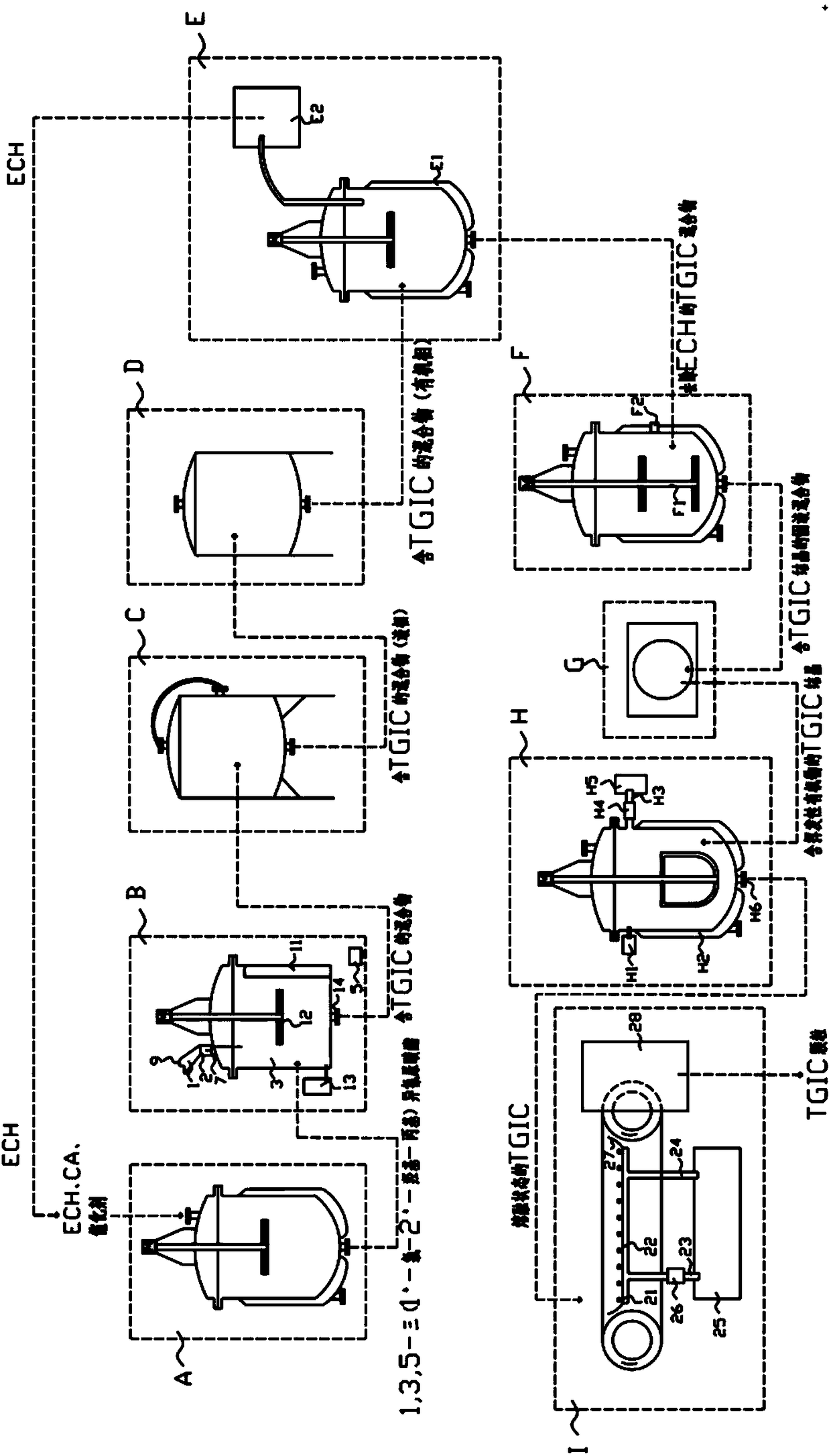

TGIC (Triglycidyl Isocyanurate) production method based on fused steel belt granulation

A production method and product technology, applied in the field of TGIC production and processing, can solve the problems of reduced yield, intensified side reactions, and easy volatilization of methanol, and achieve high recovery and utilization, improved quality and yield, and uniform feeding speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Example 1: Determination of the effect of cyclization kettle device B

[0051] 1. Production of TGIC (test group)

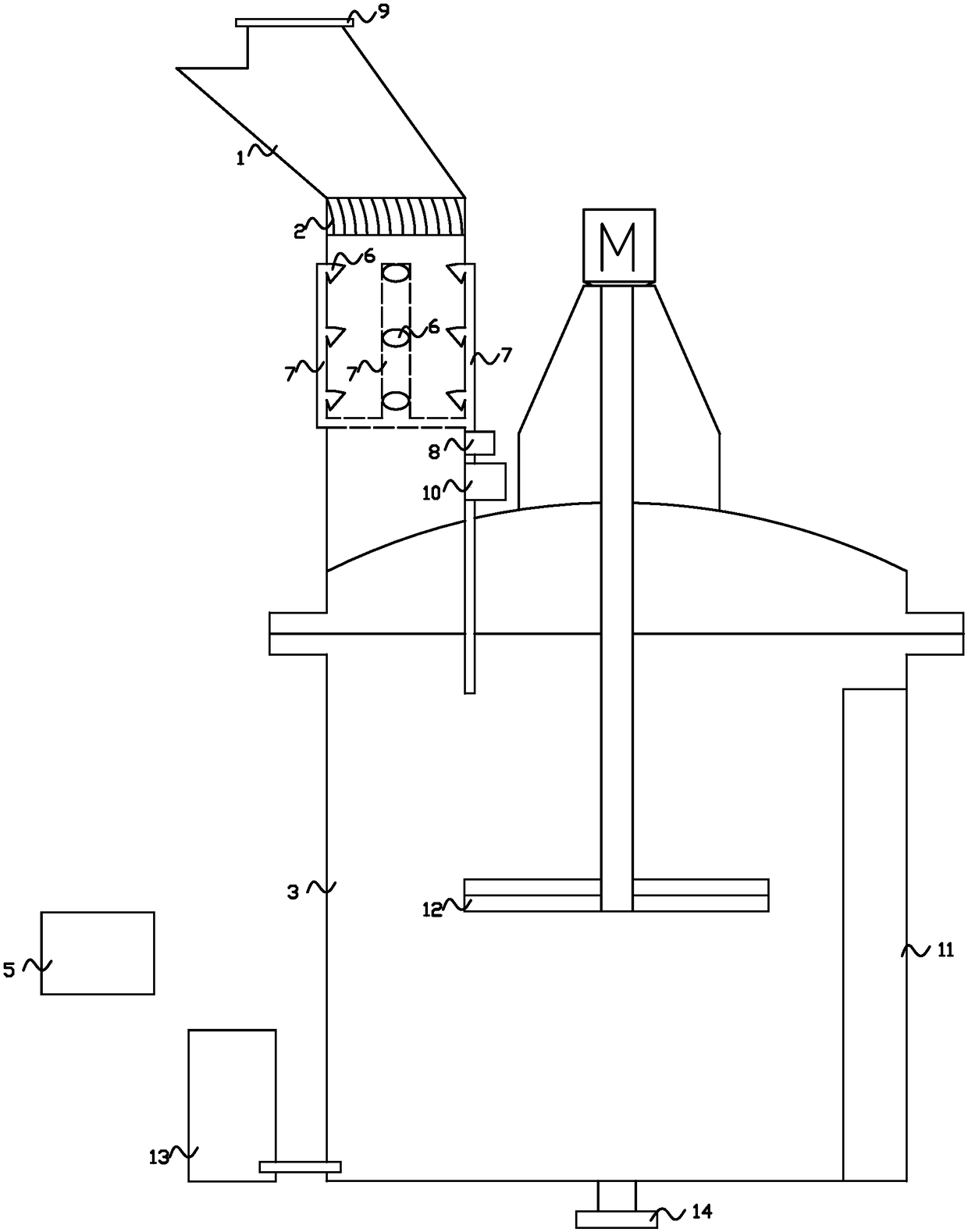

[0052] (1) Synthesis reaction: Add ECH, CA and tetramethylammonium chloride into synthesis kettle device A at a mass ratio of 7:1:0.03. The jacket A1 of the synthesis kettle was heated to 80°C with steam, and the synthesis reaction was carried out under normal pressure. The reaction was carried out for 5 hours until the mixed solution became clear and transparent, and the intermediate product: 1,3,5-tris(1'-chloro-2 '-hydroxy-propyl) isocyanurate.

[0053] (2) Cyclization reaction: add the above-mentioned intermediate product into the cyclization kettle device B, add solid alkali (99% NaOH), take the weight of the above added CA as 1, and add the weight of solid alkali as 1. The cyclization reaction is carried out under the condition of 30±5° C., and the reaction time is 1.5 h. For the specific cyclization operation, refer to the above step 2, cyclizati...

Embodiment 2

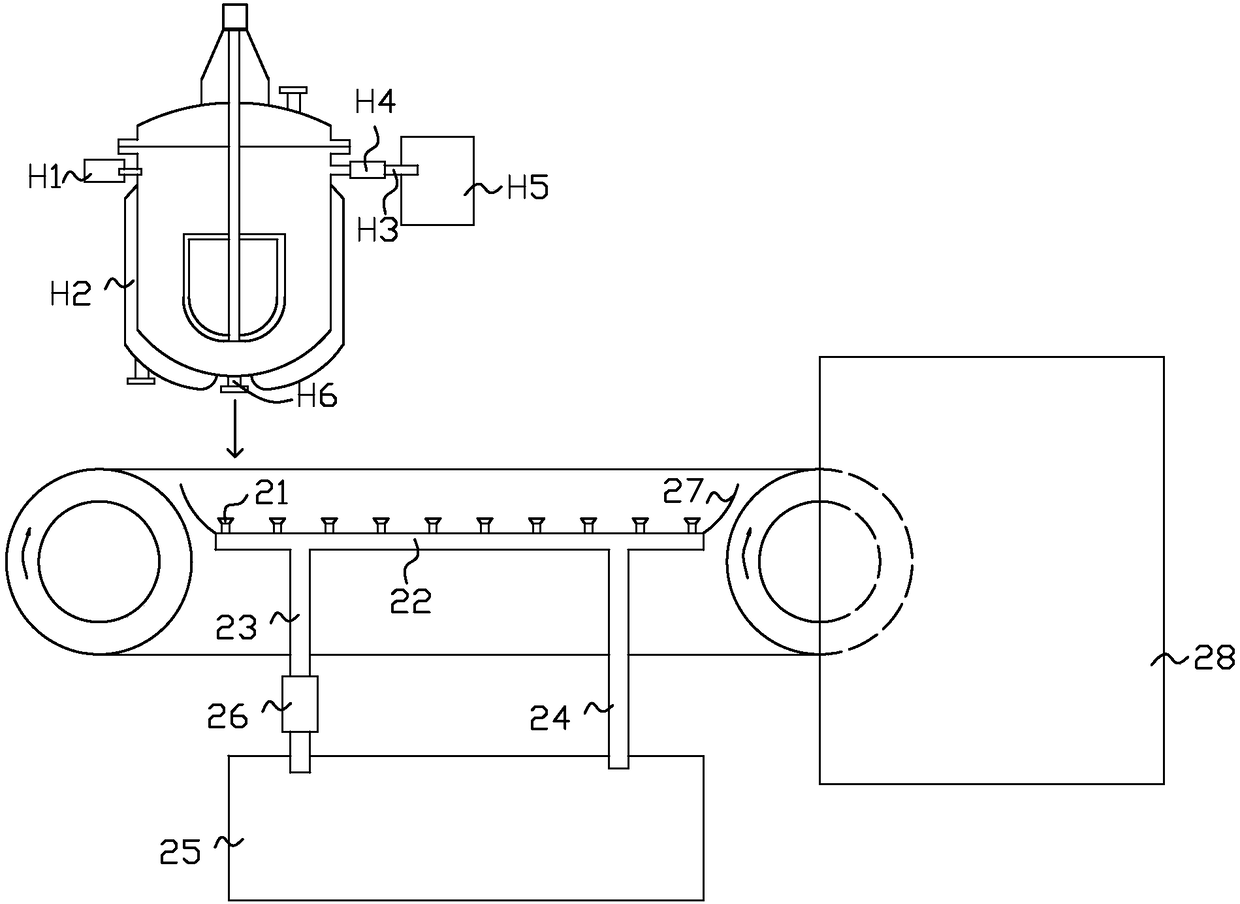

[0069] 1. Production of TGIC particles

[0070] (1) Synthesis reaction: Add ECH, CA and tetramethylammonium chloride into synthesis kettle device A at a mass ratio of 4:1:0.01. The jacket A1 of the synthesis kettle was heated to 80°C with steam, and the synthesis reaction was carried out under normal pressure. The reaction was carried out for 5 hours until the mixed solution became clear and transparent, and the intermediate product: 1,3,5-tris(1'-chloro-2 '-hydroxy-propyl) isocyanurate.

[0071] (2) Cyclization reaction: Add the above-mentioned intermediate product into the cyclization kettle device B, add solid alkali (99% NaOH), take the weight of the above added CA as 1, and add the weight of solid alkali to be 0.9. The cyclization reaction is carried out under the condition of 30±5° C., and the reaction time is 1.5 h.

[0072] (3) Primary separation: the TGIC mixture produced in step 2 is passed into the pressure filter device C for filtration, and the liquid phase obta...

Embodiment 3

[0085] 1. Production of TGIC particles

[0086] (1) Synthesis reaction: Add ECH, CA and tetramethylammonium chloride into synthesis kettle device A at a mass ratio of 7:1:0.03. The jacket A1 of the synthesis kettle was heated to 80°C with steam, and the synthesis reaction was carried out under normal pressure. The reaction was carried out for 5 hours until the mixed solution became clear and transparent, and the intermediate product: 1,3,5-tris(1'-chloro-2 '-hydroxy-propyl) isocyanurate.

[0087] (2) Cyclization reaction: add the above-mentioned intermediate product into the cyclization kettle device B, add solid alkali (99% NaOH), take the weight of the above added CA as 1, and add the weight of solid alkali as 1. The cyclization reaction is carried out under the condition of 30±5° C., and the reaction time is 1.5 h.

[0088] (3) Primary separation: the TGIC mixture produced in step 2 is passed into the pressure filter device C for filtration, and the liquid phase obtained ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com