Machine and method for winding reels of web material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

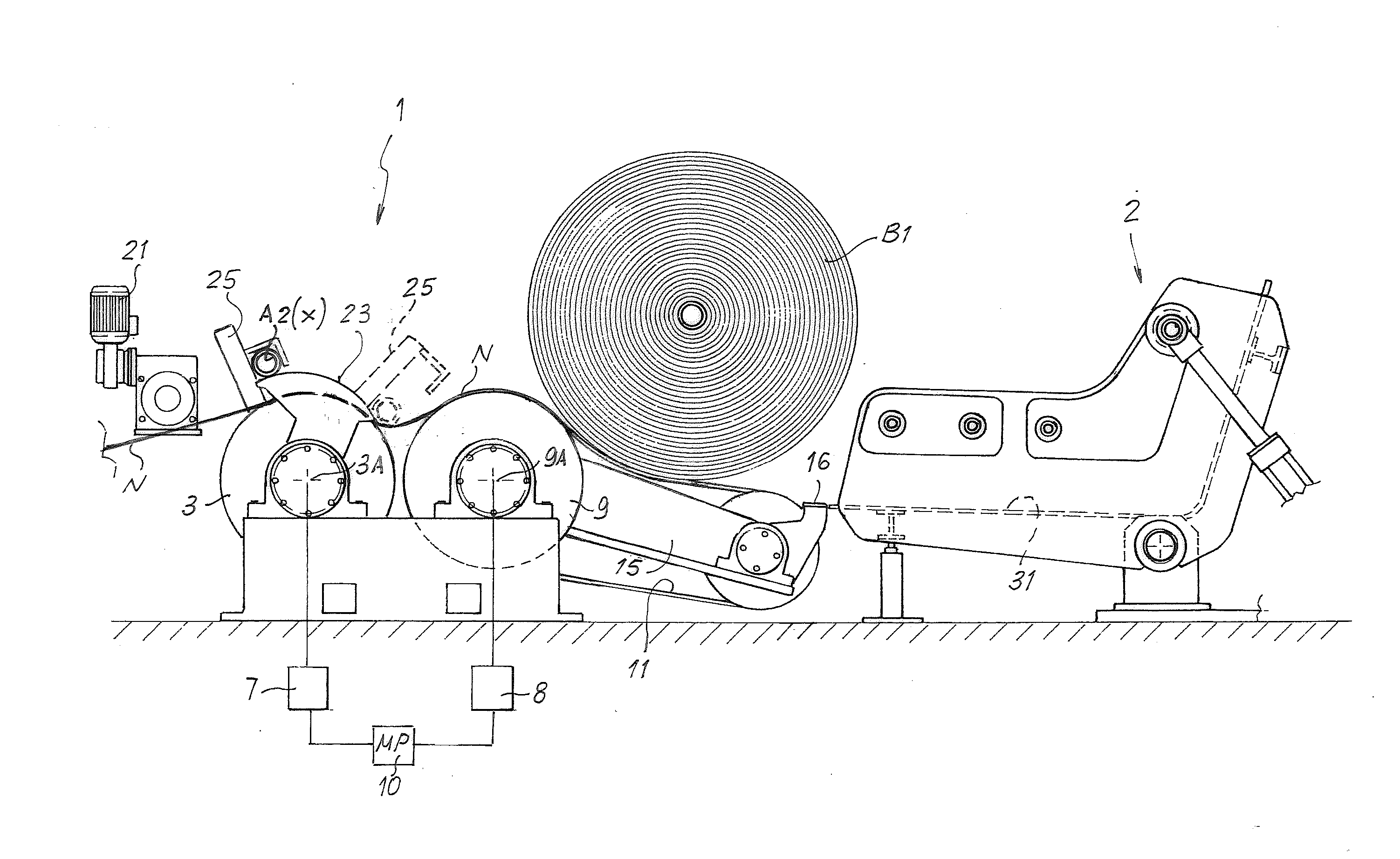

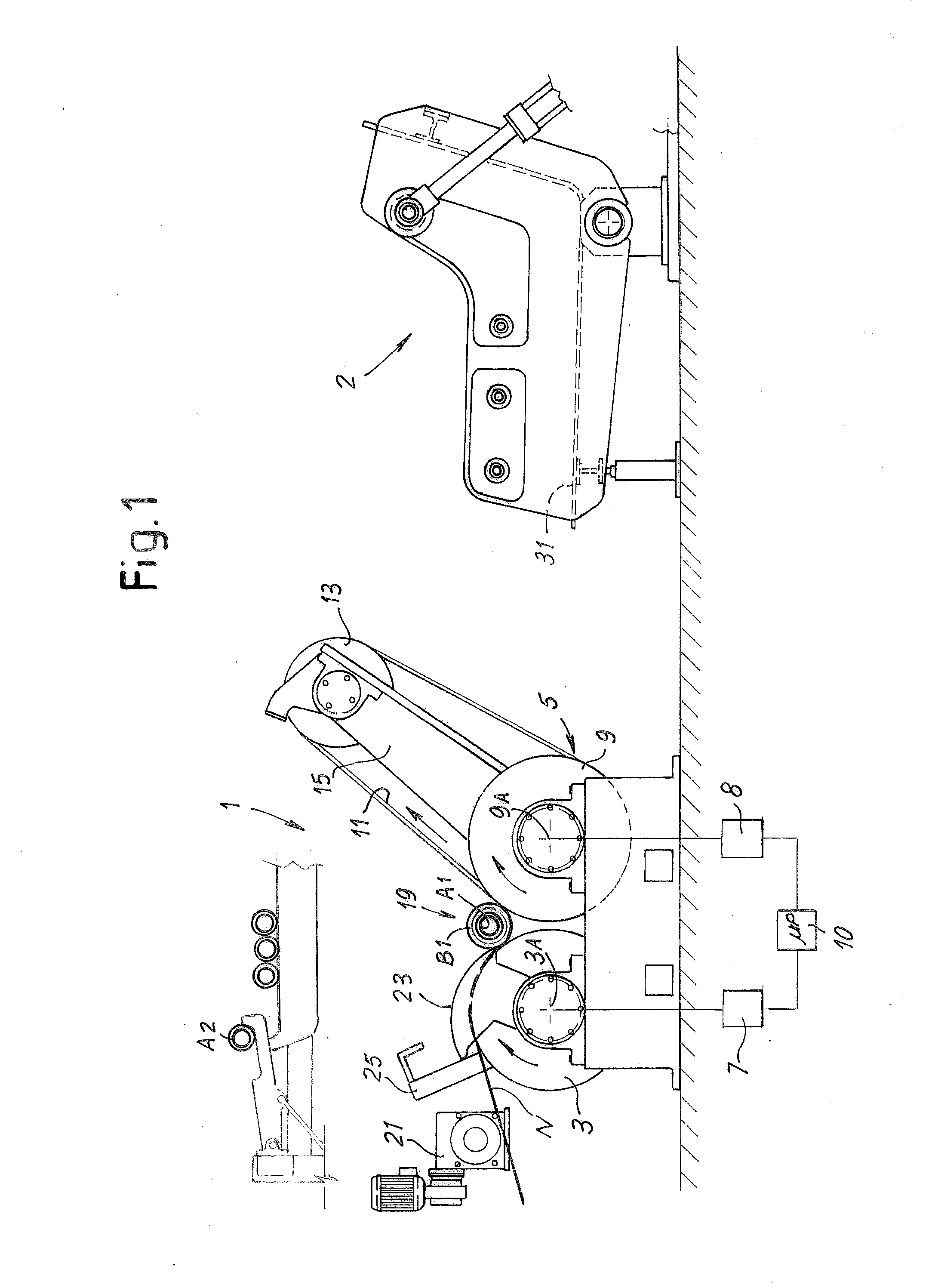

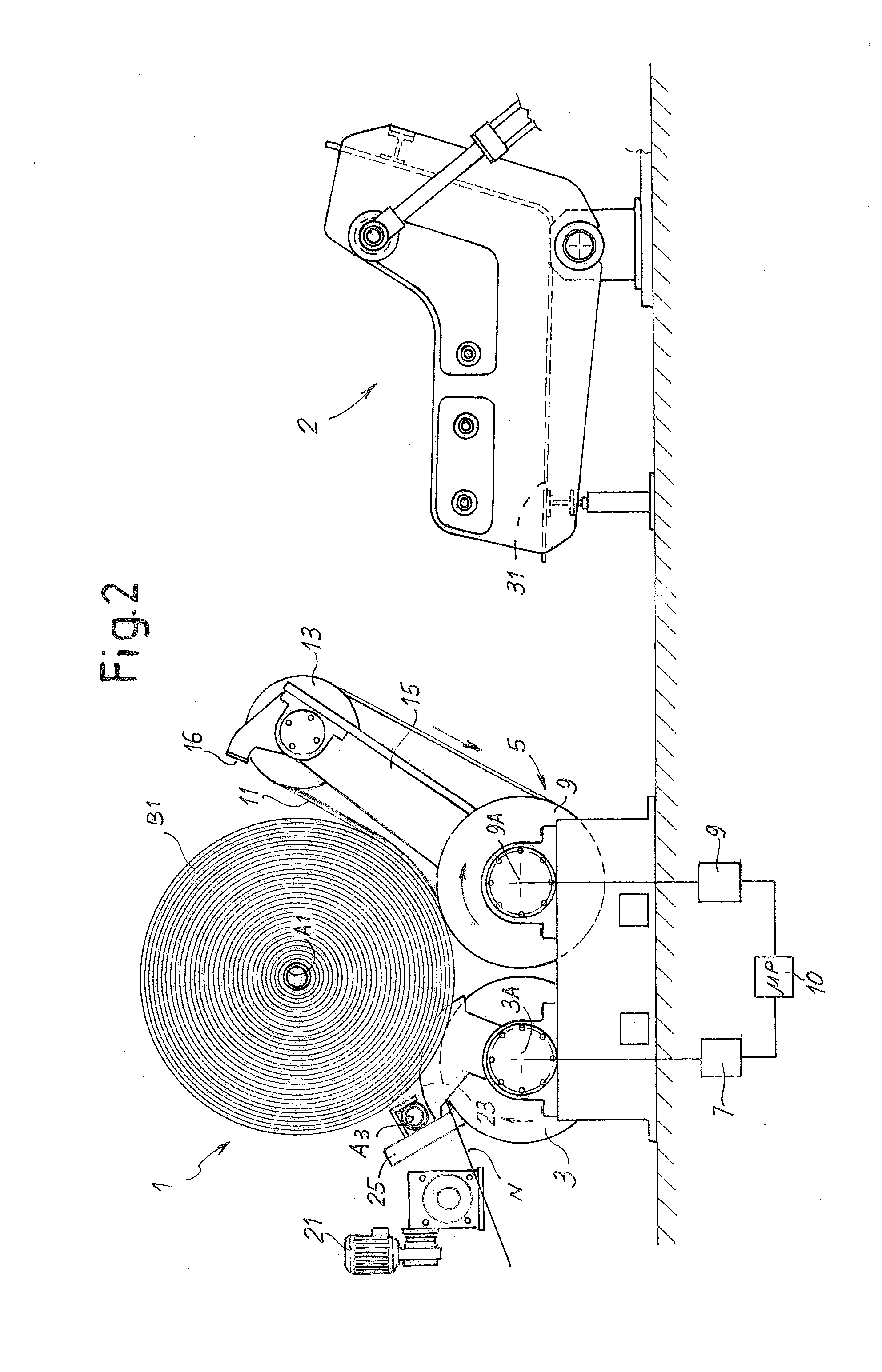

[0067]The rewinding machine, indicated in its entirety with number 1, comprises a first winding member 3 and a second winding member 5. In some embodiments the first winding member 3 is constituted by, or comprised of, a winding roller rotating around a substantially horizontal axis 3A. The rotation of the roller is controlled by an electric motor, schematically indicated with number 7.

[0068]In some embodiments, the second winding member 5 comprises a second winding roller 9 rotating around a substantially horizontal axis 9A substantially parallel to the axis 3A of the winding roller 3. The winding rollers 3 and 9 form a nip therebetween and define a winding cradle.

[0069]In some embodiments the winding roller 9 is driven into rotation by a second motor 8, distinct from the motor 7. The motors 7 and 8 are preferably connected to a central control unit 10, with which also the other members of the machine are interfaced to perform the winding cycle described below. The control unit 10 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| rotation speed | aaaaa | aaaaa |

| speed | aaaaa | aaaaa |

| speed | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com