High-quality Seed Wafer Cultivation Method of Artificial Quartz Crystal

A quartz crystal and seed crystal technology, applied in the field of artificial quartz crystal frame-shaped + X-direction crystal growth and seed wafer manufacturing, can solve the problem of no frame seed wafer processing description and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

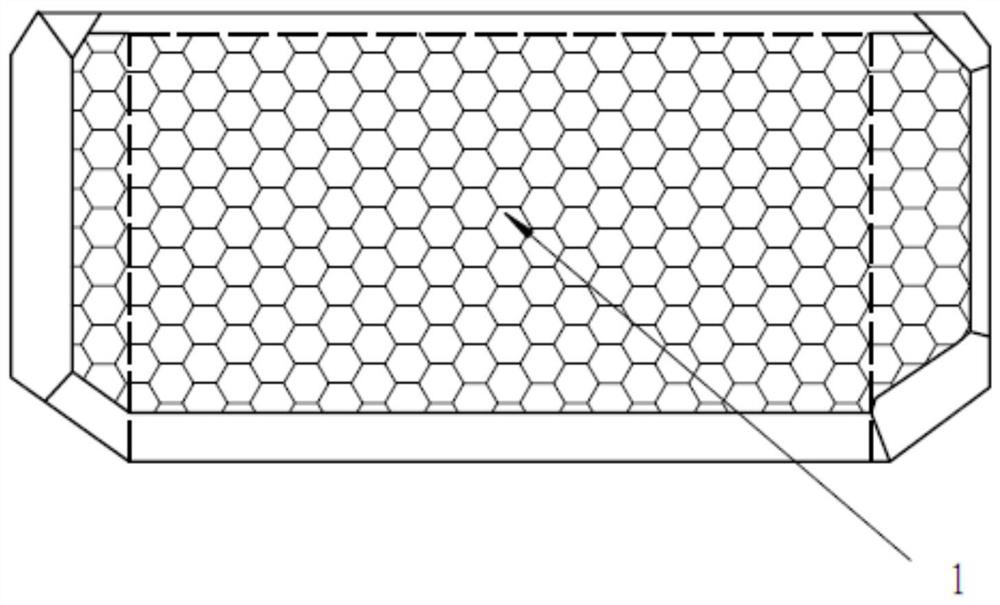

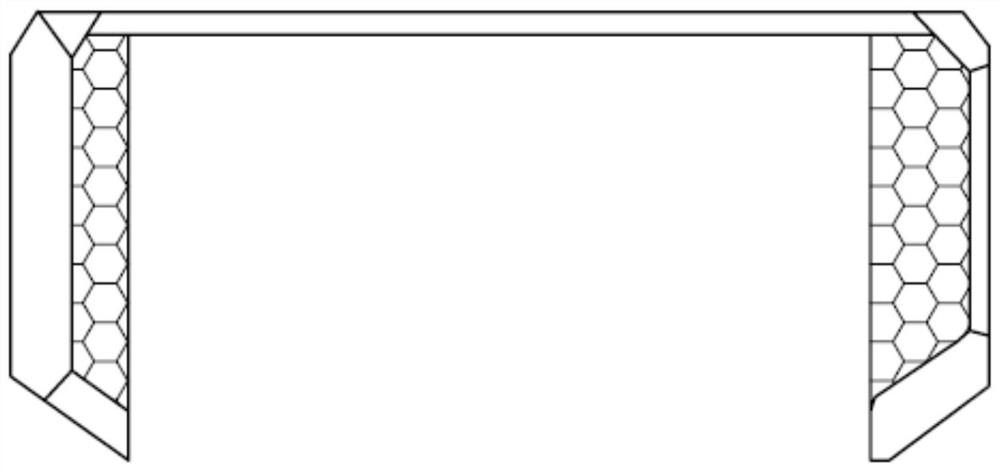

[0057] Step 1. The artificial quartz crystal is first cut into a frame-shaped crystal that only retains part of the positive and negative axis areas (cutting the frame crystal):

[0058] Artificial quartz crystals to be cut (such as figure 1 ), the crystal length (Y) is about 230mm; the crystal thickness (Z) is about 75mm; the crystal width (X) is about 100mm.

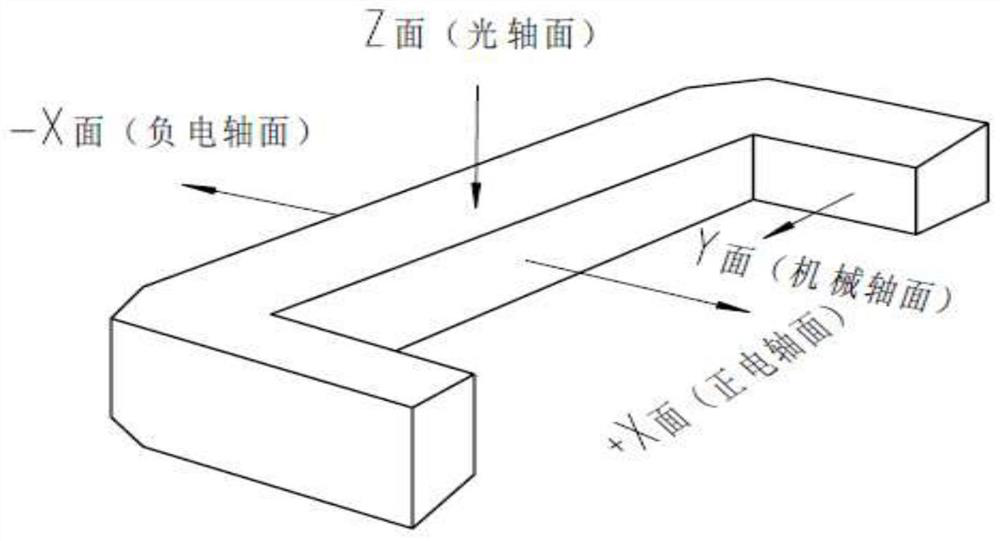

[0059] Artificial quartz crystals to be cut (such as figure 1 One Z surface (optical axis surface) and +X surface (positive electric axis surface) are ground, and the orientation accuracy of the ground two planes is guaranteed to be within ±10'; on the other unground Z surface (optical axis surface) ) to draw the part that needs to be cut off --- cut off part 1, that is, according to the common sense of this industry, draw according to the different growth mounds and regional boundaries of the Z zone and the X zone on the unground Z surface (optical axis surface) The width of the X region to be reserved is enough; th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com