Powder adding device

A technology of adding device and powder material, which is applied in the field of flour material addition, which can solve the problems of uneven feeding speed, easy blockage of the main feeding port, and affecting the mixing effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The embodiment will be further described below in conjunction with the accompanying drawings.

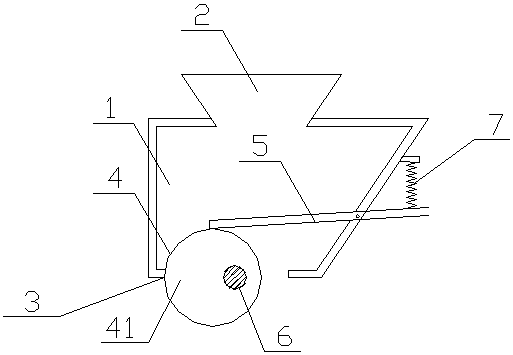

[0011] like figure 1 As shown, a powder adding device includes a powder storage bin 1, the upper part of the powder storage bin 1 is provided with a powder feeding port 2, and the lower part of the powder storage bin 1 is a powder sprinkling port 3, which is characterized in that: the powder sprinkling port 3 A cam 4 is hinged, and the longer part 41 of the cam is in contact with one side of the powder sprinkling opening 3. The top of the cam 4 bears on the flap 5, and one end of the flap 5 is hinged on the side wall of the powder storage bin 1 on the other side. The longer part 41 and the turnover plate 5 play a sealing role on the powder sprinkling opening 3, the cam 4 is installed on the central shaft 6, the central shaft 6 is connected with the driving device, and the driving device drives the cam 4 to rotate, when the longer part 41 of the cam reverses When turning in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com