Automatic cartoning machine

An automatic box machine technology, which is applied in the direction of single object, transportation, packaging, packaging, etc., can solve the problems of time-consuming, labor-intensive, heavy weight, and packaging difficulties, and achieve the effect of reducing manual work intensity and improving the efficiency of boxing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

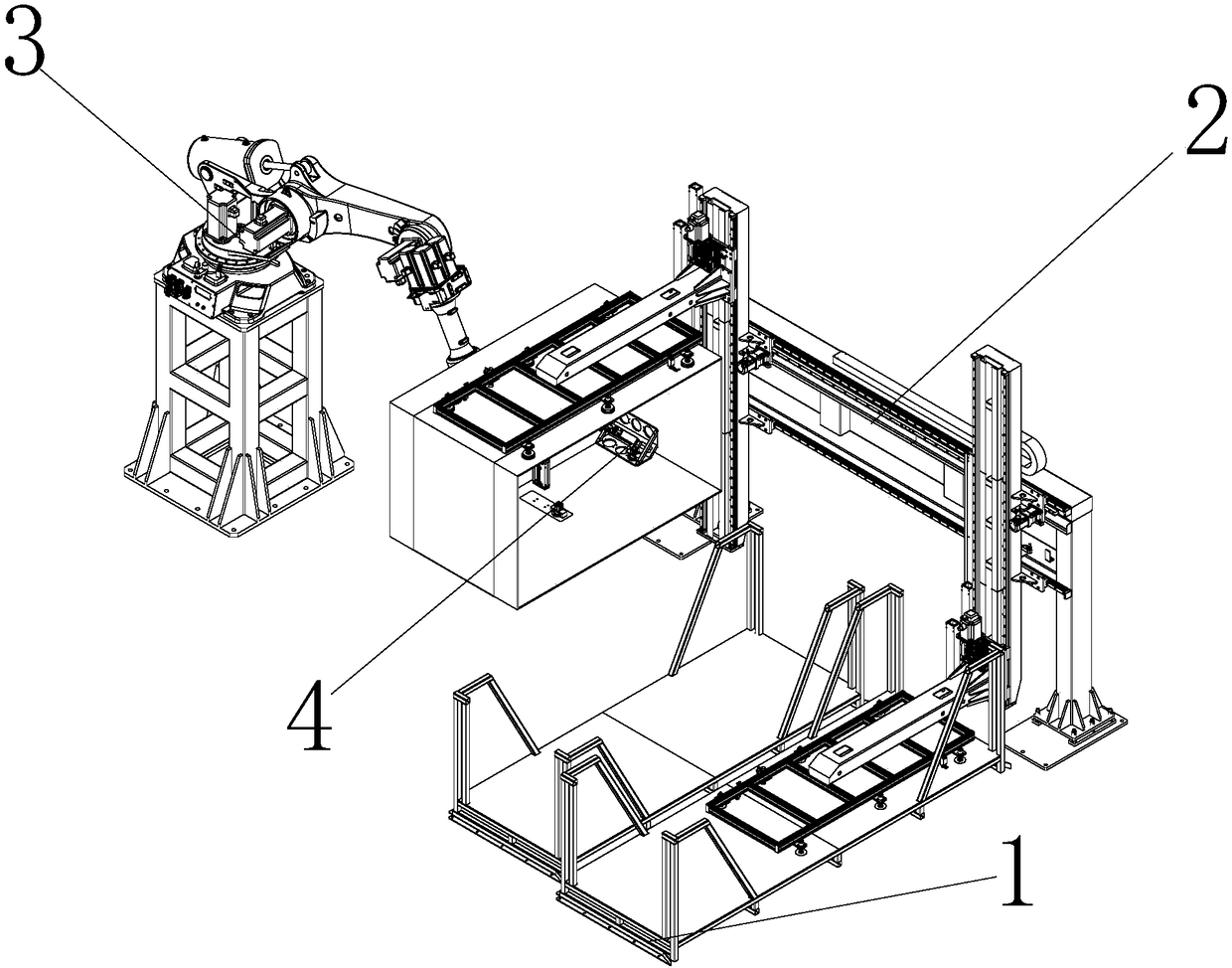

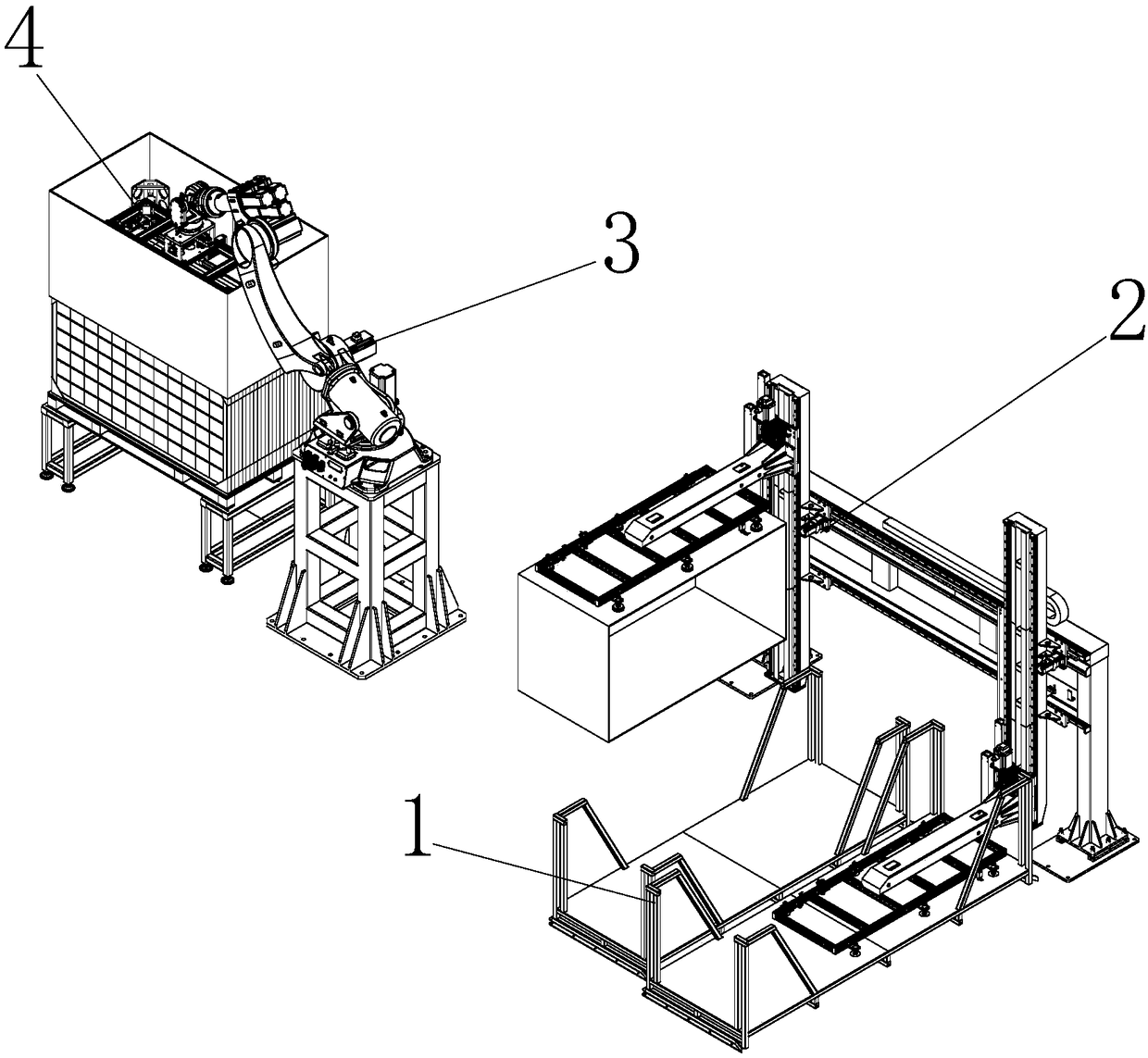

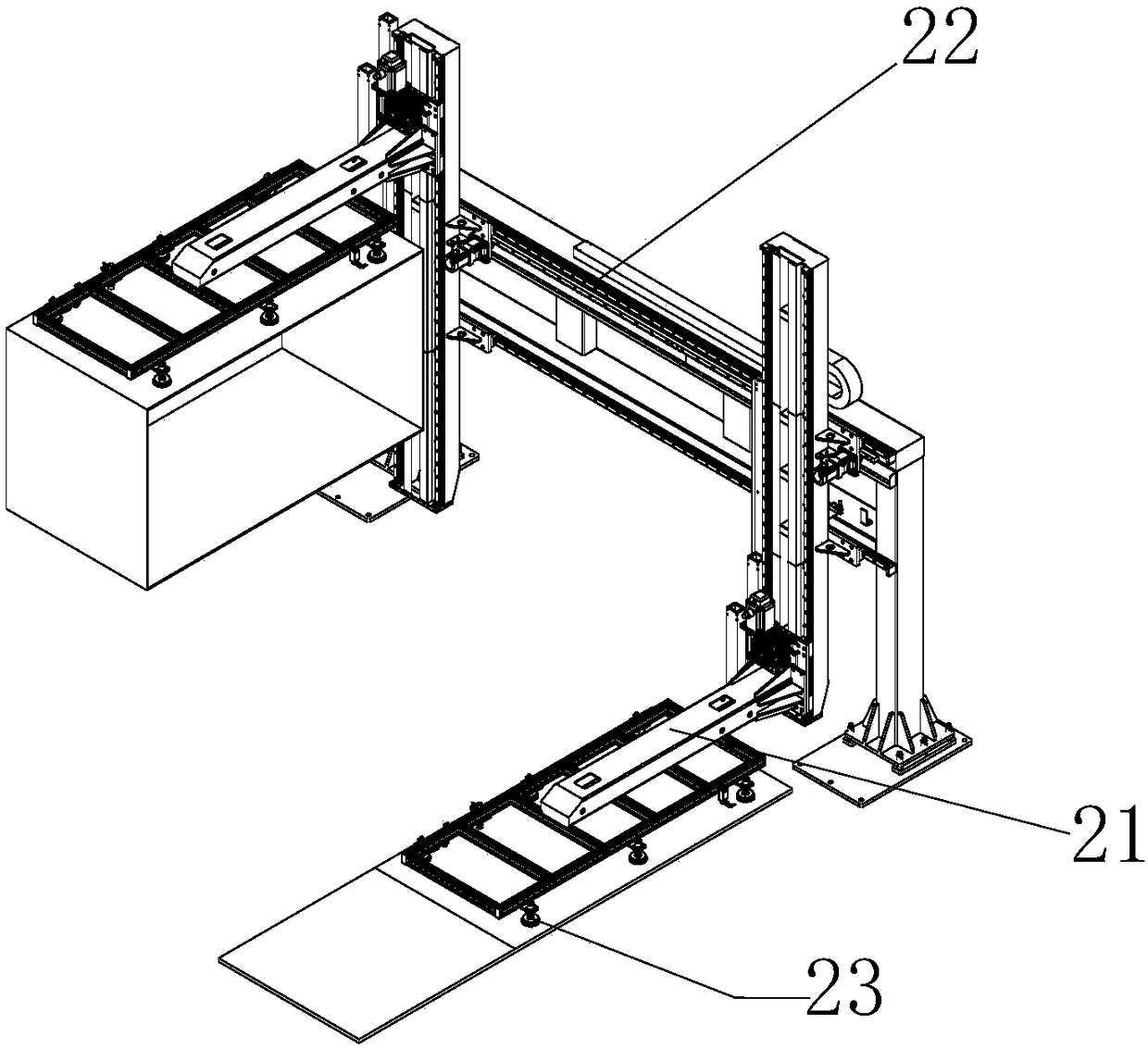

[0019] Such as Figure 1 to Figure 2 The automatic nesting machine shown includes a bin placement rack 1 for placing cartons, one side of the bin is provided with a transfer mechanism 2 for picking up the cartons, and one side of the transfer mechanism 2 is provided with a The carton on the loading mechanism 2 is set on the product by the case manipulator 3. The case manipulator 3 is provided with a case clamp 4. When in use, a plurality of folded cartons are stacked in the bin placement rack 1. When working, the transfer mechanism 2 picks up the uppermost carton in the storage bin shelf 1. During the pick-up process, the carton will be in a stretched state under its own gravity, and then the transfer mechanism 2 will stretch it out. The carton is transferred to the sleeve manipulator 3, and then the sleeve manipulator 3 extends into the inner...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com