Energy-saving environment-friendly steel slag tank

An energy-saving, environmentally friendly, steel slag tank technology, applied in the field of steel slag treatment equipment, can solve the problems of not installing an environmental protection filter for discharging steam, unable to mix water with steel slag, affecting the surrounding air environment, etc. effect, the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

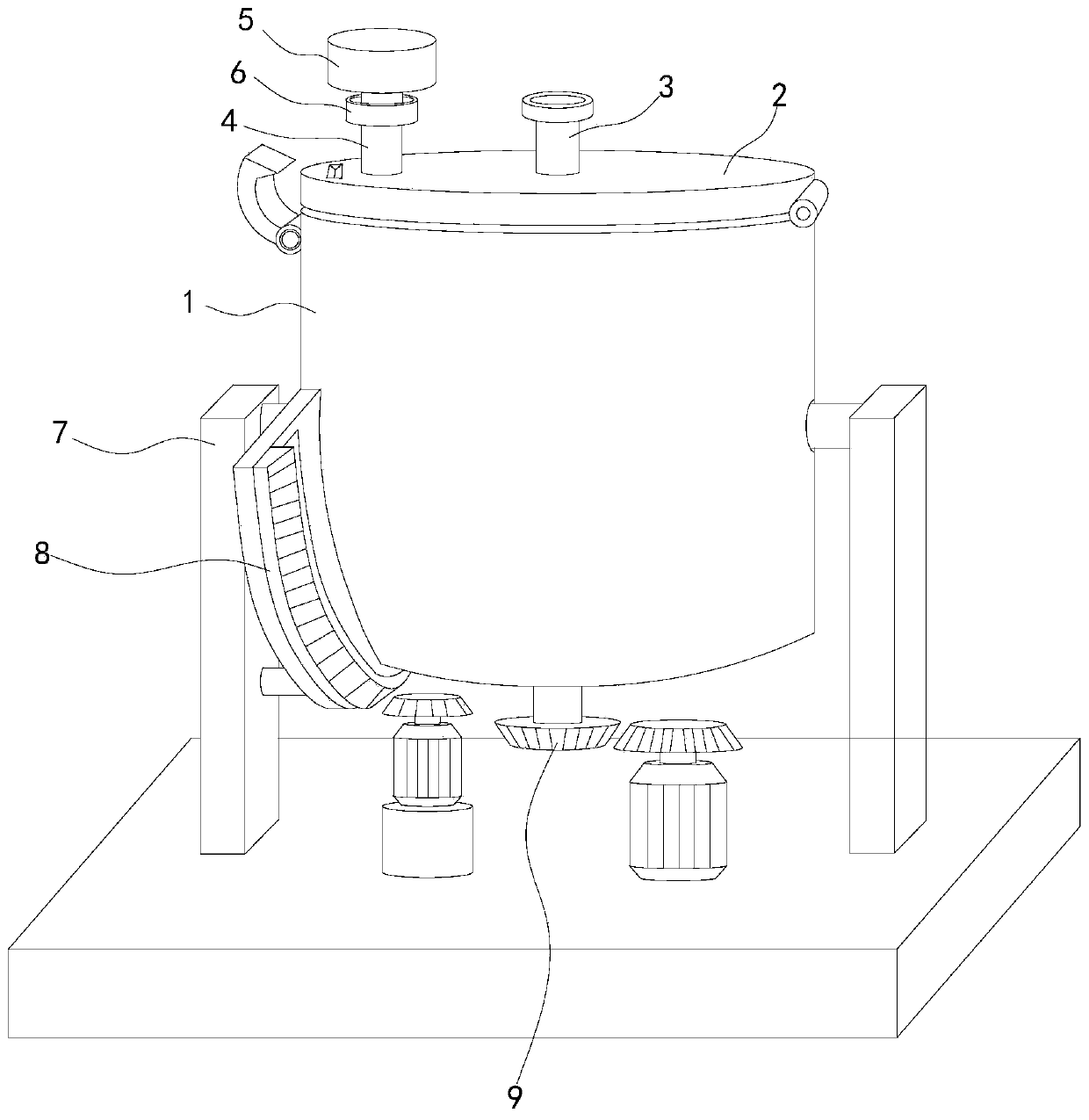

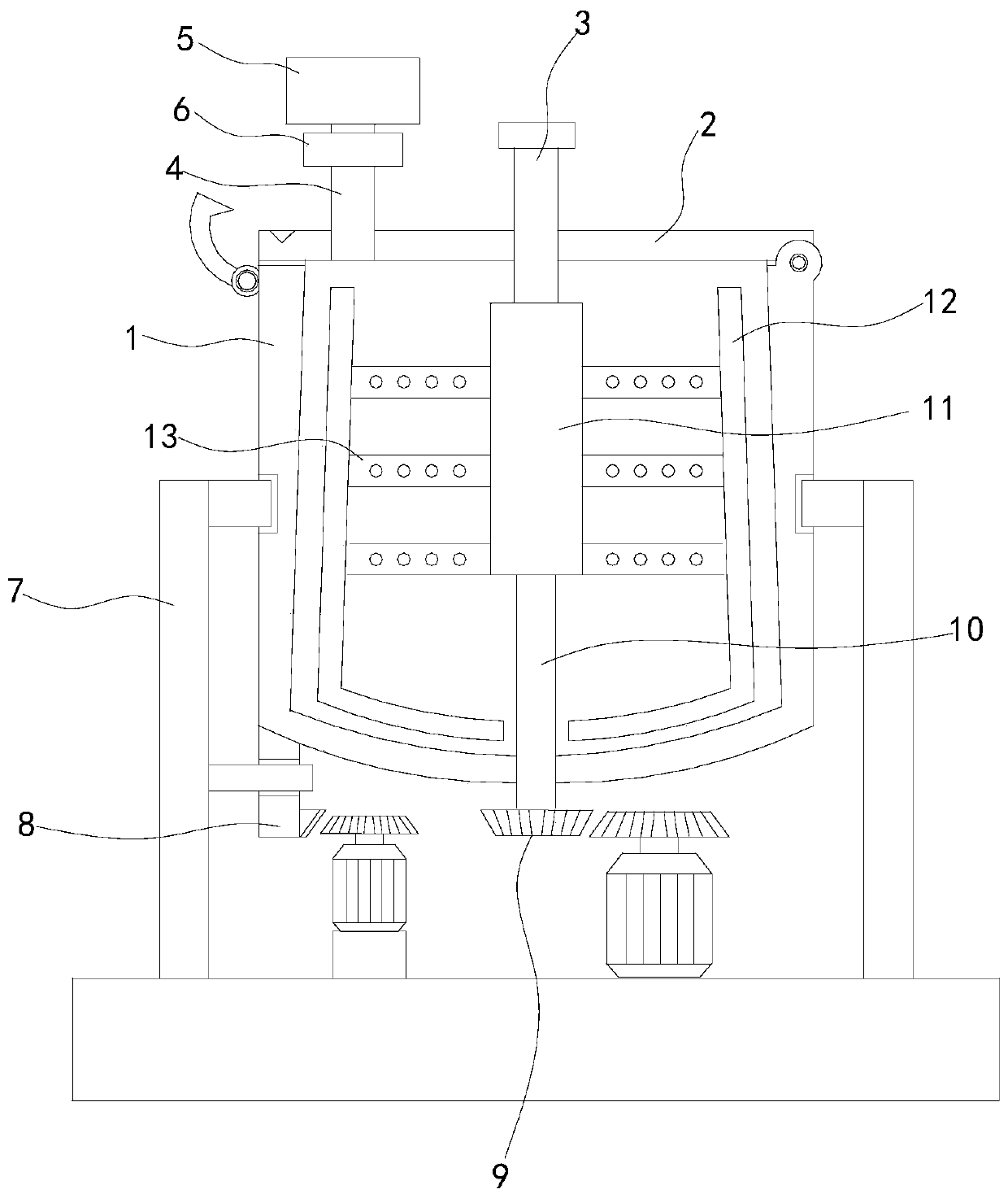

[0026] see Figures 1 to 7 , a schematic plan view of an energy-saving and environment-friendly steel slag tank and a schematic view of a three-dimensional structure.

[0027] An energy-saving and environment-friendly steel slag tank, comprising a steel slag tank main body 1, a top cover 2 is movably installed on the upper end of the steel slag tank main body 1, an air outlet pipe 4 is fixedly installed on the upper end of the top cover 2, and a slag removal device 5 is fixedly installed on the upper end of the air outlet pipe 4. A water storage pipe 10 is fixedly installed inside the tank main body 1 , a stirring rod 13 is fixedly installed on both sides of the water storage pipe 10 , and a slag scraper 12 is fixedly installed on the outer end of the stirring rod 13 .

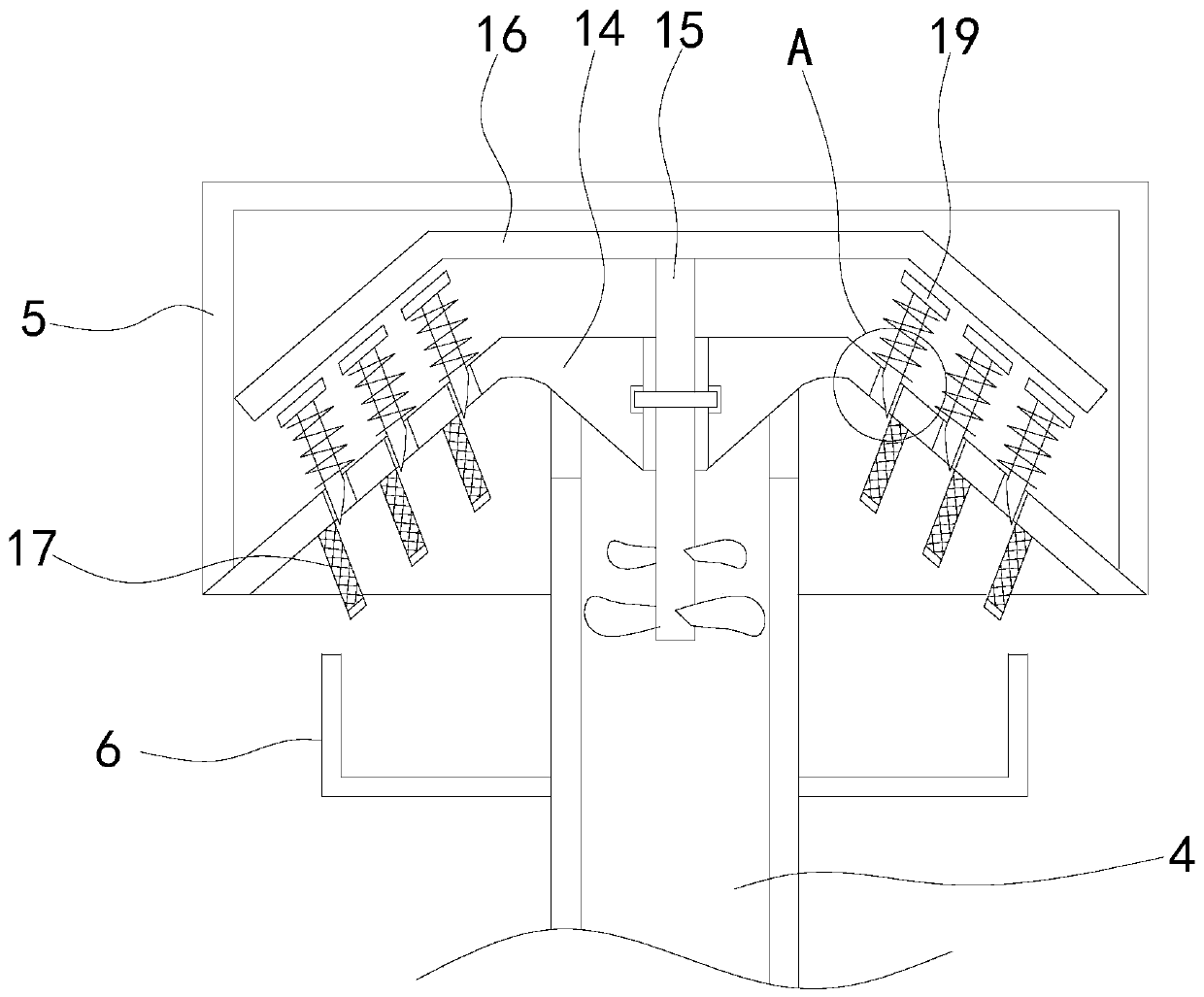

[0028] In specific implementation, an air guide plate 14 is fixedly installed on the upper end of the air outlet pipe 4, and the air guide plate 14 is set in the shape of a conical cone, and the center is coni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com