Cloth conveying method and cloth conveying device for sewing machine

A technology of a cloth feeding device and a sewing machine, which is applied in the directions of sewing machine components, cloth feeding mechanisms, sewing equipment, etc., can solve the problems of inconsistent pinhole spacing and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

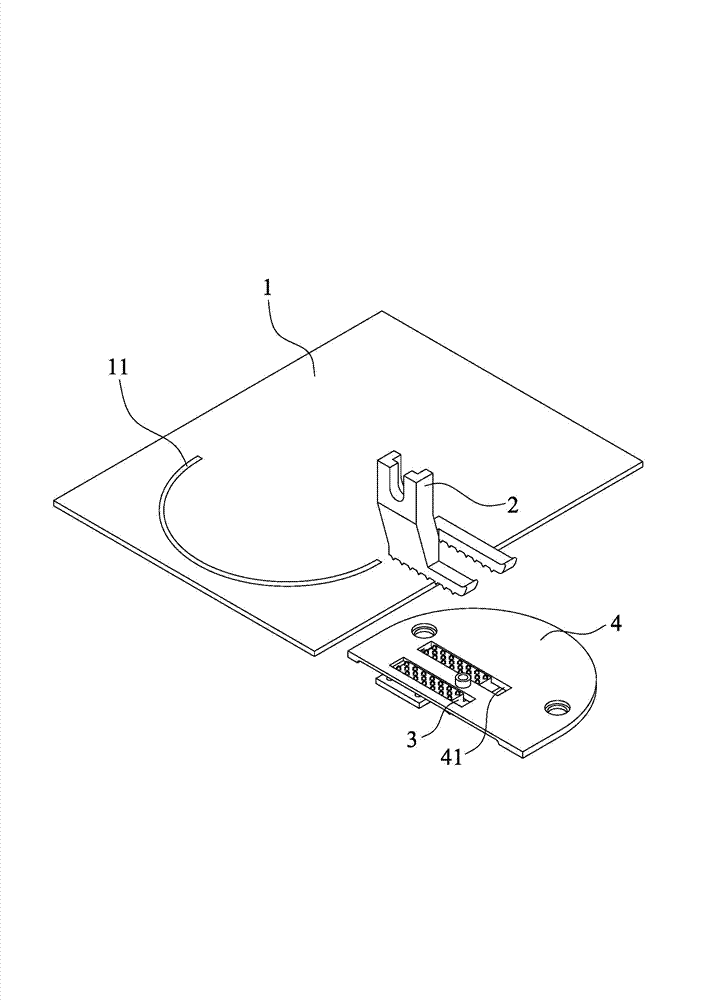

[0019] Such as figure 2 , image 3 Shown, the present invention is a kind of sewing machine feeding method, and it comprises the following steps:

[0020] (1) Put the sewing material in template 1;

[0021] (2) Put the template 1 on the top surface 31 of the tooth plate of the cloth feeding dog 3;

[0022] (3) The cloth feed dog 3 moves in an approximately elliptical trajectory perpendicular to the horizontal working surface under the joint action of the cloth feed mechanism and the tooth lifting mechanism of the sewing machine. and drive the template 1 to push forward or backward to complete the cloth feeding. At the same time, the needle of the sewing machine moves along the guide groove 11 on the template 1 to complete the sewing.

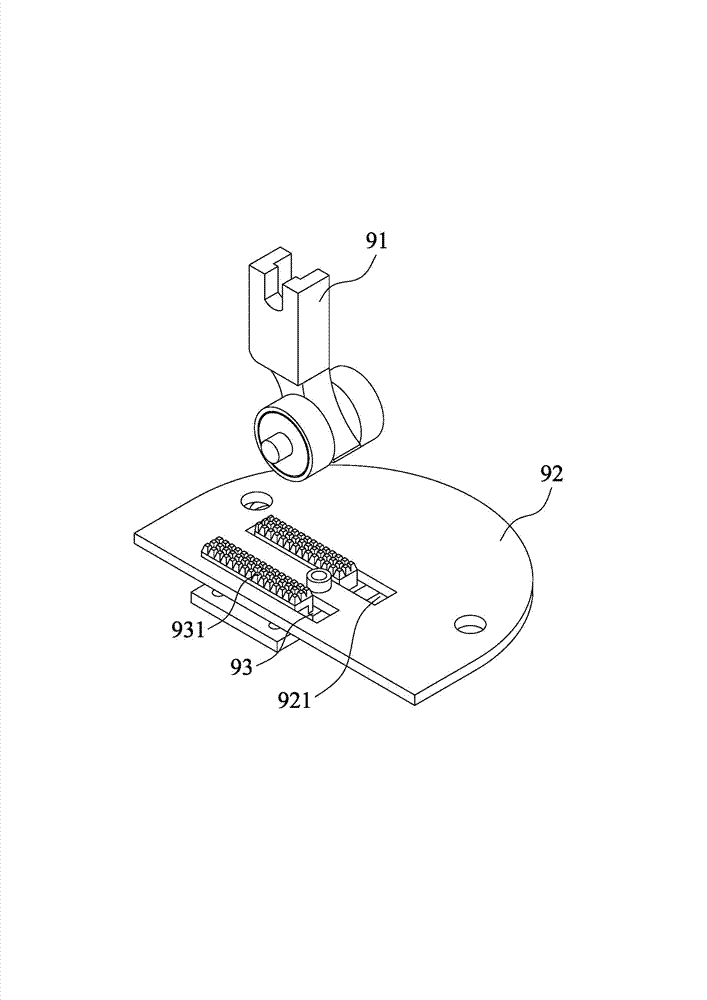

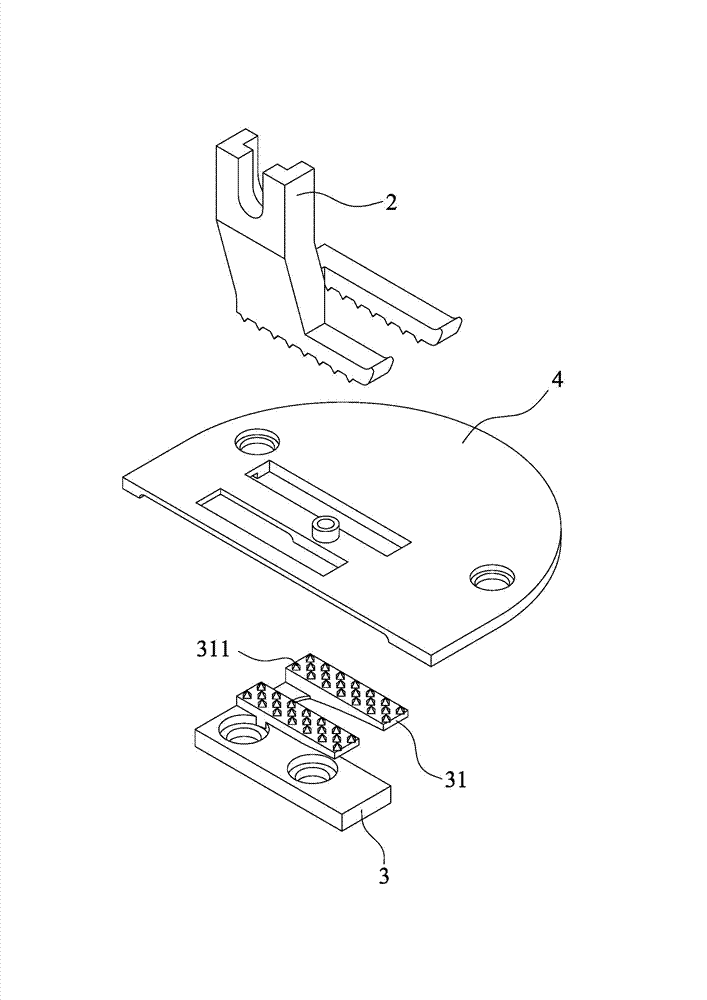

[0023] Such as image 3 As shown, the present invention is a sewing machine cloth feeding device, which includes a template 1, a presser foot 2, a cloth feeding dog 3, and a needle plate 4.

[0024] The present embodiment adopts the doubl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com