Material lifting and conveying device for hotpot condiment processing

A technology for conveying device and hot pot bottom material, which is applied in the direction of conveyor, transportation and packaging, loading/unloading, etc. It can solve the problems of poor adjustment of height, labor-intensive handling, and inconvenient adjustment, so as to achieve uniform feeding speed and smooth feeding Good effect and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

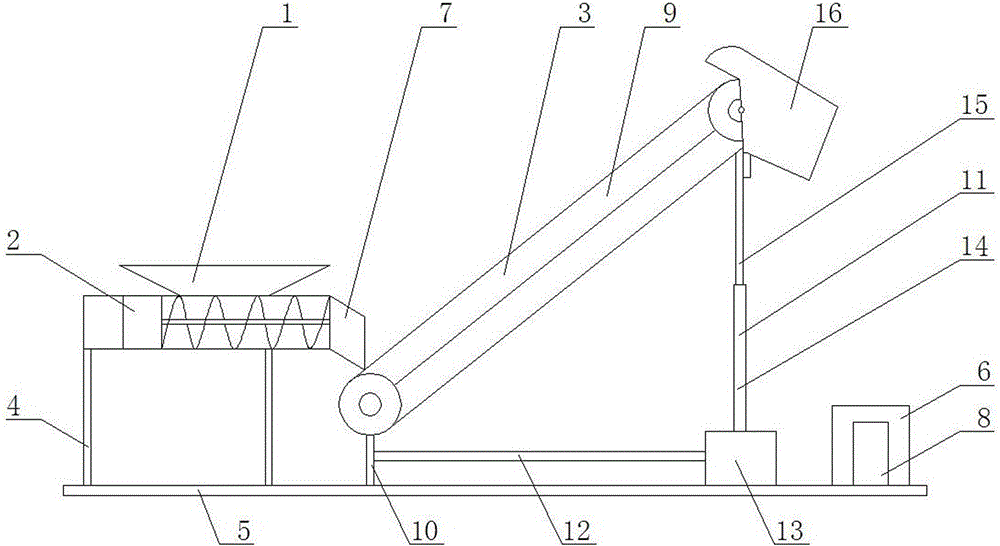

[0015] like figure 1 Shown, a kind of material hoisting conveying device for chafing dish bottom material processing comprises feed hopper 1, screw feeder 2, lifting conveyer belt 3, support frame 4, base 5, control box 6, described feed hopper 1 device On the upper end of the screw feeder 2, the right end of the screw feeder 2 is equipped with a discharge pipe 7, and the right end of the discharge pipe 7 is a lifting conveyor belt 3; The middle device at the top of the base 5 lifts the conveyor belt 3, and the right side device at the top of the base 5 controls the control box 6;

Embodiment 2

[0017] like figure 1 As shown, the lifting conveyor belt 3 is composed of a conveyor belt 9, a left fixed support leg 10, a right lifting support leg 11, and a fixed frame 12; the left lower end of the conveyor belt 9 is supported by a left fixed support leg 10, and the right lower end is supported by a The right lifting support leg 11 is supported, and the left fixed support leg 10 and the right lifting support leg 11 are connected by a fixed frame 12; the right lifting support leg 11 is a hydraulic lifting support device, which is composed of a hydraulic drive device 13, a telescopic sleeve 14, The lifting support shaft 15 is formed; the bottom end of the hydraulic drive 13 is installed on the base 5, the telescopic sleeve 14 is installed at the upper end, the lifting support shaft 15 is installed inside the telescopic sleeve 14, and the lifting support shaft 15 upper end is connected and supports the conveyor belt.

Embodiment 3

[0019] like figure 1 As shown, the material belt of the conveyor belt is a corrugated material belt.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com