Laser beam machine

A laser processing machine and laser beam technology, applied in laser welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of inadvertently cutting materials, lowering nesting efficiency, and difficulty in high-speed processing, and achieve the elimination of inadvertently cutting materials. , Reduce the production manpower, and realize the effect of high speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

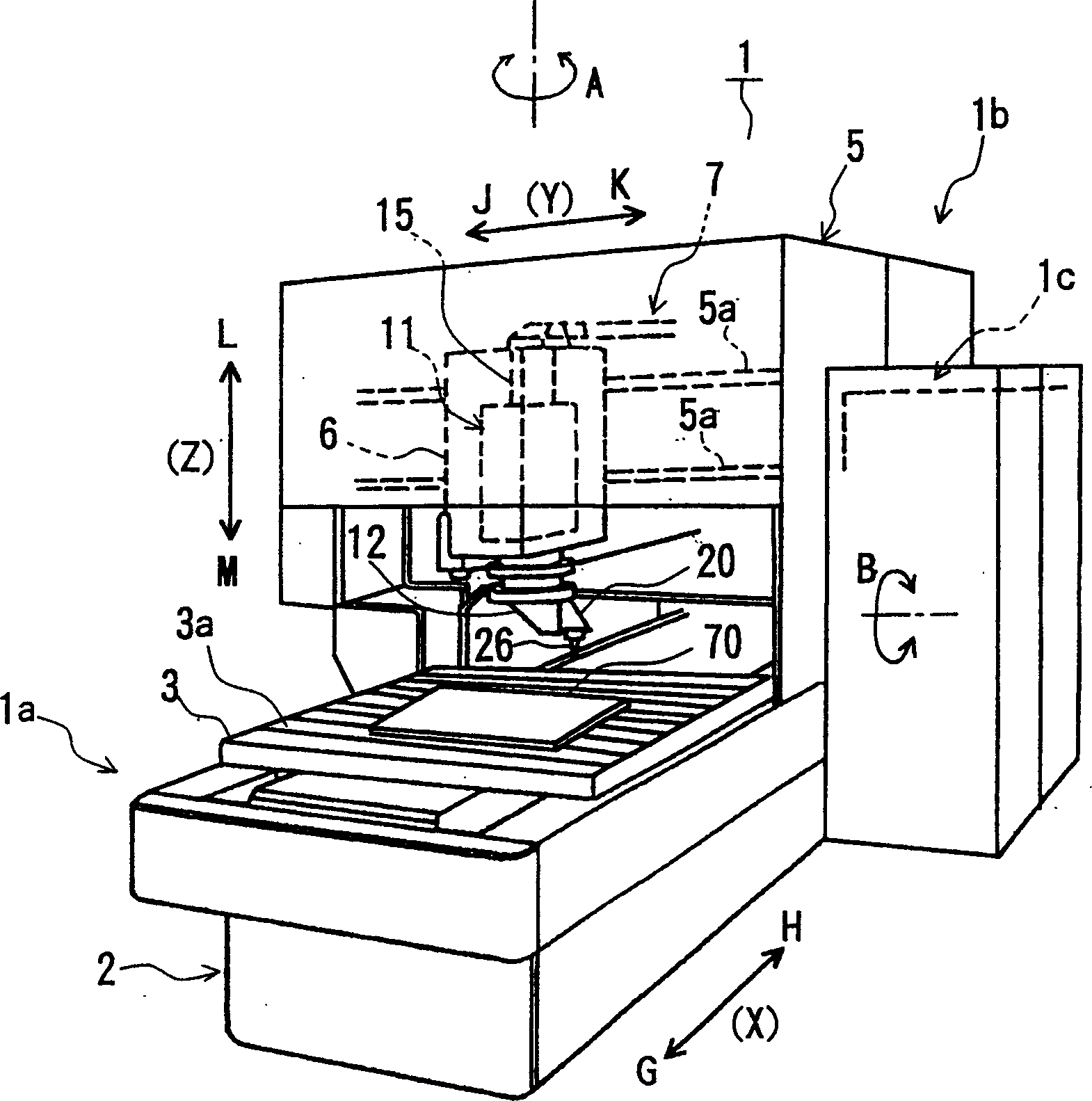

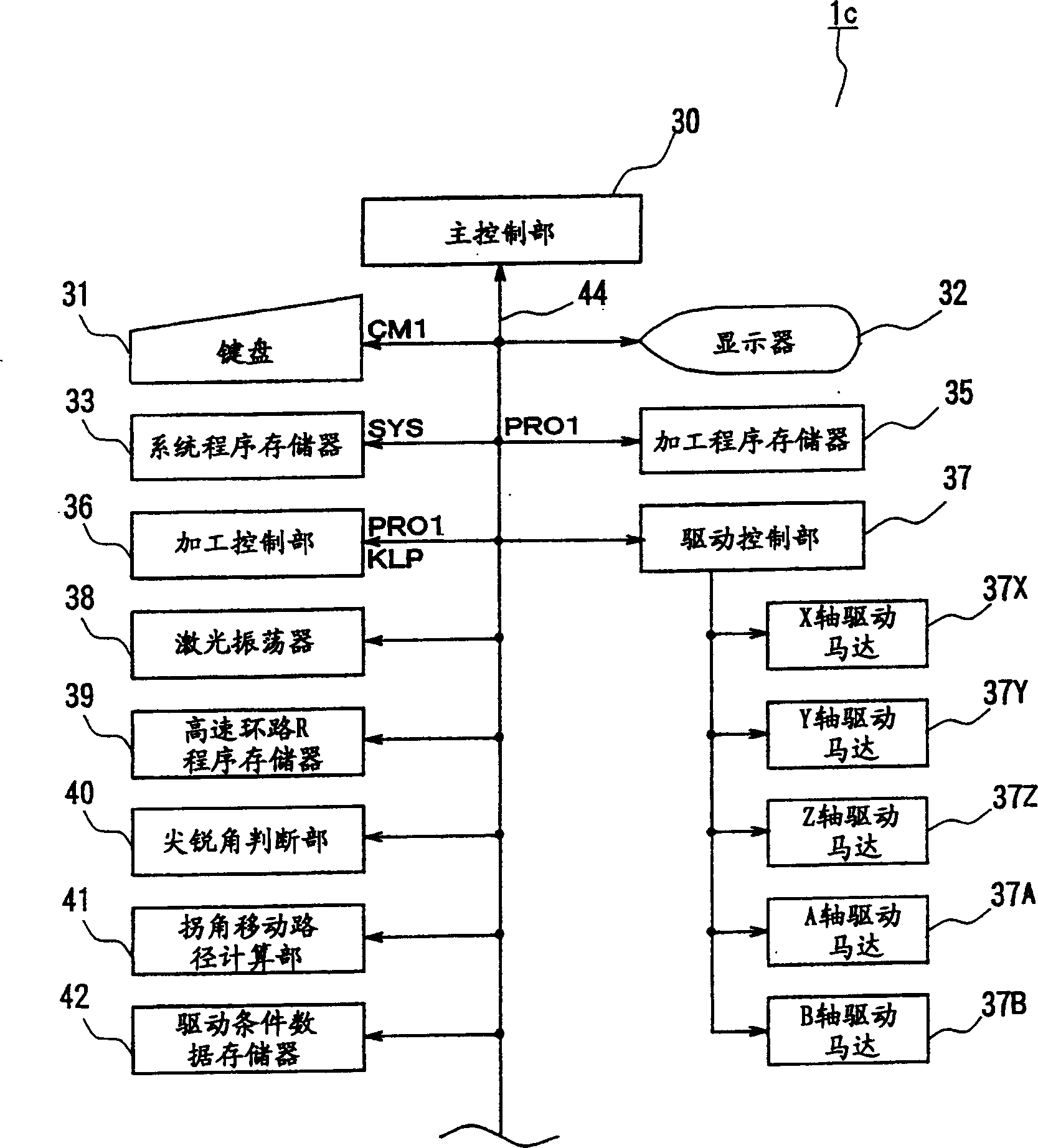

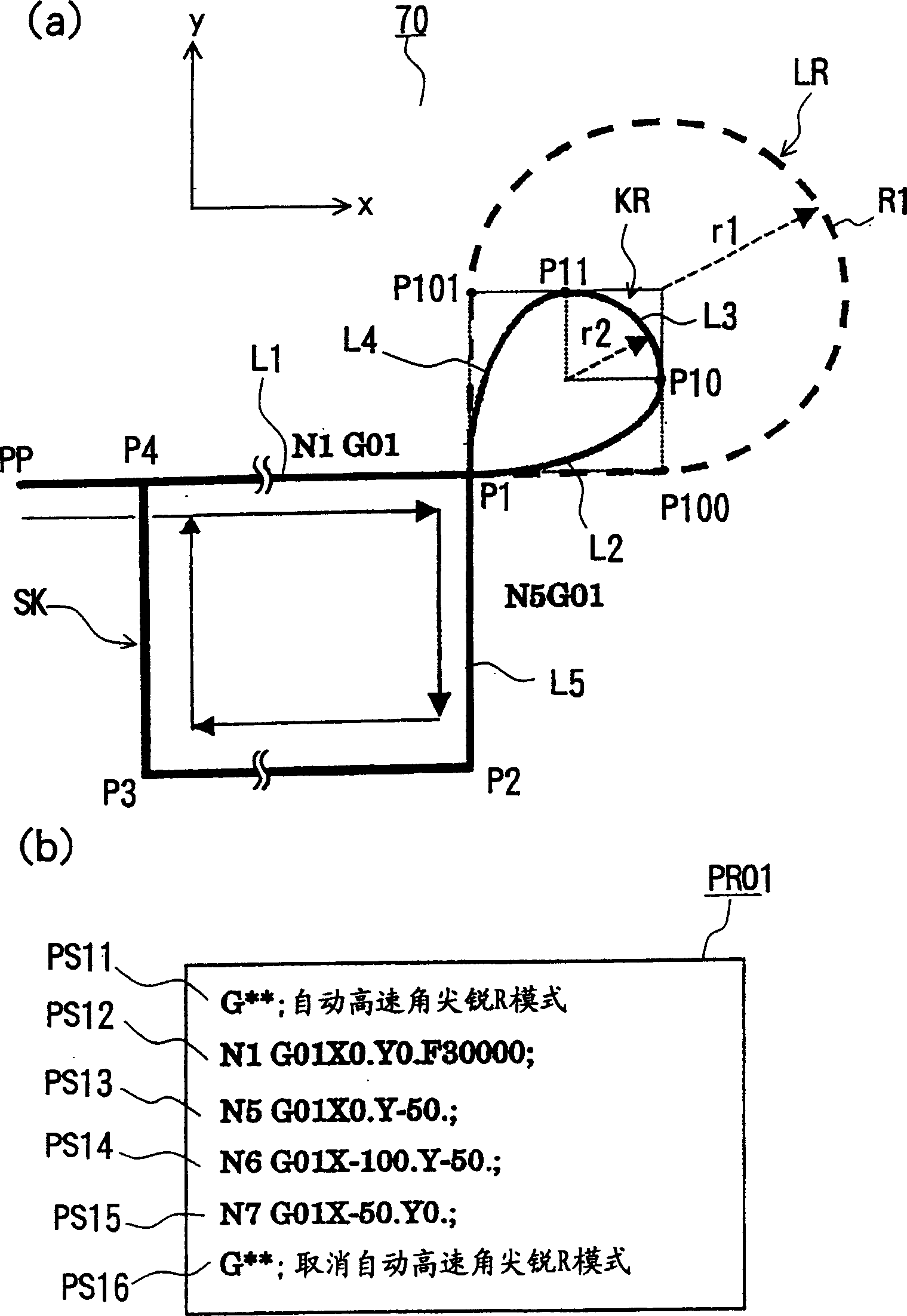

[0025] figure 1 It is an overall perspective view of a laser processing machine applicable to the present invention, figure 2 yes figure 1 A block diagram of the control device in the laser processing machine, image 3 It is a diagram showing an example of the cutting form near the corner part of the workpiece, (a) is a diagram of a high-speed loop R of the moving path, (b) is a diagram of an example of a machining program, Figure 4 is a flowchart showing the contents of the automatically generated program JSP which is a subroutine of the high-speed loop R program, Figure 5 It is an explanatory diagram of the execution of the high-speed loop R program, (a) is an explanatory diagram of the calculation of the moving path, (b) is a moving diagram of the nozzle along the high-speed loop R, Figure 6 is a graph of each cutting path based on the corner angle.

[0026] Laser processing machine 1 applicable to the present invention, such as figure 1 As shown, for example, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com