Patents

Literature

163results about How to "Improve nesting efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

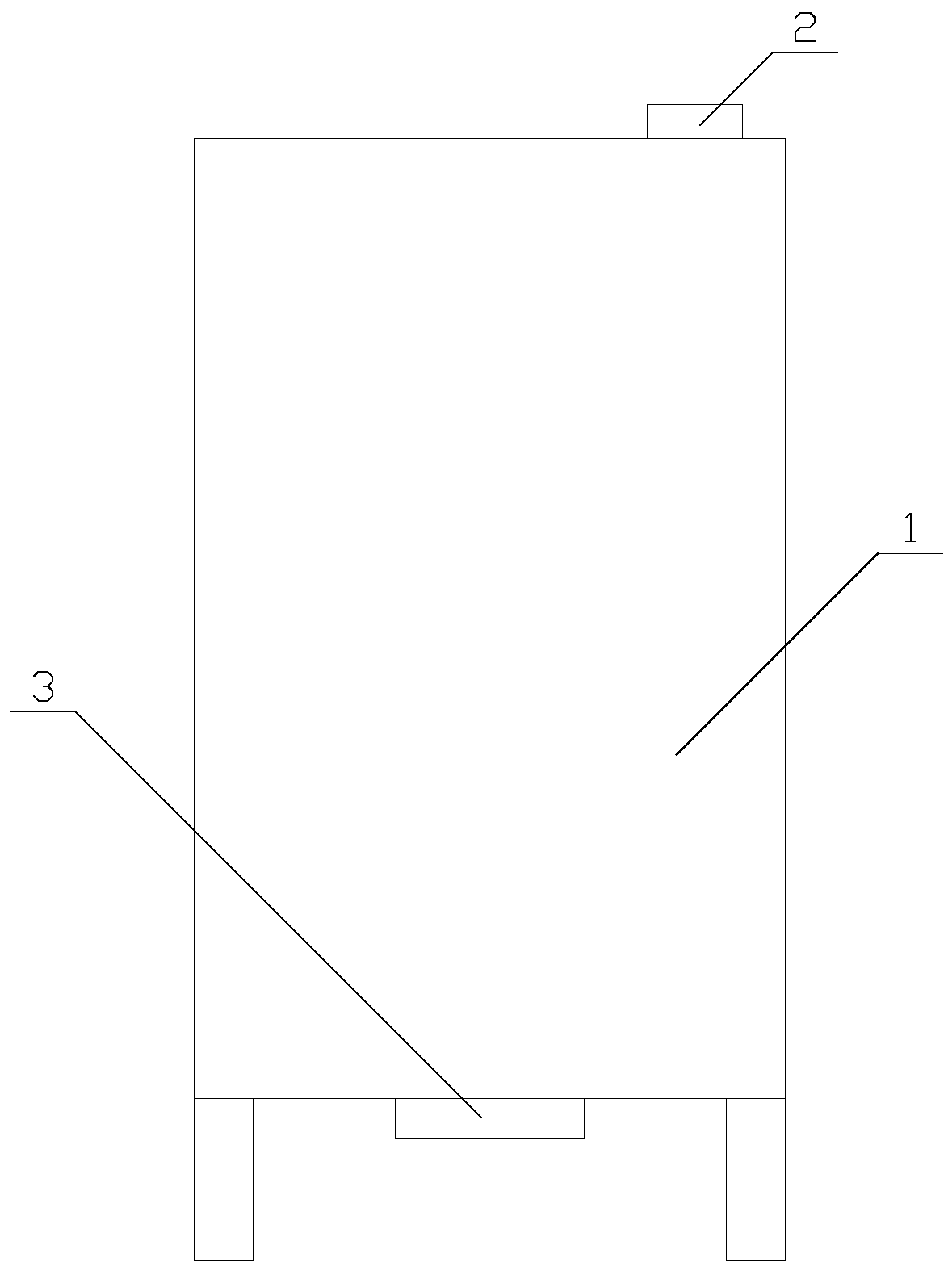

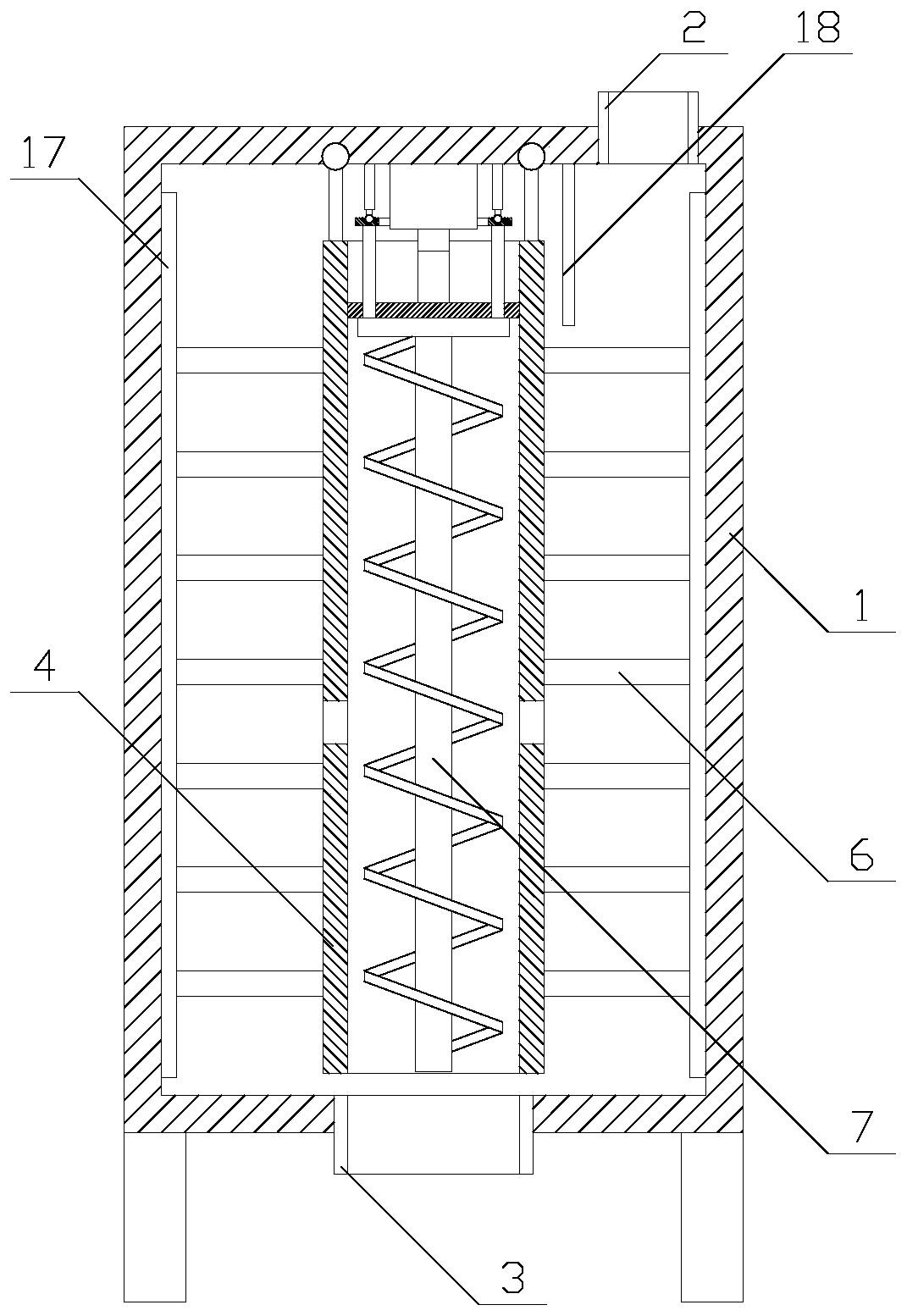

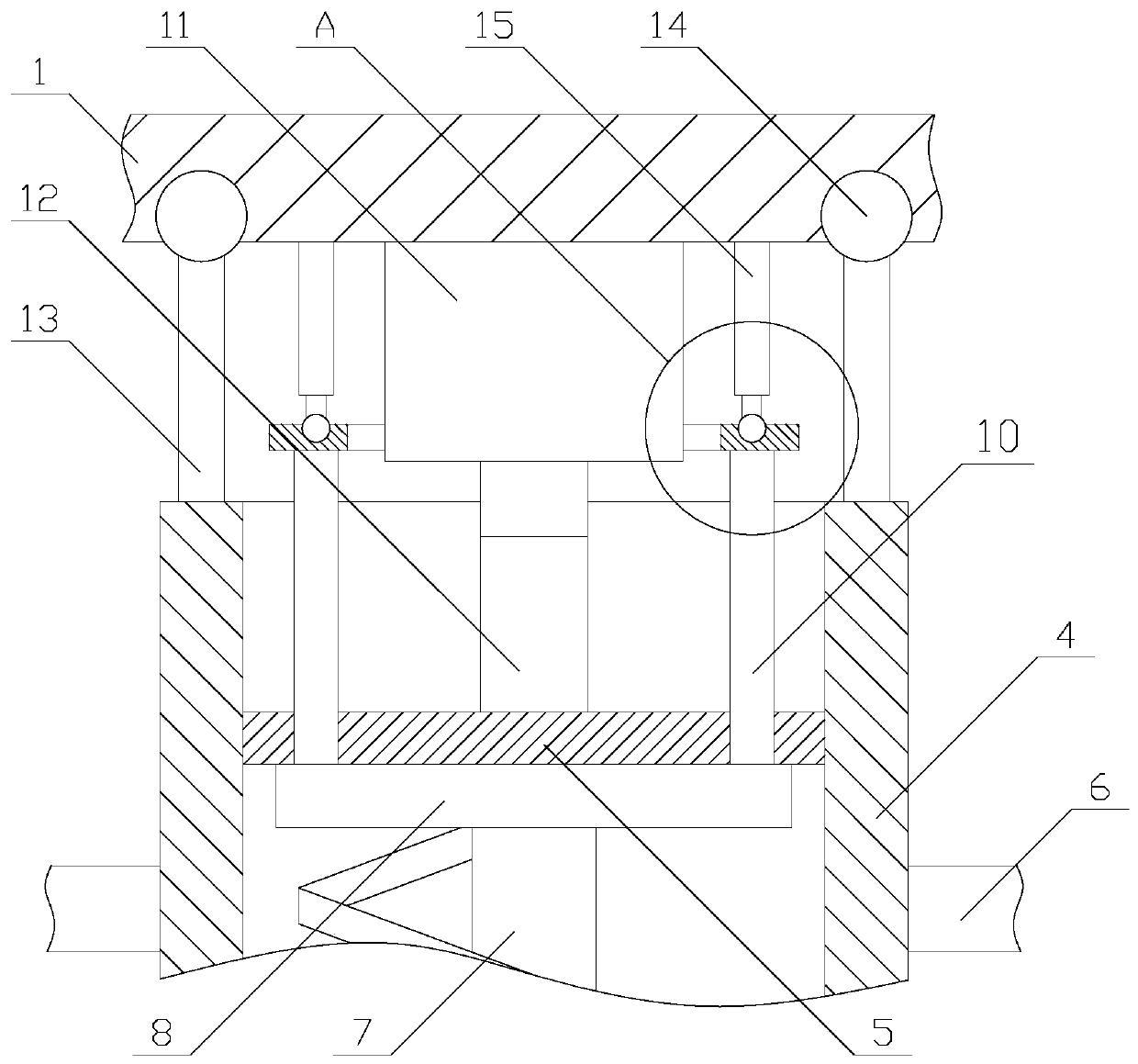

Two-way stirring anti-deposition building mortar mixing and discharging tank

InactiveCN107599170AEasy to addEvenly distributedCement mixing apparatusArchitectural engineeringEngineering

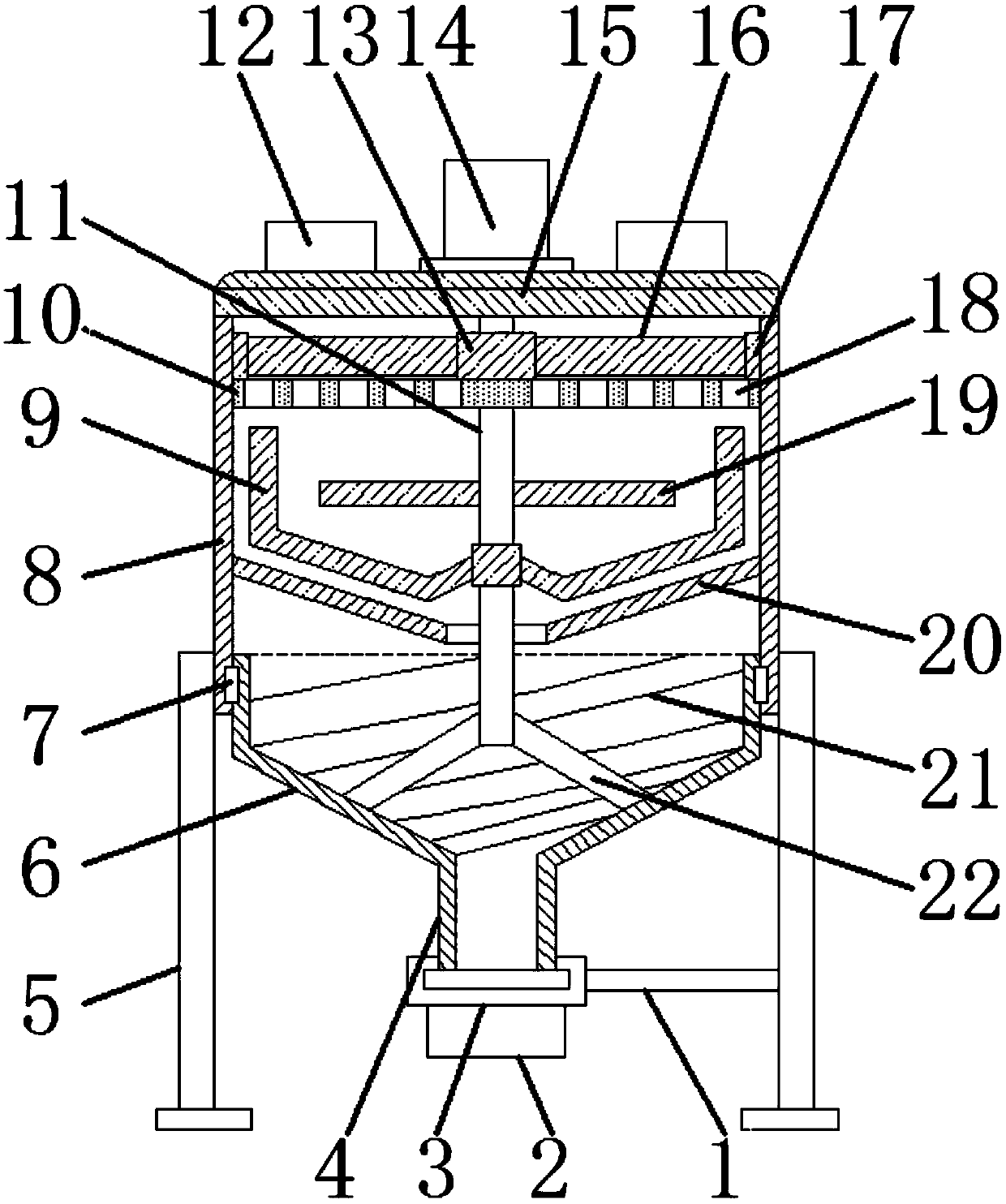

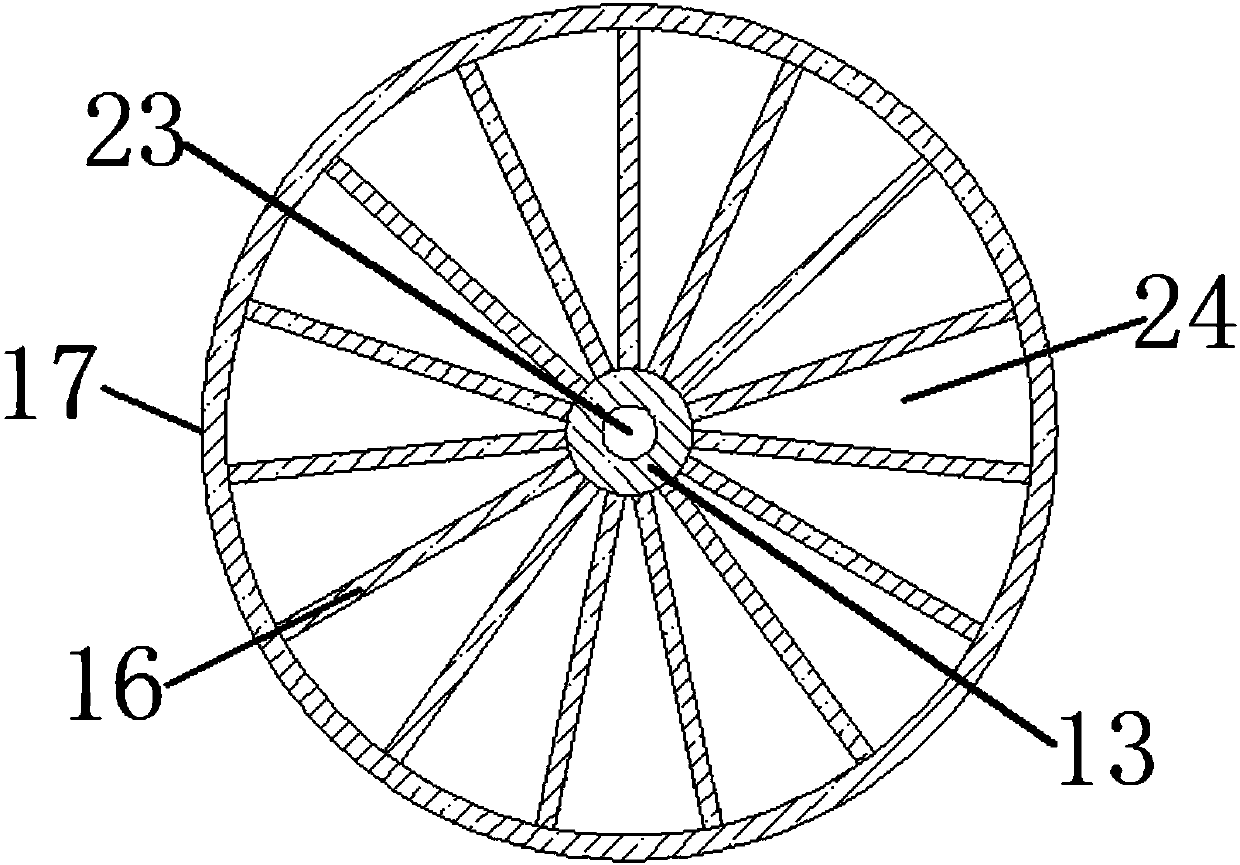

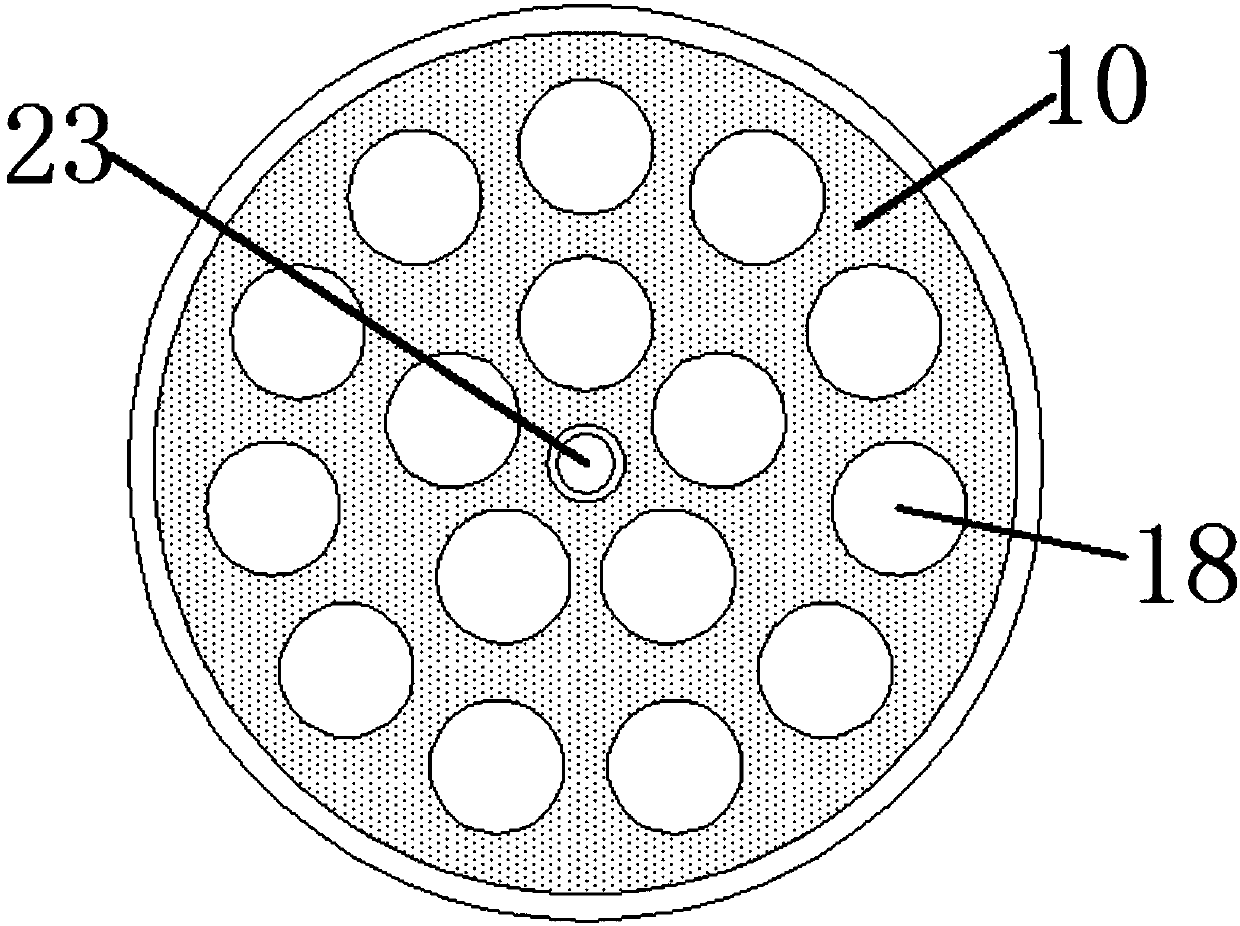

The invention discloses a two-way stirring anti-deposition building mortar mixing and discharging tank. The two-way stirring anti-deposition building mortar mixing and discharging tank comprises a discharging hopper, a mixing tank body, a uniformizing disc, a pushing rod, a buffering hopper and a spiral guiding bar. A rack is welded to the bottom side of the mixing tank body, and a tank cover is connected to the top end of the mixing tank body. A motor is mounted in the middle of the top end of the tank cover and connected with a rotating shaft. The uniformizing disc is arranged below the pushing rod and welded to the inner wall of the mixing tank body. A plurality of distributing holes are uniformly formed in the uniformizing disc. The discharging hopper is mounted at the bottom of the mixing tank body and provided with the spiral guiding bar. When the discharging hopper rotates anticlockwise, pouring mortar in a spiral diversion groove slides towards the upper side and the outer sideunder stirring of the spiral guiding bar so as to be prevented from being deposited; and when the discharging hopper rotates clockwise, the pouring mortar in the spiral diversion groove slides towards the lower side and the inner side under stirring of the spiral guiding bar and moves to a discharging pipe to be discharged rapidly so as to prevent deposition blocking, and thus the building mortardischarging efficiency is improved.

Owner:杨光

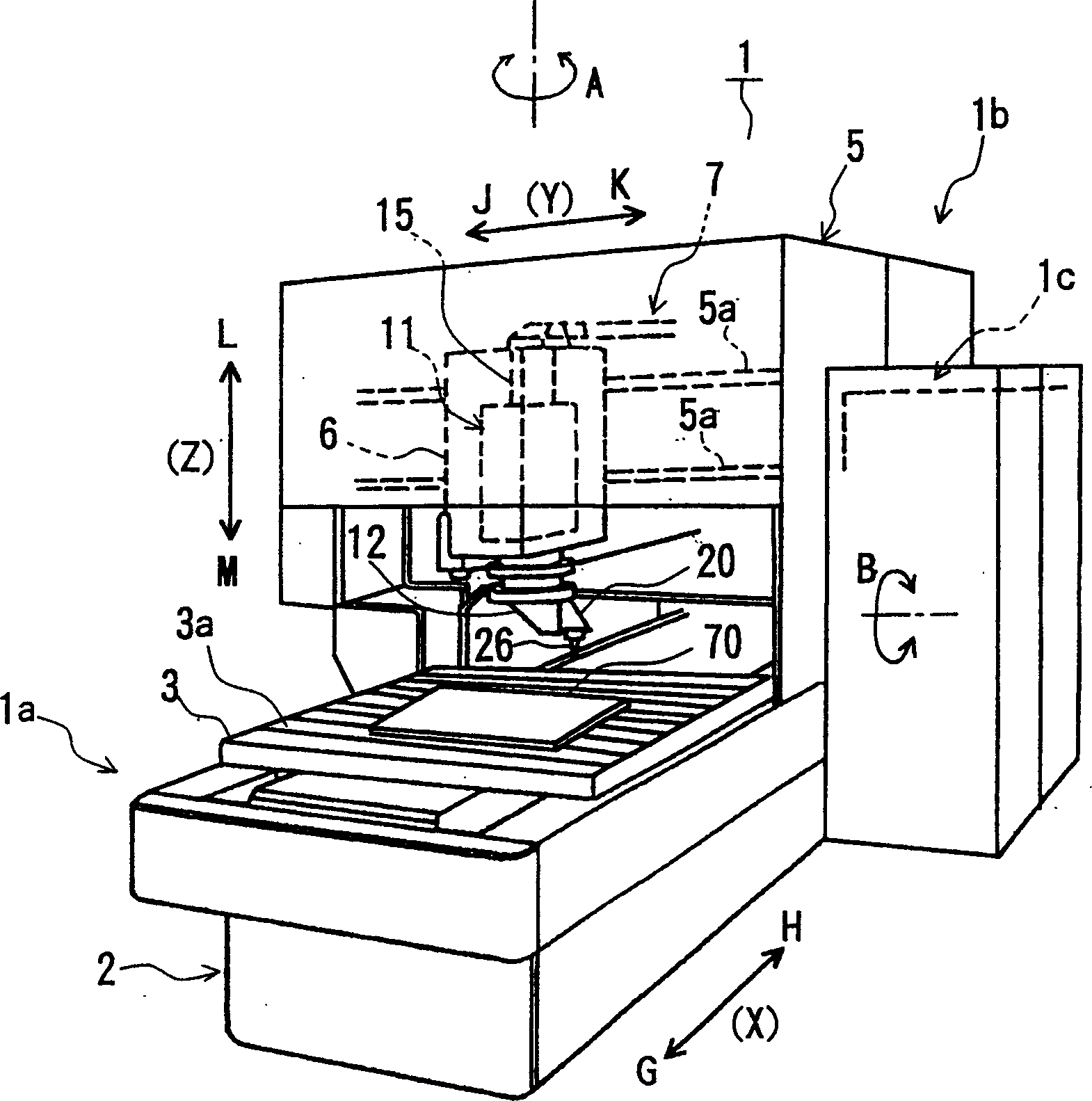

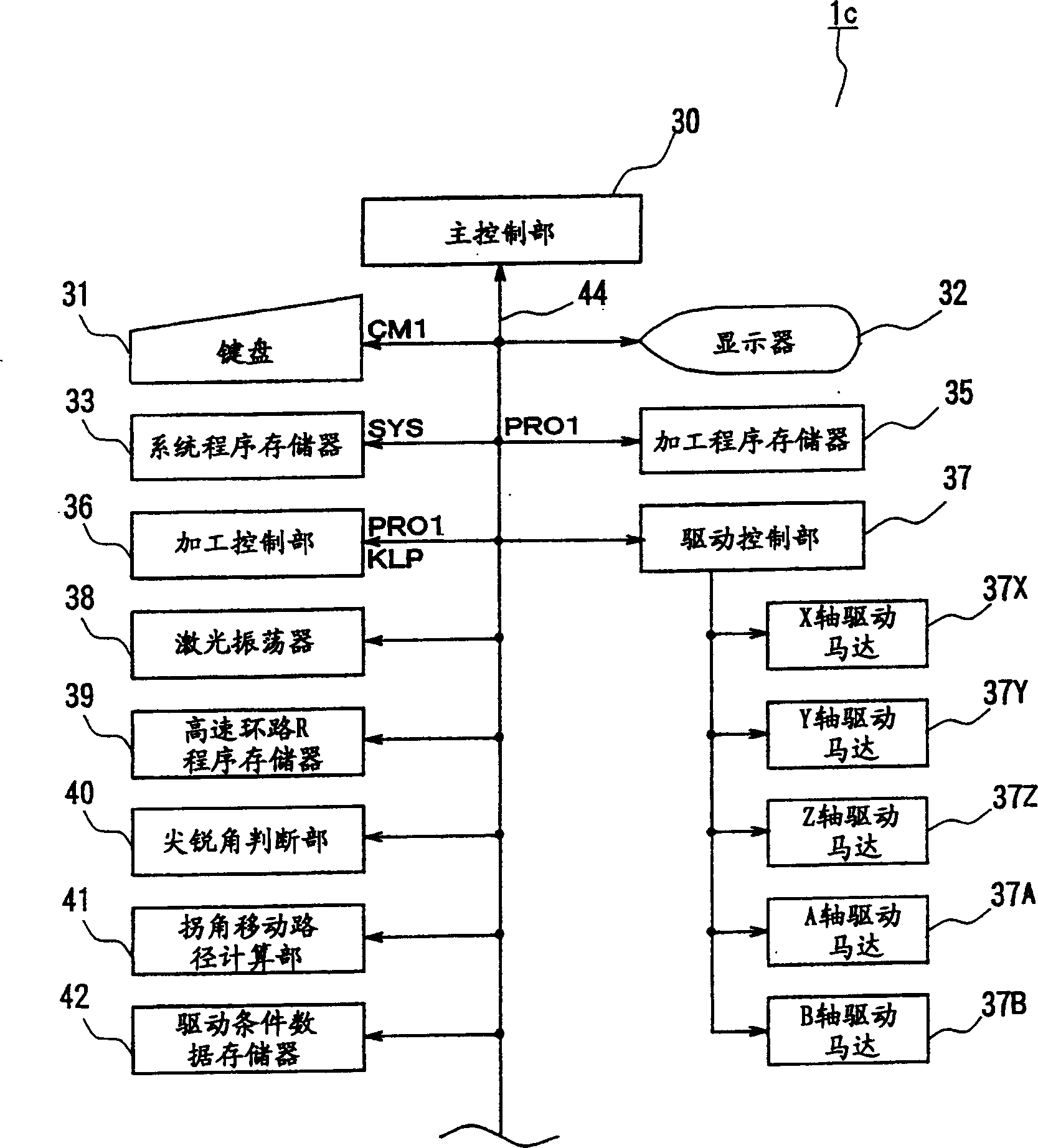

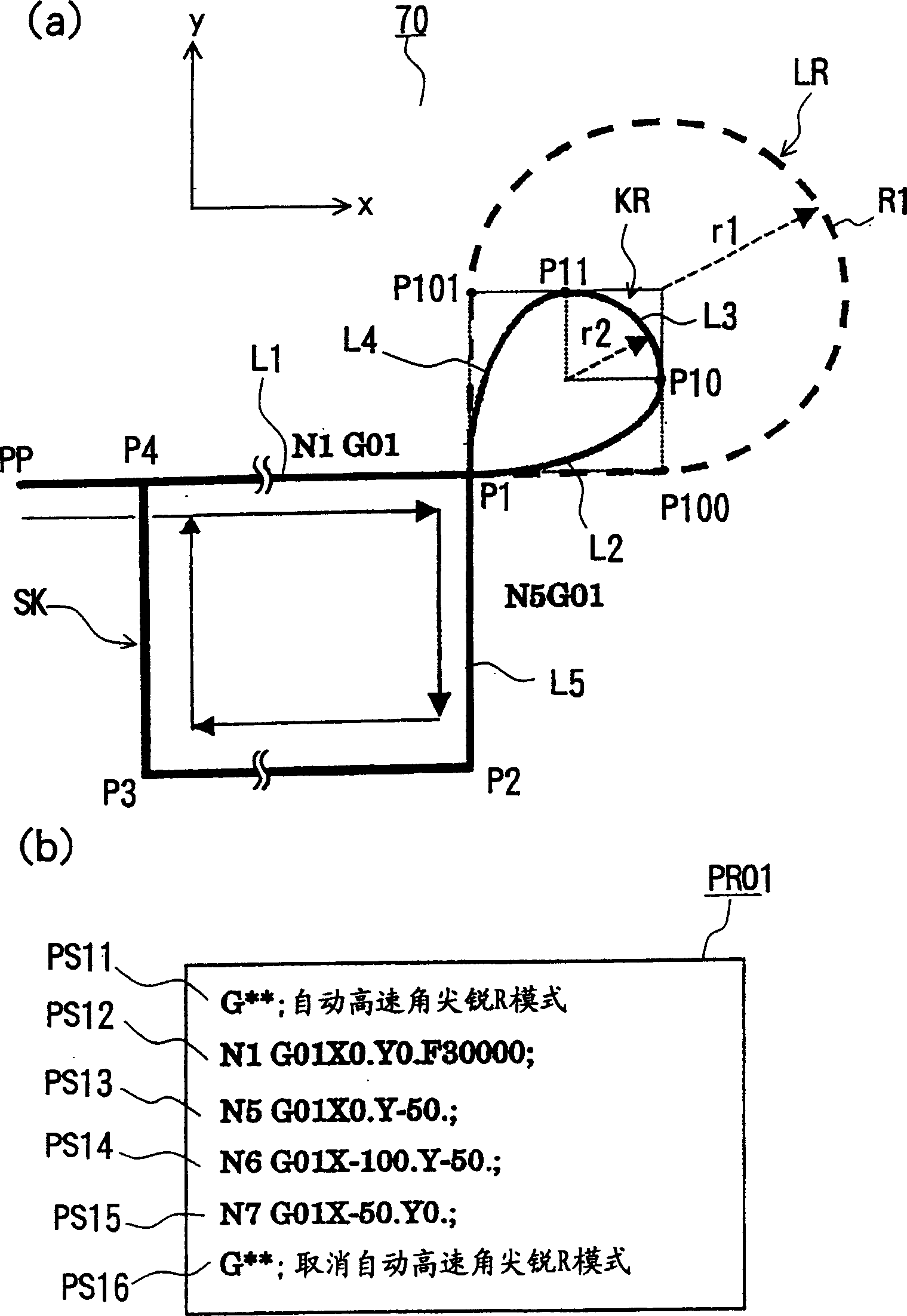

Laser beam machine

InactiveCN1467590AEasy to processReduce production manpowerLaser beam welding apparatusNumerical controlEngineeringLaser beams

A sharp corner judgment means judges as to whether a corner of cut shape in a workpiece is a sharp corner is not on the basis of a machining program. When the corner is regarded as the sharp corner, an additional locus producing means for producing sharp corner produces an additional locus for producing sharp corner when machining on the corner regarded as the sharp corner, and a sharp corner machining execution means executes machining on the corner on the basis of the produced additional locus for producing sharp corner. Then, the additional locus for producing sharp corner can be automatically produced for the sharp corner so as to execute machining.

Owner:YAMAZAKI MAZAK KK

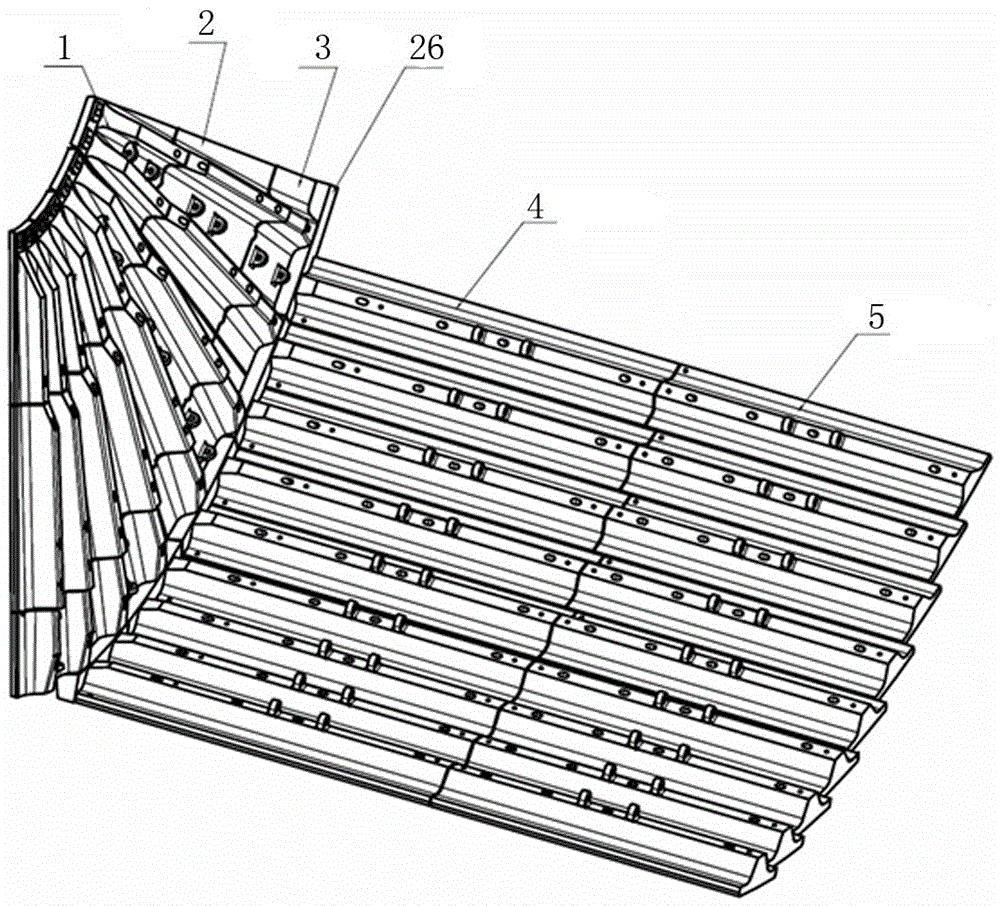

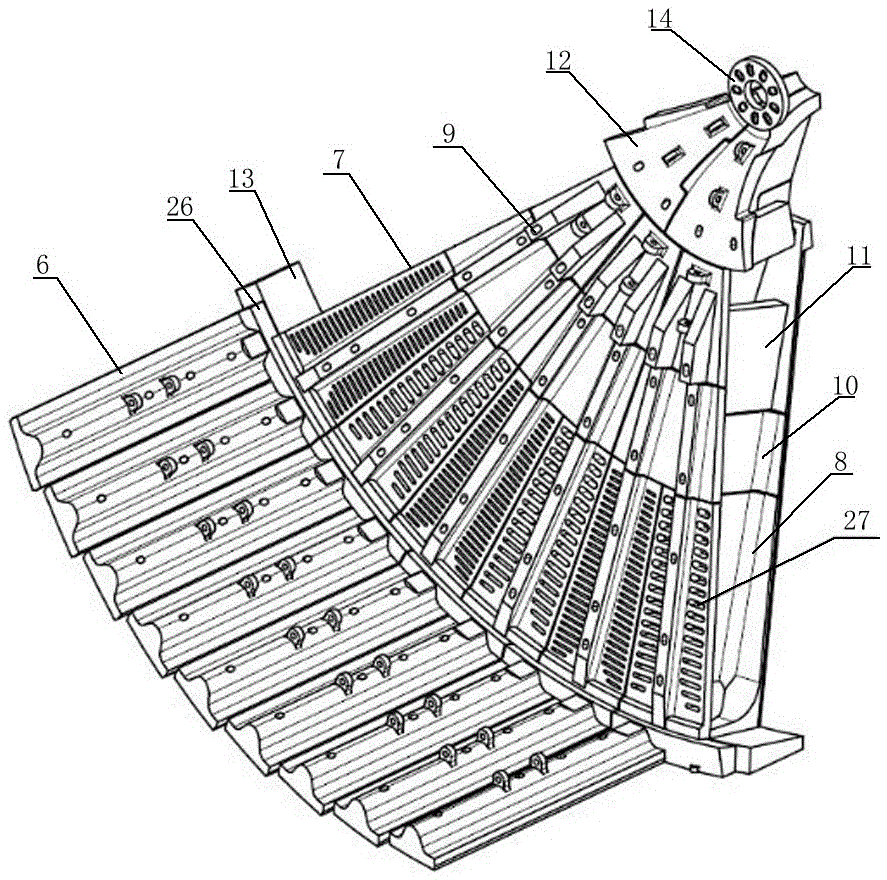

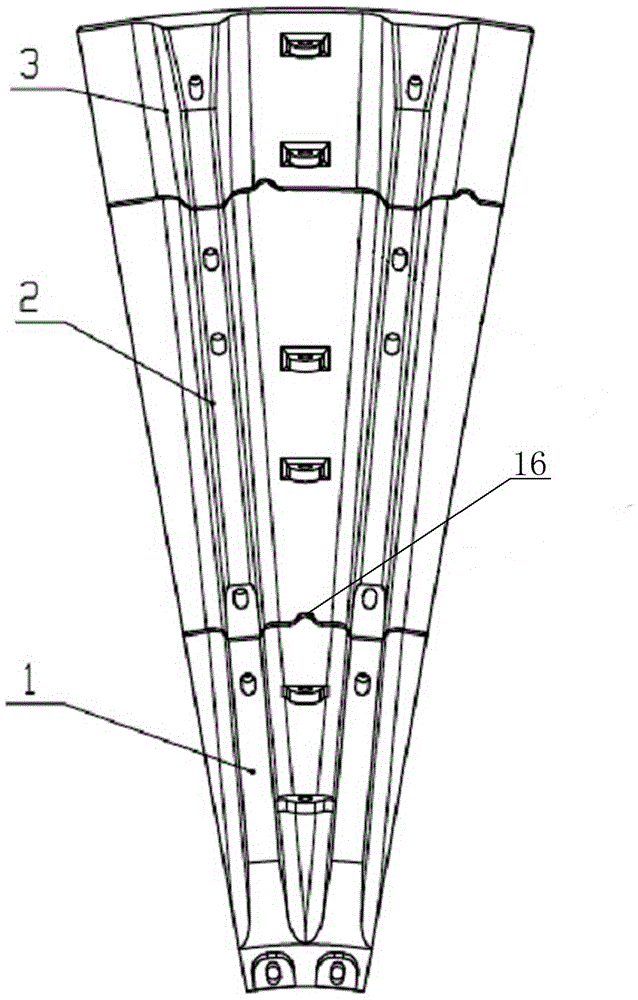

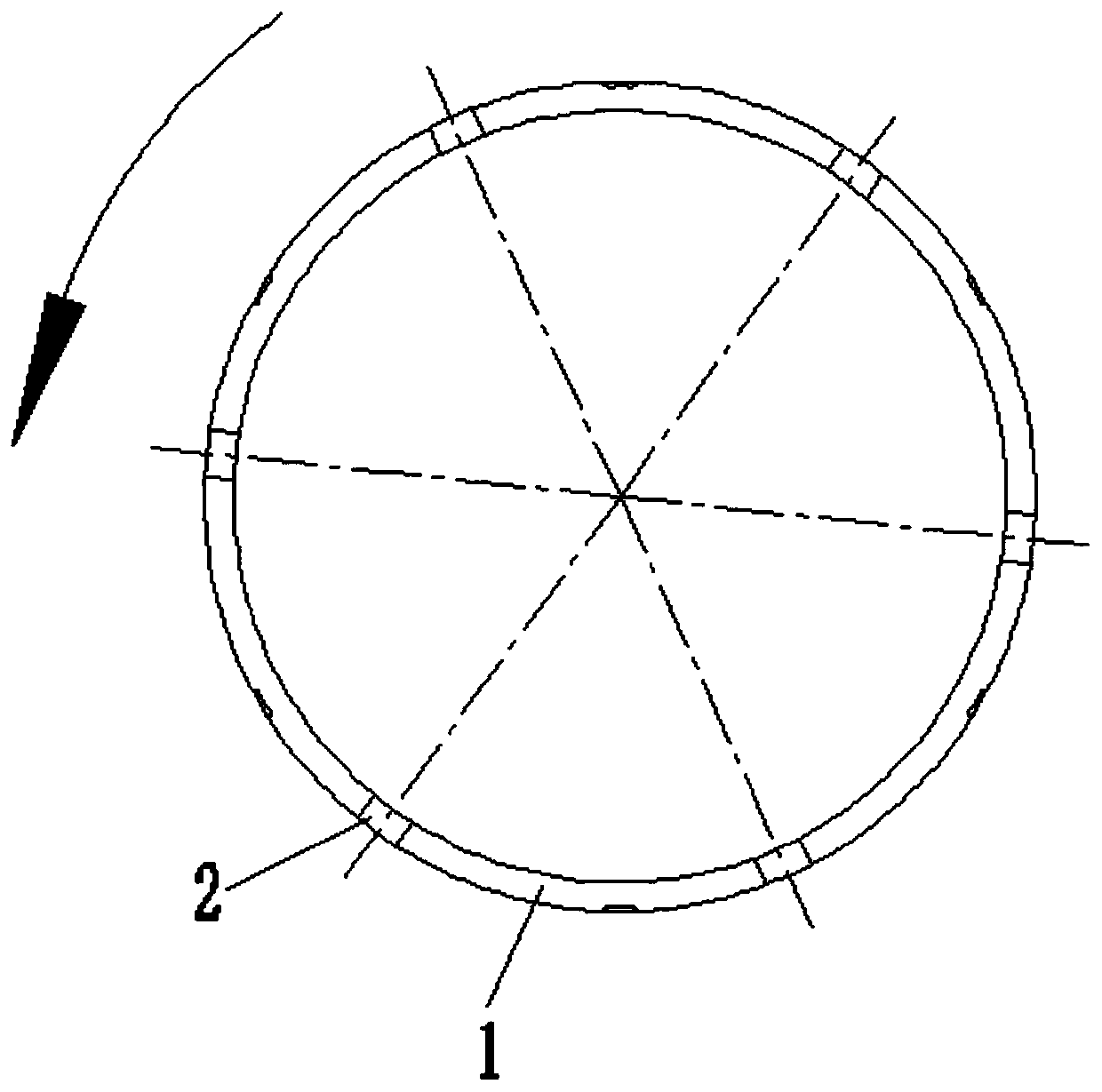

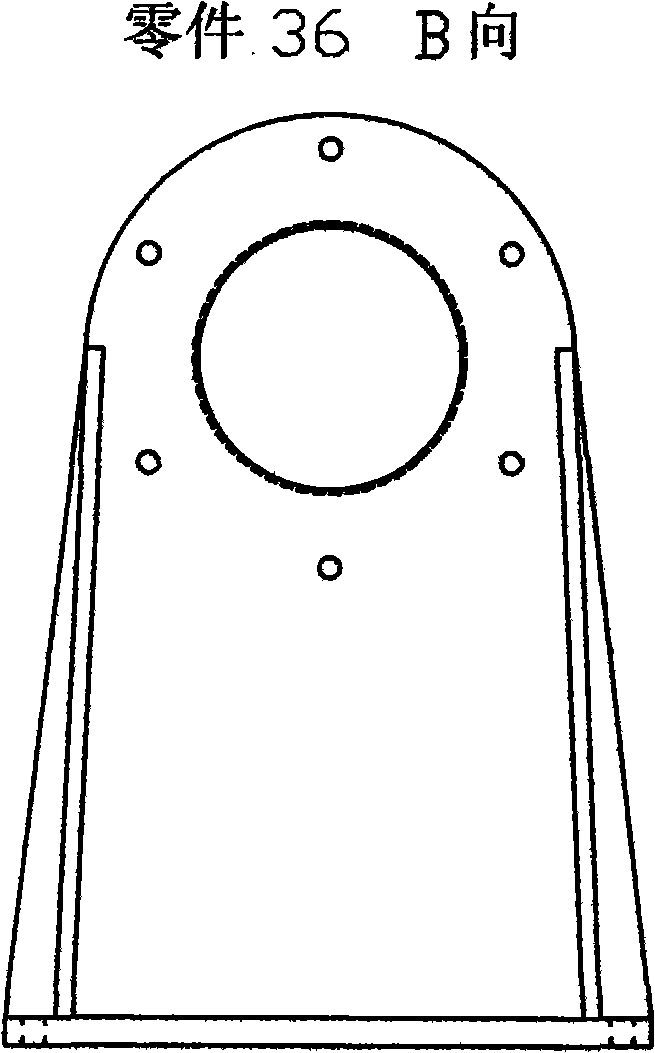

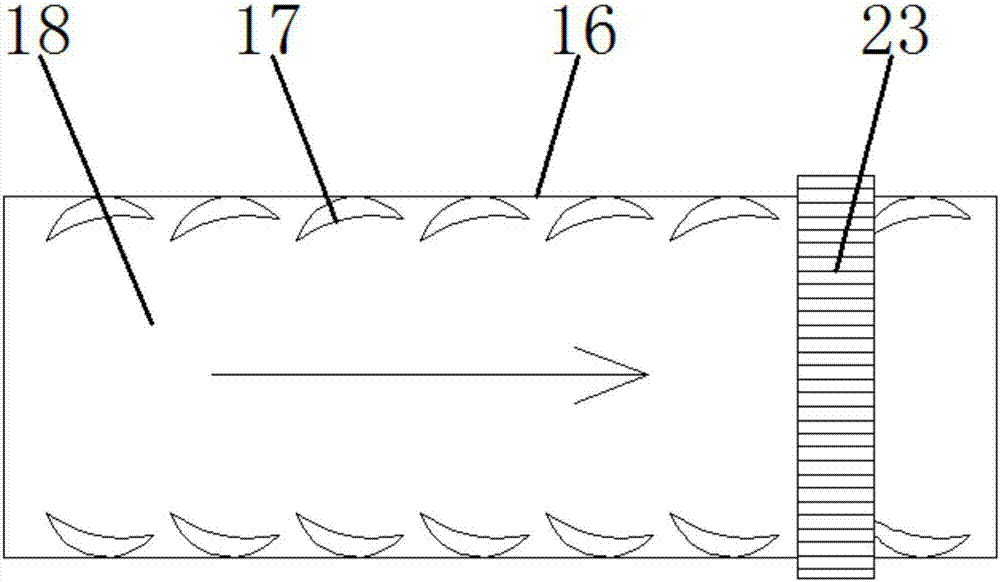

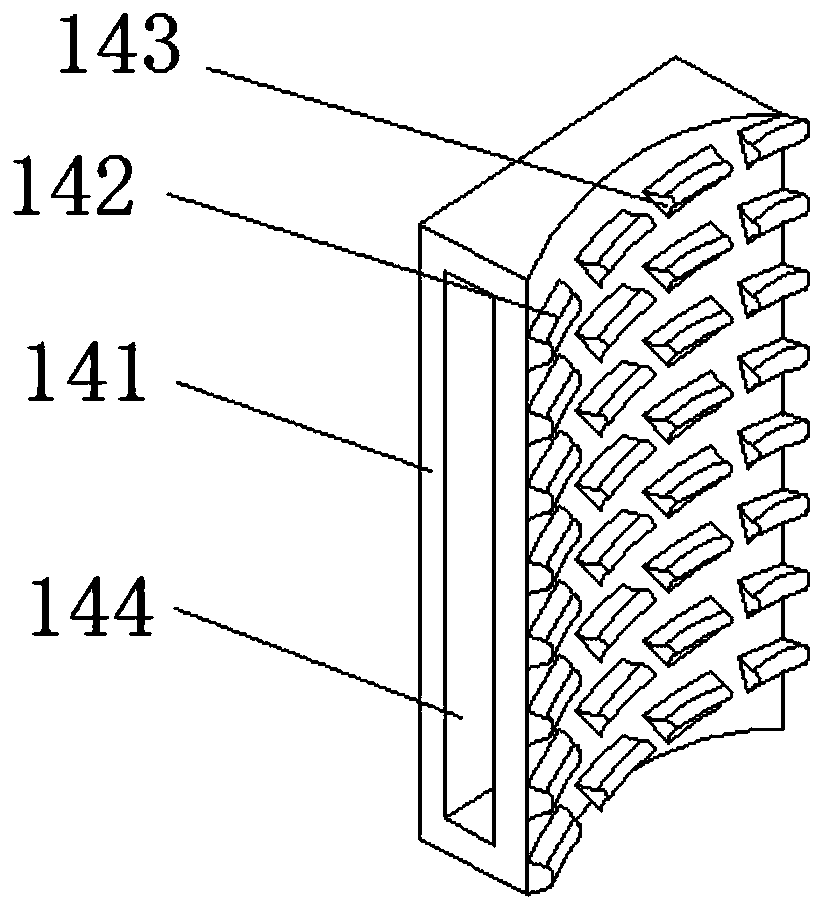

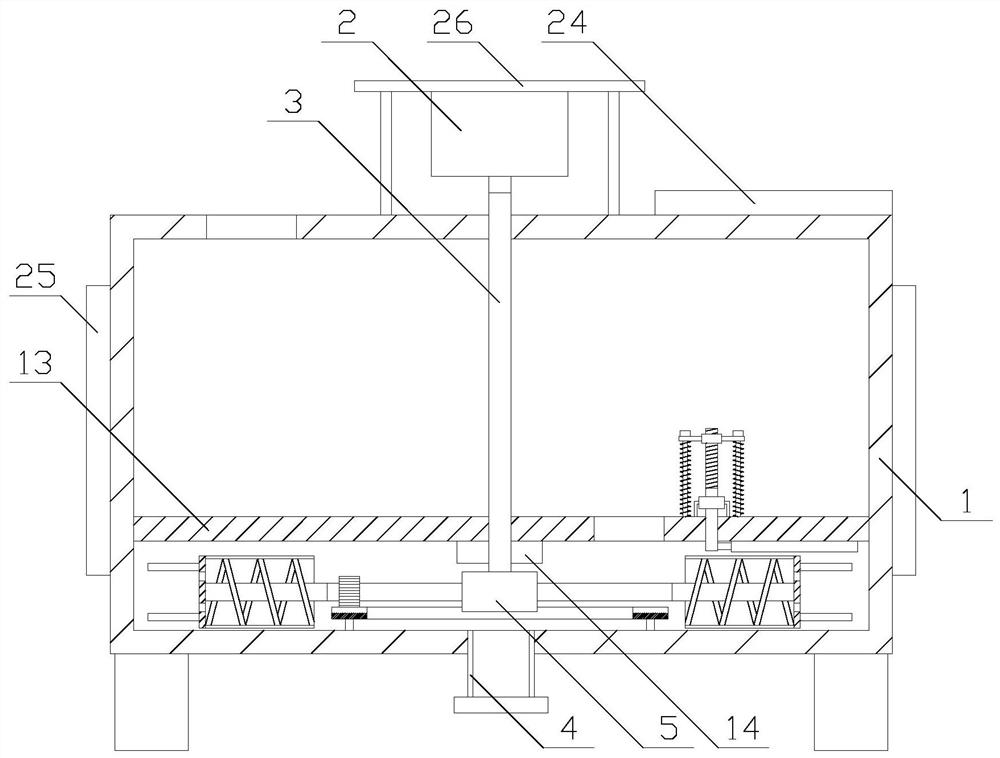

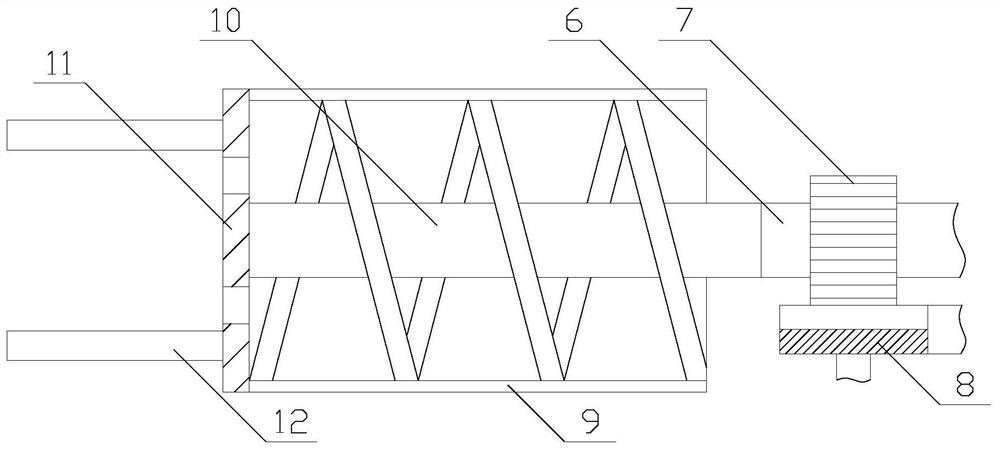

Novel liner plate structure used for large autogenous mill

The invention discloses a novel liner plate structure used for a large autogenous mill. The novel liner plate structure comprises a feeding end liner plate, a cylinder liner plate, a discharging end liner plate and a filling ring. The feeding end liner plate comprises a feeding end inner ring liner plate body, a feeding end middle ring liner plate body and a feeding end outer ring liner plate body, all of which are sequentially connected. The cylinder liner plate comprises a feeding end cylinder liner plate body, a middle section cylinder liner plate body and a discharging end cylinder liner plate body. The discharging end liner plate comprises a grid plate, an insensate stone window, an external ore pulp elevator, a discharging end middle liner plate body, a middle ore pulp elevator, an inner ring ore pulp elevator, a material discharging device and the like. A flat-head bolt hole is formed in the material discharging device, and an anti-loosening structure is further arranged at the position, corresponding to the flat-head bolt hole, on the material discharging device. The anti-loosening structure comprises a flat-head bolt, an anti-loosening steel bowl, a large gasket, a lock nut, an anti-loosening bolt, an anti-loosening nut and the like. The problems that during running of the mill, ore pulp circular flow scours an end cover, the filling ring falls, the service life of the cylinder liner plate bodies is not equal, discharging cannot be conducted in time through a discharging opening, the flat-head bolt loosens, and insensate stone is not discharged smoothly can be effectively solved.

Owner:CITIC HEAVY INDUSTRIES CO LTD

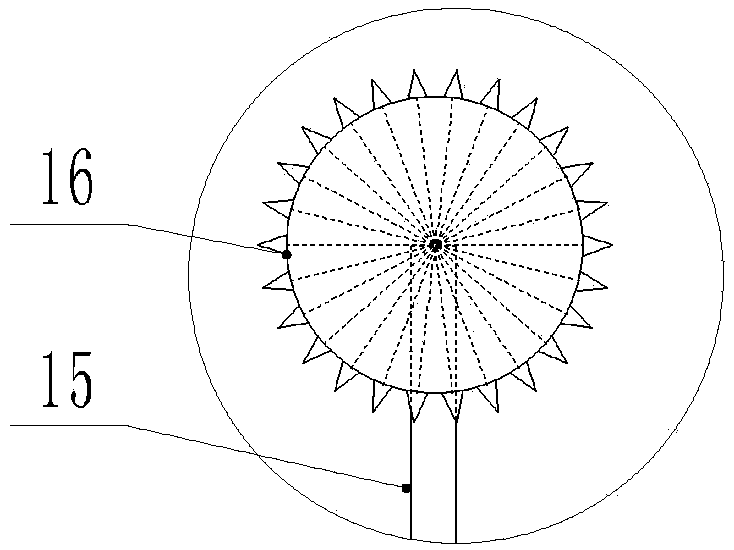

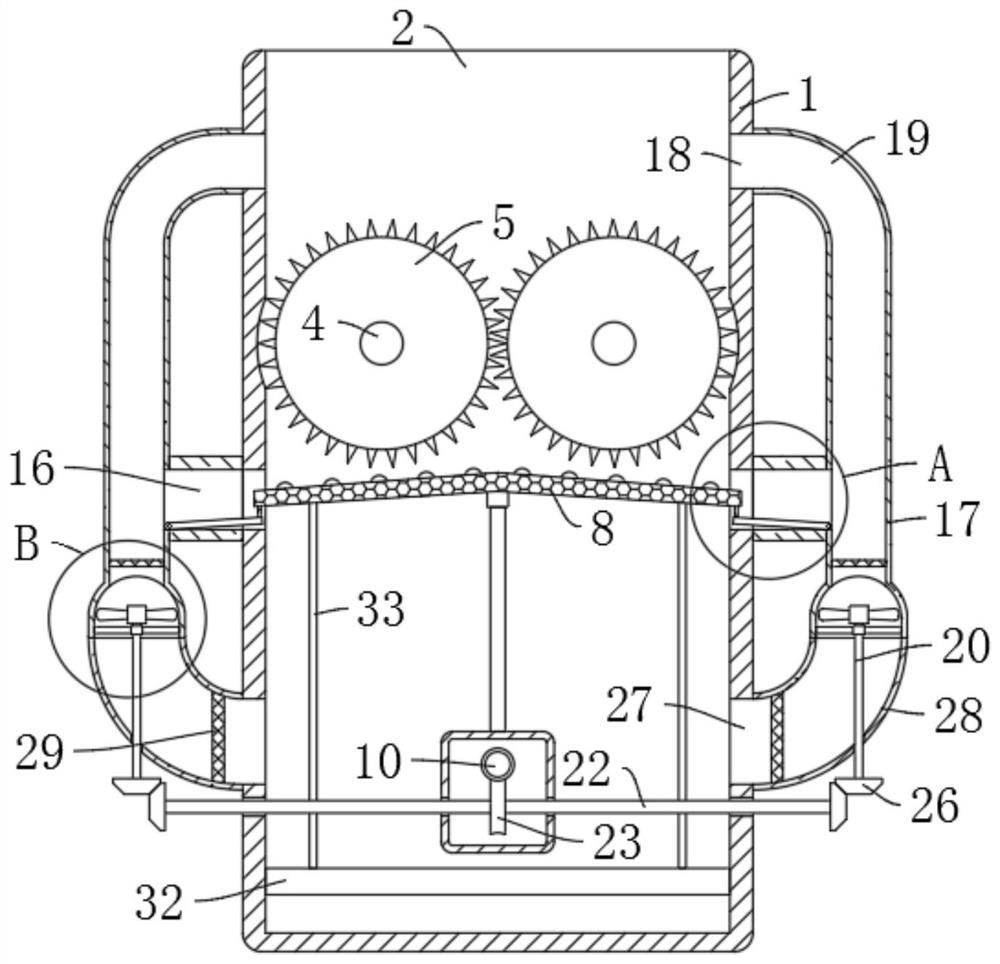

Garbage smashing and treating device for garbage landfills

The invention relates to the technical field of smashing devices, and discloses a garbage smashing and treating device for garbage landfills. The garbage smashing and treating device comprises a tank.A feed inlet and a discharge outlet are formed in the tank, a smashing cutter is rotationally arranged in the tank and is connected with a power mechanism, the power mechanism comprises a cylindricalcam, a gear is rotationally arranged on an oblique plane of the cylindrical cam, the smashing cutter comprises a head and blades, the blades are rotationally arranged on the head, the head is hingedinto the tank, push handles are connected onto blade surfaces of the blades, and ejector rods are hinged onto the push handles, are clamped in tooth spaces of the gear and are butted onto the obliqueplane of the cylindrical cam. The garbage smashing and treating device has the advantage that the problem of influence on the garbage smashing quality due to the fact that garbage sleeves existing smashing cutters can be solved by the aid of the garbage smashing and treating device.

Owner:贵州杉海沿环保科技有限责任公司

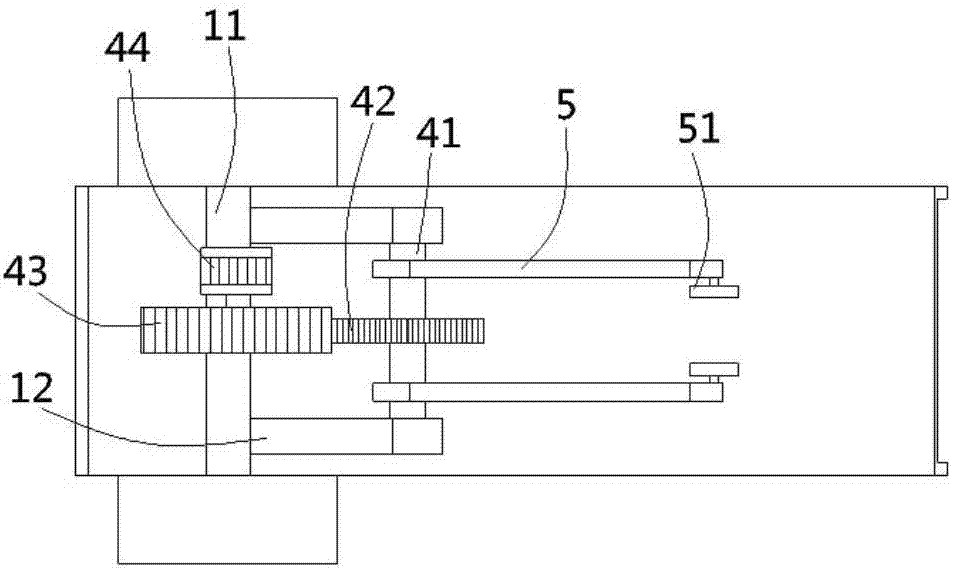

Convenient stirring equipment for artificial board processing

InactiveCN111203130AIngenious structurePracticalRotary stirring mixersTransportation and packagingDrive shaftElectric machinery

The invention relates to convenient stirring equipment for artificial board processing. The convenient stirring equipment comprises a main body, a discharge pipe and a sealing cover, wherein the mainbody is cylindrical and is vertically arranged; the sealing cover covers the top end of the main body and is hermetically connected with the main body; the discharge pipe and the main body are coaxially arranged; the discharge pipe is arranged at the bottom of the main body; a sealing device is arranged on the discharge pipe; a stirring mechanism and two auxiliary mechanisms are arranged in the main body; the stirring mechanism comprises a driving motor, a transmission shaft, a bearing, a stirring rod, an eccentric wheel and two stirring assemblies; each stirring assembly comprises a fixed pipe, a connecting pipe, a one-way valve, an extruding plate, a connecting rod, a ball, a through hole and an outlet hole. According to the convenient stirring equipment for artificial board processing,the function of stirring artificial board manufacturing raw materials is achieved through the stirring mechanism, the stirring uniformity is improved, and in addition, the discharging efficiency and convenience are improved through the auxiliary mechanisms.

Owner:王海山

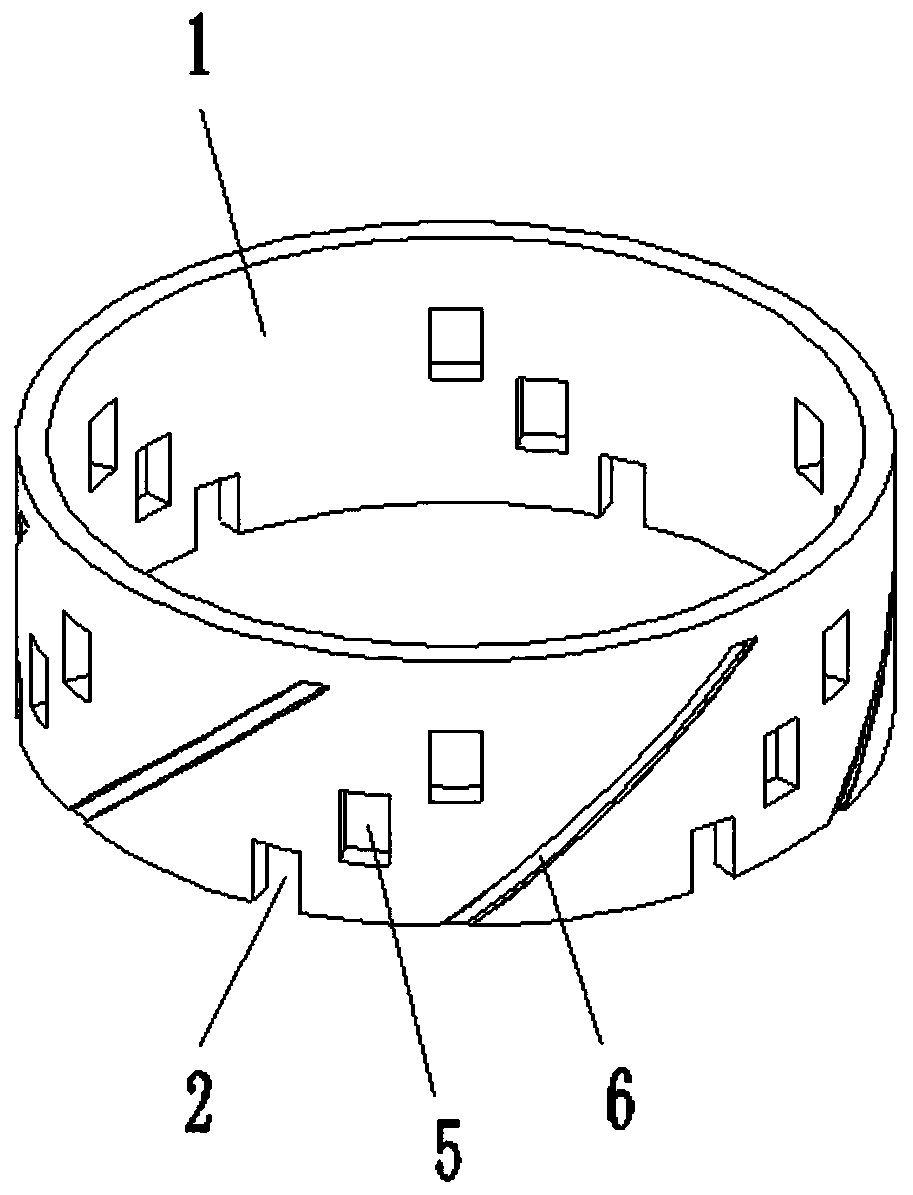

High-speed efficient drill bit

PendingCN110919877AEasy dischargeGuaranteed to workStone-like material working toolsEngineeringMachining

The invention relates to a high-speed efficient drill bit. The drill bit comprises a working ring and a discharging opening, wherein the working ring is of a cylinder structure, multiple discharging opening rings are annularly distributed at the bottom of the side wall of the working ring so that scraps can be discharged during rotary machining of the working ring, and symmetrical center lines oftwo side edges of the bottom of the discharging opening or the center lines of an included angle formed by the two side edges of the bottom of the discharging opening does not pass through the circlecenter of a bottom face of the working ring. The drill bit is advantaged in that the scraps can be subjected to mechanical thrust of the discharging opening towards an outer side of the working ring along with rotation of the working ring in the discharging opening, the scraps can be discharged from the discharging opening more easily under the action of the mechanical thrust, and that the drill bit can work at high speed and high efficiency is guaranteed.

Owner:GUILIN CHAMPION UNION DIAMOND CO LTD

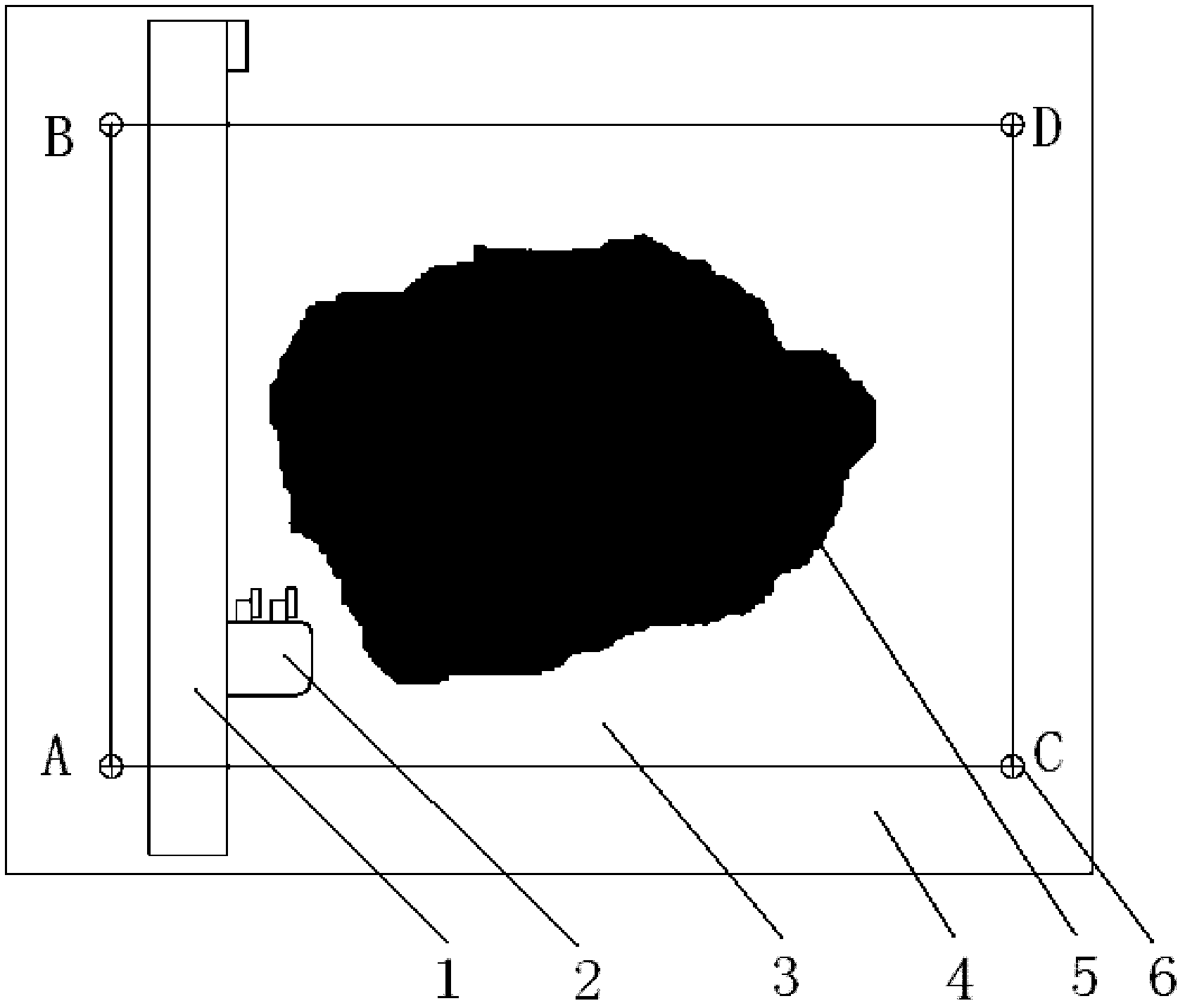

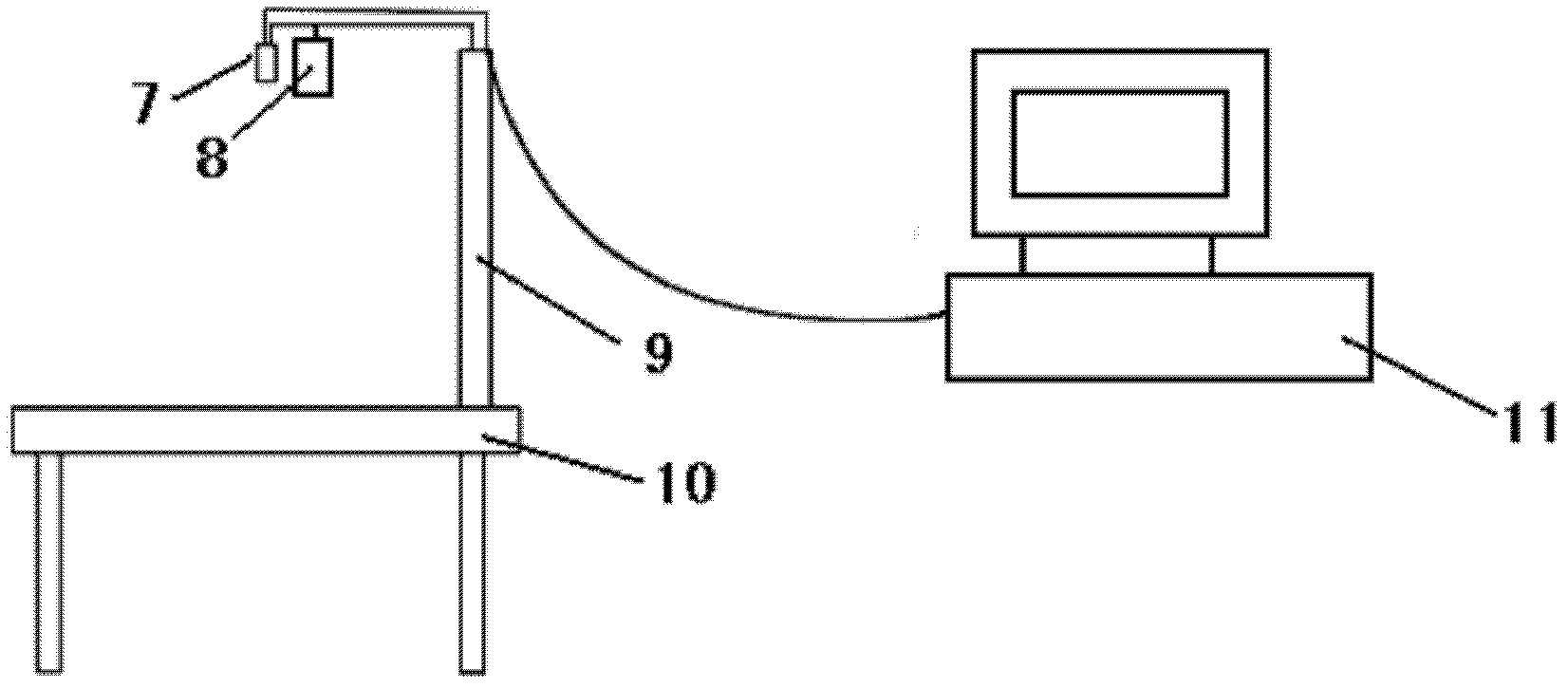

Dermis cutting device and dermis cutting method

InactiveCN103160622AHigh precisionAccelerateLeather clicking/perforating/clickingSkins/hides/leather/fur manufacturing apparatusDermisBiomedical engineering

The invention provides a dermis cutting device and a dermis cutting method. The dermis cutting device comprises a flat plate cutting machine, a computer, and a camera used for obtaining the shape of dermis in an operation area. The camera is arranged above the operation area of the flat plate cutting machine, and connected with the computer. A layout processing unit and an image correcting unit are arranged in the computer in an integrated mode. The dermis cutting method includes the steps of defining the operation area, obtaining an image, correcting the image, arranging materials, cutting the dermis and the like. The dermis cutting device and the dermis cutting method are easy to complement, low in cost, good in operability, and particularly suitable for cutting irregular materials, and little in material waste.

Owner:张平

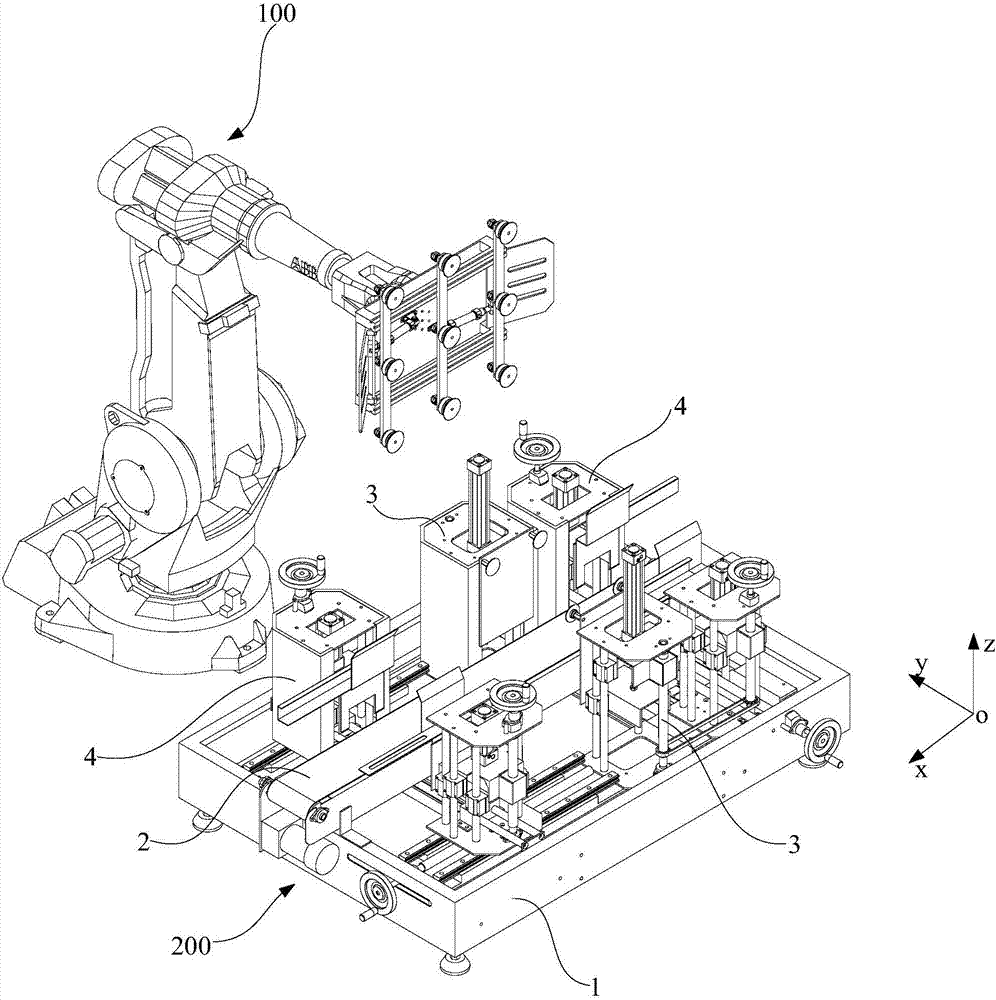

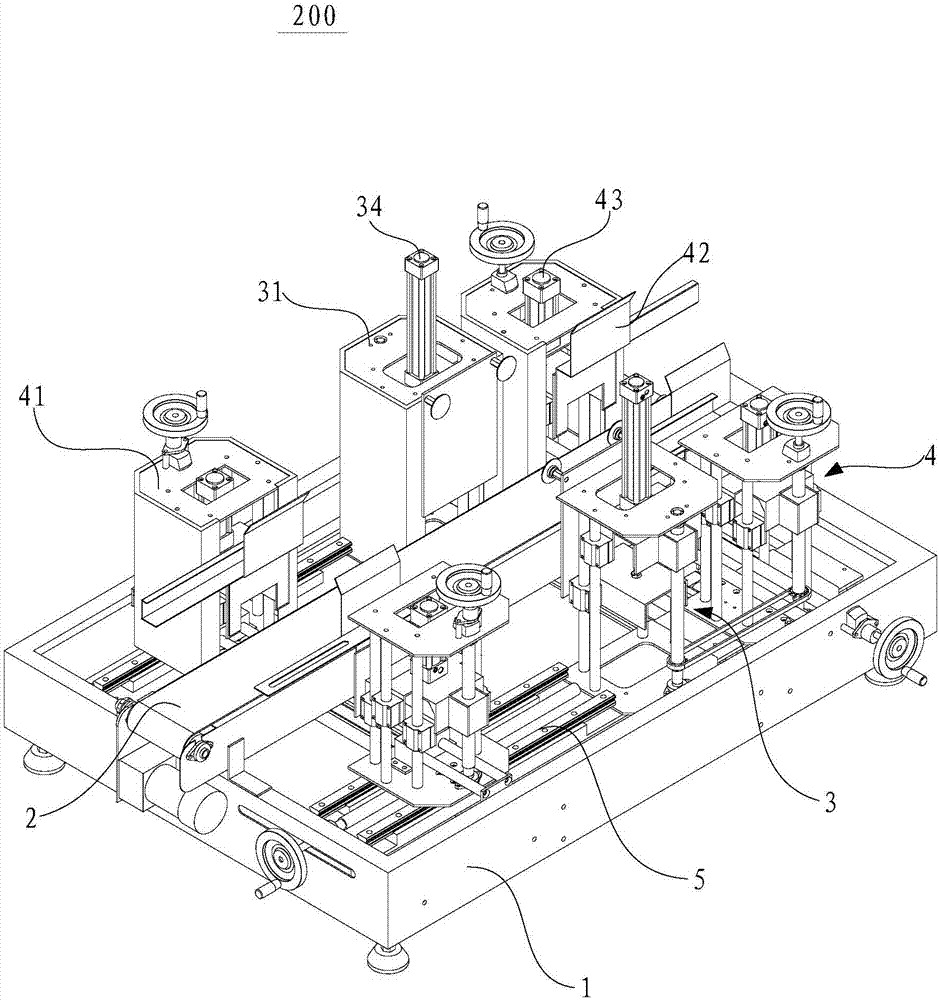

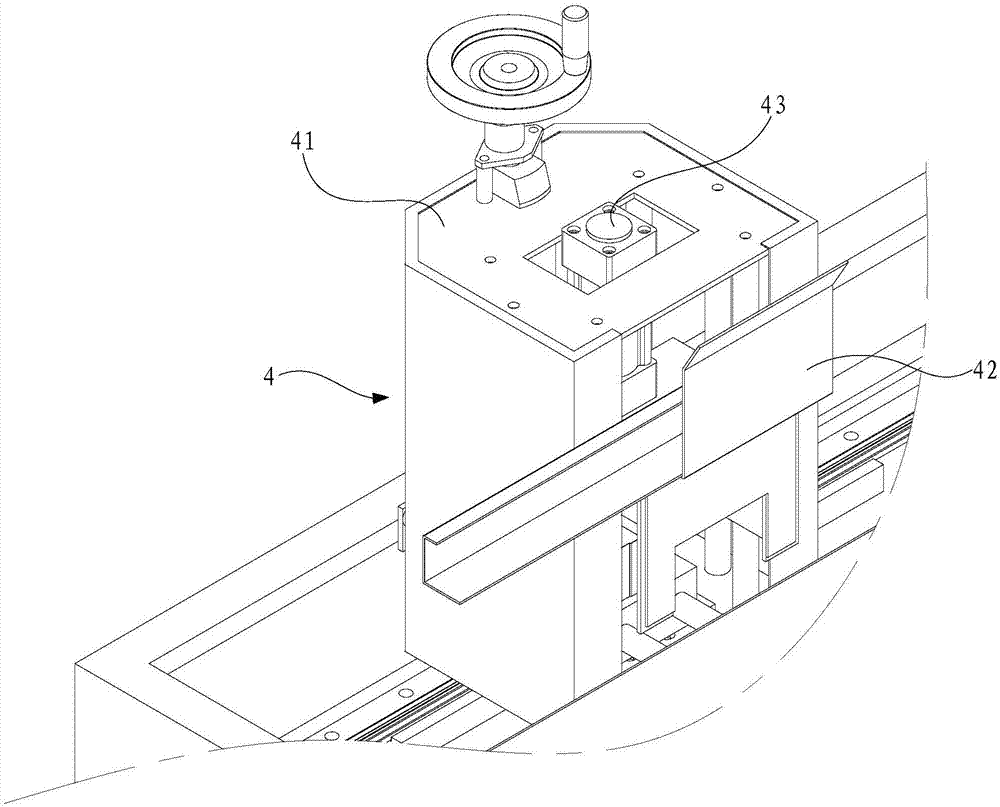

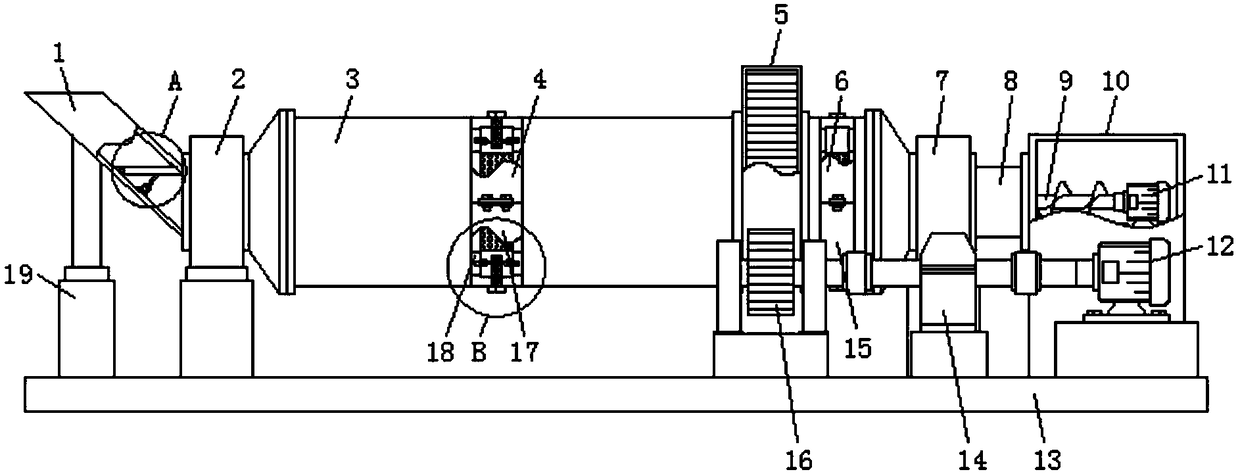

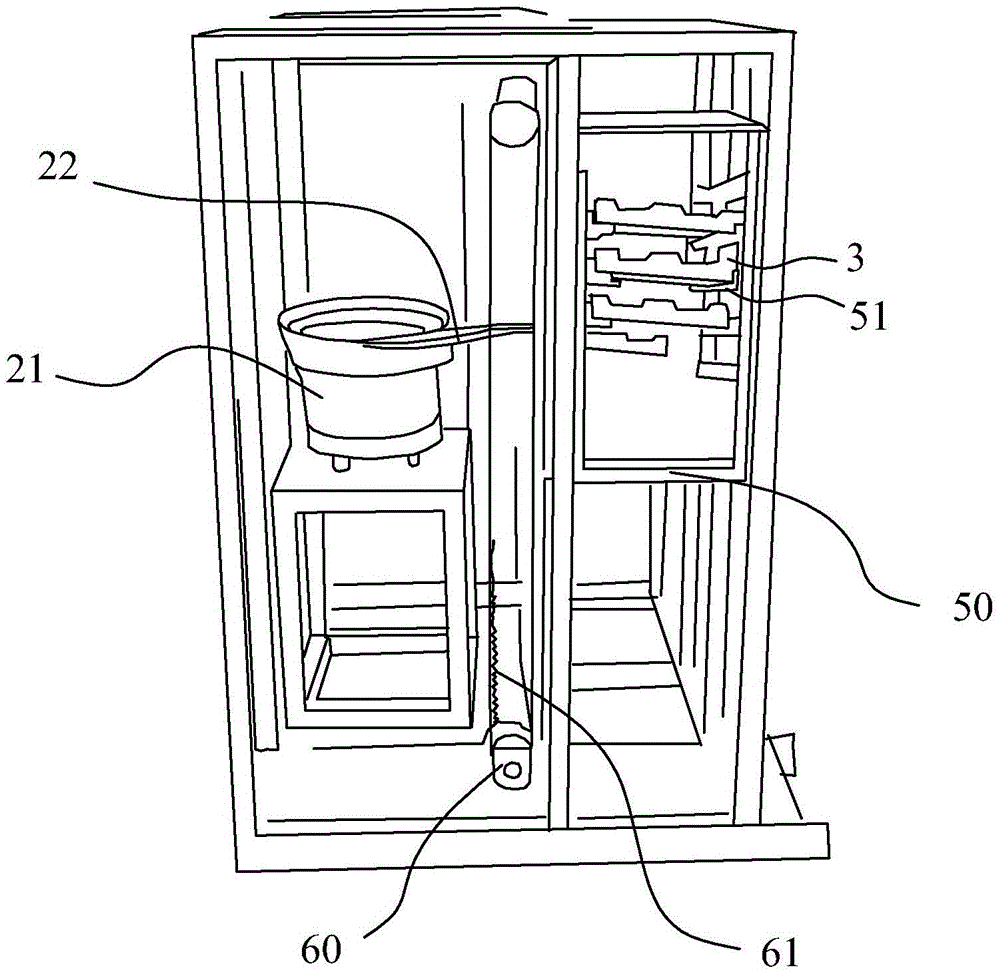

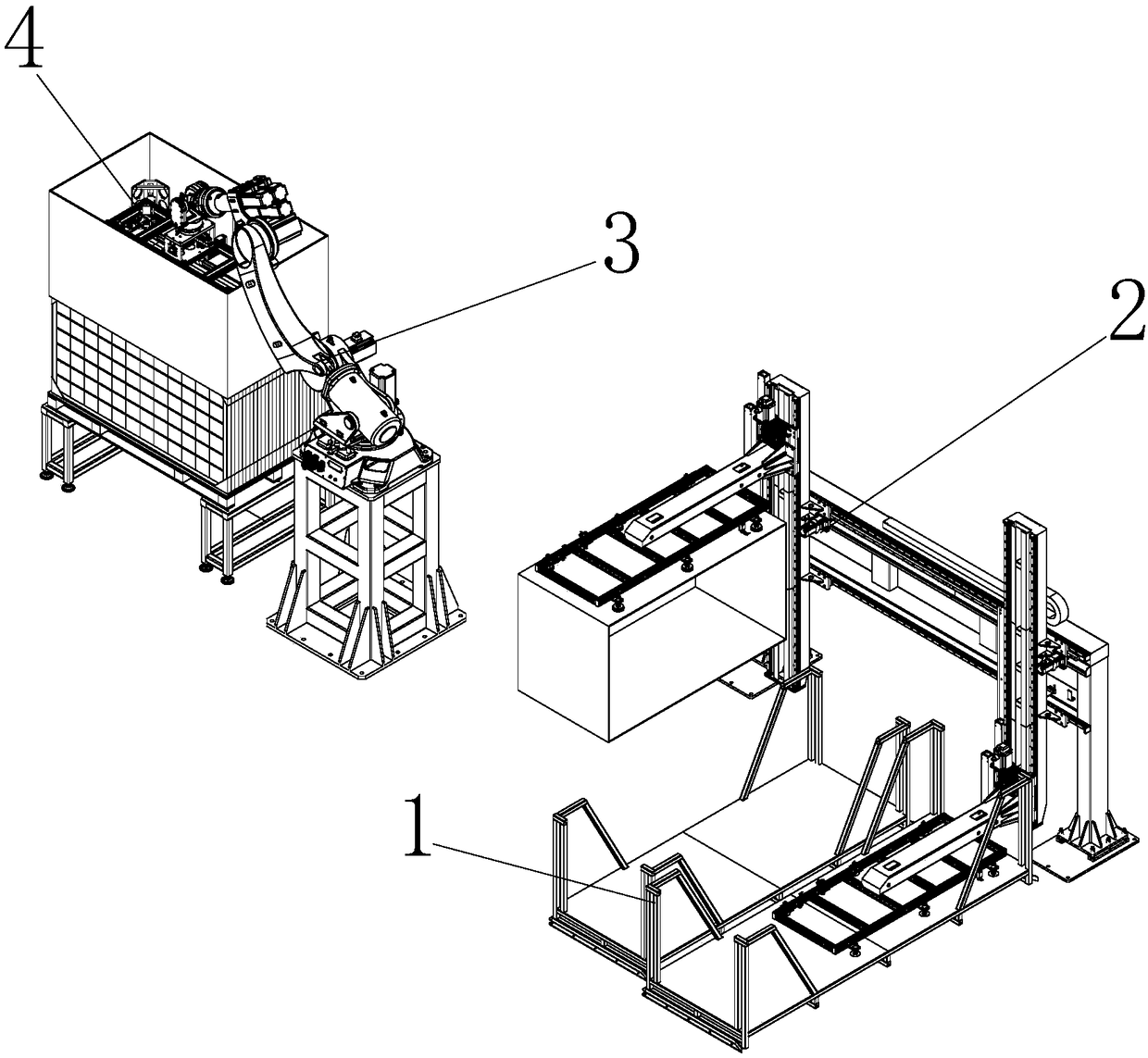

Automatic casing machine

PendingCN107572051ACompact structureReasonable layoutIndividual articlesCartonPulp and paper industry

The invention discloses an automatic casing machine. The automatic casing machine comprises a casing manipulator and a case expanding device, wherein the casing manipulator is used for arranging a paper case on the periphery of a product from the top of the product in a sleeving manner; the case expanding device comprises a machine base and a conveying track arranged on the machine base; the caseexpanding device further comprises two suction cup mechanisms arranged on the two opposite sides of the conveying track; any suction cup mechanism comprises a first fixing base and a suction cup assembly capable of being installed on the first fixing base in a sliding manner; and each suction cup assembly can slide between the two first fixing bases in a telescopic manner to adsorb the paper caseand expand the paper case. The automatic casing machine is compact in structure, reasonable in arrangement and capable of expanding the bottom of the paper case to avoid the interference between the bottom edge of the paper case and the bottom holder edge of the product, and therefore the casing operation is fast and accurately completed, and the casing efficiency is effectively improved.

Owner:深圳市纬华机械有限公司

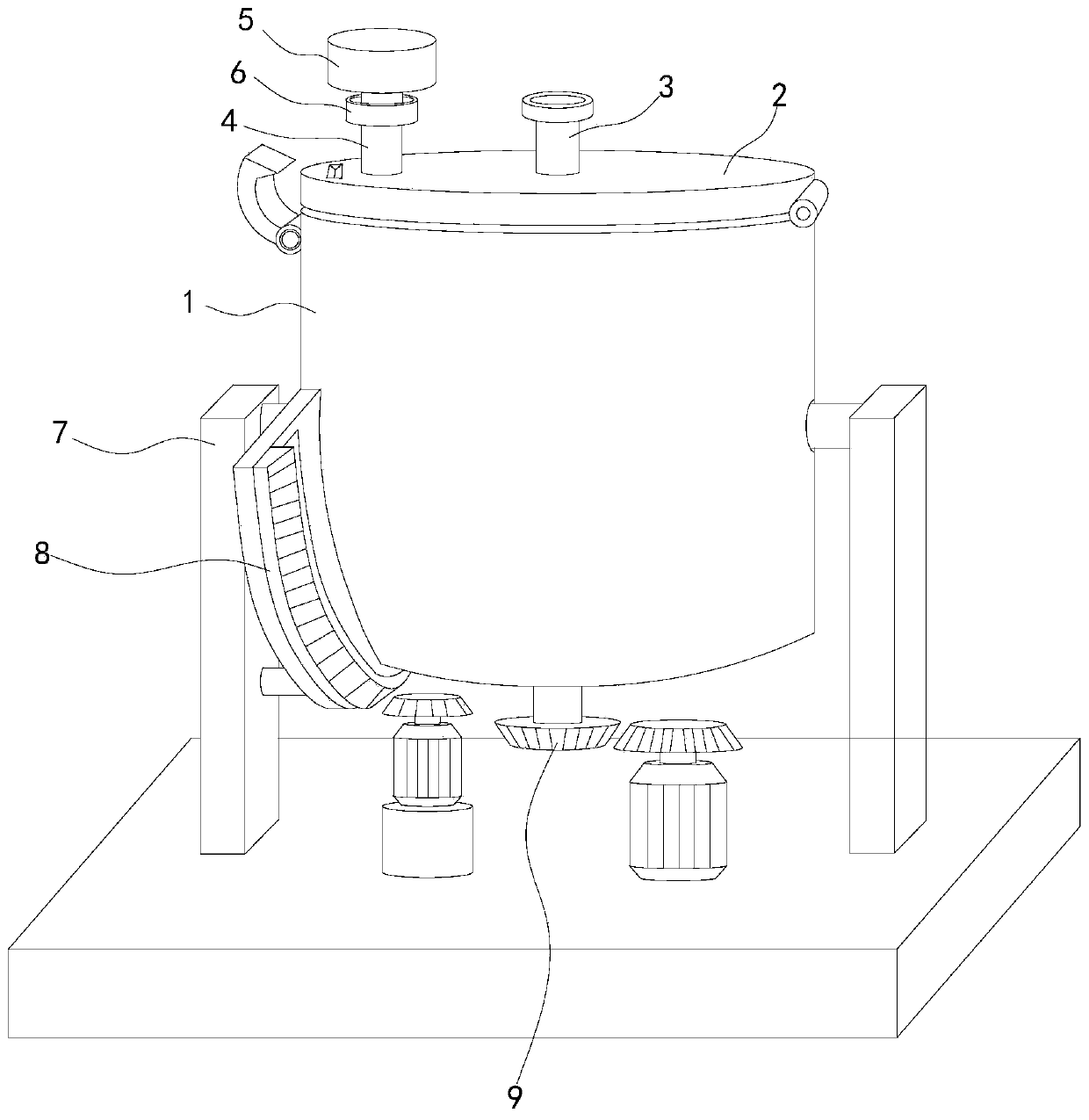

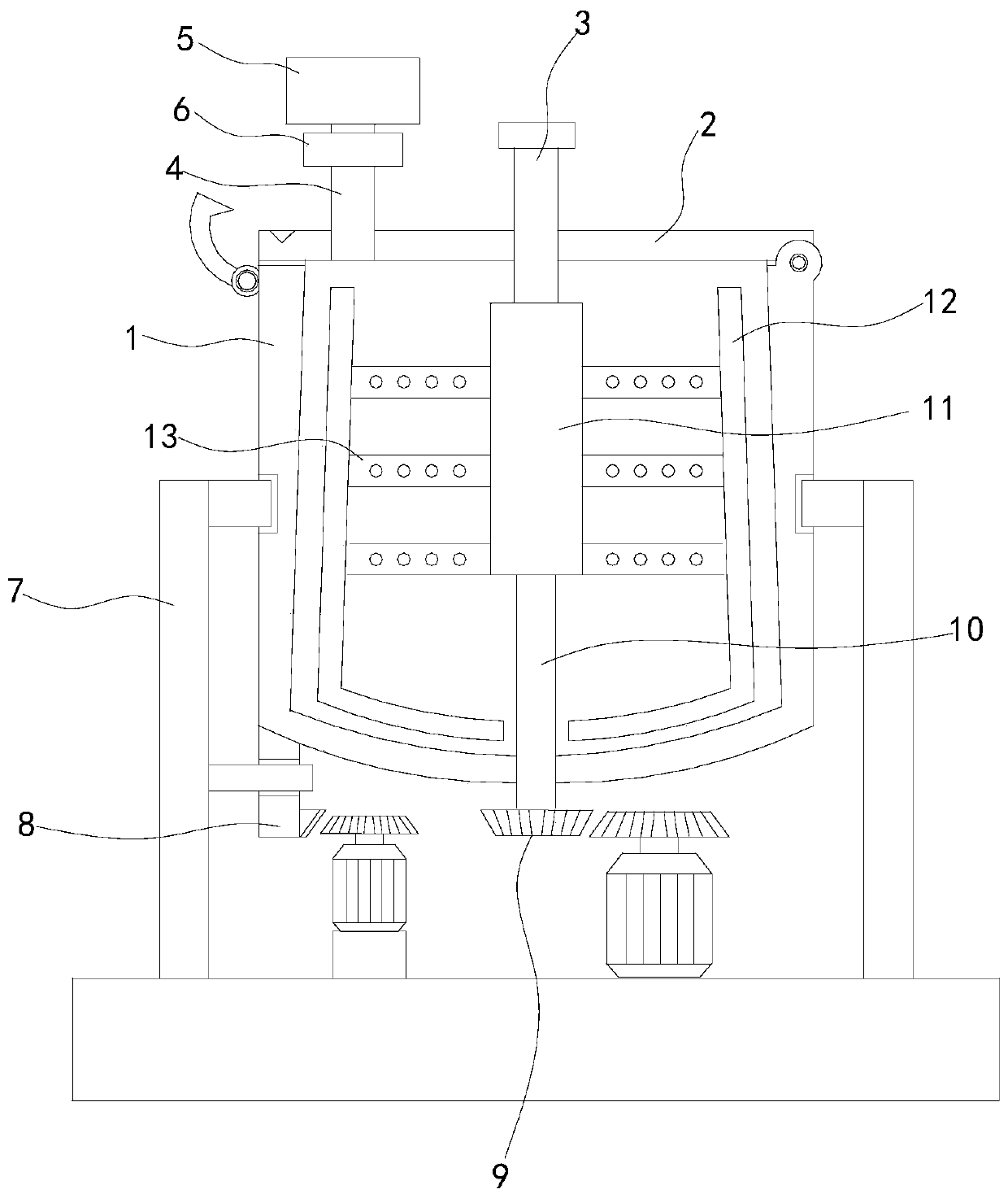

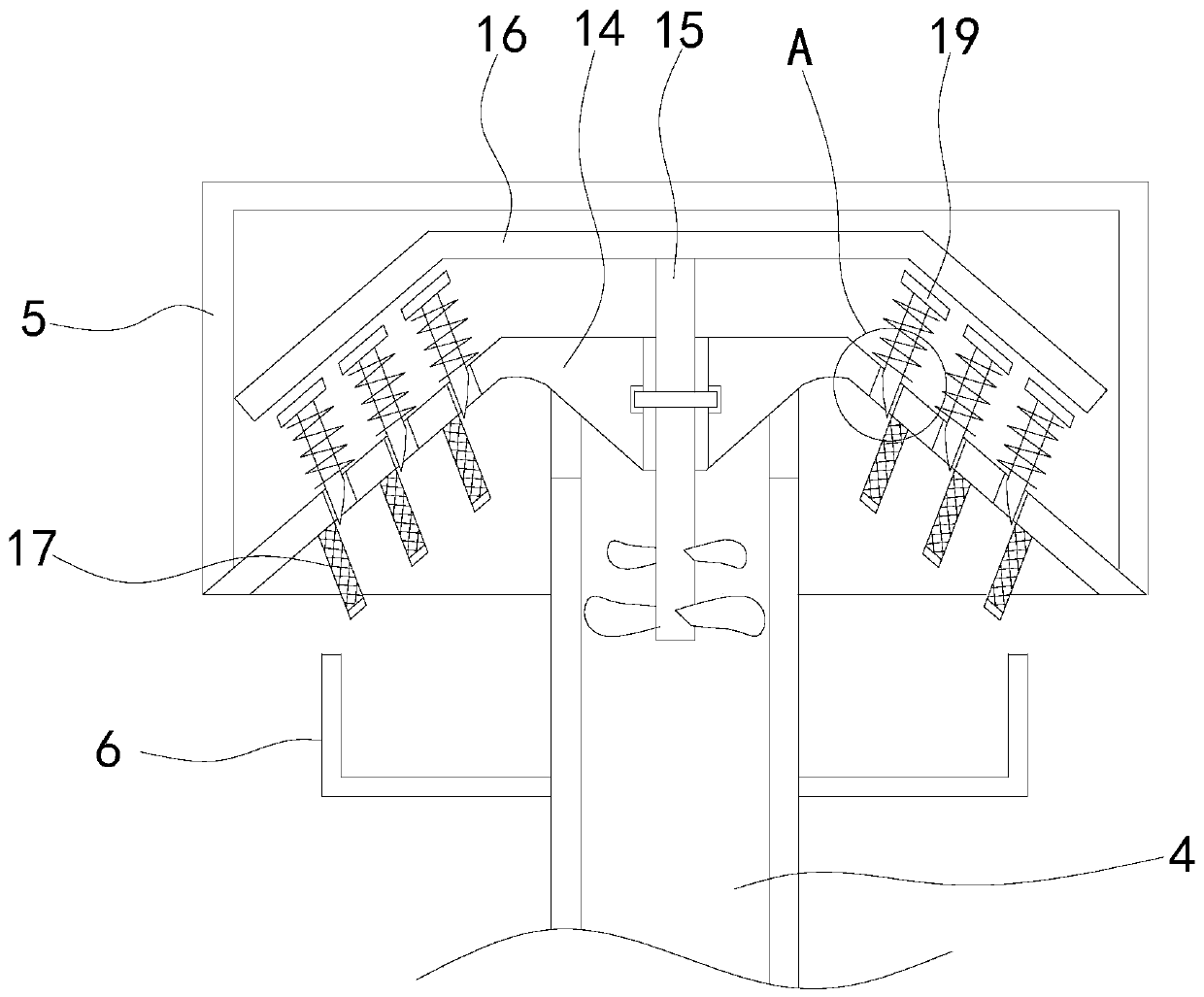

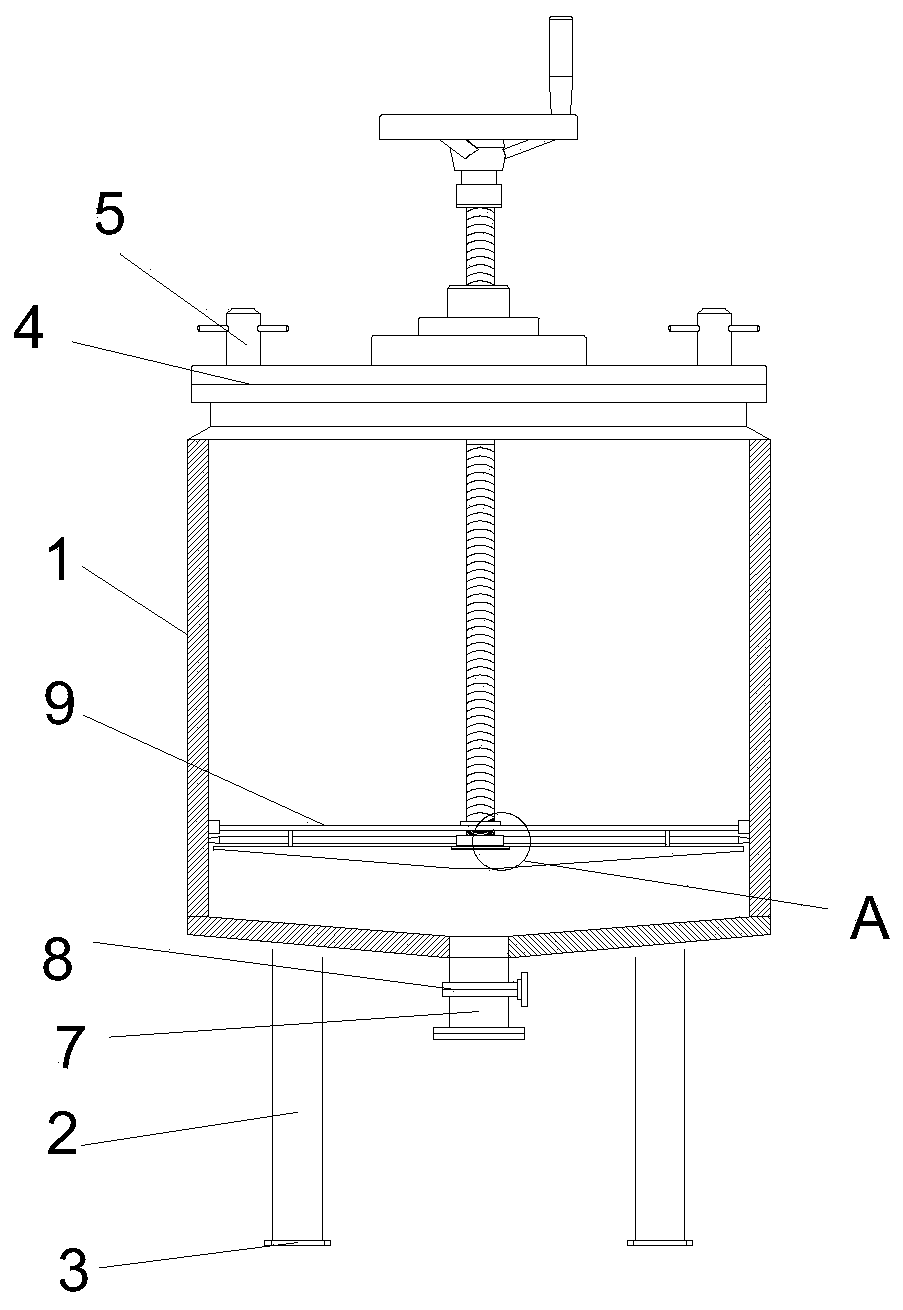

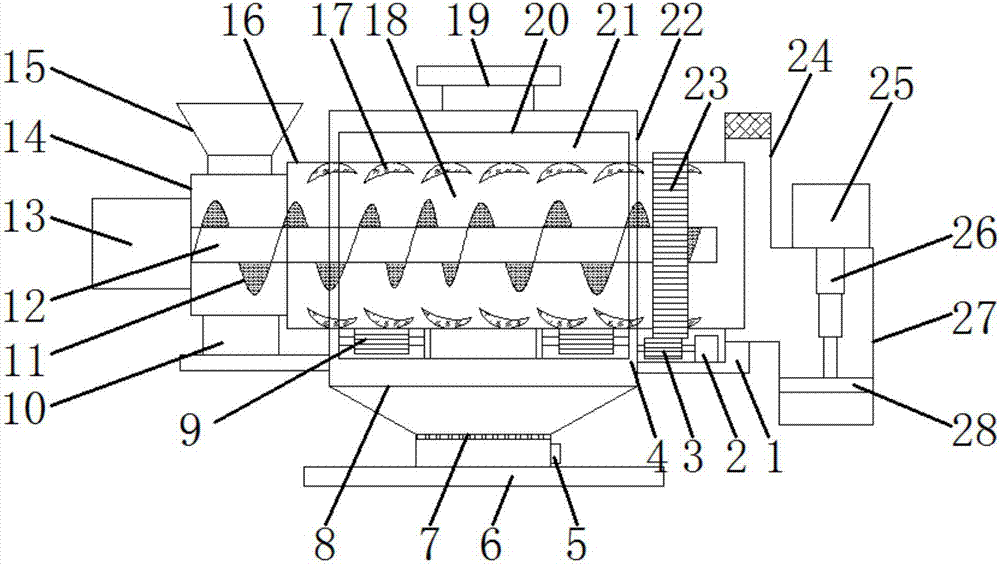

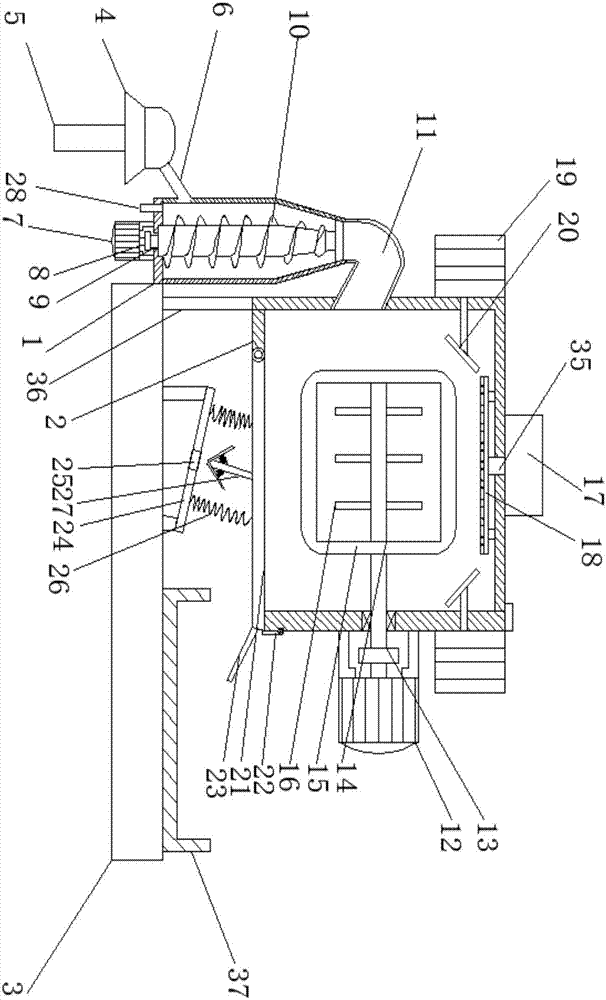

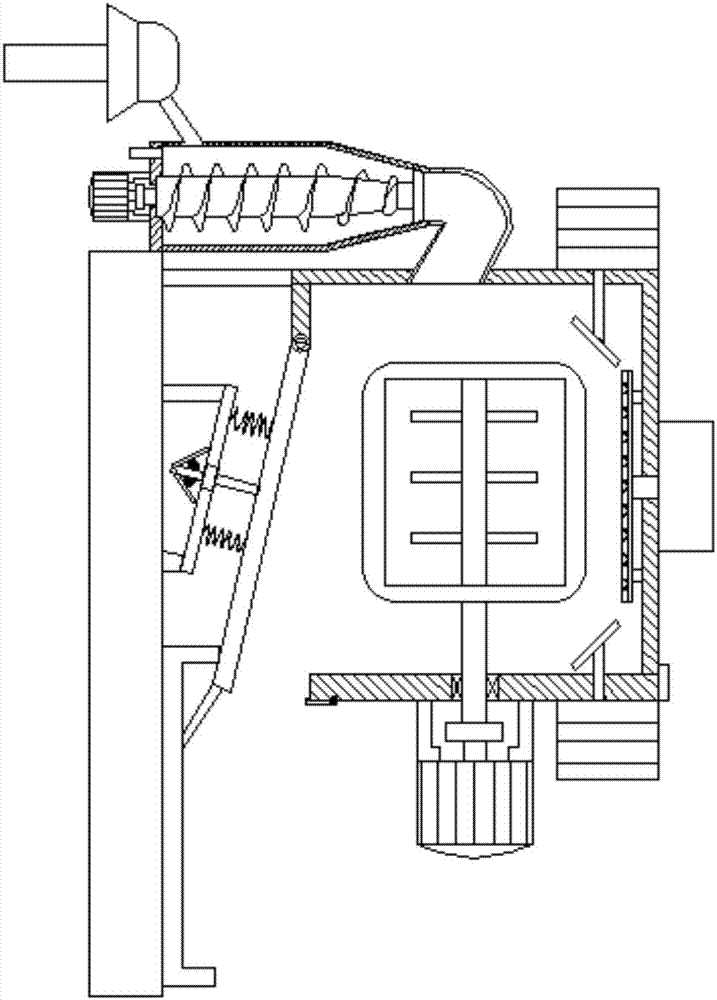

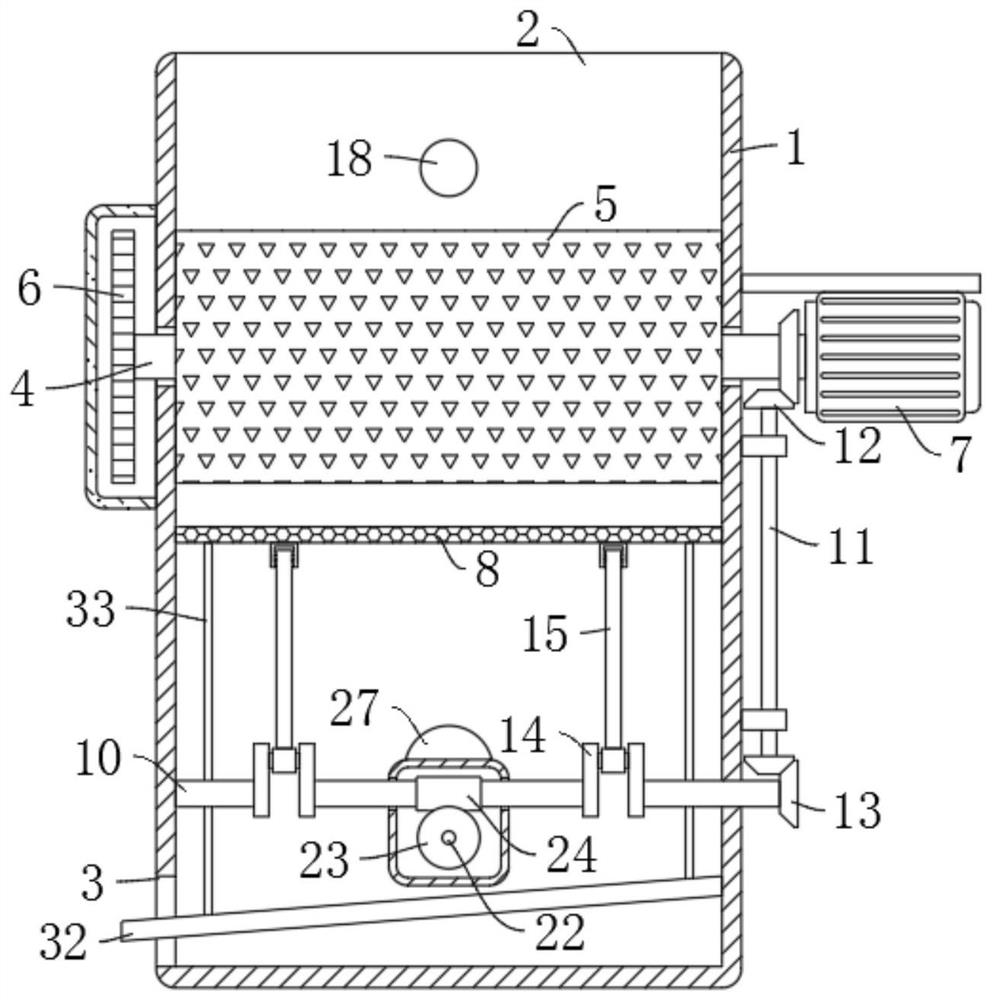

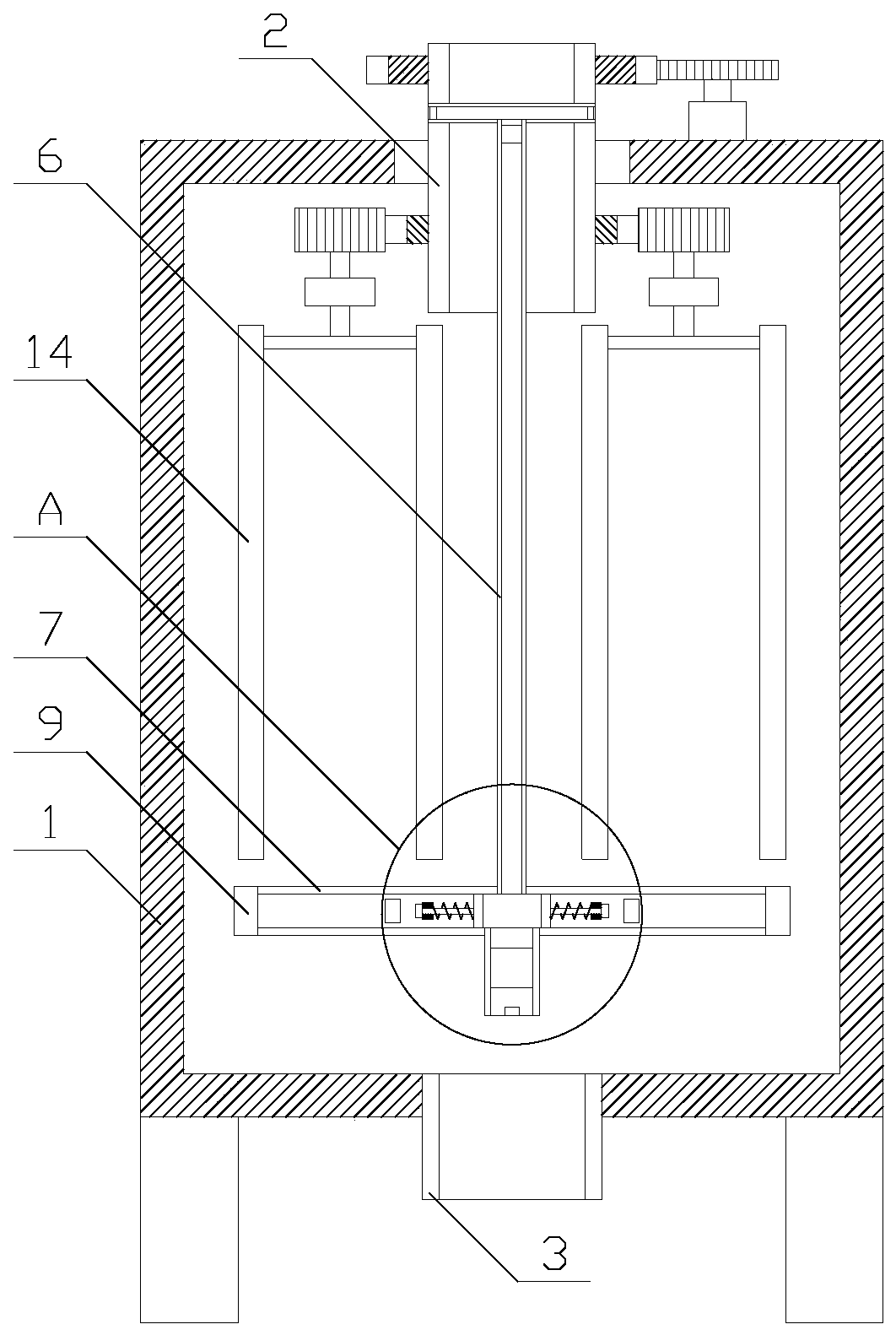

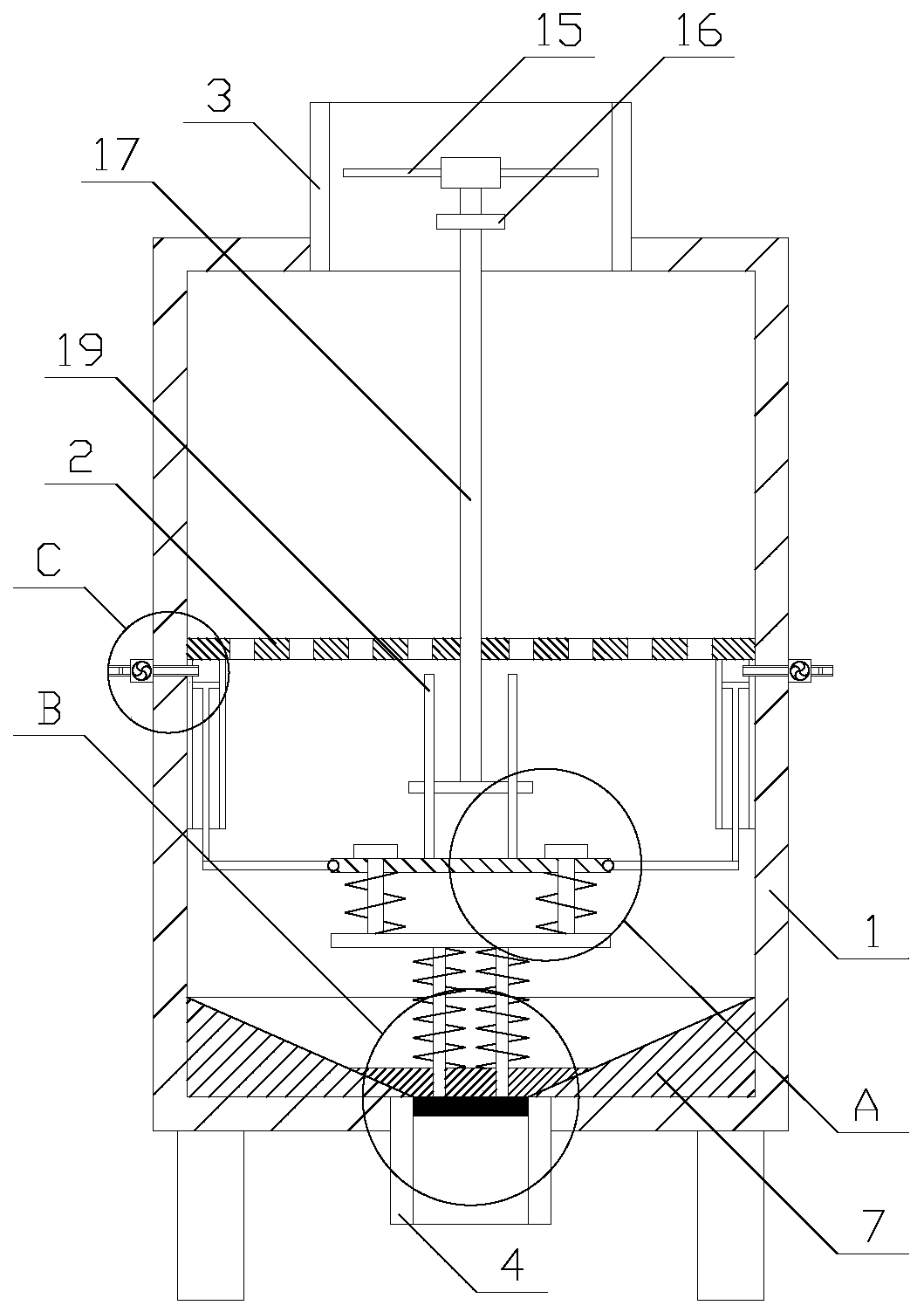

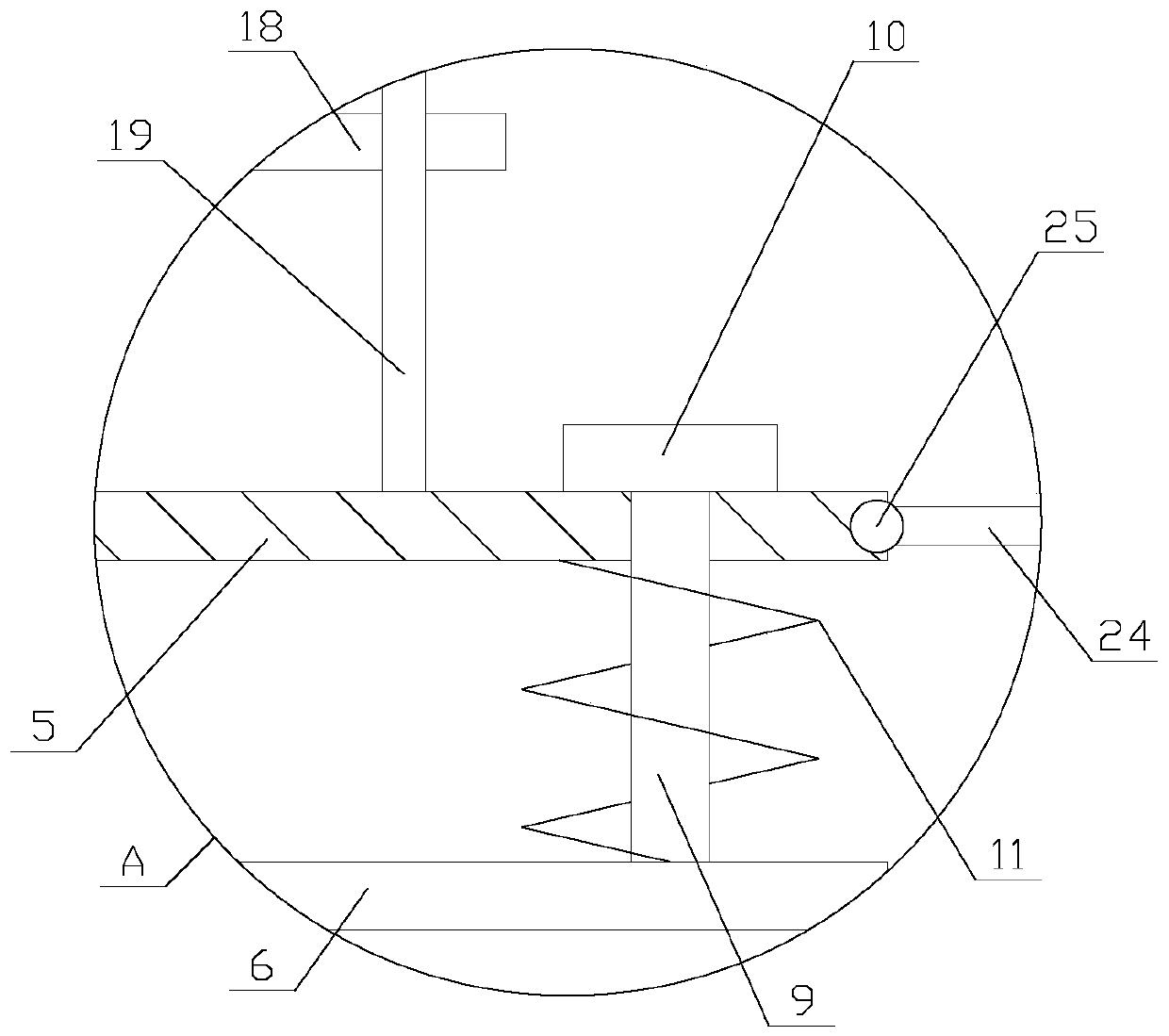

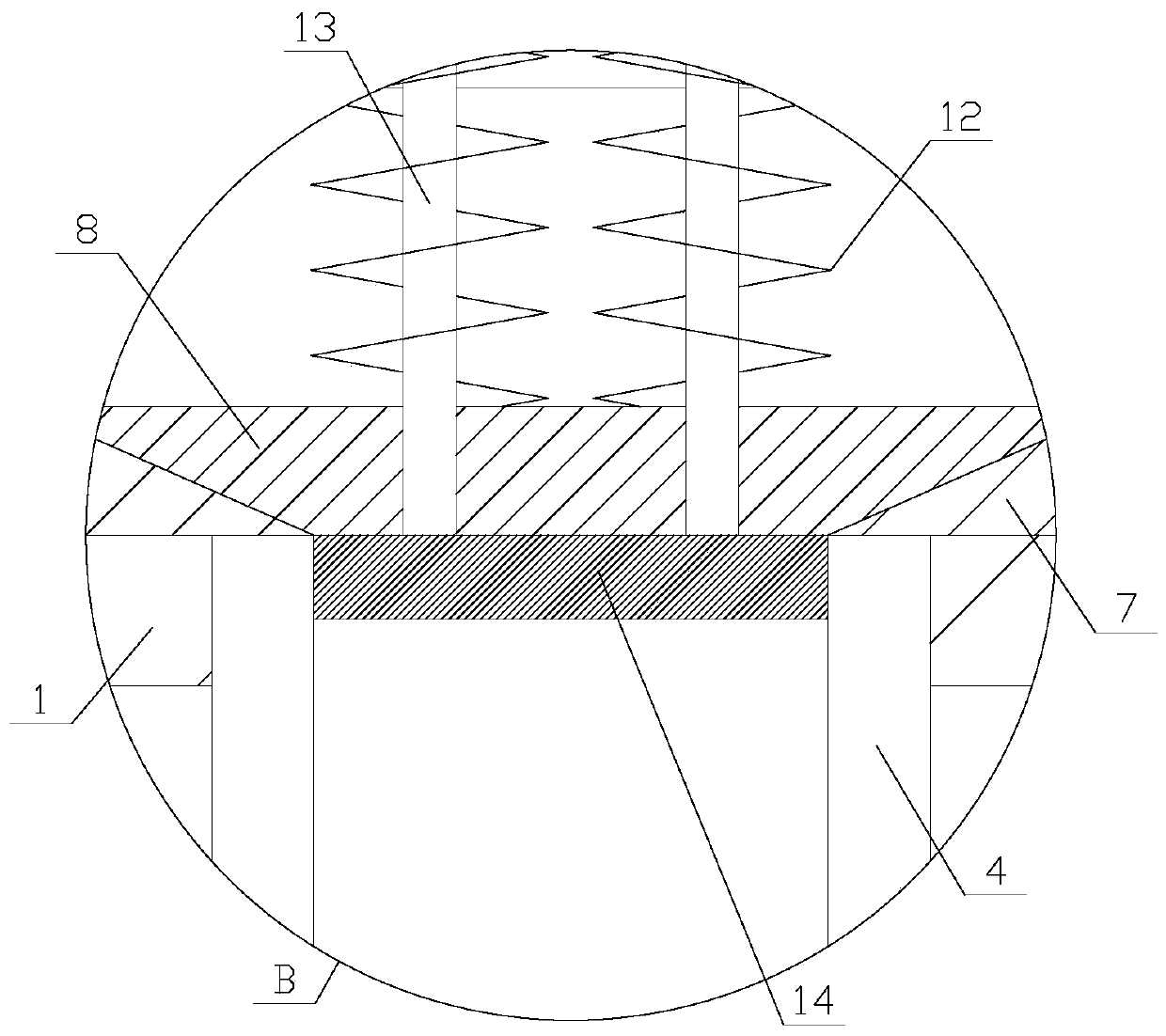

Coal chemical industry apparatus with high stirring effect and high discharging efficiency

InactiveCN110124561APracticalImprove nesting efficiencyTransportation and packagingRotary stirring mixersDischarge efficiencyEngineering

The invention relates to a coal chemical industry apparatus with a high stirring effect and a high discharging efficiency. The apparatus comprises a main body, a feeding tube and a discharging tube, the main body has a cylindrical shape, the discharging tube and the main body are coaxially arranged, the feeding tube is parallel to the discharging tube, a gap is arranged between the axis of the feeding tube and the axis of the main body, the discharging tube is arranged at the bottom end of the main body, the feeding tube is arranged at the top end of the main body, the feeding tube and the discharging tube are both communicated with the main body, the discharging tube is provided with a sealing device, a stirring mechanism is arranged in the main body, the stirring mechanism comprises a power assembly, a stirring assembly and a pushing assembly, and the stirring assembly comprises a connecting tube, a driving disc, at least two supporting units and at least two stirring units. The coalchemical industry apparatus with the high stirring effect and the high discharging efficiency enhances the stirring effect, and also improves the discharging efficiency.

Owner:SHENZHEN BEIYOUTONG NEW ENERGY TECH DEV CO LTD

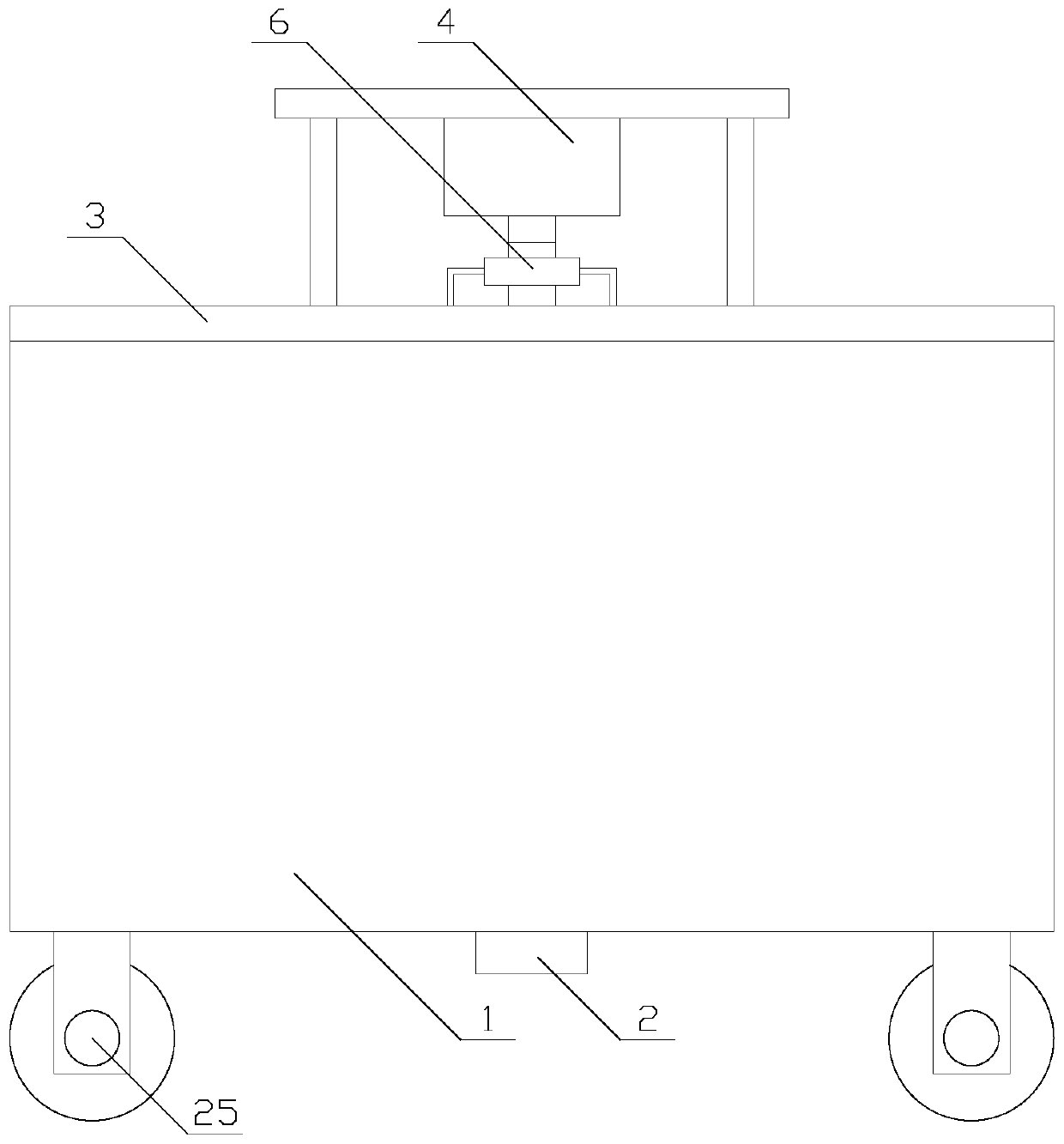

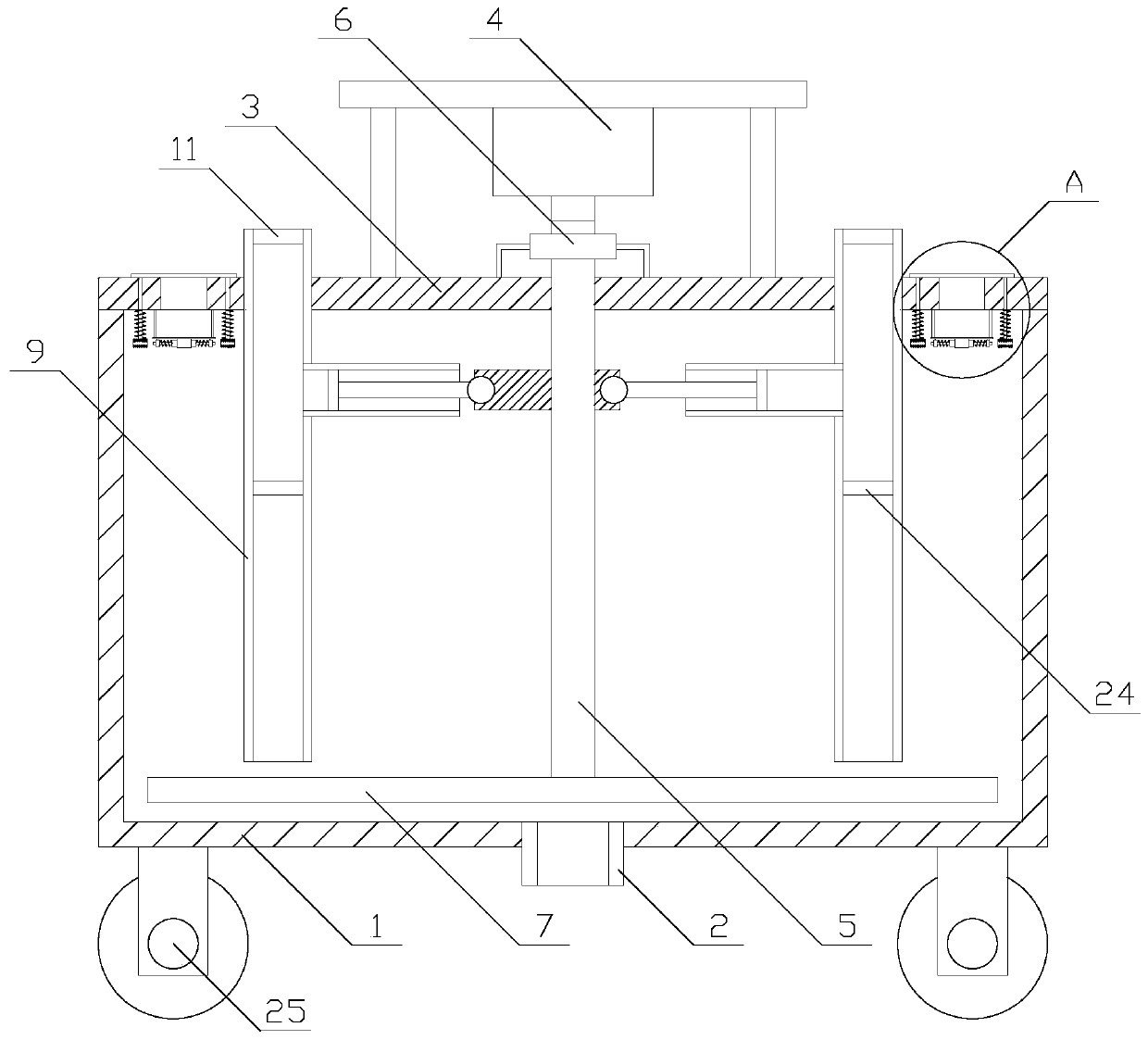

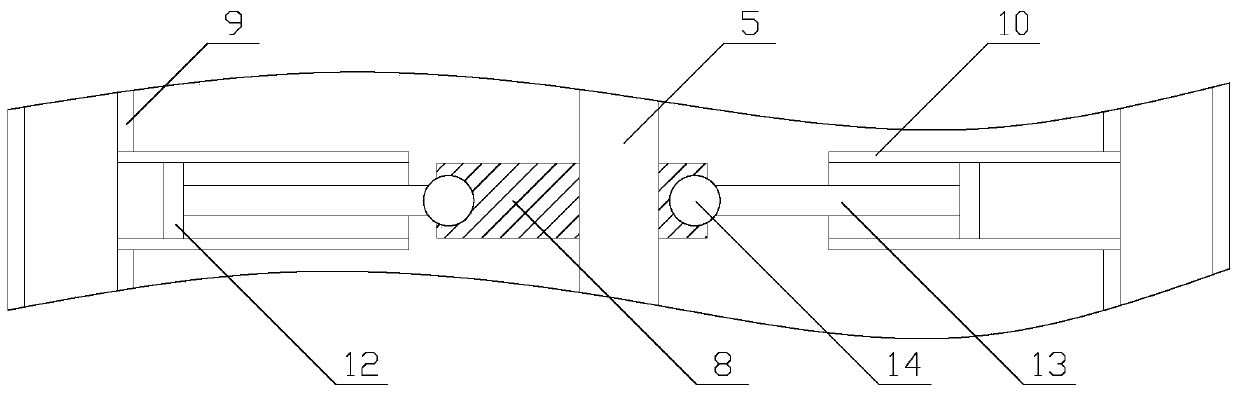

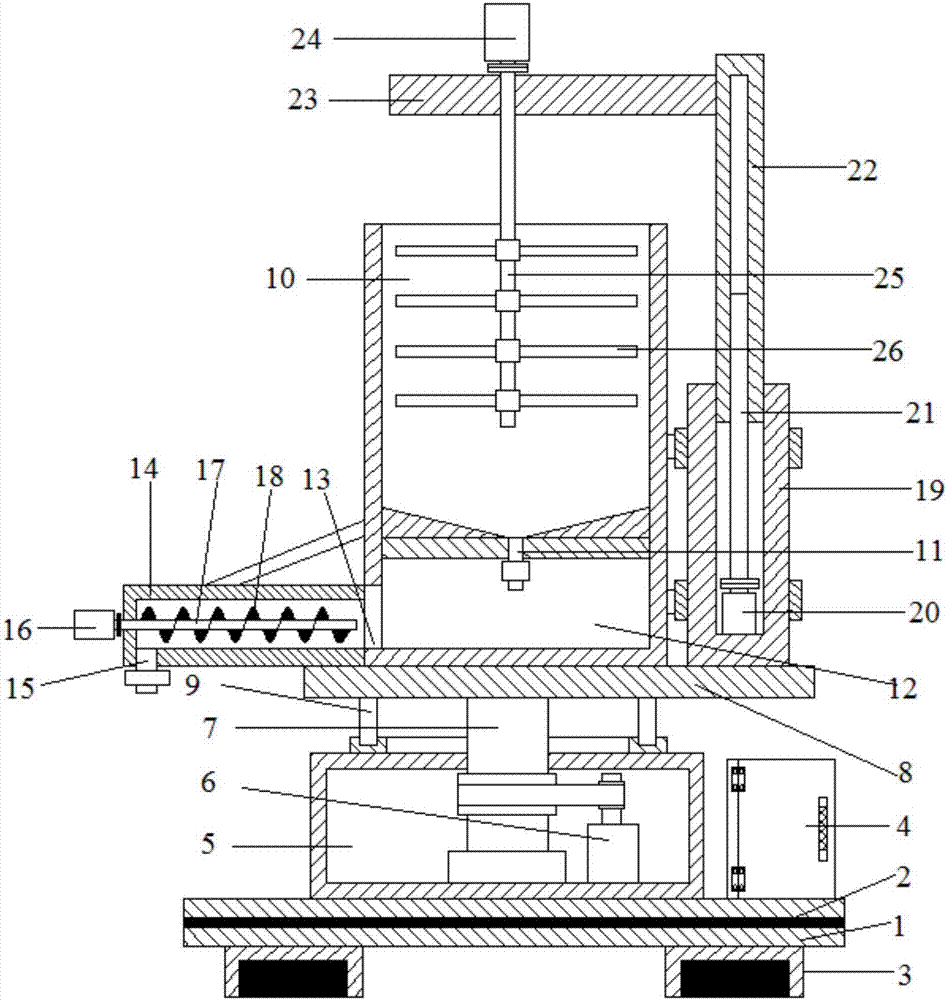

Concrete stirring device for building construction

InactiveCN107498710AImprove stirring efficiencyImprove nesting efficiencyDischarging apparatusCement mixing apparatusArchitectural engineeringBuilding construction

The invention discloses a concrete mixing equipment for building construction, which comprises a base, an electric control box is arranged at the right end of the upper side of the base, a protection chamber is arranged at the upper side of the base, a first motor is arranged at the right end inside the protection chamber, and a first motor is arranged at the left side of the first motor. There is a rotating shaft, the upper side of the rotating shaft is provided with a support plate, the upper side of the support plate is provided with a stirring chamber, the lower side of the stirring chamber is provided with a discharge pipe, the lower side of the discharge pipe is provided with a storage chamber, and the left side of the storage chamber is provided with a delivery chamber There is a discharge pipe at the left end of the lower side of the conveying chamber, a support tube at the right end of the support plate, a third motor inside the support tube, a screw rod on the upper side of the third motor, and a telescopic screw rod at the upper and outer ends of the screw rod. Rod, telescopic rod left upper end is provided with connecting plate, and the upper side of connecting plate is provided with the 4th electric motor, and the fourth motor lower side is provided with stirring shaft, and stirring shaft lower side outer end is provided with stirring bar. The invention can effectively facilitate the mixing of concrete, improve the mixing efficiency of equipment, and can effectively facilitate the discharge of concrete.

Owner:陆春土

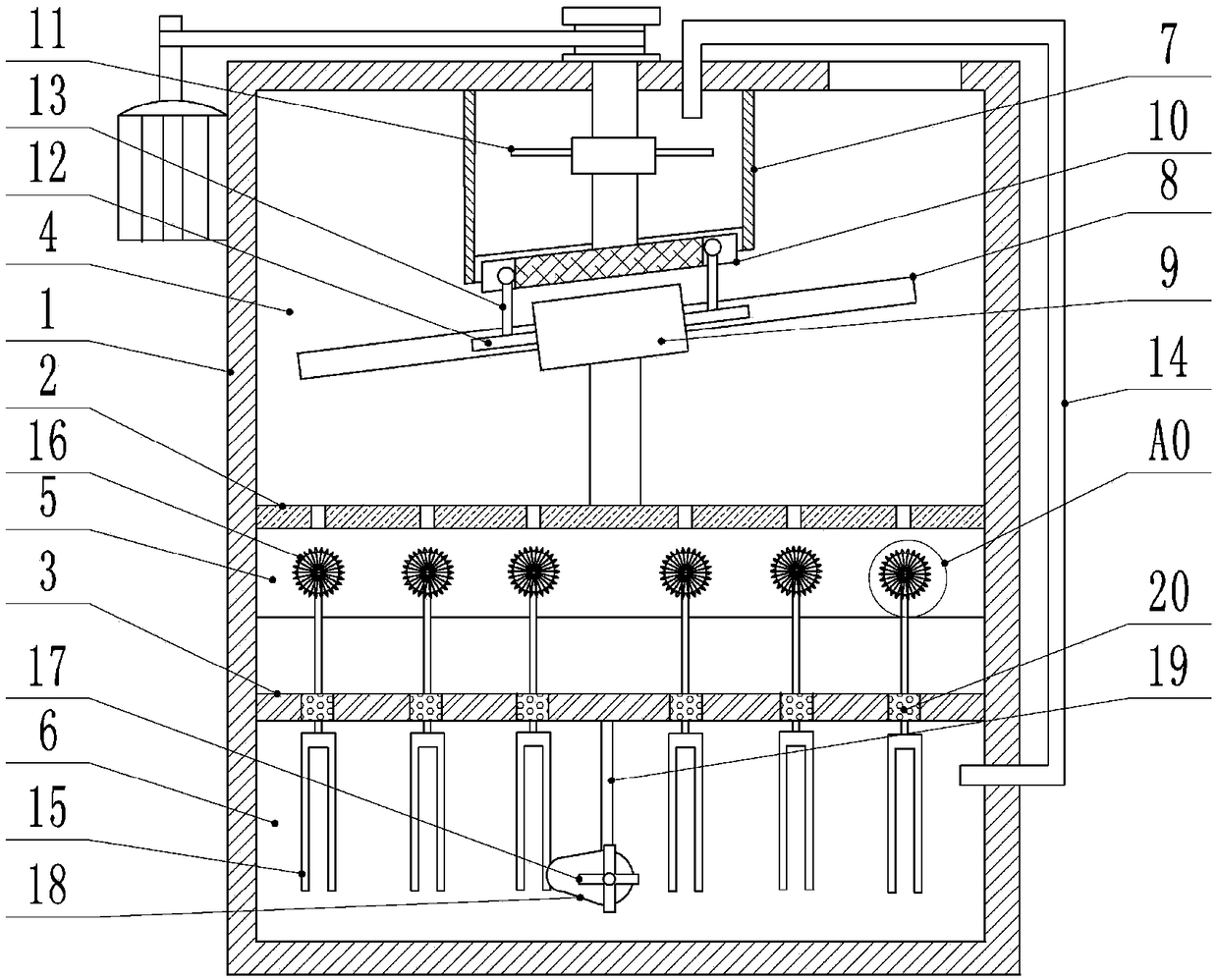

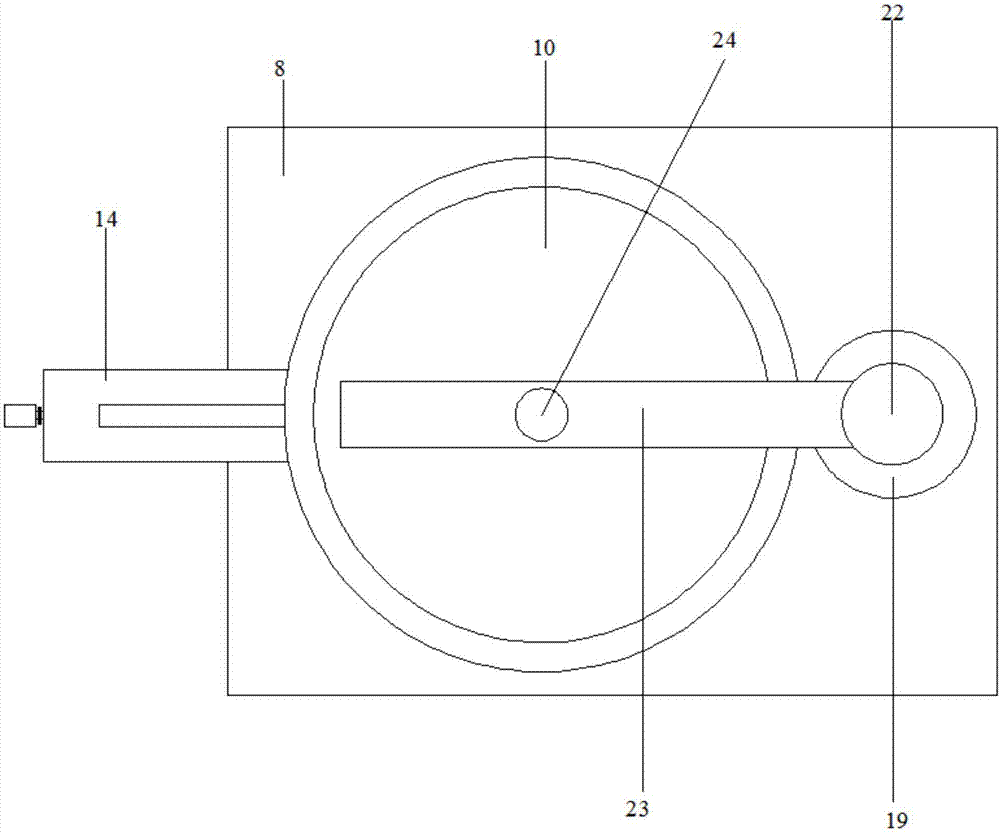

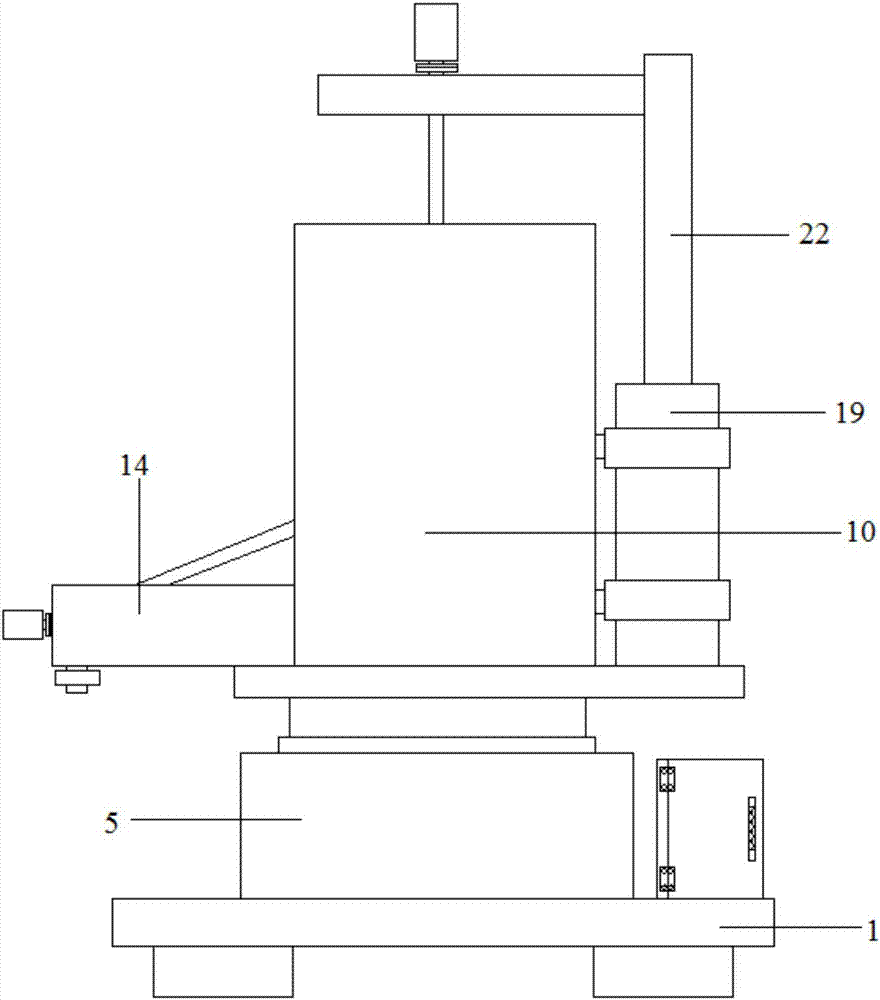

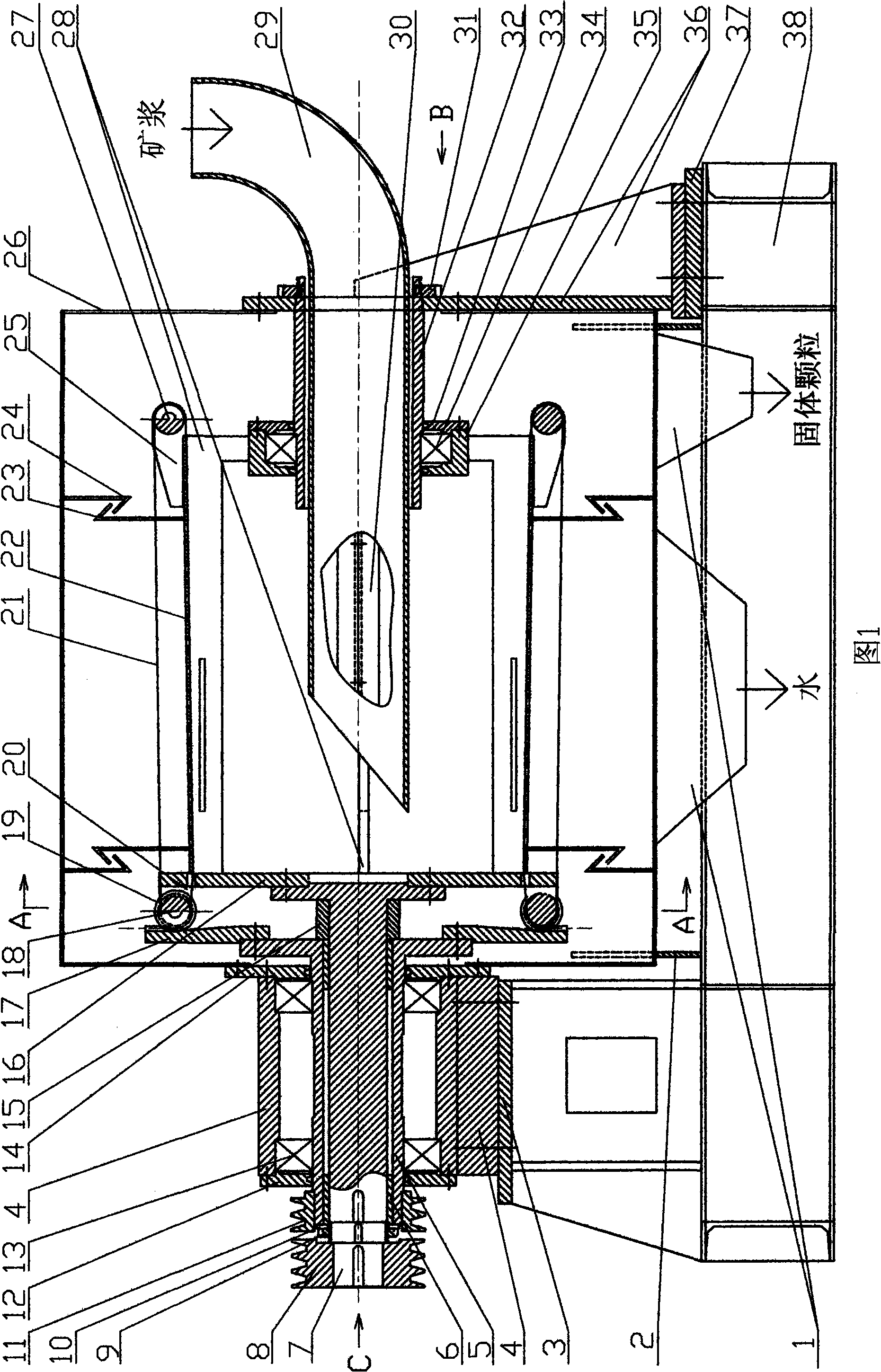

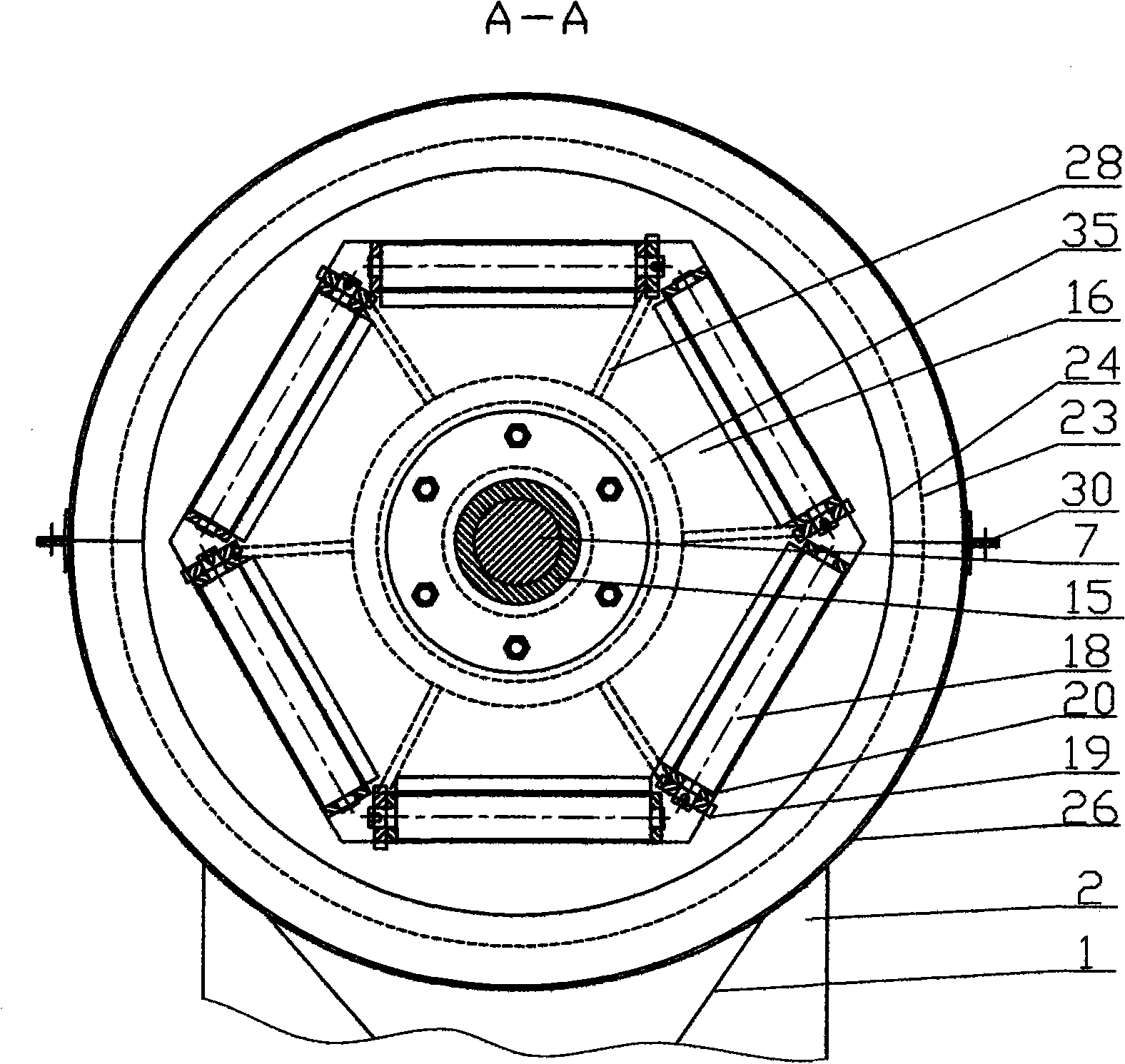

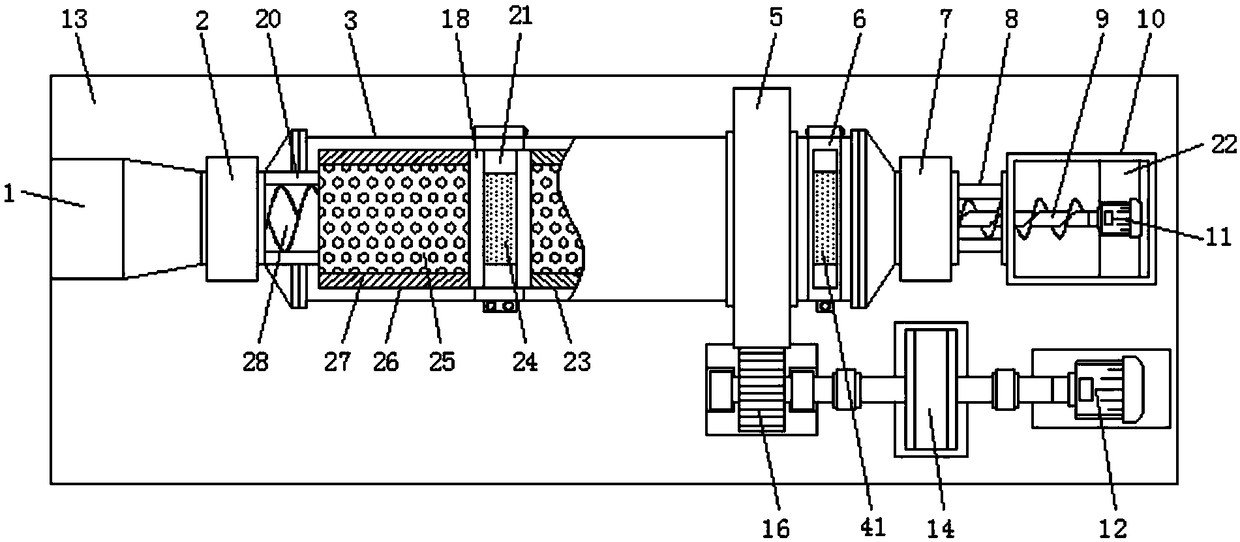

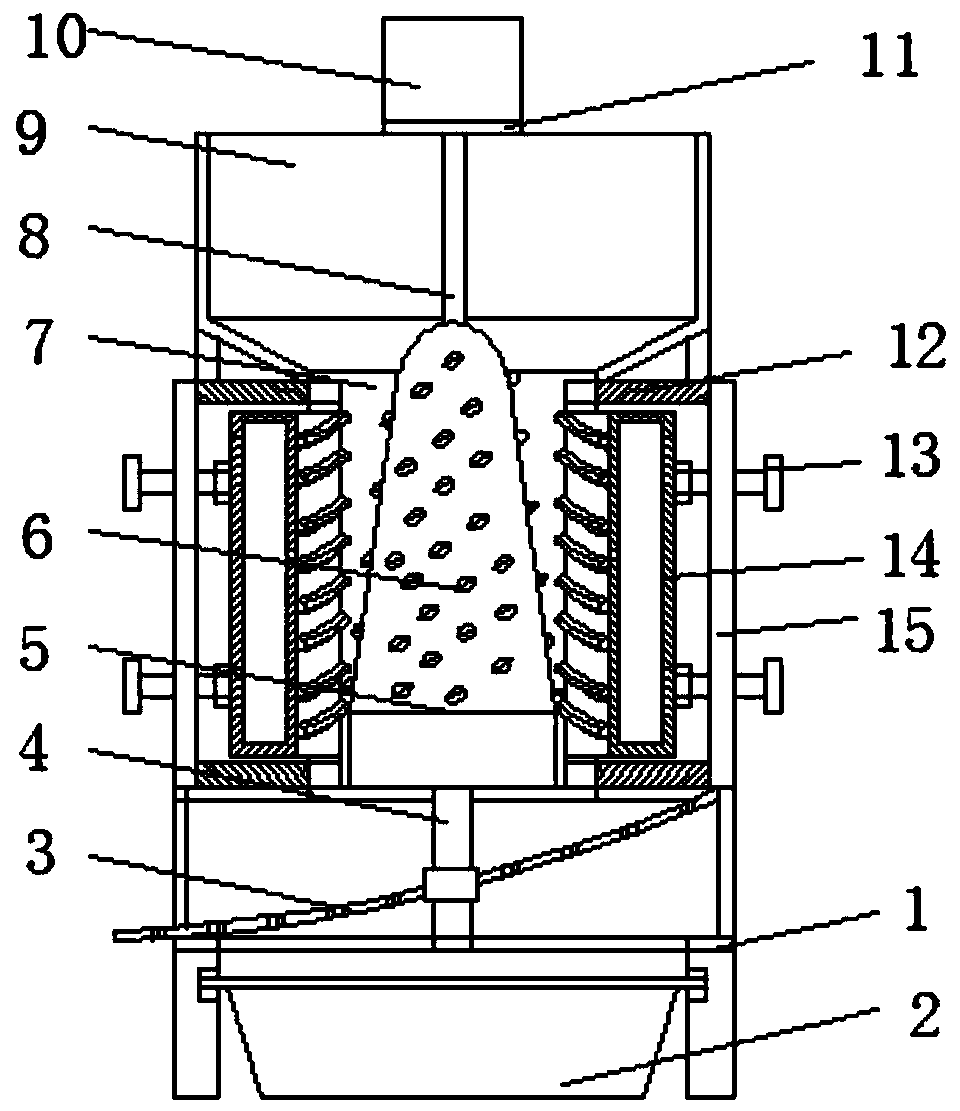

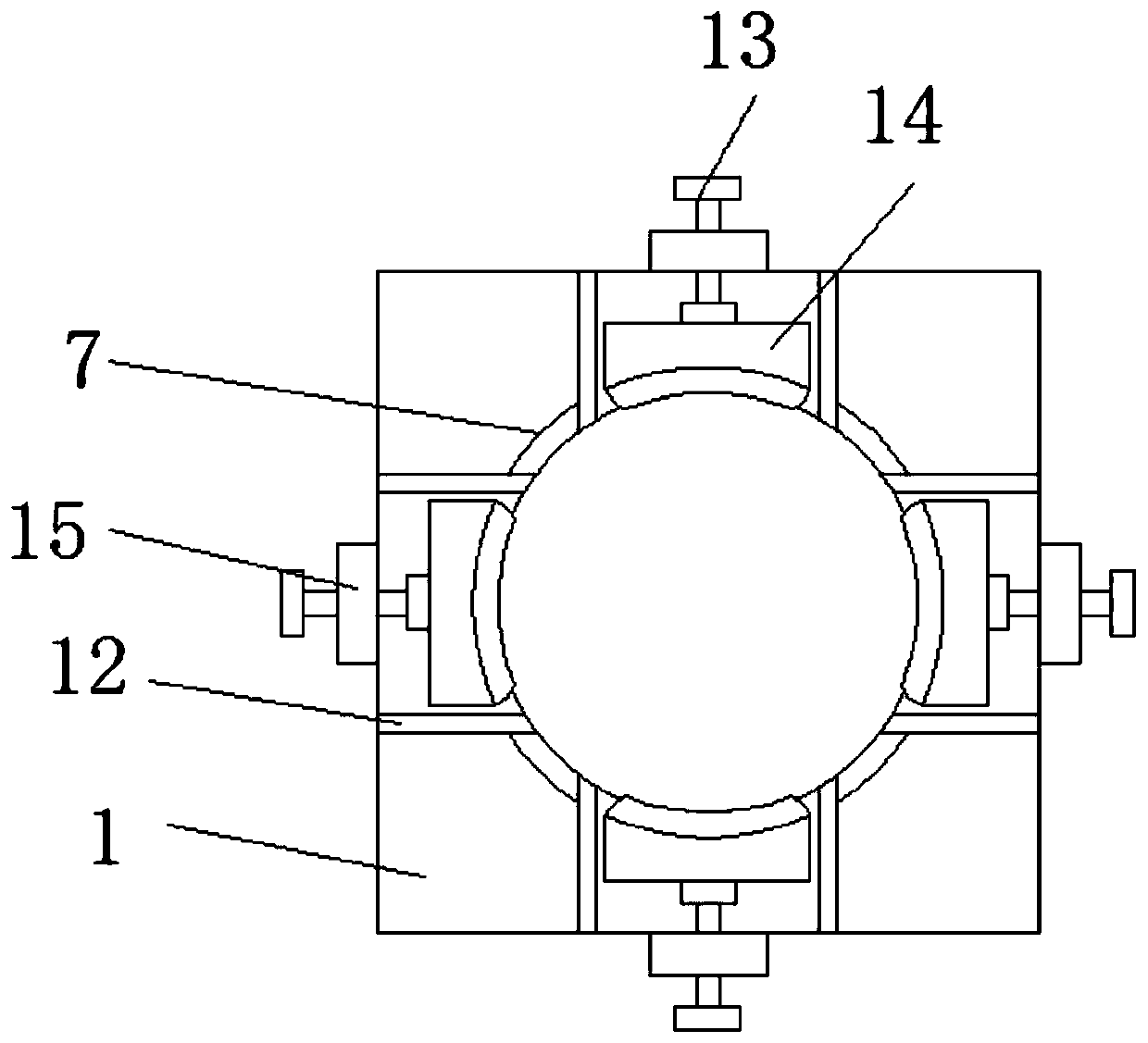

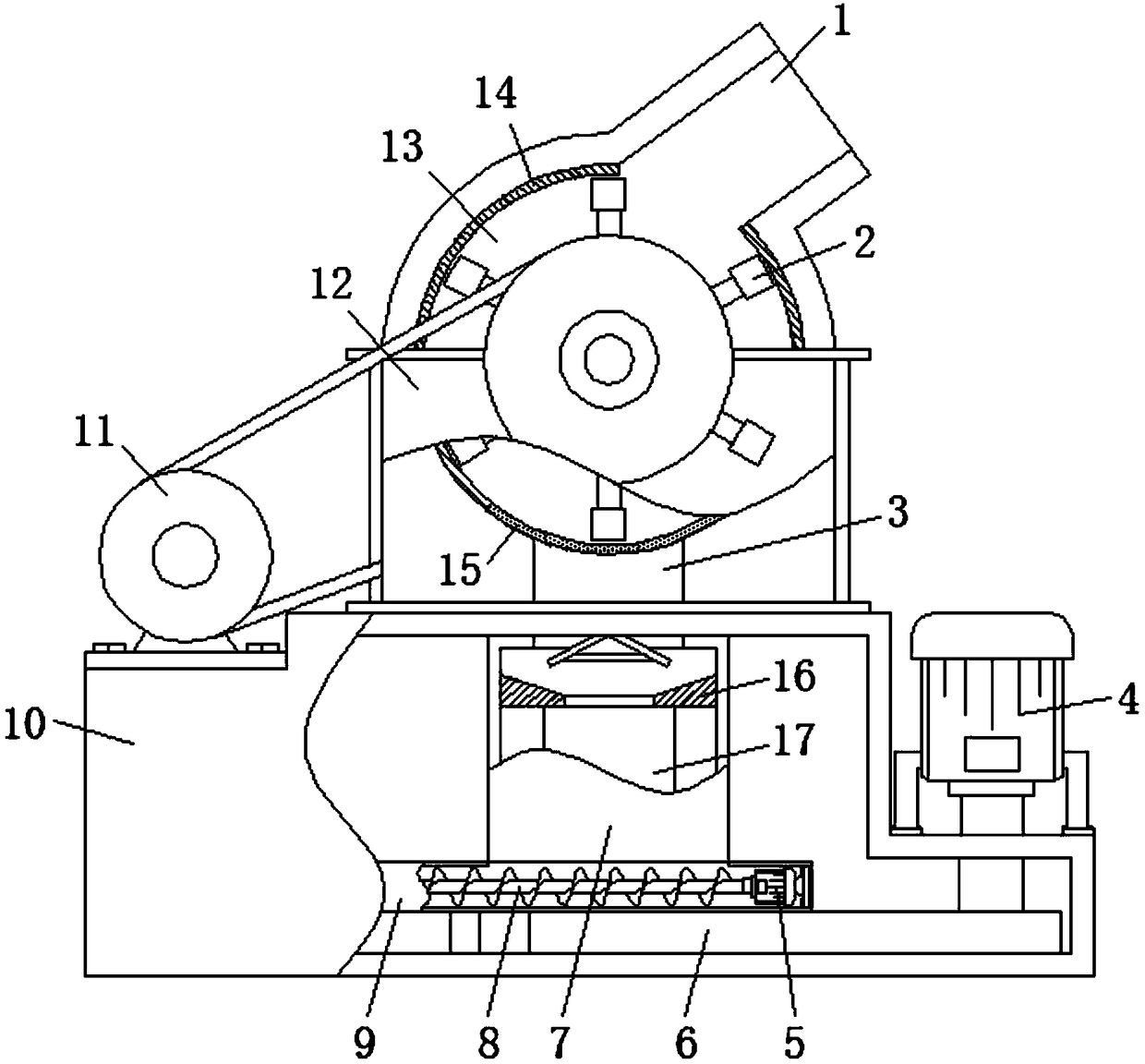

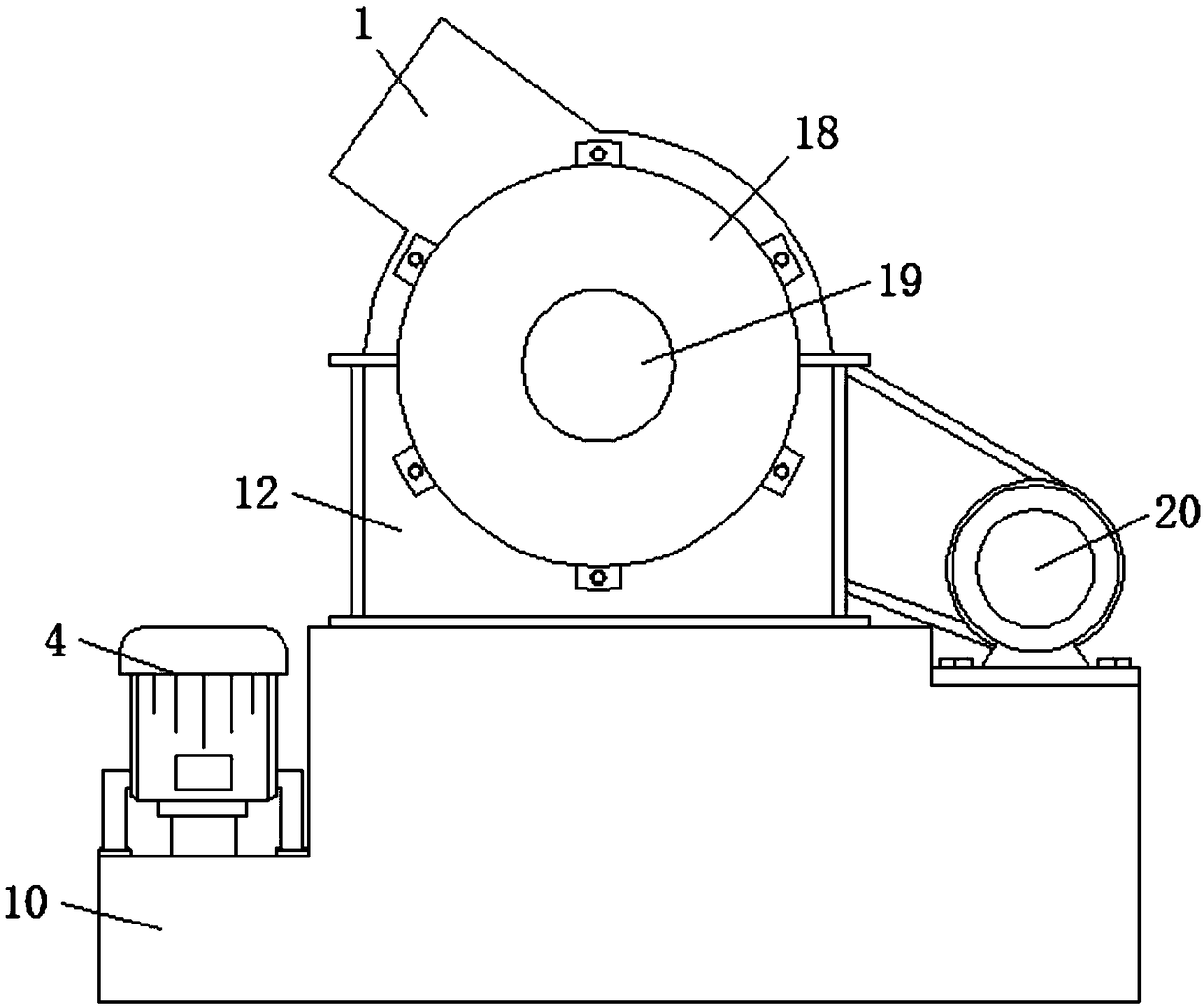

Centrifugation filter-belt dewaterer

InactiveCN101357278AImprove dehydration efficiencyImprove nesting efficiencyMoving filtering element filtersDischarge efficiencyCentrifugation

A centrifugal kinetic filter belt dehydrator pertains to the field of dehydration equipment for environmental protection, ore beneficiation, etc. In order to simplify the complex process of the existing dehydration process, and lower the manufacturing cost and energy consumption of the equipment, the centrifugal kinetic filter belt dehydrator adopts a rotatable filter belt and a right pyramid-shaped rotary dehydration drum structure, so that the dehydration and discharge efficiency is extremely high, and continuous dehydration operation can be realized. The dehydrator is characterized by simple operation, low energy consumption, low manufacturing cost, and the like, and the dehydrator is especially applicable to the field of dehydration equipment for environmental protection, ore beneficiation, etc.

Owner:孙照峰

Energy-saving environment-friendly steel slag tank

The invention relates to the field of steel slag treatment devices, in particular to an energy-saving environment-friendly steel slag tank. The energy-saving environment-friendly steel slag tank comprises a steel slag tank body. The upper end of the steel slag tank body is movably provided with a top cover, and the upper end of the top cover is fixedly provided with a gas outlet pipe. The upper end of the gas outlet pipe is fixedly provided with a slag removing device. A water storage pipe is fixedly installed inside the steel slag tank body. Stirring rods are fixedly installed on the both sides of the water storage pipe. Slag scraper plates are fixedly installed at the outer ends of the stir rods. A filter plate is arranged in a circular ring shape to prevent steam from taking out slag inside the steel slag tank body. Through grooves are formed inside a gas guide plate, slag removal blocks are movably installed at the upper end of the gas guide plate, after the rotating plate rotates,by means of the wavy bent arrangement of the inner side of the rotating plate, the rotating plate intermittently drives the slag removal blocks to overcome the action force of springs to downwards pass through the through grooves and scrape the slag blocked on the filter plate, the slag is made to move downward to enter the slag collecting box, so that the filter plate can be prevented from beingblocked, and centralized processing of the slag is convenient.

Owner:练素霞

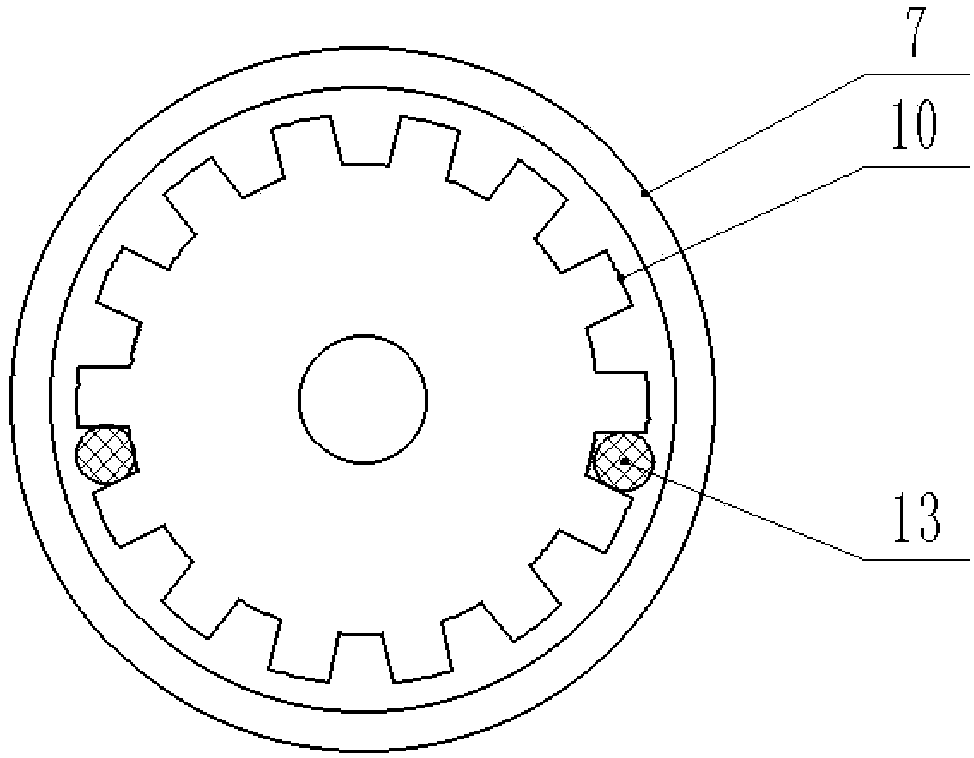

Dry type ball mill for mineral separation

The invention discloses a dry type ball mill for mineral separation. The dry type ball mill for the mineral separation comprises a cylinder. A first lower seat, a second lower seat and a large gear are installed on the cylinder. The first lower seat and the second lower seat are located on the two sides of the large gear correspondingly. One side of the first lower seat and one side of the secondlower seat are rotationally connected with a first upper cover and a second upper cover correspondingly through hinges. The inner portions of the first upper cover and the second upper cover are bothinternally provided with moving clamping grooves. The inner portions of the first lower seat and the second lower seat are both provided with fixing clamping grooves. According to the dry type ball mill for mineral separation, locating rings, a first bin partition plate, lock grooves, fixing bolts, bolt holes, lock rods, reset springs and a second bin partition plate are arranged, when the bin partition plates are replaced, the fixing bolts on the upper covers and the lower seats are disassembled first of all, the lock rods on the two sides of the bolt holes lose limitation after the fixing bolts are disassembled, under rebounding of the reset springs, the lock rods shrink into the bin partition plates, so that limitation between the bin partition plates and the locating rings is eliminated, the bin partition plates are in the movable state, and then bolts between the upper covers and the lower seats are unscrewed through a tool.

Owner:日照市莒县鑫友矿业有限公司

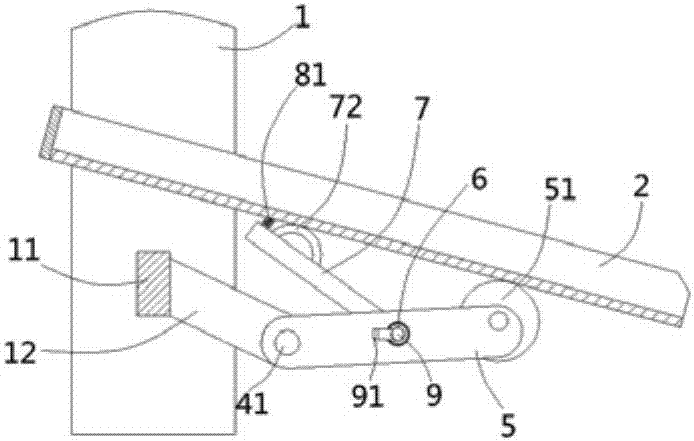

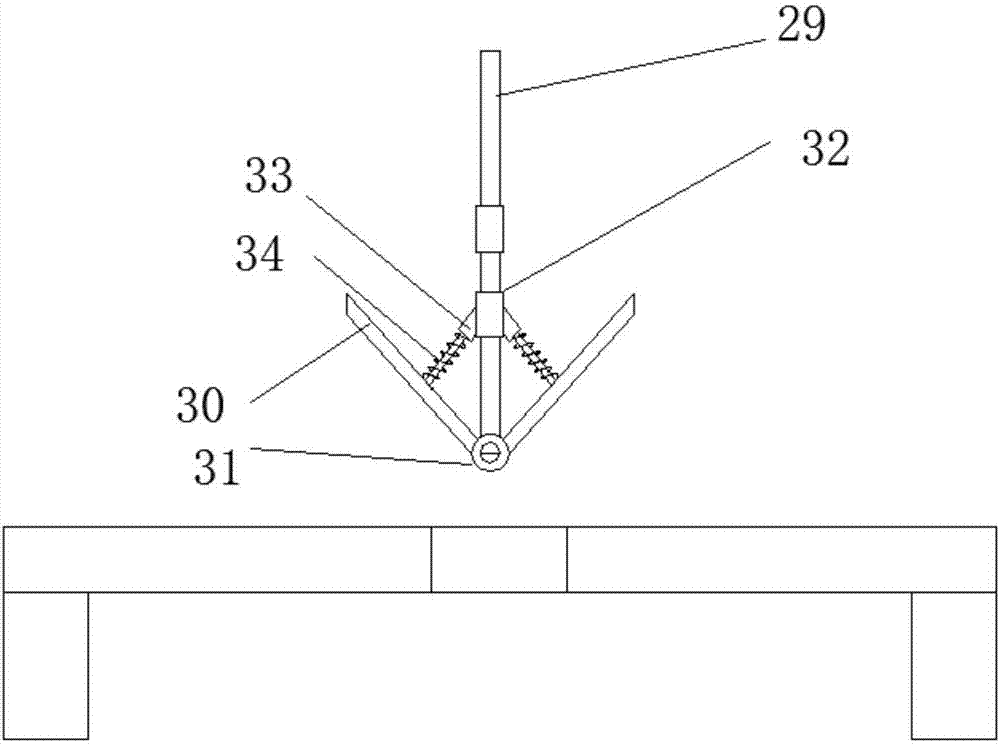

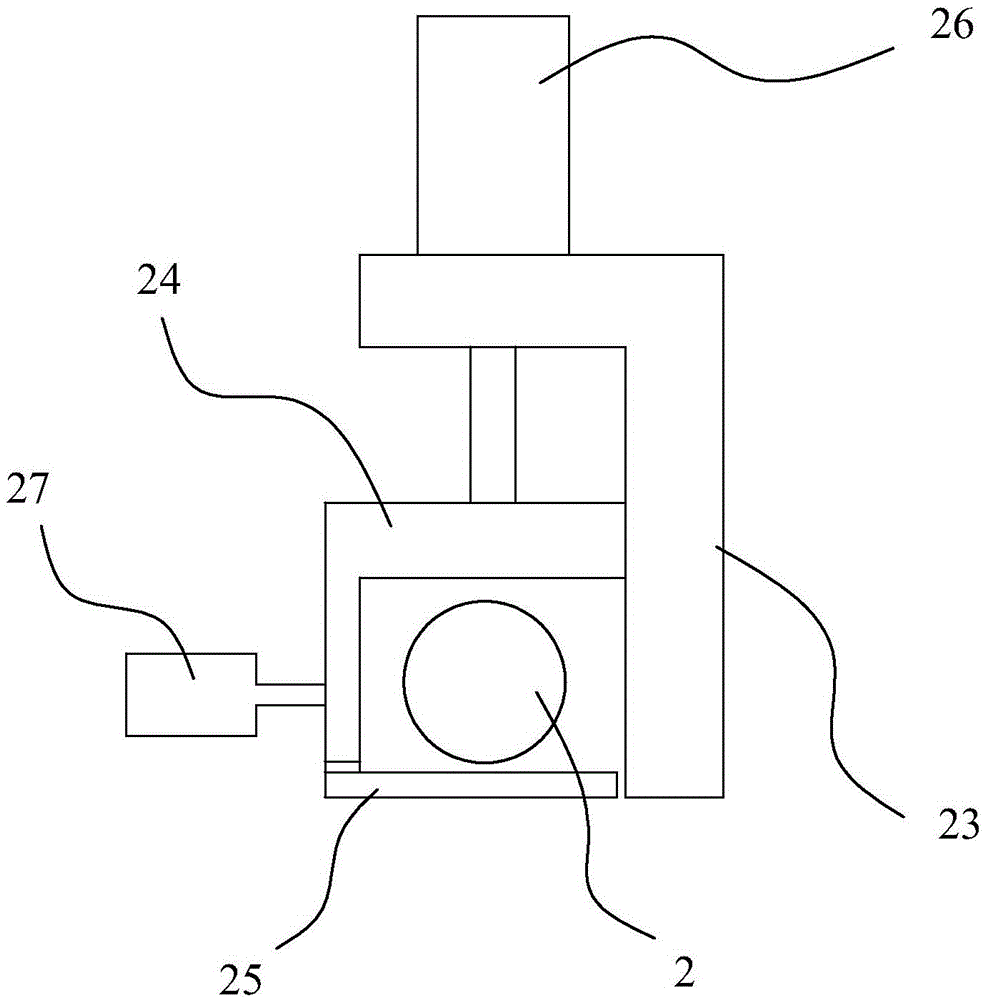

Waste landing point-variable waste discharge mechanism

ActiveCN107962129AAchieve dischargeImprove nesting efficiencyStripping-off devicesTorsion springLanding point

The invention discloses a waste landing point-variable waste discharge mechanism. The waste landing point-variable waste discharge mechanism comprises stand columns on a punching machine; an inclineddischarge groove plate is arranged between the stand columns; a rotating shaft is hinged between the stand columns; support rods are fixedly inserted in the two sides of the rotating shaft; one ends of the support rods butt against the bottom surface of the discharge groove plate; a support shaft is inserted between the support rods; beating rods are inserted in the two sides of the support shaft,and are provided with arc beating plates; pressure springs are fixed on the beating rods on one sides above the beating plates; one end of the support shaft penetrates through the support rods, and is inserted with a torsion spring; the two ends of the torsion spring are respectively fixed on the side walls of the support rods and the support shaft; a limiting rod is inserted in the end side wallof the support shaft, and cooperates with a spline of the support shaft; limiting keys are molded on the side wall of the limiting rod; limiting grooves are molded on the side walls of the support rods; and the limiting keys are inserted in the limiting grooves. The waste landing point-variable waste discharge mechanism is variable in waste landing point, is suitable for loading wastes in large waste frames, and meanwhile, can realize smooth discharge of wastes.

Owner:金鹏飞

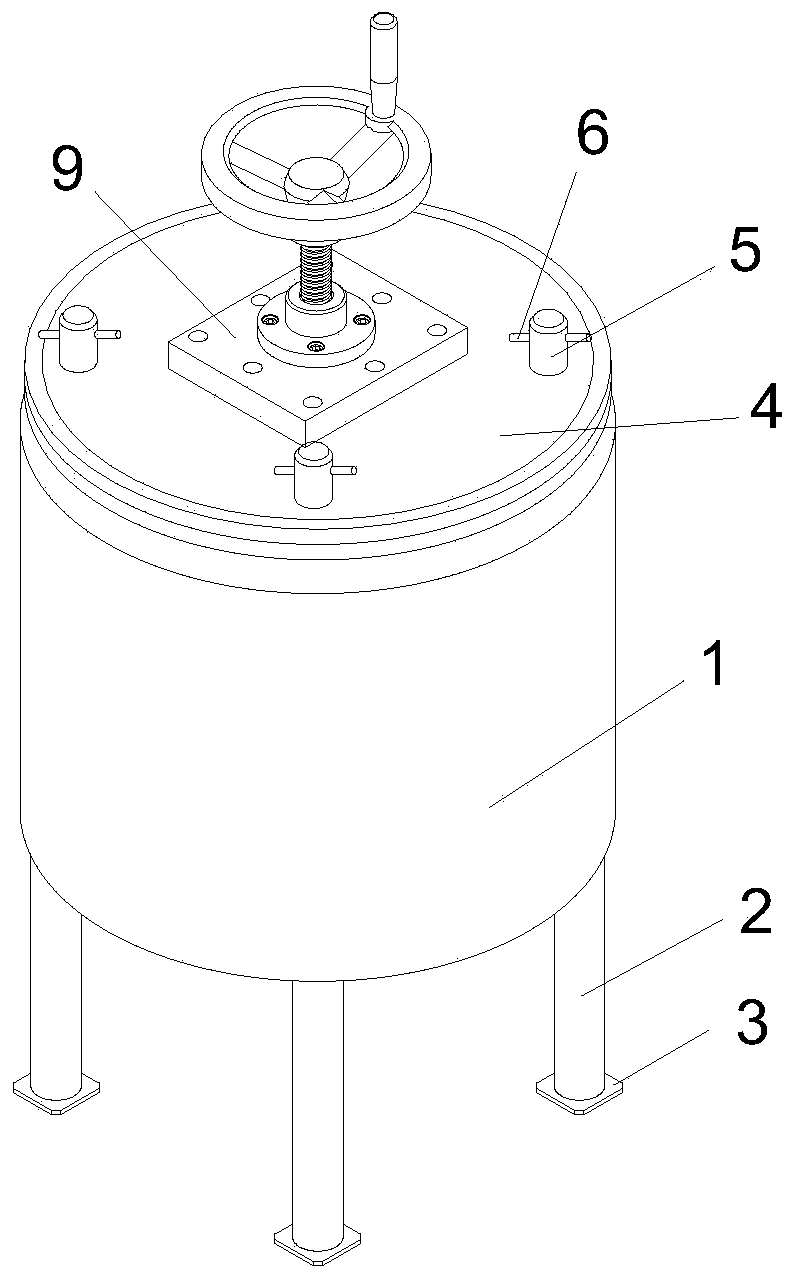

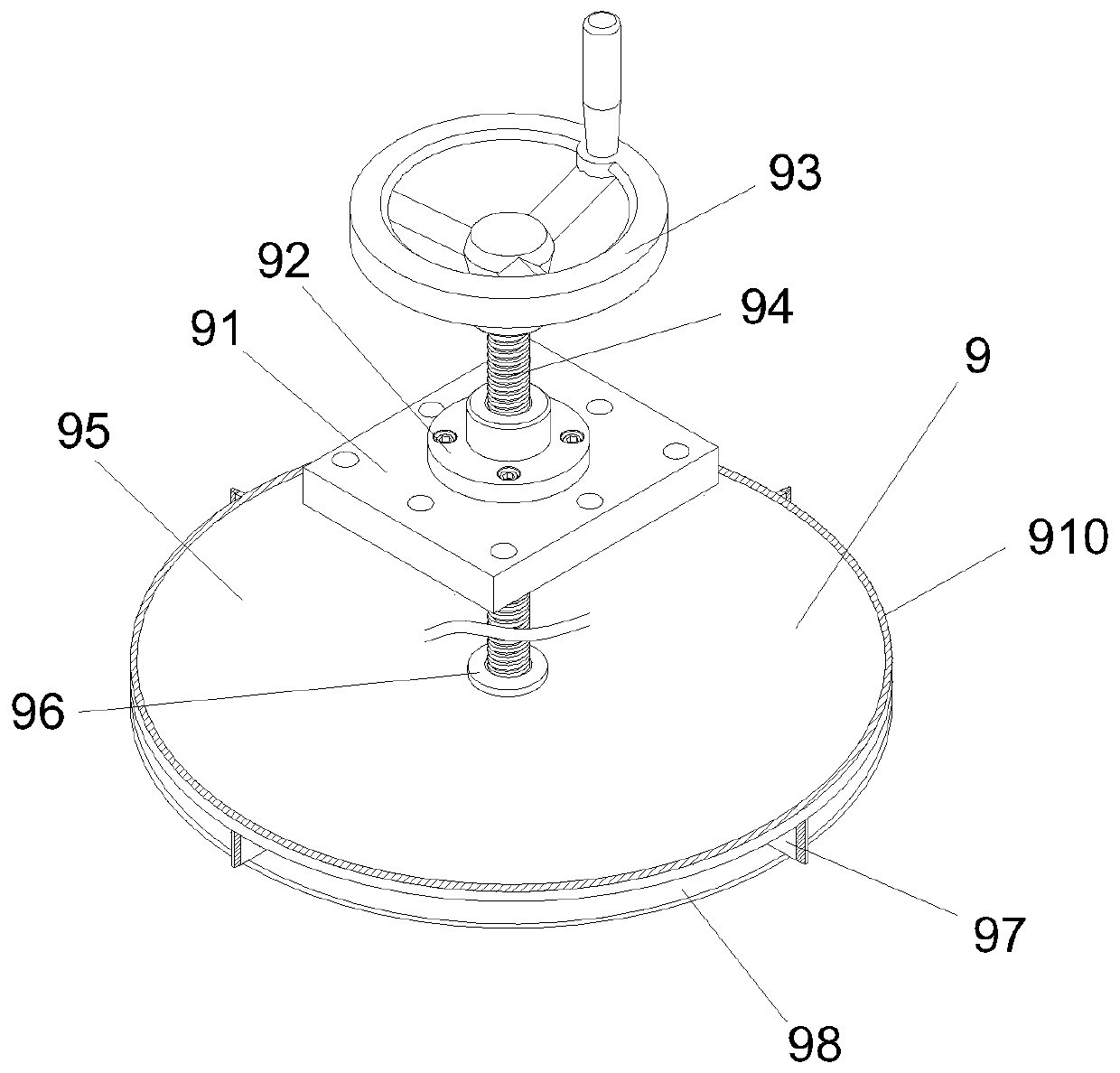

Safe transportation tank for polyurethane resin

ActiveCN110817165AIncrease unloading speedImprove cleanlinessLarge containersPolymer scienceEngineering

The invention discloses a safe transportation tank for polyurethane resin. The safe transportation tank for polyurethane resin comprises a tank body, supporting legs, foot pads, a sealing cover, a locking bolt, a knob, a discharge port, a discharge valve and an extrusion and pushing device. According to the safe transportation tank for polyurethane resin, the extrusion and pushing device is arranged in the tank body, and when discharging is carried out, a hand wheel is rotated to drive a pressing plate through a screw rod so as to extrude and push downward the internal storage polyurethane resin, so that the discharging of the polyurethane resin is accelerated; a cleaning device is arranged at the bottom of a partition top plate, and the polyurethane resin adhering to the inner wall of thetank body is scraped off through a scraping head on a scraping plate, so that the cleanliness of the inside of the tank body is improved; and meanwhile, a sealing structure is arranged on an outer ring of the partition top plate, a mounting fixing frame is tightly attached to the partition top plate, and then a center ring, a first side sealing ring and a second side sealing ring seal the partition top plate, so that the polyurethane resin is prevented from passing through the gap between the extrusion and pushing device and the inner wall of the tank body, and the discharging efficiency is improved.

Owner:东莞市嘉洋塑胶科技有限公司

Boiler heating type feed dehumidifying and drying device

InactiveCN107388761AImprove thermal conductivityEvenly distributedDrying machines with non-progressive movementsDrying solid materialsDischarge efficiencyCombustion

The invention discloses a boiler-heating type feed dehumidification and drying equipment, which comprises a base, a drying drum, a heat-conducting inner furnace body and a heat-retaining outer furnace body. There is a heat-conducting inner furnace body, a flue gas passage is set between the heat-conducting inner furnace body and the heat-insulating outer furnace body, a chimney is installed on the top of the heat-insulating outer furnace body, and the chimney communicates with the flue gas passage, and the heat-conducting inner furnace body is below The thermal insulation outer furnace body is set as a combustion furnace; the heat-conducting inner furnace body is provided with a heating furnace cavity, and a drying drum is worn in the heating furnace cavity; the heat-conducting inner furnace body has good heat conduction effect and can evenly distribute heat. Realize the full utilization of the heat generated by combustion, the heating effect is good and the heating is uniform; the tumbling and stirring of the feed is improved to avoid the accumulation of the feed on the inner wall of the drying drum, which improves the uniformity of the feed mixing, which is conducive to the full heating and drying of the feed, and improves the Improve the quality and effect of feed drying and improve the discharge efficiency of feed.

Owner:赵娜

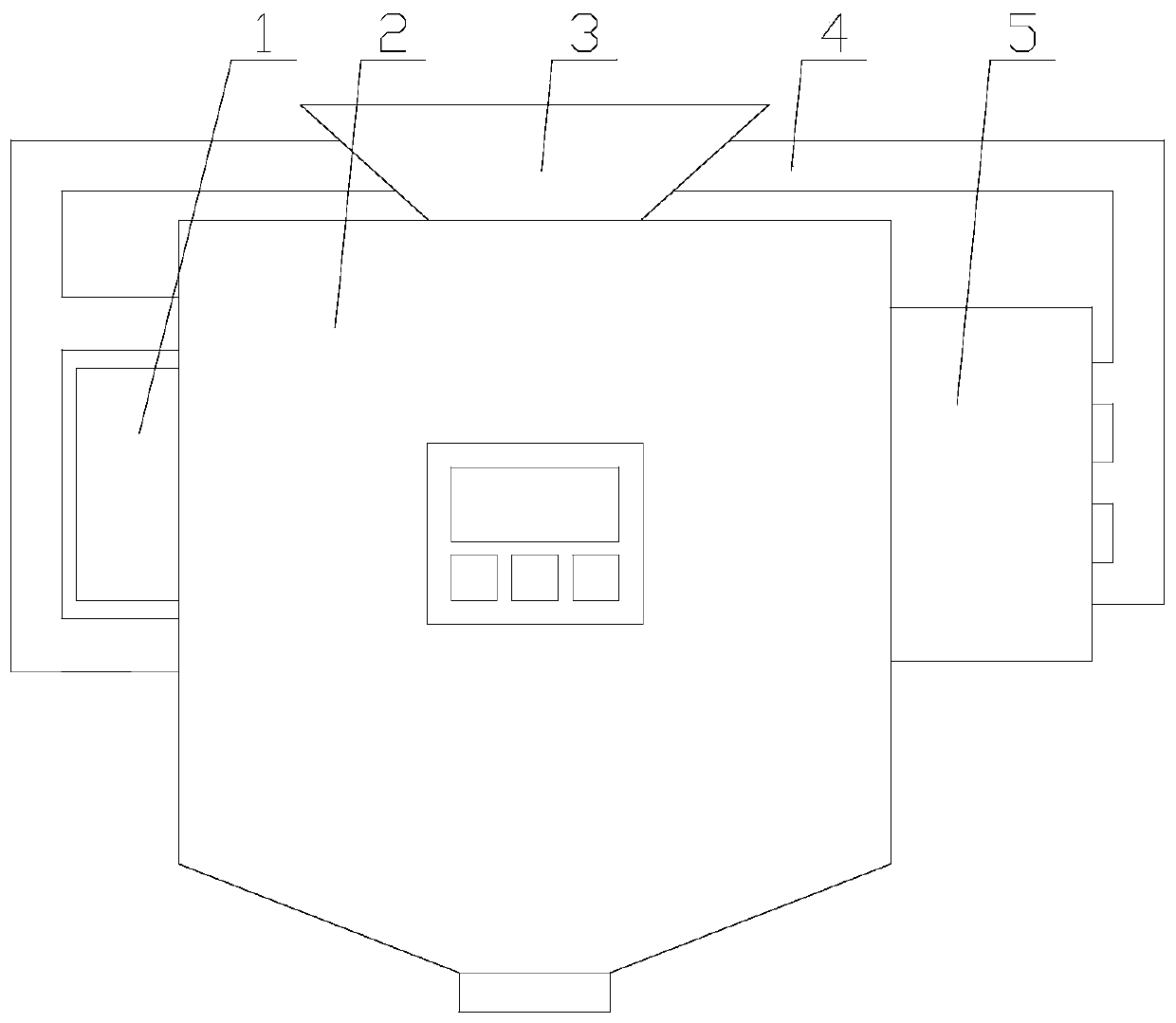

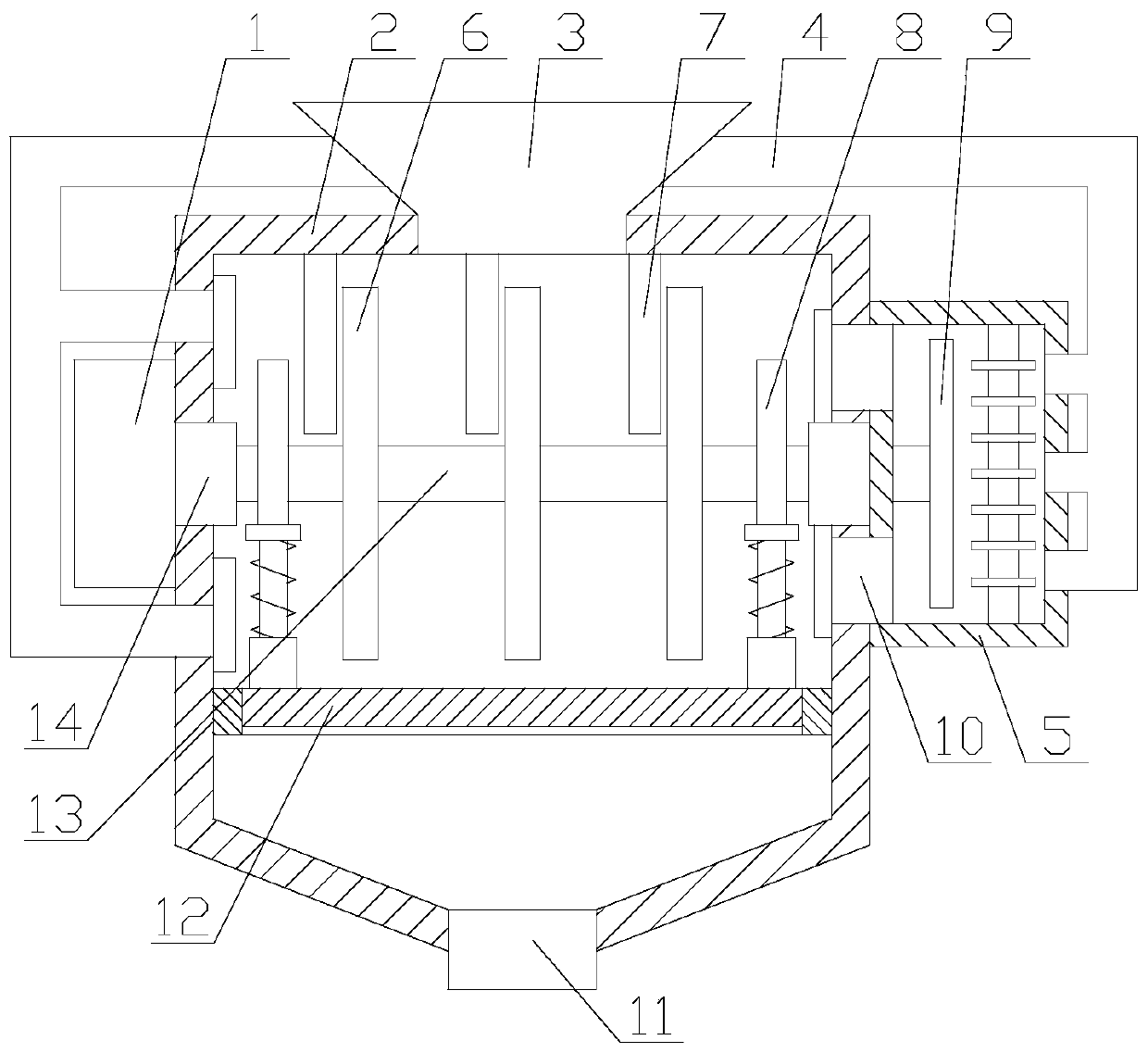

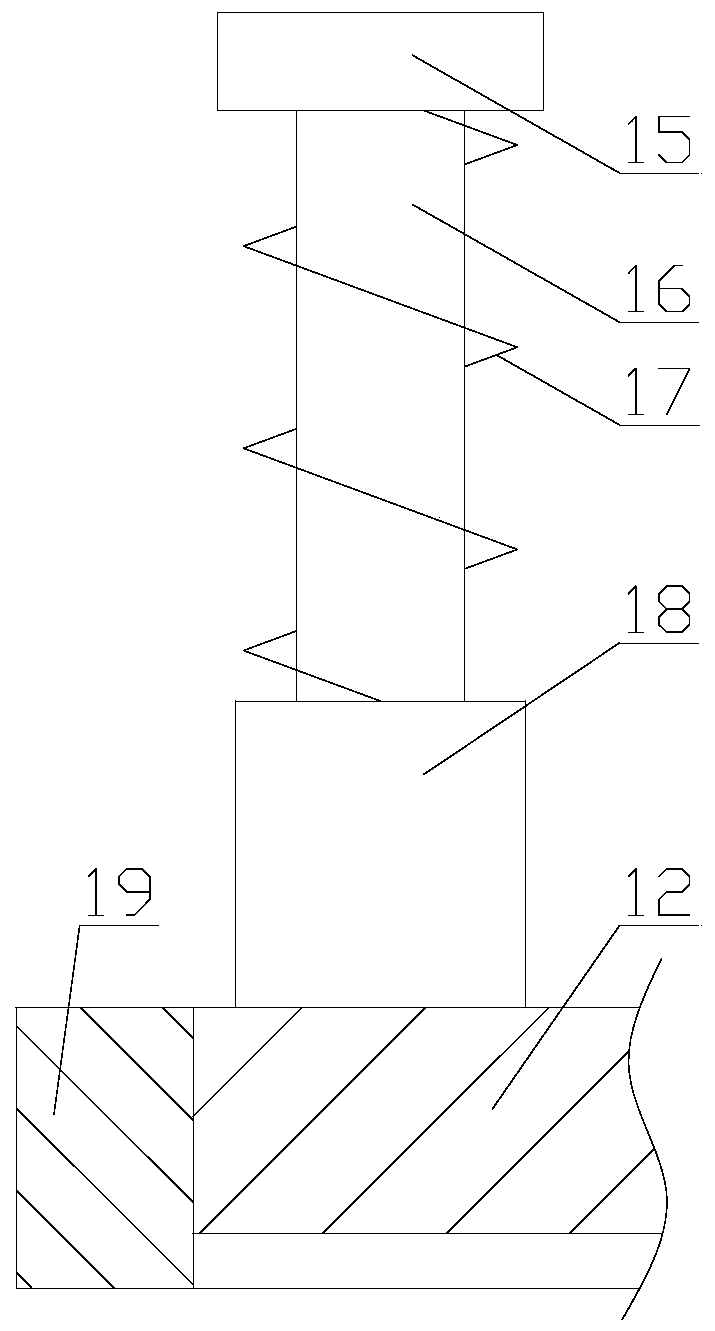

Nesting material for artificial breeding wasps

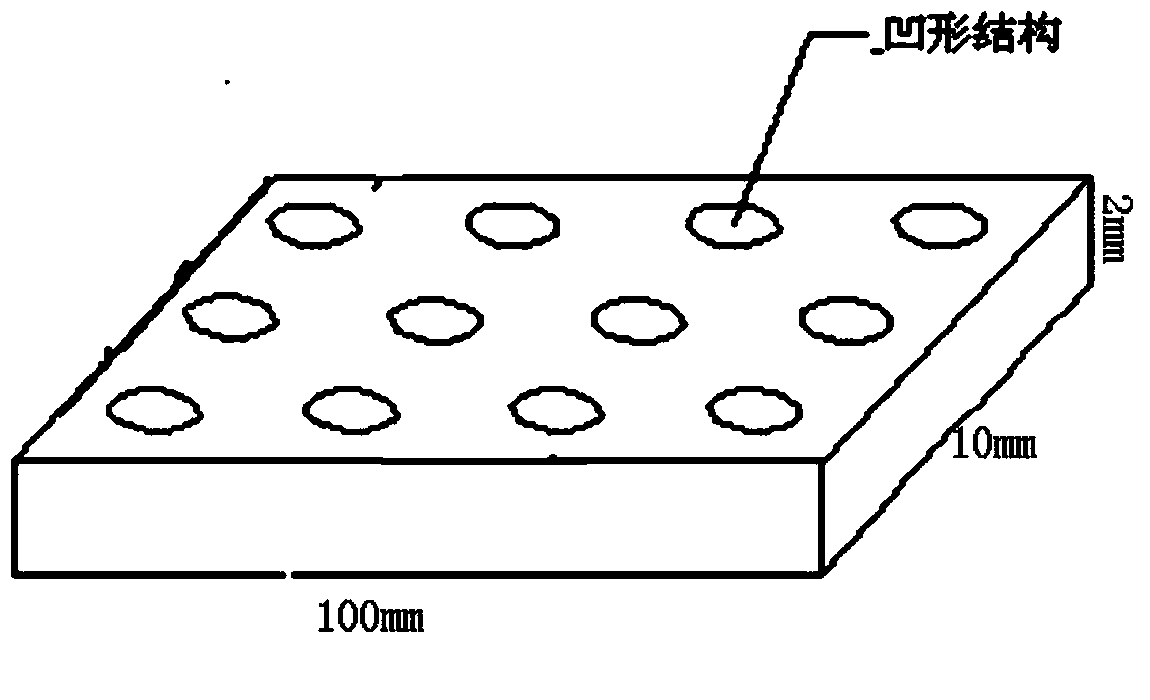

ActiveCN104285907ANesting time shortenedImprove nesting efficiencyAnimal husbandryEucalyptusBiotechnology

The invention discloses a nesting material for artificial breeding wasps. The nesting material comprises, by weight, 1-30 parts of cedar skin, 1-30 parts of red eucalyptus skin, 1-30 parts of maize straw, 1-30 parts of wheat straw and 1-10 parts of edible gum. By the nesting materials, nesting time for the wasps is greatly shortened, and nesting efficiency is greatly improved.

Owner:天峨县全盛蜂业科技有限公司

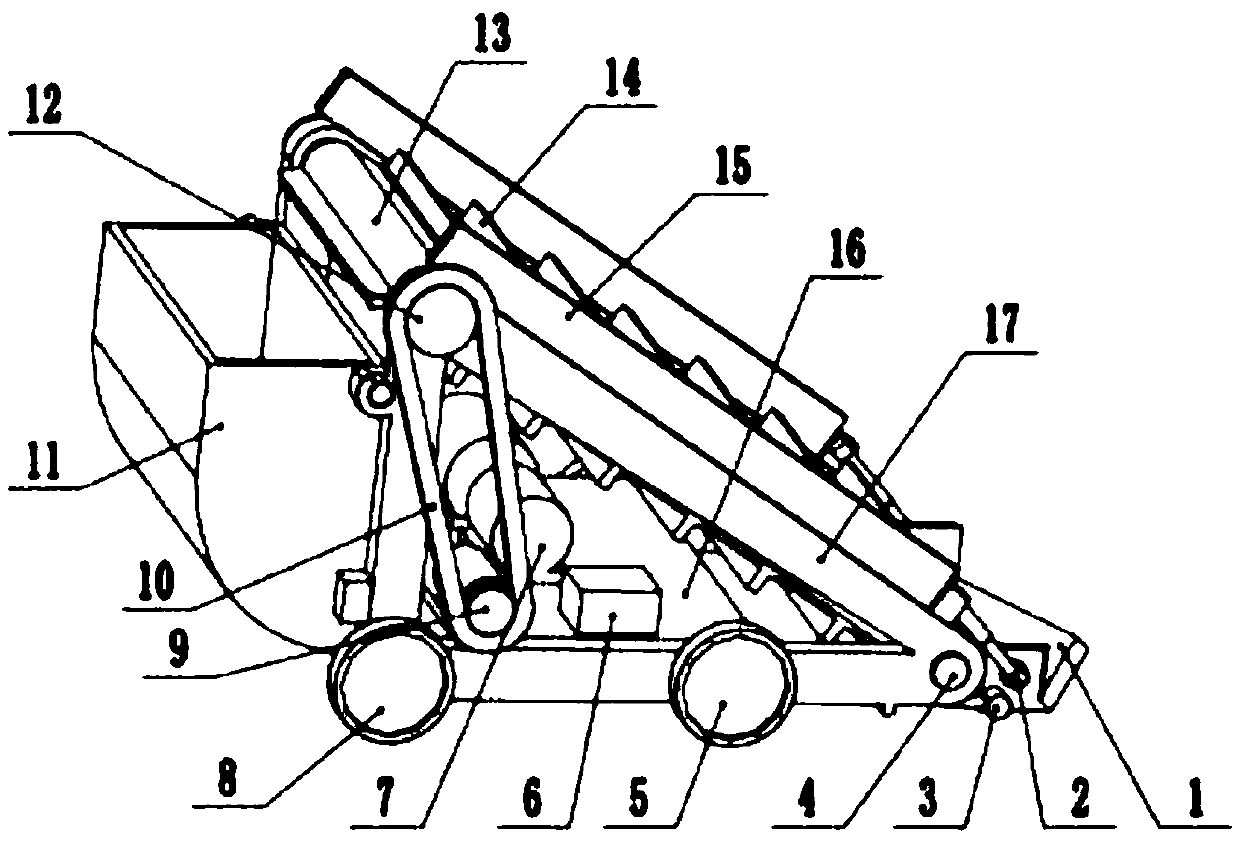

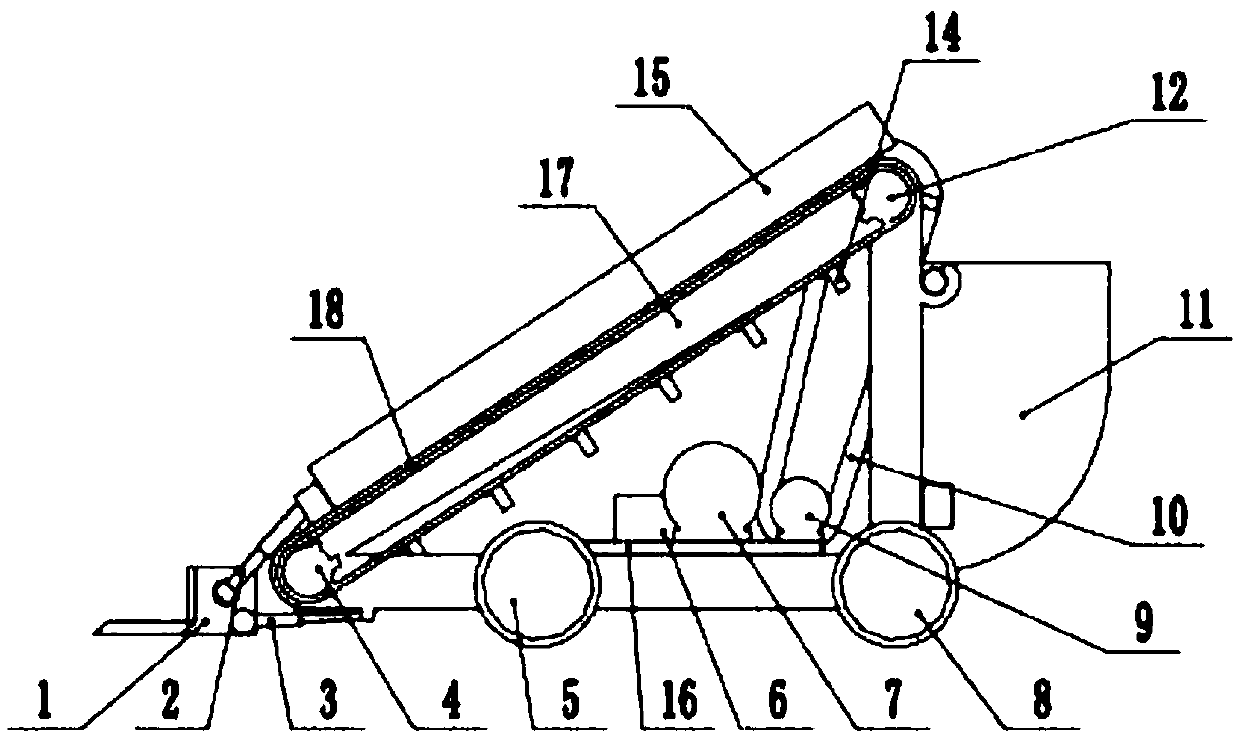

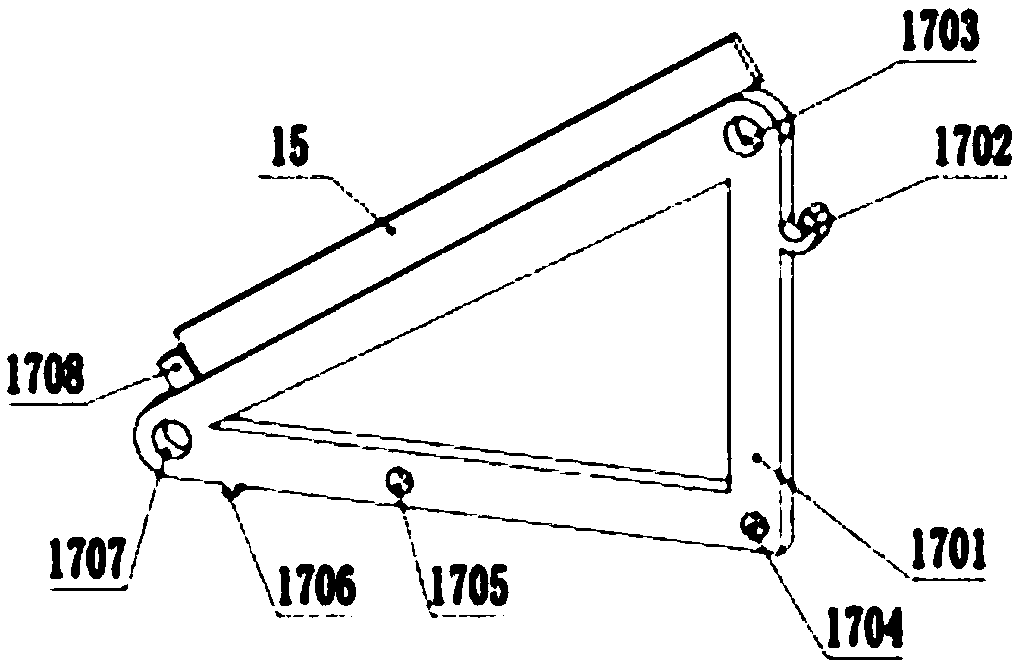

Self-propelled pavement floor tile recycling device

The invention provides a self-propelled pavement floor tile recycling device and belongs to the field of municipal administration machinery. The self-propelled pavement floor tile recycling device iscomposed of a front shovel, a first hydraulic cylinder, a second hydraulic cylinder, a lower transmission shaft, a front wheel, a controller, a hydraulic energy supply module, a rear wheel, a hydraulic motor, a first chain, a storage box, an upper transmission shaft, a transmission belt, a material conveying plate, a baffle plate, a lower plate, a rack and a second chain; specifically, the self-propelled pavement floor tile recycling device is a device for shoveling pavement floor tiles by adopting a V-shaped shovel bucket and intensively collecting the floor tiles through a conveyor belt; when the self-propelled pavement floor tile recycling device works, the transmission is stable, the floor tile recycling efficiency is high, noises are small and a lot of manpower and material resourcesare saved; the efficiency of recycling the pavement floor tiles is greatly improved.

Owner:宁波态晟通新材料有限公司

Environment-friendly riverway silt disposal device

The invention discloses an environment-friendly river silt treatment device, which comprises a material conveying chamber, an air-drying chamber and a base. The bottom of the air-drying chamber is equipped with a bottom plate, and the bottom plate and the outer wall of the air-drying chamber are closed by fastening bolts. , the right end of the bottom plate is connected with a discharge plate, the base is located below the air-drying chamber, the front and rear sides of the air-drying chamber are provided with fixing columns, and the air-drying chamber is installed on the base through the fixing columns , the middle position of the base is equipped with an underframe, the middle position of the upper wall of the underframe is provided with a limit hole, the bottom end of the bottom plate is installed with a first spring, and the bottom of the first spring is The end is connected with the bottom frame, and the bottom end of the bottom plate is equipped with a limit rod; the beneficial effects of the present invention are: combined with the stirring operation, the discharge of water vapor is accelerated, and the dehydration quality is improved; synchronous extrusion, crushing sludge, high discharge efficiency, Avoid discharge clogging.

Owner:佛山市广师自动化科技有限公司

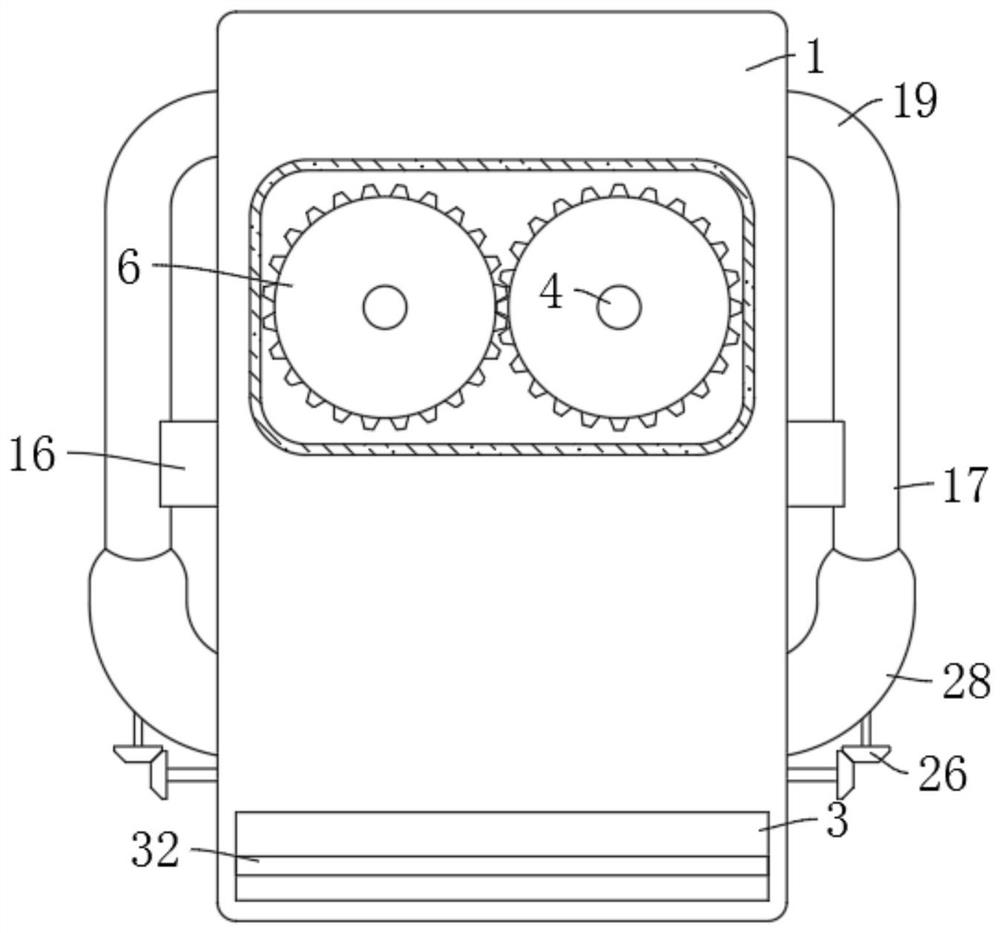

Environment-friendly recycling, crushing and separating equipment for waste electronic components

ActiveCN112452412AImprove screening efficiencyImprove crushing efficiencySievingDispersed particle filtrationElectric machineryProcess engineering

The invention discloses environment-friendly recycling, crushing and separating equipment for waste electronic components, and belongs to the field of electronic component recycling. The Environment-friendly recycling, crushing and separating equipment for waste electronic components comprises a box body, two crushing rollers which are matched with each other are rotatably connected into a feedingopening through two rotating shafts, a motor is fixedly installed on the side wall of the box body, the output end of the motor is fixedly connected with one end of one rotating shaft, a screening plate slidably connected with the box body is arranged at the lower end of the crushing rollers, the two sides of the upper end of the screening plate are obliquely arranged downwards, sliding grooves matched with the screening plate are formed in the left side wall and the right side wall of the box body, a shaking mechanism connected with the screening plate is arranged at the lower end of the screening plate, and the outer wall of the box body is provided with an automatic recovery mechanism and a dust collection mechanism which are connected with the sliding grooves. The box body can automatically recover coarse particles in the crushing process and then crush coarse particles, the crushing quality is improved, and dust in the crushing process can be sucked away and filtered.

Owner:苏州斯睿研智能科技有限公司

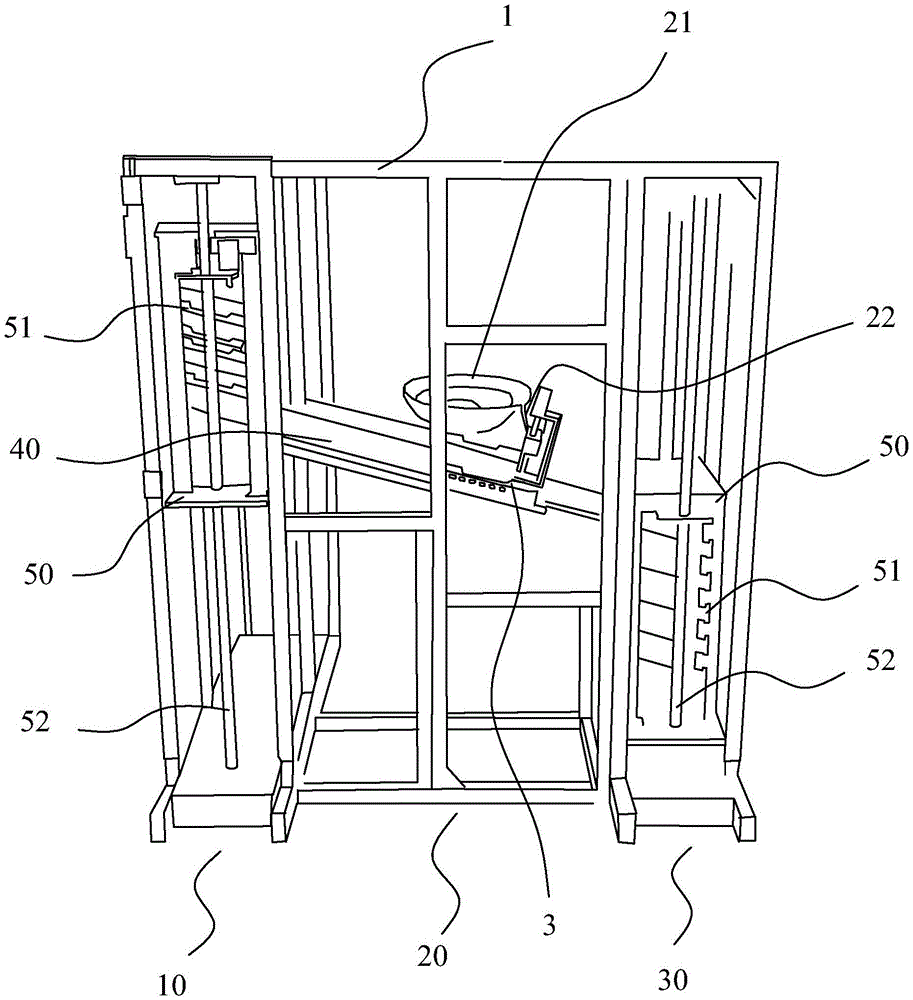

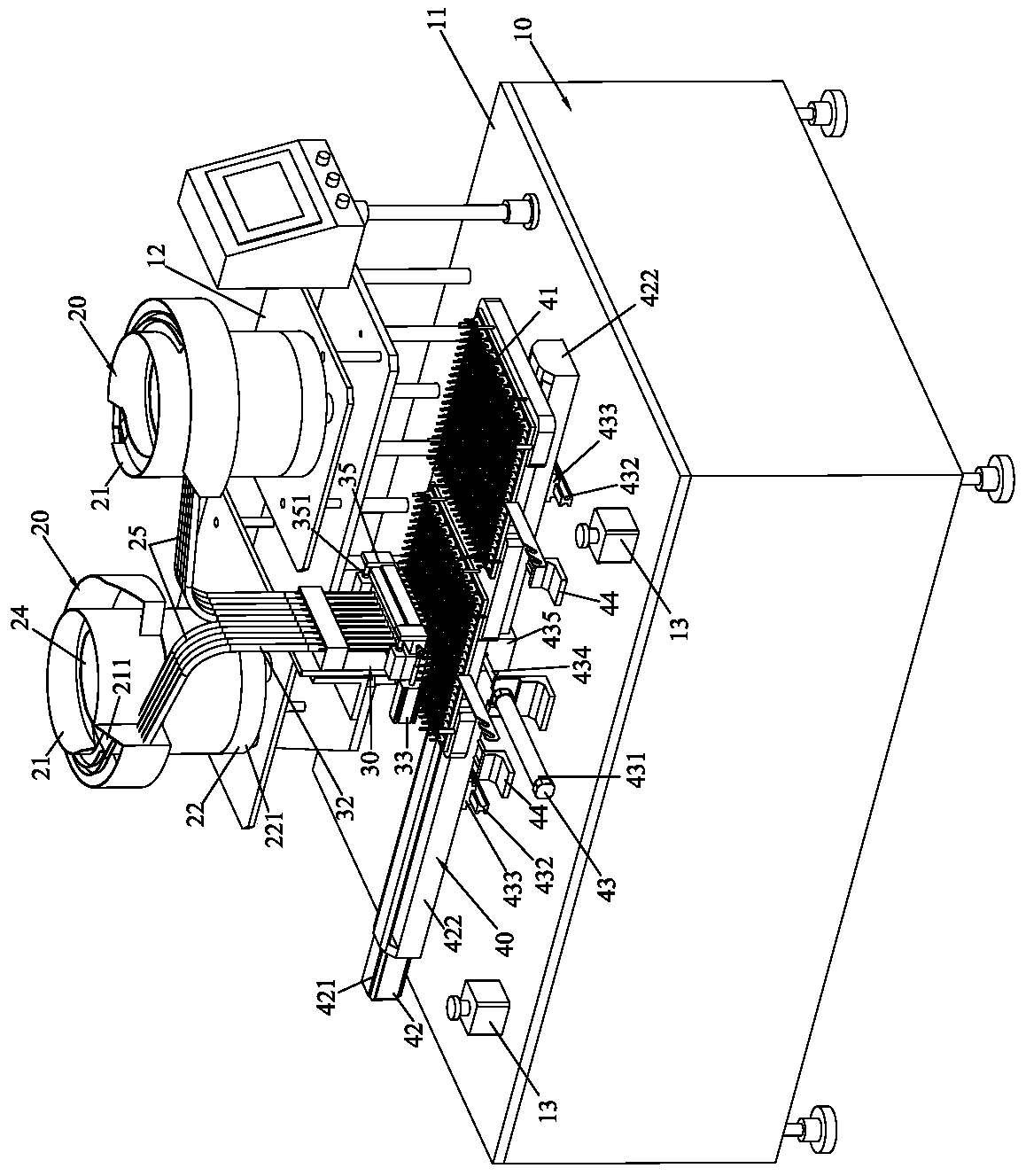

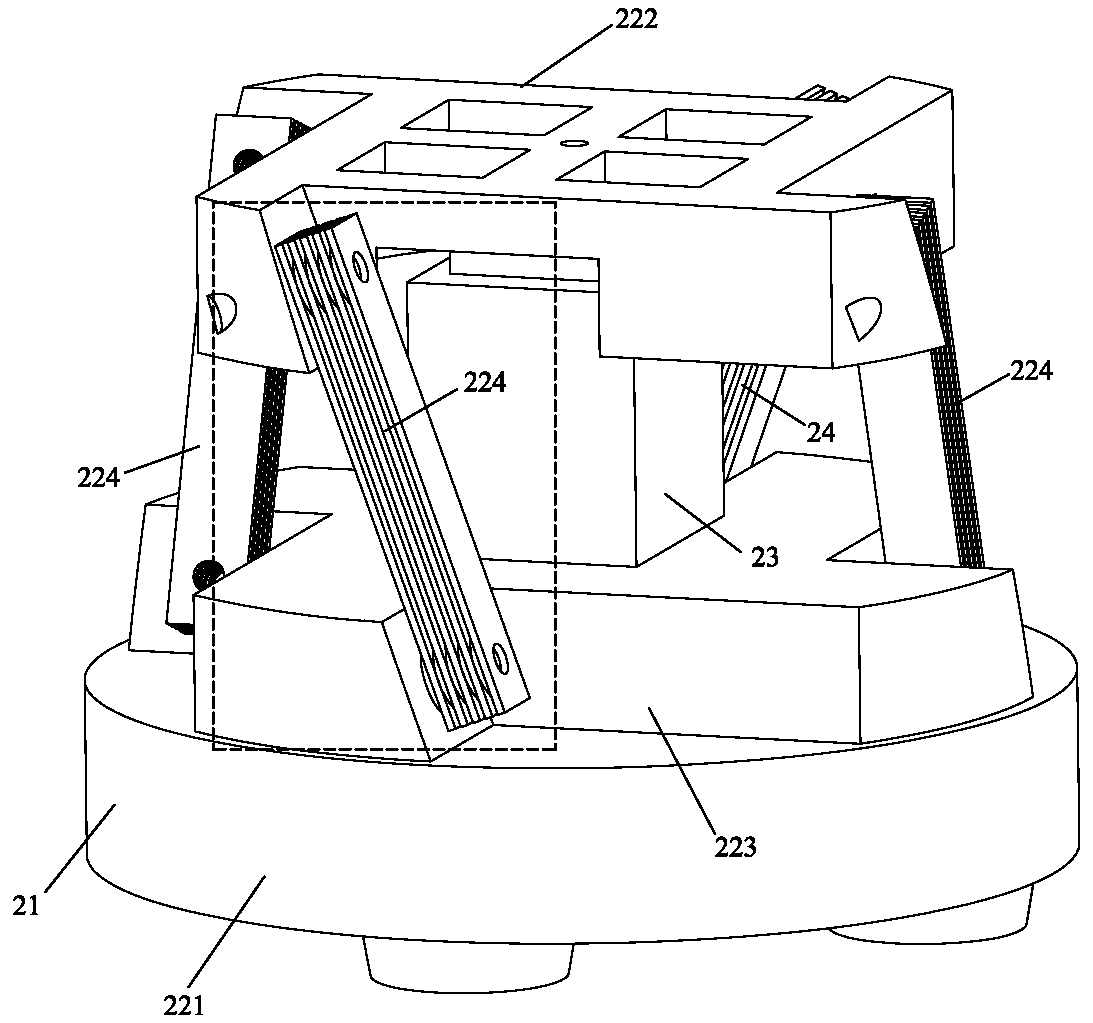

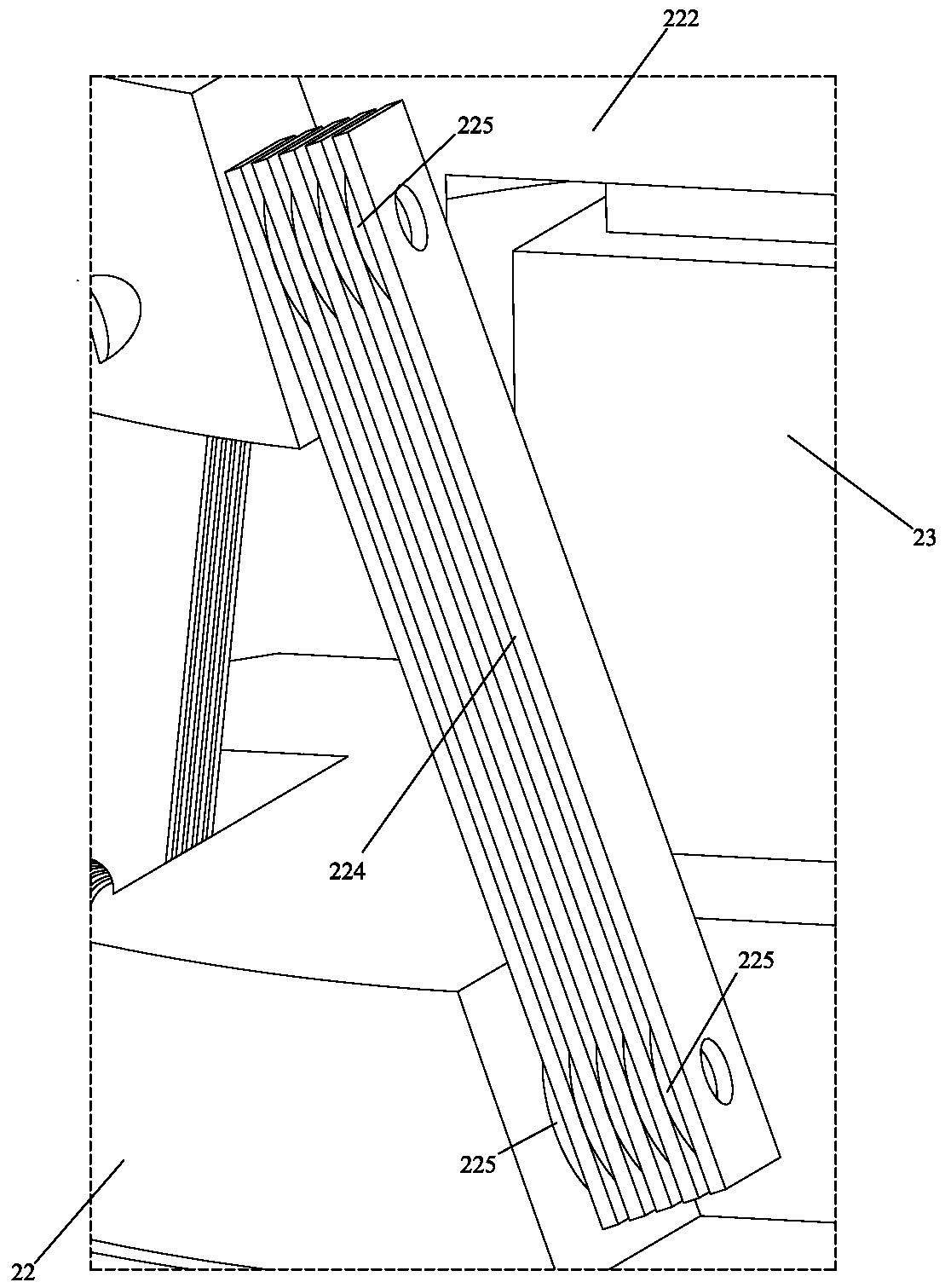

Automatic arranging machine for capacitors

ActiveCN106206084AFully automatedContinuous productionCapacitor manufactureConveyor partsCapacitanceEconomic benefits

The invention provides an automatic arranging machine for capacitors. The automatic arranging machine comprises a rack, a tray supply mechanism, a capacitor arranging mechanism and a tray discharge mechanism, wherein the tray supply mechanism, the capacitor arranging mechanism and the tray discharge mechanism are arranged on the rack; a tray on the tray supply mechanism is transferred to the capacitor arranging mechanism through a transfer rail; the arranged tray on the capacitor arranging mechanism is transferred to the tray discharge mechanism through the transfer rail; the capacitor arranging mechanism comprises a vibrating tray and an arranging device arranged above the transfer rail; the arranging device is provided with a trough which is vertical to the conveying direction of the transfer rail; the trough is provided with a downward opening or closing opening; the vibrating tray is connected with the trough through an arranging rail; and after the trough is full, the opening or closing opening is opened and the capacitors which are arranged in a whole row fall into the tray. By the automatic arranging machine for the capacitors, the manual labor can be reduced; a potential quality hazard due to direct contact with the capacitors by a hand is avoided; meanwhile, the automatic production efficiency of the capacitors is also improved; the production cost is reduced; and the economic benefits of enterprises are improved.

Owner:广东南方宏明电子科技股份有限公司

Raw material mixing device with high discharge efficiency for meat product industry

ActiveCN110537561AVarious mixing methodsIngenious structureMeat mixing apparatusDischarge efficiencyPulp and paper industry

The invention relates to a raw material mixing device with high discharge efficiency for a meat product industry. The raw material mixing device with the high discharge efficiency for the meat productindustry comprises a main body, a feeding pipe, a discharging pipe, and a first bearing, the main body is in an cylindrical shape, the feeding pipe and the discharge pipe are both arranged coaxiallywith the main body, the discharge pipe is arranged at the bottom end of the main body, a mounting hole is formed in the top end of the main body, the first bearing is located in the mounting hole, thefeeding pipe penetrates through the mounting hole, the inner ring of the first bearing is mounted on the feeding tube, the outer ring of the first bearing is sealed to and fixedly connected with theinner wall of the mounting hole, the main body is provided with a stirring mechanism and an auxiliary mechanism, the stirring mechanism comprises a power component, a connecting tube, a transmission tube, a rotating tube, a power gear, two sealing blocks, and two or more stirring components. According to the raw material mixing device with the high discharge efficiency for the meat product industry, the stirring effect is realized through the stirring mechanism, and the discharging efficiency is also improved through the auxiliary mechanism.

Owner:临沂金锣文瑞食品有限公司

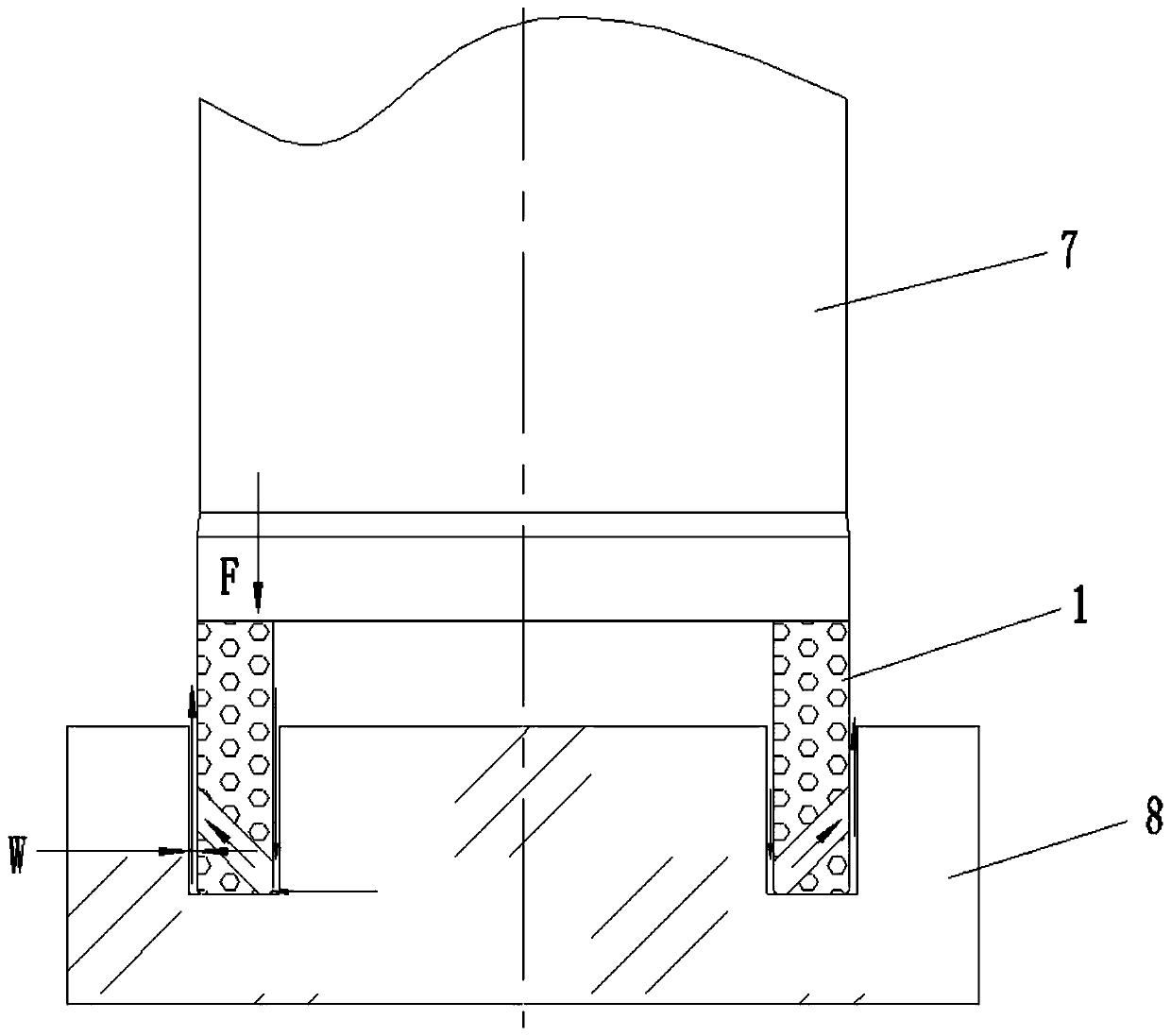

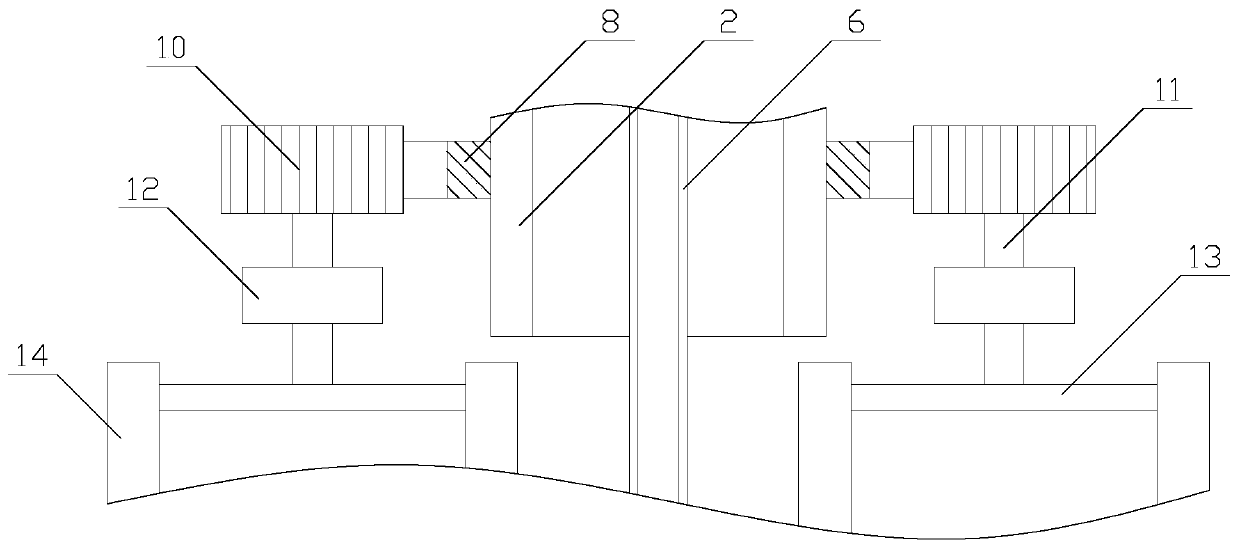

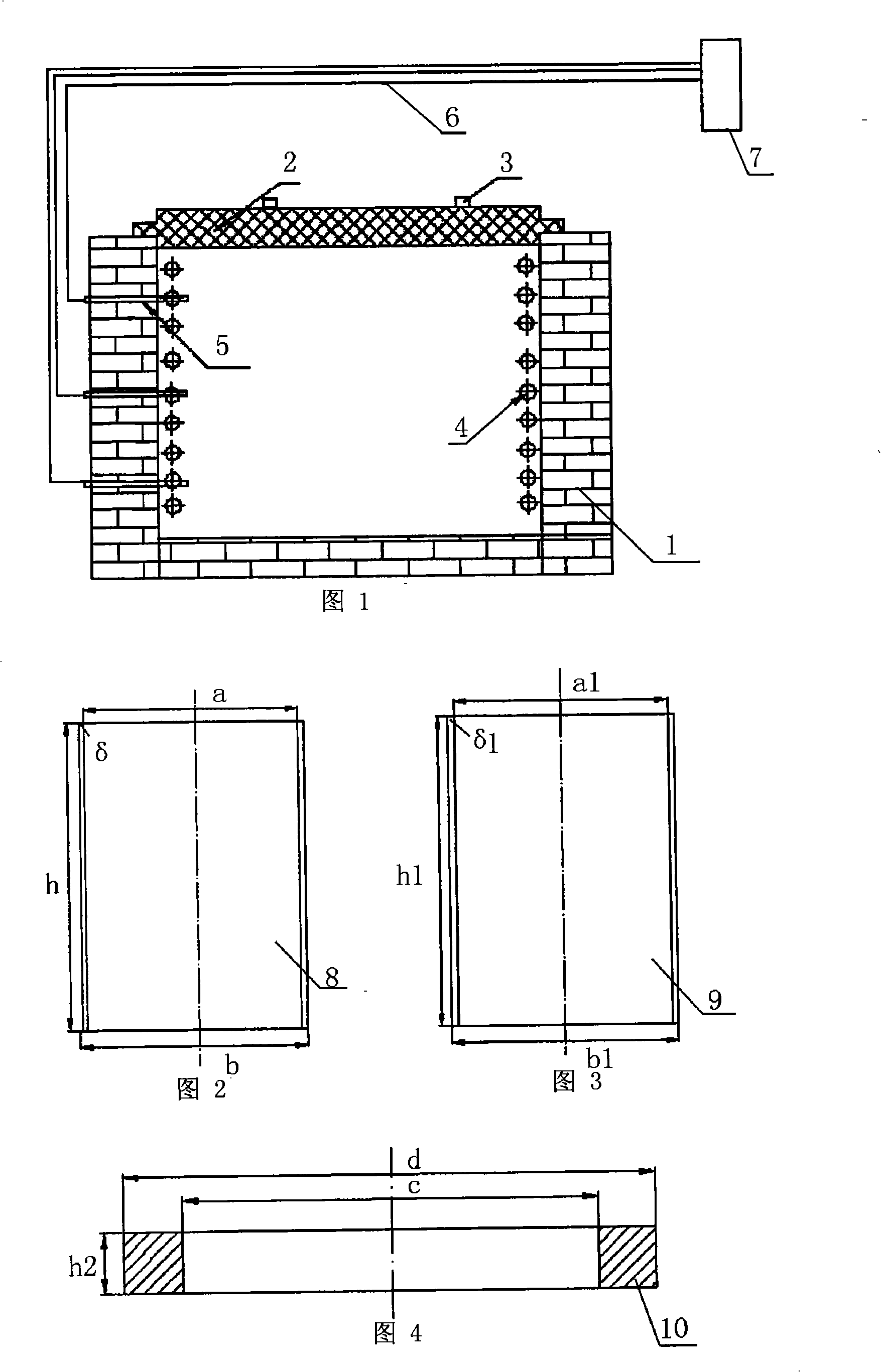

Nonuniform heating enclosed method in large-sized high-pressure bottle heat sleeve stove

InactiveCN101347886AImprove nesting efficiencyPressure vesselsMetal working apparatusEngineeringBottle

The invention relates to an in-furnace non-uniform heating shrink fit method of a large high pressure vessel shrink fit barrel; the outside of an inner barrel and the inside of an outer barrel are firstly processed, and the upper and lower ends of the outer barrel are symmetrically drilled with exhaust vents; a face flange is mounted at the bottom of a pit furnace; the outer barrel is lifted into the furnace and placed on the face flange; the outer barrel is heated by the furnace, the temperature of the outer barrel is controlled to be 380-450DEG C from top to bottom, and the temperature is kept for 1-2h; the inner barrel is directly sheathed in the outer barrel in the furnace and when the temperature in the furnace drops to below or equal to 80 DEG C, the shrink fit of the inner and outer barrels is completed. As the invention adopts the in-furnace shrink fit mode, the situations of blockage and incapability to sheathe due to the excessive shrinking of the outer barrel caused by excessively quick temperature reduction outside the furnace can be avoided; the outer barrel forms trapezoid linear structure which is large at the bottom and small at the top by non-uniform heating; if the inner barrel can enter successfully, the shrink fit can be carried out smoothly due to relatively large swelling amount at the lower end, thus improving the shrink fit efficiency.

Owner:YICHANG JIANGXIA MARINE MACHINERY

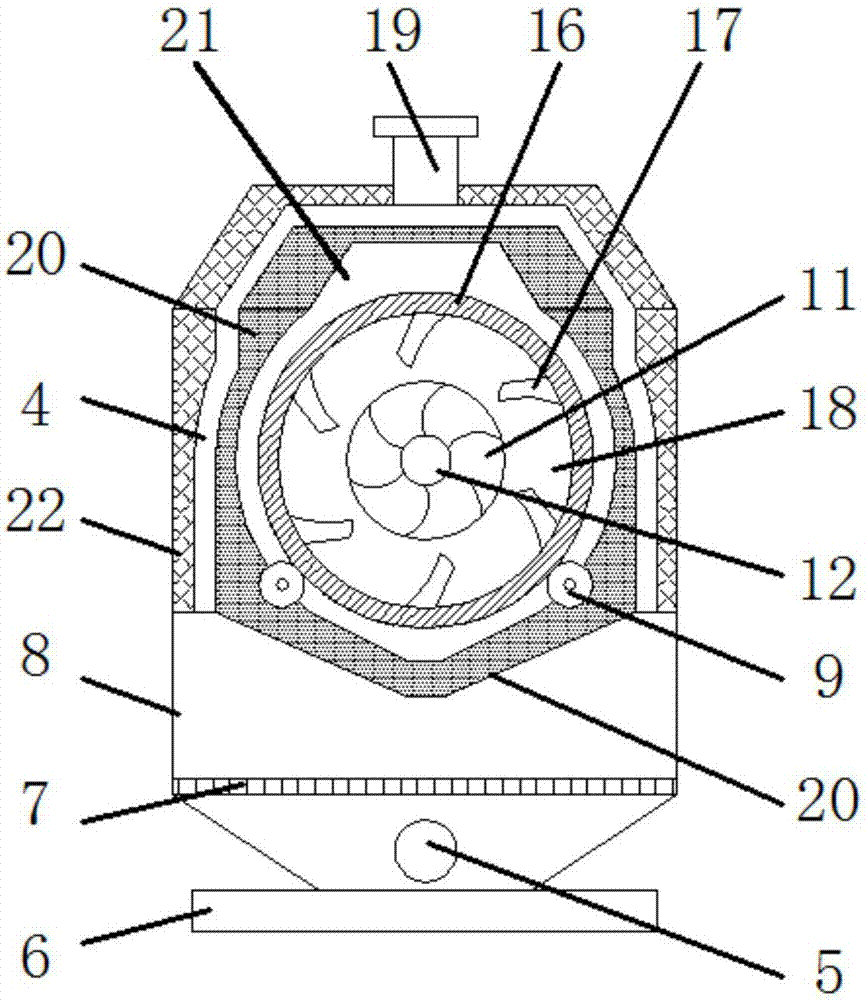

Straw pulverizer with drying function

InactiveCN111527895AImprove crushing effectImprove nesting efficiencyDrying gas arrangementsCuttersDrive shaftElectric machine

The invention discloses a straw pulverizer with a drying function. The straw pulverizer with the drying function comprises a main body, a feeding hopper and a discharging pipe and further comprises acutting mechanism and a drying mechanism, wherein the cutting mechanism comprises a motor, a driving shaft, a screen, two transmission assemblies, two mounting bearings, at least two first blades andat least two second blades; the drying mechanism comprises a power cylinder, a heating rod, fan blades, a circulating pipe and at least two communicating pipes; and each transmission assembly comprises a supporting sleeve, an eccentric wheel, a supporting rod and a spring. According to the the straw pulverizer with the drying function, straw is cut through the cutting mechanism, the straw pulverizing effect of the straw pulverizer is improved, and the straw can be dried through the drying mechanism, so that the discharging efficiency of the straw is improved, and the working efficiency of thestraw pulverizer is improved.

Owner:南京浩睿达环保科技有限公司

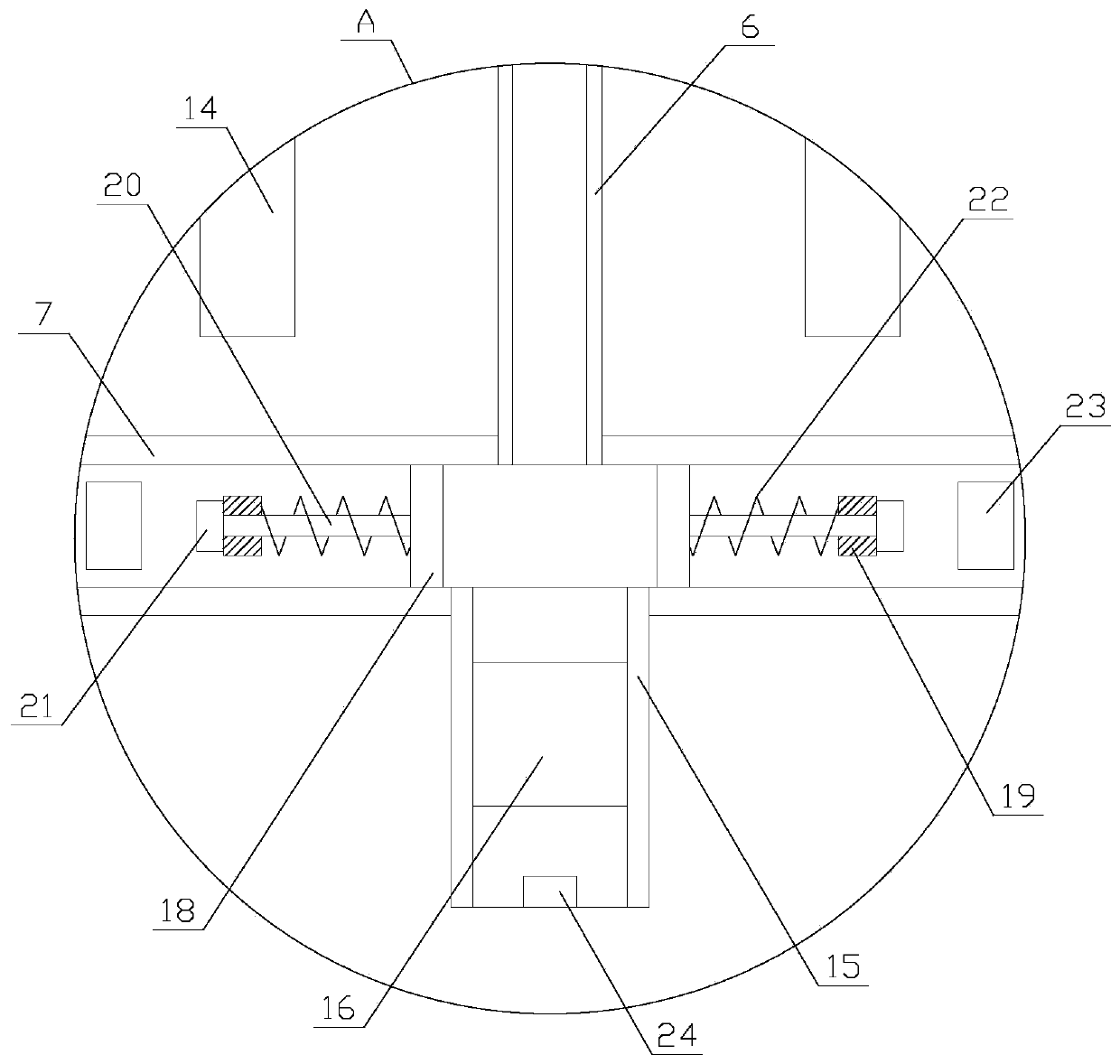

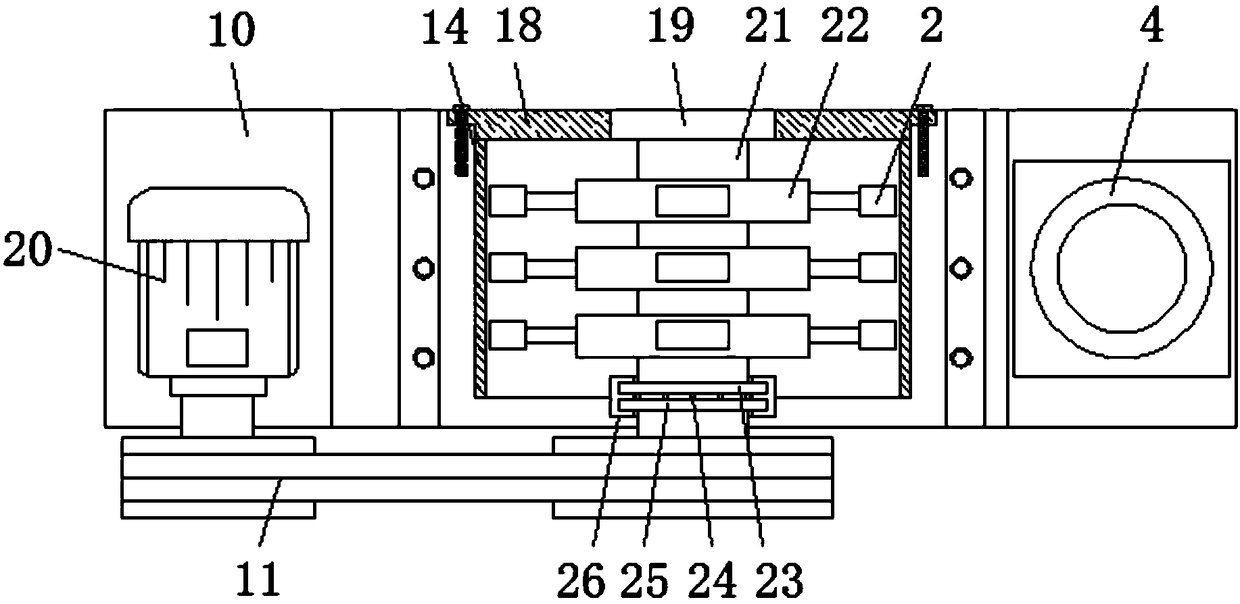

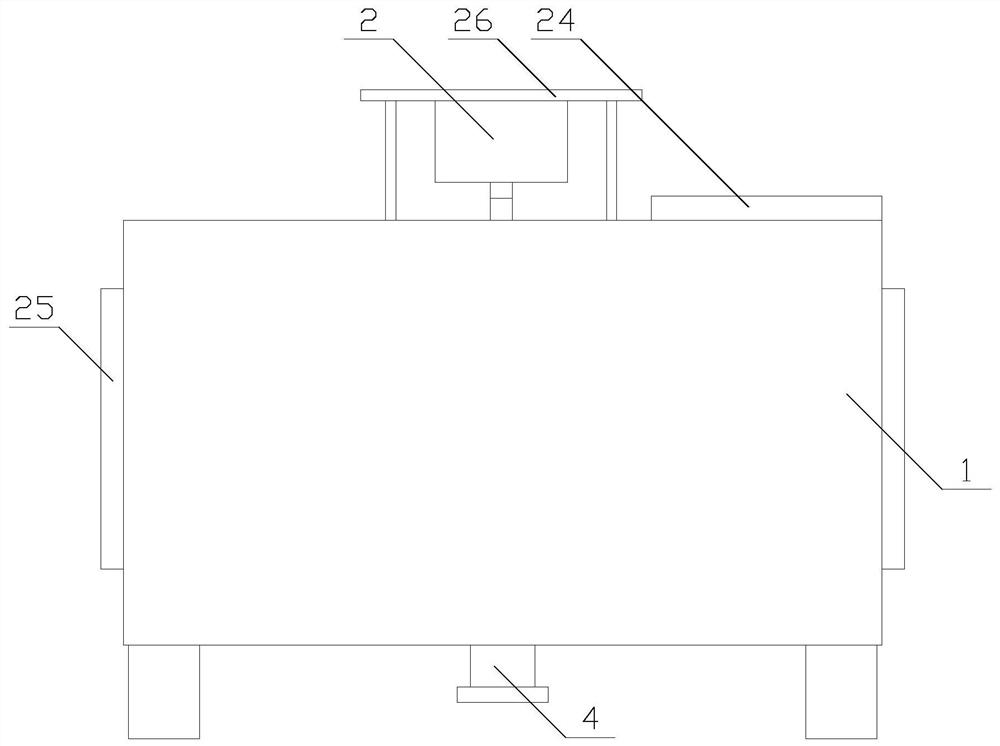

Automatic arranging device for magnet rings

The invention discloses an automatic arranging device for magnet rings. The automatic arranging device comprises a worktable, a feeding mechanism, an ordered blanking device and a magnet ring discharging table, wherein the feeding mechanism is arranged on a bracket, and comprises a chassis, a rotating mechanism, a vibrating mechanism, a spiral ascending channel and a return channel; the ordered blanking device comprises a feeding base, a feeding pipe, an ejector pin driving mechanism and an ejector pin mechanism; the magnet ring arranging table comprises a magnet ring arranging plate, a left-right driving mechanism and a front-back driving mechanism; the ordered blanking device is arranged in the automatic arranging device, under the cooperation of the ejector pin mechanism and the ejectorrod driving mechanism, the magnet rings can fall orderly under a controlled condition, and meanwhile, under the cooperation of the front-back driving mechanism and the left-right driving mechanism ofthe magnet ring arranging table, the magnet rings orderly falling in the previous process can be arranged to any position of the magnet ring arranging plate, so that the arranging efficiency can be greatly improved, and the magnet rings arranged on the magnet ring arranging plate are neater.

Owner:DONGGUAN HAITIAN MAGNETIC IND CO LTD

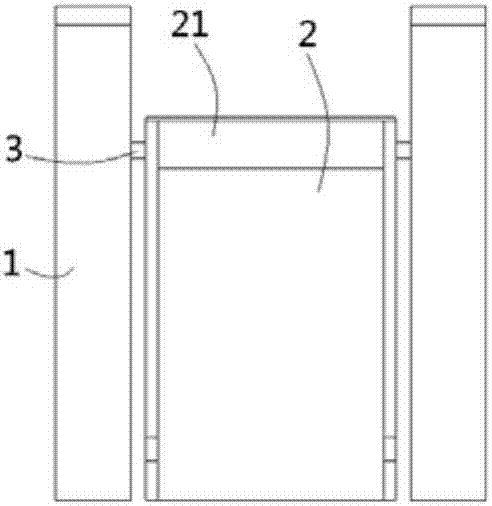

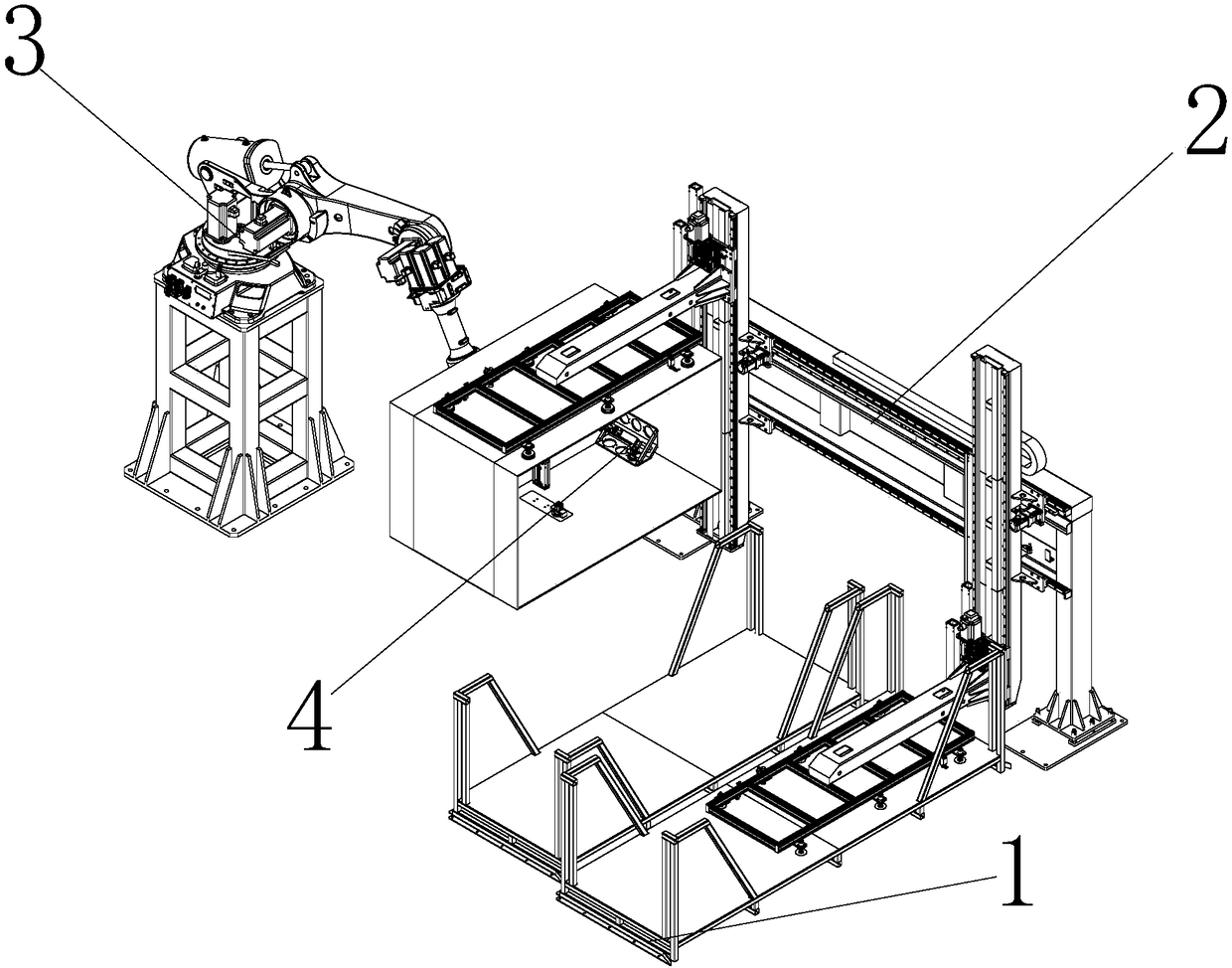

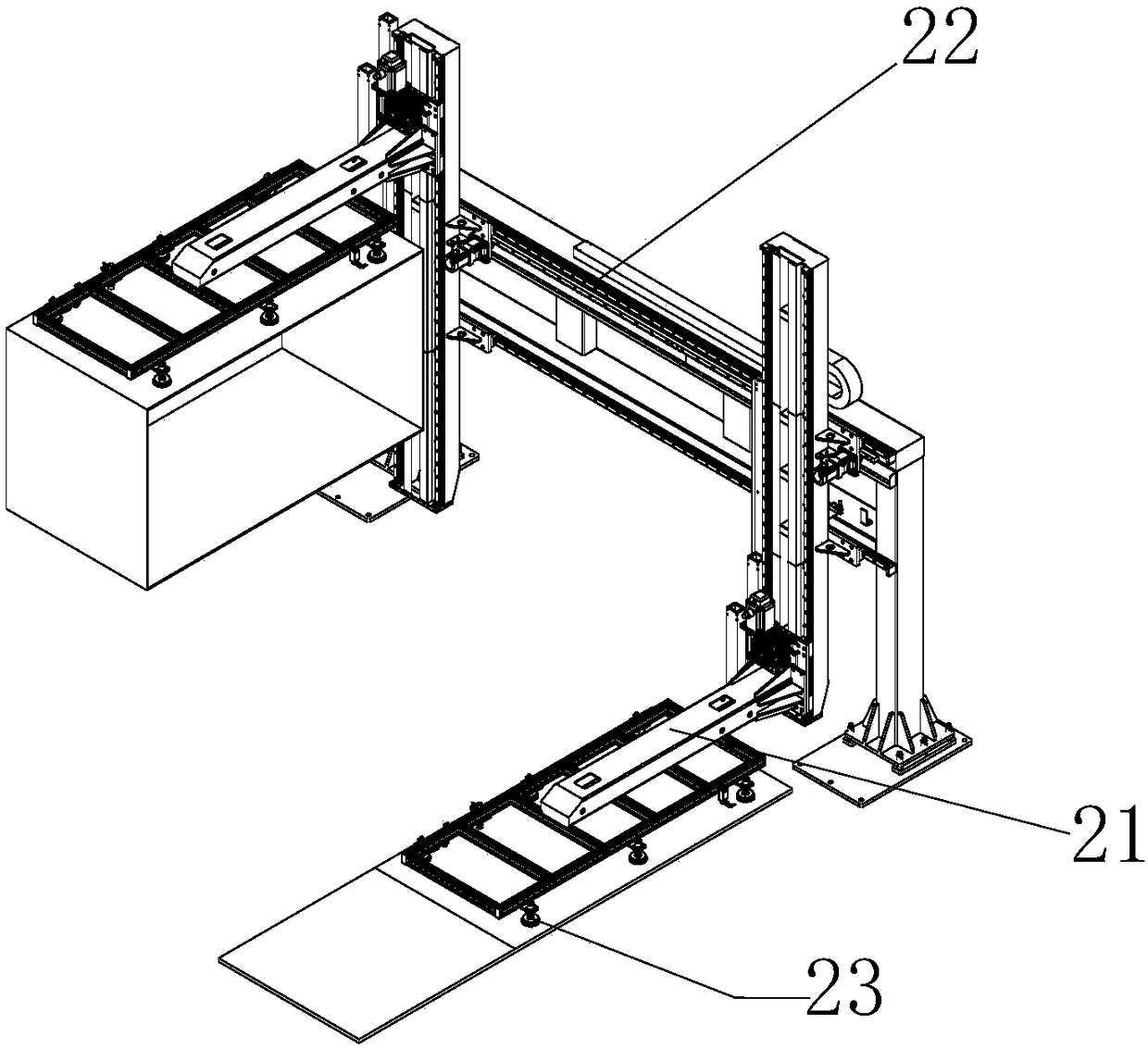

Automatic cartoning machine

ActiveCN108216760AReduce manual labor intensityImprove nesting efficiencyIndividual articlesCartoning machineEngineering

The invention discloses an automatic cartoning machine which mainly comprises a feed bin holder for holding cartons. A transferring mechanism for gripping the cartons is arranged at one side of the feed bin, a cartoning manipulator for packaging the cartons on the transferring mechanism to products is arranged at one side of the transferring mechanism, and is provided with a cartoning clamp. By the automatic cartoning machine, the folded cartons can be sucked and expanded automatically, and can carton photovoltaic modules; the whole cartoning process is automatic without manual work, and thus,manual work intensity is reduced while cartoning efficiency is improved.

Owner:SUZHOU UR INTELLIGENT TECH CO LTD

Corn threshing device for agricultural product processing

InactiveCN111386863AImprove nesting efficiencyKeep intactThreshersAgricultural engineeringAgricultural science

The invention belongs to the technical field of agricultural product processing, particularly relates to a corn threshing device for agricultural product processing. To solve the problems that an existing threshing device causes blockage easily during threshing due to horizontal movement of most corn ears, thereby affecting working efficiency, the following scheme is provided: the corn threshing device comprises a base, a box structure is arranged above the base, a barrel is fixedly mounted at the top end of the base, a feed hopper is fixedly mounted at the top end of the barrel, and a transverse plate is fixedly mounted at the top end of the feed hopper. Corn ears are gradually twisted by threshing teeth and an outer threshing mechanism when passing through the barrel, so that the corn kernels are threshed, the threshed corn kernels are screened by a grid screen plate, corncobs are discharged from the upper side of the grid screen plate adopting the arc-shaped structure, the threshingwork of corn is completed, the device realizes soaking and threshing by the aid of gravity and twisting force when moving the corn ears downwards, blockage caused by stay of the corn kernels and corncobs in the device is avoided, and the threshing efficiency is improved.

Owner:黄东锋

Incineration equipment for urban garbage collection and with high discharging efficiency

InactiveCN111237780AEasy to moveIngenious structureIncinerator apparatusGrain treatmentsEnvironmental engineeringGarbage collection

The invention relates to incineration equipment for urban garbage collection and with high discharging efficiency. The incineration equipment comprises a body, a mesh plate, an exhaust pipe and a slagdischarging pipe. The body is cylindrical and is vertically arranged. The exhaust pipe and the slag discharging pipe are coaxial with the body. The exhaust pipe is arranged at the top end of the body. The slag discharging pipe is arranged at the bottom end of the body. The mesh plate is arranged in the body and is perpendicular to the body. The mesh plate is fixed to the inner wall of the body. An incineration device is arranged in the body. A crushing mechanism and an auxiliary mechanism are arranged in the body and are both arranged on the side, close to the slag discharging pipe, of the mesh plate. According to the incineration equipment for urban garbage collection and with high discharging efficiency, the function of crushing waste slag in the body is achieved through the crushing mechanism, the waste slag can be moved into the slag discharging pipe conveniently, and moreover, the slag discharging efficiency is improved through the auxiliary mechanism.

Owner:GUANGZHOU OUSHU ENVIRONMENTAL PROTECTION TECH CO LTD

Efficient sand producing machine for constructional engineering

PendingCN109317256AEasy to disassembleGuaranteed precise transmissionGrain treatmentsArchitectural engineering

The invention discloses an efficient sand producing machine for constructional engineering. The machine comprises a sand producing machine main body. A crushing chamber is formed in the sand producingmachine main body, a second bearing pedestal is installed on the inner wall of one side of the crushing chamber, a second bearing and a third bearing are installed inside the second bearing pedestal,the second bearing is located on one side of the third bearing, a connection rod is connected between the second bearing and the third bearing, a side door is fixedly connected with the outer wall ofone side of the sand producing machine main body through a bolt, a first bearing pedestal is installed in the middle position of the side door, and a first bearing is installed inside the first bearing pedestal. Since the first bearing pedestal, the second bearing, the first bearing, a limiting groove and a limiting pin are arranged, during overhaul and replacement, a locking bolt on the first bearing pedestal in the middle position of the side door is unscrewed tightly, a spring rebounds after the locking bolt is unscrewed, a push block is pushed into an installation groove, meanwhile, a lock rod is taken out of the limiting pin through a push rod, and axial unlocking of a main shaft is achieved.

Owner:东莞润如智能科技有限公司

Daily chemical product production equipment with defoaming function

InactiveCN112007557AImprove stirring efficiencyImprove the mixing effectRotary stirring mixersTransportation and packagingDrive shaftElectric machinery

The invention relates to daily chemical product production equipment with a defoaming function. The daily chemical product production equipment comprises a box body, a driving motor, a transmission shaft and a discharge pipe, the box body is in a cuboid shape, the discharge pipe is arranged at the bottom of the box body and is communicated with the box body, a sealing device is arranged on the discharge pipe, the driving motor is arranged above the box body and is fixedly connected with the top of the box body, an assembling hole is formed in the top of the box body, the transmission shaft vertically penetrates through the assembling hole, the transmission shaft is in sliding and sealed connection with the inner wall of the assembly hole, the driving motor is in transmission connection with the top end of a transmission shaft, a stirring mechanism and an auxiliary mechanism are arranged in the box body, the stirring mechanism comprises a first bearing, a stirring rod, a connecting assembly and two stirring assemblies, the daily chemical product production equipment with the defoaming function achieves the function of stirring raw materials through the stirring mechanism, and besides, the function of eliminating bubbles is achieved through the auxiliary mechanism.

Owner:王钟海

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com