Patents

Literature

164results about How to "Slow down the feed rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

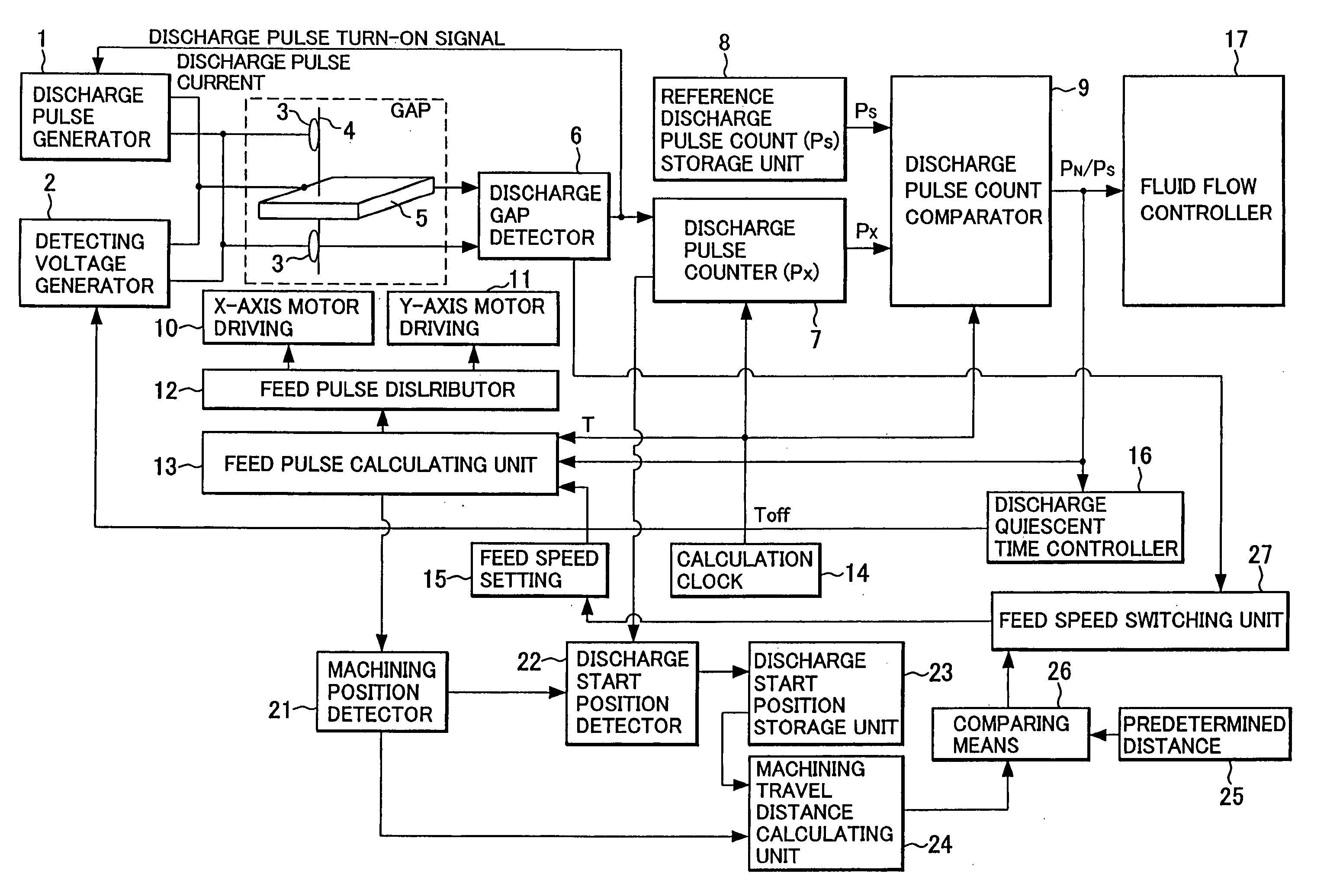

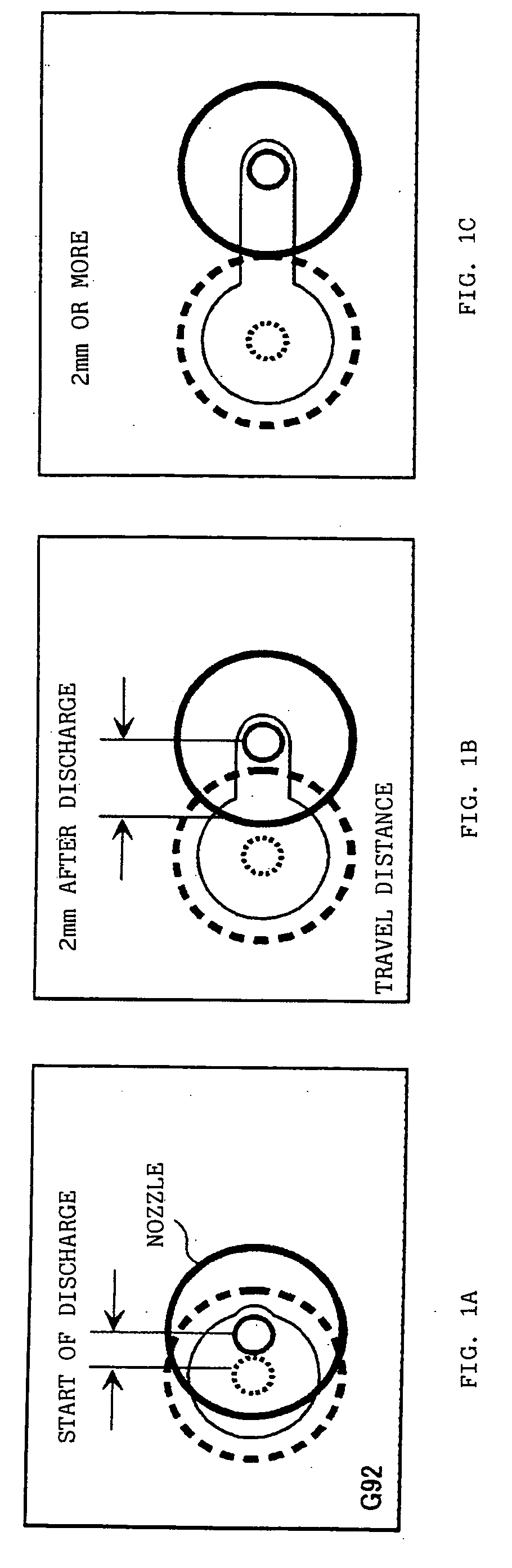

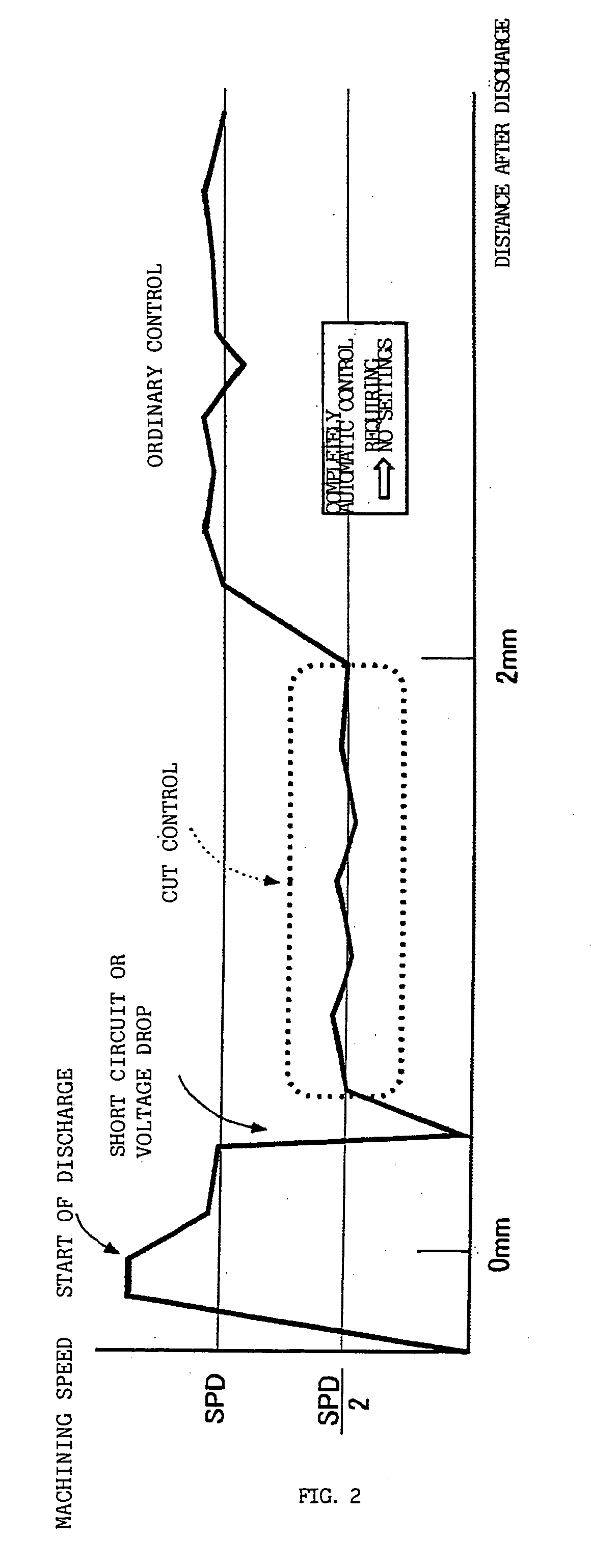

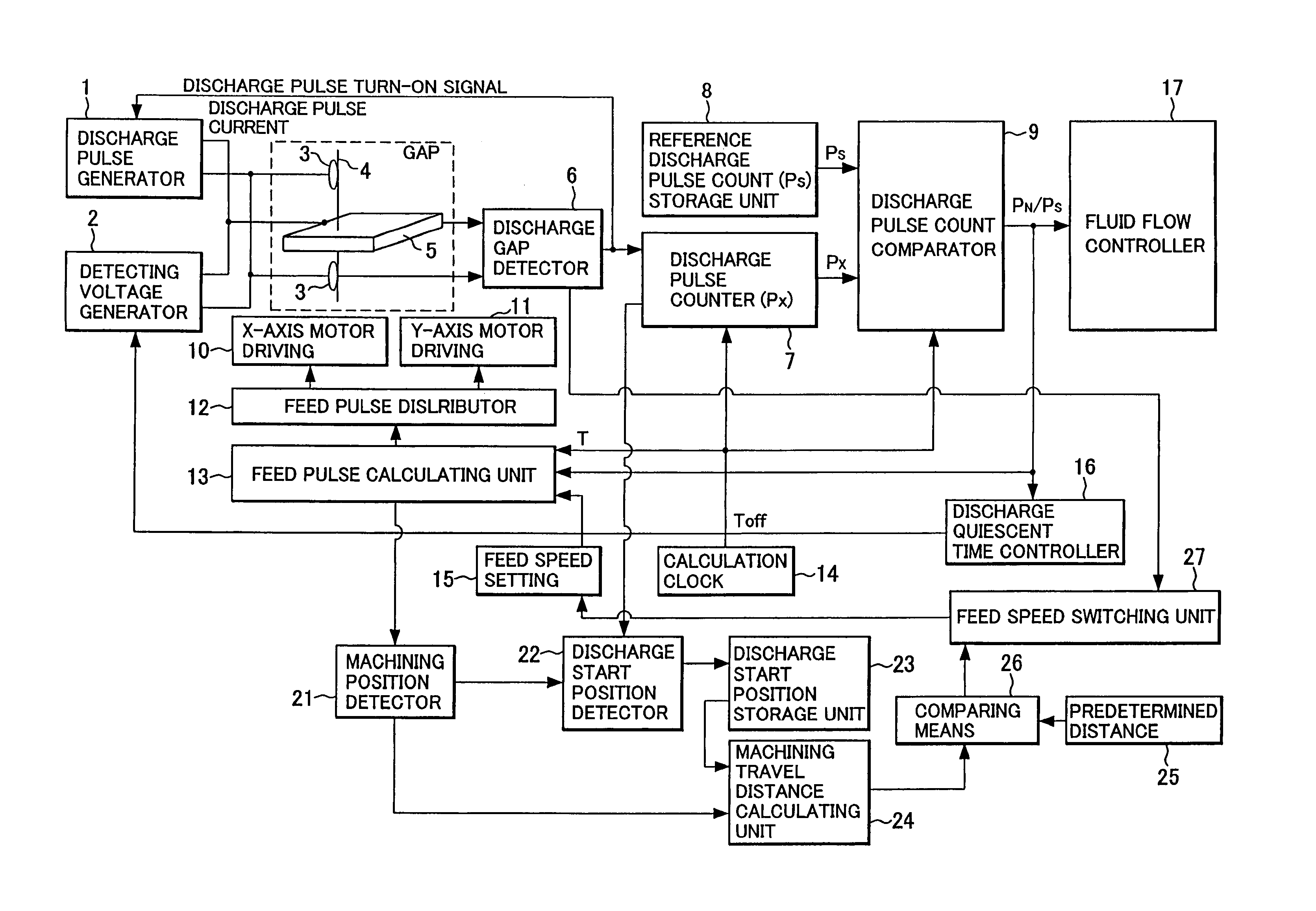

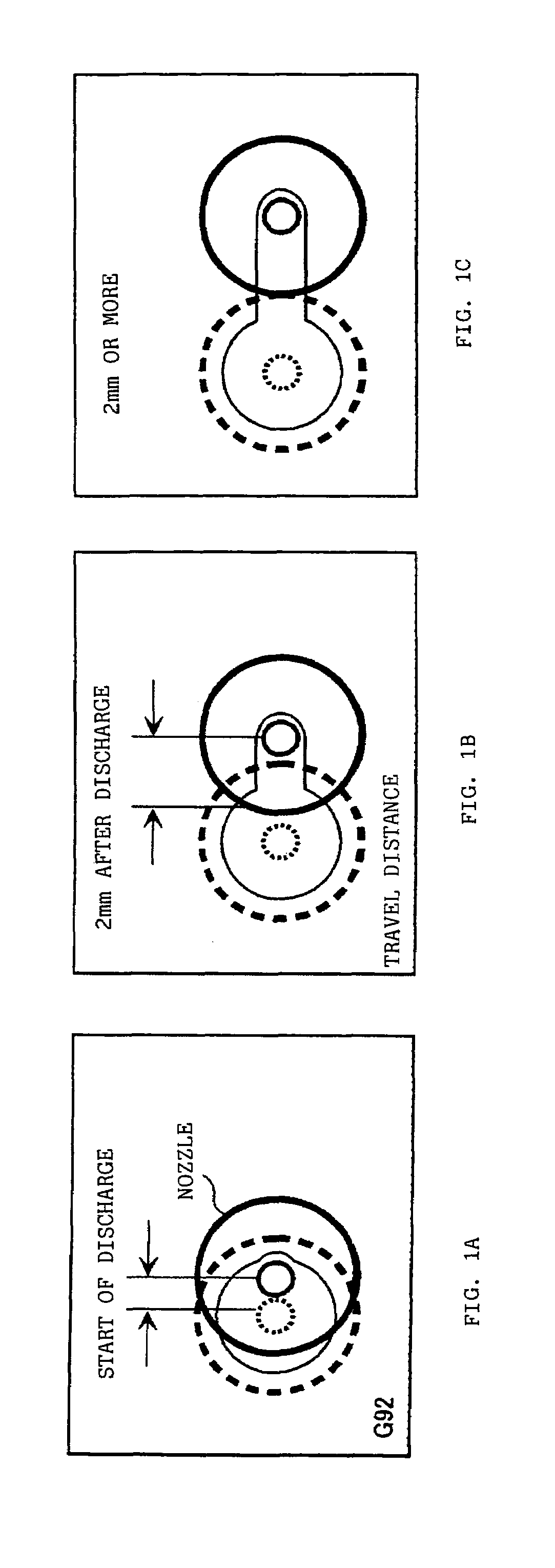

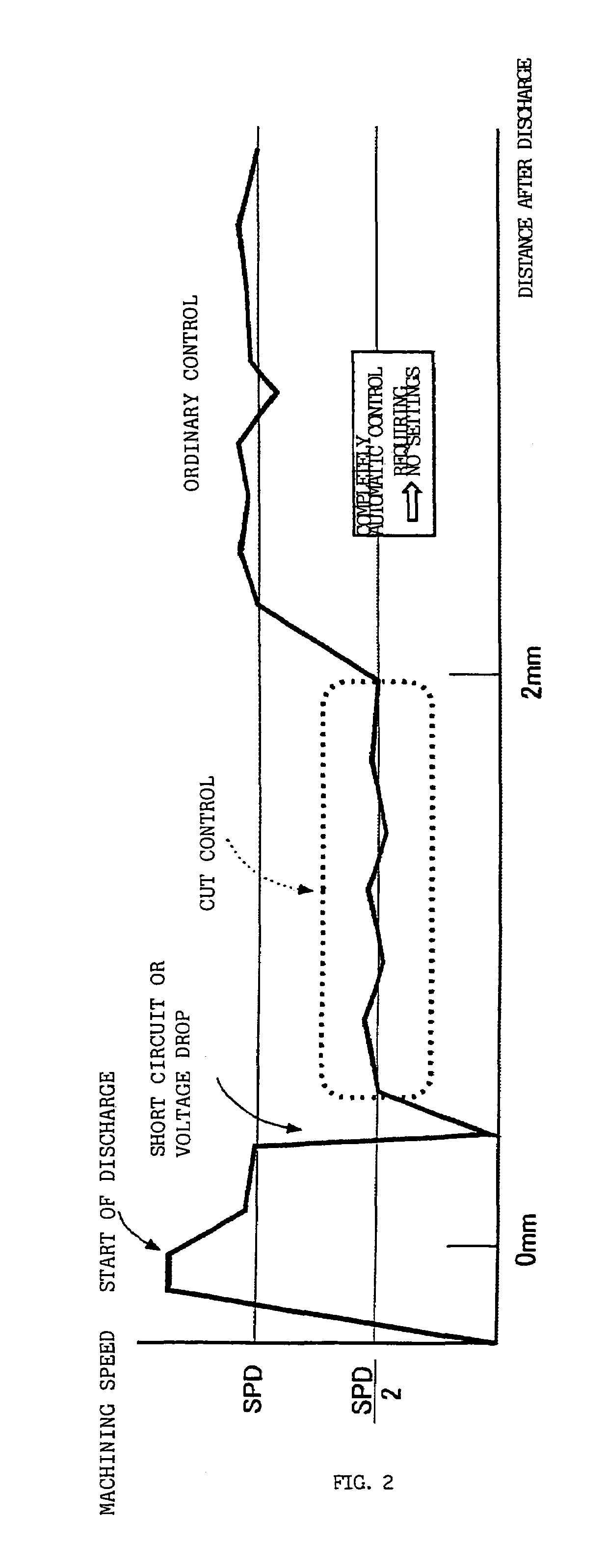

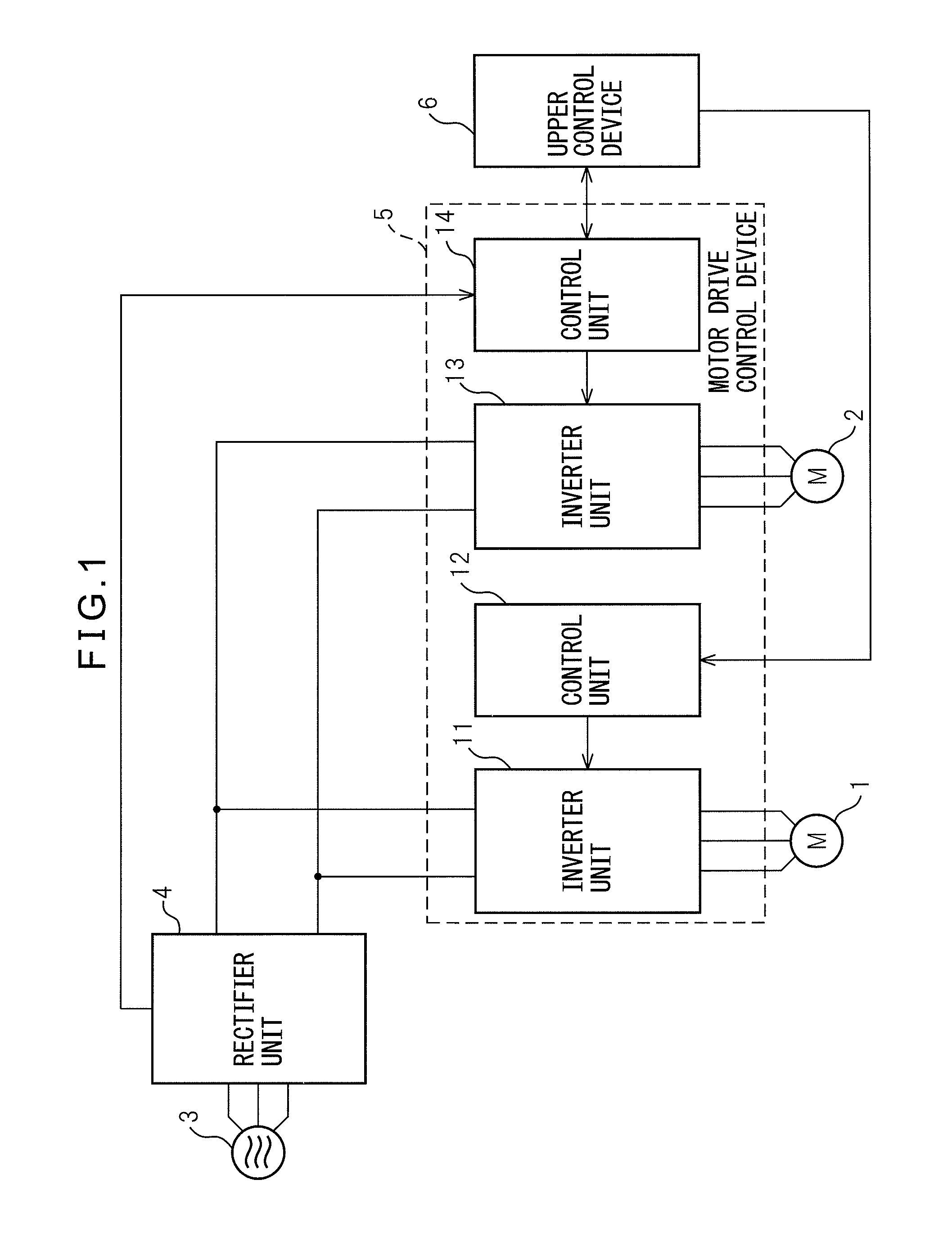

Controller for a wire electrical discharge machine

ActiveUS20050269296A1Stable machiningReducing efficiency of machineElectric circuitsVelocity reductionMachining

Set feed speed is lowered when a short circuit is detected in a range within which machining is unstable, the range starting from the point at which discharge is detected after machining starts from a machining start point, thus control is carried our according to a machining rate, thereby preventing successive occurrence of short circuits. When machining proceeds beyond the unstable range, the lowered feed speed is returned to the normal feed speed.

Owner:FANUC LTD

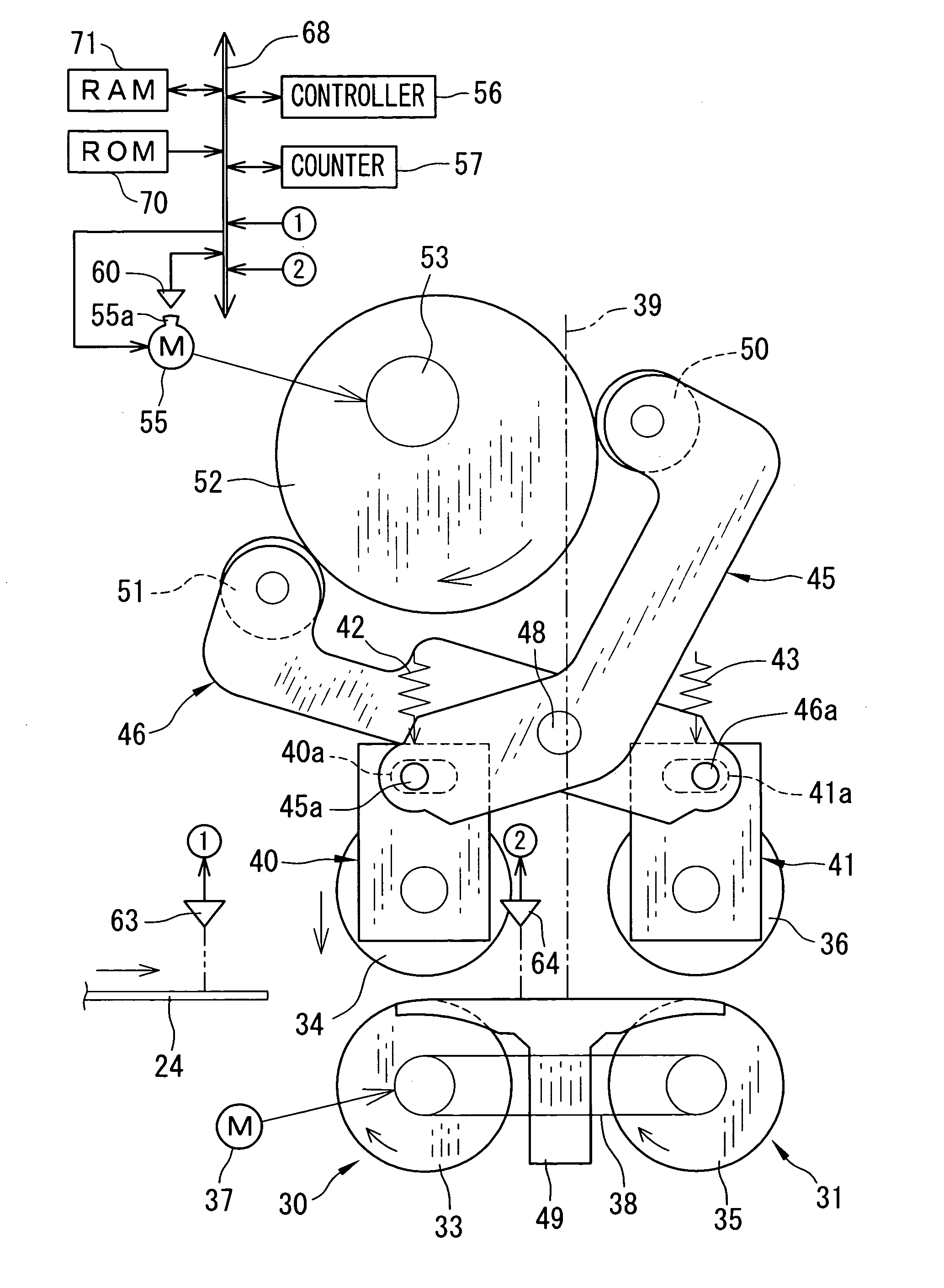

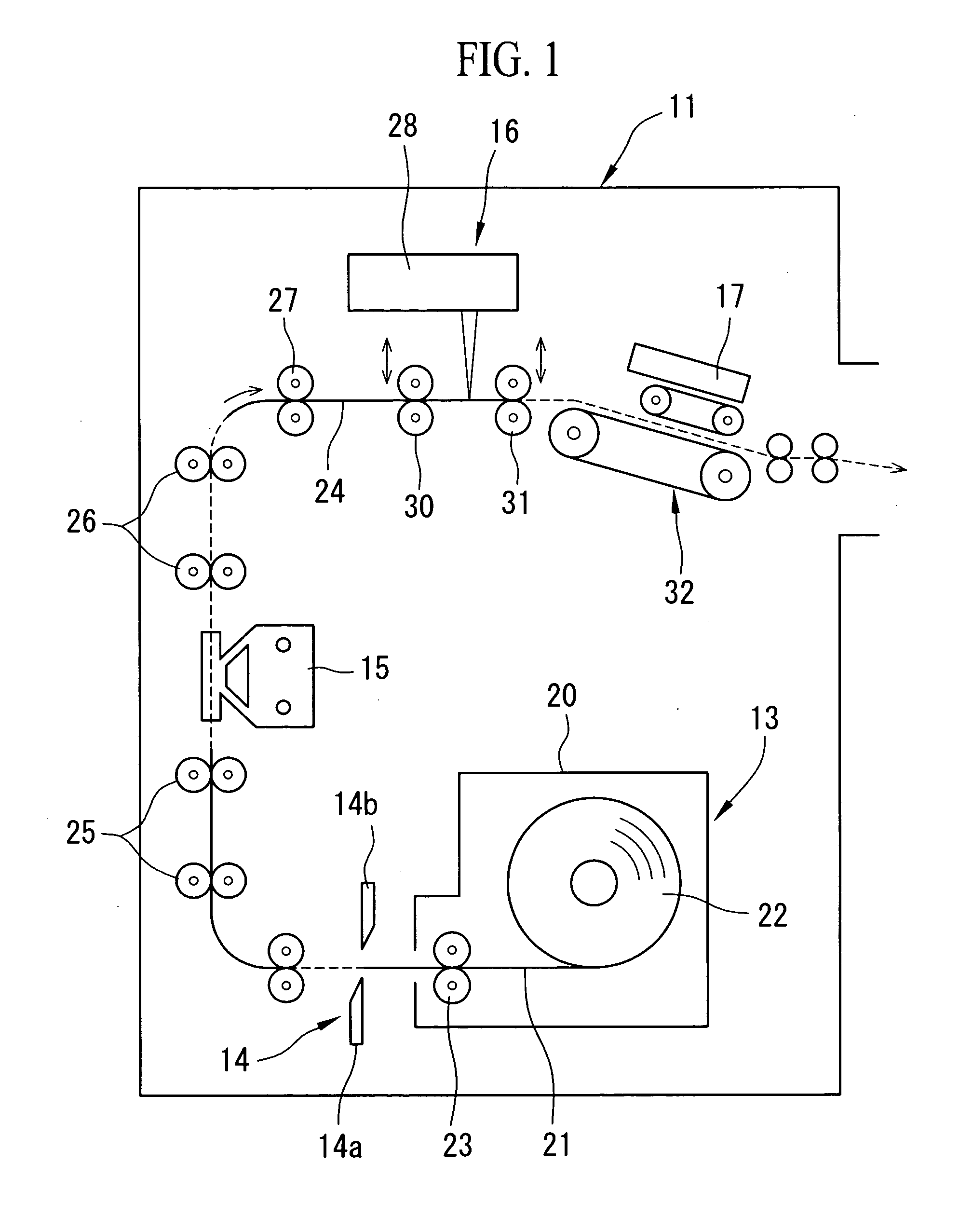

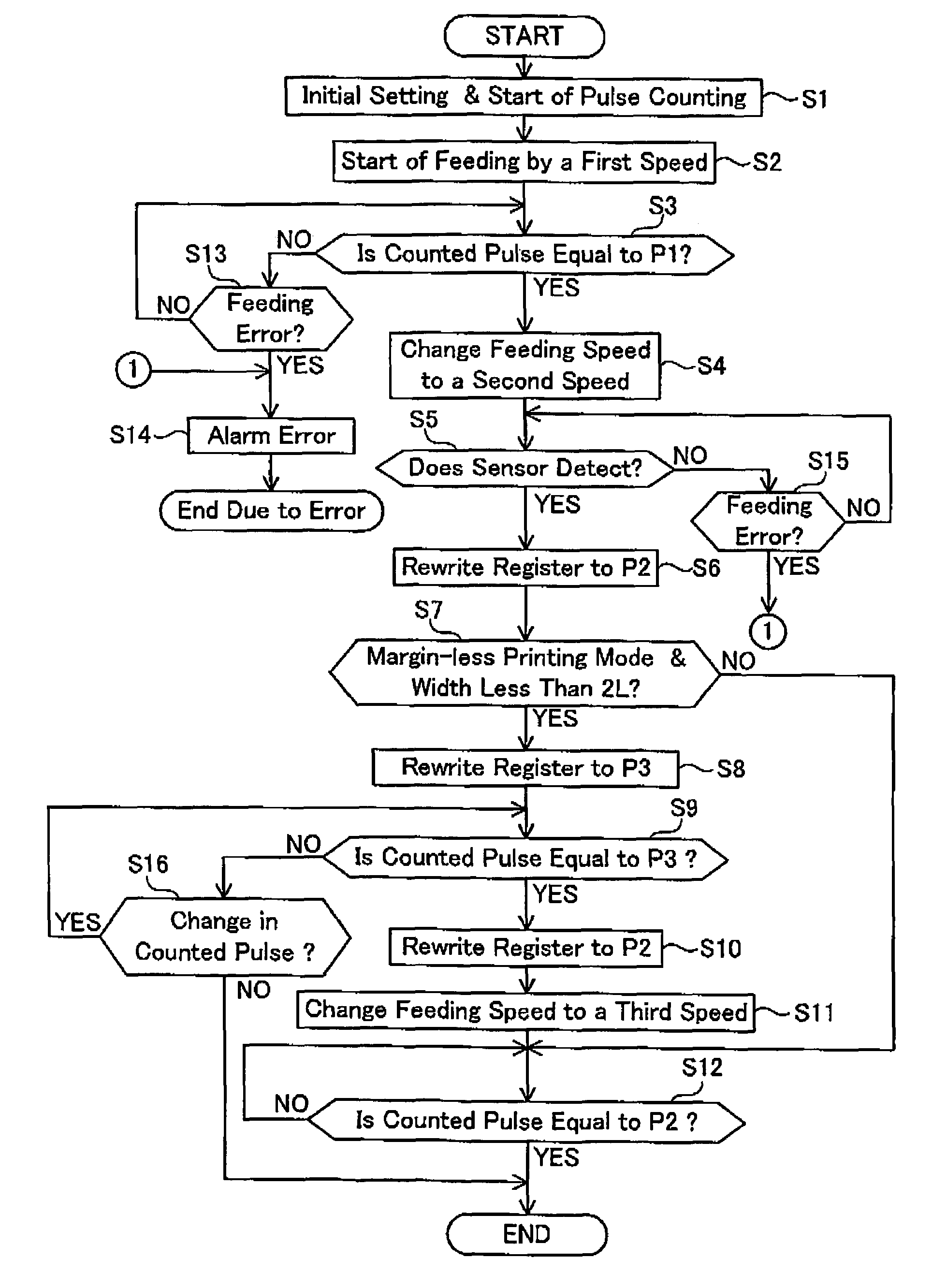

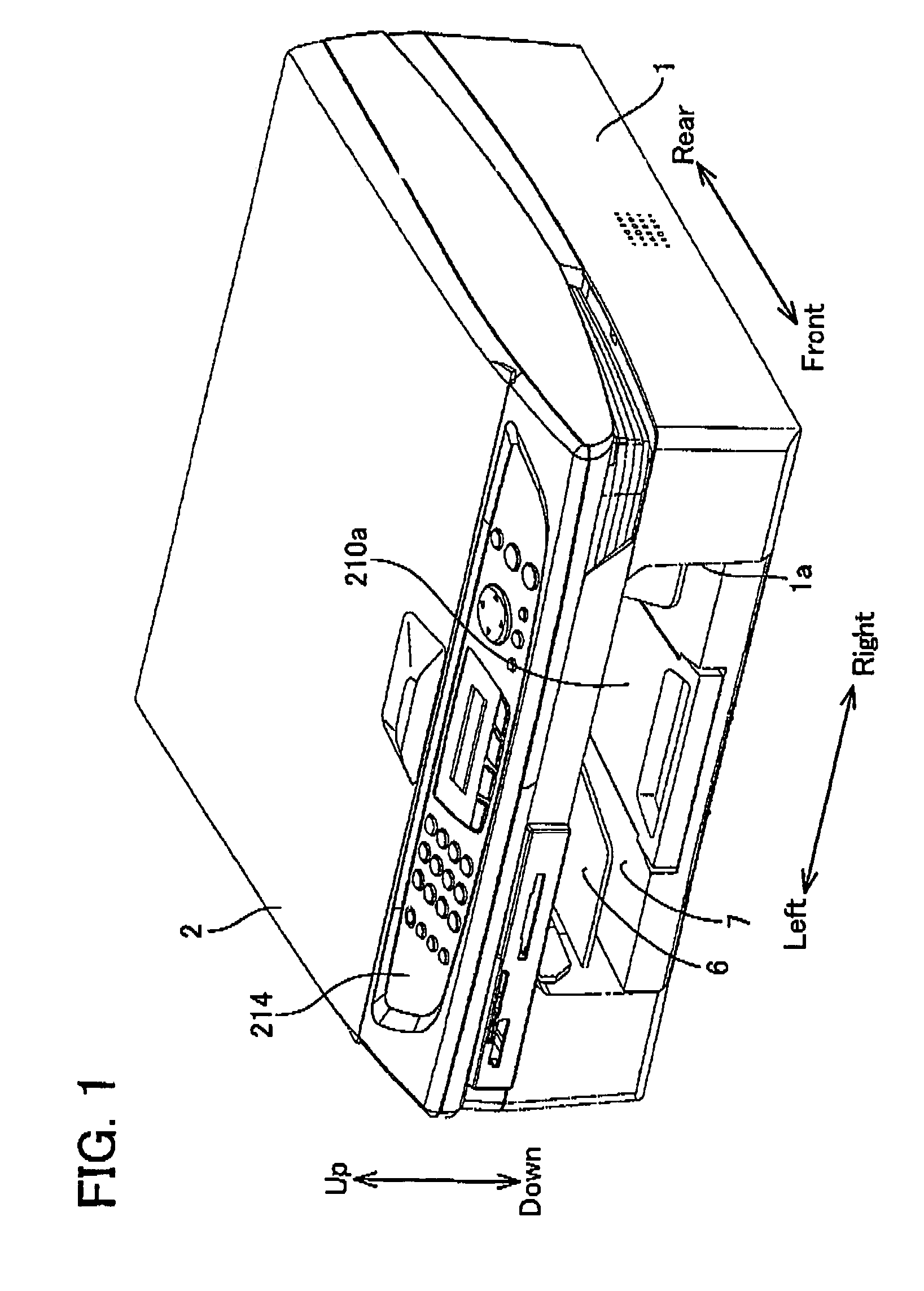

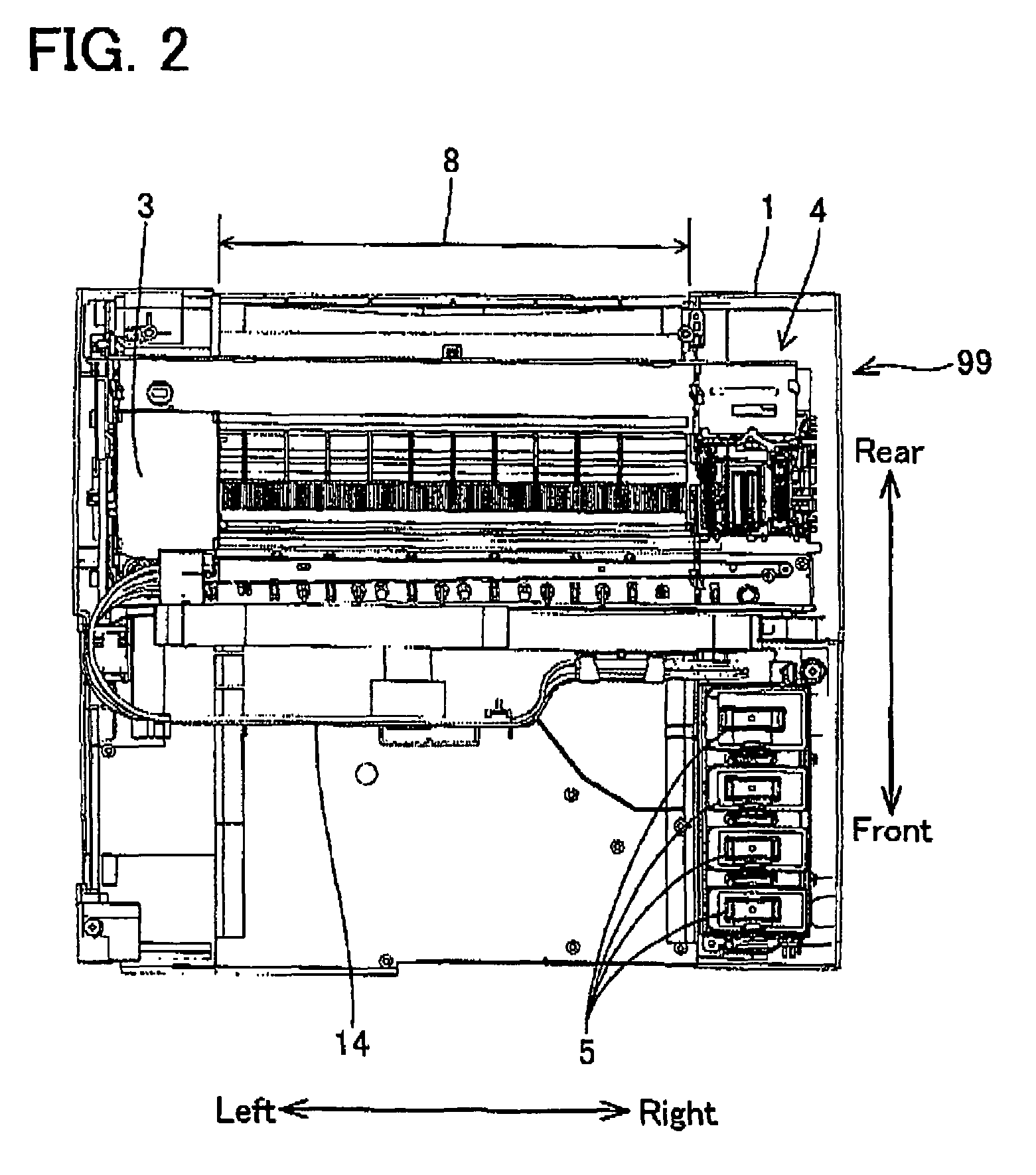

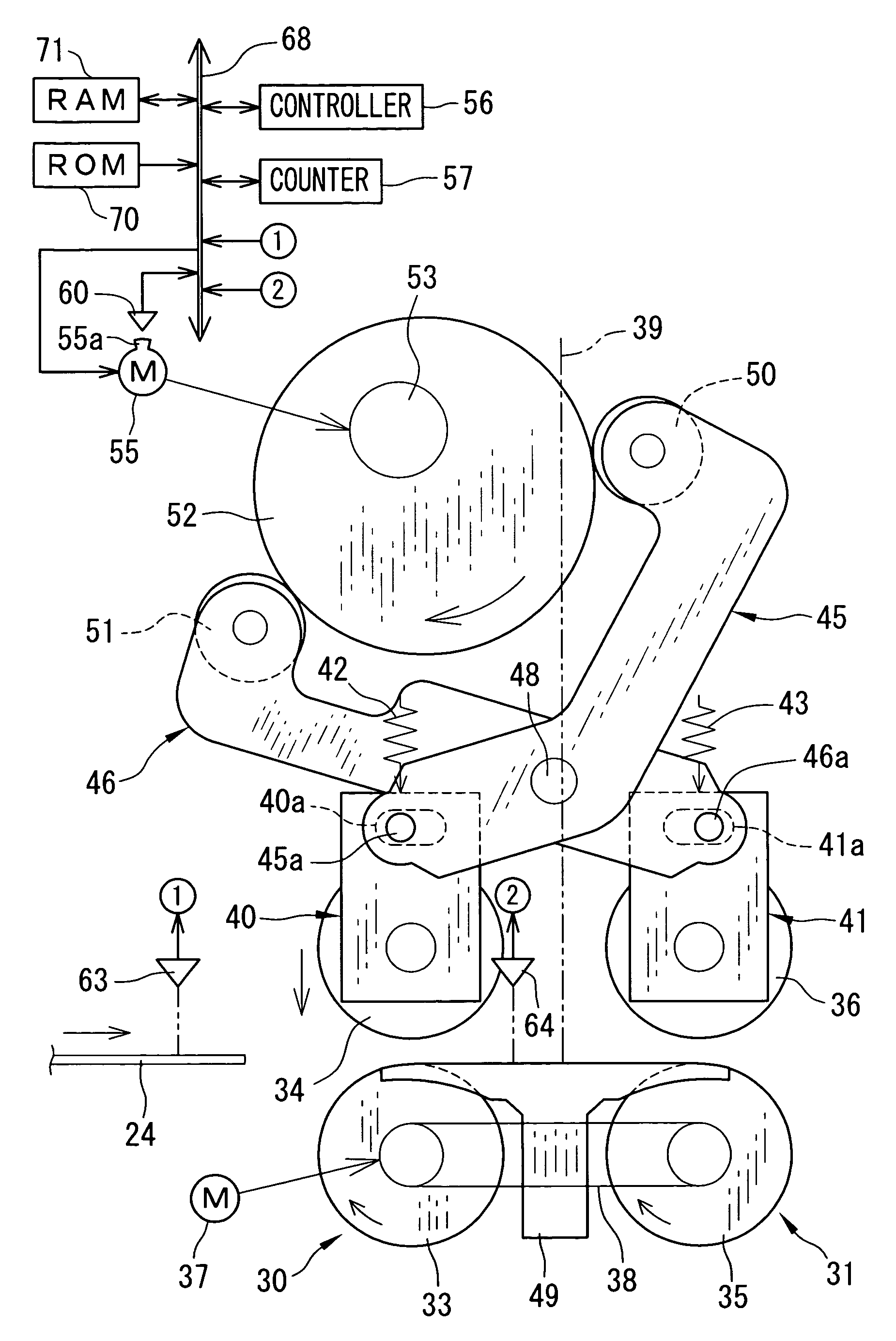

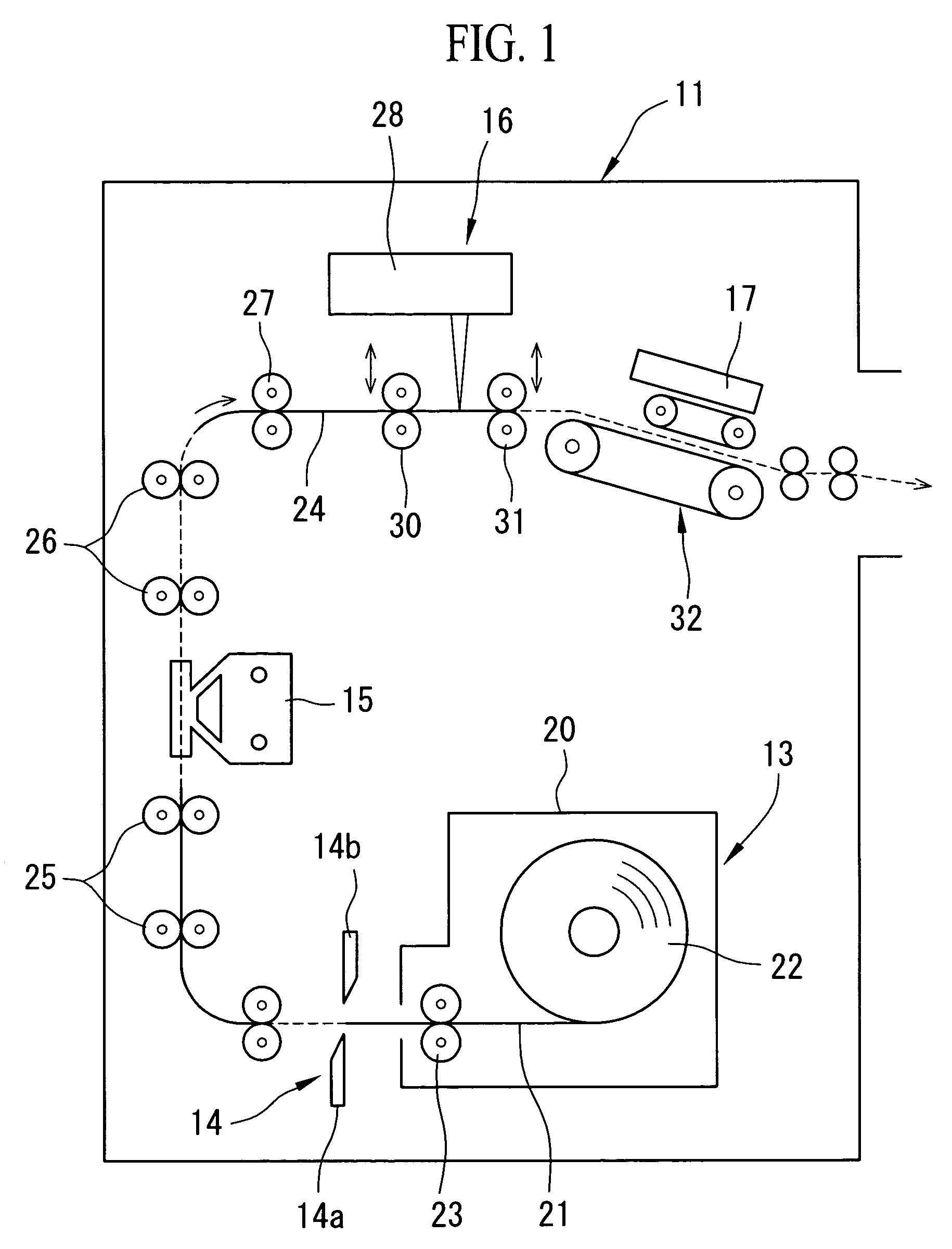

Feeding method and apparatus for sheet-shaped recording material

ActiveUS20050067775A1Slow down the feed rateGuaranteed uptimeOther printing apparatusArticle feedersPosition sensorPaper sheet

Feeding roller pairs are respectively constituted of a capstan roller and a nip roller. The nip roller is movable between a nip position and a release position. When movement timing of the nip rollers overlap, a pulse motor for moving the nip rollers is successively driven. For example, a drive-pulse speed for the pulse motor is detected at the moment that the downstream nip roller is moved to the nip position (at the moment that a predetermined time has passed after detecting a recording-paper sheet with a position sensor). And then, the drive-pulse speed is changed in accordance with the detected drive-pulse speed to drive the pulse motor at a prescribed speed.

Owner:FUJIFILM CORP

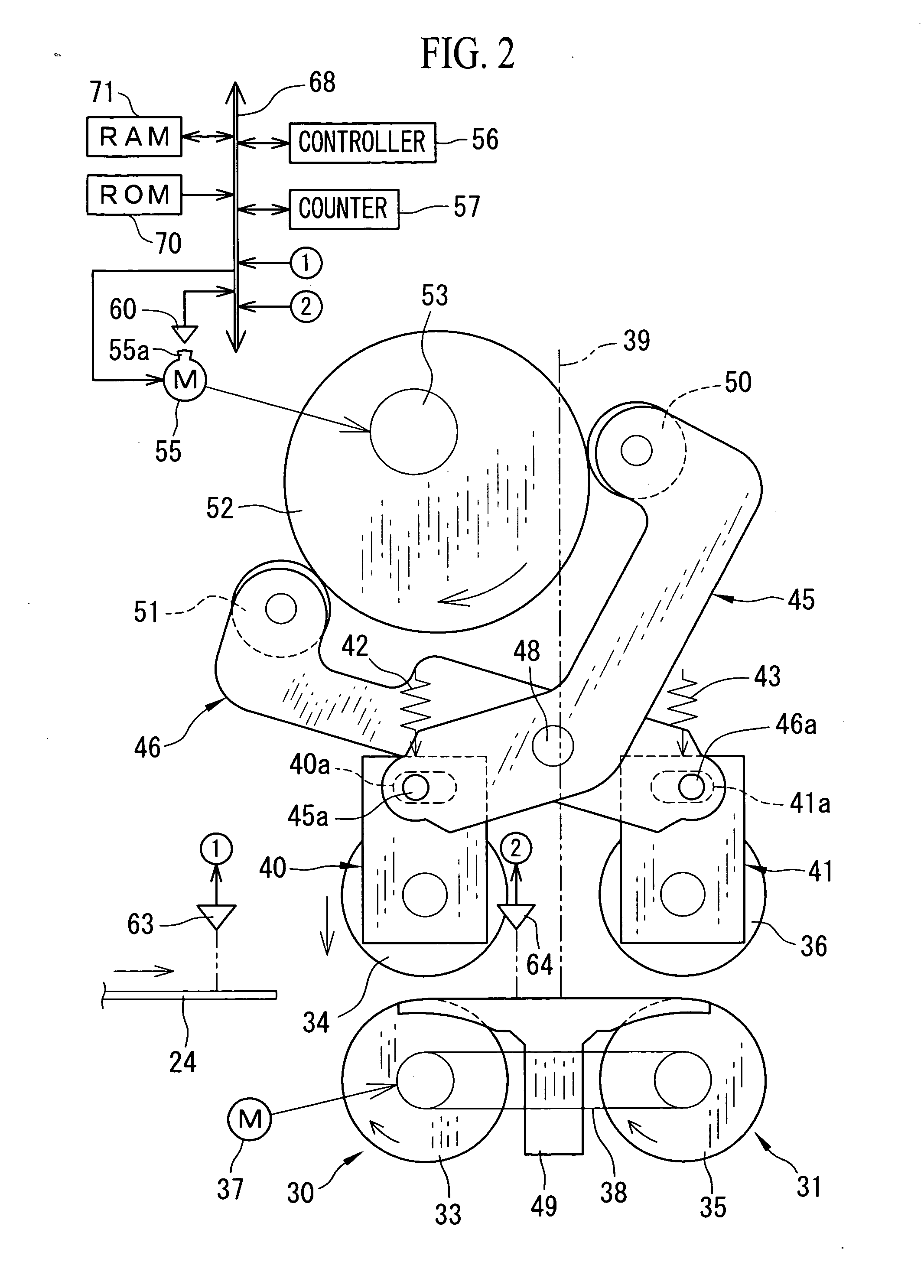

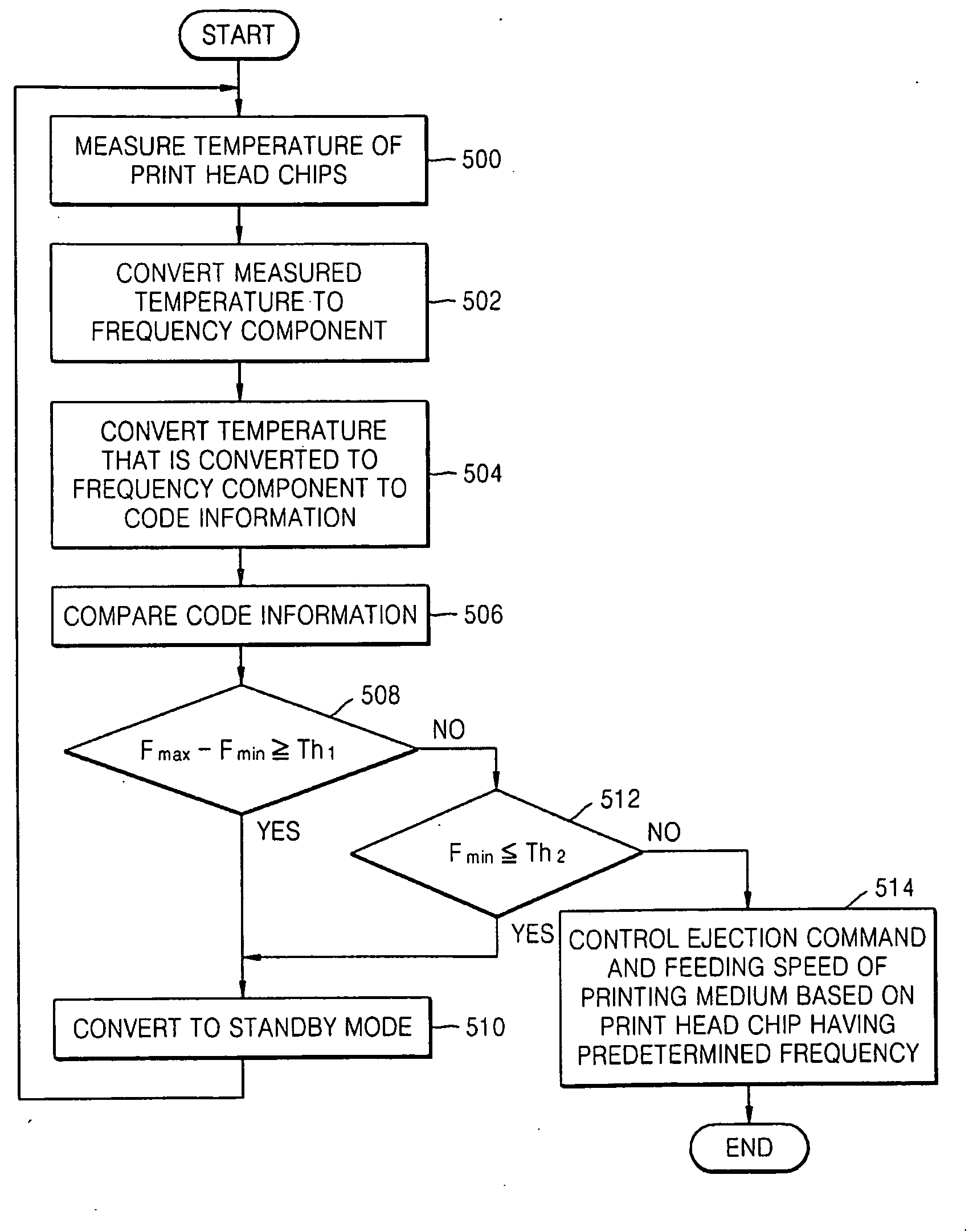

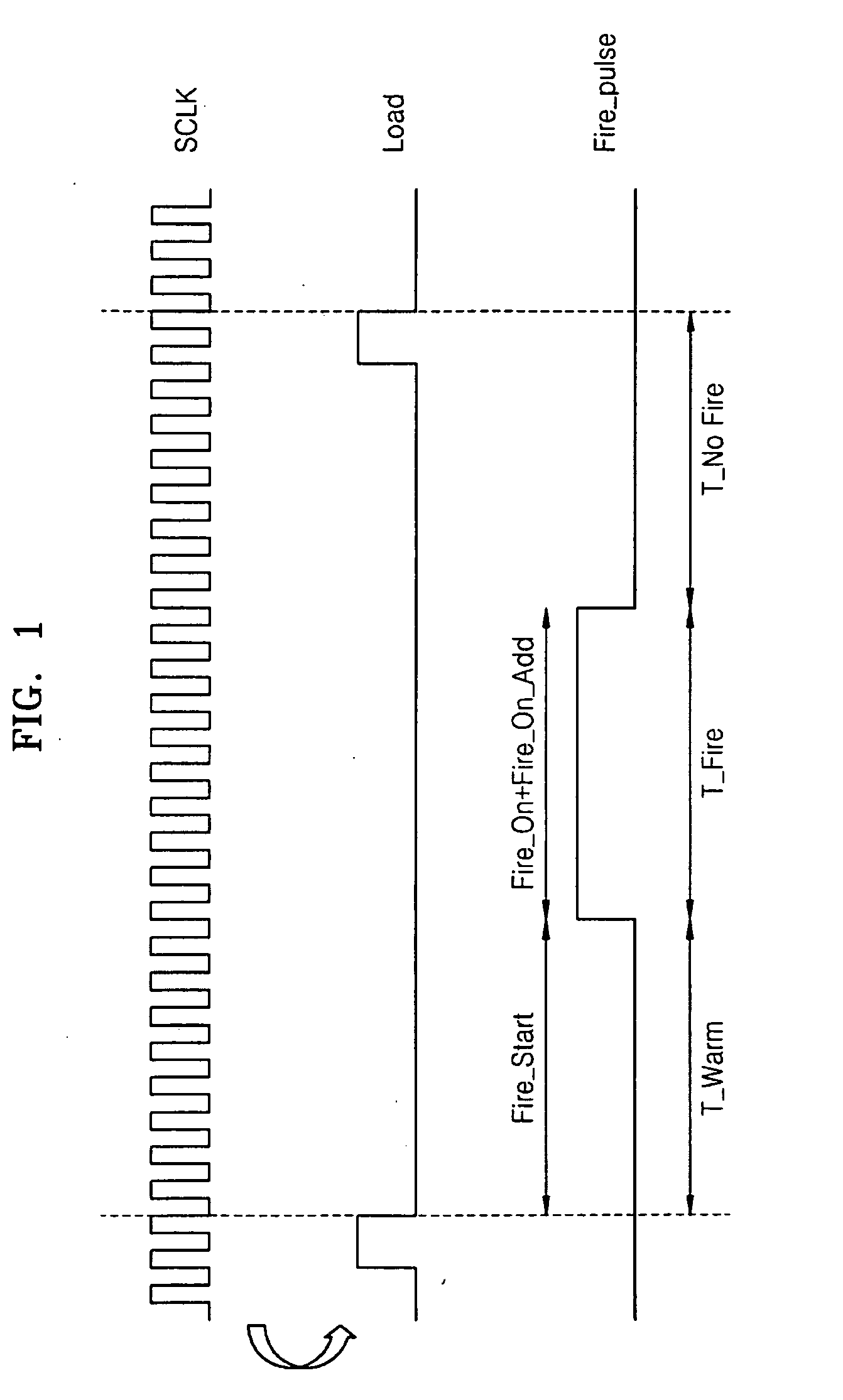

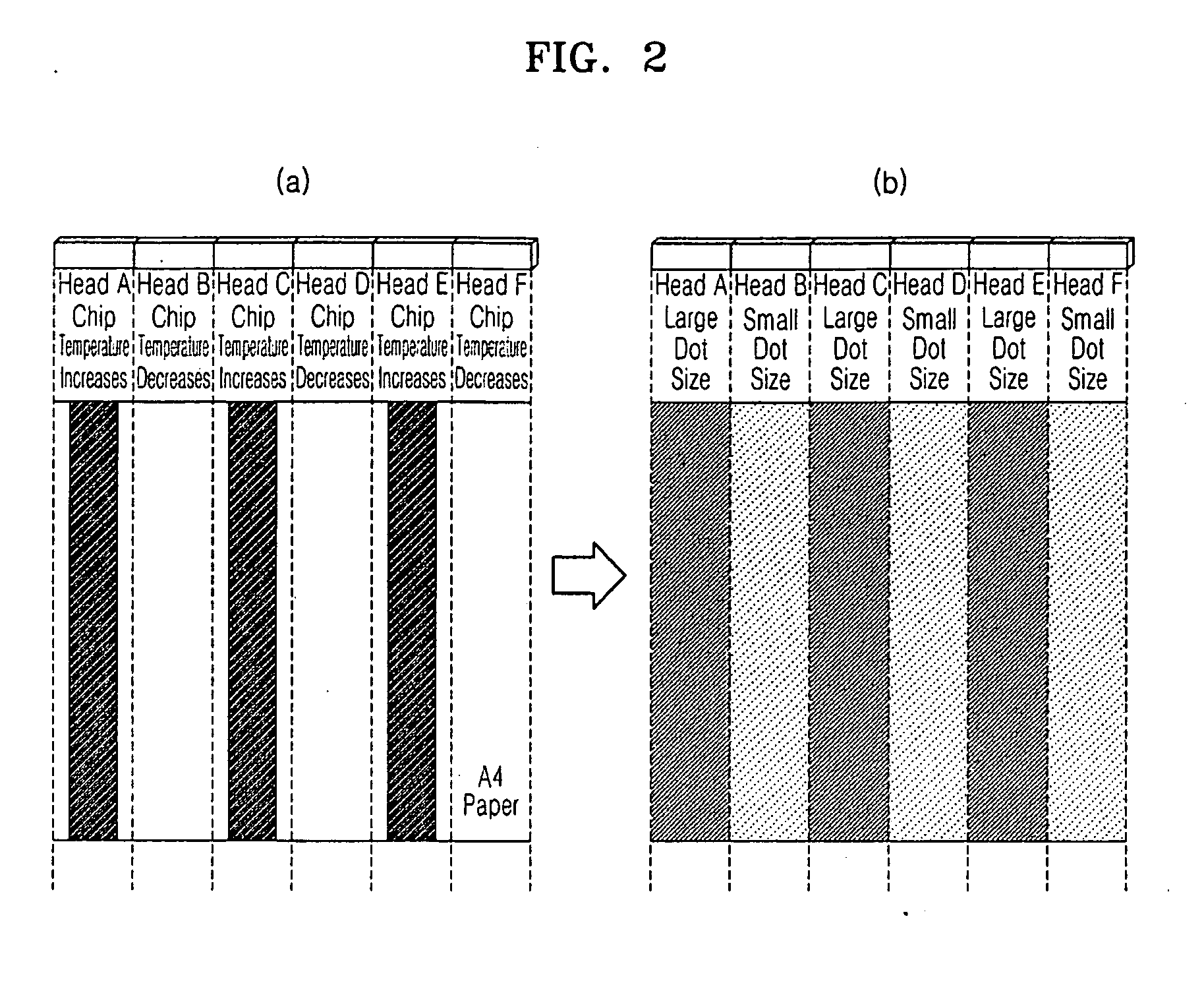

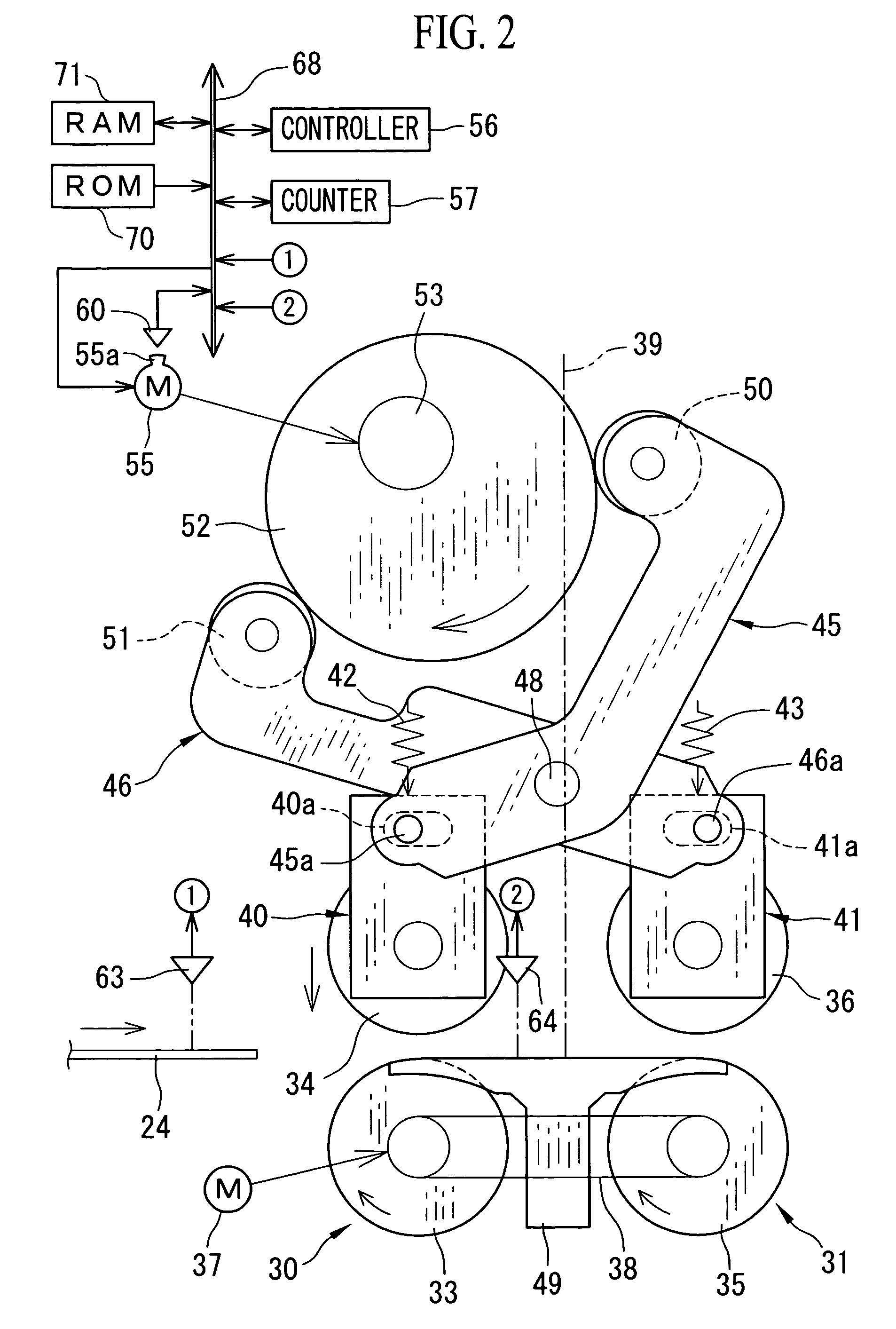

Apparatus for and method of controlling jetting of ink in inkjet printer

InactiveUS20100002036A1Shorten the timeSlow down the feed rateThermometer detailsOther printing apparatusEngineeringInkjet printing

Provided are an apparatus and method of controlling jetting of ink of an inkjet printer. The apparatus includes at least one print head chip, which includes a temperature sensor for sensing the temperature of the print head chip and a voltage controlled oscillator (VCO) for converting the sensed temperature to a frequency component. The apparatus may also include a counter, which converts the frequency component to a code information using a reference frequency component, and a controller, which controls the ink jetting operation of the at least one print head chip based on the code information and / or the frequency component.

Owner:HEWLETT PACKARD DEV CO LP

Controller for a wire electrical discharge machine

ActiveUS6998562B2Little riskShorten speedElectric circuitsElectrical discharge machiningVelocity reduction

Set feed speed is lowered when a short circuit is detected in a range within which machining is unstable, the range starting from the point at which discharge is detected after machining starts from a machining start point, thus control is carried our according to a machining rate, thereby preventing successive occurrence of short circuits. When machining proceeds beyond the unstable range, the lowered feed speed is returned to the normal feed speed.

Owner:FANUC LTD

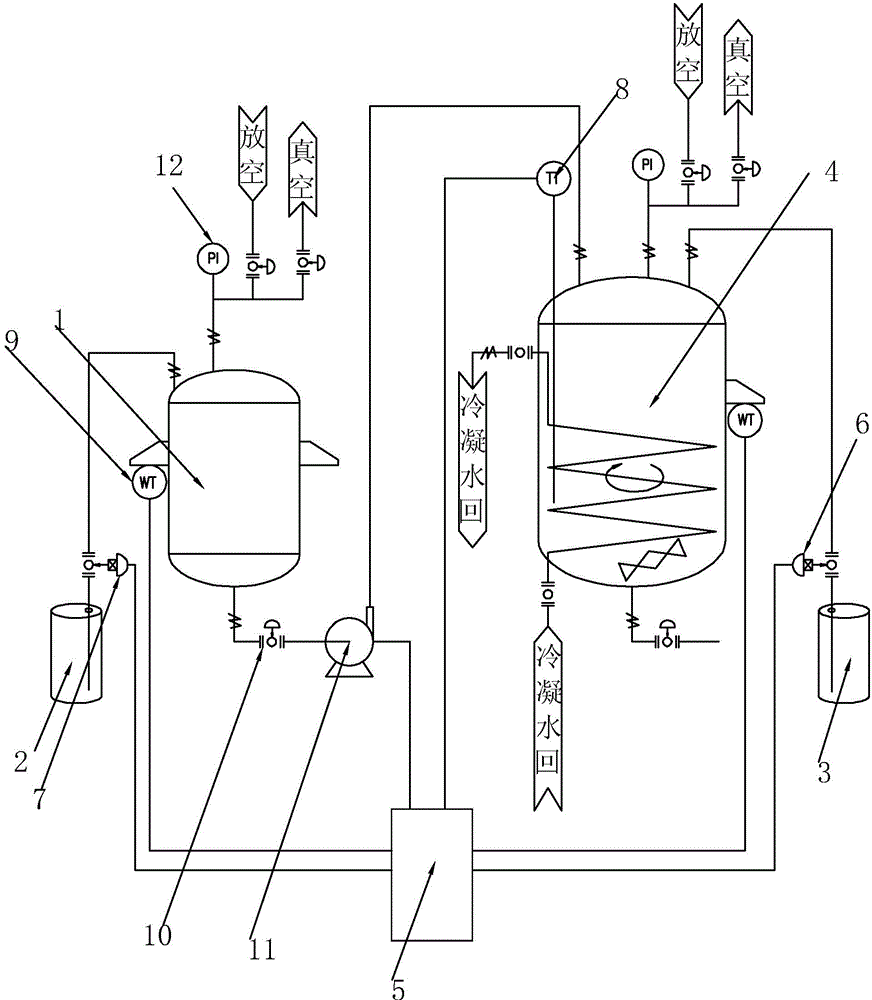

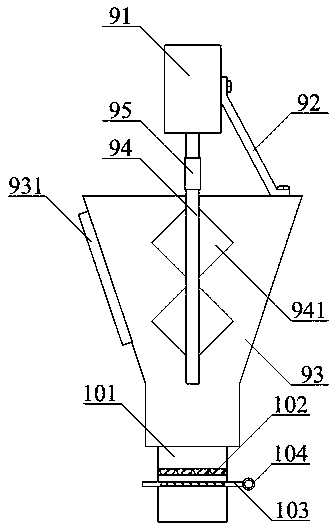

Neutralization reaction device and automatic control method

InactiveCN104474988AAccurate measurementSlow down the feed rateChemical/physical/physico-chemical processesLiquid-gas reaction processesAutomatic controlMechanical engineering

The invention discloses a neutralization reaction device. The technical scheme is that the neutralization reaction device comprises a caustic soda liquid metering tank, a caustic soda liquid barrel, an acid liquid barrel, a neutralization kettle, a PLC, a first adjusting valve and an accurate control unit, wherein two material inlets are formed in the top end of the neutralization kettle, wherein one material inlet is sequentially connected with the caustic soda liquid metering tank and the caustic soda liquid barrel, and the other material inlet is connected with the acid liquid barrel; the accurate control unit is used for accurately controlling materials; the first adjusting valve is arranged on any material inlet; the neutralization kettle is internally provided with a temperature sensor, and a temperature signal in the neutralization kettle is transmitted to the PLC so as to control the switch flow rate of the first adjusting valve by the PLC. The device and the method both can be used for accurately controlling acid liquid and caustic soda liquid in real time effectively in the neutralization reaction process, so that the neutralization effect is ensured.

Owner:史学明 +1

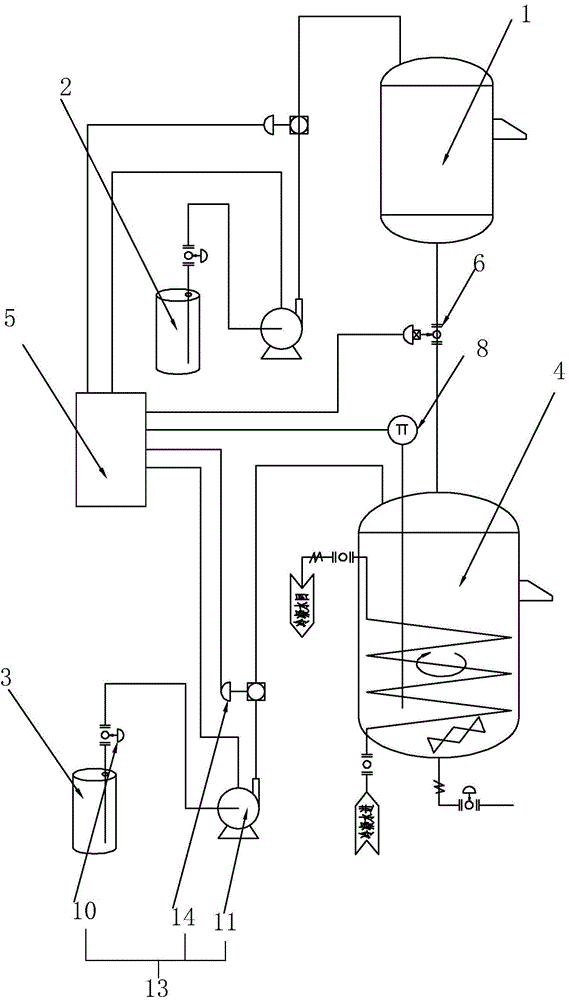

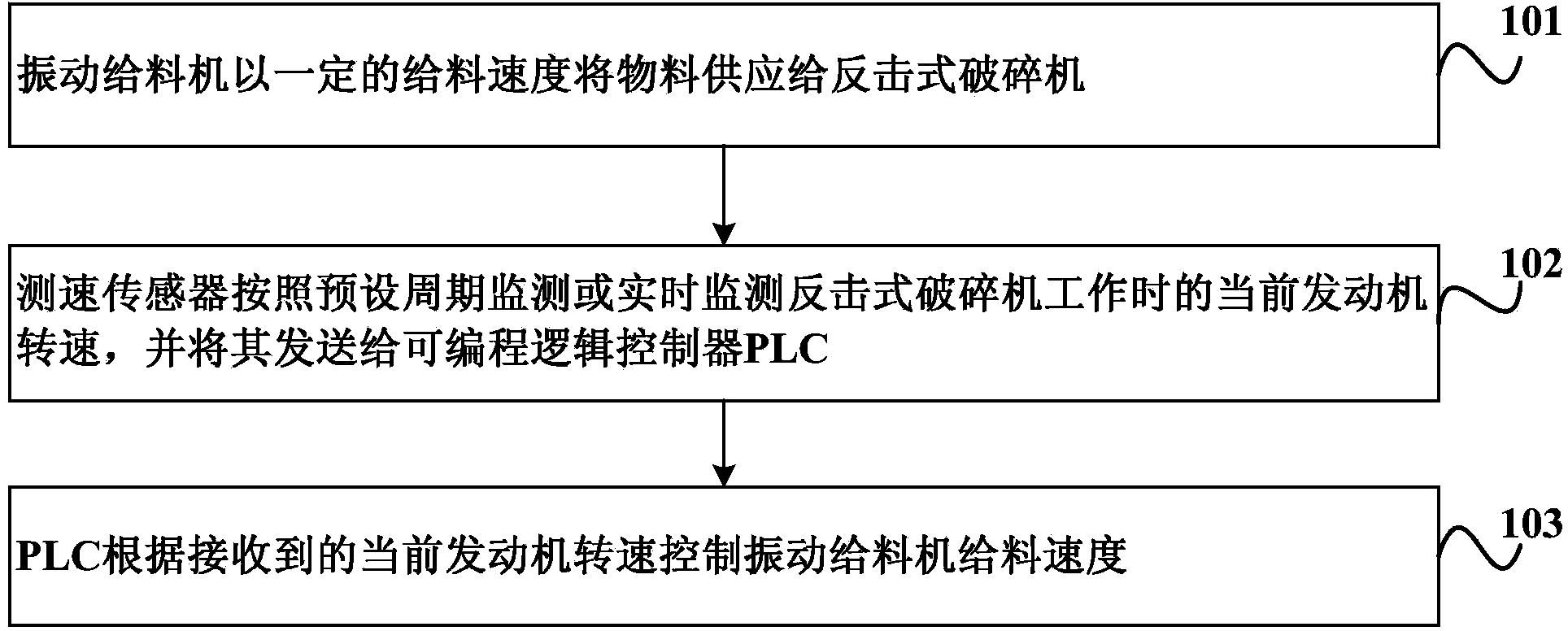

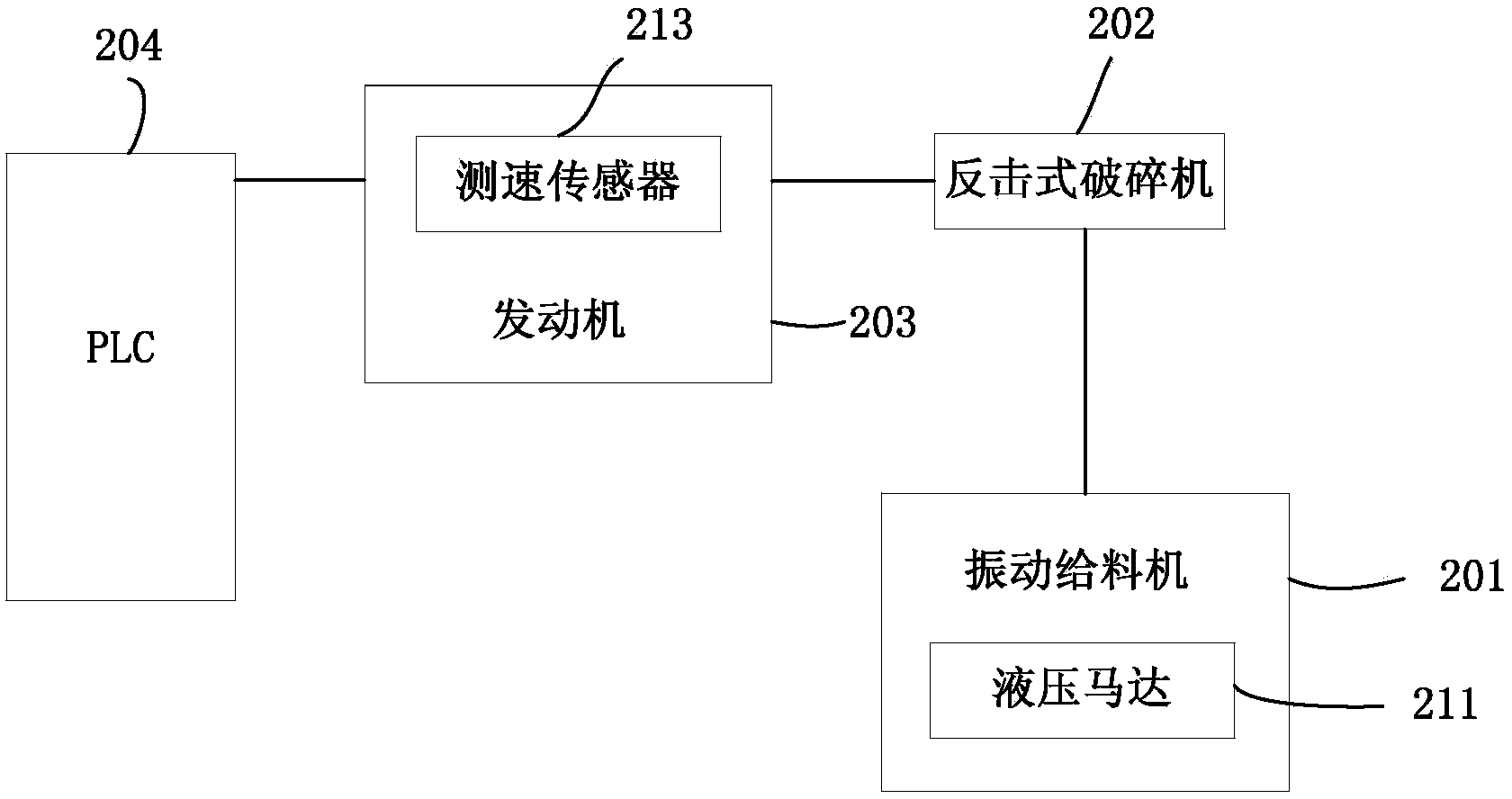

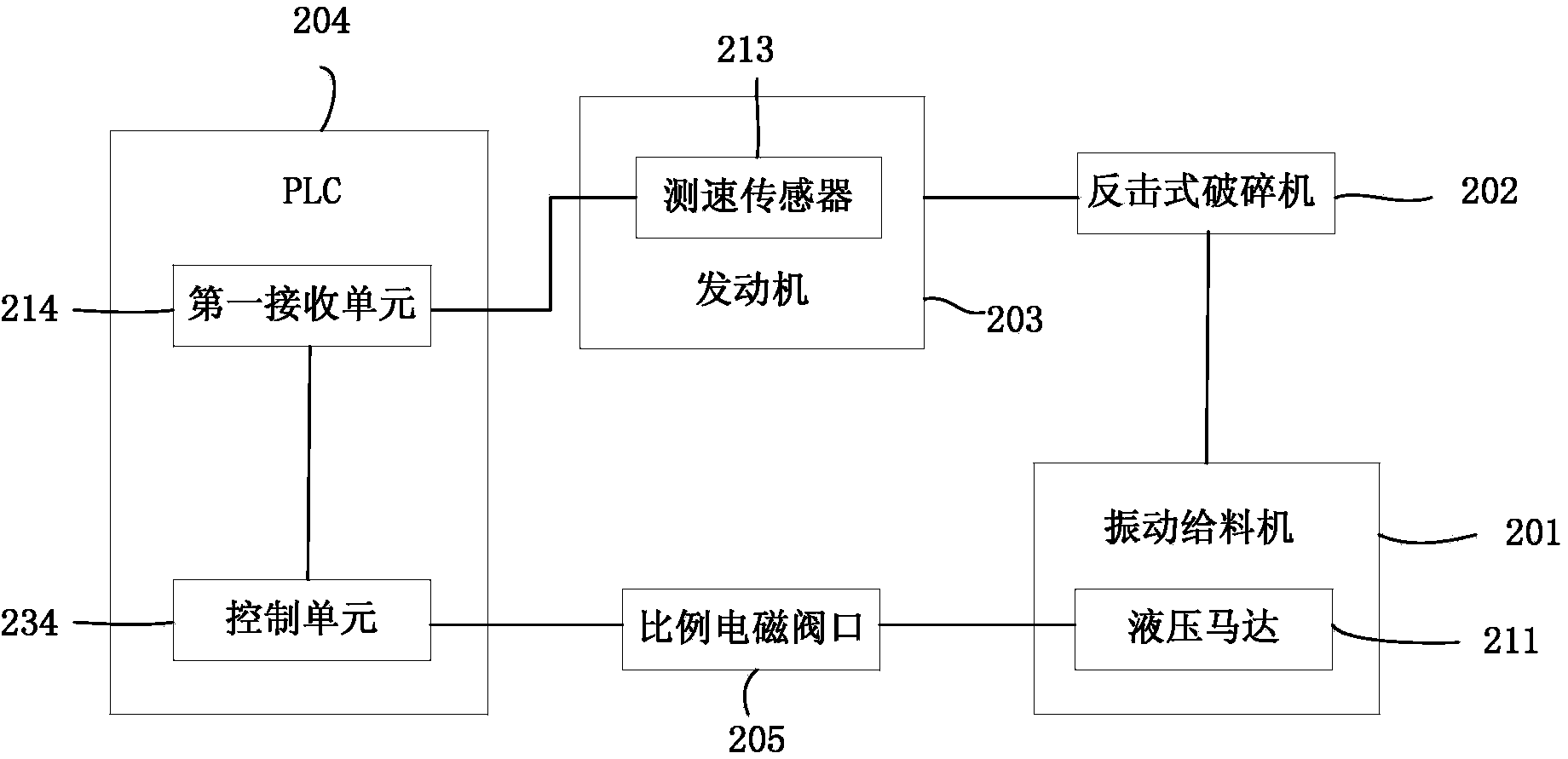

Method and system for controlling feeding speed of vibrating feeder

ActiveCN103949330AAvoid cloggingUniform feeding speedGrain treatmentsProgrammable logic controllerCrusher

The embodiment of the invention discloses a method and a system for controlling the feeding speed of a vibrating feeder. The method comprises the following steps: feeding materials to an impact crusher at a certain feeding speed by virtue of the vibrating feeder, wherein the larger the particle sizes of the materials are, the larger the load of an engine connected with the impact crusher is and the lower the rotating speed of the engine is under the condition that the feeding speed is constant; monitoring the current rotating speed of the engine during the working of the impact crusher according to a preset period or in real time by virtue of a speed measurement sensor, and sending the current rotating speed to a programmable logic controller (PLC); and controlling the feeding speed of the vibrating feeder according to the received current rotating speed of the engine by virtue of the PLC. According to the embodiment of the invention, the feeding speed of the vibrating feeder can be effectively controlled according to the intensity of the load of the engine, so that the automatic regulation of the feeding speed of the vibrating feeder is realized.

Owner:XUZHOU XCMG MINING MACHINERY CO LTD

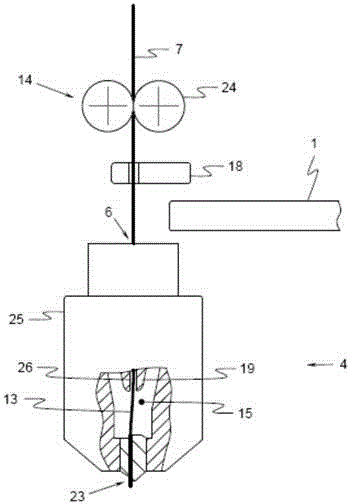

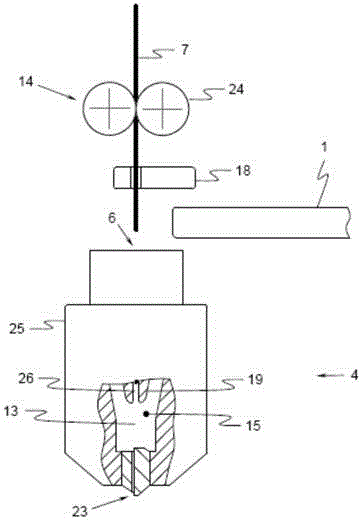

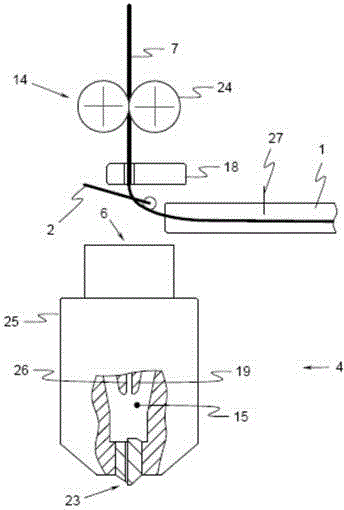

Spinning machine and method for operating the same in case of failure of an external power supply

ActiveCN104562328AAvoid damageSlow down the feed rateContinuous wound-up machinesOpen-end spinning machinesYarnEngineering

The invention relates to a method for operating a spinning machine, the spinning machine comprising a plurality of spinning units (3), fibrous composite (13) is transmitted to at least a portion of the spinning units (3) during a spinning process, in a present spinning station (4) of each spinning unit (3), rotation motion is transmitted to the fibrous composite (13), and therefore fibrous composite (13) turns into rotary yarn (7), the yarn (7) is taken off from the respective spinning station (4) through an outlet (6) and is wound up by a winding device (8), the spinning machine is supplied with power by an external power supply (10). The method is characterized in that the the yarn production in the spinning units (3) for producing the yarn (7) is stopped in case of failure or malfunction of the external power supply (10), so that a winding side yarn end is formed in the area of each spinning unit (3), each winding side yarn end is in the respective spinning station (4) or between the outlet (6) of this spinning station (4) and the winding device (8) associated with the spinning station (4), wherein the energy to for the further operation of the spinning machine until the end of yarn production is provided by at least one energy store (9). Furthermore, the invention also relates to a spinning machine which has a controller (11) which is designed to operate the spinning machine according to the above method.

Owner:MASCHINENFABRIK RIETER AG

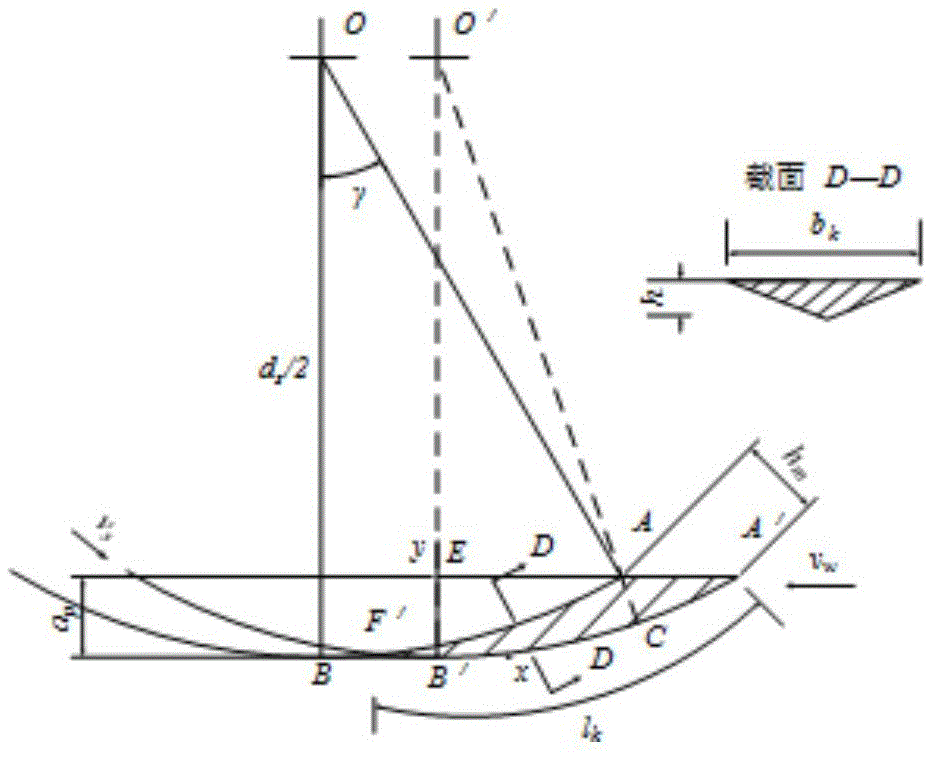

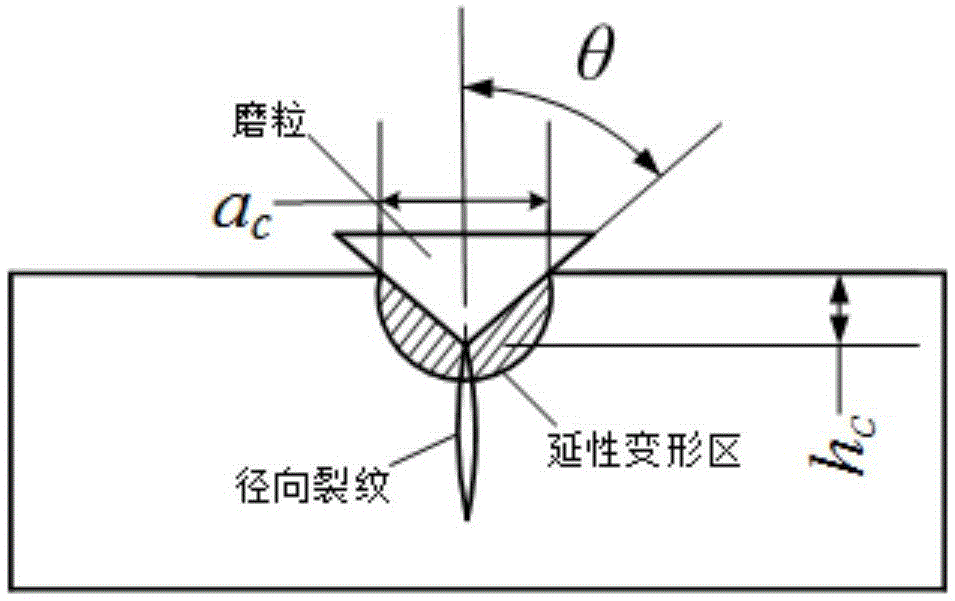

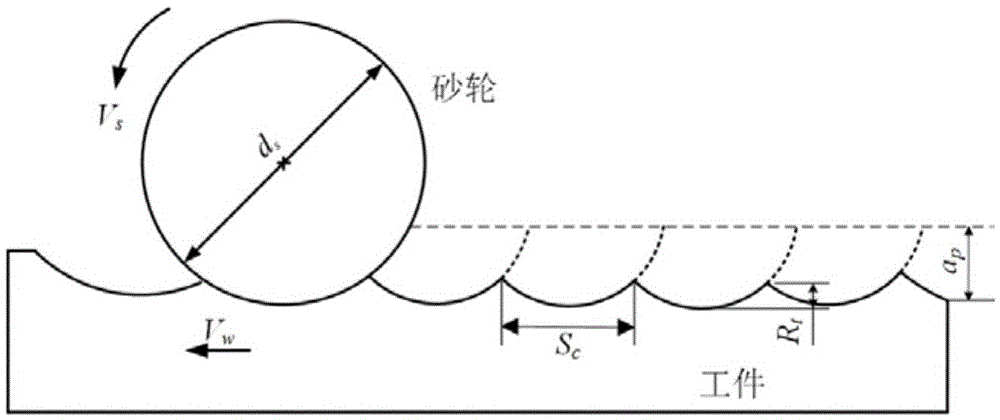

Determining method for surface roughness of grinding of microcrystallite glass ceramic

ActiveCN105415101AImprove surface roughnessSlow down the feed rateMathematical modelSurface roughness

The invention discloses a determining method for the surface roughness of grinding of microcrystallite glass ceramic. The determining method includes the steps that firstly, the maximum undeformed chip thickness is obtained; secondly, the ductility-ductile brittleness critical depth and the ductile brittleness-brittleness critical depth are obtained; thirdly, a composite grinding factor is obtained; fourthly, an empirical constant, a brittle fracture coefficient, a ductility-brittleness fracture coefficient, an empirical constant x, the brittleness fracture factor and the ductility-brittleness fracture factor are obtained; and fifthly, the surface roughness is determined according to parameters in the first step, the second step, the third step and the fourth step. According to the determining method for the surface roughness of grinding of the microcrystallite glass ceramic, the relevant coefficient of the surface roughness is determined, a mathematical model of the maximum undeformed chip thickness and the surface roughness of the microcrystallite glass ceramic is established, the influence relation of the grinding condition parameters of the microcrystallite glass ceramic on the surface roughness of grinding is determined, and the determining method is suitable for explaining the molding mechanism of the surface roughness of grinding of the microcrystallite glass ceramic.

Owner:NORTHEASTERN UNIV LIAONING

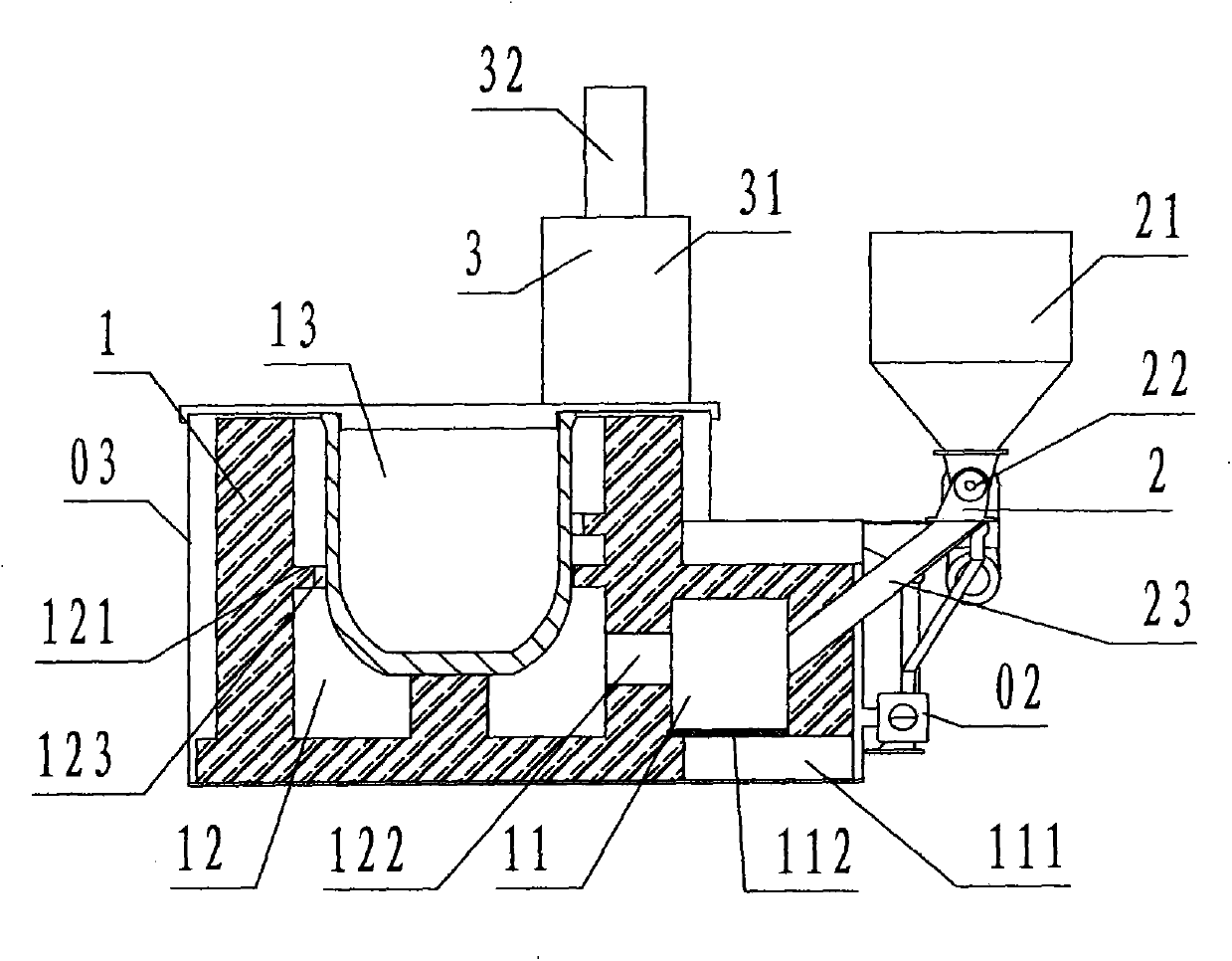

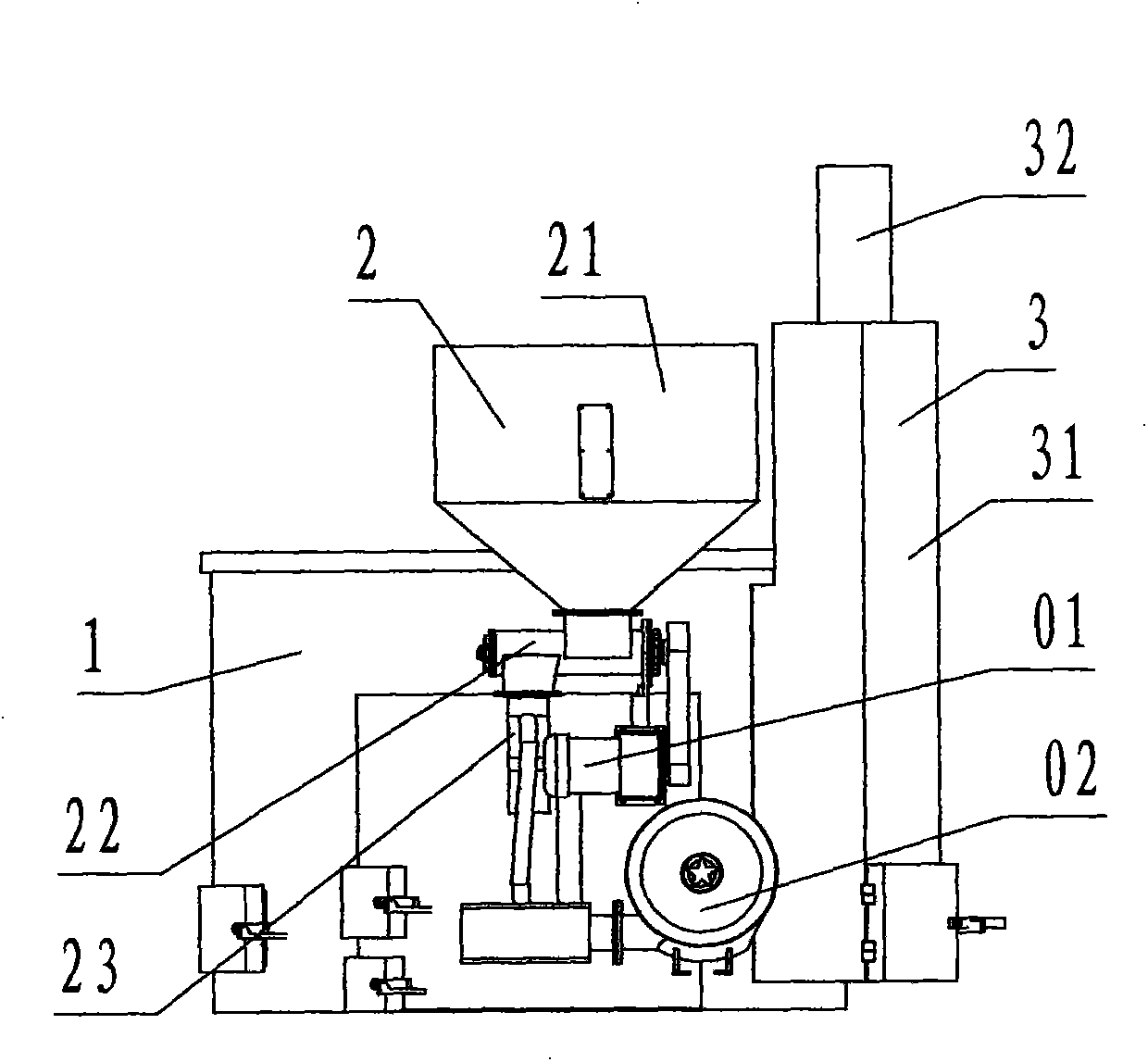

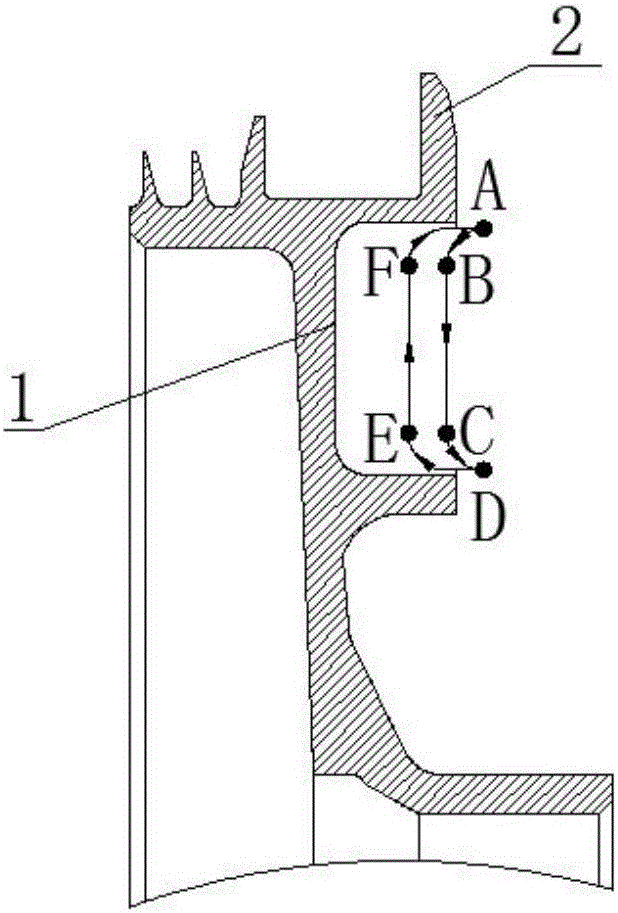

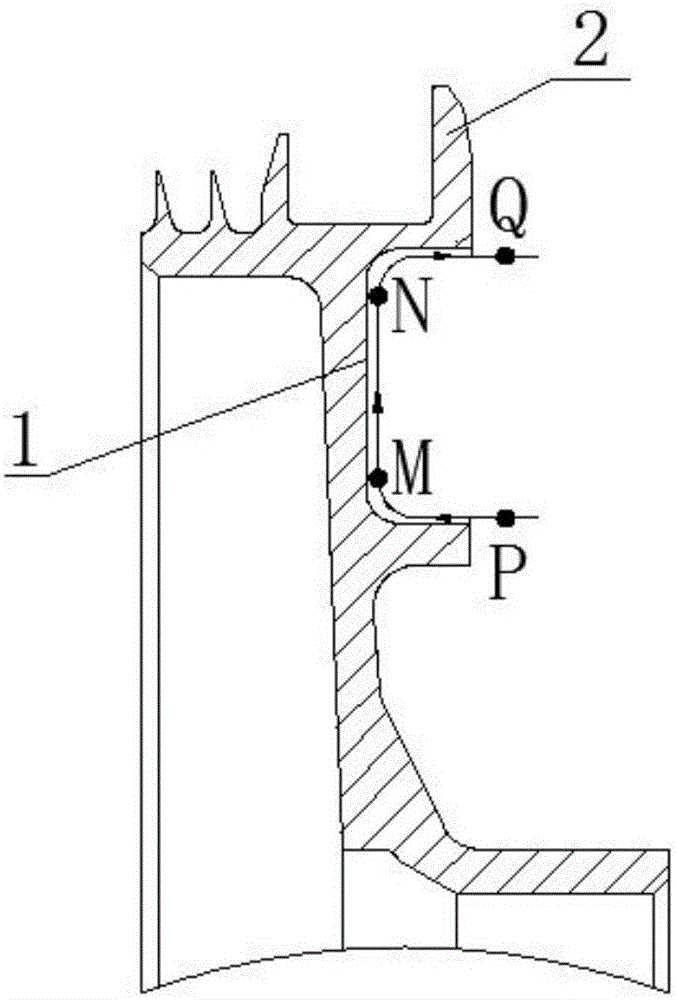

Biomass fuel aluminum melting furnace

The invention discloses a biomass fuel aluminum melting furnace. The biomass fuel aluminum melting furnace comprises a furnace body (1), a screw feeding machine (2) and a chimney (3). The furnace body is composed of a combustion chamber, a heating chamber and a crucible, and the crucible is arranged inside the heating chamber; a flame baffle layer and a hot air duct are arranged between the furnace wall of the heating chamber and the crucible; the chimney is communicated with the heating chamber; the fuel chute of the screw feeding machine is communicated with the combustion chamber. when the biomass fuel aluminum melting furnace works, solid biomass fuel is pushed into the combustion chamber by the screw feeding machine for combustion, flame generated through the combustion enters the heating chamber through a flame vent and heats the crucible around the outer wall of the crucible front bottom to top through the hot air vent under the action of the flame baffle layer, and smoke is exhausted to the atmosphere through the chimney. According to the technical scheme of the biomass fuel aluminum melting furnace, through the flow retarding function of the flame baffle layer, heat exchange is enhanced, temperature dissipation of the heating chamber is retarded and the aluminum alloy melting temperature inside the crucible can be maintained, accordingly, the biomass fuel aluminum melting furnace can achieve the objects of energy consumption reduction and cost saving.

Owner:HUZHOU YUANTE NEW MATERIALS

Highly effective deep-grinding process for engineering ceramic material

InactiveCN1788931AIncreased Plastic Removal RatioSlow down the feed rateAbrasion apparatusGrinding machinesWater basedUltra high speed

The technological process of deeply grinding engineering ceramic material in high efficiency includes: 1. trimming with resin combined super high speed diamond grinding wheel to outer circle jitter not greater than 5 microns and dressing with a dynamic balance system to make the grinding wheel possess dynamic unbalance amount less than 0.1 micron; 2. adopting water base cooling liquid with liquid pressure of 6-10 MPa; 3. grinding in the technological conditions of grinding off rate per unit grinding wheel width 20-120 cu mm / mm.s, grinding wheel linear speed 40-160 m / s, grinding depth 1-6 mm and workpiece feeding speed 0.5-6 mmin. The present invention has high structure ceramic machining efficiency, low ceramic part cost, improved ceramic part surface quality and greatly raised part reliability.

Owner:HUNAN UNIV

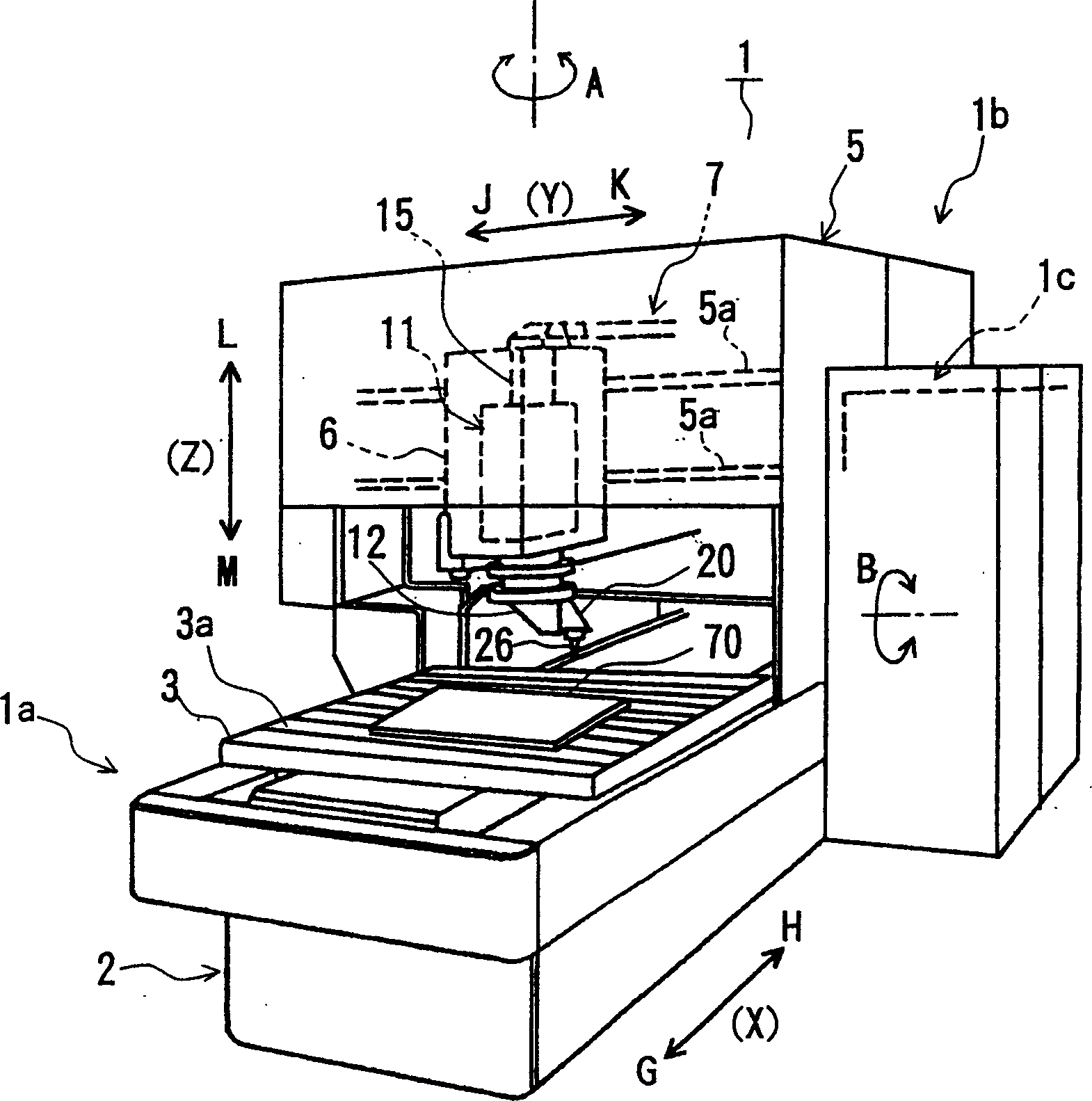

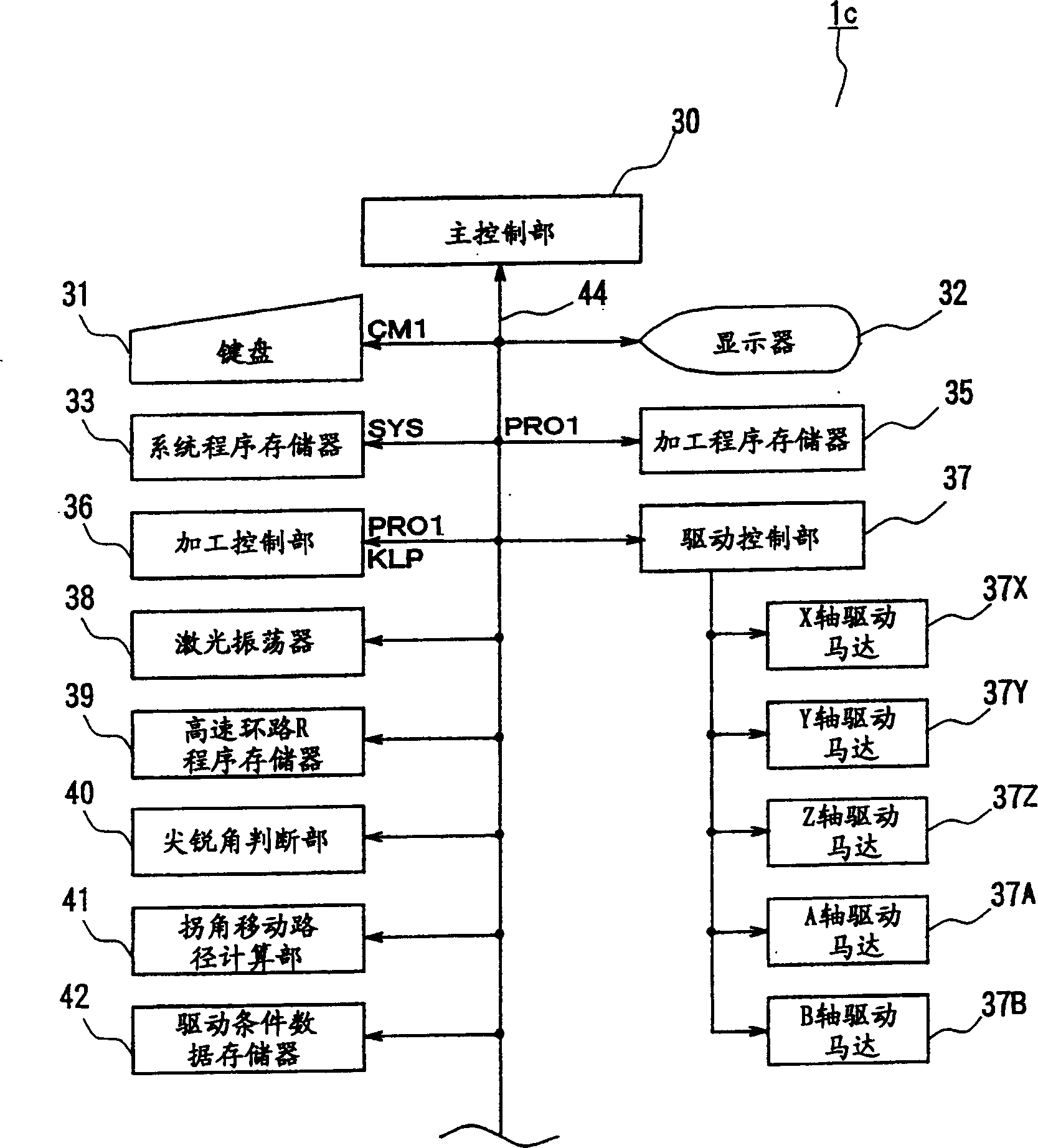

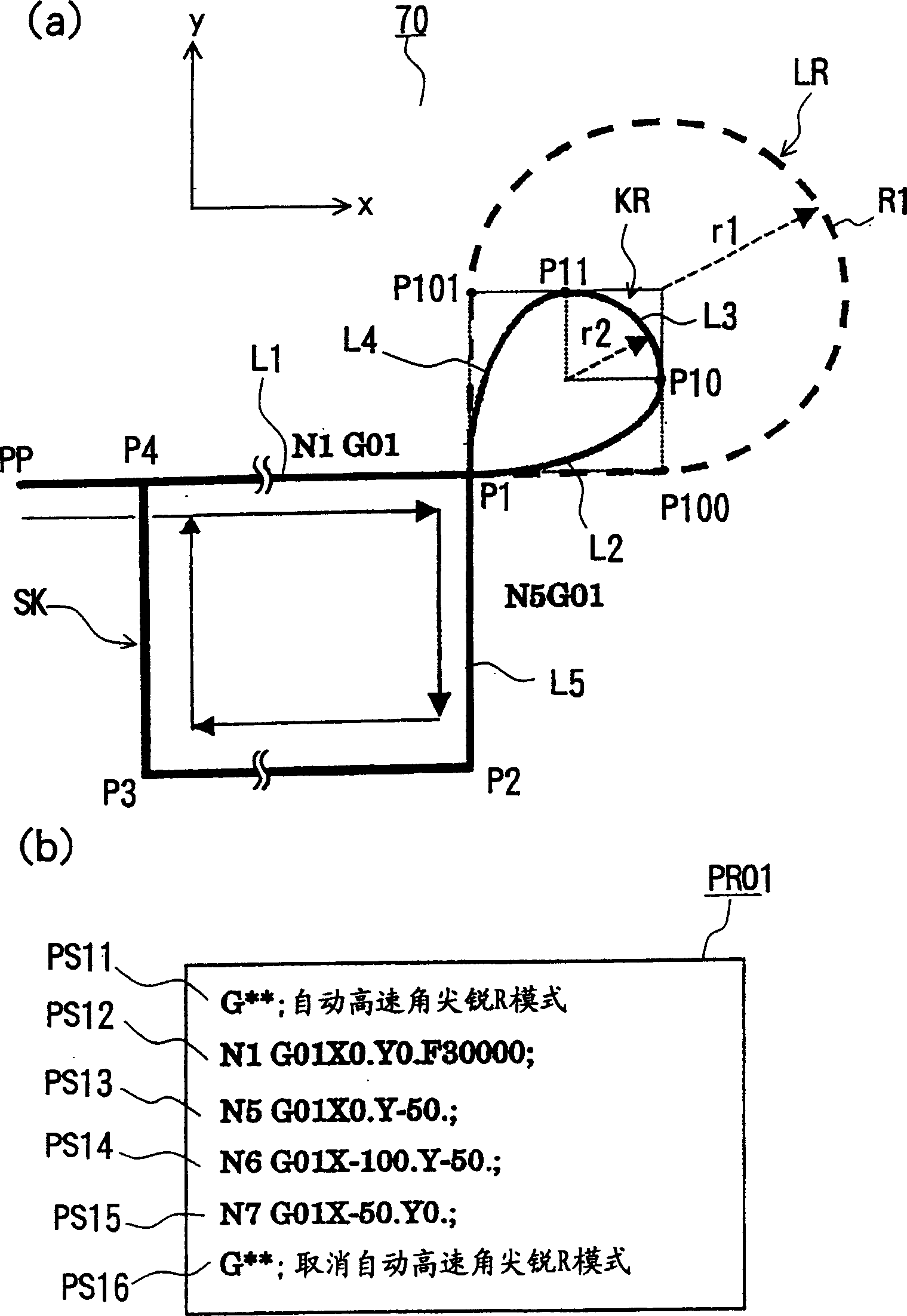

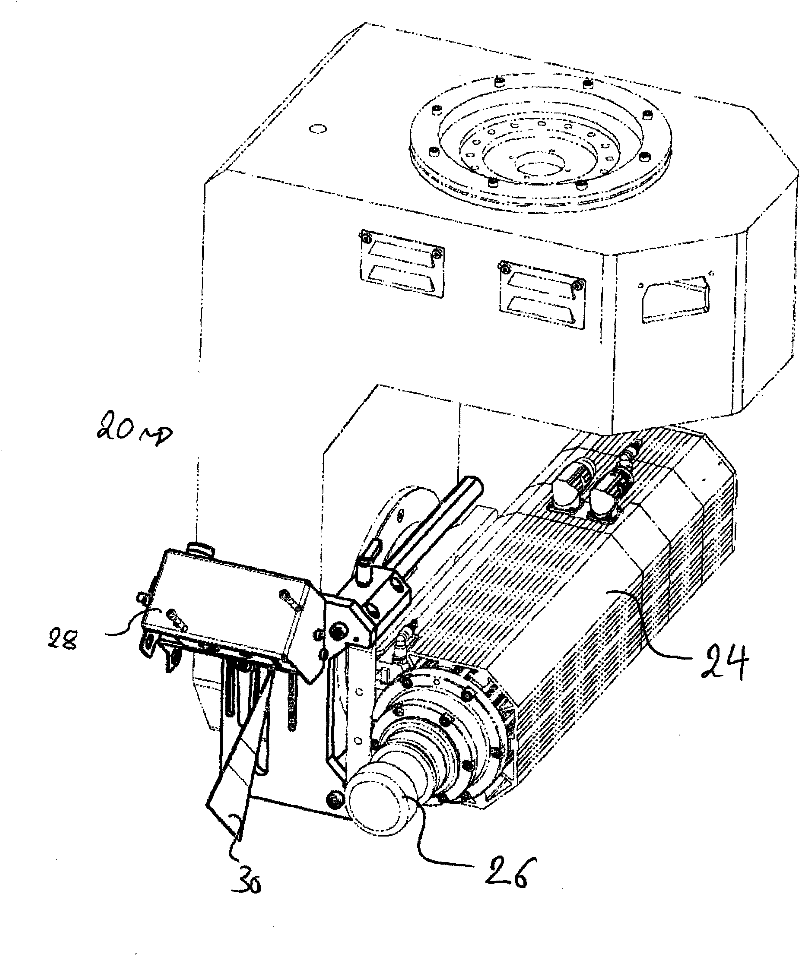

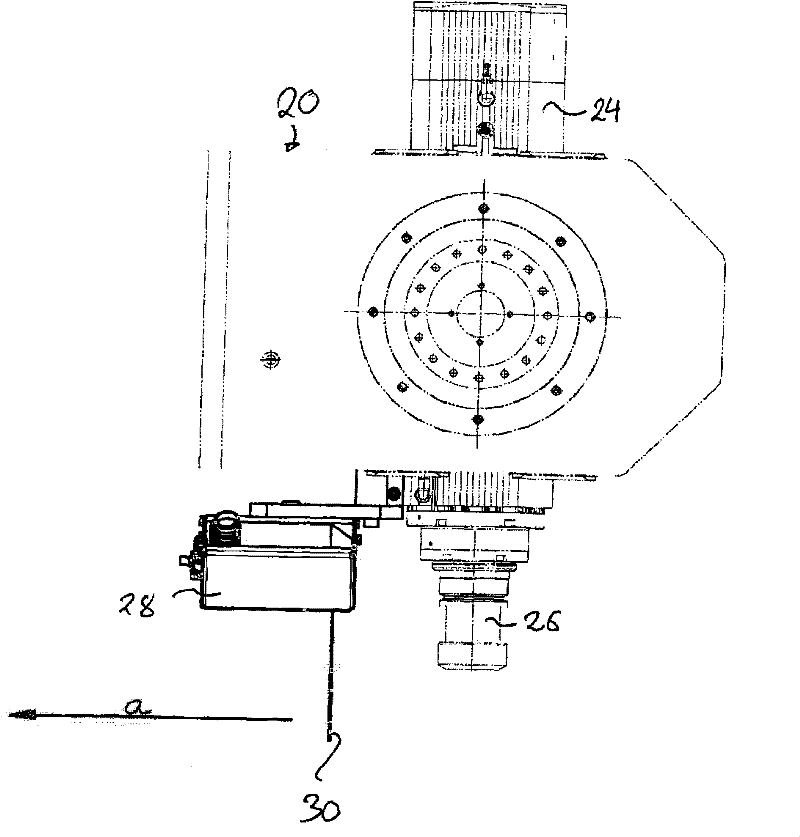

Laser beam machine

InactiveCN1467590AEasy to processReduce production manpowerLaser beam welding apparatusNumerical controlEngineeringLaser beams

A sharp corner judgment means judges as to whether a corner of cut shape in a workpiece is a sharp corner is not on the basis of a machining program. When the corner is regarded as the sharp corner, an additional locus producing means for producing sharp corner produces an additional locus for producing sharp corner when machining on the corner regarded as the sharp corner, and a sharp corner machining execution means executes machining on the corner on the basis of the produced additional locus for producing sharp corner. Then, the additional locus for producing sharp corner can be automatically produced for the sharp corner so as to execute machining.

Owner:YAMAZAKI MAZAK KK

Efficient precise grinding process for titanium alloy material

The efficient precise grinding process of titanium alloy workpiece in a conventional apparatus includes the following steps: trimming super high speed resin adhered diamond grinding wheel or ceramic bonder adhered CBN grinding wheel to outer jiggling within 5 micron and sharpening; performing real-time dynamic balancing of the grinding wheel with a dynamic balancing system to unbalance amount within 0.1 micron; and grinding titanium alloy workpiece in the conditions of water-base cooling liquid supplying pressure of 7-9 MPa, grinding wheel grinding rate of 3.3-180 cu mm / mm.s, grinding wheel linear speed of 60-150 m / s, grinding depth of 0.1-1.8 mm and workpiece feeding speed of 1-6 m / min. The present invention has high titanium alloy workpiece grinding efficiency, low cost and high grinding quality.

Owner:HUNAN UNIV

Groove machining method

The invention relates to a groove machining method. The groove machining method comprises the steps that firstly drawing side boundaries of a to-be-machined area on a blank; using a hard alloy square head groove blade to conduct rough machining on the blank to enable the hard alloy square head groove blade to move back and forth between two opposite side boundaries of the to-be-machined area; using a hard alloy round head groove blade to conduct finish machining on the blank to enable the hard alloy round head groove blade to move along the machined profile and machine the remaining allowance. By utilizing the technical scheme, different blades are used in the rough machining and finish machining stages, the blade swings back and forth in the to-be-machined area in rough machining, a combination of a straight line machining route and a curve machining route is utilized, the feed speed of the straight line machining route is high, the feed speed of the curve machining route is low, blade machining rigidity is improved, phenomena such as clip clamping and tool tipping are avoided, machining stability is enhanced, vibration of the blades in the cutting process is reduced, machining quality and efficiency are improved, and production cost is reduced.

Owner:GUIZHOU LIYANG INT MFG

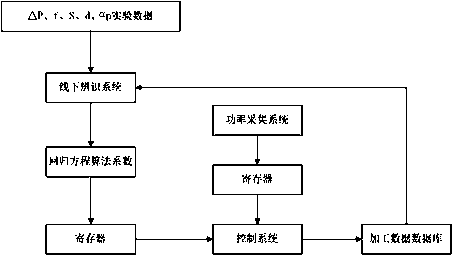

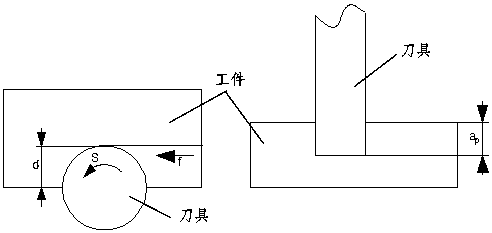

Self-adaptive control machining method with constancy of main shaft power as target

ActiveCN110539202AGuaranteed constant power processingShort computing timeAutomatic control devicesMeasurement/indication equipmentsConstant powerControl system

The invention relates to a self-adaptive control machining method with constancy of main shaft power as a target. According to the method, constancy of the main shaft power is taken as the target in the machining process, the main shaft power is controlled by changing a feeding speed, and the calculation formula of the feed speed adjustment amount delta f is simple; and an experiment is used for carrying out fitting on the formula among a target power difference value delta p, a feeding speed f, a rotating speed s, a radial cutting depth d, and an axial cutting depth a and the feeding speedadjusting amount delta f, an acquisition system is used for acquiring the above machining parameters in real time, and then the machining parameters are transmitted to a control system, a speed deltaf required by machining is calculated in the control system, and the feeding speed f is adjusted, so that constant-power machining of a workpiece is guaranteed. The method has the advantages of beingsimple in algorithm formula, short in calculation time and easier to embed into a universal numerical control system such as SIEMENS and FANUC without arranging additional equipment, and meanwhile the numerical control system can be built through a build-in PLC and a build-in CNC of the system, so that good transplanting performance is achieved, and self-adaptive control in the high-precision machining process can be realized.

Owner:CHINA YITUO GROUP +1

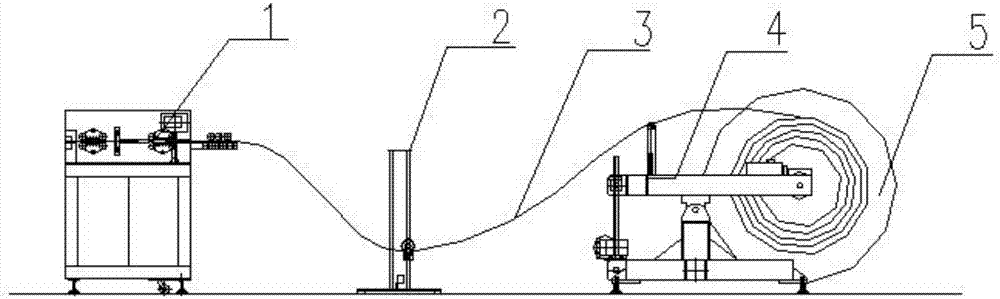

Numerical control cable maker and cable making method based on same

ActiveCN107394692AReduce laborAdapt to production needsApparatus for removing/armouring cablesApparatus for joining/termination cablesNumerical controlPull force

The invention discloses a numerical control cable maker featured by comprising a wire stripper, a wire transfer rack and a tension rack; the wire transfer rack is provided with a first driving unit used for driving a wire cylinder to rotate; the tension rack is arranged between the wire stripper and the wire transfer rack, and comprises a guide bar arranged in the vertical direction; the guide bar is provided with a wire pass rack; the cable penetrates the wire pass rack; the tension rack is also provided with a coiler; the coiler comprises a reel wire; one end of the reel wire is fixedly connected with the wire pass rack; the numerical control cable maker also comprises a control system; the control system comprises a controller and a tension sensor; the tension sensor can measure the reel wire received pulling force; the first driving unit is electrically connected with the output end of the controller; the tension rack can monitor the tension force in real time in a cable feeding process, and adjusts the cable feeding speed according to measured values, thus adapting to the cable making speed, and realizing precision feeding.

Owner:浙江华云清洁能源有限公司 +1

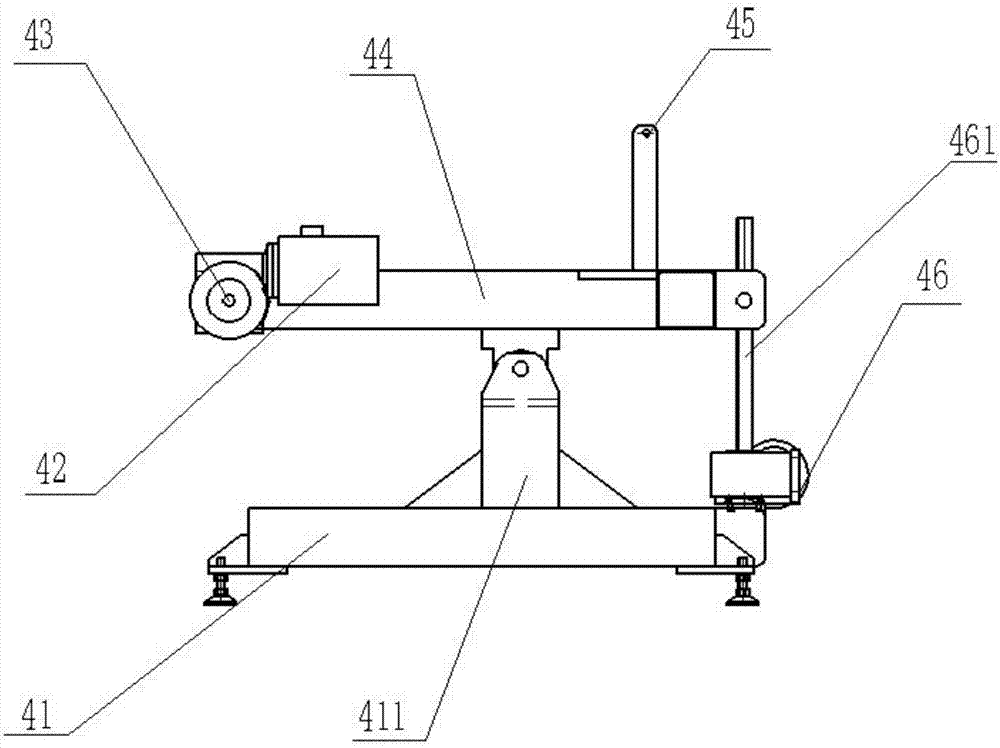

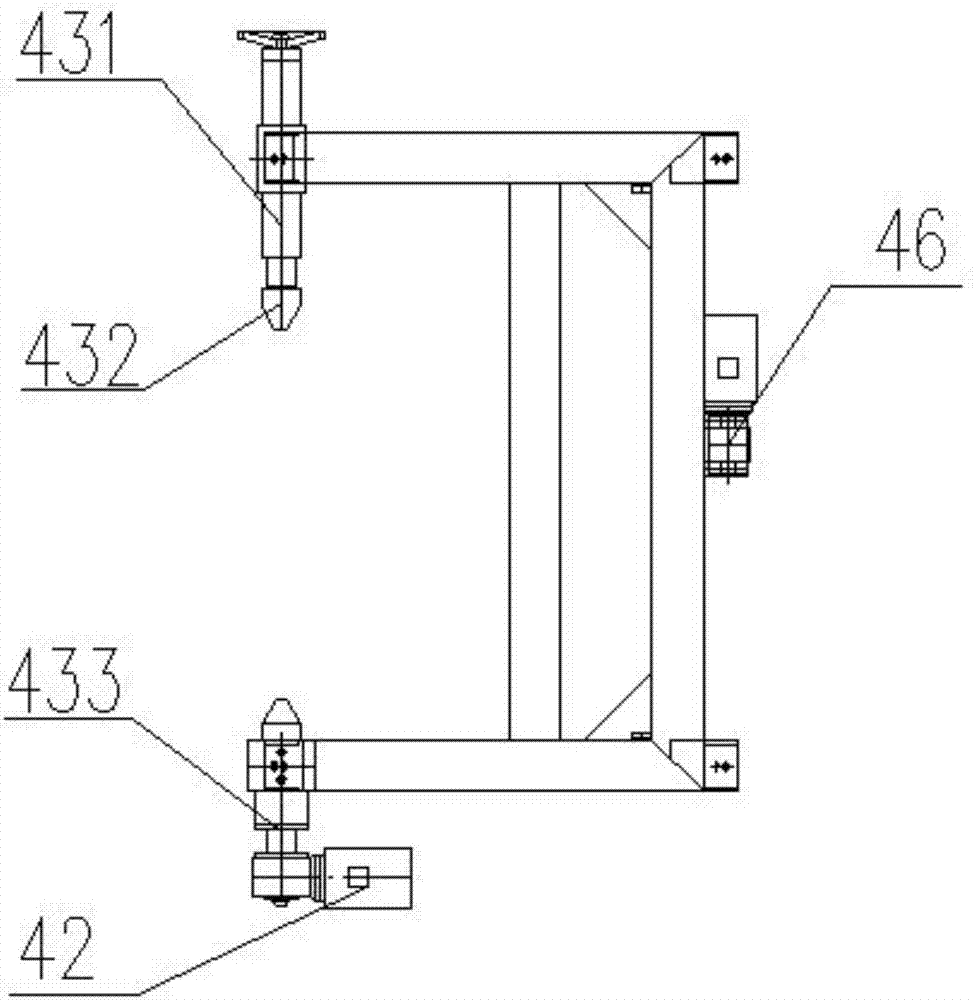

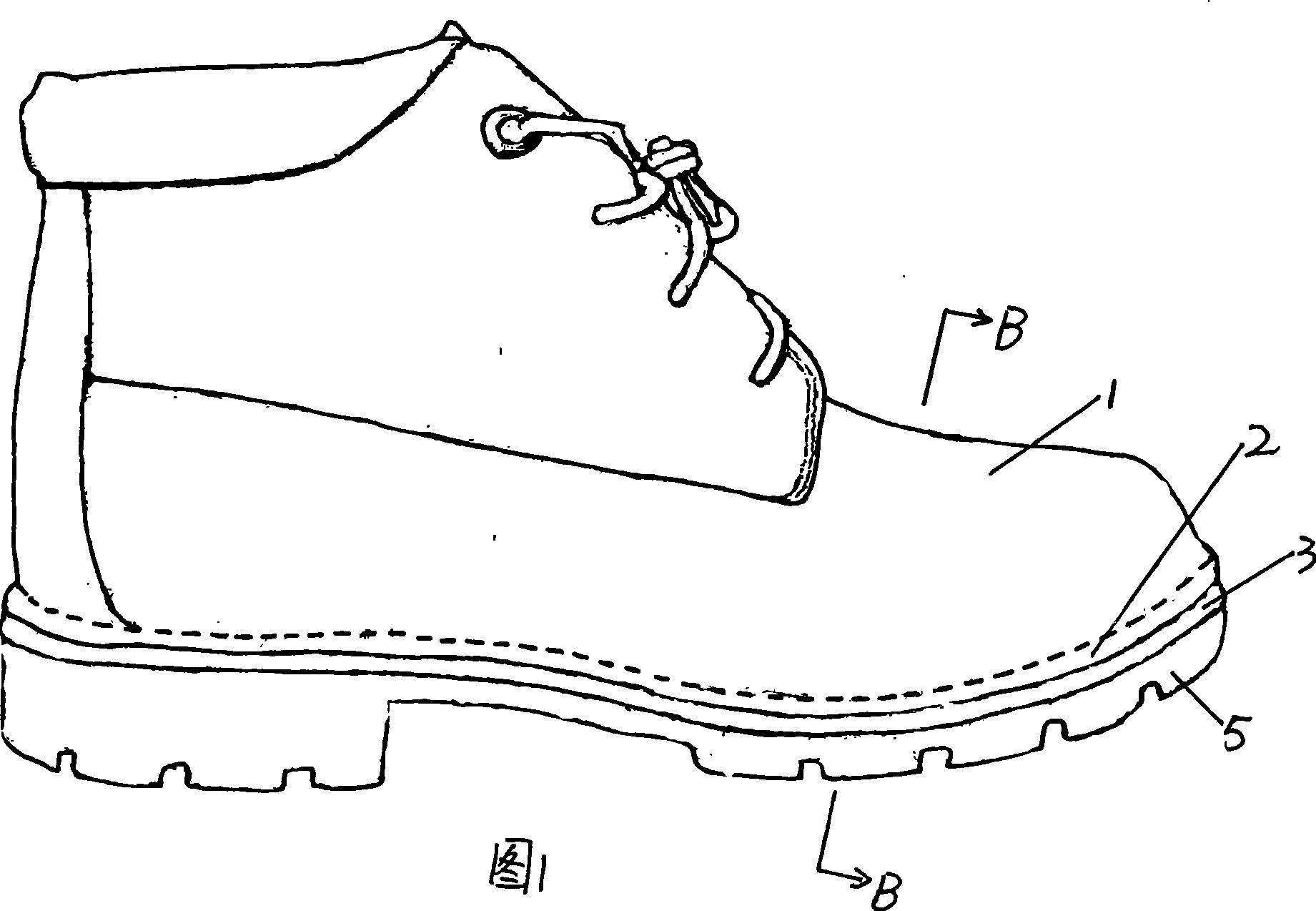

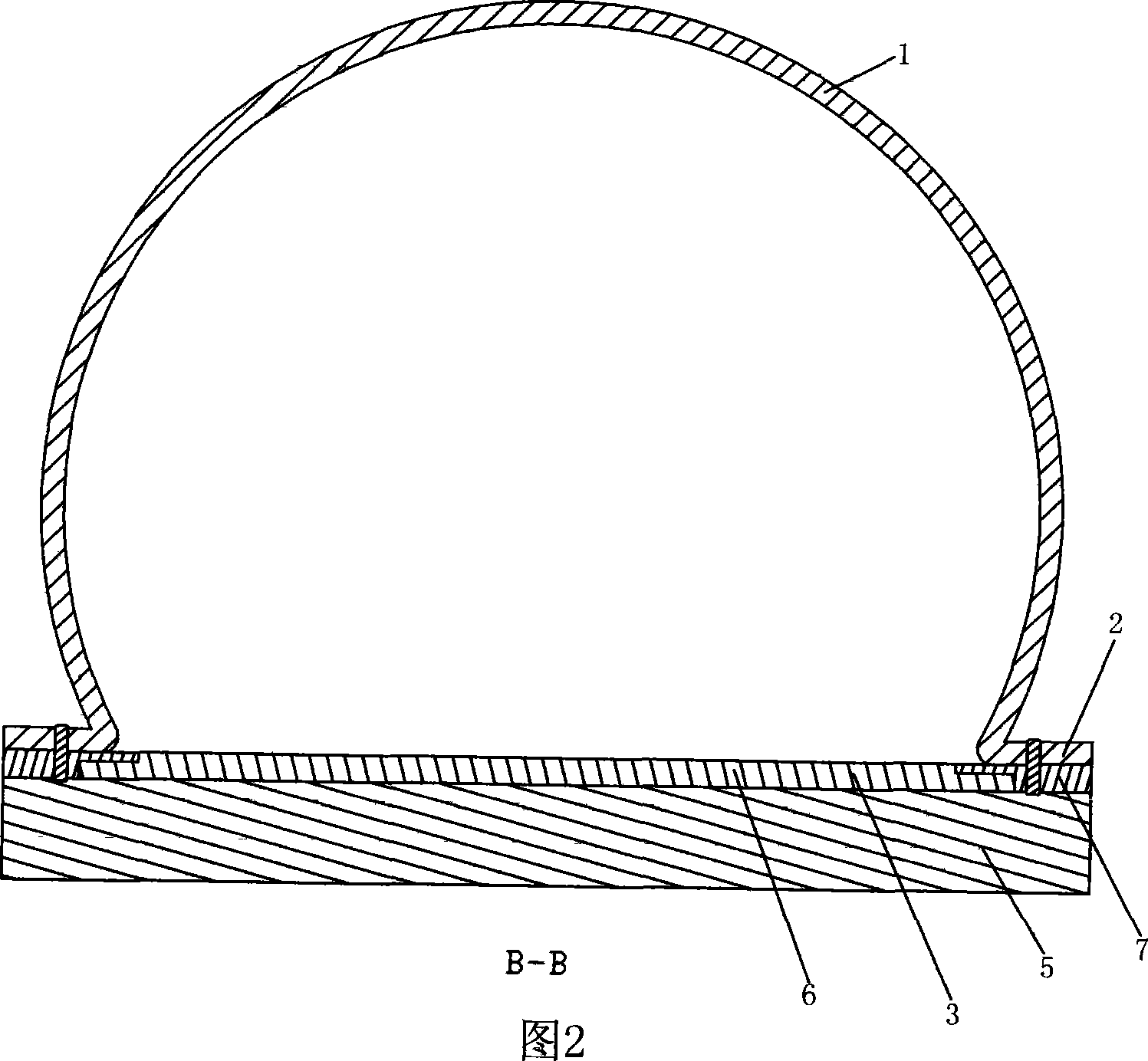

Last type leather welt sandals turning-outwards shoes, manufacture method thereof and special last pushing seat

The invention discloses a put-on last leather welt stitch-down shoe which comprises a vamp, a stitch-down edge formed by stitching down the edge of the lower end of the vamp, a leather midsole stitched with the underside of the stitch-down edge, an outsole adhered to the underside of the leather midsole, a midsole enclosed in the leather midsole, and a leather welt which can be stitched with the stitch-down edge of the vamp and is fixed and adhered to the edge of the midsole. A making method of the shoe comprises the following steps: A. molding a toe cap; B. stitching the midsole and the leather welt to form a combination leather midsole; C. adhering the stitch-down edge 10mm from the vamp state foot to the outside edge of the leather midsole in flush, and fixedly connecting the stitch-down edge of the vamp and the leather midsole into a whole body by an outside welt stitching; D. steaming the vamp to be soft, put-on last, and pushing the last with a last pushing seat; E. removing the last; F. adhering the outsole and pressing sole; G. finely grinding the edge; and H. cleaning up. The put-on last stitch-down shoe is softer, lighter and more convenient with less cost. The leather midsole in the method is formed by stitching the genuine leather midsole and the leather welt, thus the leather midsole is softer and lighter than the existing midsoles and has lower cost.

Owner:GOLDEN CHANG INDAL

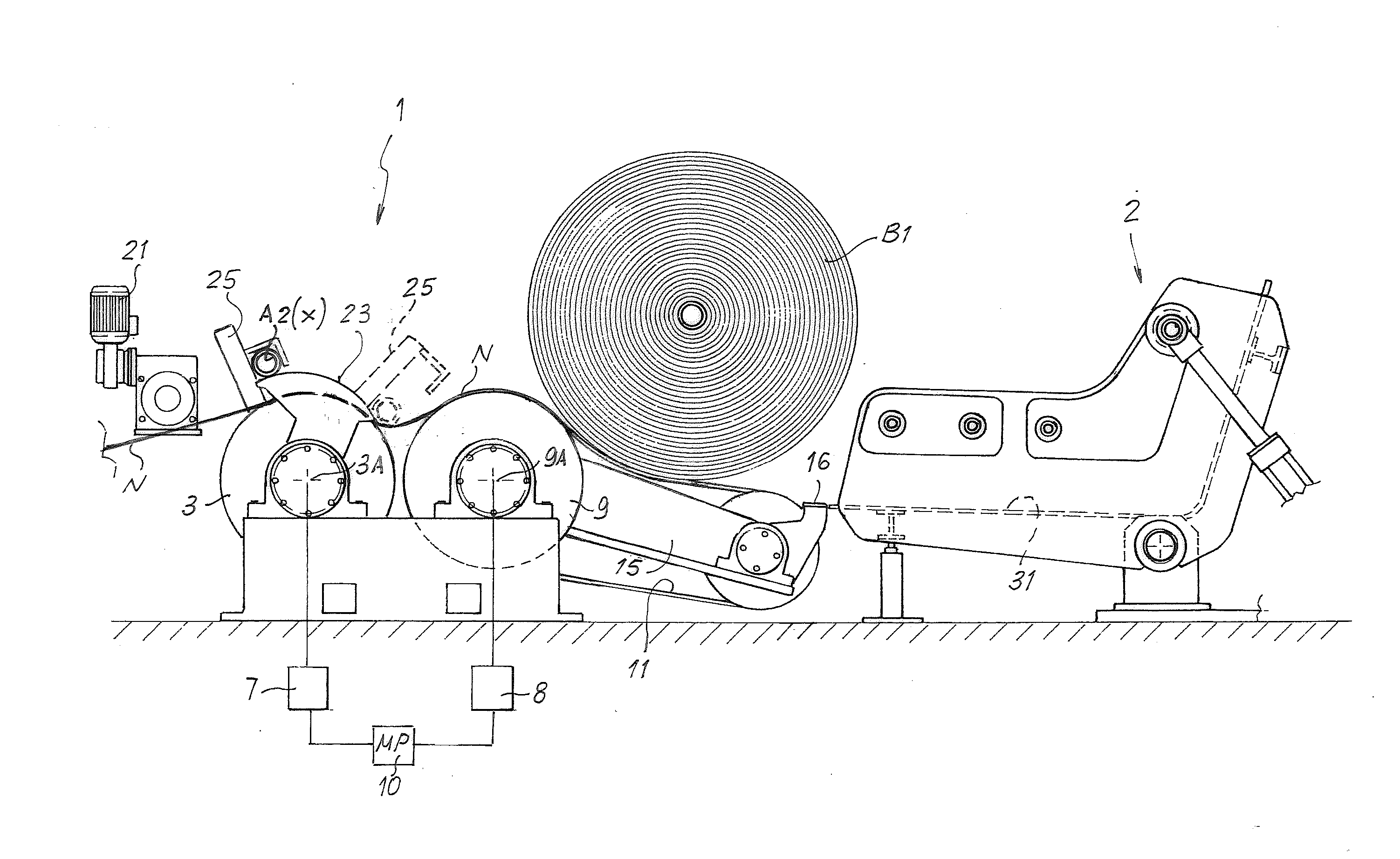

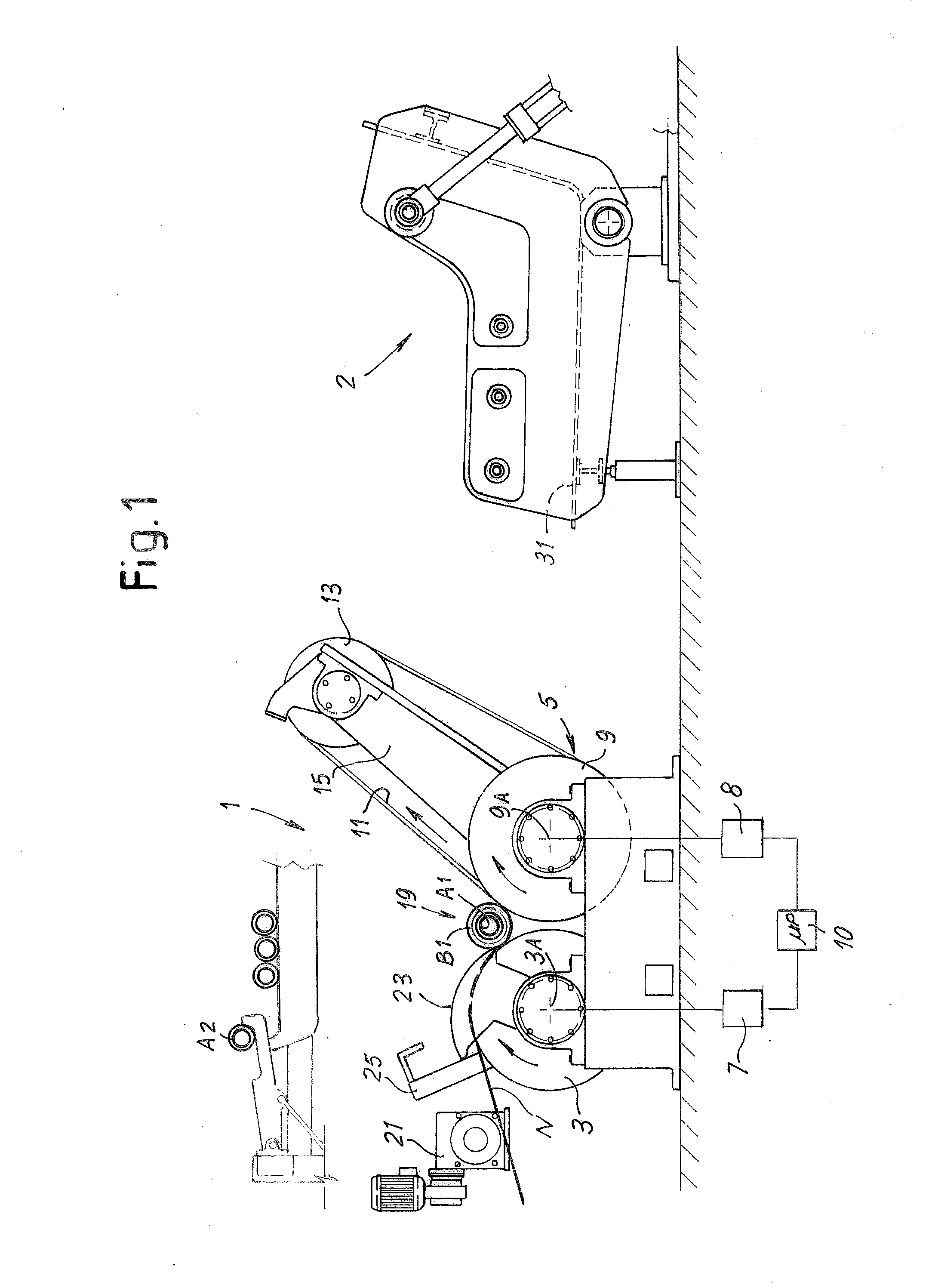

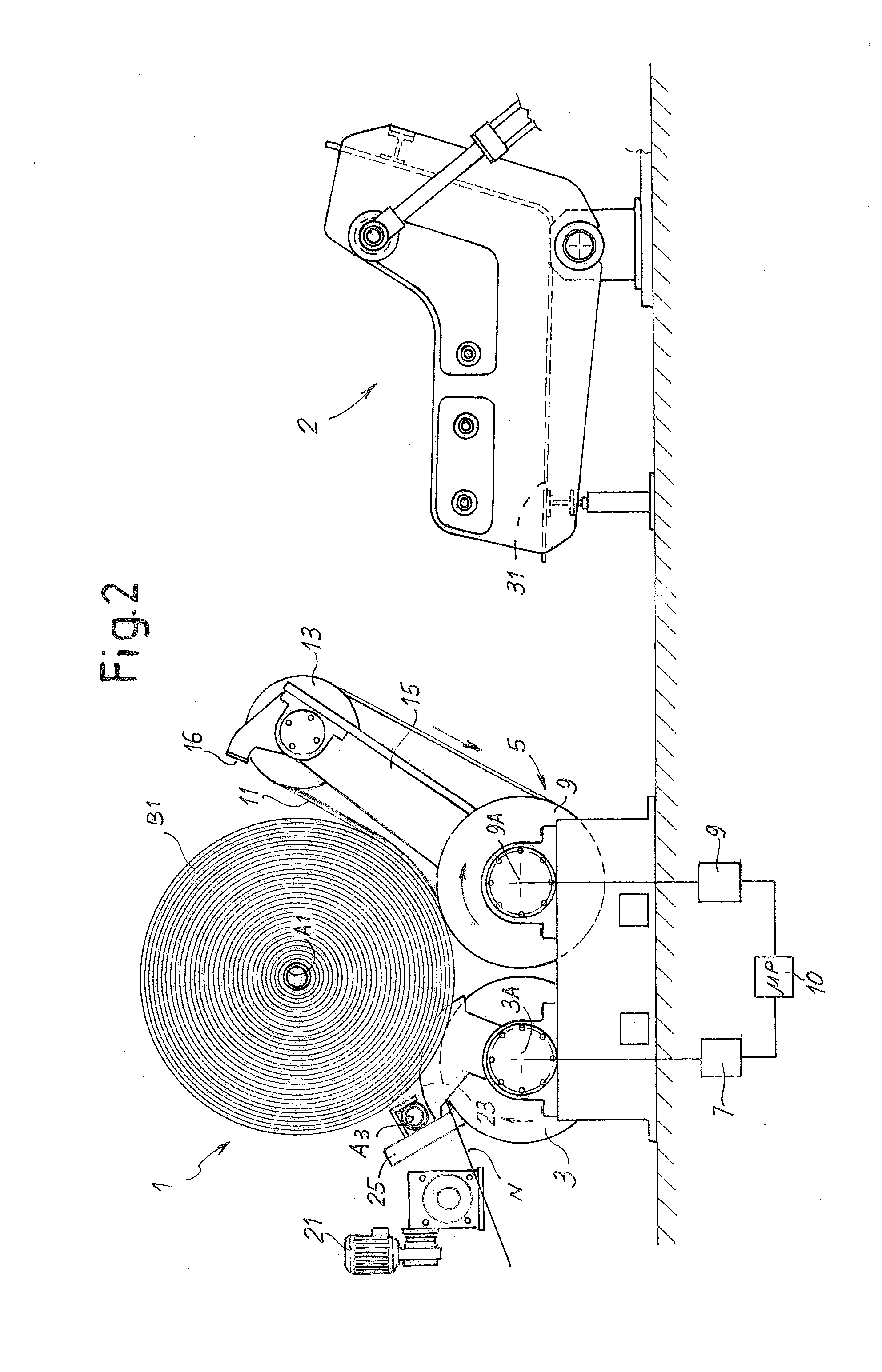

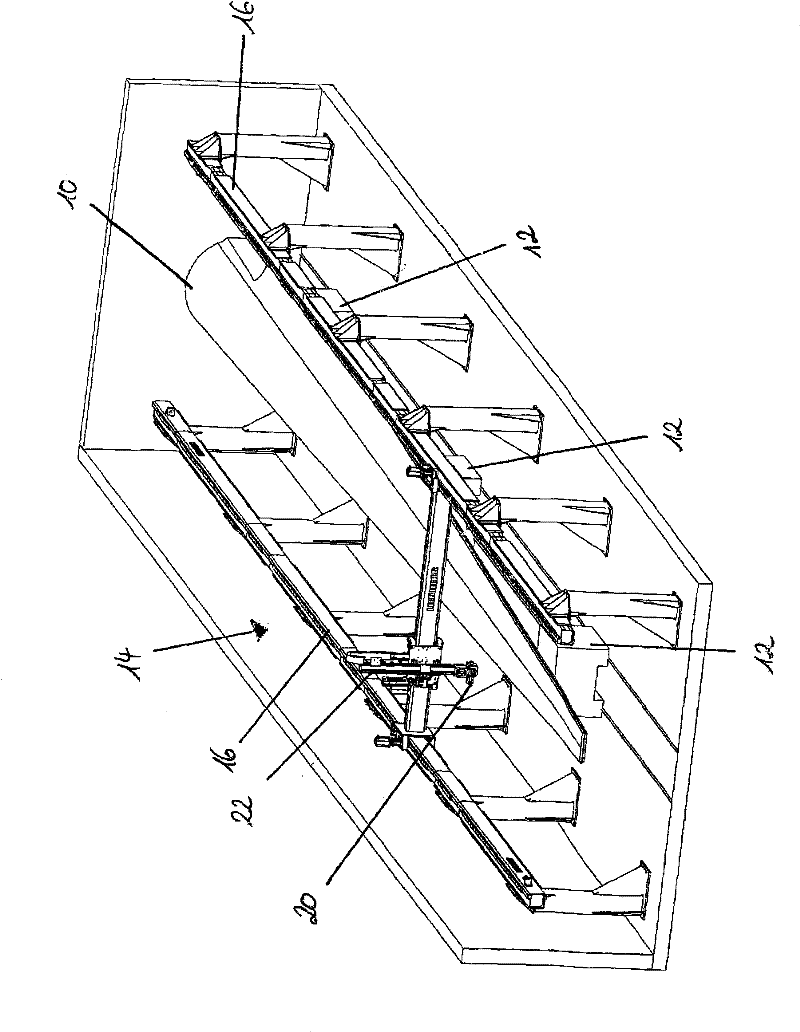

Machine and method for winding reels of web material

InactiveUS20130008995A1Overcomes drawbackSlow down the feed rateFilament handlingWebs handlingEngineeringConductor Coil

The rewinding machine comprises: a first winding member (3) and a second winding member (9) defining a winding cradle (19); a winding rod inserter (25) for introducing a winding rod (A1; A2) in the winding cradle (19) to wind a reel (B1) of web material (N) on said winding rod. The inserter (25) is arranged and designed for introducing the winding rod (A2) against the first winding member (3) towards the winding cradle (19) and the second winding member (5) is designed and arranged to allow a previously formed reel (B1) to be unloaded from the winding cradle (19).

Owner:A CELLI PAPER

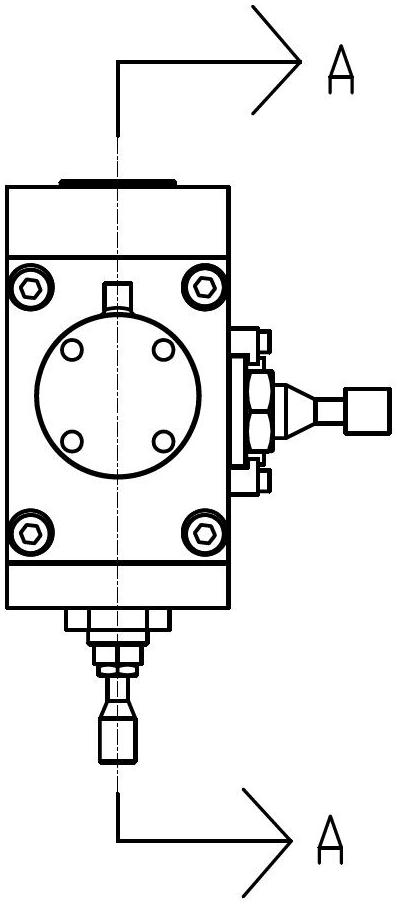

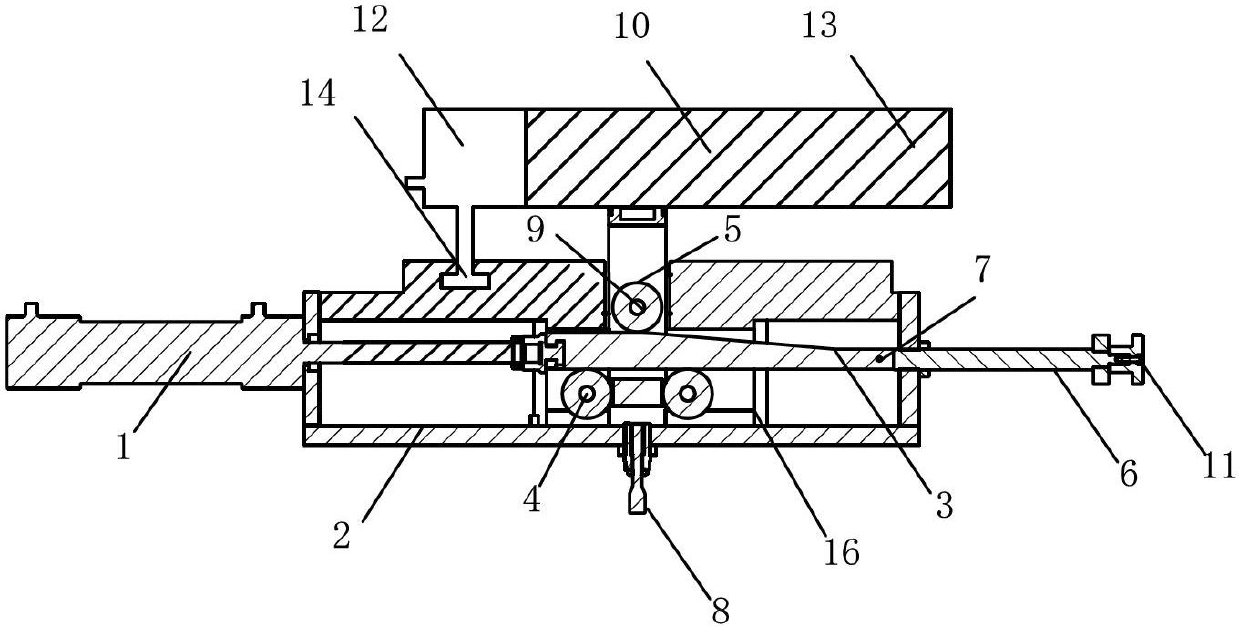

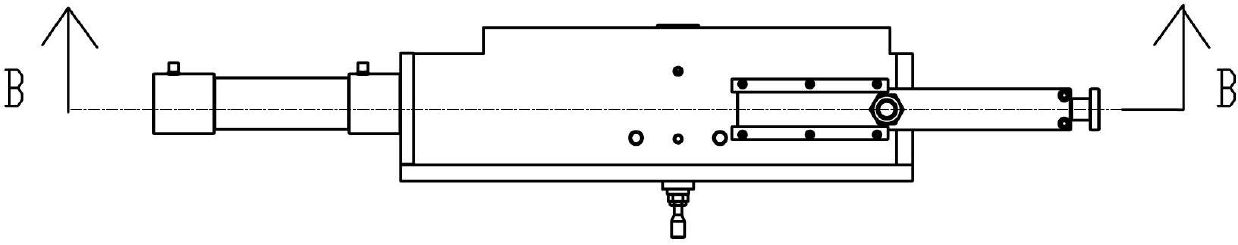

Inclined wedge type grinding head feeding device

InactiveCN102672611ARealize automatic controlSlow down the feed rateGrinding drivesControl signalEngineering

The invention discloses an inclined wedge type grinding head feeding device. The inclined wedge type grinding head feeding device comprises an engine base, a guide column, a shell, a second oil cylinder, a roller wheel, a feeding slope rod, a first oil cylinder and a sensing component, wherein the guide column is fixedly connected with the engine base; the shell is in sliding fit with the guide column and is used for arranging a grinding head; the second oil cylinder is fixedly connected with the engine base and is used for pulling the shell towards the engine base; the roller wheel is arranged on the guide column; the feeding slope rod is arranged in the shell in a sliding mode; the first oil cylinder is arranged on the shell and is used for pulling the feeding slope rod; the sensing component is used for sensing the limit position of the feeding slope rod; and a control signal of the first cylinder is from the sensing component. The feeding device can feed slowly, reduces the feeding speed in multiples, can automatically feed and retract, and can feed repeatedly for many times without fault.

Owner:ZHEJIANG YUETE TOOL

Method and apparatus for controlling the sheet feeding speed in a printer

ActiveUS7367732B2Slow down the feed rateKeep for a long timeElectrographic process apparatusOther printing apparatusLeading edgeEngineering

In order to adjust a position of a cut sheet when the cut sheet begins to be sent to a printing positions a leading edge of the cut sheet is fed towards a pair of sending rollers for sending the cut sheet to a printing position, wherein the sending rollers are held at rest or rotated in reverse. If a predetermined condition is satisfied, a feeding speed of the cut sheet decreases when the leading edge of the cut sheet reaches a position that is a predetermined distance upstream of the sending rollers. If the predetermined condition is not satisfied, the feeding speed of the cut sheet does not decrease before the leading edge of the cut sheet contacts the sending roller. A decline in printing quality and an unnecessary delay in printing time can be prevented. With the sending rollers, an effect to prevent the leading edge of the cut sheet from being fed in a slanted position is also maintained.

Owner:BROTHER KOGYO KK

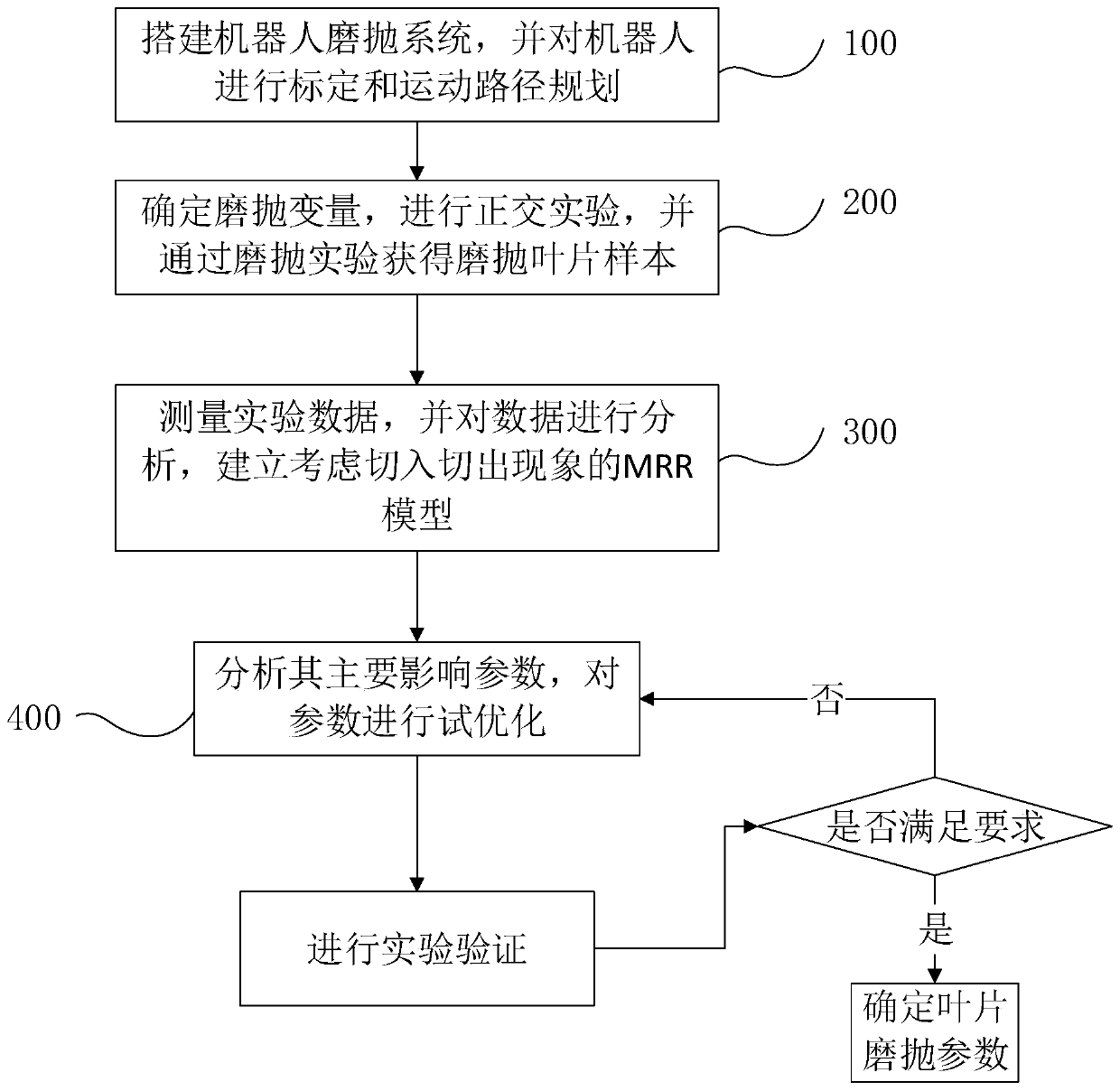

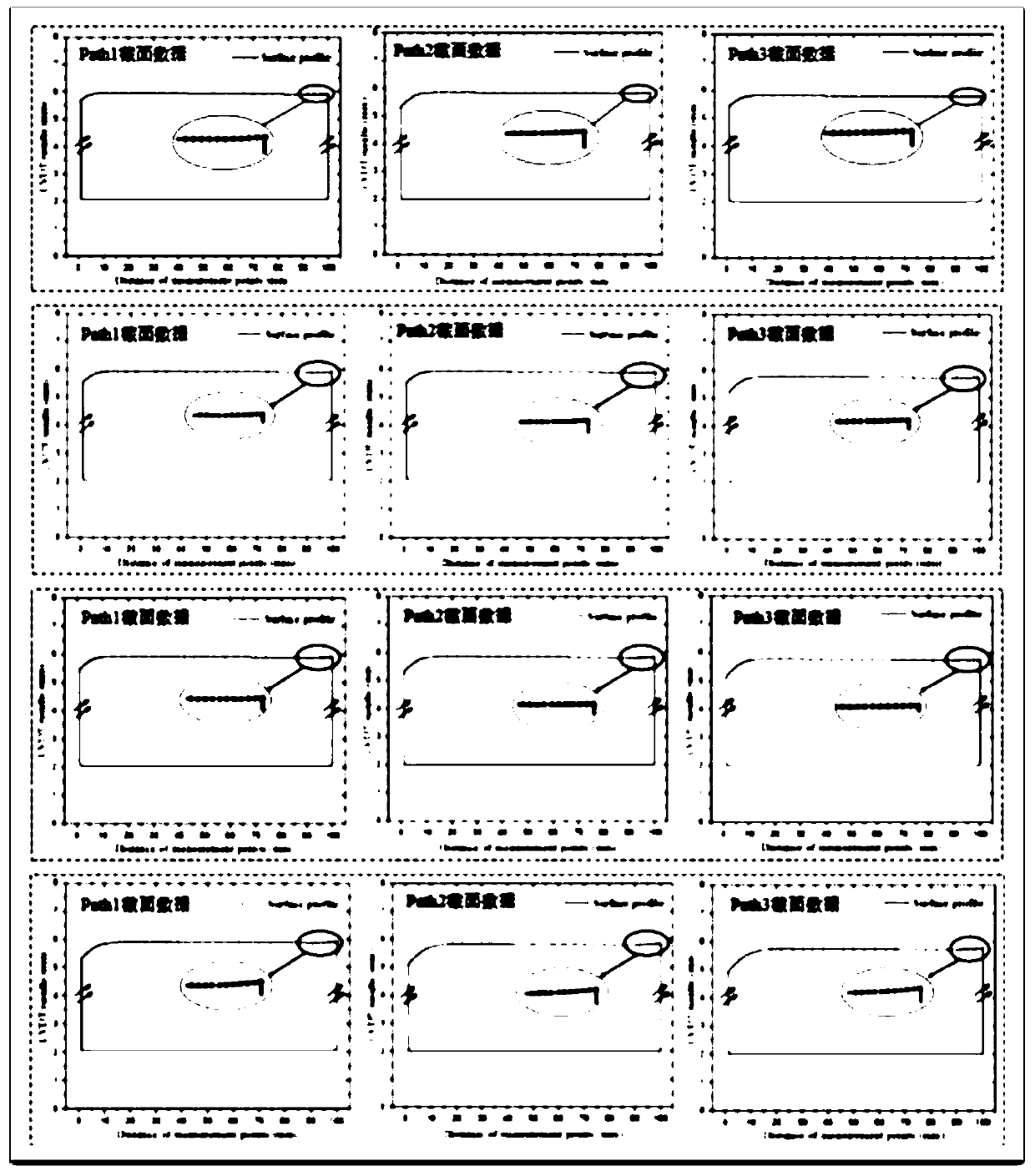

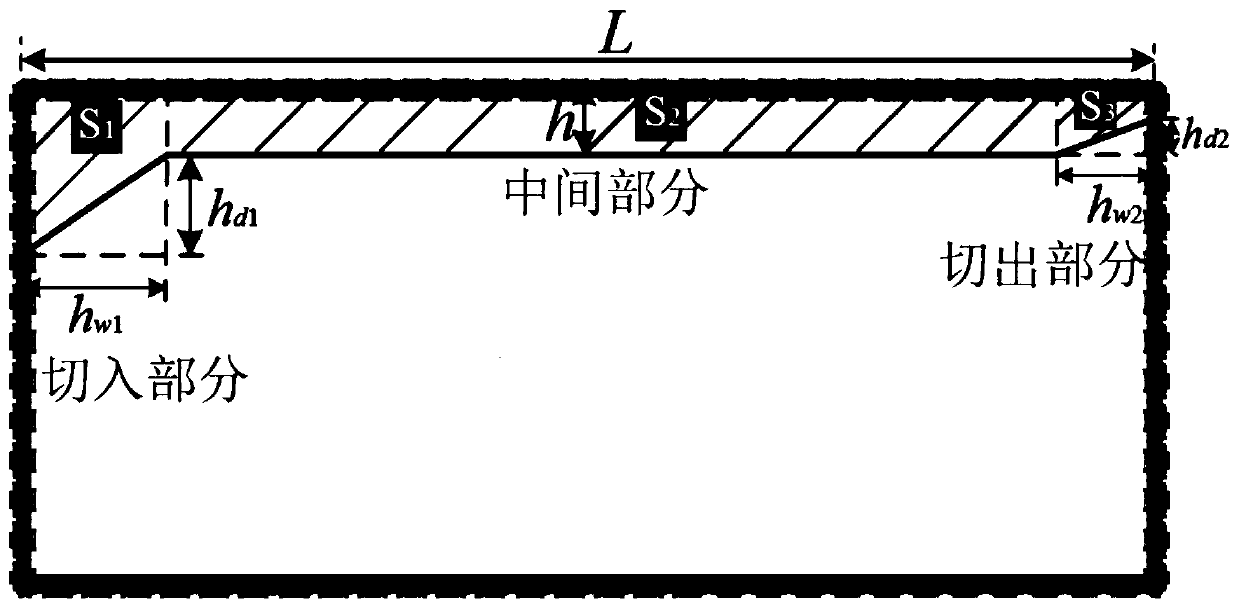

Gas compressor blade robot abrasive belt grinding and polishing machining method

ActiveCN110900379ASolve rationalitySolve the problem of underwearAutomatic grinding controlGrinding machinesMaterial removalPolishing

The invention discloses a gas compressor blade robot abrasive belt grinding and polishing machining method, which comprises the steps: S100, a robot grinding and polishing system is built, and a robotis calibrated and a motion path is planned; S200, an orthogonal experiment is carried out with the abrasive belt model, the granularity and the radius of a contact wheel of the grinding and polishingmachine as known quantities and the robot feeding speed, the abrasive belt linear speed and the grinding force as grinding and polishing variables, and a grinding and polishing experiment is carriedout on the blade through a robot grinding and polishing system, and a grinding and polishing blade sample is obtained; S300, the grinding depth, the surface roughness and the surface topography characteristics of the grinding and polishing blade sample are measured, and a cut-in, middle and cut-out part material removal rate model considering the cut-in, cut-out over-grinding or under-grinding phenomenon is established; and S400, main influence factors of the material removal rate model according to the material removal rate model is analyzed, the main influence factors during cut-in and cut-out are optimized and adjusted, and multiple groups of optimization parameters are estimated. According to the method, the phenomena of over-grinding and under-grinding are reduced to the maximum extent, and the surface quality and flatness of the workpiece are improved.

Owner:HUAZHONG UNIV OF SCI & TECH

Method for machining composite components

InactiveCN102331742ARealize processing operationsTo achieve the purpose of processingProgramme-controlled manipulatorNumerical controlEngineeringMachine tool

The present disclosure relates to a method for machining composite components in a CNC controlled machining station. In accordance with the present disclosure, a machining tool is guided along a preset tool edge by means of a measuring system, wherein it simultaneously carries out the machining operation, while the CNC control program to control the machining tool is generated in accordance with the measured result. The present disclosure furthermore relates to an apparatus for the carrying out of the method.

Owner:LIEBHERR VERZAHNTECHNIK GMBH

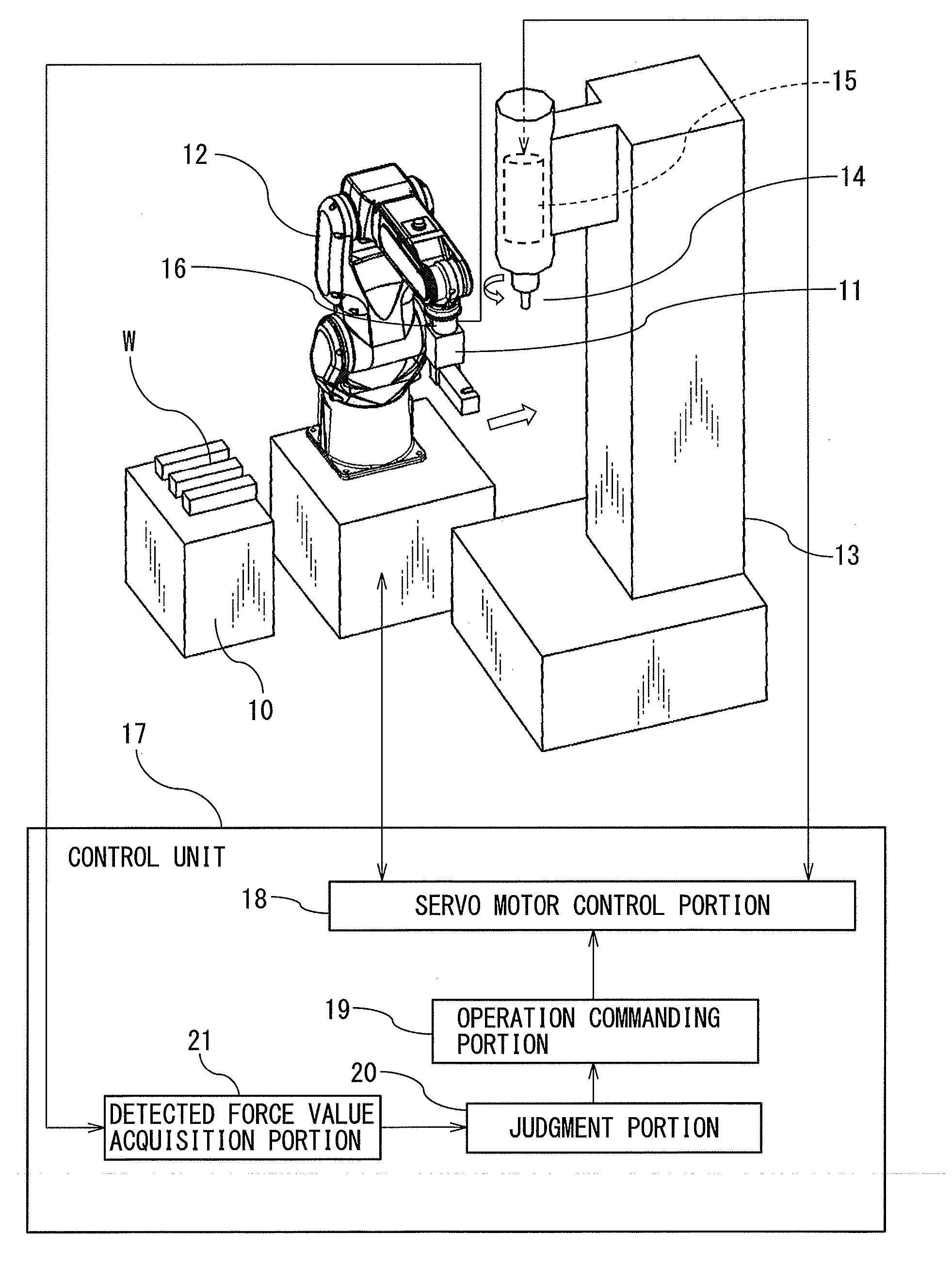

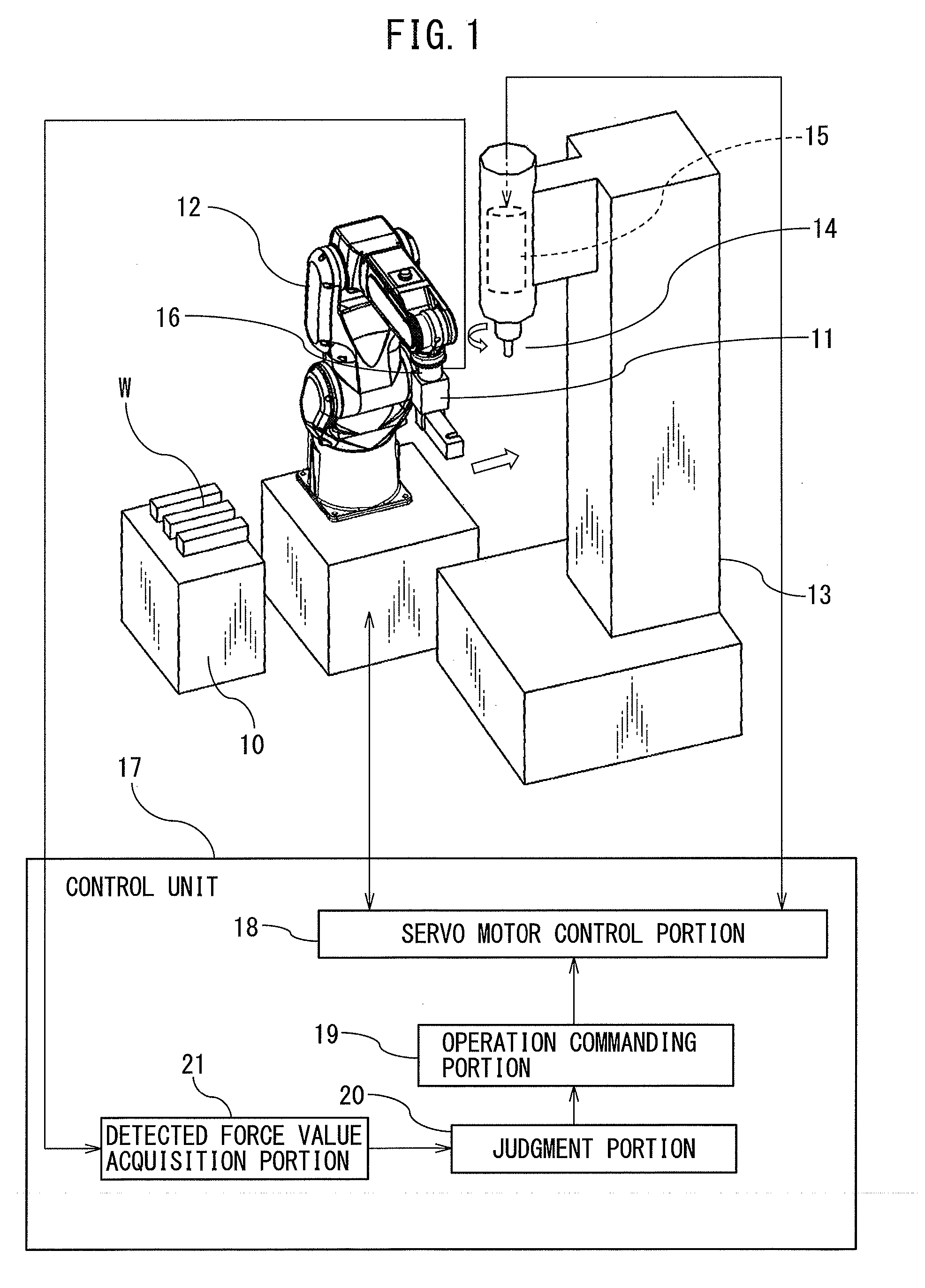

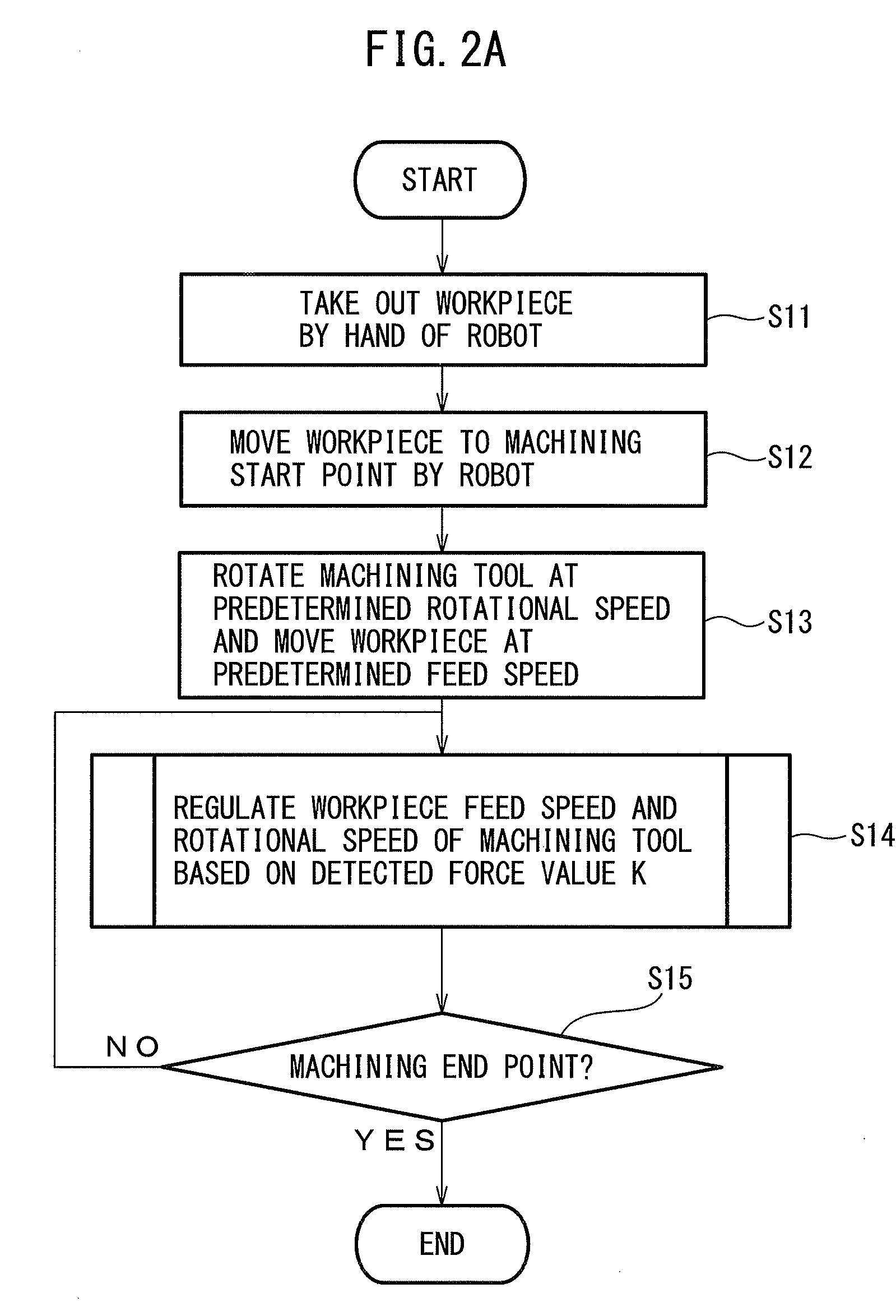

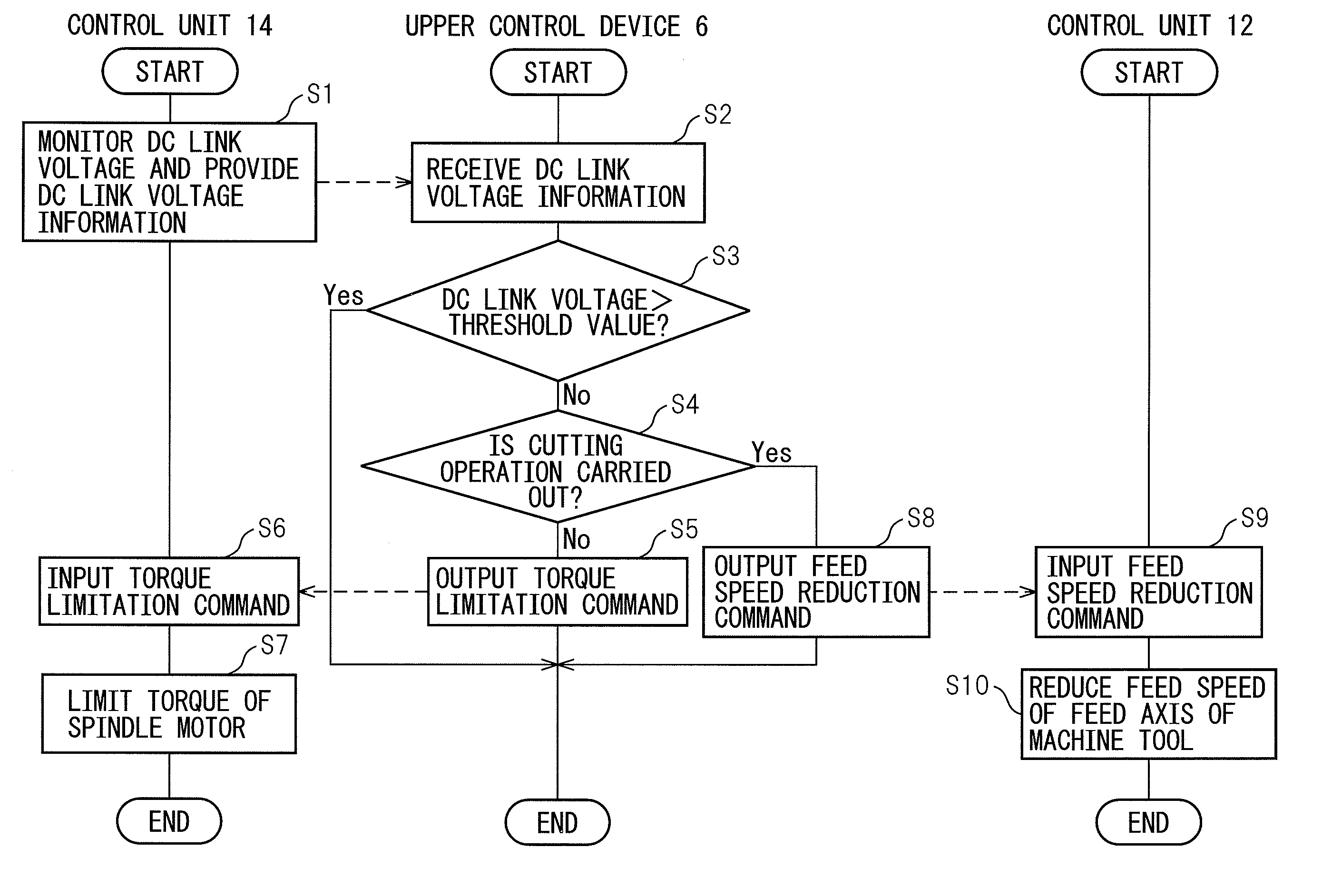

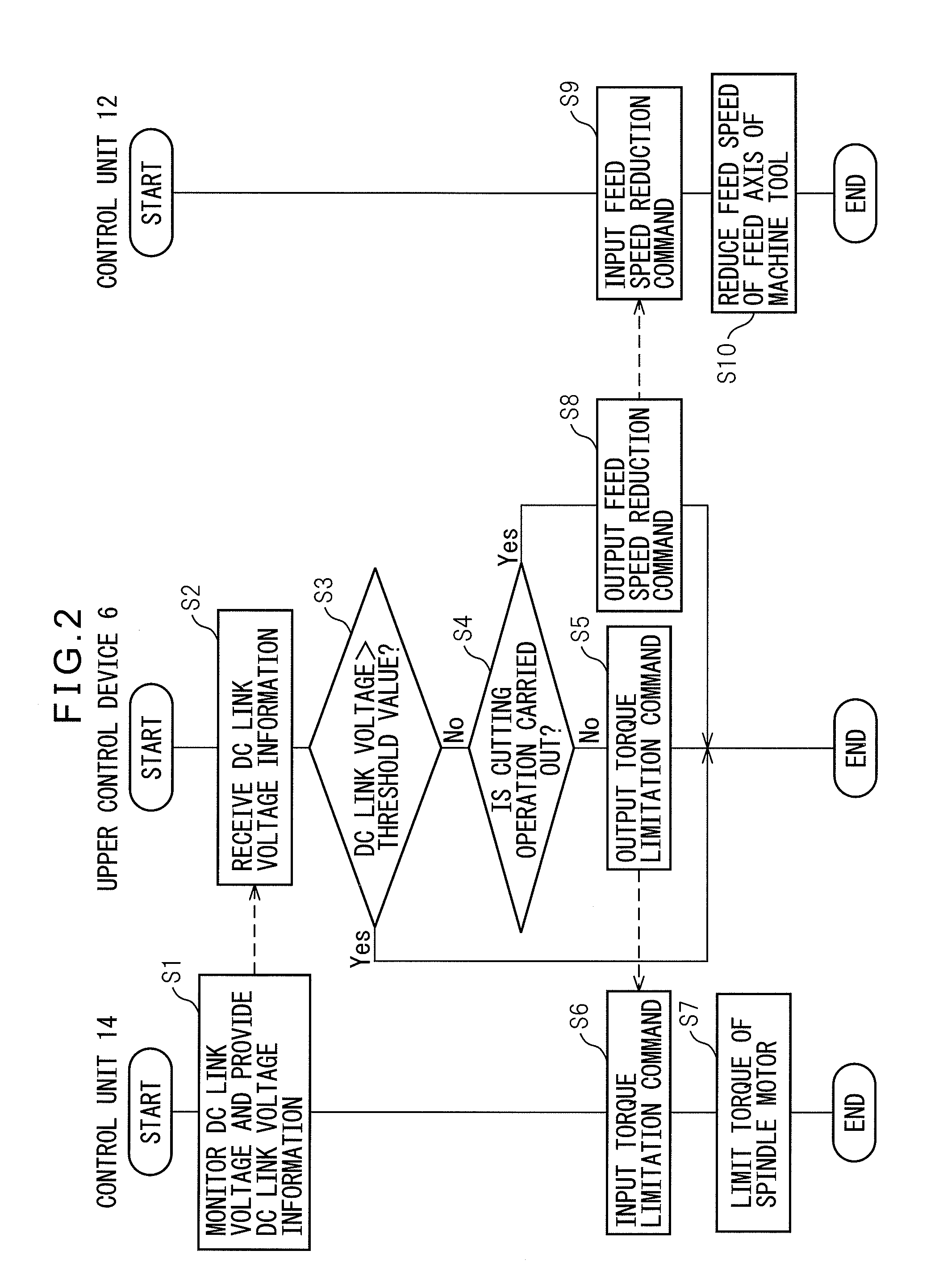

Machining system for adjusting number of revolutions of machining tool and feed speed of workpiece

ActiveUS20160332273A1Improve machine qualityQuality improvementProgramme controlProgramme-controlled manipulatorEngineeringLower threshold

A machining system of the present invention includes a robot having a hand, a processing machine to rotate a machining tool, a control unit which controls the processing machine and the robot so as to rotate the machining tool and press a workpiece held by the hand against the machining tool to thereby machine the workpiece, and a force sensor which detects force acting between the workpiece and the machining tool when the workpiece is pressed against the machining tool by the robot and is machined by the machining tool. The control unit regulates the workpiece feed speed of the robot and the rotational speed of the machining tool so that the force value detected by the force sensor is between a predetermined upper threshold and a predetermined lower threshold.

Owner:FANUC LTD

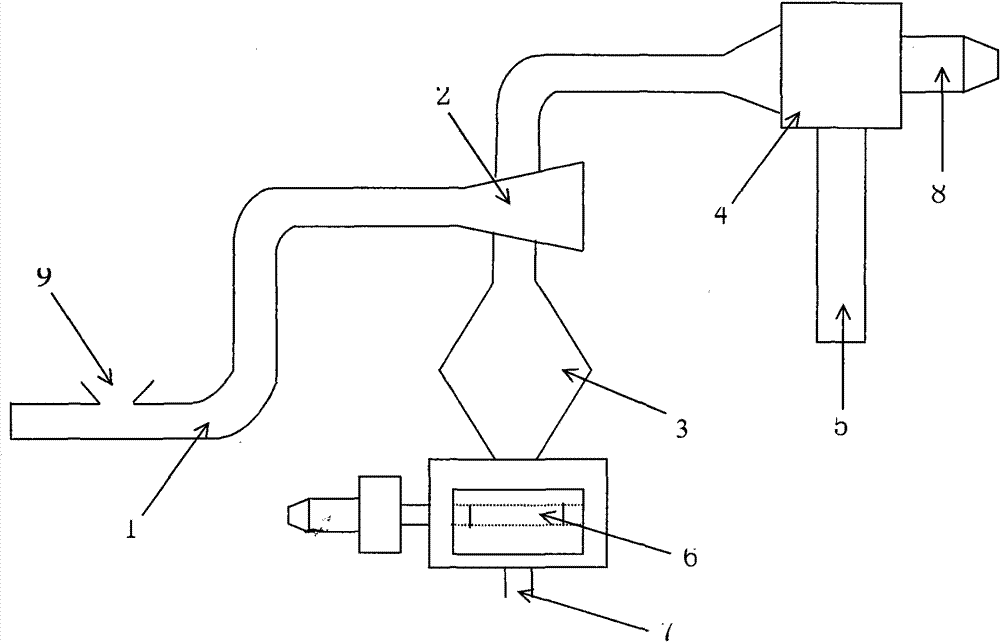

Air cooled dedusting device for producing fine rubber powder by utilizing waste tires

InactiveCN102773946AEliminate polluted environmentSlow down the feed ratePlastic recyclingDevice formEngineering

The invention discloses an air cooled dedusting device for producing fine rubber powder by utilizing waste tires. The air cooled dedusting device comprises a conveying pipe, a temperature reducing chamber, a storage chamber, an air blower, a dust storage temperature reducing chamber, and a kick-out device. One end of the conveying pipe is provided with a feed inlet. The temperature reducing chamber is arranged at the other end of the conveying pipe. The temperature reducing chamber is communicated with the storage chamber on the lower part of the temperature reducing chamber. The upper part of the temperature reducing chamber is communicated with the air blower. The dust storage temperature reducing chamber is arranged on the lower part of the air blower. With the adoption of the structure and process, except the feed inlet and feed outlet, the rest of the entire device forms a sealed system. The conveying pipe is designed in an ''S'' shape so that the feeding speed is slowed down and the temperature reducing effect is improved. Meanwhile, heat after temperature reduction and small amount of powder generated enter to the dust storage temperature reducing chamber together so as to reduce the temperature and dedust thoroughly, and therefore, quality problem of softened rubber powder and blocking and the like as well as the problem that dust pollutes the environment are solved.

Owner:山东舜合胶业有限公司

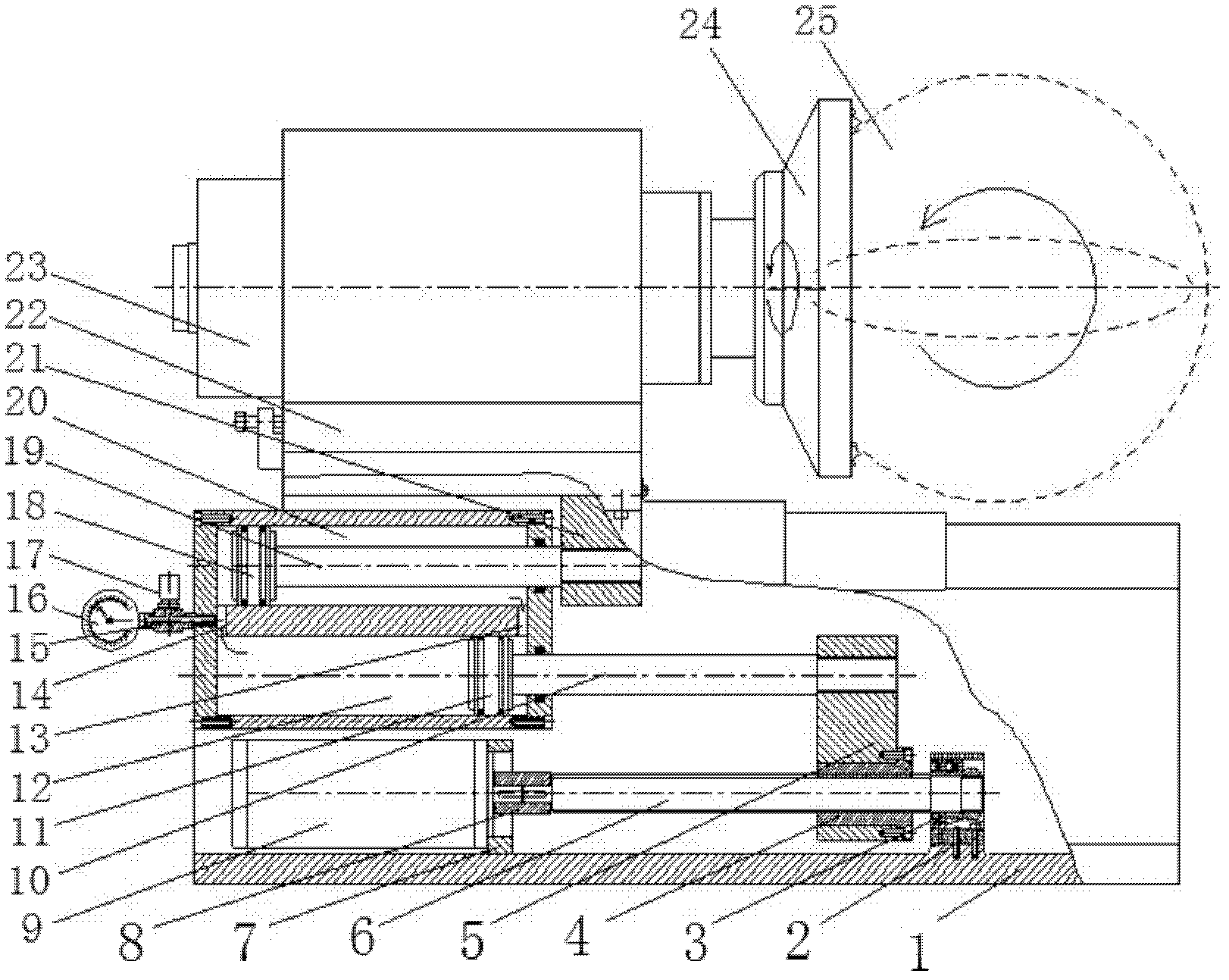

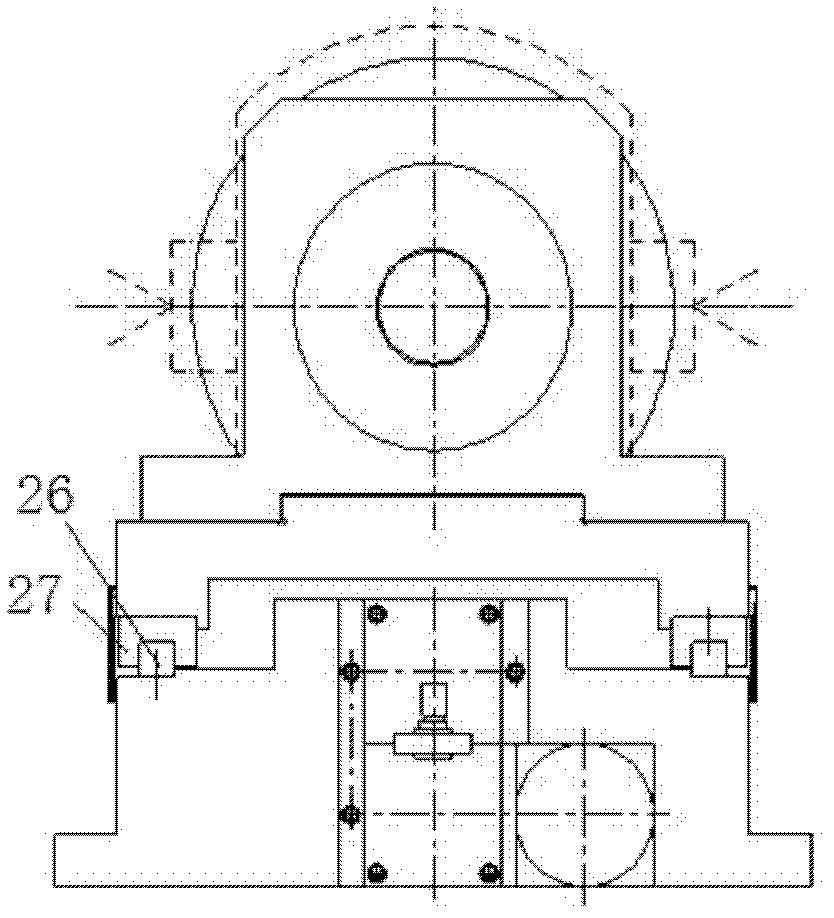

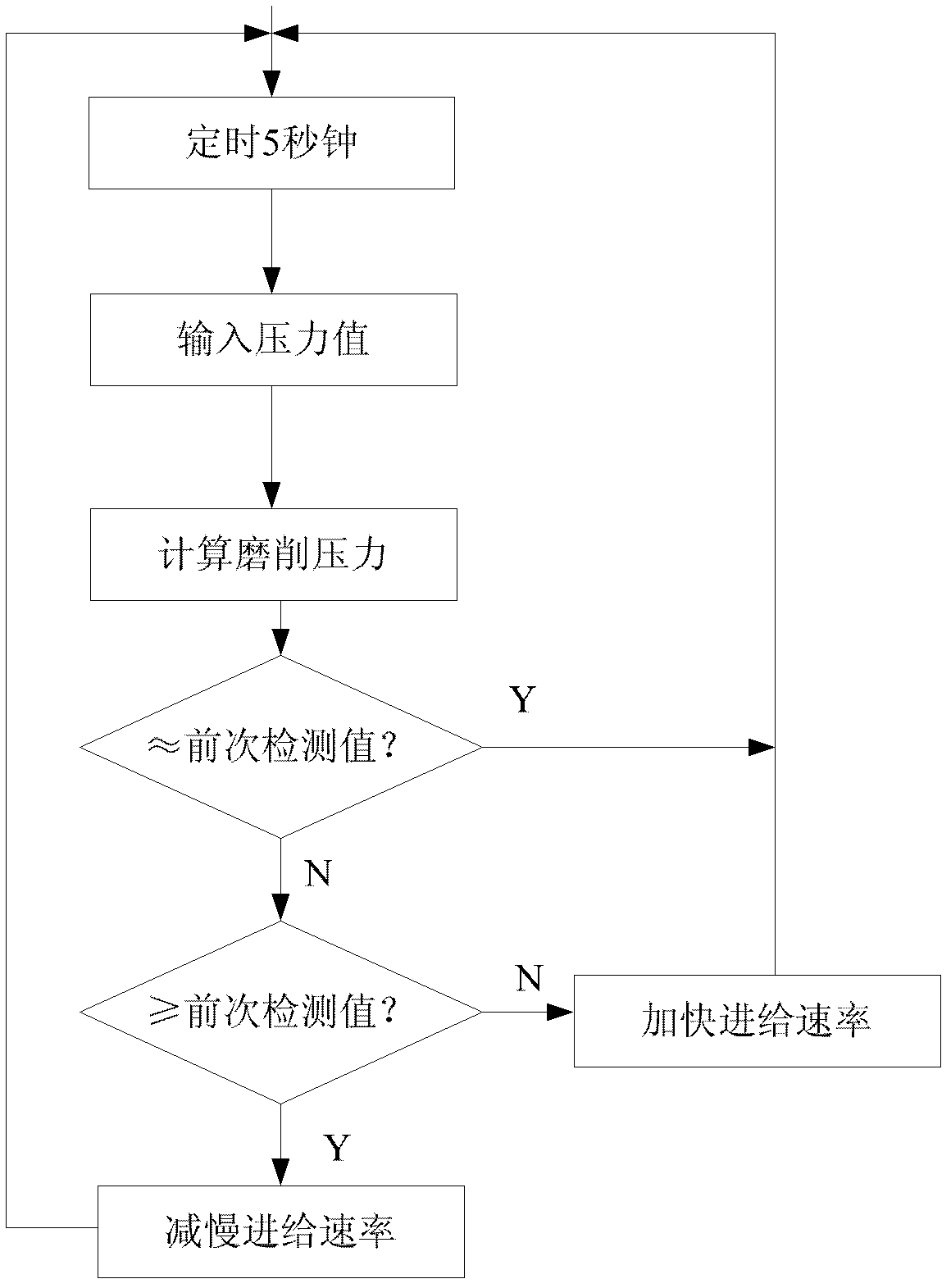

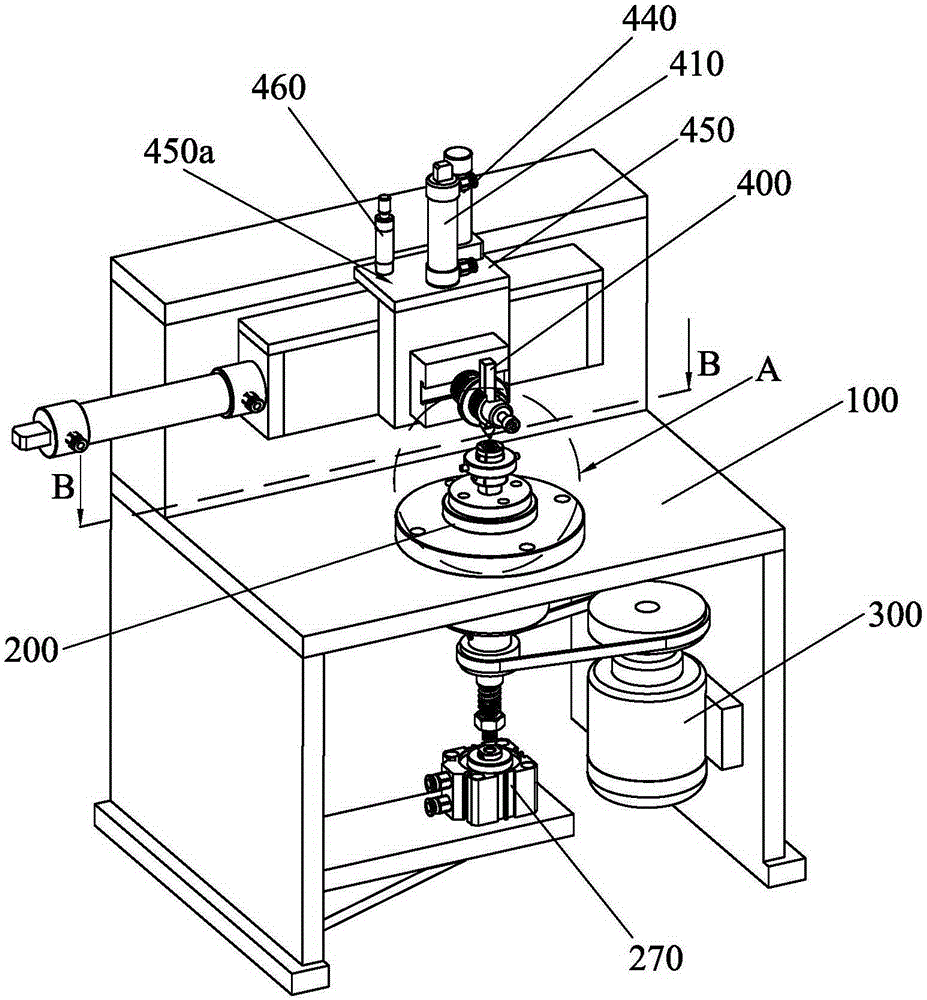

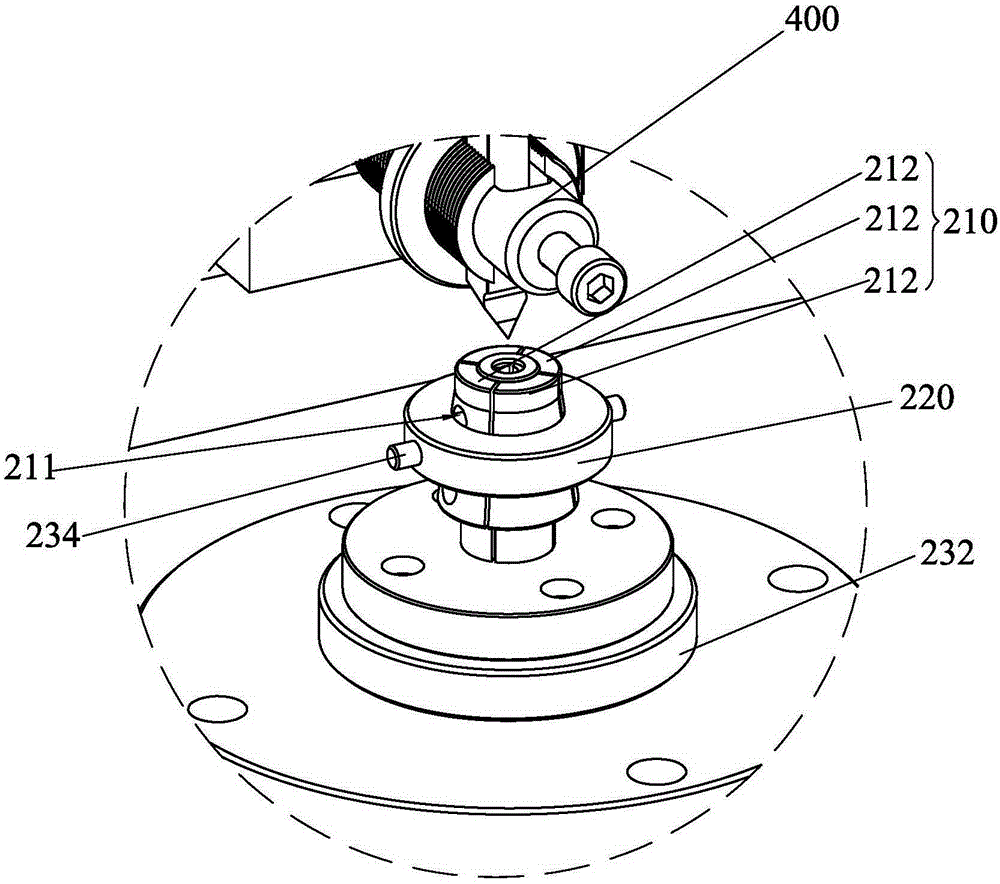

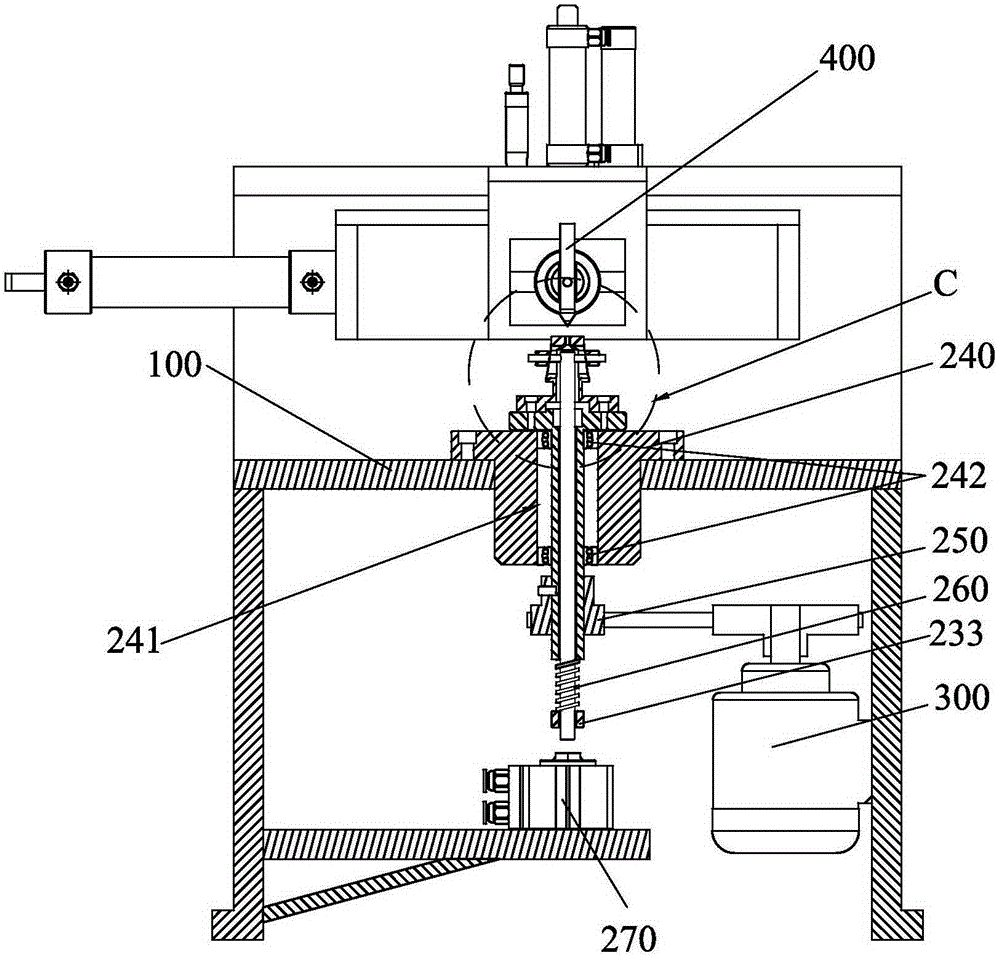

Electromechanical solution combination feeding driving control device in high-hardness spherical precision grinding and method thereof

The invention discloses an electromechanical solution combination feeding driving control device in high-hardness spherical precision grinding and a method thereof; a ball screw is driven by a servo motor to rotate; a nut of the ball screw drives a first piston rod in a first oil cylinder to linearly and to linearly move from right to left move; hydraulic oil driving the left end of a piston in the first oil cylinder flows to the left end of a piston of a second oil cylinder from the first oil cylinder through a left flow channel, so that a second piston rod is driven to move bilaterally; a grinding wheel frame sliding base is driven to carry out feeding movement through a second connection block; when the feeding speed is high and the grinding and removing speed is low, the grinding pressure can be gradually increased; the oil pressures at the left sides of the pistons of the first oil cylinder and the second oil cylinder are increased; the numerical values of a pressure sensor and a pressure gauge installed on a three-way joint are increased; and the feeding speed is determined by obtaining the pressure change of the pressure sensor. According to the device disclosed by the invention, the grinding control with constant pressure can be realized without a complex hydraulic servo system, thus, the feeding rate of a grinding device, the grinding and eliminating rate and the grinding wheel abrasive loss rate are kept balance.

Owner:SHANGHAI JIAO TONG UNIV

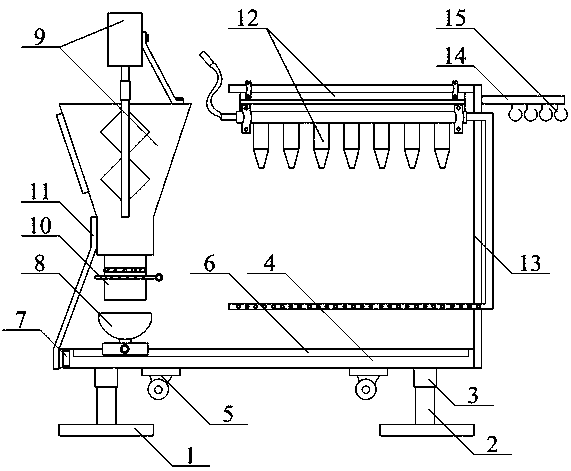

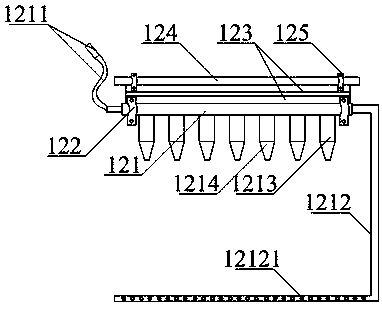

CD grain machine

ActiveCN105234493AStability is not affectedAvoid the problem of insufficient vacuum adsorption forceFeeding apparatusLarge fixed membersEngineeringMechanical engineering

The invention discloses a CD grain machine which comprises a rack, a clamping mechanism, a power device for driving the clamping mechanism to rotate and a cutter shaft mechanism for driving CD grain machining on a workpiece. The clamping mechanism comprises a locating seat used for being fixedly connected to the rack and a pull rod rotationally connected to the locating seat. A clamping barrel and a clamping barrel sleeve used for locking the clamping barrel are arranged on the upper side of the pull rod. The cross section of the outer wall of the clamping barrel is round, and the outer wall of the clamping barrel is gradually increased downwards. The outer wall of the clamping barrel is sleeved with the clamping barrel sleeve, the pull rod is connected to the clamping barrel sleeve, and the clamping barrel sleeve has the motion tendency of clamping the clamping barrel downwards all the time. The cutter shaft mechanism comprises a feeding air cylinder, a locating plate connected to the output end of the feeding air cylinder, a machining cutter driven by the feeding air cylinder, a limiting datum plane and a buffer which is connected to the locating plate and located on one side of the limiting datum plane. When the machining cutter is driven by the feeding air cylinder to move towards the workpiece, the buffer is gradually close to the limiting datum plane and abuts against the limiting datum plane. According to the CD grain machine, the machining quality of the workpiece can be improved.

Owner:东莞市发斯特精密科技股份有限公司

Multifunctional combined feeding device for animal husbandry

InactiveCN107581084AEasy to operateReduce labor operation intensityAnimal watering devicesAnimal feeding devicesWater storageSprayer

The invention provides a multifunctional combined feeding device for the animal husbandry. The feeding device comprises a landing base, an inserted link, an insert tube, a base, universal wheels, slide rails, a switch, a sliding rotation feeding plate structure, a stirrer, a component plate structure, a supporting plate, a water spraying raft structure, a longitudinal supporting beam, a cross beamand a hanging hook. According to the feeding device, the position of a water storage raft can be adjusted through a spring hinge due to the arrangement of a water storage raft, a primary hoop, the spring hinge, a hanging rod and a secondary hoop, the operation is facilitated, and the labor operation intensity is reduced; an external tap water pipe can be connected through a metal hose due to thearrangement of a metal hose, a U-shaped water feeding pipe, a sprayer and a rubber plug, water spraying operation can be carried out through the sprayer, so that breeding of the animal husbandry can be favored, and the using function of the device can be added.

Owner:领投企业管理集团(西安)有限公司

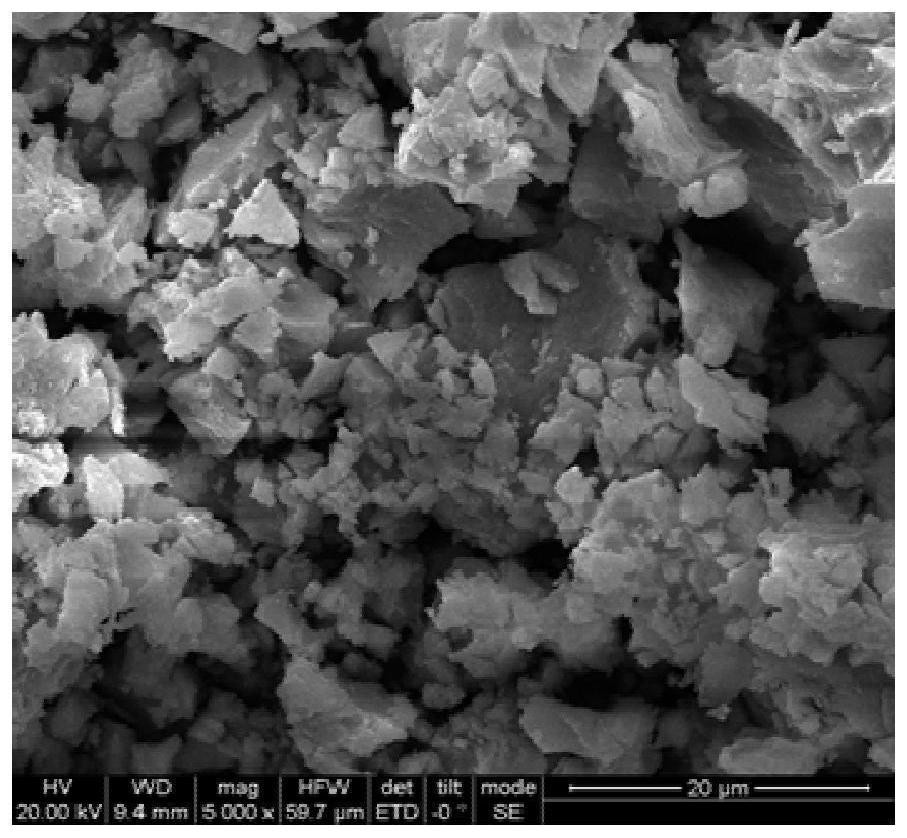

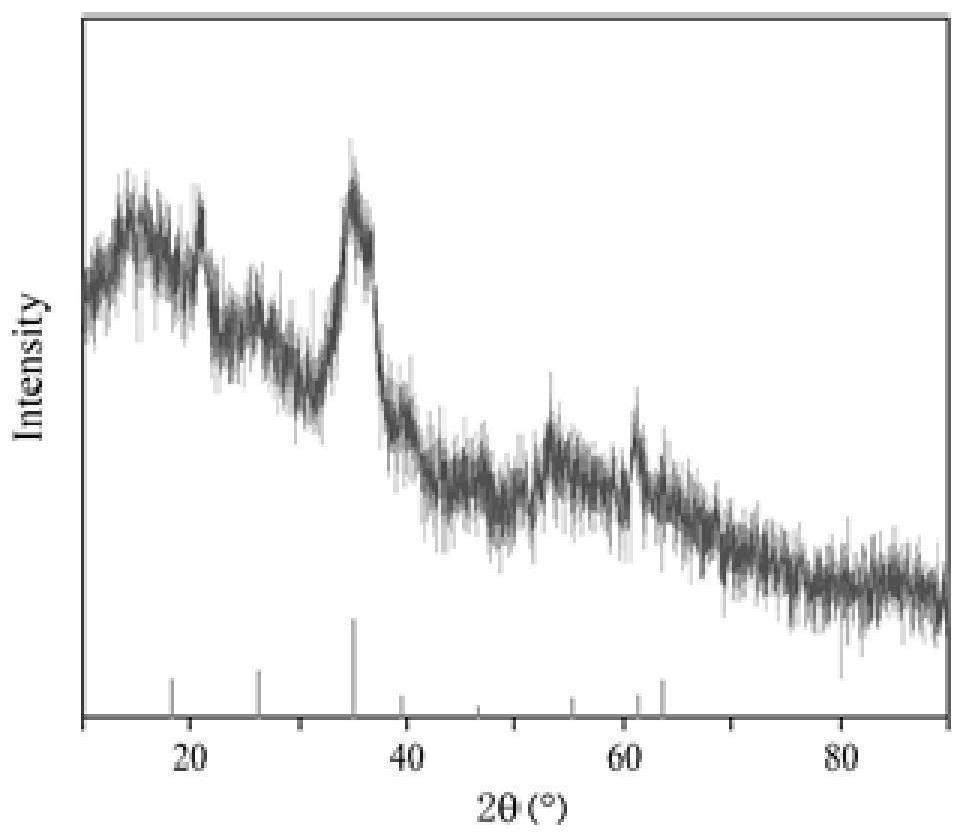

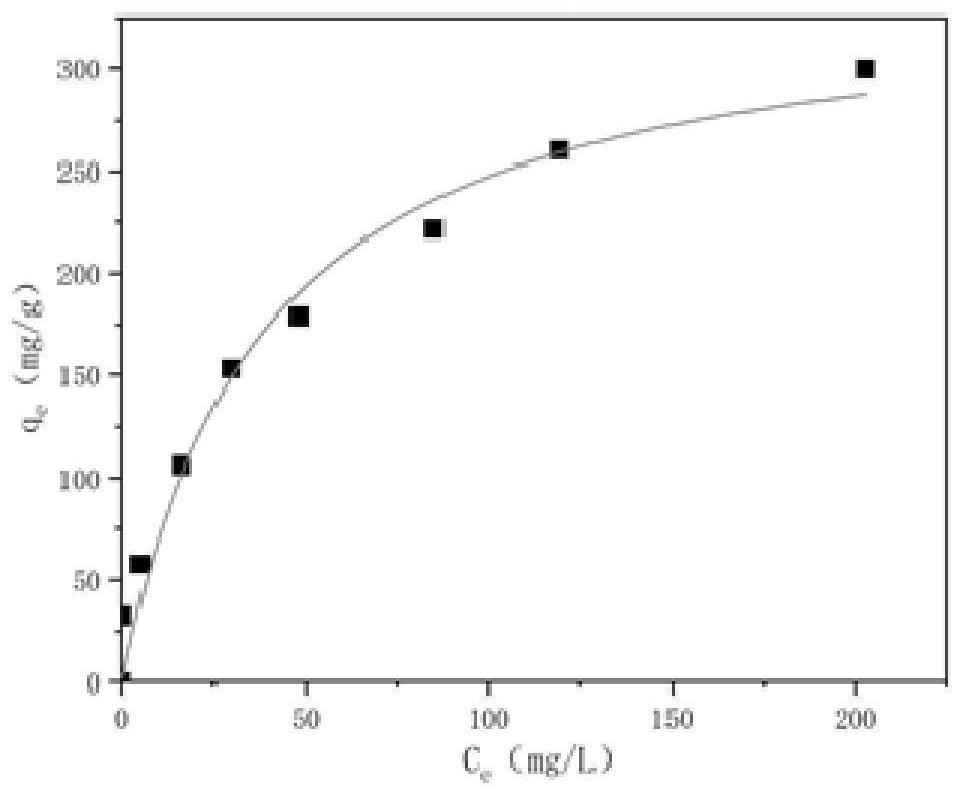

Preparation method and application of Schwertmannite

PendingCN113385138ARealize resource utilizationReasonable quantity controlOther chemical processesWater contaminantsSorbentEnvironmental engineering

The invention discloses a preparation method and application of Schwertmannite. The preparation method comprises the following steps: (1) preparing Schwertmannite by using waste iron as an iron source; and (2) removing As (III) in water by using the prepared Schwertmannite. According to the invention, waste iron blocks are prepared into Schwertmannite, wherein waste iron scraps are completely dissolved with excessive H2SO4, then the iron content is measured, the molar ratio of Fe to H2SO4 is controlled to be (0.9-1): 1, the use amount of all substances can be reasonably controlled, H2O2 is added in batches, the Fe<3+> supply speed is slowed down, the SO4<2-> content is increased, more outer-layer SO4<2-> complexes are generated, As (III) in water can be effectively removed by using the Schwertmannite as an adsorbent, the adsorption reaction time is short, the treated As (III) range is wide (10-200 mg / L), the maximum As (III) adsorption capacity under the same treatment condition is remarkably higher than that of an existing adsorbent, and the product has wide application prospects.

Owner:南京贝克特环保科技有限公司

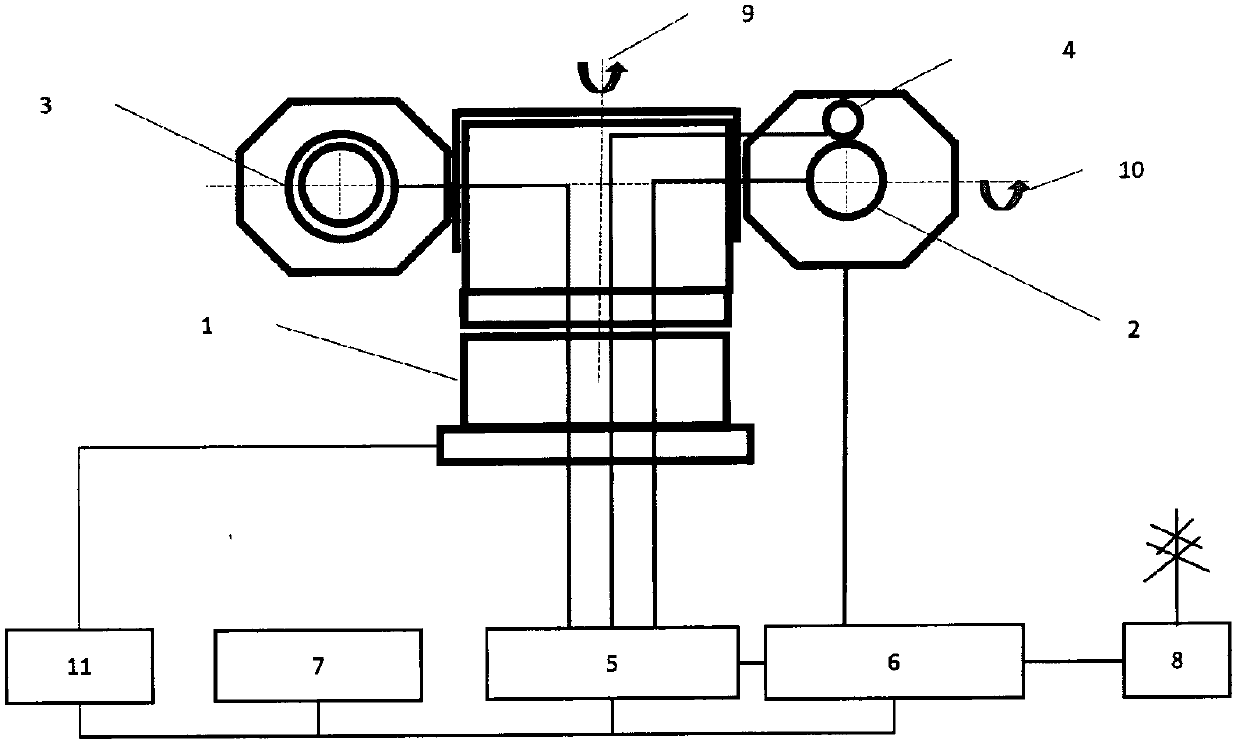

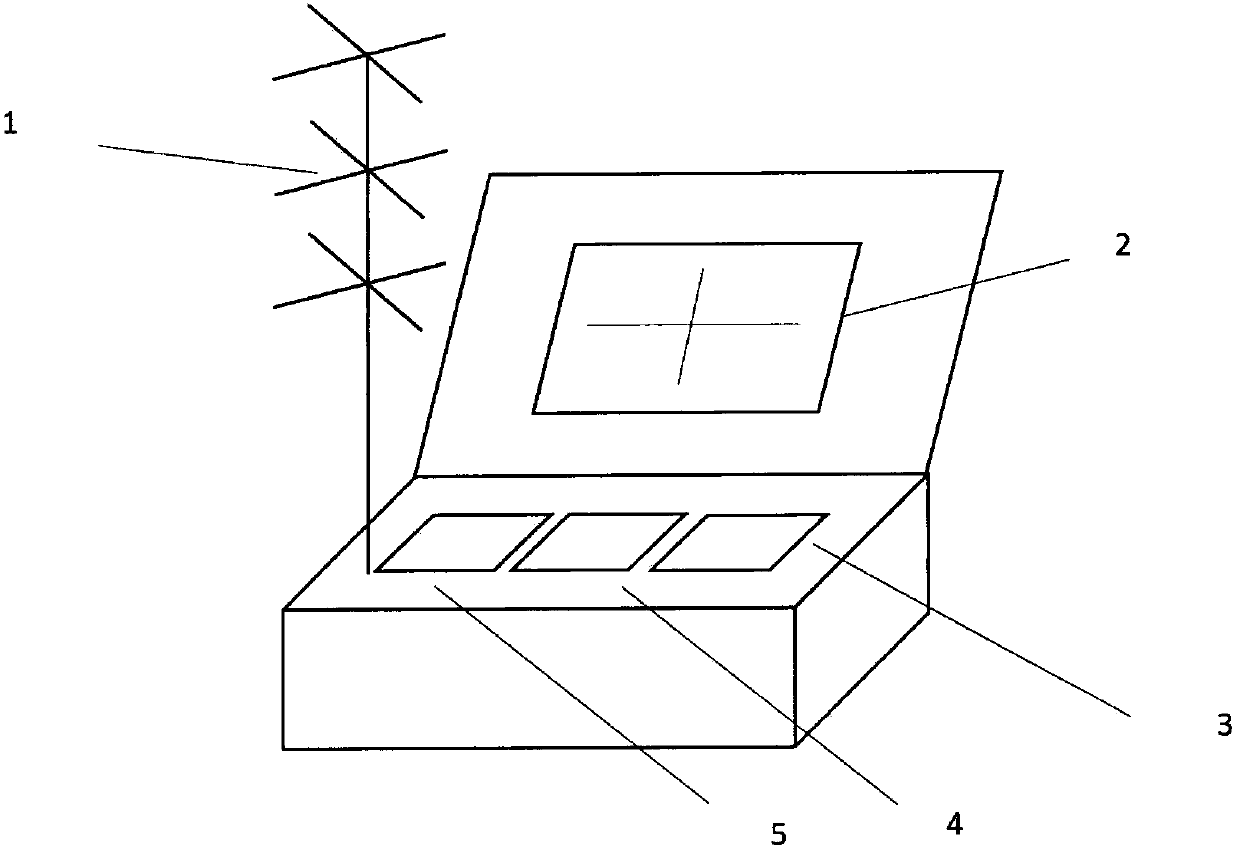

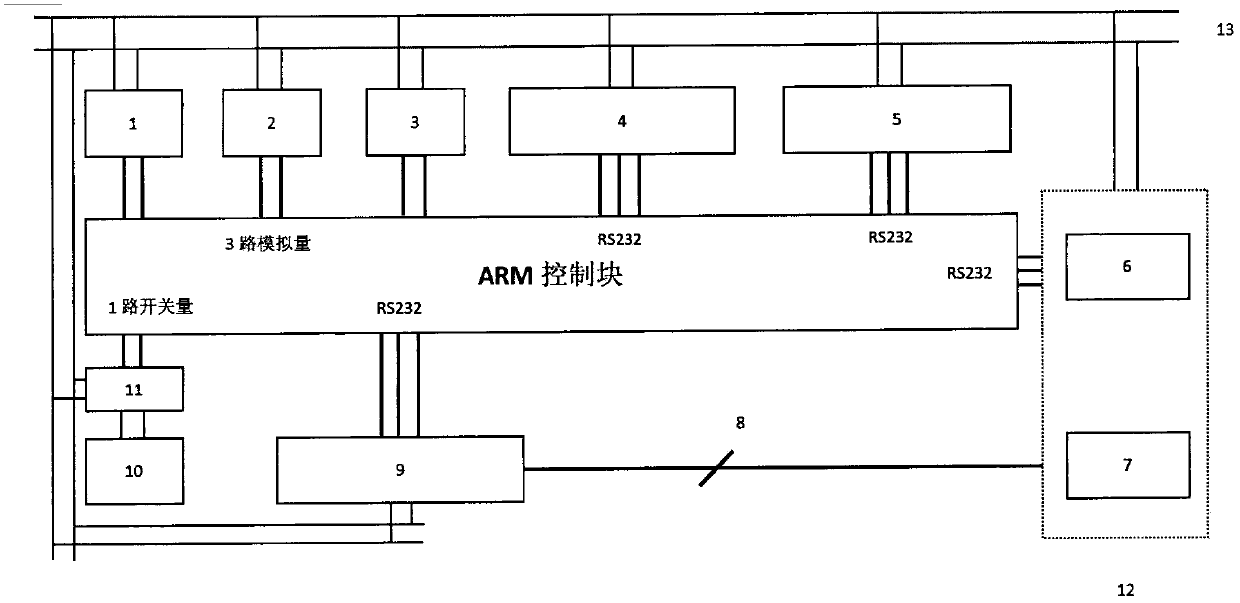

Pose measurement and load sensing device for unmanned earth moving machine

InactiveCN107816079AEliminate fluctuationsSlow down the feed rateSoil-shifting machines/dredgersLaser rangingRemote control

The invention relates to a pose measurement and load sensing device for a unmanned earth moving machine, and mainly solves the problems of operation target confirmation and pose measurement related tothe operation process of the unmanned earth moving machine and load change rule sensing in the working process of an operation head. The device comprises the structures and the contents of a high-precision holder, a focal distance-change and aperture-change camera, an illumination device, a laser distance measurement sensor, an embedded control amplifying module, a remote image and data transmission system, and a display screen with cross lines; oil pressure sensors mounted in an oil inlet of the mounting head and an oil outlet of a main pump are used for detecting pressure change rules; anda remote end operation hand is helped to realize precise and effective control of the feeding speed, the feeding quantity and the feeding direction of the operation head. The device has the followingadvantages: cheap, reliable and practical pose measurement and load sensing solutions and devices are provided for remote control of precise and effective operations.

Owner:ARMY ENG UNIV OF PLA

Feeding method and apparatus for sheet-shaped recording material

ActiveUS7222849B2Slow down the feed rateGuaranteed uptimeOther printing apparatusArticle feedersEngineeringPosition sensor

Owner:FUJIFILM CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com