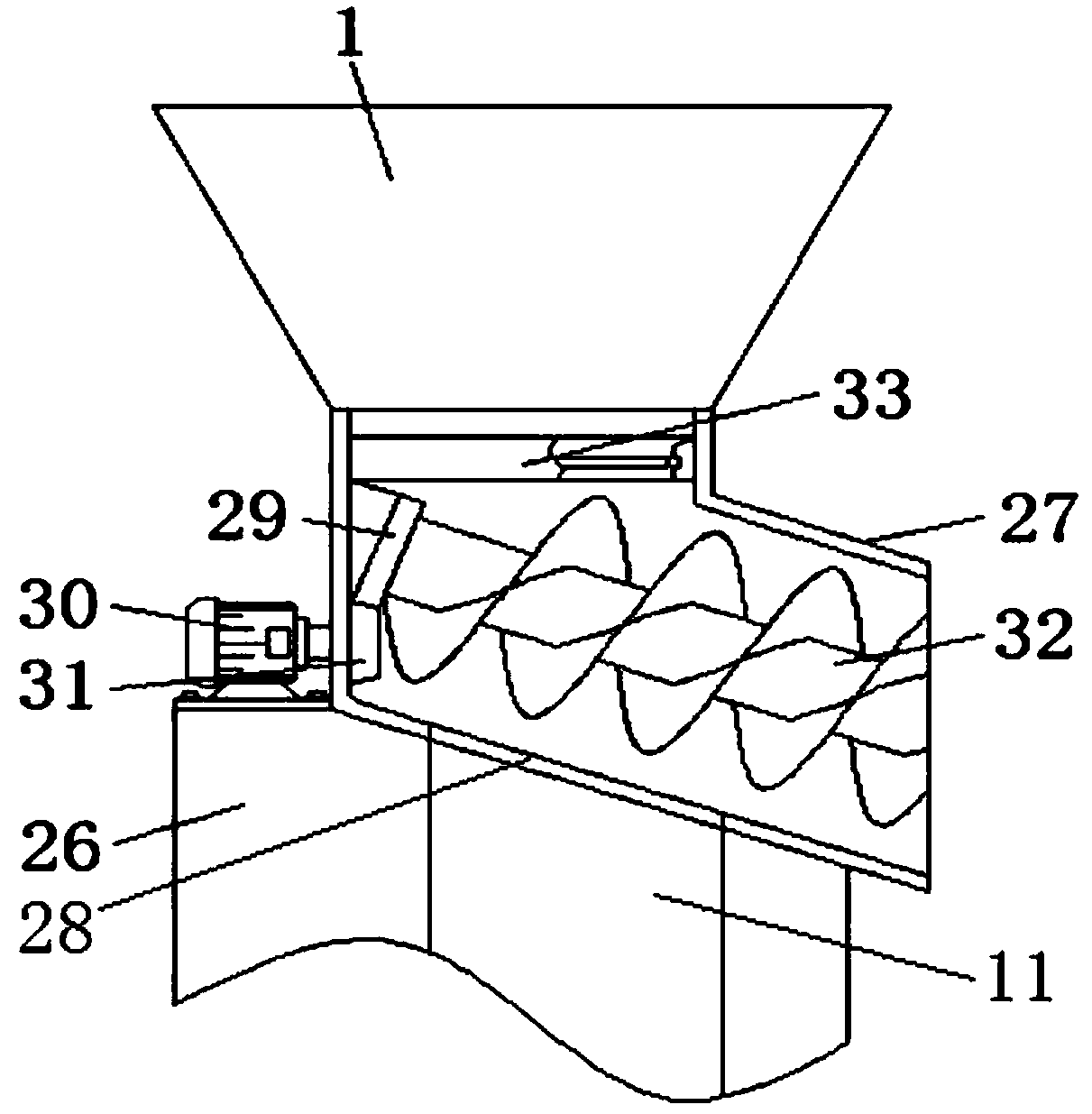

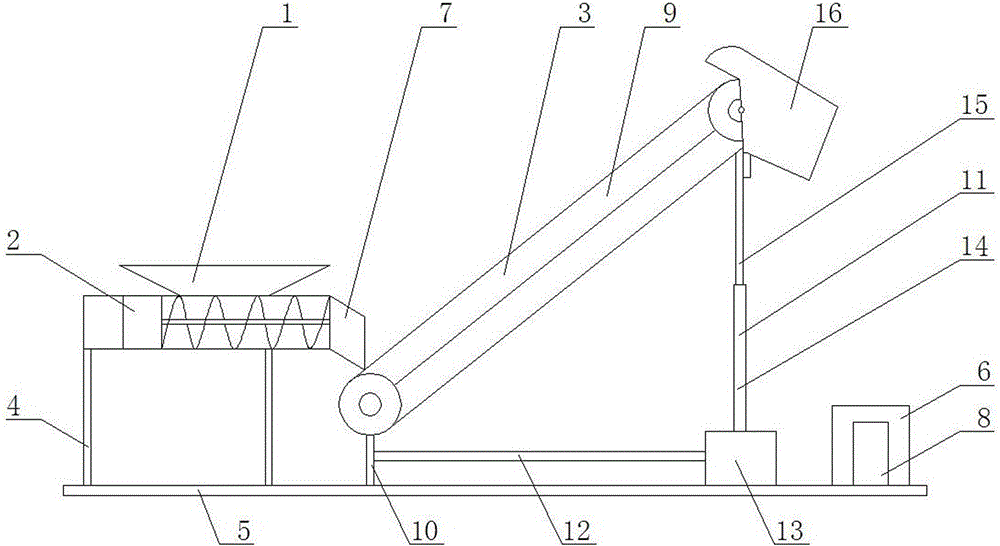

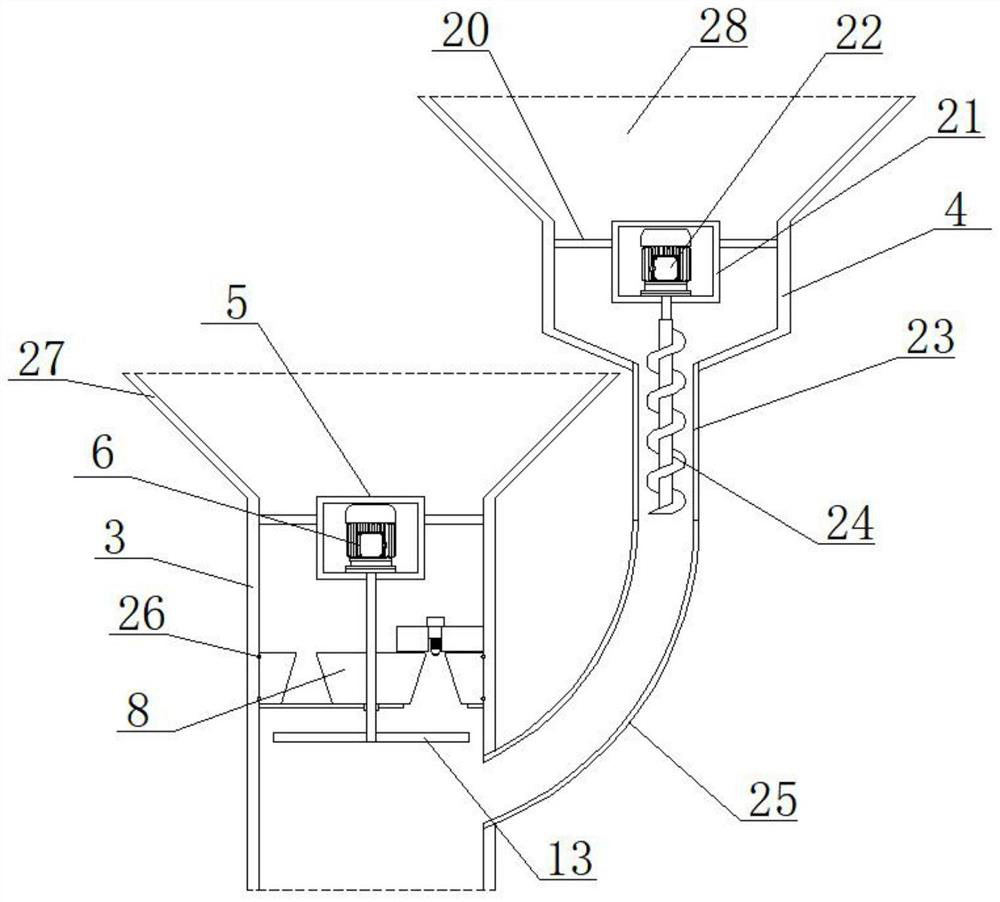

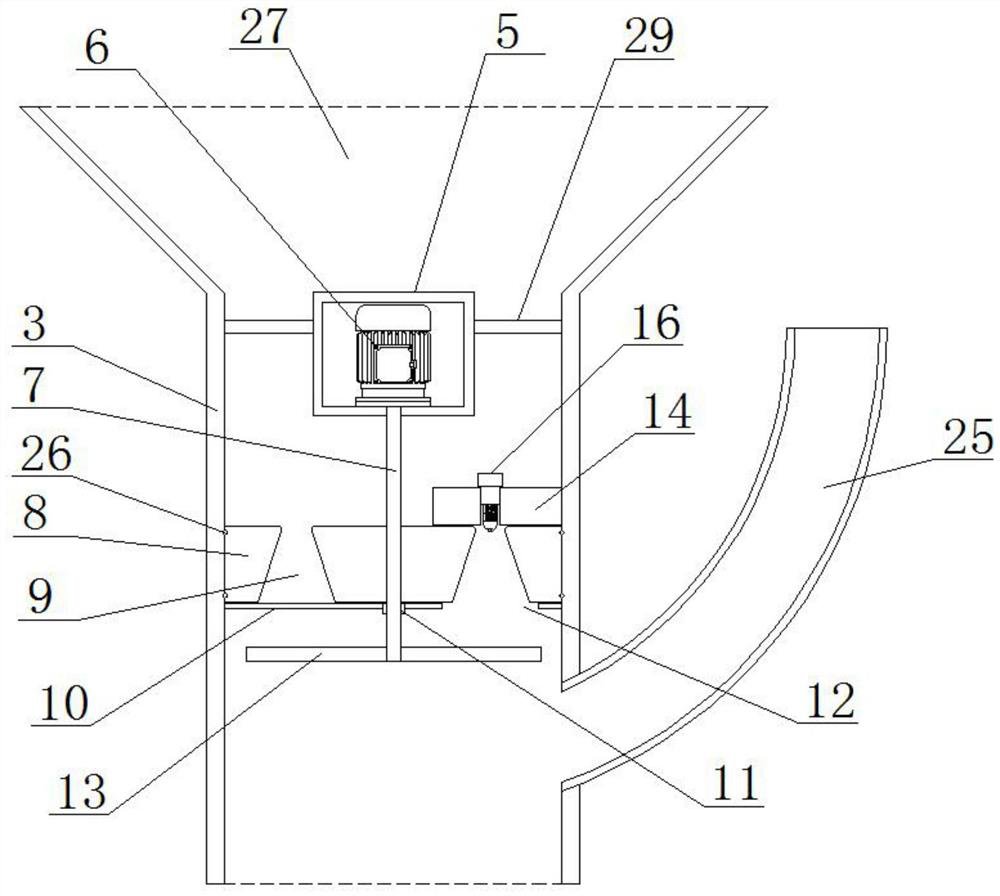

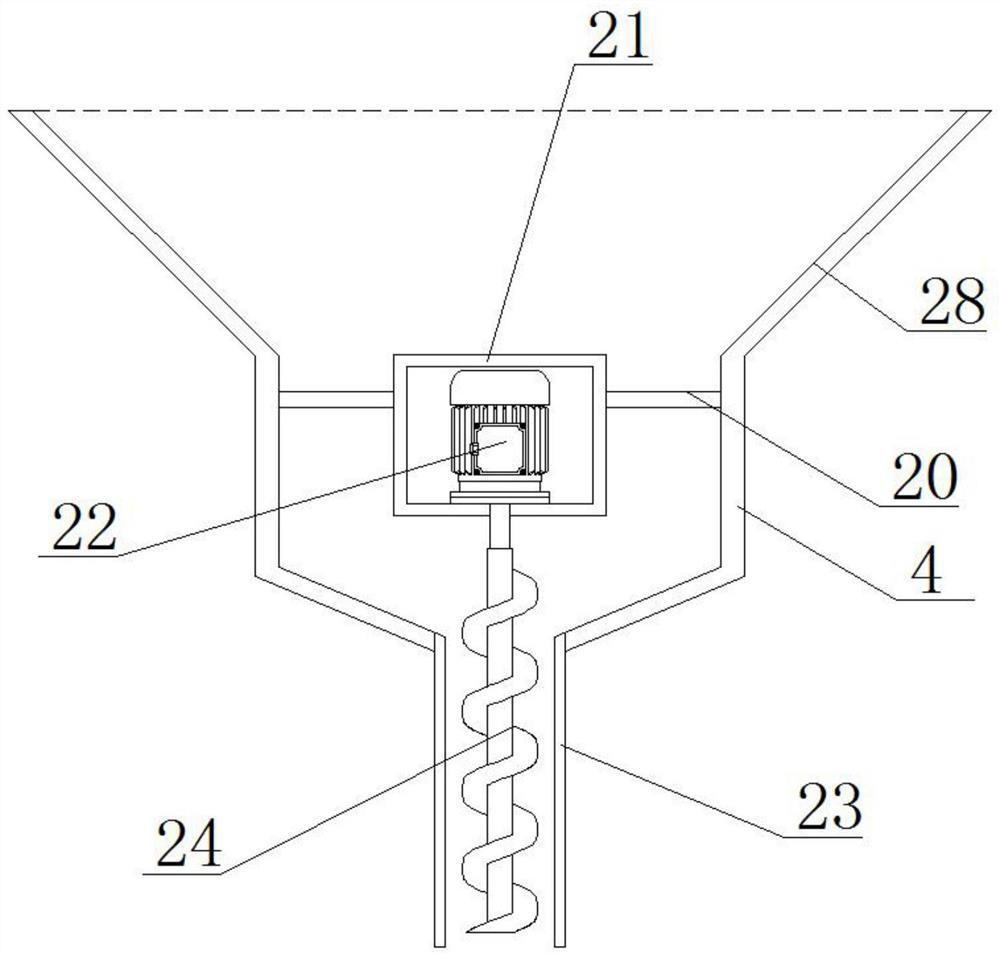

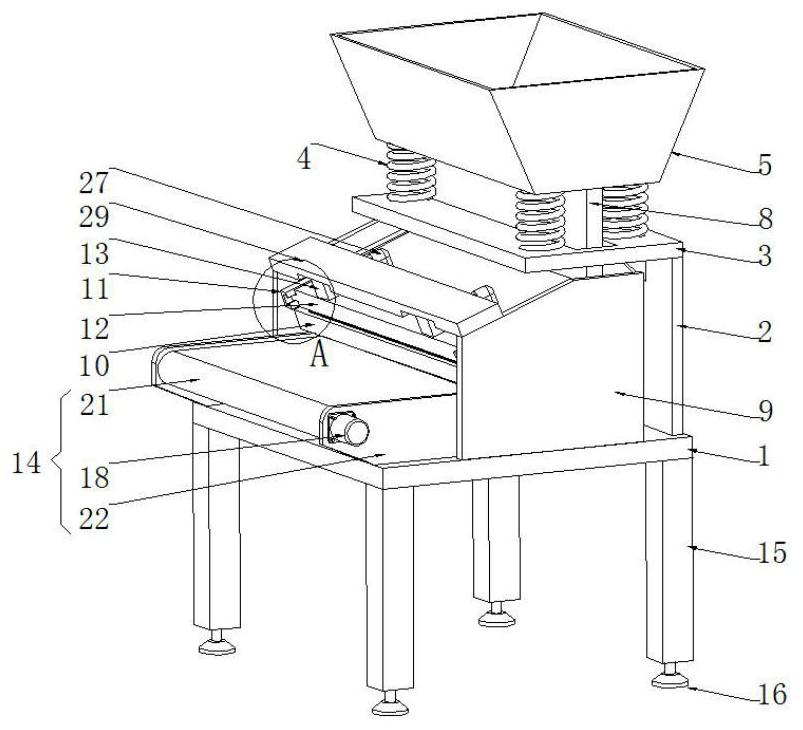

Material lifting and conveying device for hotpot condiment processing

InactiveCN106044276AEasy to adjustUniform feeding speedConveyorsLoading/unloadingMaterial supplyEngineering

A material lifting and conveying device for hot pot bottom material processing, including a feeding hopper, a screw feeder, a lifting conveyor belt, a support frame, a base, and a control box. Install the discharge pipe, the right end of the discharge pipe is the lifting conveyor belt; the bottom of the screw feeder is installed on the left side of the top of the base through the support frame; the lifting conveyor belt is installed in the middle of the top of the base, and the control box is installed on the right side of the top of the base ; A controller is installed inside the control box, and the controller is connected to control the screw feeder and the lifting conveyor belt. The present invention uses a screw feeder to feed the lifting conveyor belt, the feeding speed is uniform, and the feeding effect is better. A rotary feeder is installed at the upper right end of the lifting conveyor belt, which is convenient to adjust the conveying direction of the material according to the actual situation. The bottom end of the lifting conveyor belt is jointly supported by the left fixed support leg and the right lifting support leg. The actual required height can be adjusted through the right lifting support leg, and the operation is more convenient.

Owner:HARBIN LING CHUN WEI DAO FOOD DEV

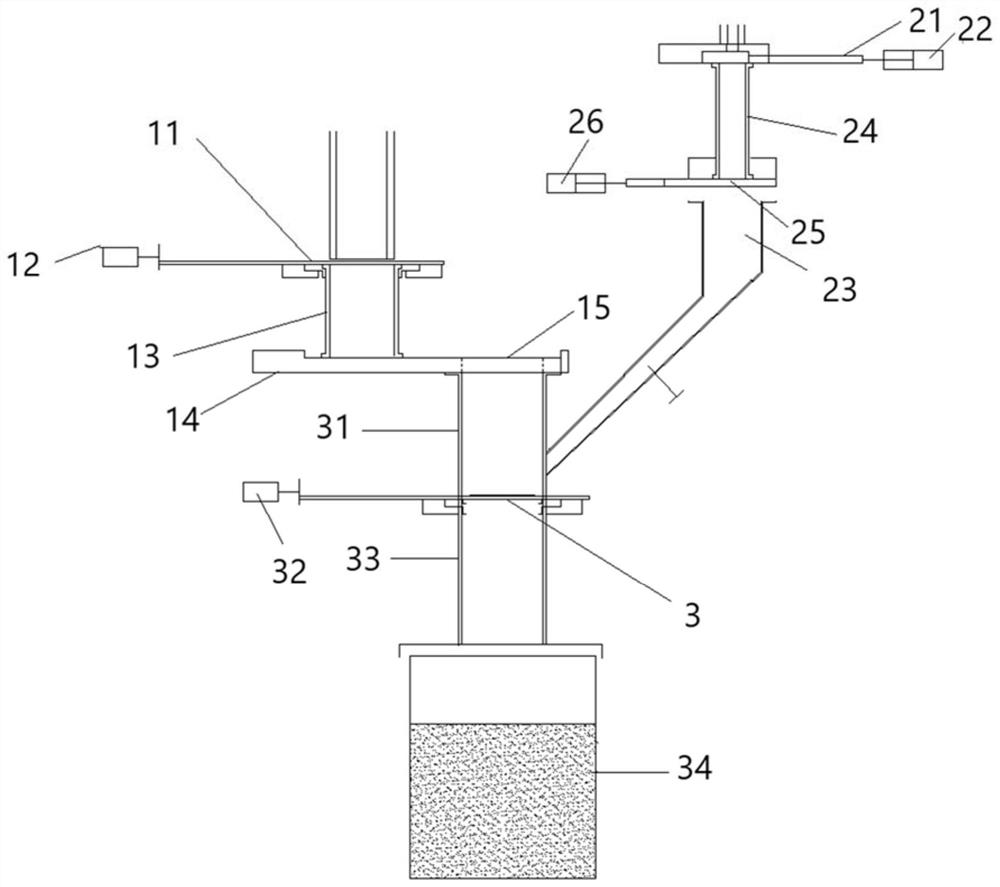

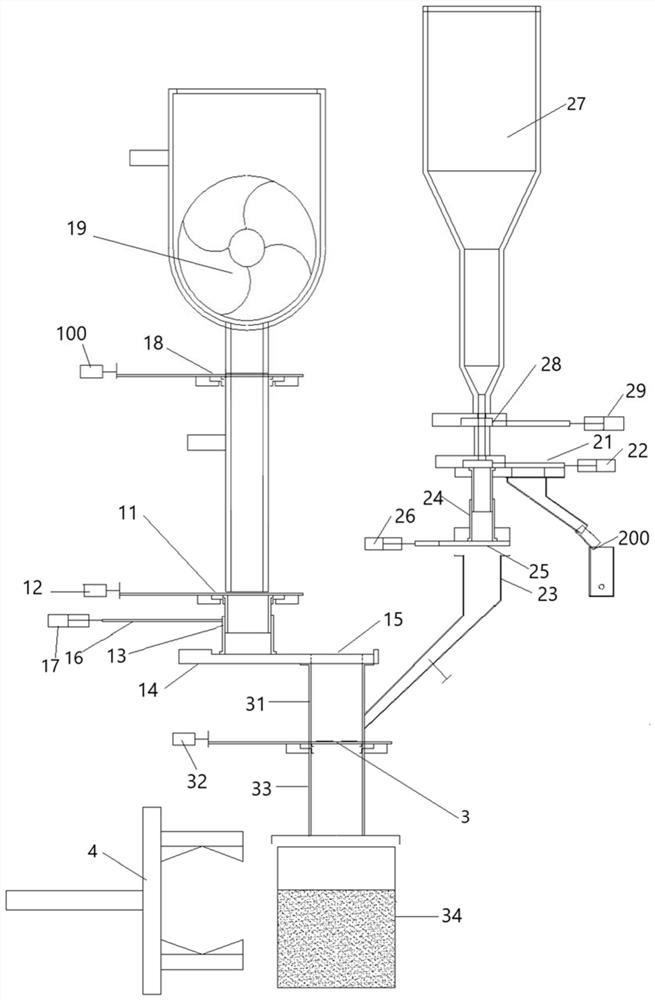

Device and method for simultaneously metering and mixing two or more materials

ActiveCN111634700AHigh feed accuracyIncrease productivityFlow mixersMixer accessoriesProcess engineeringGraphite

The invention relates to the field of equipment, in particular to a device and a method for simultaneously metering and mixing two or more materials, and more particularly relates to metering and uniform mixing of two materials, namely matrix graphite powder and dressing particles, when the two materials are fed into a material tank. According to the device for simultaneously metering and mixing two or more materials, quantitative mixing of the materials can be completed through the arrangement of a scraper blade, a quantifying cup and a material discharging control device in a material quantifying device and the arrangement of a mixing screen and a charging container in a mixing device, the process is automatically completed, the technological process is simple, and the production efficiency is high. According to the device and the method for simultaneously metering and mixing two or more materials, the production process of quantitative powder adding, particle adding and mixing performed in a fuel area is successfully simplified, the production efficiency is improved under the condition of meeting the element design requirement, and the requirement of large-scale production of spherical fuel elements is met.

Owner:TSINGHUA UNIV

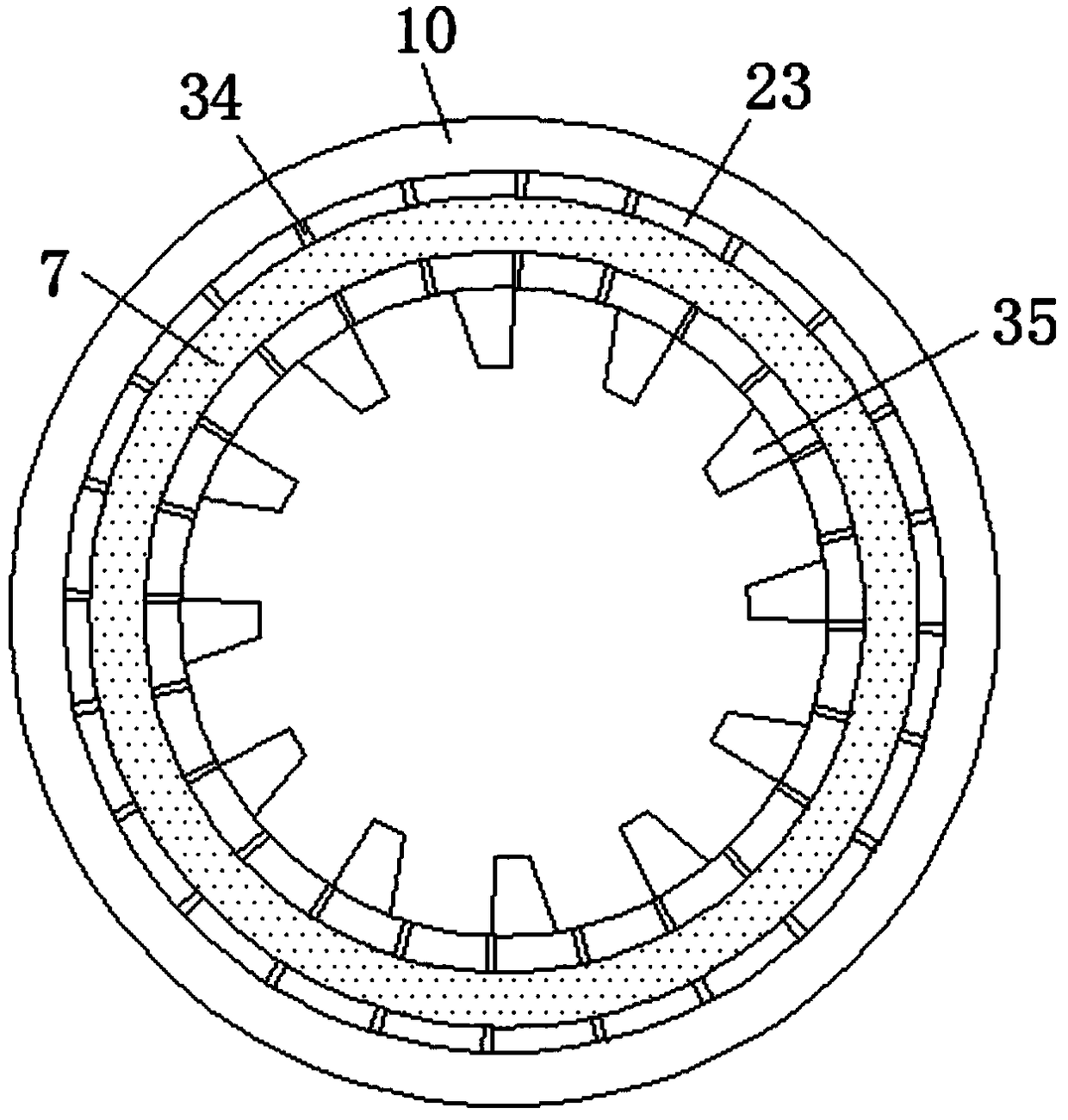

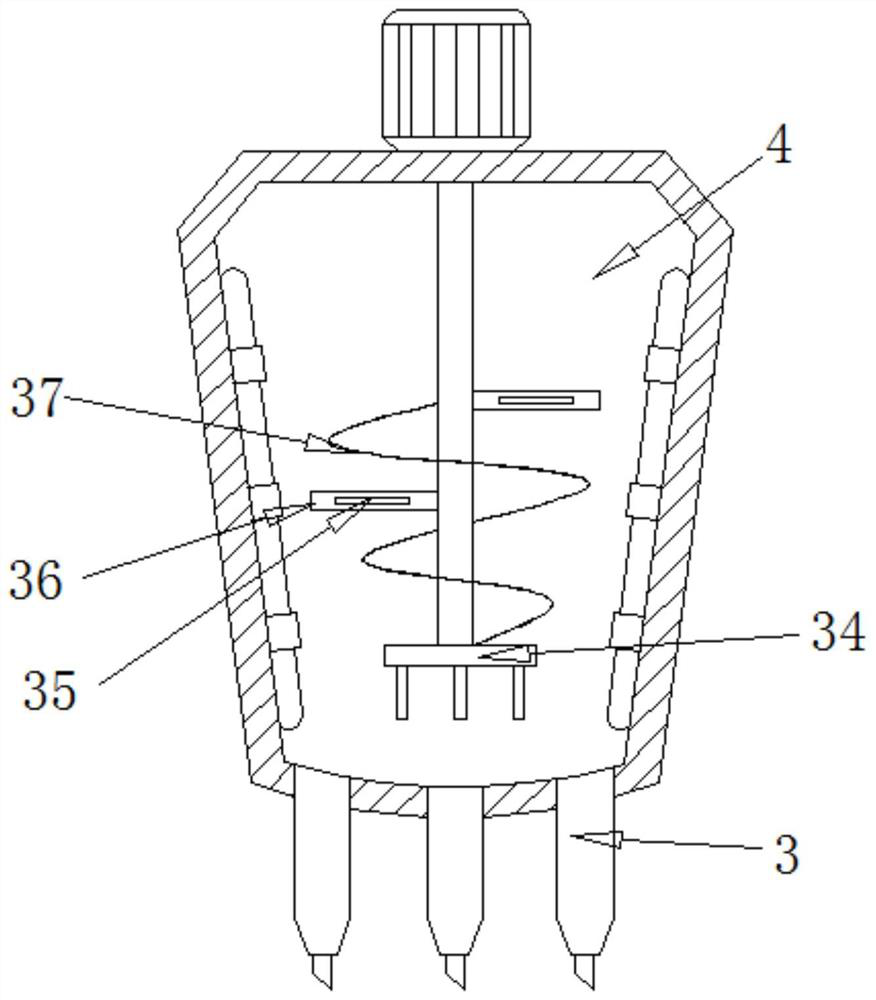

Discharging device for zinc oxide particle production

InactiveCN108002011AUniform feedingSmooth feedingConveyorsControl devices for conveyorsEngineeringSingle chip

The invention discloses a discharging device for zinc oxide particle production. The discharging device comprises an outer shell and a rotating roller; an inner shell is arranged on the inner side ofthe outer shell through a lower bearing and an upper bearing; a spiral plate is fixed inside the inner shell; the interior of the spiral plate is fixedly connected to the rotating roller; a feed portis formed in the upper end of the outer shell; an alarm lamp arranged at the upper end of the outer shell is arranged on one side of the feed port; a mounting plate is arranged right above the outer shell; a motor is fixed to the right lower end of the mounting plate; and the output end of the motor is in meshing connection with the upper end of the rotating roller. The discharging device has theadvantages that the outer shell, the inner shell, the alarm lamp, a single-chip microcomputer, a display screen, the motor, the rotating roller, the spiral plate, a first discharge port, a second discharge port and a gravity sensor are arranged, and therefore the problems that the discharging speed of an existing discharging device is not uniform and stable enough, an intelligent detection mechanism is lacked, and the amount of zinc oxide particles in the discharging device cannot be checked and known in time can be solved.

Owner:XINGHUA SANYUAN ZINC

Dust removal packaging machine and application method thereof

PendingCN109279058AAvoid contaminationPrevent inaccurate feedingSolid materialEngineeringScrew conveyor

The invention relates to a dust removal packaging machine and an application method thereof, and belongs to the technical field of packaging equipment. The dust removal packaging machine comprises a shell, a feeding device, a conveying device and a sealing device; an air inlet and an air outlet are formed in the two opposite face side walls of the shell, an ion fan is arranged on the air inlet, the feeding device comprises a feeding hopper, a spiral conveyor and a feeding pipe, a rotating shaft is horizontally arranged in the feeding hopper, and is fixedly connected with a breaking roller, the conveying device comprises a first conveying belt and a second conveying belt, partition boards are arranged on the first conveying belt evenly at intervals, the sealing device comprises a telescopic air cylinder and two swing arms, the two swing arms are hinged, telescopic rods are fixedly connected to the lower ends of the two swing arms, hot pressing rollers are arranged at the top ends of the telescopic rods, and compression springs are arranged between the hot pressing rollers and the swing arms. The ion fan of the dust removal packaging machine can neutralize material surface static electricity, the particle materials can be effectively prevented from being tainted with dust in the packaging link, and the interior of the shell can be subjected to dust removal.

Owner:南京钢诺智能装备有限公司

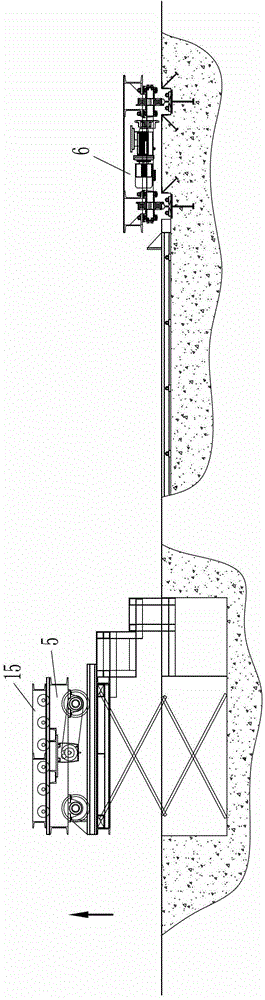

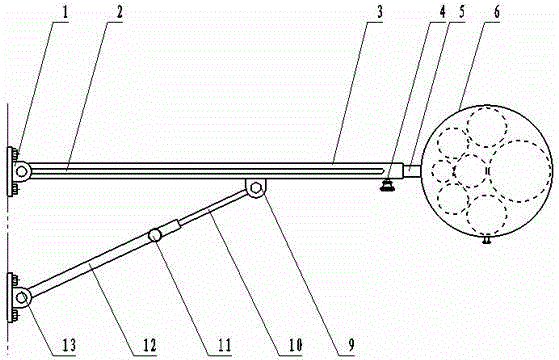

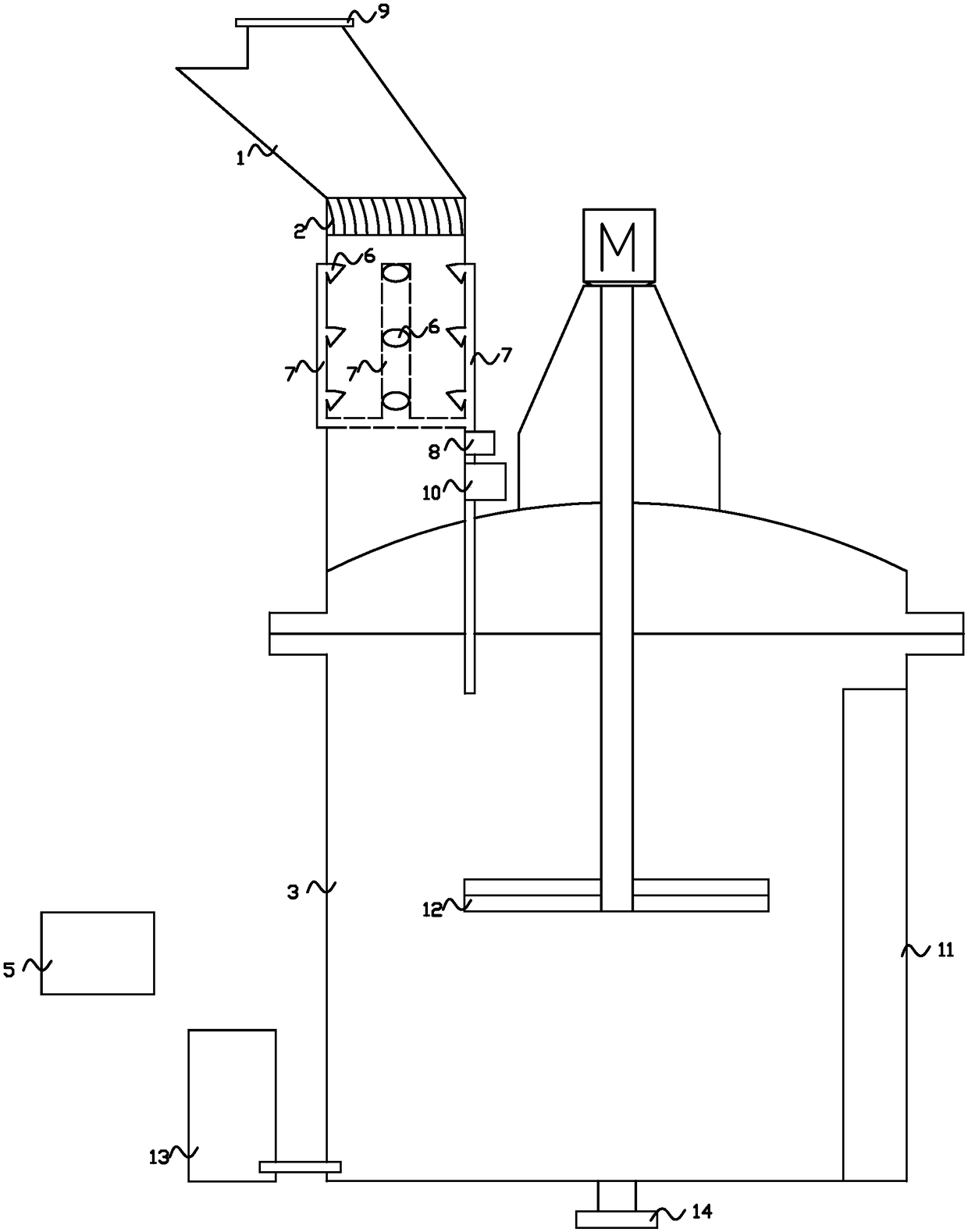

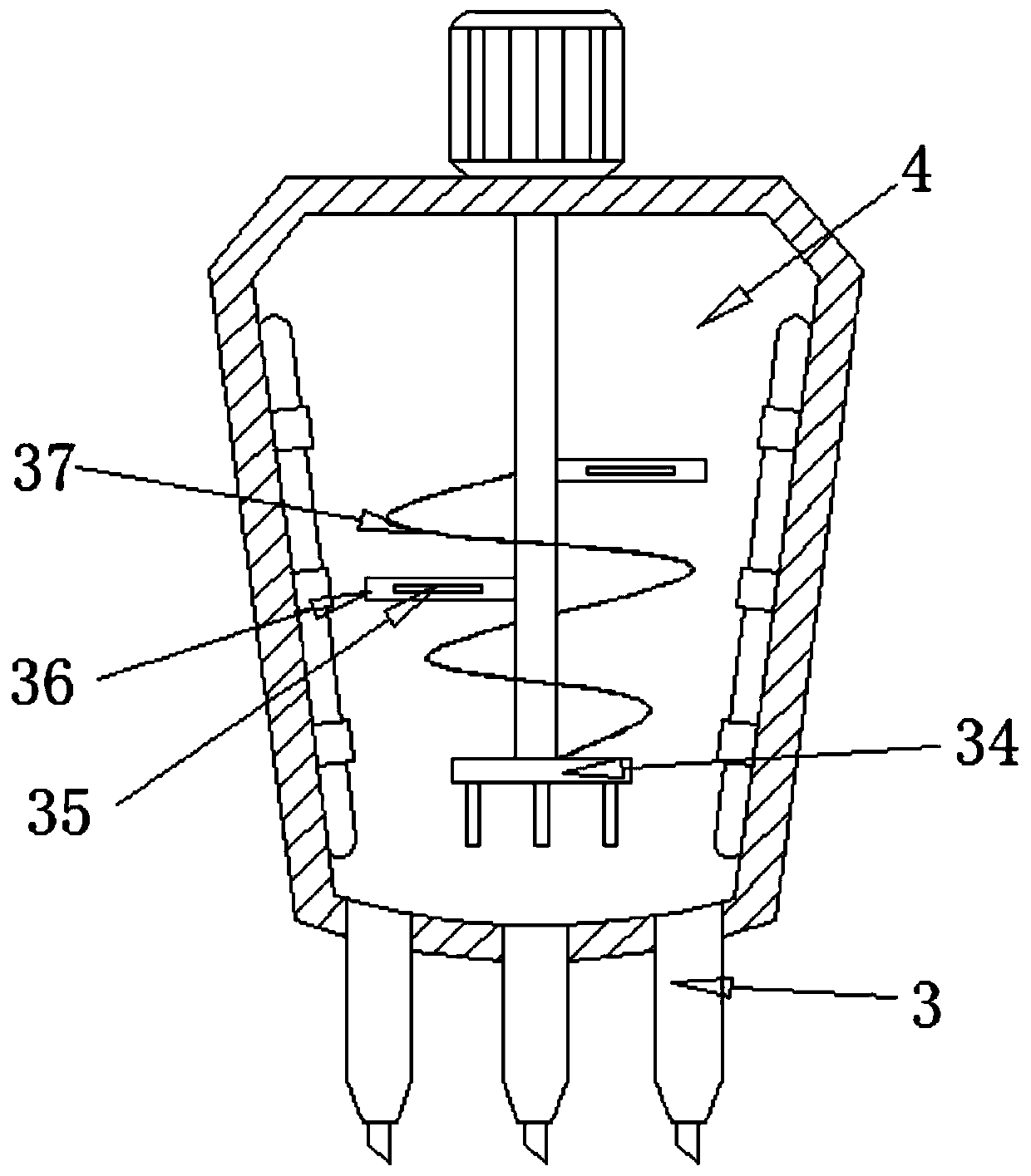

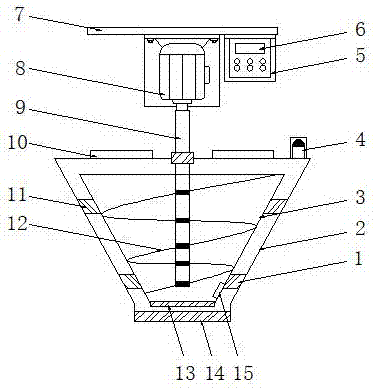

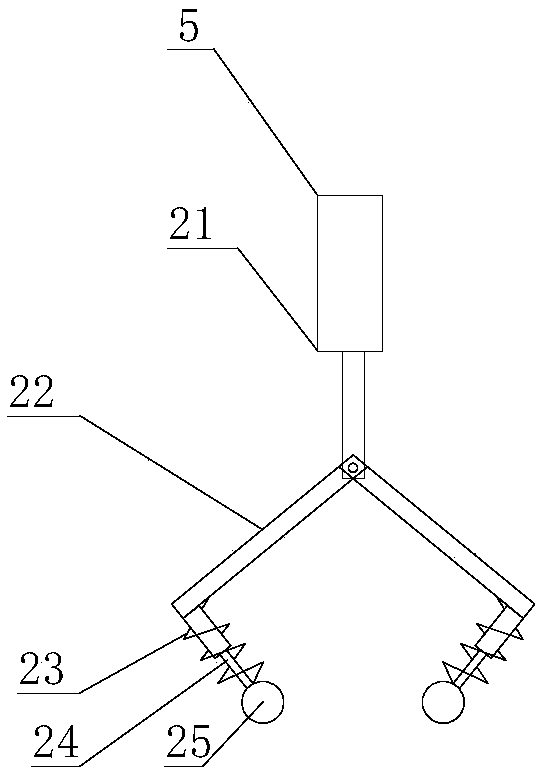

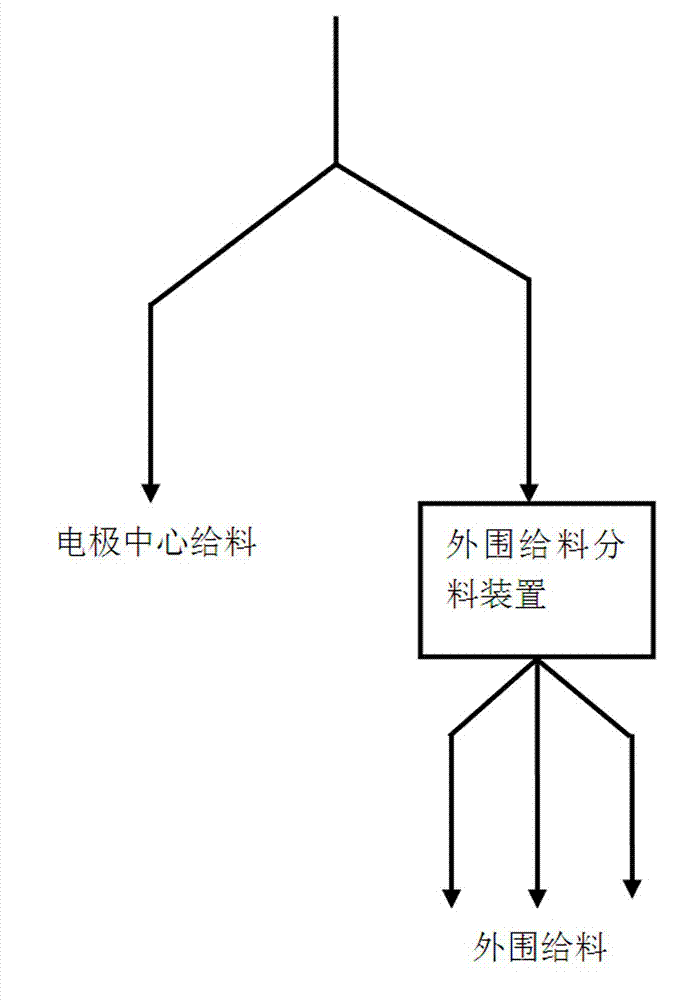

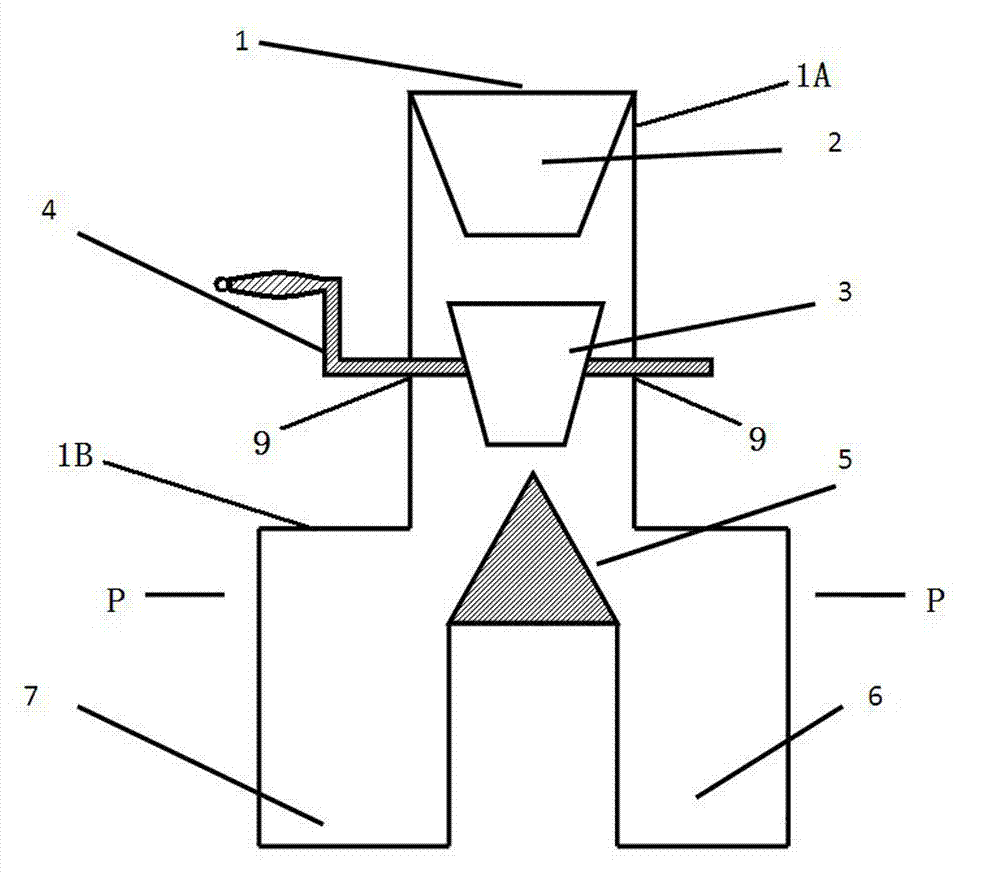

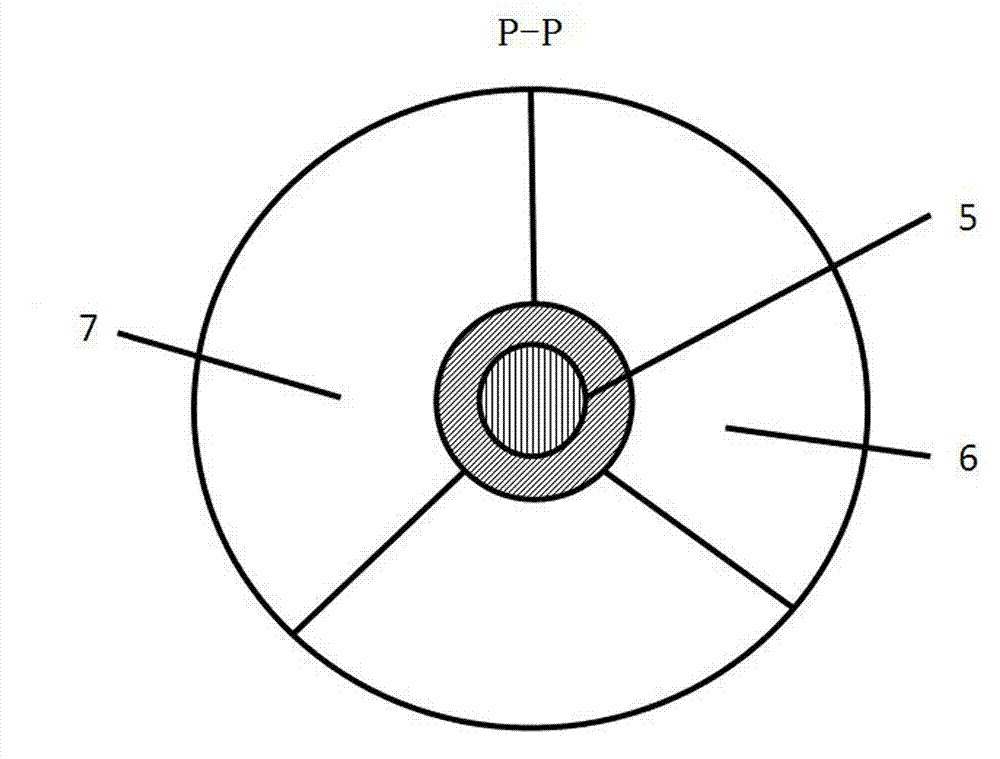

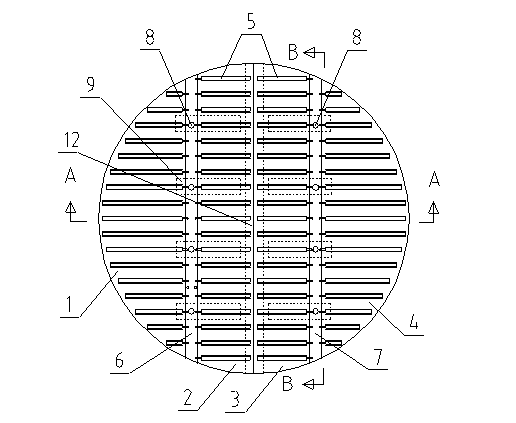

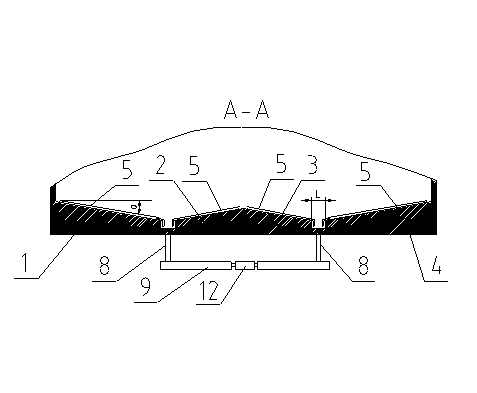

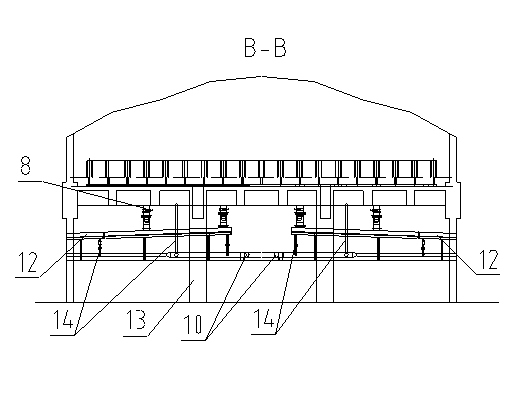

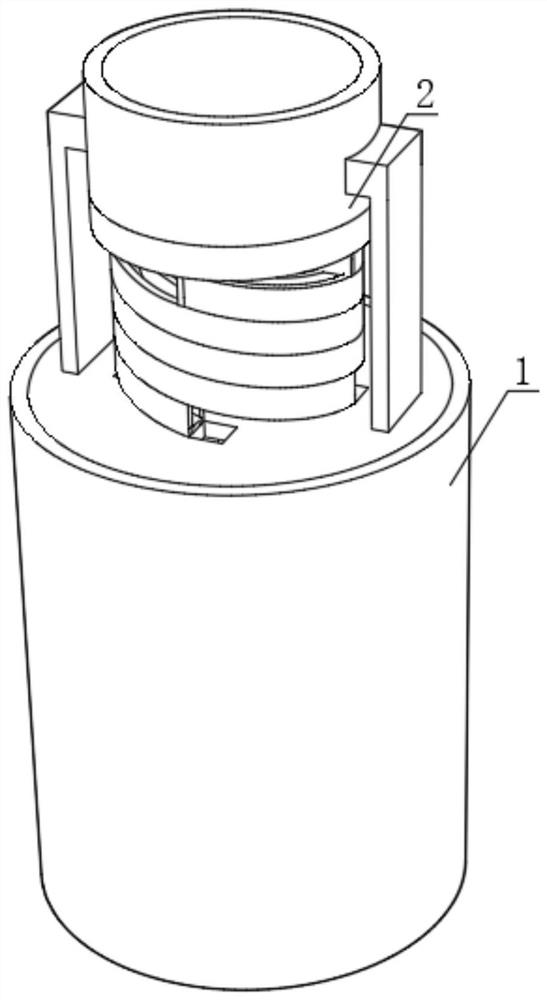

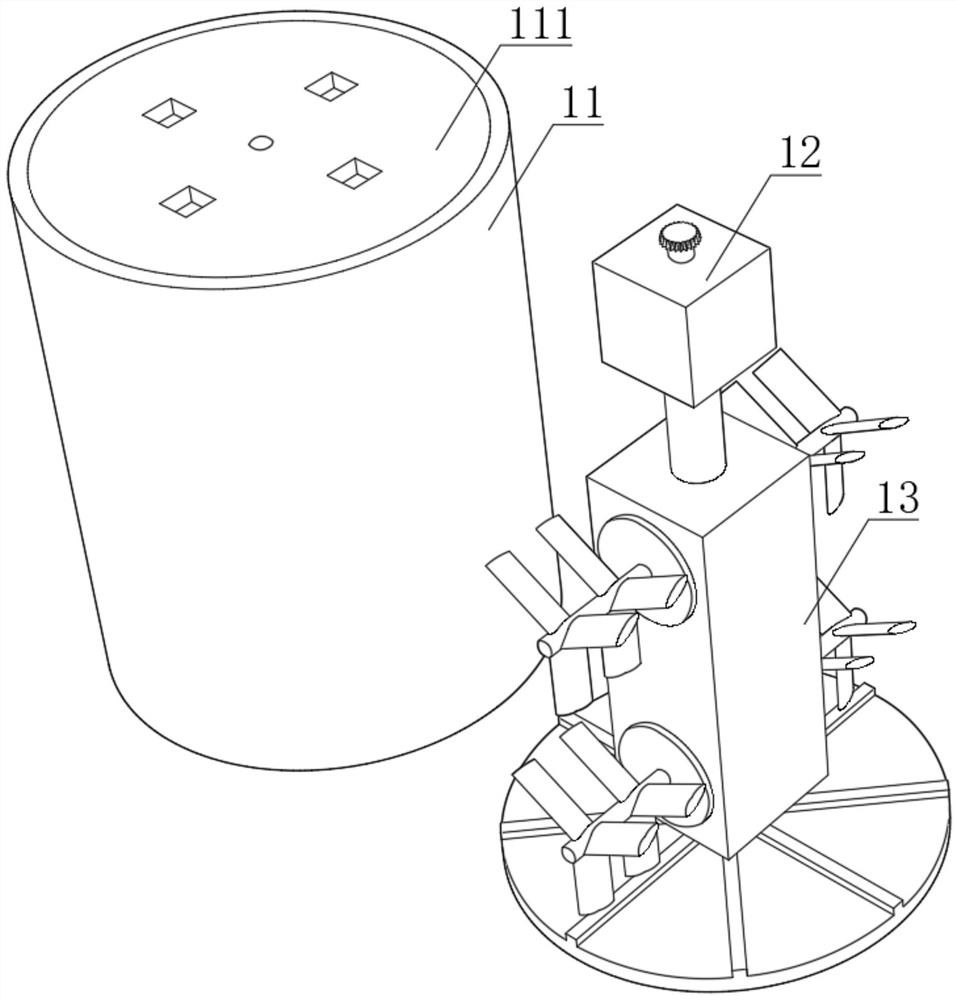

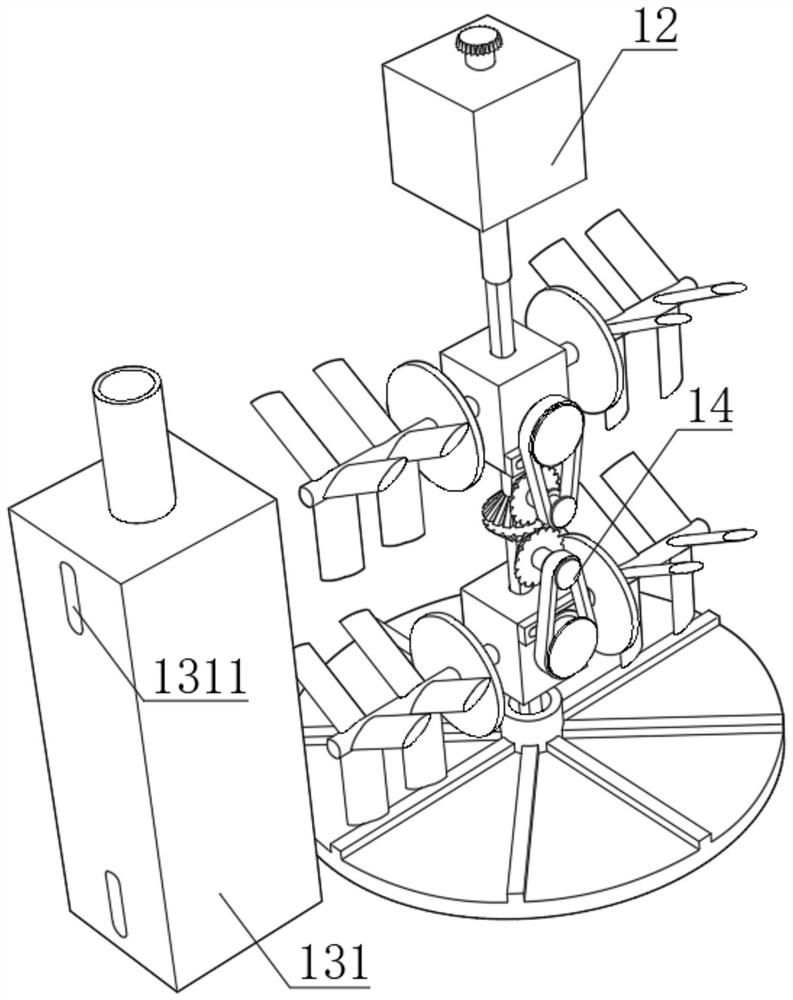

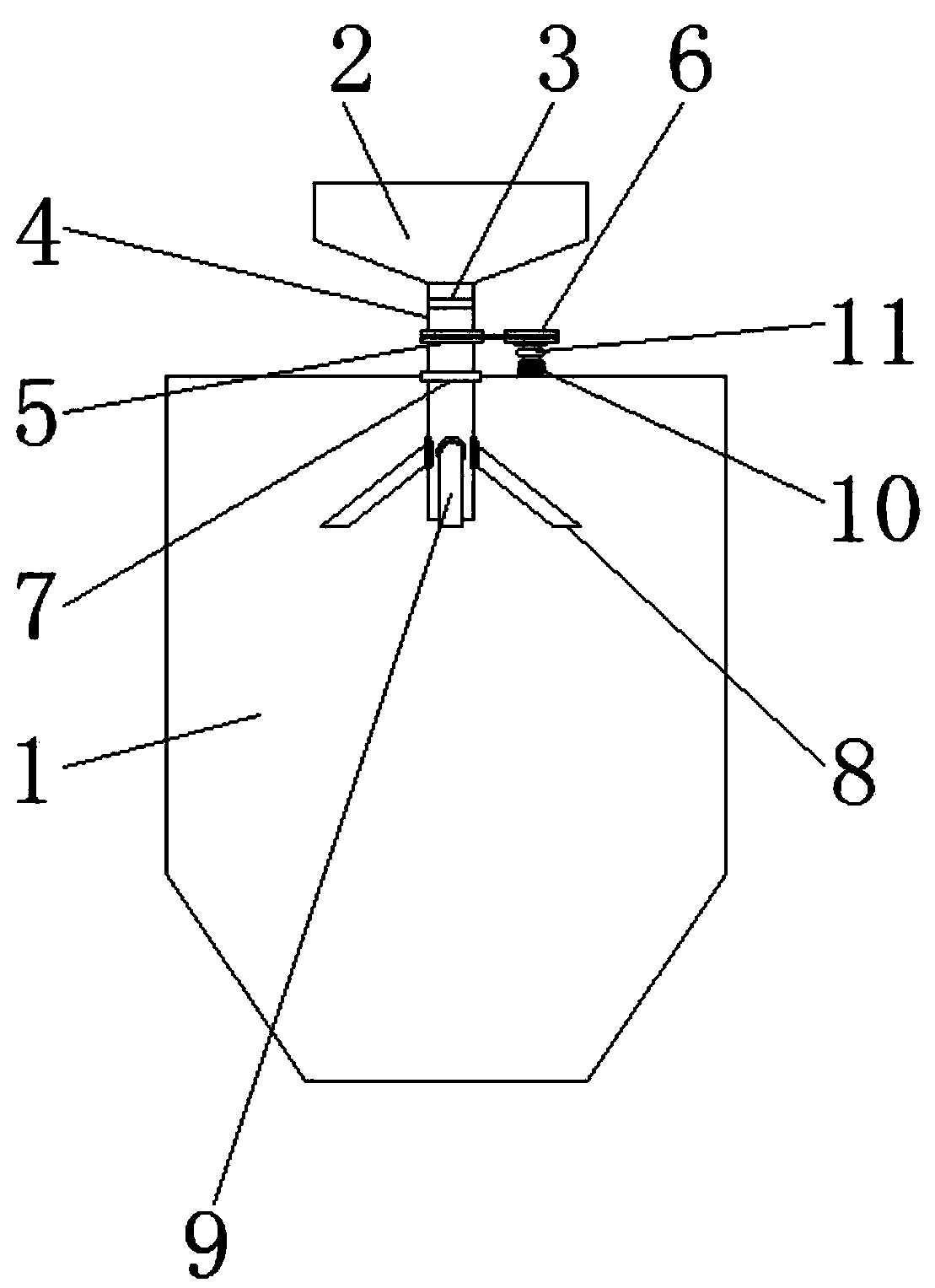

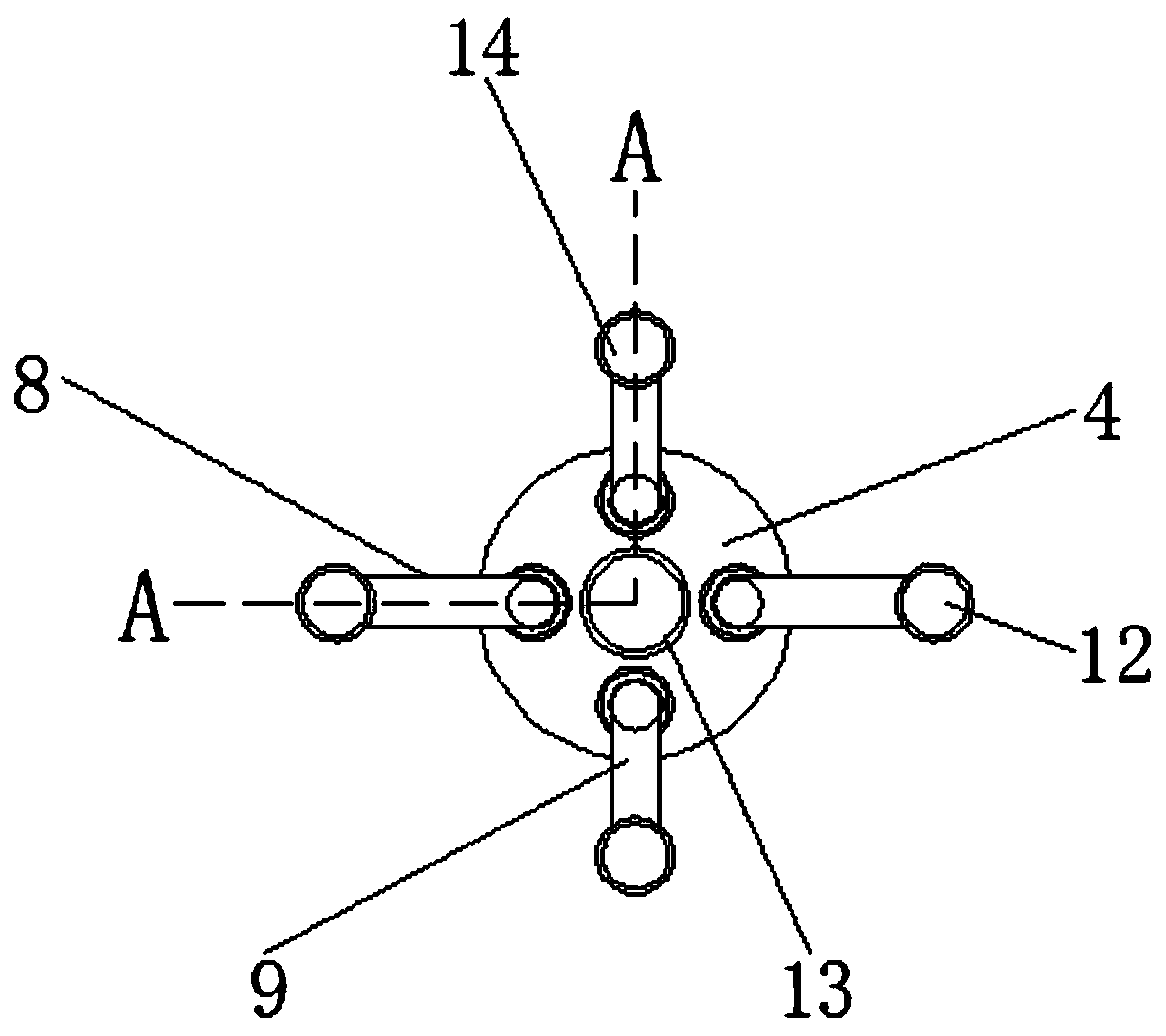

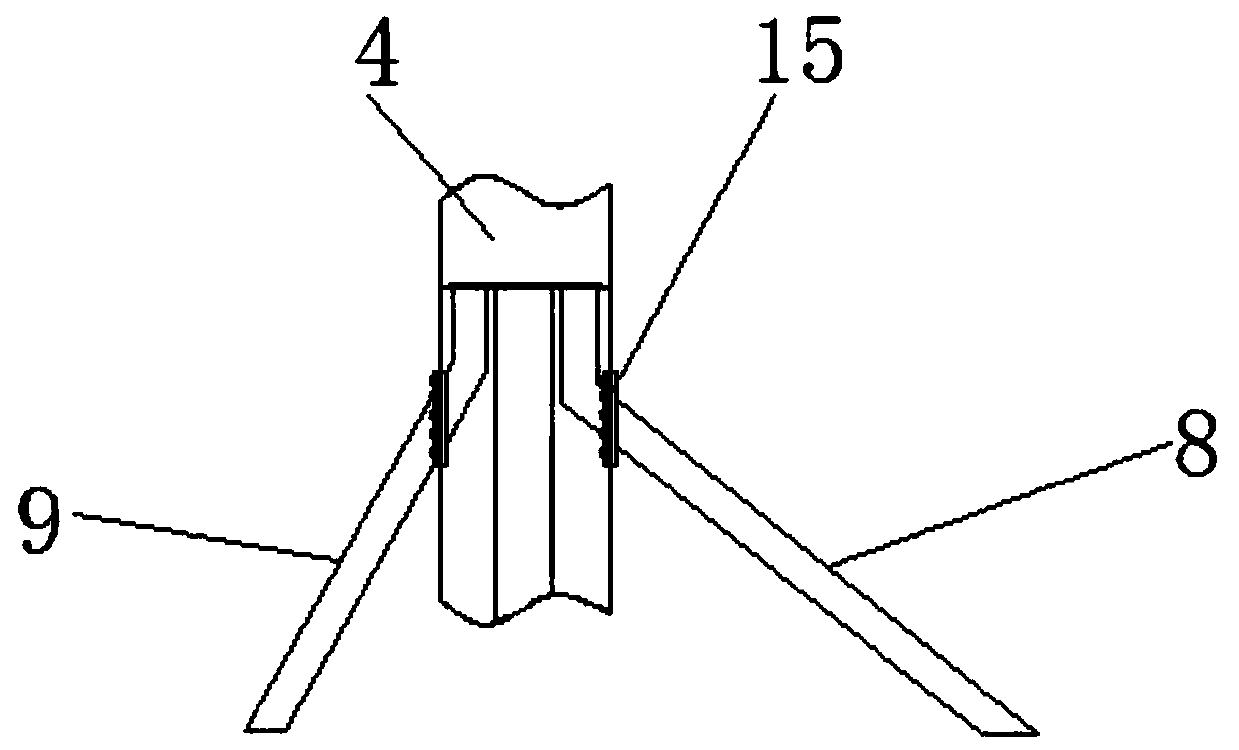

Peripheral feeding and separating device of direct current electric arc furnace for titanium slag smelting

InactiveCN102865738AFlow distributionConsistent feeding speedLighting and heating apparatusDc arc furnaceEngineering

Provided is a peripheral feeding and separating device of a direct current electric arc furnace for titanium slag smelting. From top to bottom, a separating mechanism is sequentially provided with a material collector (2), a blanking cup (3) with an adjustment handle (4), a round separating cone (5) and no less than one blanking port (6) annularly distributed on the round separating cone (5). The peripheral feeding and separating device has the advantages of being simple in structure, reliable to use and capable of uniformly distributing conveying materials onto a plurality of blanking points.

Owner:YUNNAN METALLURGICAL XINLI TITANIUM IND CO LTD

Aluminum oxide storage bin

The invention provides an aluminum oxide storage bin and belongs to the field of storage. The aluminum oxide storage bin guarantees convenient discharging and meanwhile solves the problem that an existing cone bucket type aluminum oxide storage bin, particularly an aluminum oxide storage bin with a large-diameter bin bucket needs a high foundation and is high in civil engineering cost. The bin bottom of the storage bin is formed by sequentially connecting a first bottom board, a second bottom board, a third bottom board and a fourth bottom board in a sealing mode, in the direction from the first bottom board to the fourth bottom board, the upper board surface of the first bottom board and the upper board surface of the third bottom board incline downwards, the upper board surface of the second bottom board and the upper board surface of the fourth bottom board incline upwards, the bottom of a first discharging groove and the bottom of a second discharging groove are communicated with the upper ends of sliding pipes respectively, the lower ends of the sliding pipes are communicated with feeding ends of first pneumatic sliding pipes in a one-to-one correspondence mode, draught fans are further arranged on the storage bin, and an air supply port of each draught fan is communicated with an air inlet of the corresponding first pneumatic sliding pipe through an air pipe. The aluminum oxide storage bin is used for storing and conveying aluminum oxide.

Owner:GUIYANG AL-MG DESIGN & RES INST

Preparation method of microbial fertilizer capable of efficiently exerting fertilizer efficiency and microbial fertilizer

PendingCN114149289APromote rootingPromote germinationBio-organic fraction processingShaking/oscillating/vibrating mixersBacillus licheniformisLivestock manure

The invention discloses a preparation method of a microbial fertilizer capable of efficiently exerting fertilizer efficiency and the microbial fertilizer, belongs to the technical field of microbial fertilizers, and aims to solve the problems that the existing chemical fertilizer is relatively high in cost, relatively large in environmental pollution and not beneficial to long-term use, and stirring equipment in the preparation of the microbial fertilizer is not uniform enough for stirring various raw materials. The common means for stirring is to directly mix all the raw materials, and the stirring efficiency is influenced; the corn straw, the wheat straw, the peanut shells and the livestock manure are crushed and mixed, the decaying agent is prepared from the bacillus subtilis, the bacillus licheniformis, the bacillus megatherium, the aspergillus oryzae and the yeast, and the mixed material is subjected to decaying fermentation, so that the plant growth can be promoted, the investment is further reduced, the green development is realized, and the economic benefit is increased. And in practical application, environmental hazards can be reduced, and the soil environment can be improved.

Owner:王二利

Calcined coke bin anti-segregation device having even shaking function

The invention discloses a calcined coke bin anti-segregation device having an even shaking function. The calcined coke bin anti-segregation device comprises a coke bin main body and a bearing, the bearing is installed at the middle position of the top end above the coke bin main body, a discharge main pipe penetrates through the inside of the bearing, the top end of the discharge main pipe is connected to a material gathering groove, the bottom of a second connecting shaft is connected to a motor through a speed reducer, the bottom of the motor is mounted above the top end of the coke bin mainbody, a first discharge branch pipe and a second discharge branch pipe which are connected through a flange are arranged at the position, close to the lower portion, of the exterior of the dischargemain pipe, the bottoms of the first discharge branch pipe and the second discharge branch pipe penetrate a first discharging opening and a third discharging opening correspondingly, and the bottom ofthe discharge main pipe penetrates through a second discharge opening. When the calcined coke bin anti-segregation device having the even shaking function is used, the uniformity of discharged calcined coke can be well guaranteed in the overall calcined coke discharging process.

Owner:HUNAN CHUANGYUAN NEW MATERIALS

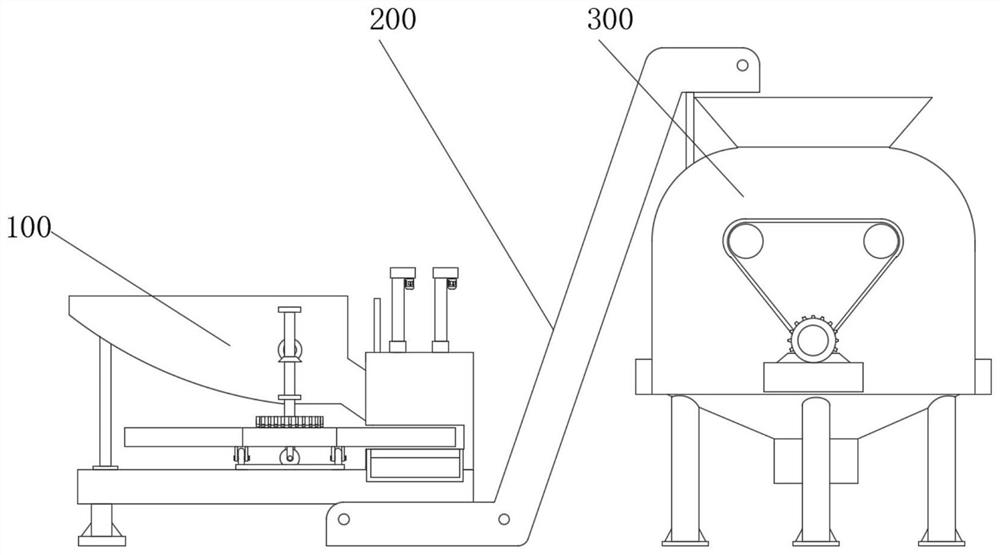

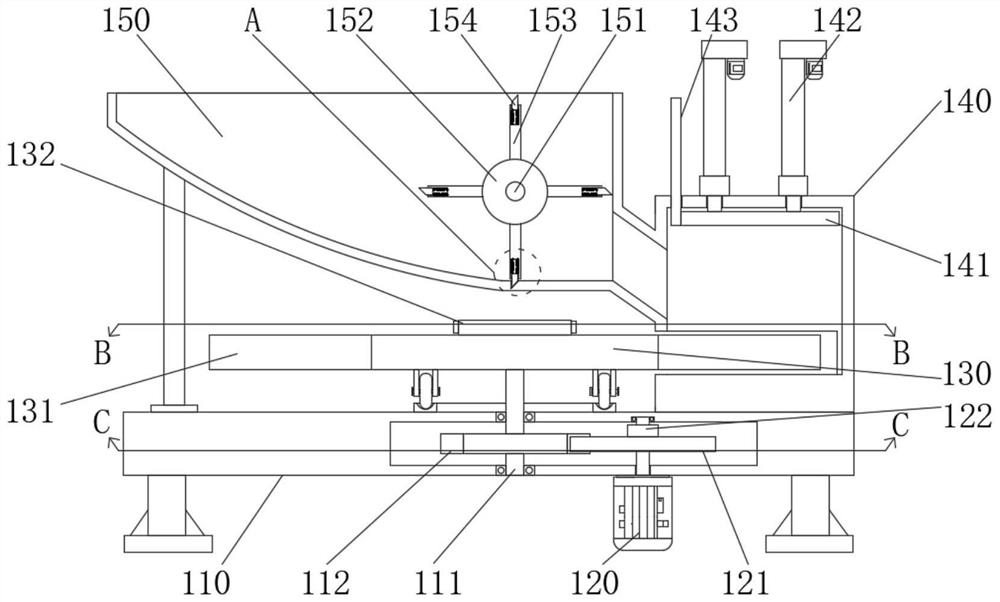

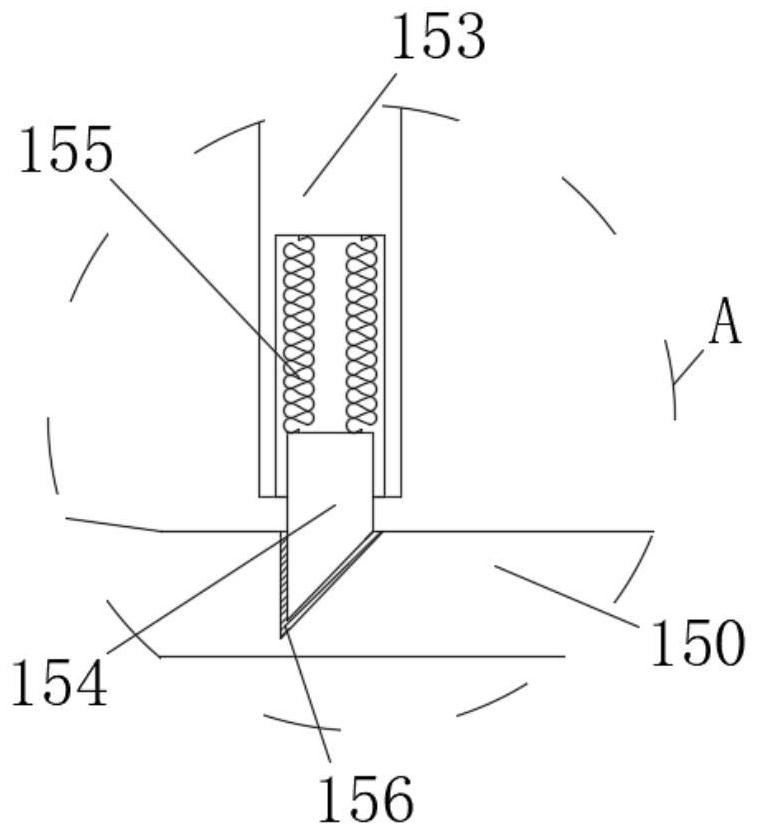

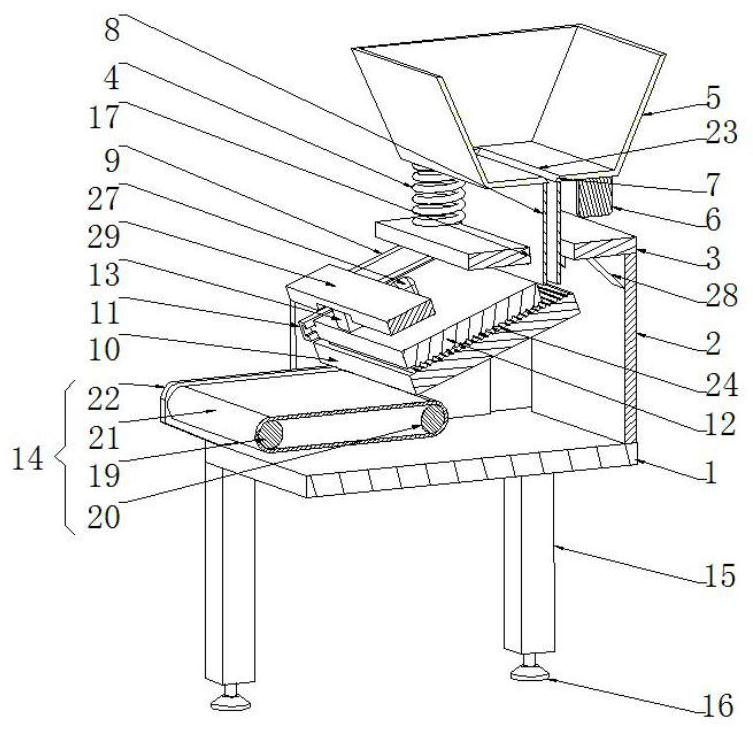

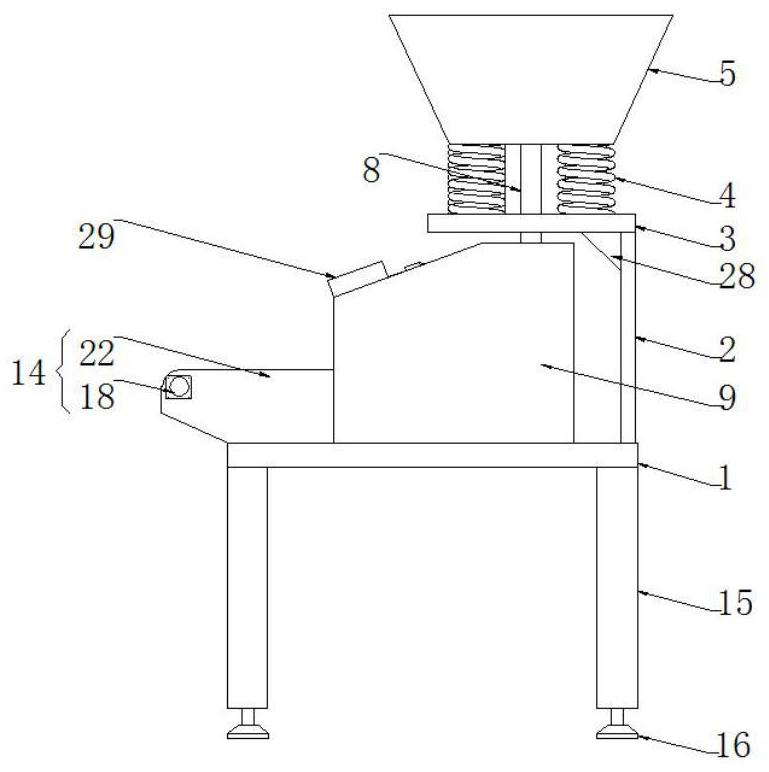

Crushing device capable of continuously feeding for waste plastic toys

InactiveCN112045900AUniform and appropriate particle sizeImprove crushing effectPlastic recyclingPressesGear wheelElectric machinery

The invention relates to the technical field of crushing devices, in particular to a crushing device capable of continuously feeding for waste plastic toys. The crushing device comprises a dischargingmechanism, a first motor, a hydraulic rod, a conveying belt main body and a second motor, wherein the discharging mechanism comprises a bottom plate, the top end of a rotating shaft is fixedly connected with a second turntable, and the top end of the bottom plate is fixedly connected with a pressing bin; and a first rotating roller is fixedly connected to the middle of a first rotating rod, firstsprings are evenly and fixedly connected to the sides, close to the first rotating roller, of inserting plates, the middle of a fixing piece is connected with the first rotating rod through a bevel gear, a carrier plate is fixedly connected to one side of an inner bin, the middle of the output end of the second motor is sleeved with a second rotating roller, and a belt is arranged on one side ofthe inner bin. The crushing device has a good crushing effect on spherical or other plastic toys difficult to crush, the discharging speed is uniform, the particle size of finished materials is uniform and appropriate, and the recycling value is high.

Owner:王增容

Aluminum alloy casting machine convenient for conveying material

The invention belongs to the technical field of casting, and particularly relates to an aluminum alloy casting machine convenient for conveying a material. The aluminum alloy casting machine comprisesa casting machine integrated body and a casting chamber. One side of the casting machine integrated body is fixedly provided with a material conveying tower. The lower end of the casting chamber is fixedly provided with a support platform. A position of one side, adjacent to the casting chamber, above the support platform is provided with a material conveying pipe. A position, adjacent to the upper end of the casting chamber, of the upper end of the casting machine integrated body is fixedly provided with a first radiator, and a position, adjacent to the other side of the casting machine integrated body, of the other side of the casting chamber is fixedly provided with a control box. The inner surface of the control box is fixedly provided with a refrigerating water tank, and one side ofthe refrigerating water tank is fixedly provided with a refrigerator. The aluminum alloy casting machine convenient for conveying the material is provided with the refrigerating water tank, a second radiator and a flow control plate, is capable of improving the working efficiency of the casting machine, and enabling a worker to control the material conveying conveniently, the use is more convenient, and the aluminum alloy casting machine has the better using prospect.

Owner:NANJING JIAMING DIE CASTING FACTORY

Method and system for controlling feeding speed of vibrating feeder

ActiveCN103949330BAvoid cloggingUniform feeding speedGrain treatmentsProgrammable logic controllerEngineering

The embodiment of the invention discloses a method and a system for controlling the feeding speed of a vibrating feeder. The method comprises the following steps: feeding materials to an impact crusher at a certain feeding speed by virtue of the vibrating feeder, wherein the larger the particle sizes of the materials are, the larger the load of an engine connected with the impact crusher is and the lower the rotating speed of the engine is under the condition that the feeding speed is constant; monitoring the current rotating speed of the engine during the working of the impact crusher according to a preset period or in real time by virtue of a speed measurement sensor, and sending the current rotating speed to a programmable logic controller (PLC); and controlling the feeding speed of the vibrating feeder according to the received current rotating speed of the engine by virtue of the PLC. According to the embodiment of the invention, the feeding speed of the vibrating feeder can be effectively controlled according to the intensity of the load of the engine, so that the automatic regulation of the feeding speed of the vibrating feeder is realized.

Owner:XUZHOU XCMG MINING MACHINERY CO LTD

Multi-station weighing machine and method

ActiveCN105466533BEven by forceAchieve ultra-precise weighingSpecial purpose weighing apparatusControl systemComputer module

Owner:ZHUHAI HUALI FRICTION MATERIAL

Powder adding device

The invention discloses a powder adding device. The powder adding device comprises a powder storage bin, wherein a powder adding inlet is formed in the upper portion of the powder storage bin, and a powder sprinkling outlet is formed in the lower portion of the powder storage bin. The powder adding device is characterized in that a cam is hinged to the powder sprinkling outlet, and the longer portion of the cam is in contact with one side of the powder sprinkling outlet; a turnover plate abuts against the upper portion of the cam, and one end of the turnover plate is hinged to the side wall ofthe other side of the powder storage bin; and a cam is installed on a centre shaft, and the centre shaft is connected with a drive device. Through the mode, the powder adding device has the advantageof uniform powder sprinkling speed.

Owner:CHANGGE HENGER PORCELAIN

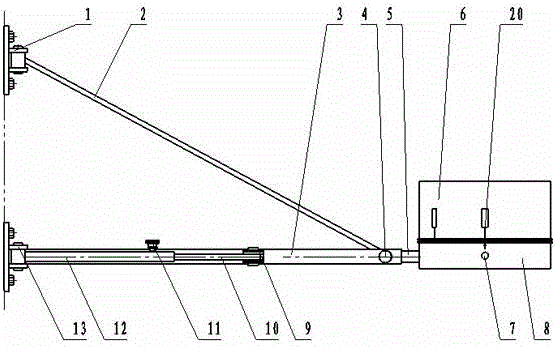

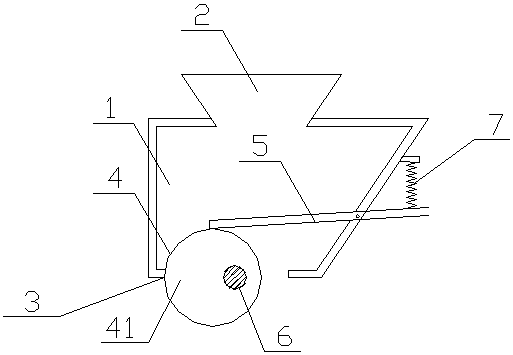

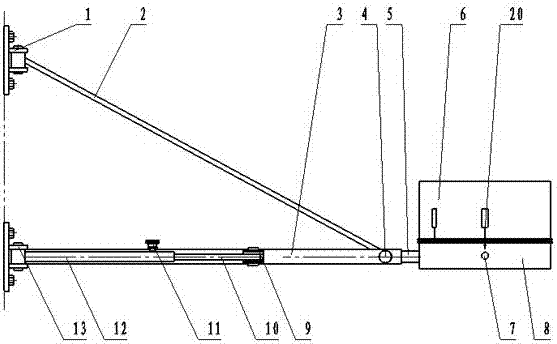

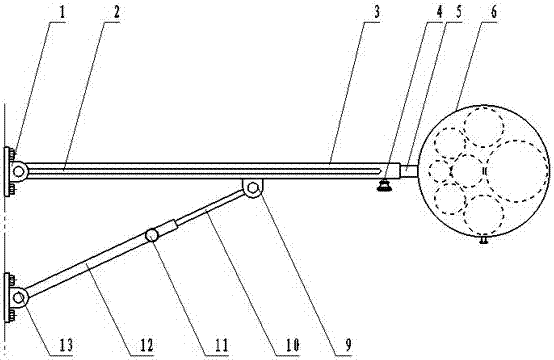

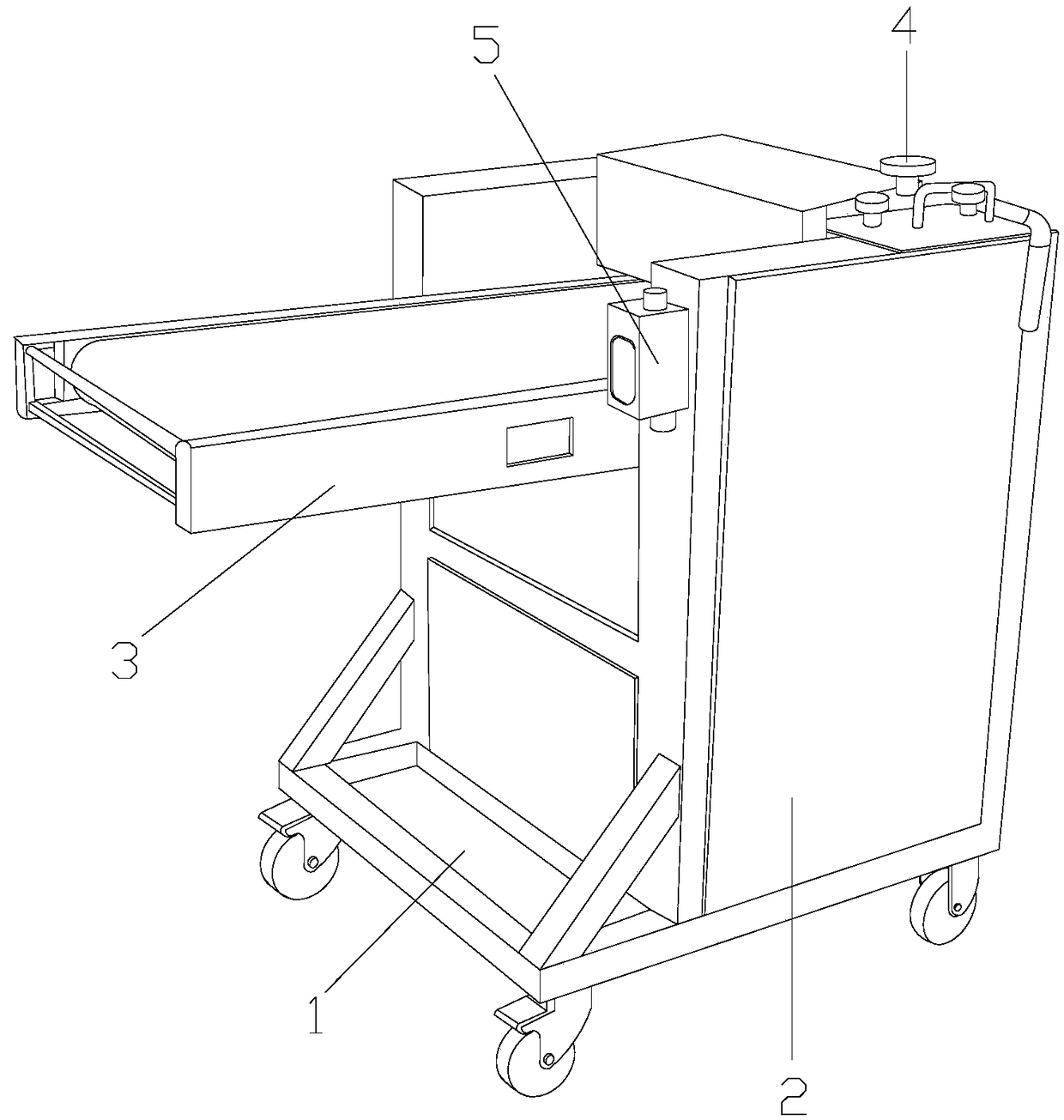

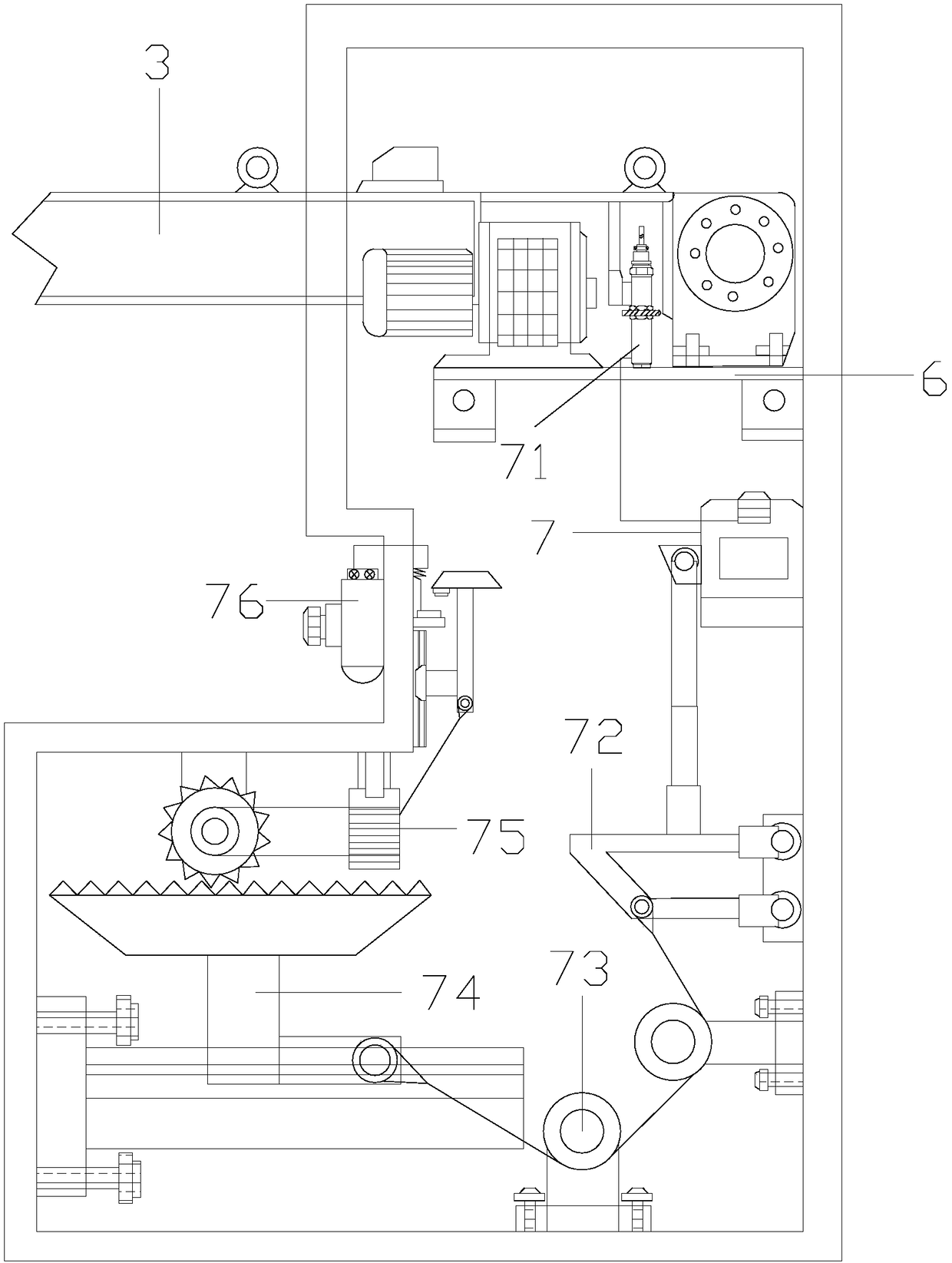

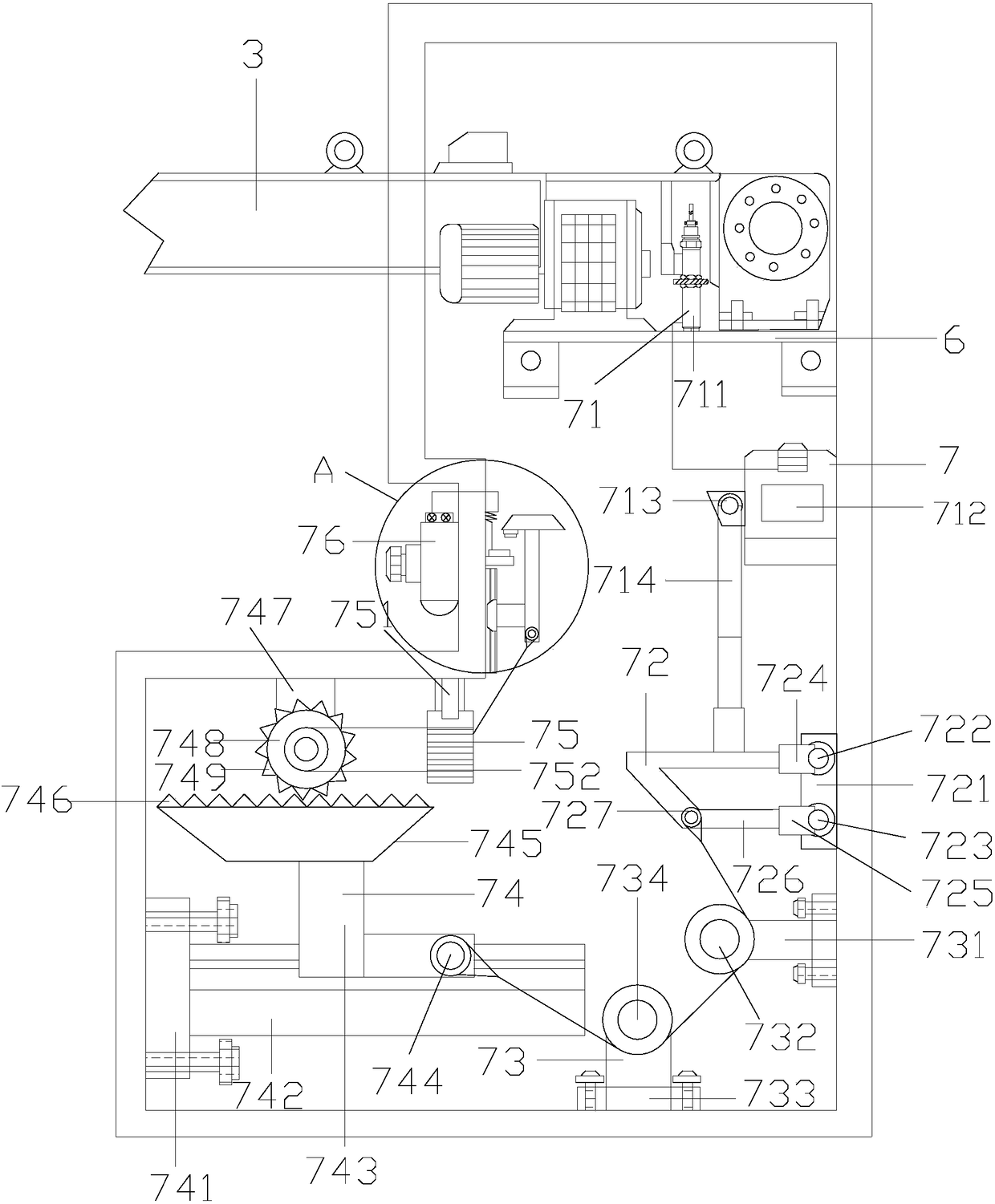

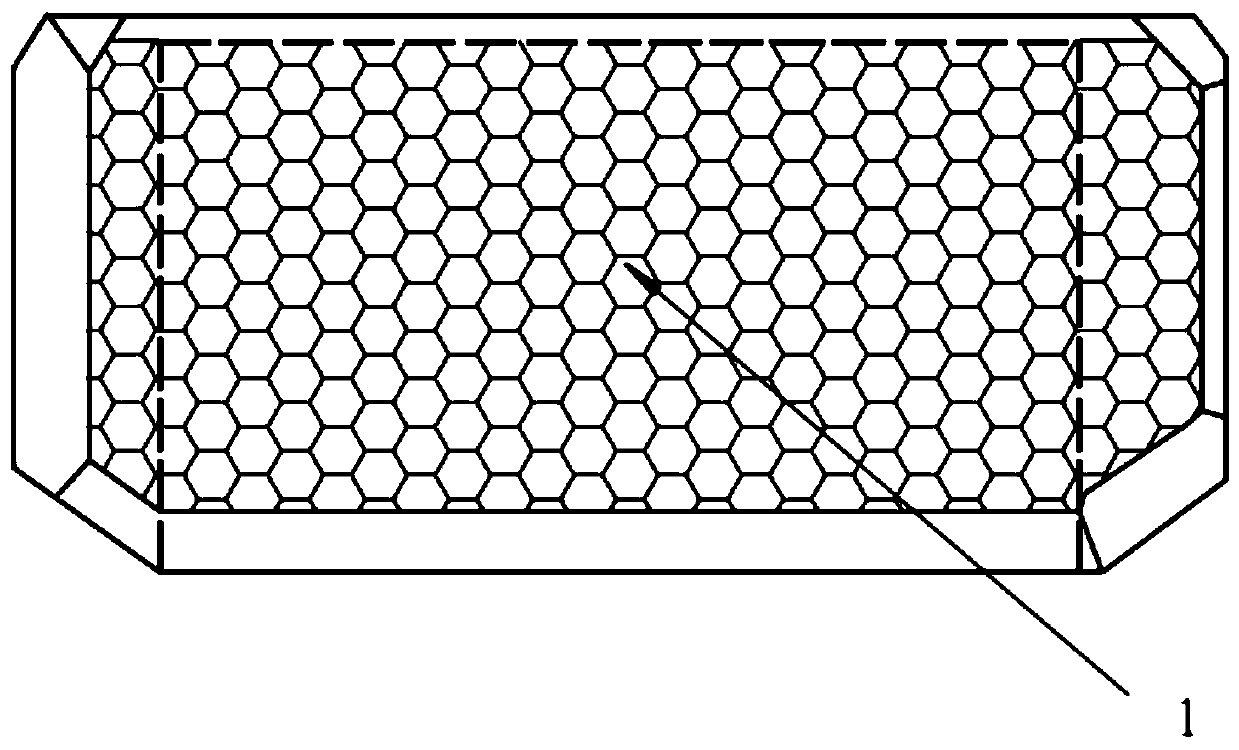

Vine cutting machine

The invention discloses a vine cutting machine and belongs to the technical field of vine cutting equipment. The vine cutting machine comprises a base, a feeding device, a transmission component, a blade and a motor. The feeding device is arranged on the base; the motor is mounted on the base; the blade is mounted on an output shaft of the motor; one end of the transmission component is connectedwith the output shaft of the motor; the other end of the transmission component is movably connected with the feeding device; the motor drives the blade to rotate; the feeding device is driven by thetransmission component to perform feeding. Green fodder is conveyed to the blade at a uniform speed through the feeding device for the purpose of cutting; the feeding speed is uniform; the length of the cut fodder is uniform; working efficiency is high, labor intensity is low, and safety and reliability are good. In use, an upper roller may slide up and down according to the quantity of green fodder, so that blocking of the feeding device is avoided effectively.

Owner:NANNING UNIV

Combined Seasoning Storage Adder

The invention discloses a combined seasoning storage adder and relates to the technical field of cooking utensils. It is equipped with a plurality of seasoning boxes (16) in an upper box (6) with a top cover (19) on the upper end. The top of these seasoning boxes (16) is provided with a material inlet and the bottom is provided with a material outlet; each The discharge port at the bottom of the seasoning box (16) is connected with a discharge valve arranged at the bottom of the upper box (6); the upper box (6) is mounted on the lower box (8) through a rotating shaft, and the lower box (8) is connected with a Parts, the box wall of the lower box (8) is equipped with a feeding button (7), and the switch control end (15) of each discharge valve passes the feeding button along with the upper box (6) and the trajectory of the lower box rotation (8). (7) is located in the stroke space at one end inside the lower box (8). The combined seasoning storage adder can solve the problems of inconvenient use and hygienic cleaning of the existing seasoning containers.

Owner:GUANGXI UNIVERSITY OF TECHNOLOGY

Automatic food machinery wave cutting equipment

ActiveCN108406904AQuality assuranceGuaranteed efficiencyMetal working apparatusEngineeringPulsed wave

The invention discloses automatic food machinery wave cutting equipment. The automatic food machinery wave cutting equipment structurally comprises a supporting frame, a rack, a conveying belt, a cutter regulating key, a pressure regulating valve, an impulse wave device and a specification abnormity induction and prompting device; the rack is fixedly welded on the surface of the upper end of the supporting frame; the impulse wave device is fixedly connected with the upper part of an inner cavity of the rack; the conveying belt is vertically connected with the surface of the left end of the impulse wave device and the impulse wave device penetrates out of the conveying belt; and the specification abnormity induction and prompting device is movably connected with the lower part of the innercavity of the rack. When food is subjected to wave cutting processing operation, the material feeding speed is uniform, the product quality is improved, certain induction and detection operation can be carried out on specifications such as the thickness and the width of the food after being subjected to wave cutting through the impulse wave component of the equipment, and certain prompting handling is carried out under the condition that the thickness and the width do not reach the standards, so that the situation the wave cutting quality and the wave cutting efficiency can achieve the expected effect is ensured, and ordered proceeding of subsequent food processing work is also ensured.

Owner:宁夏四季青冷链物流有限公司

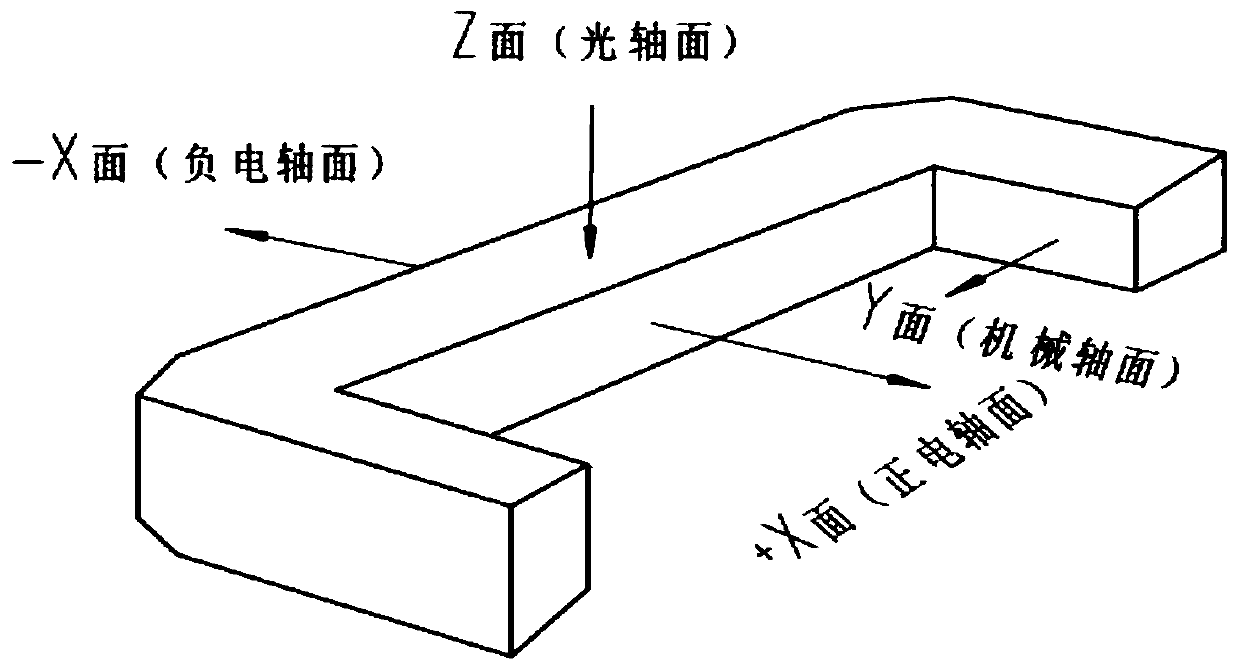

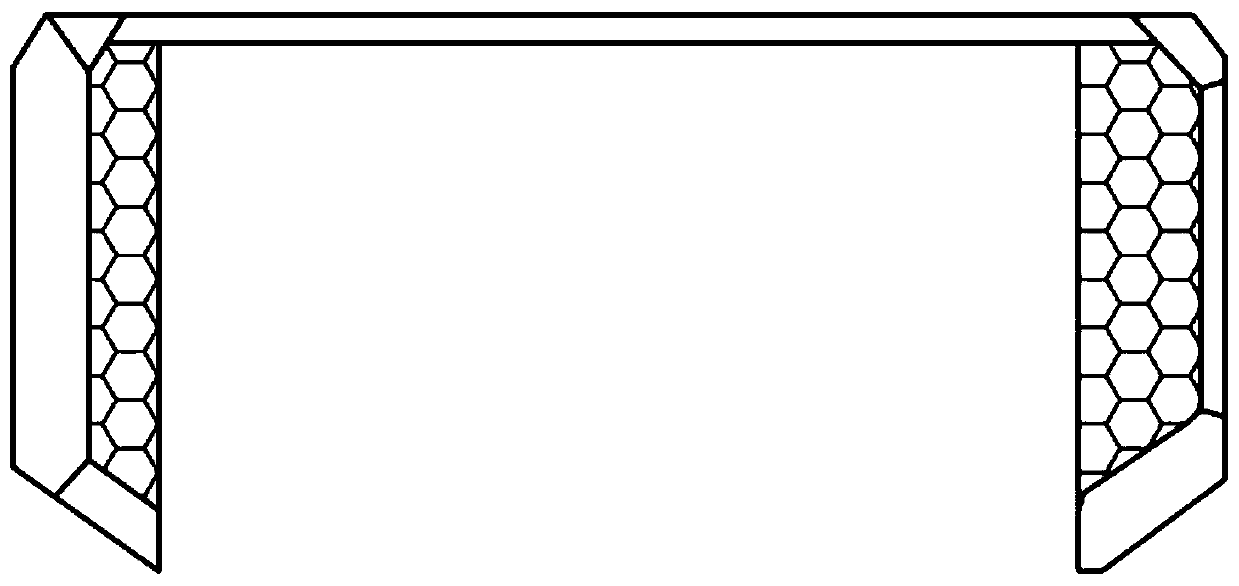

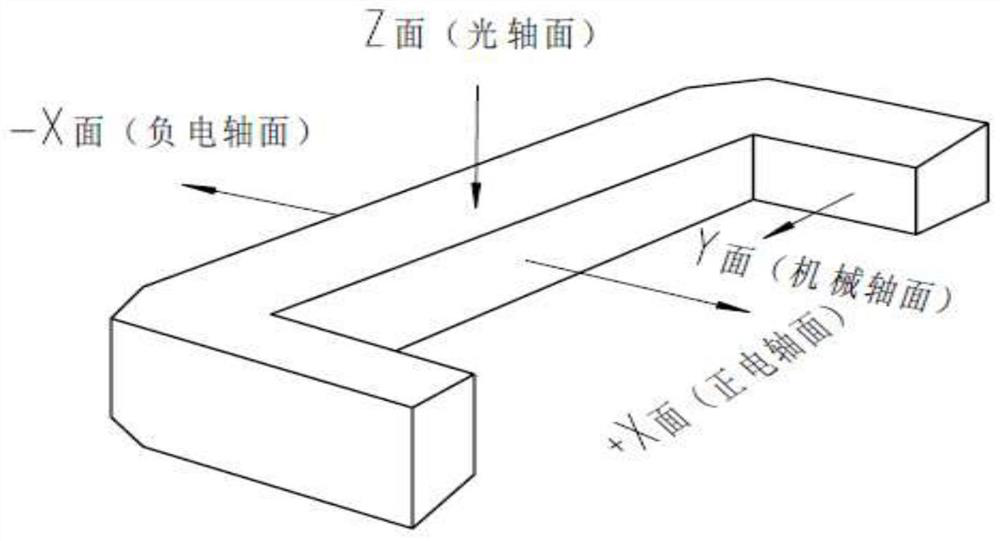

High-quality seed crystal wafer cultivation method for artificial quartz crystal

ActiveCN110747502AUniform feeding speedPolycrystalline material growthFrom normal temperature solutionsPhysical chemistryWafer dicing

The invention discloses a high-quality seed crystal wafer cultivation method for an artificial quartz crystal. The method comprises the following steps: 1, cutting the artificial quartz crystal to becut to form a frame crystal only reserving a part of positive and negative electric axis areas; 2, cutting the frame crystal to form frame seed crystal wafers; 3, putting the frame seed crystal wafersinto a high-pressure kettle, and growing the crystal; and 4, cutting the grown part of the frame crystal to obtain the high-quality seed crystal wafer. The characteristic that the crystal grown in the +X direction (positive electric axis direction) of the quartz crystal does not inherit the defects of the seed crystal wafer is utilized to cultivate the high-quality seed crystal wafer is cultivated, and the seed crystal wafer cutting is carried out on the grown part of the crystal, so that the high-quality seed crystal wafer with a low corrosion tunnel density is obtained.

Owner:山东博达光电有限公司

A solid material dissolution extraction device for industrial design

ActiveCN109954293BEasy to separateImprove scraping performanceSolid solvent extractionEngineeringPipe

The invention discloses a solid material dissolution extraction device for industrial design, which comprises a bottom plate and a first extraction box. The top outer wall of the bottom plate is fixed with a first mounting frame and a second mounting frame by bolts. One side of the second mounting frame is The outer wall is fixed with a second extraction box by bolts, and the outer walls on both sides of the second extraction box are welded with stabilizing bars, and the outer wall on one side of the stabilizing bar is welded to the outer wall on one side of the second mounting frame, and one side of the first mounting frame The outer wall is welded with two equidistant fixed blocks, and the two fixed blocks are movably fixed with connecting sleeve rods through bolts. The curved structure of the arc-shaped rod of the present invention can simultaneously scrape materials that are not on the same straight line, which improves the scraping ability of the device and the separation ability of the device for residues, and the sawtooth groove can crush and separate stubborn residues , because the volume of the interlayer between the splitter vane and the inner wall of the splitter tube is constant, the feeding speed of the melt becomes uniform.

Owner:北京华诺信得科技有限公司

High-quality Seed Wafer Cultivation Method of Artificial Quartz Crystal

ActiveCN110747502BUniform feeding speedPolycrystalline material growthFrom normal temperature solutionsPhysical chemistryWafer dicing

The invention discloses a method for cultivating high-quality seed wafers of artificial quartz crystals, which comprises the following steps: 1. cutting the artificial quartz crystals to be cut into frame crystals which only retain part of the positive and negative electric axis regions; 2. cutting the frame crystals into Frame seed wafer; 3. Place the frame seed wafer in an autoclave for crystal growth; 4. Cut the growing part of the frame crystal to obtain a high-quality seed wafer. The present invention utilizes the characteristics that the crystals grown in the +X direction (positive electric axis direction) of the quartz crystal will not inherit the defects on the seed wafer to cultivate high-quality seed wafers, and cut the grown part of the crystals into the seed wafers. Thus, a high-quality seed wafer with low etch tunnel density is obtained.

Owner:山东博达光电有限公司

A waste wire peeling device for enameled wire production

ActiveCN110233007BUniform feeding speedAvoid pollutionBasic electric elementsElectronic waste recyclingReciprocating motionProcess engineering

The invention discloses a waste wire peeling device for enameled wire production. The waste wire peeling device comprises a bottom plate, and a uniform-speed blanking mechanism and an automatic peeling mechanism which are positioned on the bottom plate, wherein the uniform-speed blanking mechanism vibrates enameled wire waste in a hopper out of a blanking port through a vibration exciter; the automatic peeling mechanism drives a movable rubbing plate to reciprocate through two groups of air cylinders and the guiding action of two groups of guide rails is adopted, so that a bulge between the movable rubbing plate and a fixed rubbing plate removes a paint surface on the surface of an enameled wire. The polluting the environment can be avoided in the peeling process, and the internal conducting wire cannot be damaged.

Owner:江西博能上饶线材有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com