Upper piece equalizing system

A technology that balances systems and workpieces, applied to conveyor objects, transportation and packaging, etc., can solve problems such as process impact, work efficiency, workpiece accumulation, etc., to achieve uniform loading speed and improve work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with the embodiment shown in the accompanying drawings, the present invention is described in detail as follows:

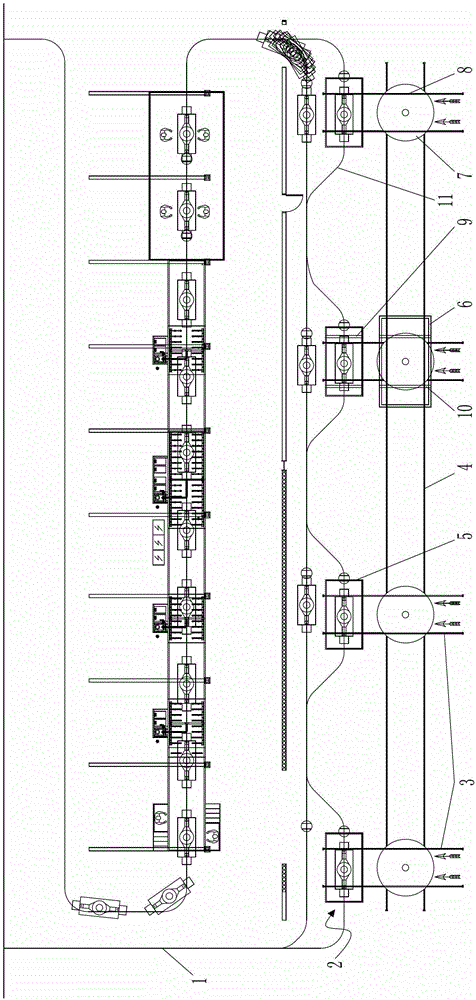

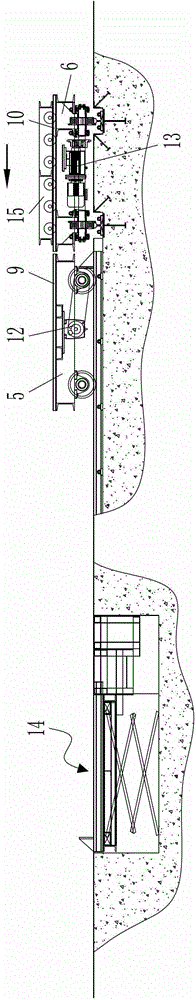

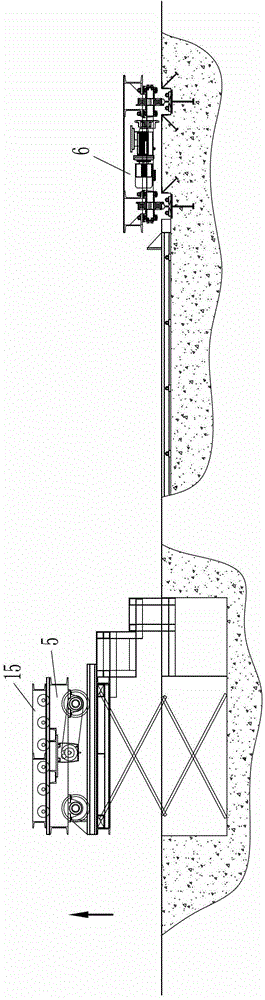

[0021] as attached figure 1 to attach Figure 4 As shown, the load equalization system of the present invention includes a closed loop chain 1 for transporting workpieces with a load zone. The loop chain 1 has a plurality of equidistantly distributed workpiece suspension positions, and the load zone corresponds to a plurality of preorders. The workpiece output end of the station has a plurality of upper part positions 2, and longitudinal rails 3 are respectively arranged between each upper part position 2 and the workpiece output ends of the corresponding plurality of previous stations, and transverse rails 3 are intersected with these longitudinal rails 3. rail 4, the longitudinal rail 3 is provided with a first trolley 5 that can slide along it, and the transverse rail 4 is provided with a second trolley 6 that can slide along ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com