Patents

Literature

52results about How to "Improve drop efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

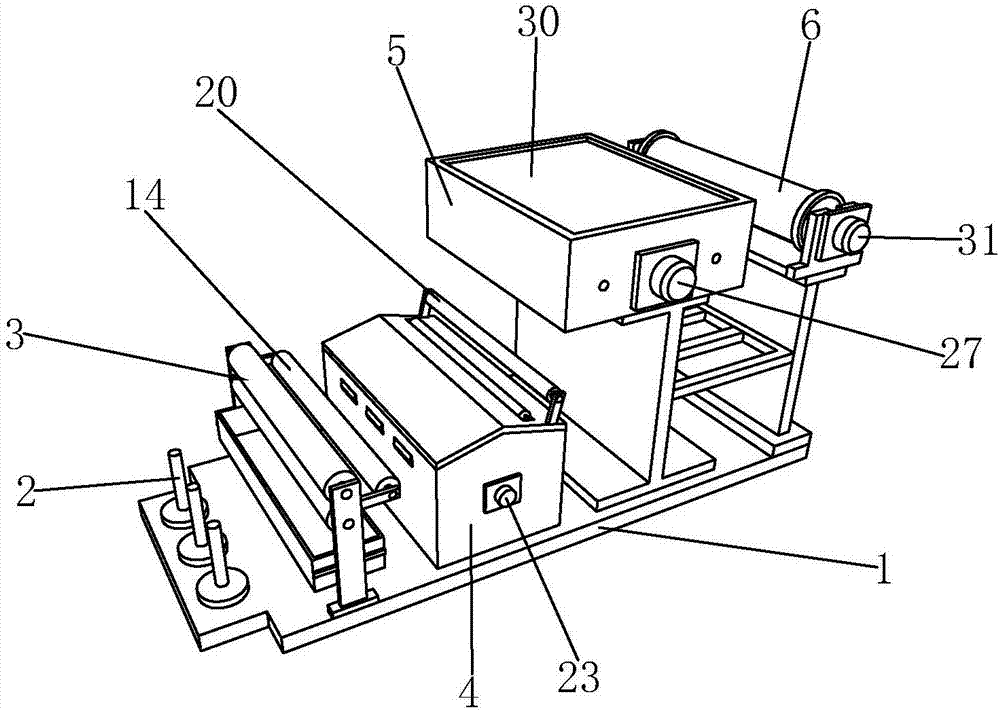

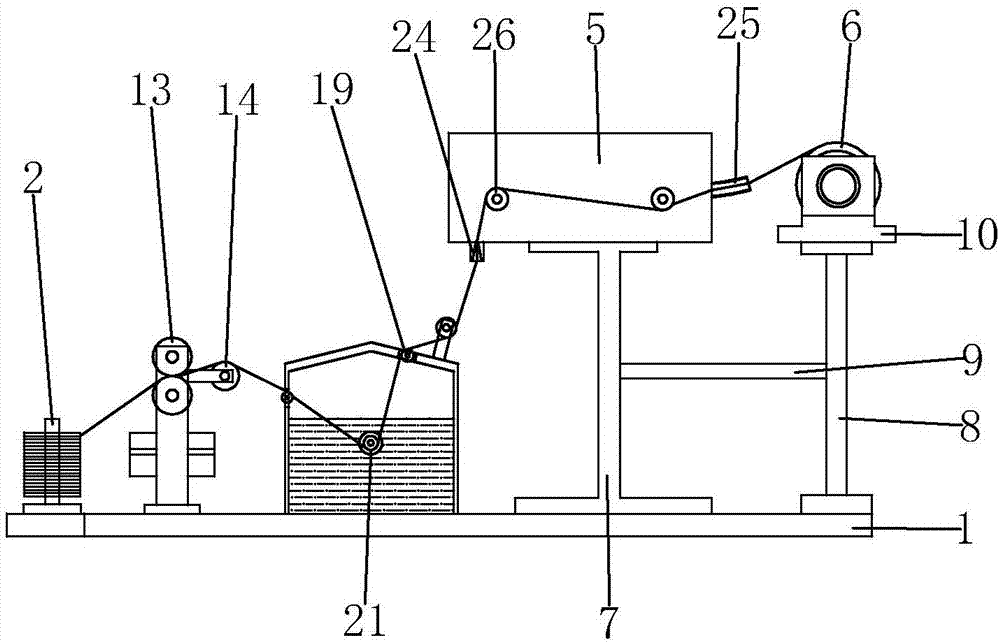

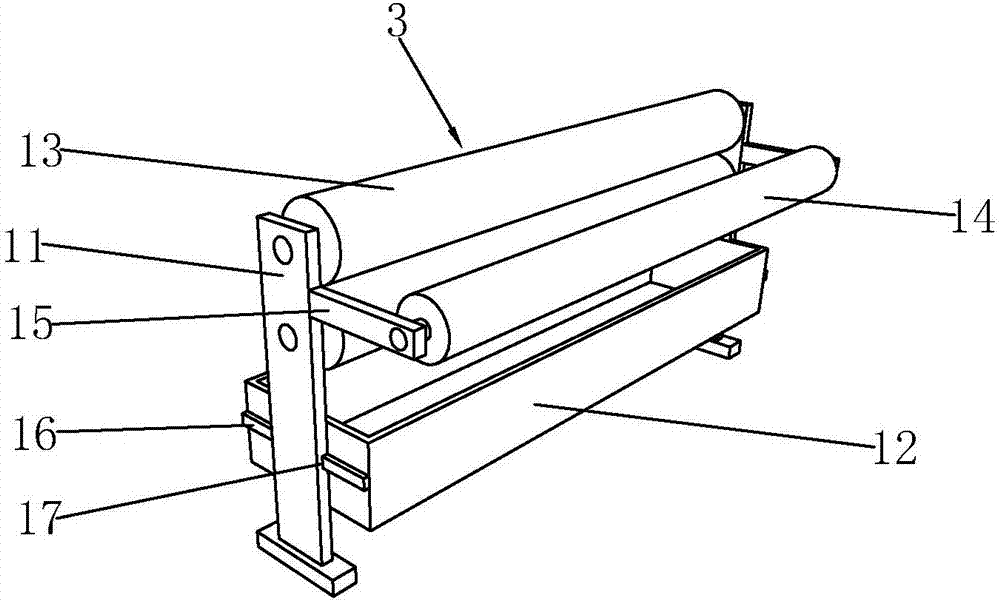

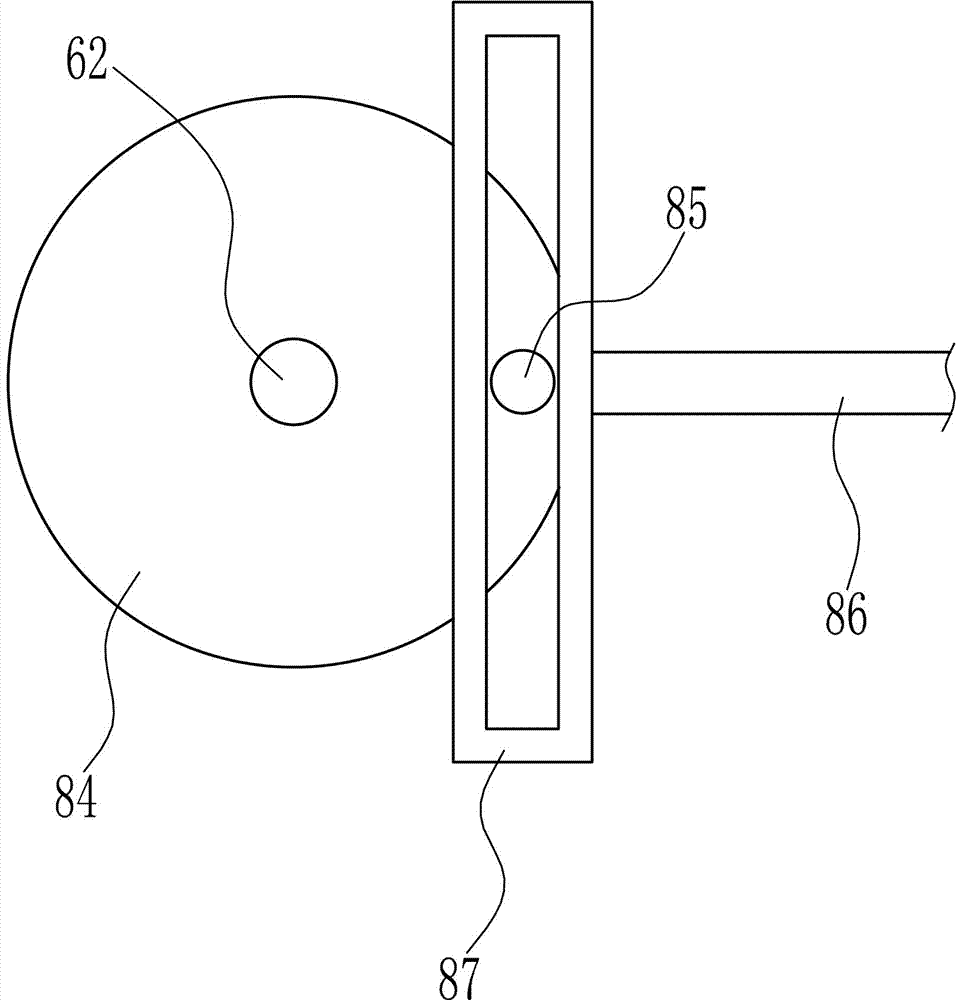

Yarn dyeing device for textile production

InactiveCN106930024AFlexible connectionEasy to cleanTextile treatment containersSucessive textile treatmentsYarnEngineering

The invention discloses a yarn dyeing device for textile production, which comprises a supporting platform, on which a bobbin holder, a yarn feeding mechanism, a dye box, an air-drying box and a take-up roller are respectively arranged, and on the yarn feeding mechanism, there are Waste box, one side of the dye box is provided with a feeding trough, the top surface of the dye box is provided with an outlet slot, the inside of the dye box is provided with a dyeing roller, the dyeing roller is evenly distributed with wire grooves, and the outside of the dye box is provided with a drive motor. The driving motor is connected to the dyeing roller. There is an inlet hose at the bottom of the air-drying box. The lead roller is connected with a take-up motor on one side of the take-up roller. The invention has the advantages of simple structure, flexible connection, multi-strand yarn dyeing at one time, and winding together, high working efficiency, good dyeing effect, and high quality and good performance of the obtained yarn product.

Owner:嵊州市靖洁纺织机械有限公司

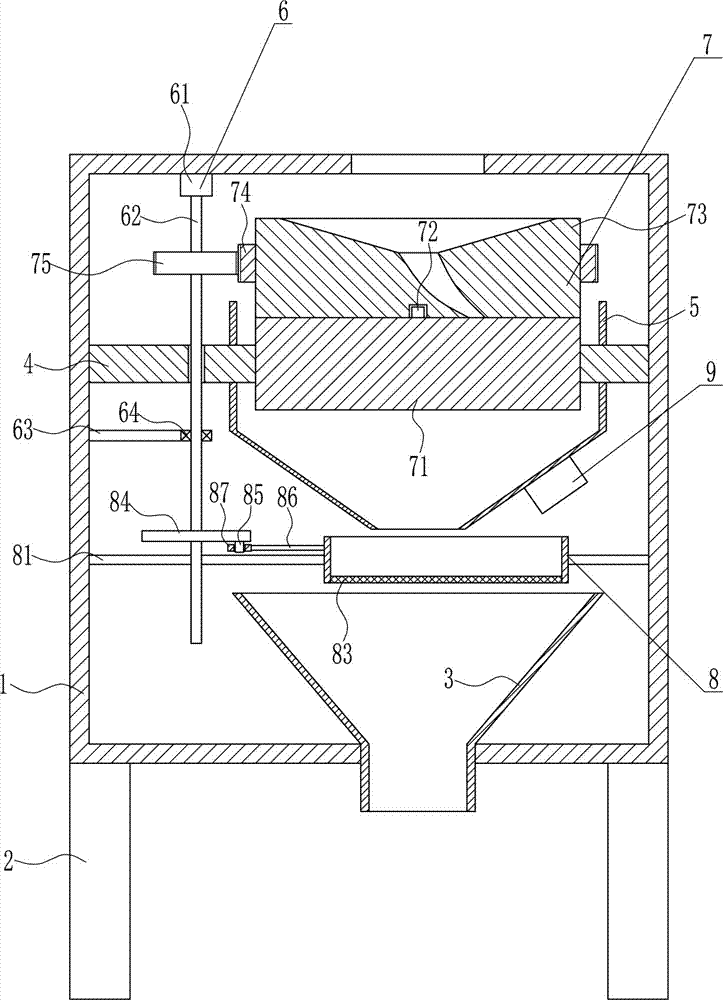

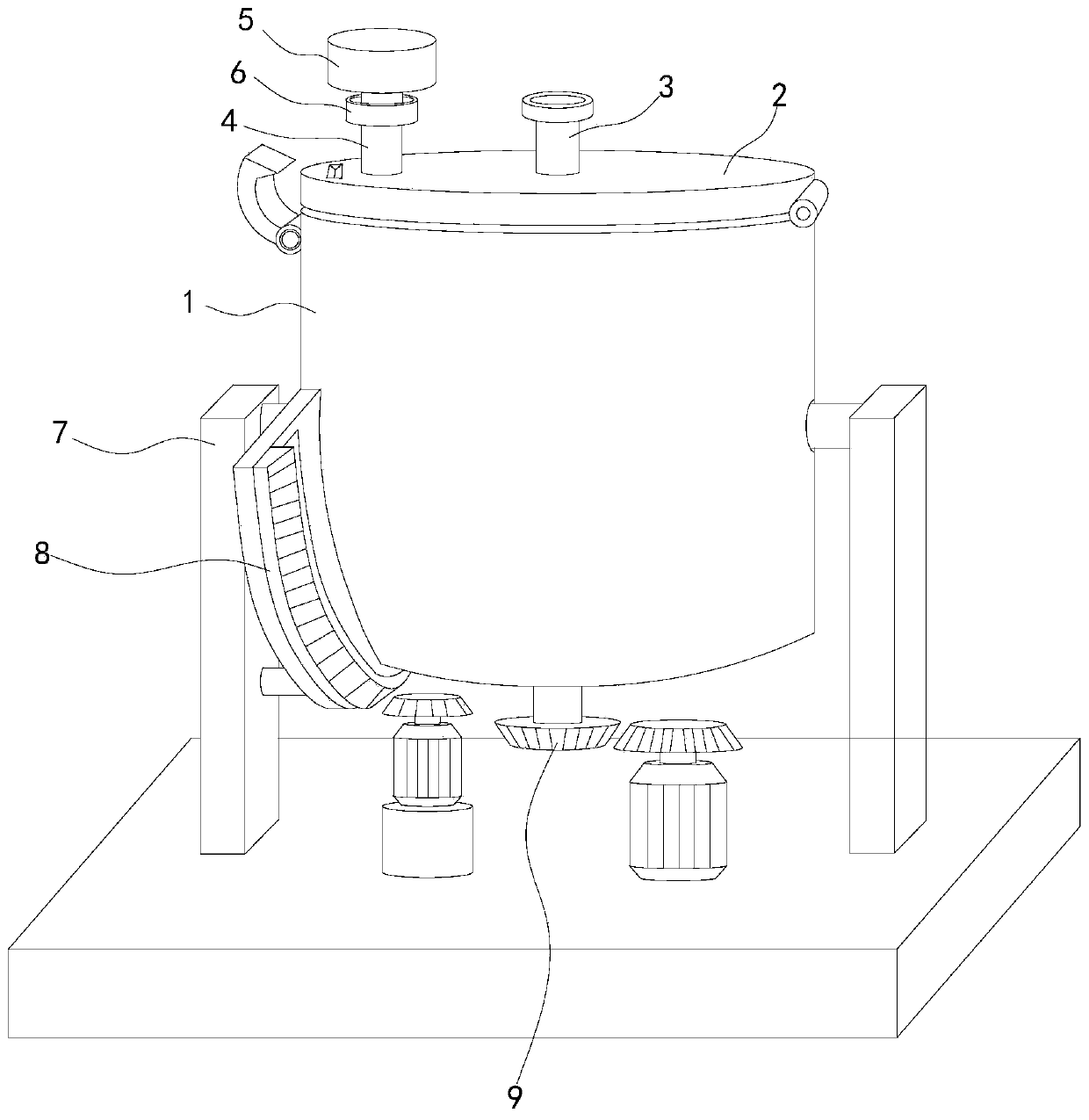

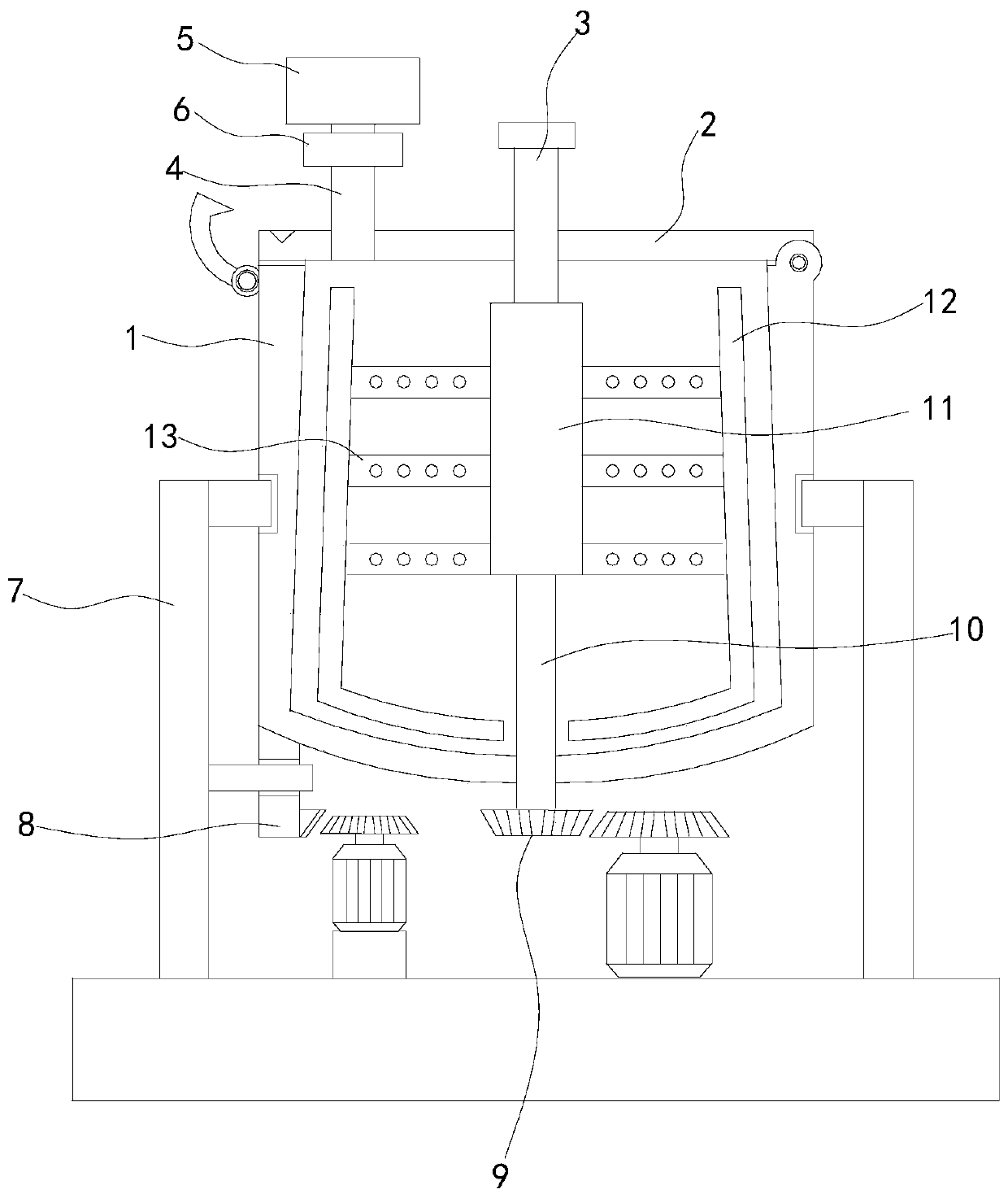

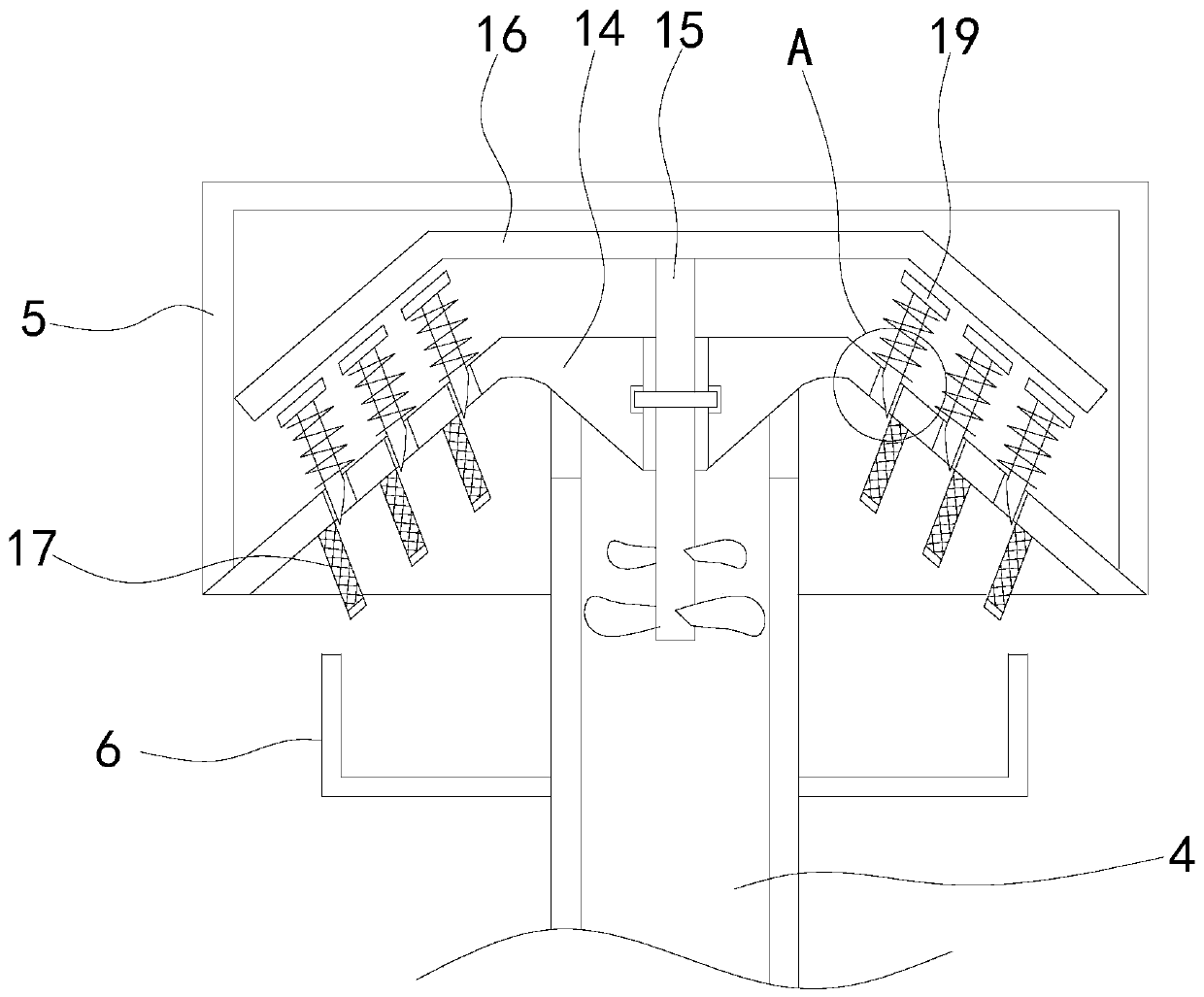

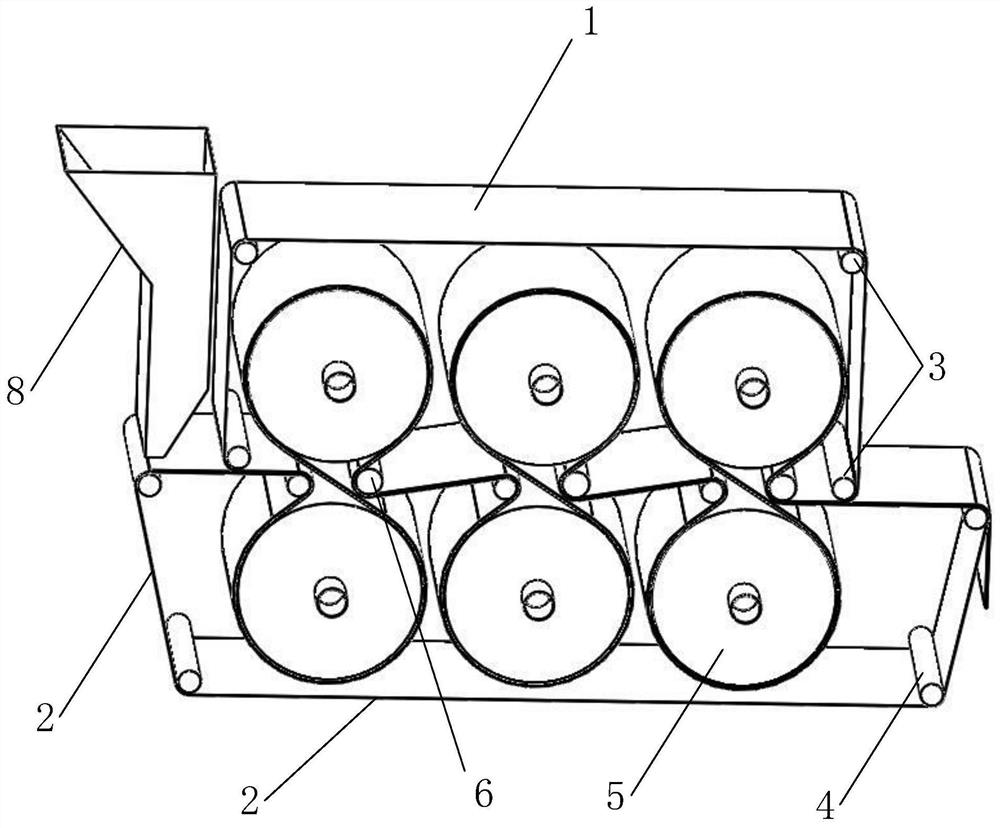

Efficient grinding equipment for chemical raw materials

The invention relates to grinding equipment, in particular to efficient grinding equipment for chemical raw materials. In order to solve the technical problems, the invention provides the efficient grinding equipment for chemical raw materials, and the efficient grinding equipment is high in grinding efficiency, is good in grinding effect, and saves time and labor. The efficient grinding equipmentfor the chemical raw materials comprises a box body and the like, wherein supporting legs are mounted on bottom four corners of the box body; the bottom in the box body is in nested connection with adischarge hopper; transverse rods are arranged on the middle parts at left and right sides in the box body; a material collecting hopper is arranged between the transverse rods at left and right sides; the transverse rods penetrate through the upper part of the material collecting hopper; the material collecting hopper is positioned above the discharge hopper; a drive device is arranged at the left side of the top in the box body; a grinding device is arranged in the material collecting hopper; and the drive device is matched with the grinding device. According to the efficient grinding equipment disclosed by the invention, the drive device drives the grinding device and a screening device to operate, the grinding device efficiently grinds the chemical raw materials, and the screening device screens the grinded chemical raw materials.

Owner:深圳高佳研机械研究设计有限公司

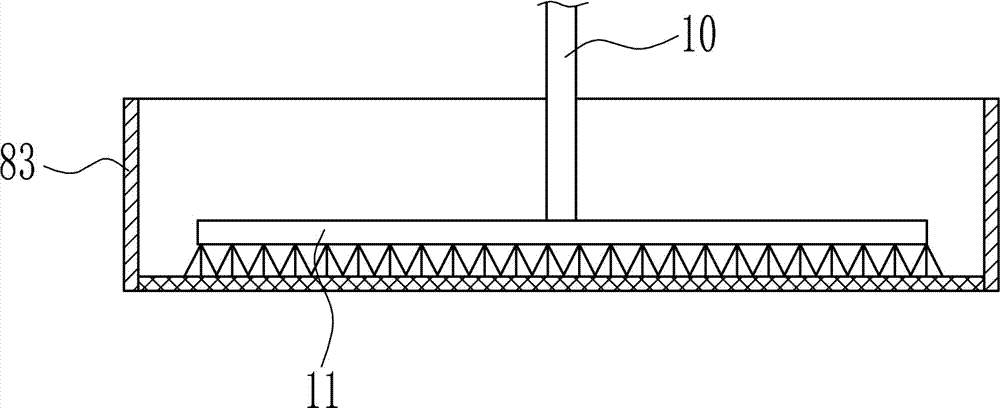

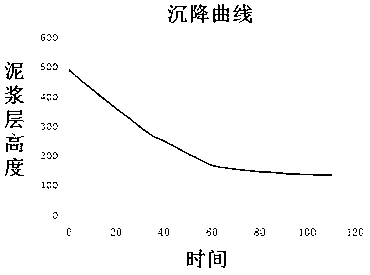

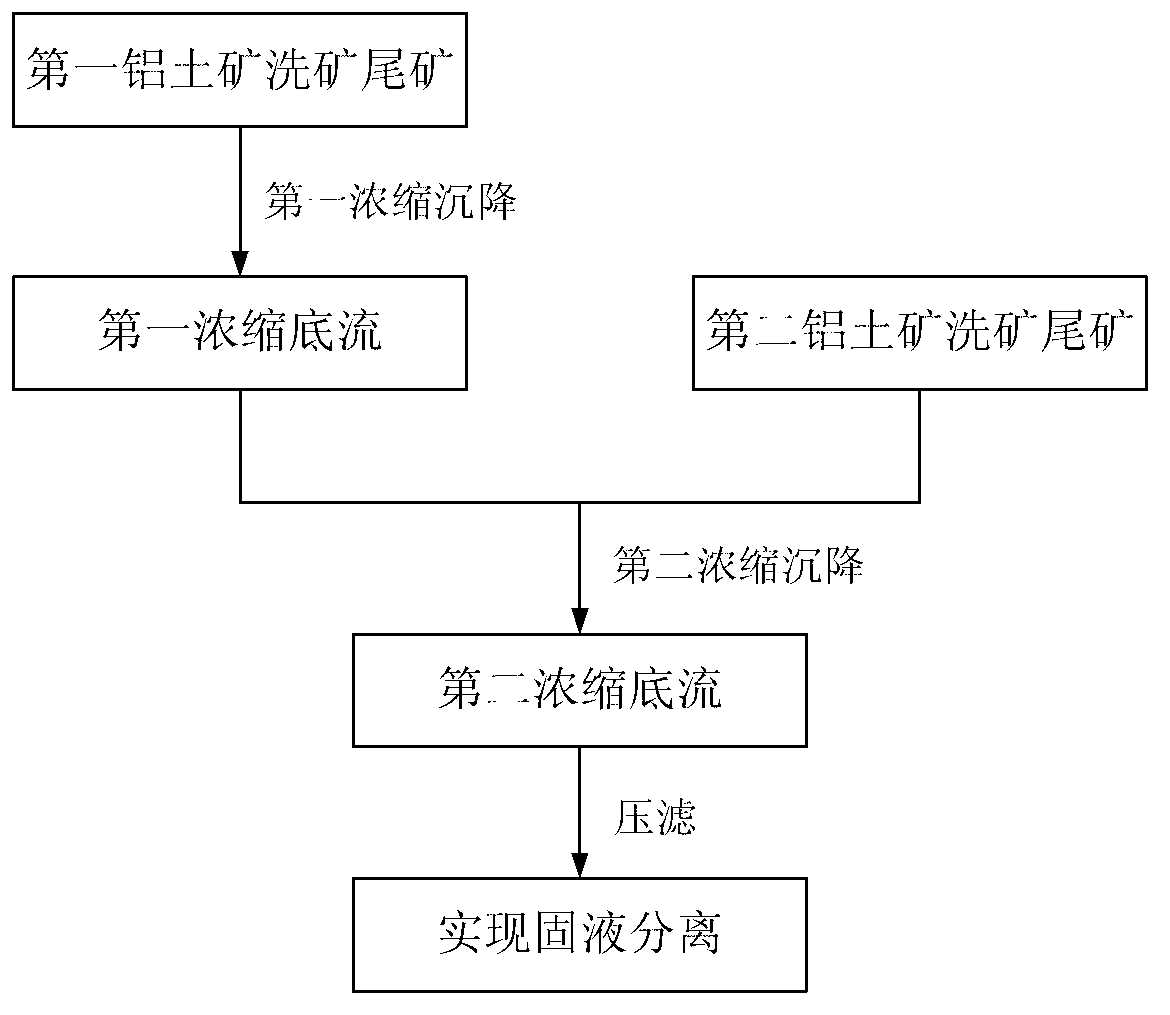

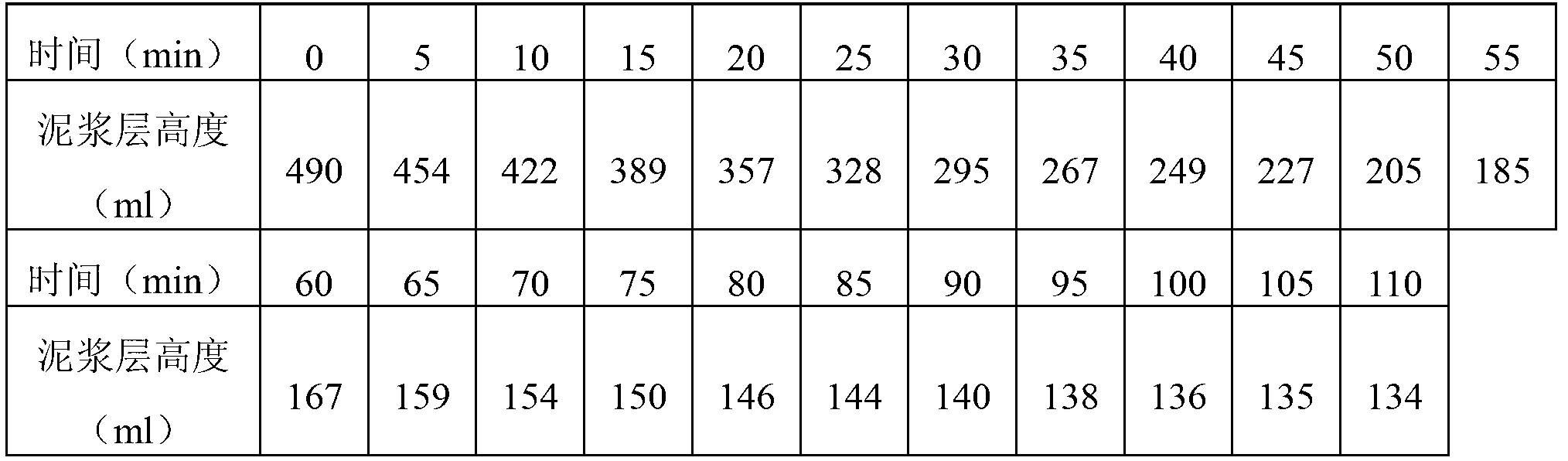

Method for processing monohydrallite ore washing gangue

ActiveCN103316760AFully recycleAvoid pollutionFiltration circuitsWet separationWater resourcesEngineering

The invention discloses a method for processing monohydrallite ore washing gangue. The method includes: conveying first monohydrallite ore washing gangue to an efficient thickener so as to perform first concentration sedimentation on the first monohydrallite ore washing gangue, and first concentration underflow can be obtained; the first concentration underflow can be collected and mixed with second monohydrallite ore washing gangue to be conveyed to the efficient thickener, second concentration sediment can be performed, and second concentration underflow can be obtained; the second concentration underflow can be conveyed to a filter press for filter pressing, and solid-liquid separation can be obtained. The method for processing monohydrallite ore washing gangue is easy and convenient, fast, efficient and less in energy consumption, does not need to add additional devices compared with a conventional method, requires low cost, is good in solid-liquid separation effect, can fully recycle water in the gangue, accordingly can effectively save water resources and avoid environment pollution, and is particularly suitable for processing the monohydrallite ore washing gangue which is tiny in granule, large in viscosity, not apt to settle and difficult to process by adopting a conventional method.

Owner:YUNNAN WENSHAN ALUMINUM

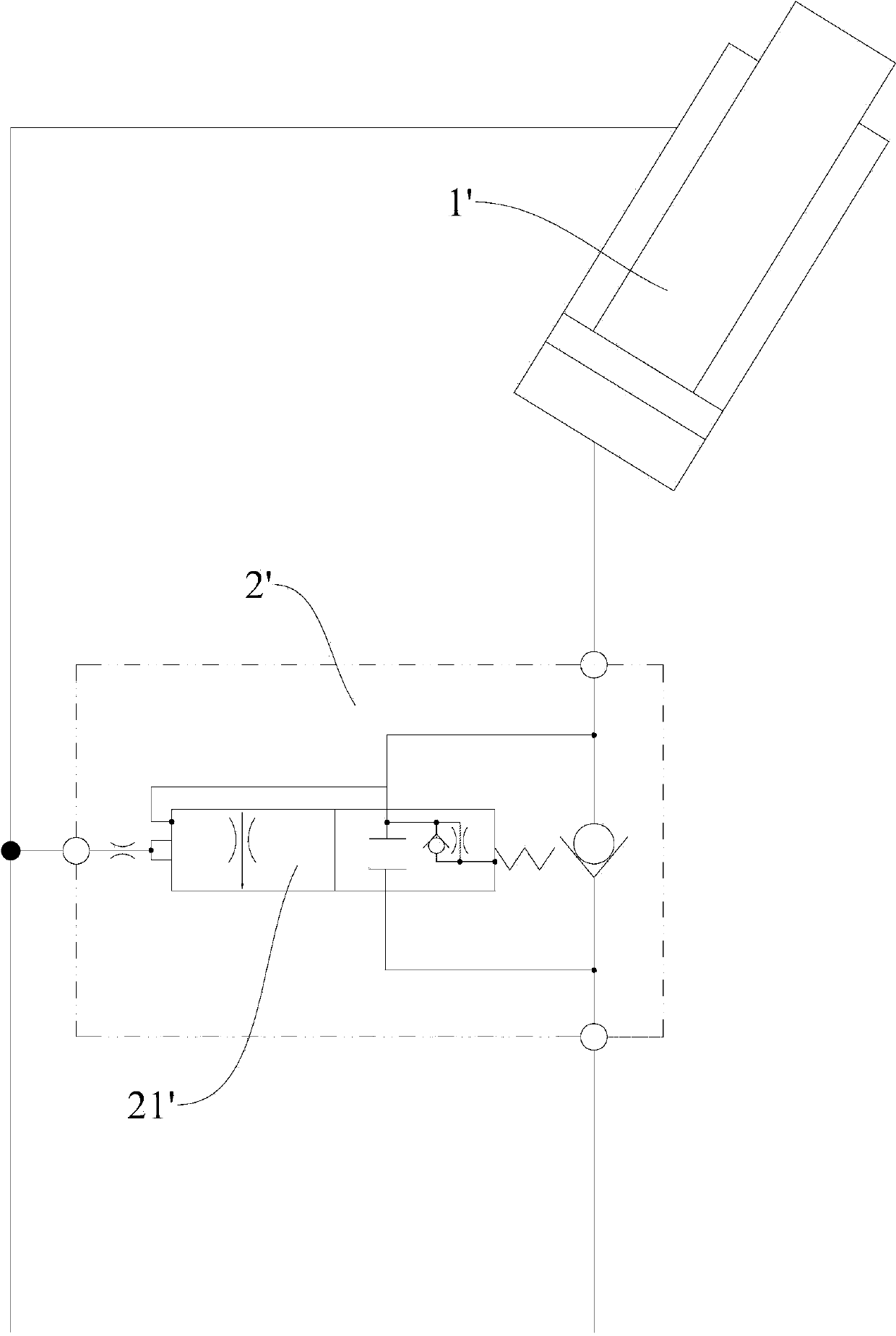

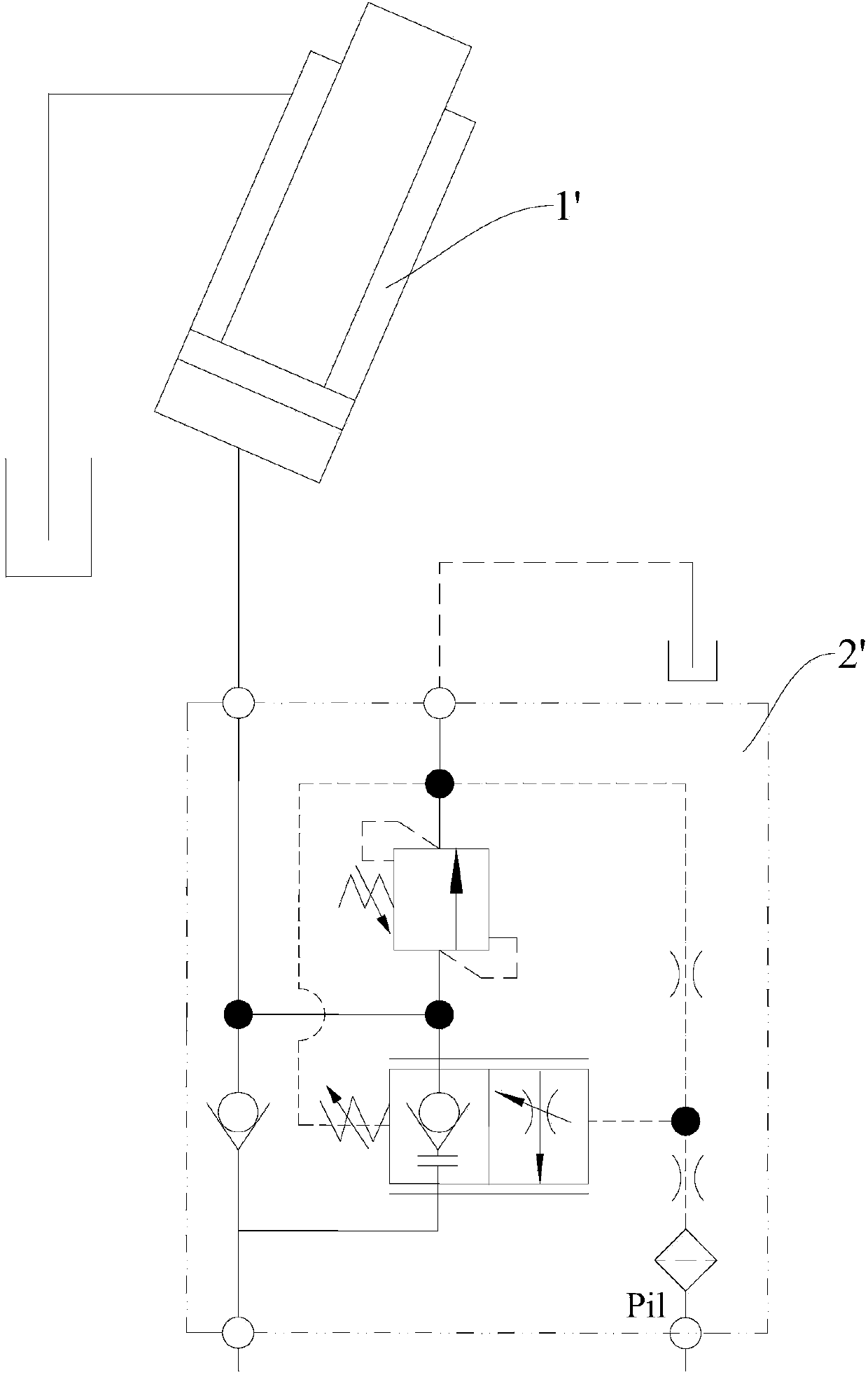

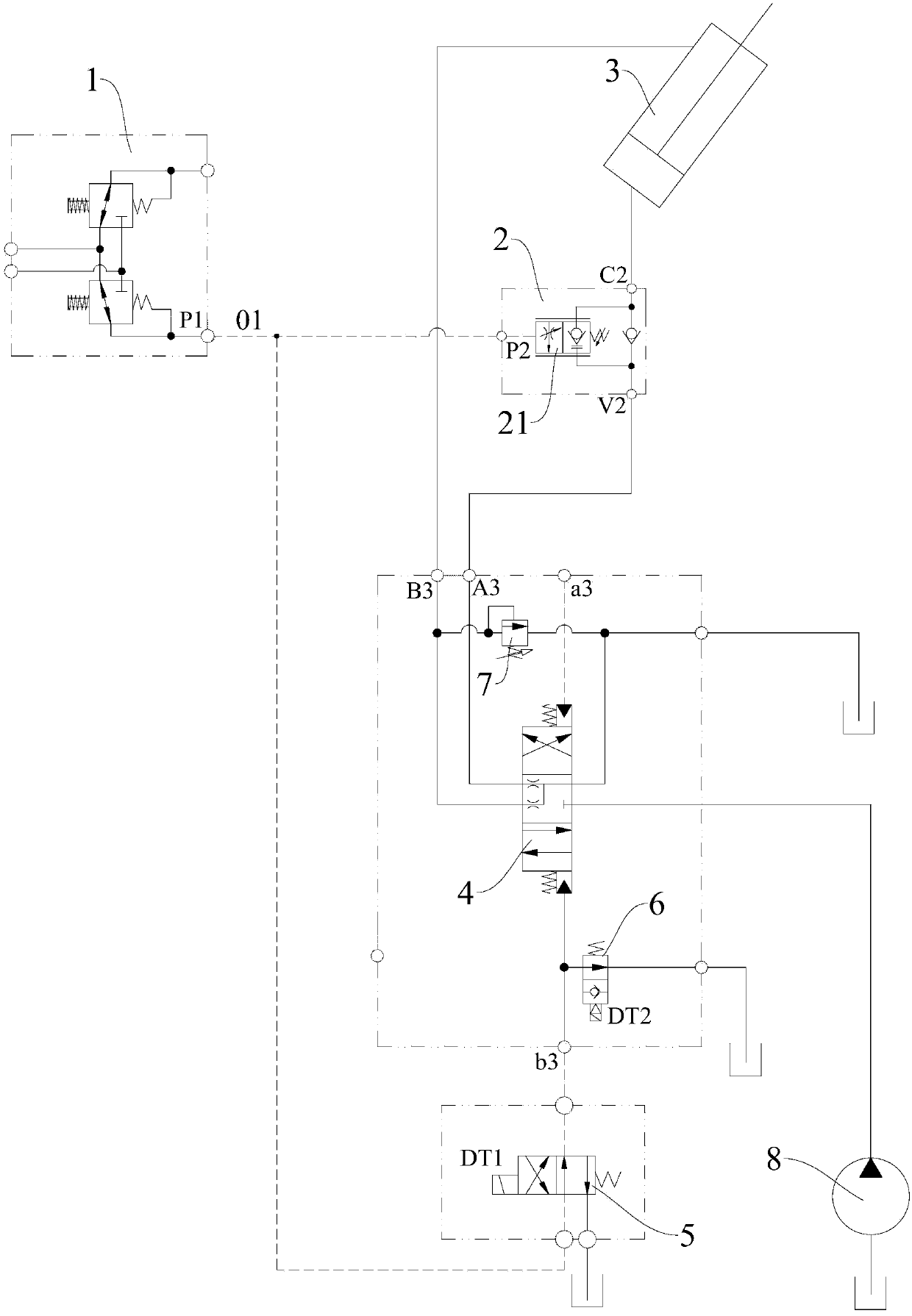

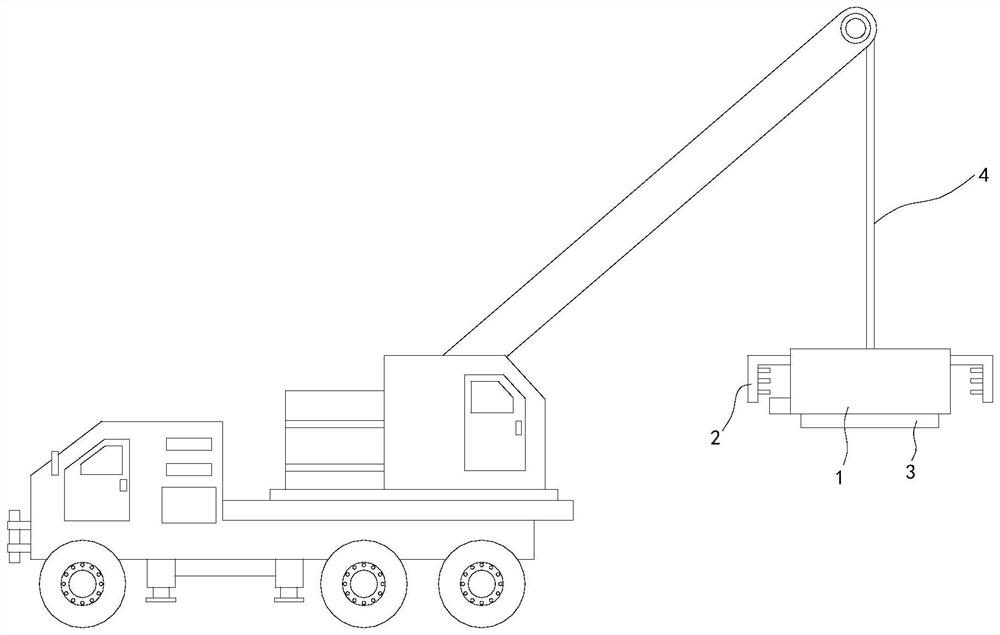

Amplitude falling hydraulic system and engineering machinery

InactiveCN103723640AIncreased fall start speedThe falling amplitude starts smoothly and without jitterServomotor componentsServomotorsControllabilityStreamflow

The invention relates to the technical field of amplitude variation of engineering machinery and discloses an amplitude falling hydraulic system and the engineering machinery. The amplitude falling hydraulic system comprises an amplitude variation oil cylinder, a control oil path, a main reversing valve and an amplitude variation balance valve with a flow saturation characteristic, wherein a rod cavity and a rodless cavity of the amplitude variation oil cylinder are respectively connected to a first working oil opening of the main reversing valve and a free oil outlet of the amplitude variation balance valve; a second working oil opening of the main reversing valve is connected to a free oil inlet of the amplitude variation balance valve; the output end of the control oil path is connected to a control oil opening of the amplitude variation balance valve and an amplitude falling control oil opening of the main reversing valve. According to the amplitude falling hydraulic system and the engineering machinery, the amplitude falling starting speed in a large angle can be effectively increased; furthermore, control pressure of the amplitude variation balance valve comes from the control oil path and cannot be affected by a load, so that amplitude falling can be steadily started without shake; moreover, the amplitude variation balance valve has the flow saturation characteristic, so that the safety and the controllability of the amplitude falling operation can be effectively improved.

Owner:SANY AUTOMOBILE HOISTING MACHINERY

Energy-saving environment-friendly steel slag tank

The invention relates to the field of steel slag treatment devices, in particular to an energy-saving environment-friendly steel slag tank. The energy-saving environment-friendly steel slag tank comprises a steel slag tank body. The upper end of the steel slag tank body is movably provided with a top cover, and the upper end of the top cover is fixedly provided with a gas outlet pipe. The upper end of the gas outlet pipe is fixedly provided with a slag removing device. A water storage pipe is fixedly installed inside the steel slag tank body. Stirring rods are fixedly installed on the both sides of the water storage pipe. Slag scraper plates are fixedly installed at the outer ends of the stir rods. A filter plate is arranged in a circular ring shape to prevent steam from taking out slag inside the steel slag tank body. Through grooves are formed inside a gas guide plate, slag removal blocks are movably installed at the upper end of the gas guide plate, after the rotating plate rotates,by means of the wavy bent arrangement of the inner side of the rotating plate, the rotating plate intermittently drives the slag removal blocks to overcome the action force of springs to downwards pass through the through grooves and scrape the slag blocked on the filter plate, the slag is made to move downward to enter the slag collecting box, so that the filter plate can be prevented from beingblocked, and centralized processing of the slag is convenient.

Owner:练素霞

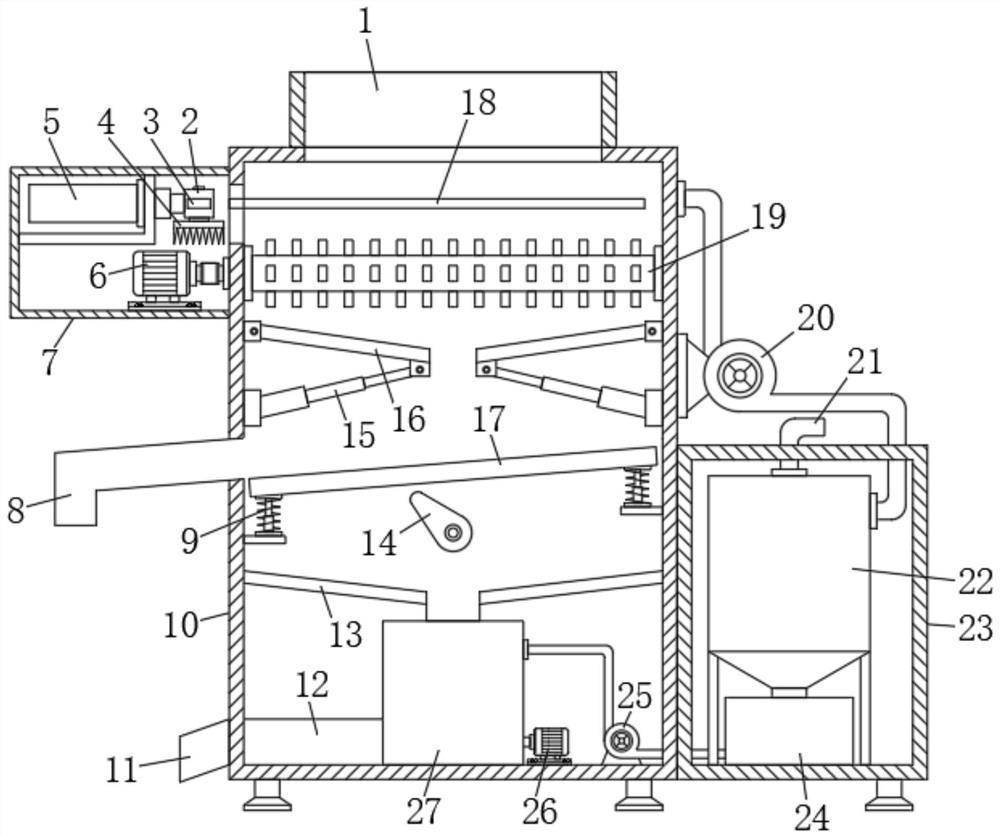

Environment-friendly construction waste treatment equipment for civil engineering

InactiveCN112892701ACleaning upAchieve cleanupGrain treatmentsConstruction engineeringWaste material

The invention discloses environment-friendly construction waste treatment equipment for civil engineering, and relates to the technical field of civil engineering. The environment-friendly construction waste treatment equipment for the civil engineering comprises a machine body, wherein a feeding hopper is arranged at the top end of the machine body, a crushing mechanism is arranged above the interior of the machine body, a vibration screening mechanism is arranged in the middle of the interior of the machine body, a collecting mechanism is arranged at the bottom of the interior of the machine body, one side of the machine body is connected with a first discharging pipe corresponding to the vibration screening mechanism, and one side of the bottom of the machine body is connected with a second discharging pipe communicating with the collecting mechanism. According to the environment-friendly construction waste treatment equipment, through the arrangement of a cleaning brushing mechanism, the crushing mechanism can be cleaned and brushed, so that the crushing mechanism is cleaned, crushed materials are effectively prevented from remaining on the crushing mechanism, rapid crushing of waste materials is facilitated, the crushing efficiency of the crushing mechanism is greatly improved, and the working efficiency of the equipment is improved favorably.

Owner:CHENGDU NORMAL UNIV

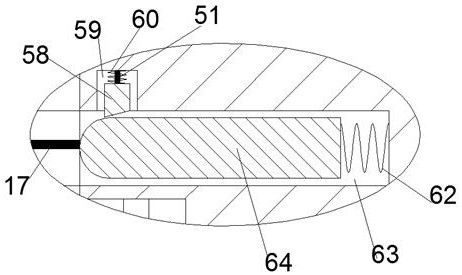

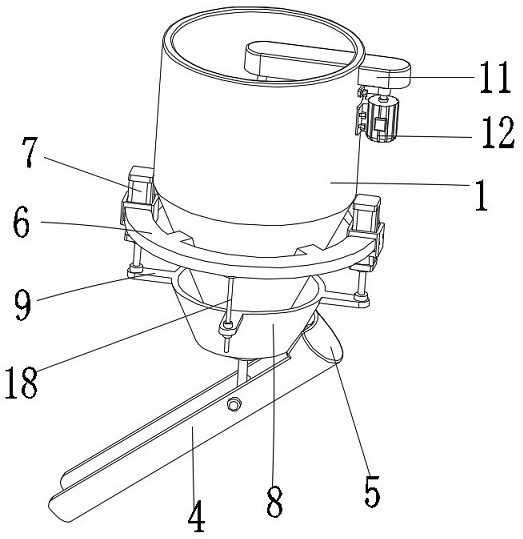

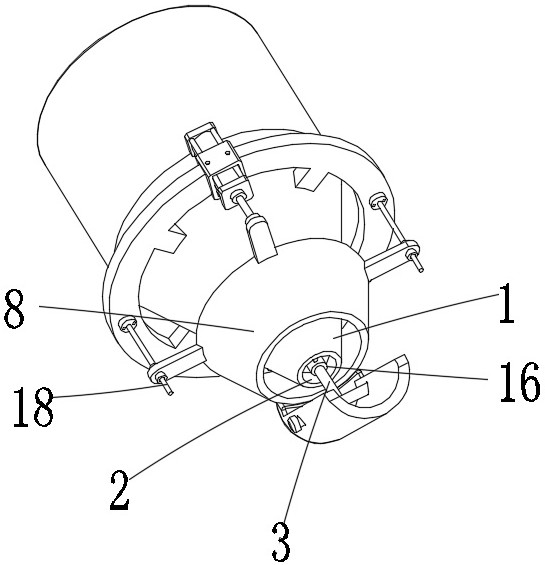

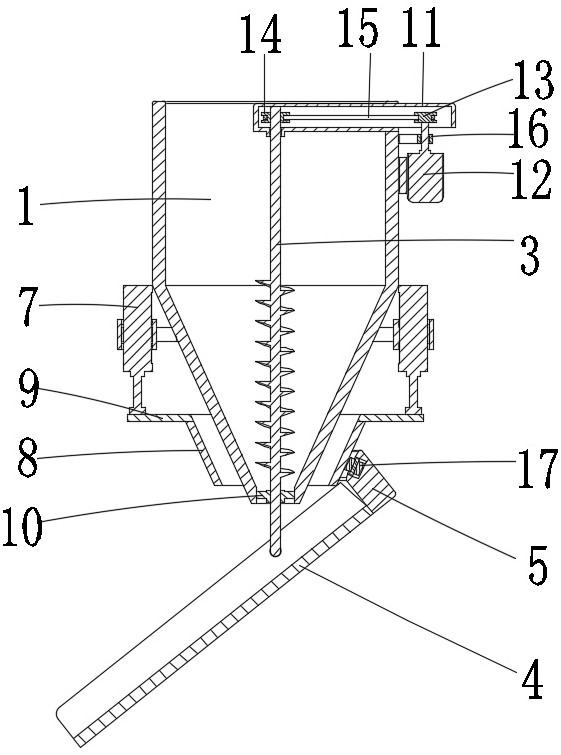

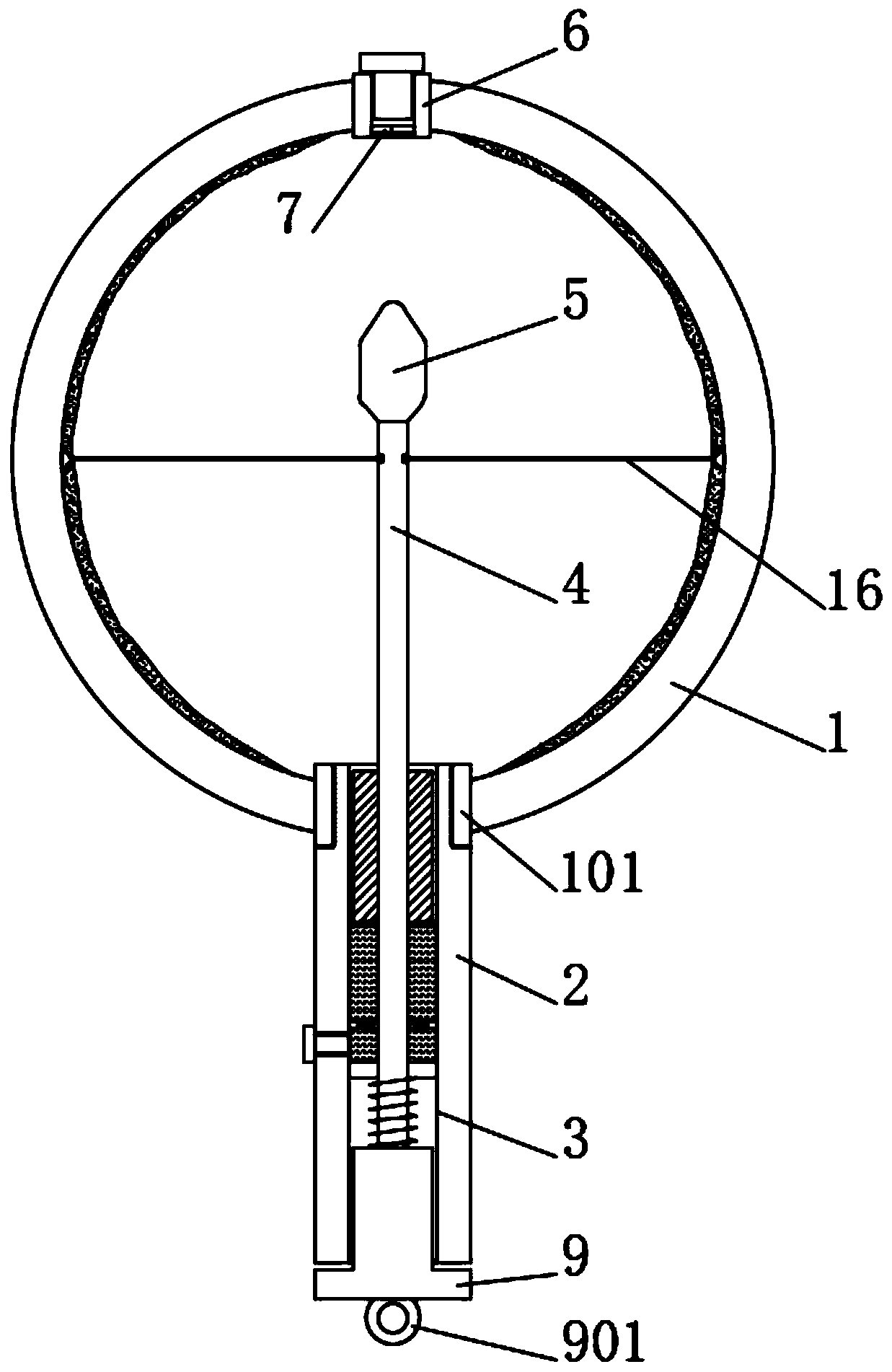

Portable semen plantaginis collecting device

ActiveCN112586185APrevent problems such as fruit bursting and fallingPrevent problems such as bursting and fallingPicking devicesAnimal sciencePLANTAGO SEED

The invention relates to the technical field of medicine collection, and discloses a portable semen plantaginis collecting device. The device comprises a picking barrel, a collecting barrel is fixedlymounted at the top of the picking barrel, pressing devices distributed in an annular array are sequentially arranged on the outer wall of the picking barrel from top to bottom, each pressing device comprises a pressing rod, and one end of each pressing rod extends into a picking barrel cavity; and a friction plate is fixedly installed at one ends of the pressing rods, and a sweeping device is arranged on the inner wall of the friction plate. According to the portable semen plantaginis collecting device, through the arrangement of the sweeping device, when a permanent magnet A is randomly andrapidly pressed, under the combined action of mutual attraction of magnetic force and mutual repulsion of the magnetic force, a permanent magnet C on the pressed friction plate vibrates, and the vibration of the permanent magnet C drives hard bristles to shake ceaselessly, when the hard bristles shake when getting close to the outer wall of semen plantaginis, the shaking hard bristles further improve the falling efficiency of semen plantaginis fruits, and the semen plantaginis picking efficiency is further improved.

Owner:泉州台商投资区一创工业设计有限公司

Long-distance transmission device for fire alarm

ActiveCN112991664AImprove long-distance transmission efficiencyPracticalCombination devicesGeneral water supply conservationEngineeringData transmission

The invention relates to the technical field of fire fighting, and discloses a long-distance transmission device for fire alarm, which comprises a lower box body, an upper box body is arranged at the top of the hollow part of the lower box body, a partition plate is fixedly connected to the inner wall of the joint of the lower box body and the upper box body, and a suction pump is fixedly mounted at the center of the top of the partition plate. A smoke alarm is fixedly installed in the center of the top of the upper box body, and air suction holes distributed in an annular array mode are formed in the annular outer wall of the top of the upper box body. According to the long-distance transmission device for fire alarm, the lower box body moves directionally in a shopping mall, the suction pump sucks air in the shopping mall into a cavity of the lower box body through an air suction pipe, a suction cover and an air suction hole, a smoke alarm detects the air, and a data transmission device feeds back detected signals to a background to achieve the purpose of long-distance transmission of the fire alarm. According to the invention, the long-distance transmission efficiency of the fire alarm in the shopping mall is improved, and the purpose of detecting the fire alarm in the shopping mall in real time for 24 hours is achieved.

Owner:帕沃电子技术有限公司

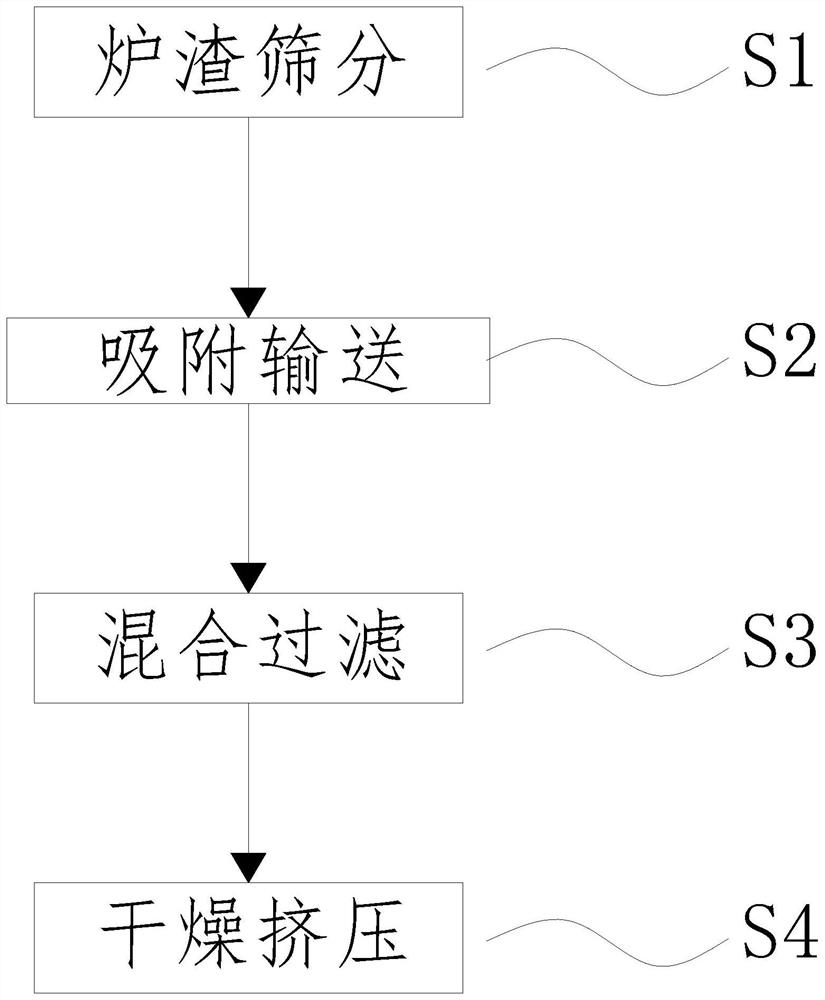

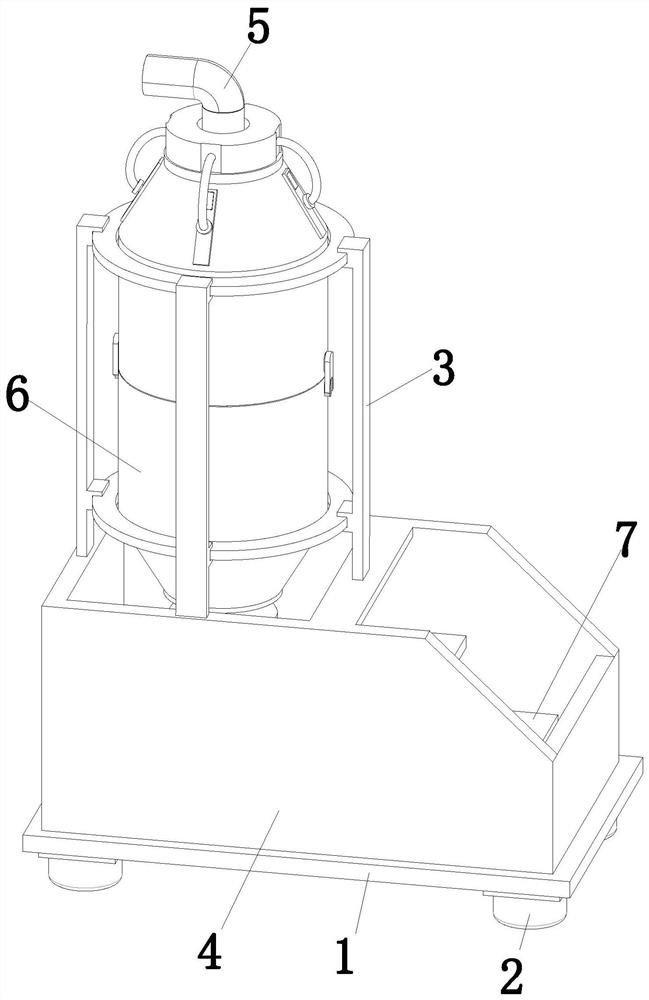

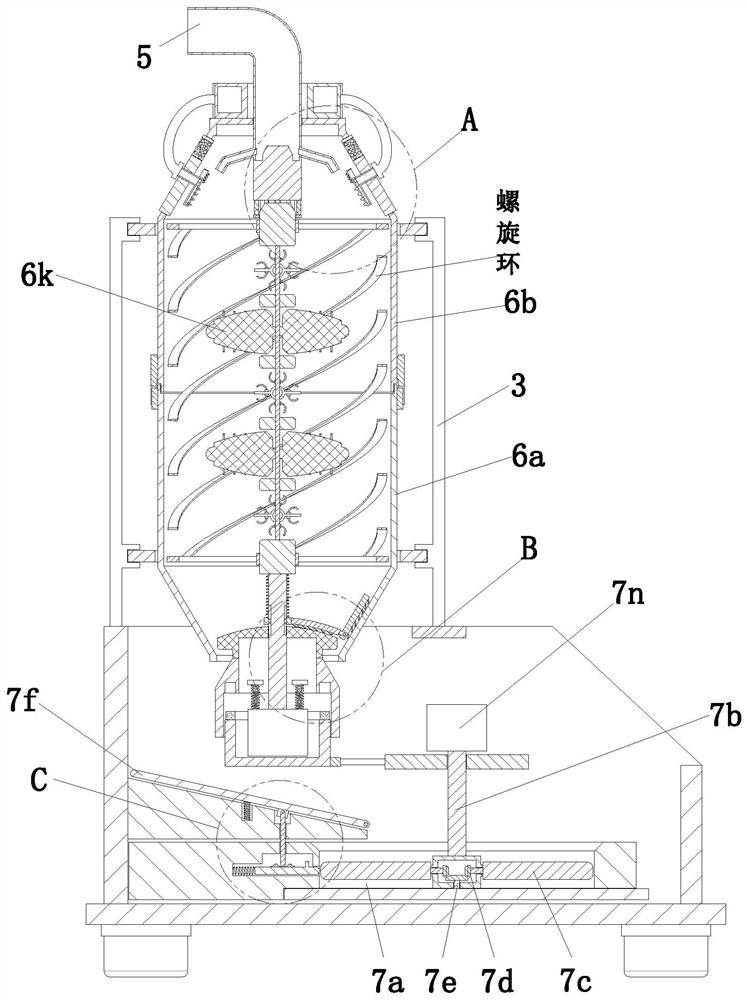

Industrial boiler slag solid waste comprehensive environment-friendly treatment method

InactiveCN113244721ARealize secondary recyclingQuick installationTransportation and packagingSolid waste disposalBoiler furnaceBoiler slag

The invention relates to an industrial boiler slag solid waste comprehensive environment-friendly treatment method, in particular to an industrial boiler slag solid waste comprehensive environment-friendly treatment device which comprises a mounting bottom plate, supporting legs, a supporting frame, a collecting box, a feeding port, a mixing mechanism and a stirring mechanism. The method can solve the problems that in the process of an industrial boiler slag solid waste comprehensive environment-friendly treatment method, the mixing proportion and the mixing degree of dust and water mist are difficult to control, mixed dust slurry is difficult to effectively scrape, mixed loose dust slurry is difficult to convey and guide, and the adhesion and accumulation phenomena of the dust slurry are generated, the mixed dust slurry is difficult to push and flatten in the circumferential direction, and the drying efficiency and the forming effect of the slurry dust are reduced.

Owner:苏哲

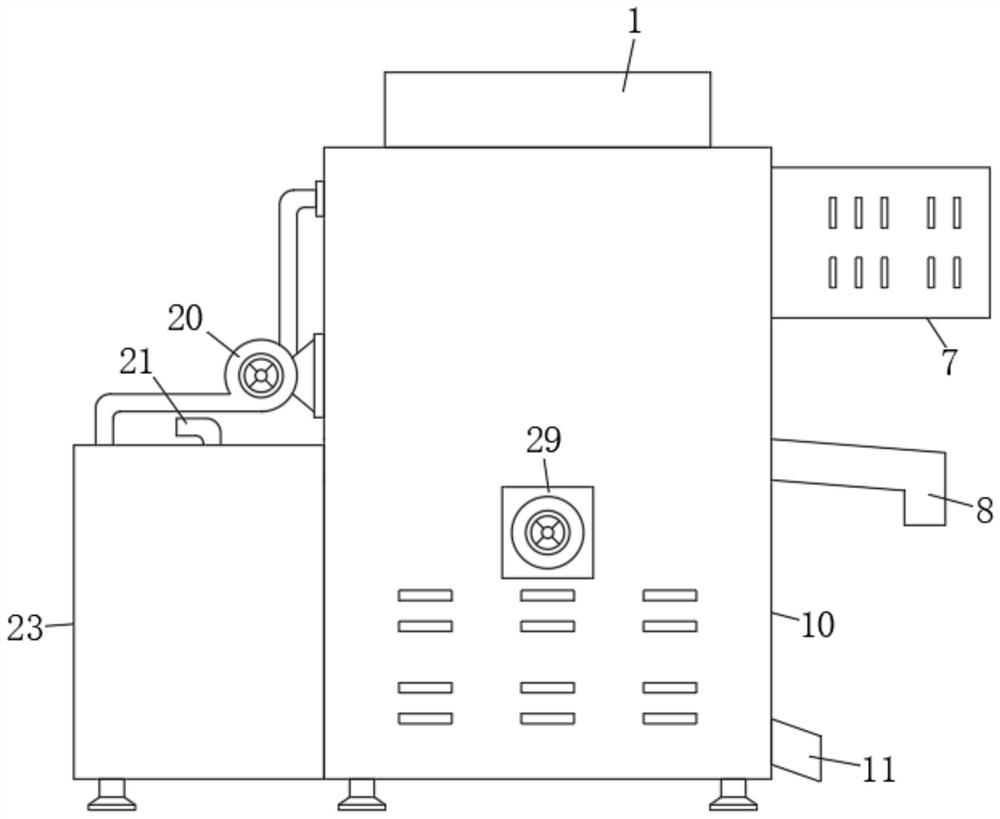

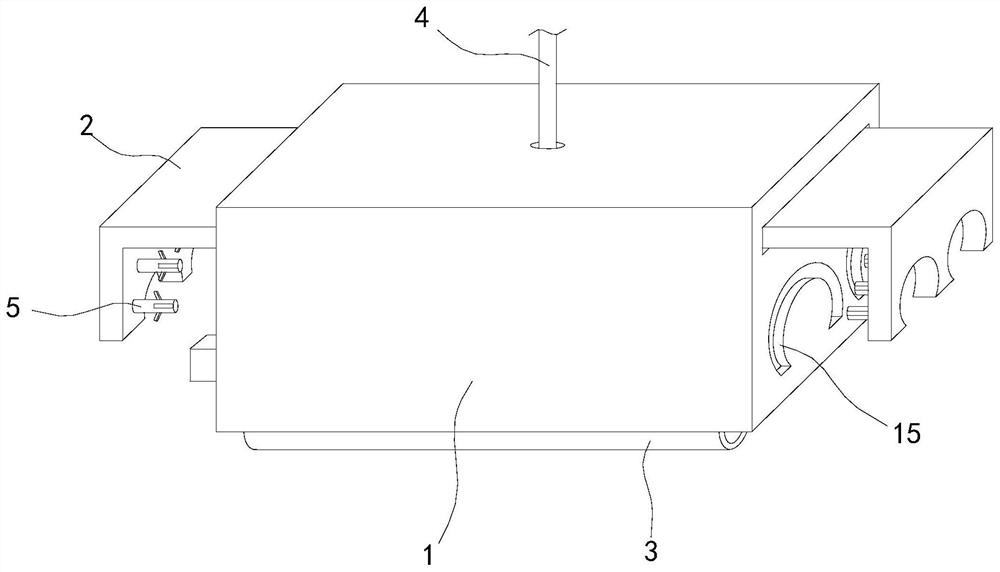

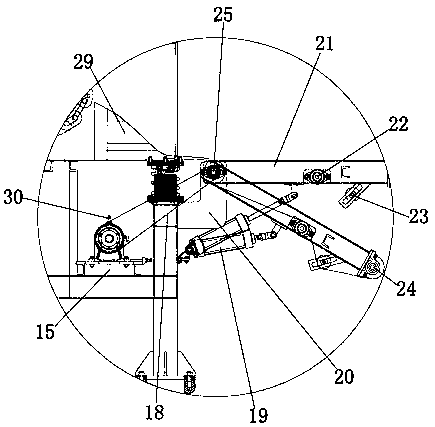

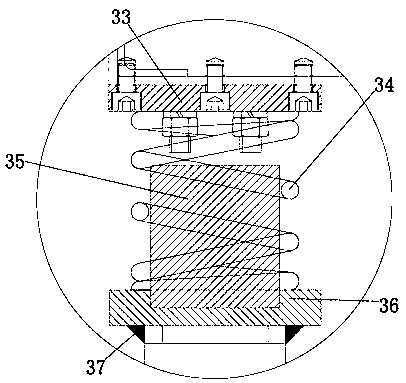

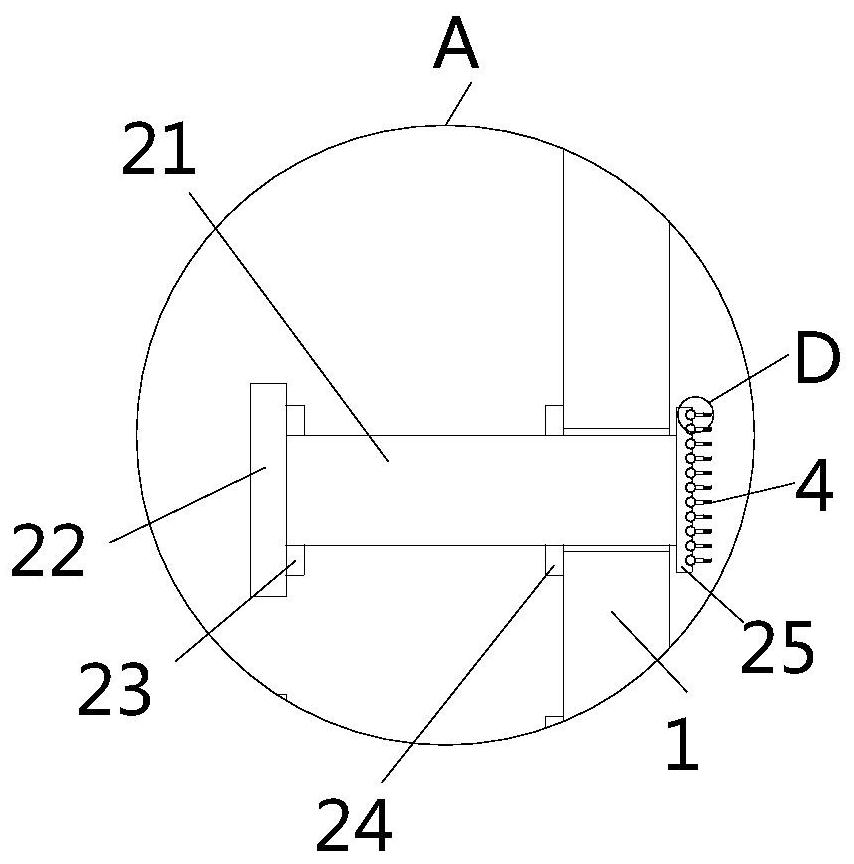

Limiting-fixing hoisting device for steel pipe

InactiveCN111675117AImprove securityGuaranteed uptimeLoad-engaging elementsCranesClassical mechanicsPipe

The invention relates to the field of hoisting equipment for steel pipes, and specifically relates to a limiting-fixing hoisting device for a steel pipe. The limiting-fixing hoisting device for the steel pipe comprises a device main body, wherein reinforcing plates are movably installed at the two sides in the device main body, and a steel pipe fixing device is movably installed at the lower end in the device main body. An elastic rotary shaft is fixedly installed between the steel pipe fixing device and a limiting-clamping plate, a baffle is fixedly installed at the outer side of the steel pipe fixing device, and the limiting-clamping plate is enabled to rotate outwards under the action of the elastic rotary shaft until the limiting-clamping plate makes contact with the baffle; when the steel pipe fixing device is driven to rotate, through formation for a limiting groove in the outer side of the steel pipe fixing device and through semi-arc-shaped configuration for the limiting-clamping plate, the limiting-clamping plate is enabled to receive the steel pipe at the lower end of the device main body into the limiting-clamping plate and then to be driven towards the interior of the steel pipe fixing device, and then form a complete circle with the limiting groove to carry out limiting-fixing on the steel pipe which is received inside, so that the safety during hoisting for the steel pipe is improved.

Owner:谢红菊

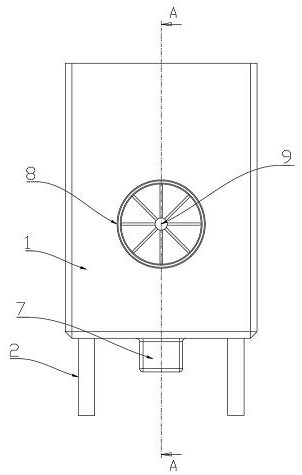

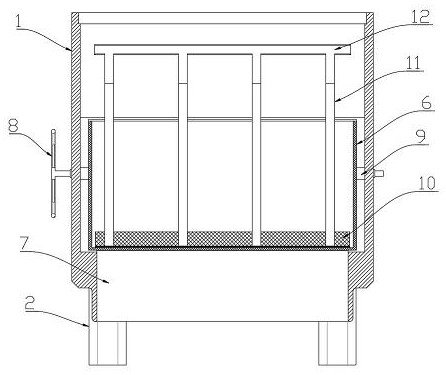

Paper guiding device for printing packaging equipment

InactiveCN108860857AClosely connectedImprove stabilityPackaging machinesPower flowPulp and paper industry

The invention discloses a paper guiding device for printing packaging equipment. The paper guiding device for the printing packaging equipment comprises a box body. The top of the box body is providedwith a feed port. The right side of the feed port is provided with a locking box. The locking box is connected with the box body. The bottom of the box body is provided with landing legs. A bottom plate is arranged between the landing legs. The outer walls of the right sides of the landing legs are provided with a support. According to the paper guiding device for the printing packaging equipment, by means of cooperation of a first motor, a second motor, scraping plates and a conveyor belt, under the action of a discharging plate and a discharging belt, the first motor and the second motor are alternate current servo motors, and by improving the power generated by the current through the motors, the rotating speeds of the motors are adjusted; and by adjusting the rotating speeds of the motors, the falling efficiency of paper is improved, the defect that during discharging, machine clamping is prone to being caused in avoided, the working efficiency is improved, the service life is prolonged, and the production cost is reduced.

Owner:FANCHANG COUNTY ZHUSHI PRINTING

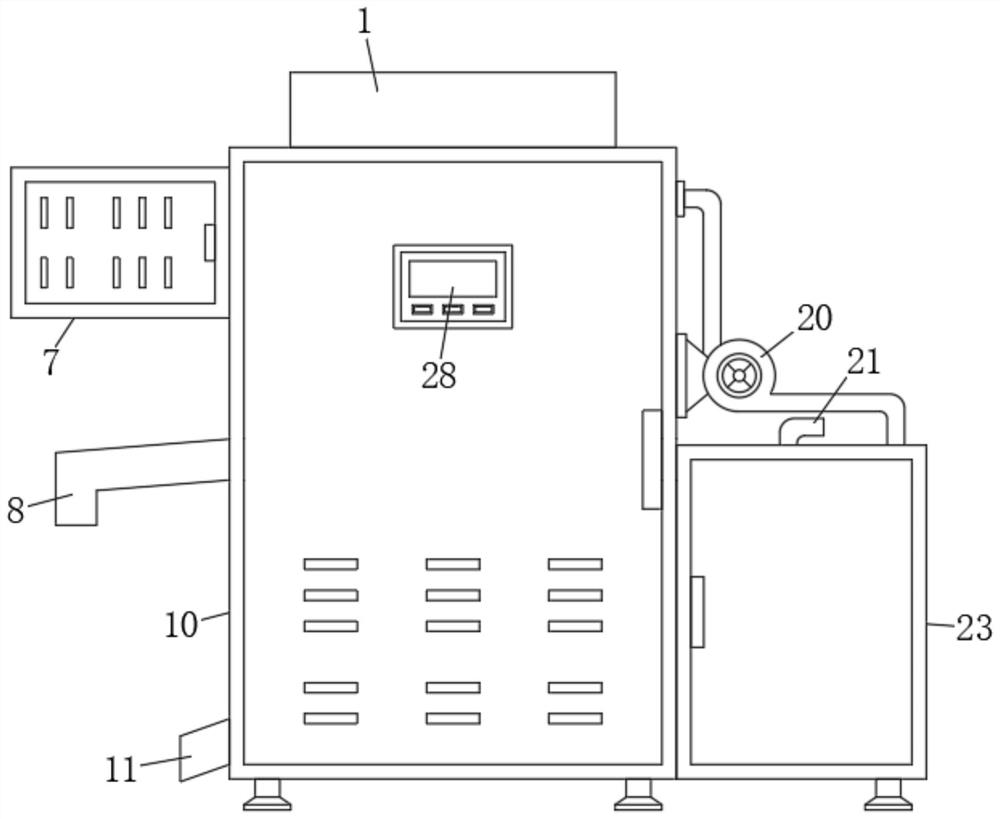

Biomass energy crushing recovery device

The invention relates to the technical field of biomass energy, and discloses a biomass energy crushing recovery device which comprises a box body. An inlet is formed in the top of the box body, and an outlet is formed in the bottom of the box body; a drying fan is fixedly connected to the outer wall of the box body, and a water storage tank and a ventilation groove are formed in the inner wall of the box body; a motor is fixedly connected to the back face of the inner wall of the box body; and a vibration classification disinfection and sterilization mechanism is arranged in the box body. According to the biomass energy crushing recovery device, through arrangement of the vibration classification disinfection and sterilization mechanism, waste crops and waste wood can be sterilized and disinfected in real time when being crushed and recycled, and mildew caused by fermentation of residual moisture after crushing of the waste crops and the waste wood is avoided; meanwhile, a large amount of crushed waste crops containing moisture can be prevented from adhering to the surface of an inclined sliding plate through vibration of the inclined sliding plate, and then the efficiency that the waste crops enter circular classification holes in a classified mode and fall is improved; and the waste crops are easy to dry by hot air entering the box body through the ventilation groove via vibration.

Owner:花德虎

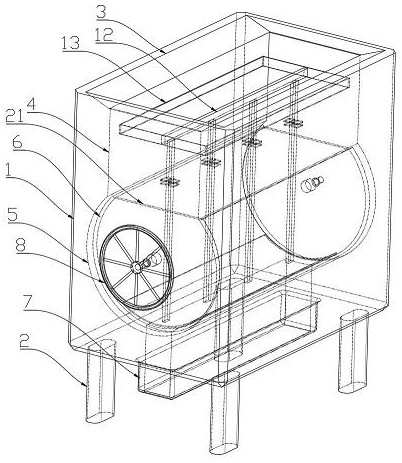

Waste velvet classification treatment and recovery device for garment processing factory

InactiveCN111113978AEasy to importEasy to storeDispersed particle filtrationTransportation and packagingAir blowerMechanical engineering

The invention discloses a waste velvet classification treatment and recovery device for a garment processing factory. The waste velvet classification treatment and recovery device comprises a rack, asupporting plate, an extrusion mechanism, a collection hopper, a discharge pipe, a driving mechanism and a control mechanism, wherein the supporting plate is mounted at the bottom of an inner cavity of the rack; the extrusion mechanism is arranged on the surface of the top of the rack; the collection hopper is arranged on one side of the surface of the top of the extrusion mechanism; the dischargepipe is arranged at the output end of the extrusion mechanism; and the driving mechanism is arranged on the left side of the extrusion mechanism. According to the waste velvet classification treatment and recovery device, waste velvet falling from the collection hopper can be conveyed and compressed through the extrusion mechanism and is discharged through the discharge pipe, so that the waste velvet can be guided into a collection box, and compression and collection of the waste velvet are completed; driving power can be provided for the extrusion mechanism through the driving mechanism; andmeanwhile, a vortex blower and an air outlet pipe are matched with each other, so that the falling efficiency of the waste velvet can be improved.

Owner:亳州新诚达时装有限公司

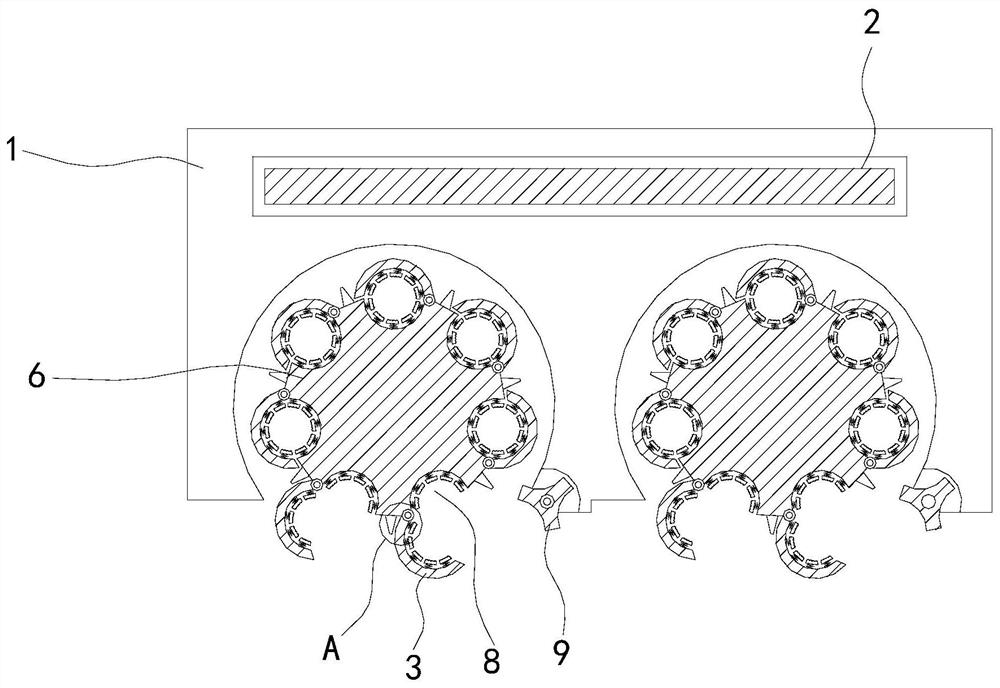

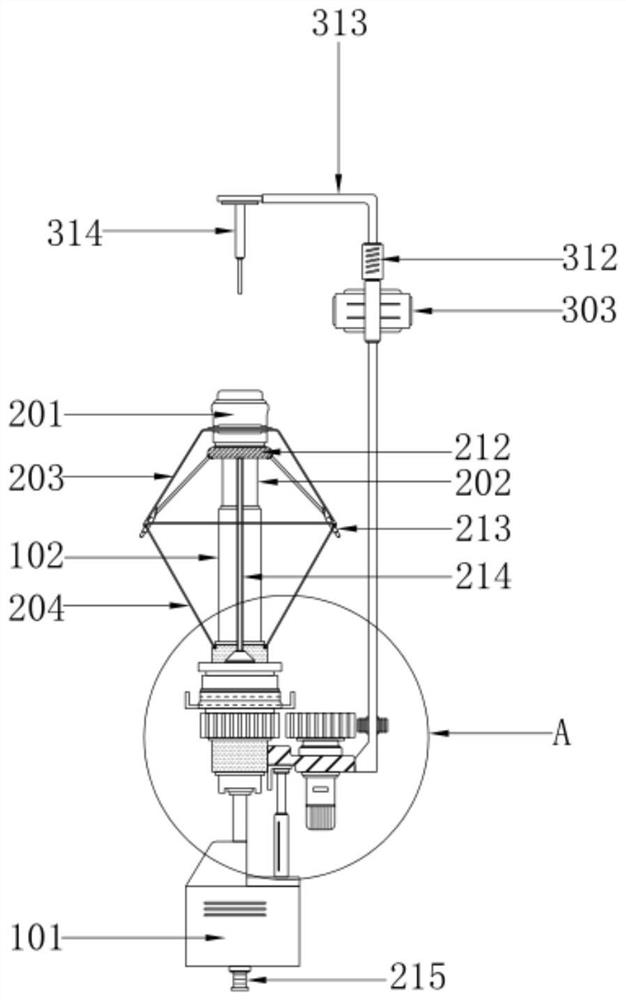

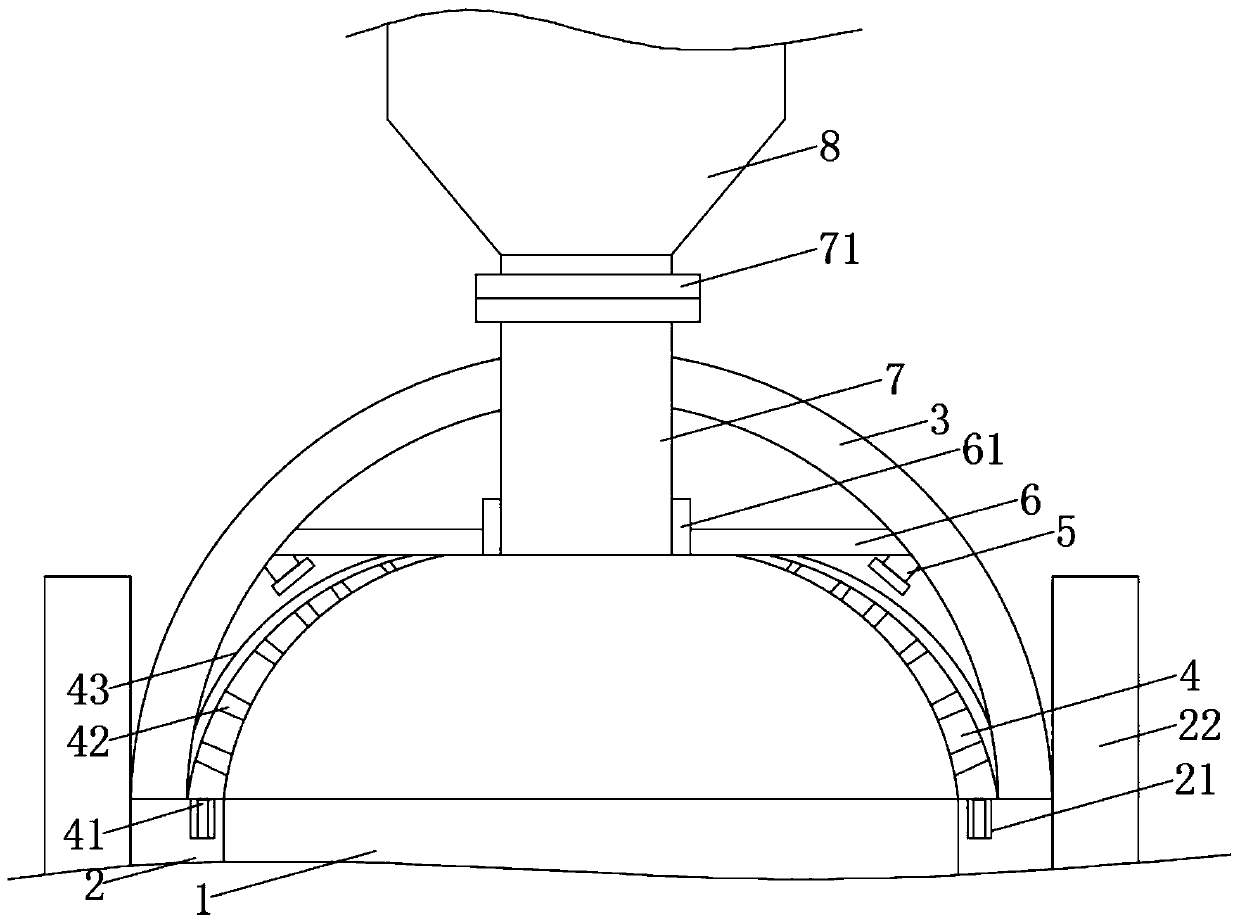

Building gravel screening device

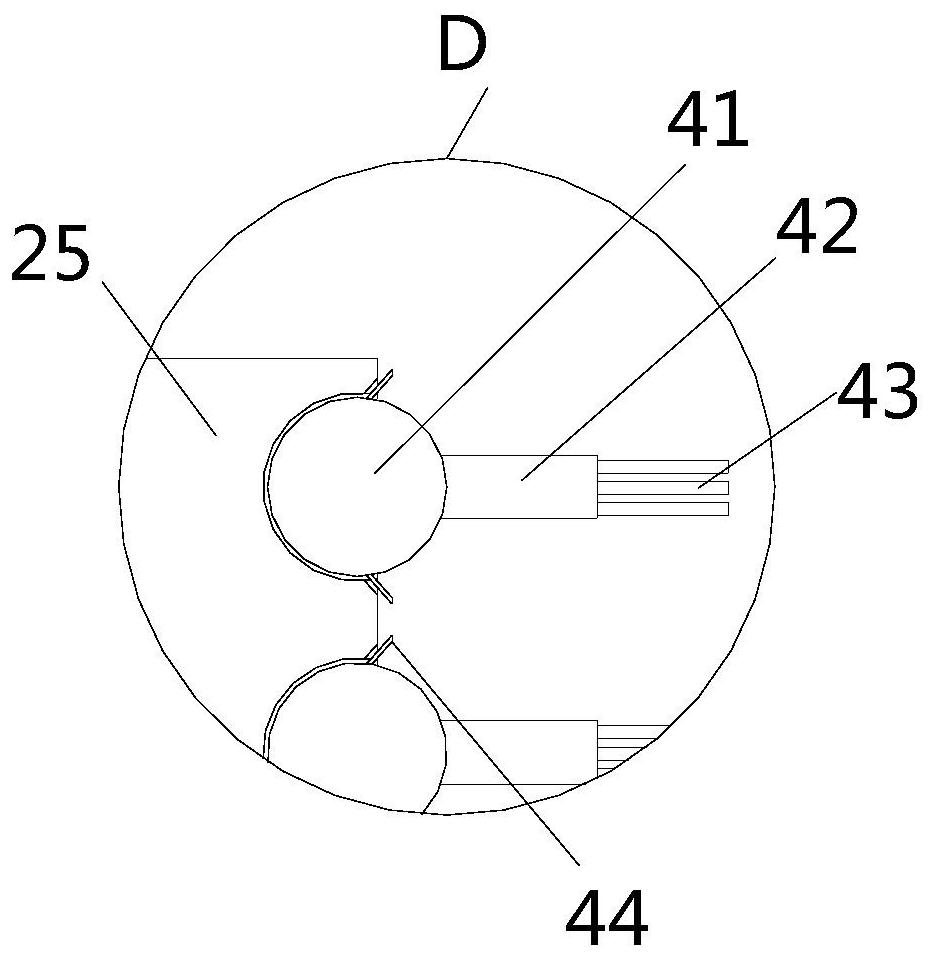

PendingCN113318961AImprove drop efficiencyIncrease productionSievingScreeningGeotechnical engineeringStructural engineering

The invention relates to the field of buildings, and particularly discloses a building gravel screening device which comprises a shell, supporting legs, a filling opening and a discharging cavity, wherein a horizontal rotary screening cavity of a cylindrical structure is formed in the shell, a rotary net cylinder rotating around a center shaft is coaxially mounted in the rotary screening cavity, a fixed net plate is arranged in the rotary net cylinder, the height of the rotary net cylinder is changed to adapt to gravel in the rotary net cylinder, and the gravel clamped on screening holes of the rotary net cylinder moves to the lower side of the fixed net plate to make contact with the fixed net plate. Through the fixed net plate arranged inside, sand in the rotary net cylinder can be stirred, so that the falling efficiency of sand grains is improved; the fixed net plate can be in contact with the sand clamped on screening holes of the rotary net cylinder; the sand is ground and cut under the condition of relative movement of the fixed net plate and the rotary net cylinder, so that tangential force is applied to the sand clamped in the fixed net plate, and the sand is separated from the screening holes; and meanwhile, the reciprocating relative movement plays a role in grinding and cutting the gravels clamped in the device, so that the yield of fine sand is increased.

Owner:吴雷

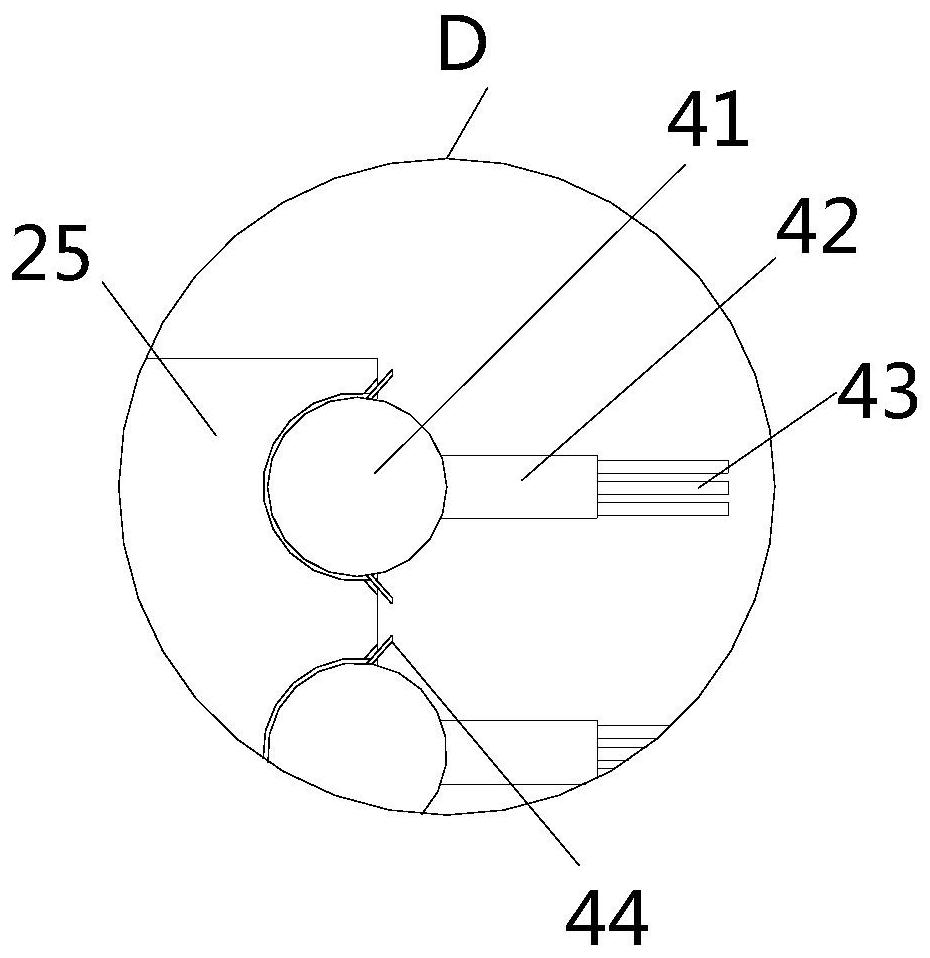

Water-cooling fire grate type biomass gasification furnace

ActiveCN113528193AReduced gravitational potential energyLower initial temperatureHollow bar grateGasification processes detailsWater vaporEnvironmental engineering

The invention relates to the technical field of biomass gasification, and discloses a water-cooling fire grate type biomass gasifier which comprises an ash passing channel, a water tank is fixedly installed at the bottom of the ash passing channel, an ash discharging hopper is fixedly installed at the upper end of the ash passing channel, and an energy reducing device is arranged on the inner side wall of the ash passing channel. A turntable is fixedly mounted in the middle of the energy reducing device. The energy reducing device is arranged in the ash passing channel, gravitational potential energy of ash is used as power for rotation of the fan blades to reduce the gravitational potential energy of the ash, meanwhile, the contact area of the fan blades and the ash is increased through the fan blades and the through holes of the fan blades, and heat of the ash passes through the eccentric rod and the heat conduction ring, the heat is used for the expansion effect of gas in the gas containing cavity to reduce the initial temperature of ash, the water impact phenomenon is reduced by reducing the potential energy and temperature of downward impact of the ash, the temperature of water vapor is reduced, and the impact phenomenon in the water tank is reduced.

Owner:赣州市怡辰宏焰能源科技有限公司

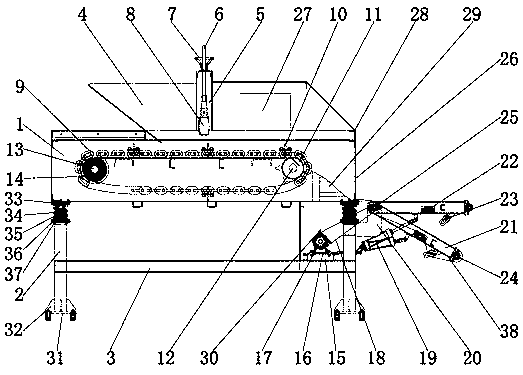

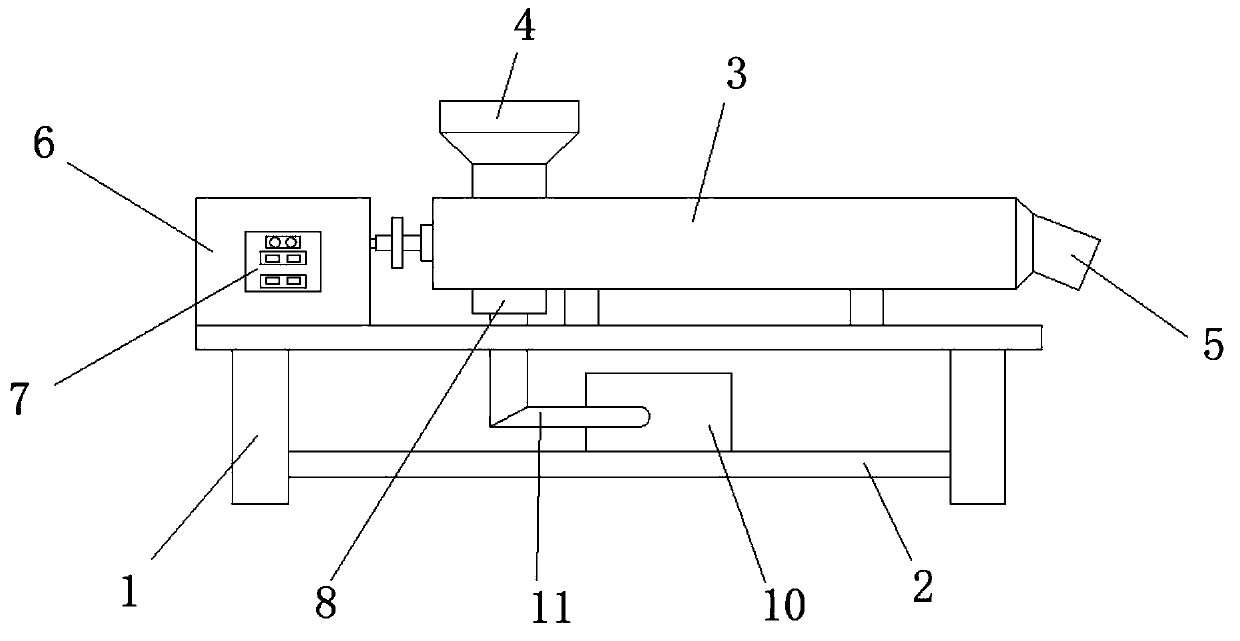

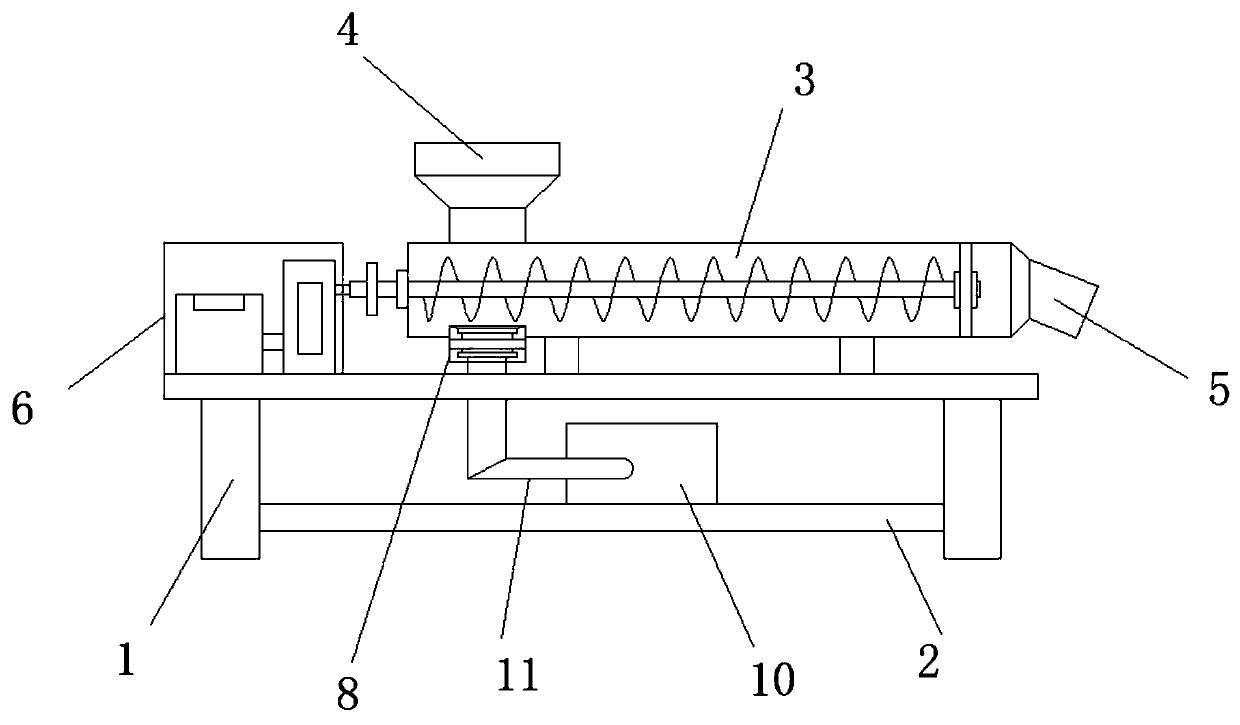

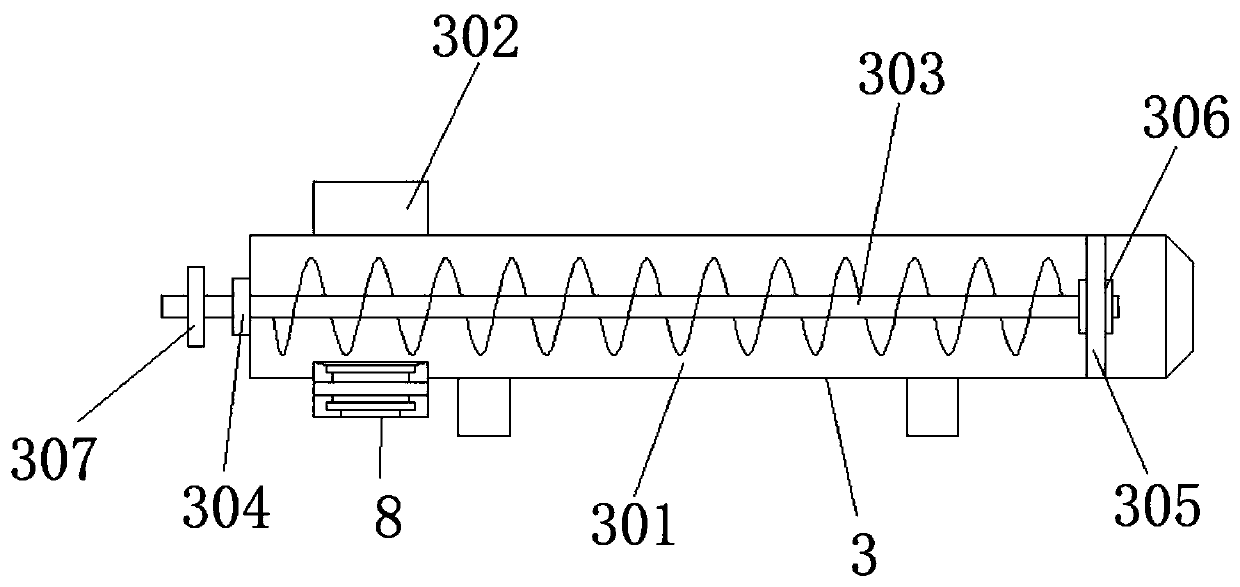

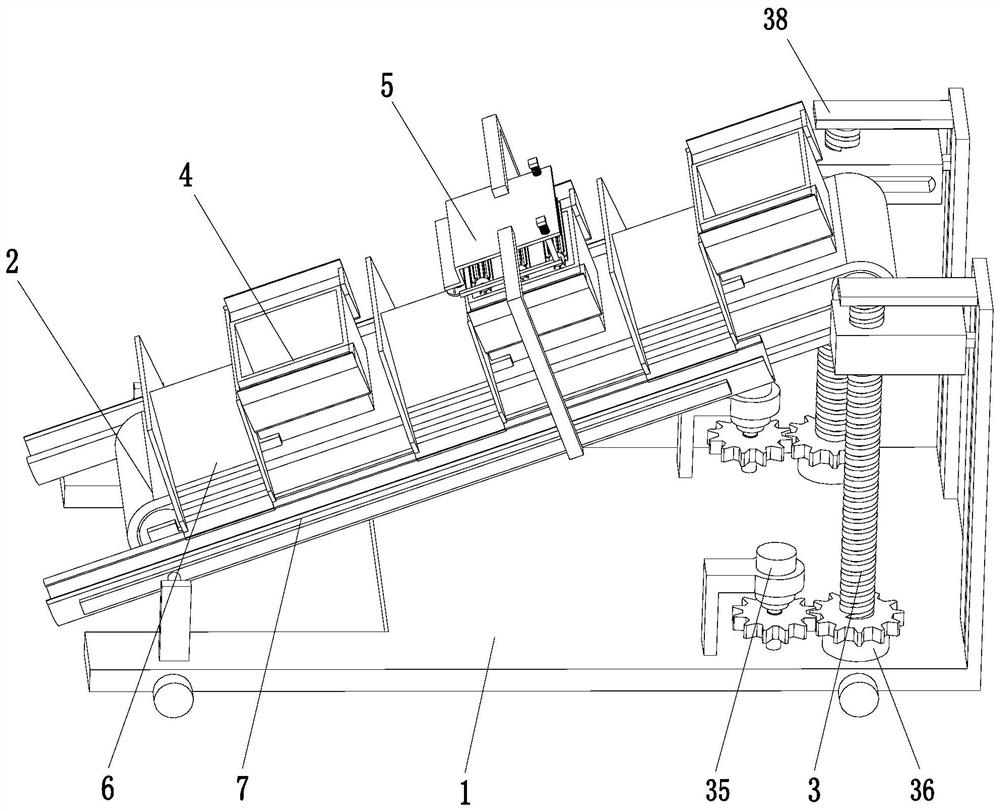

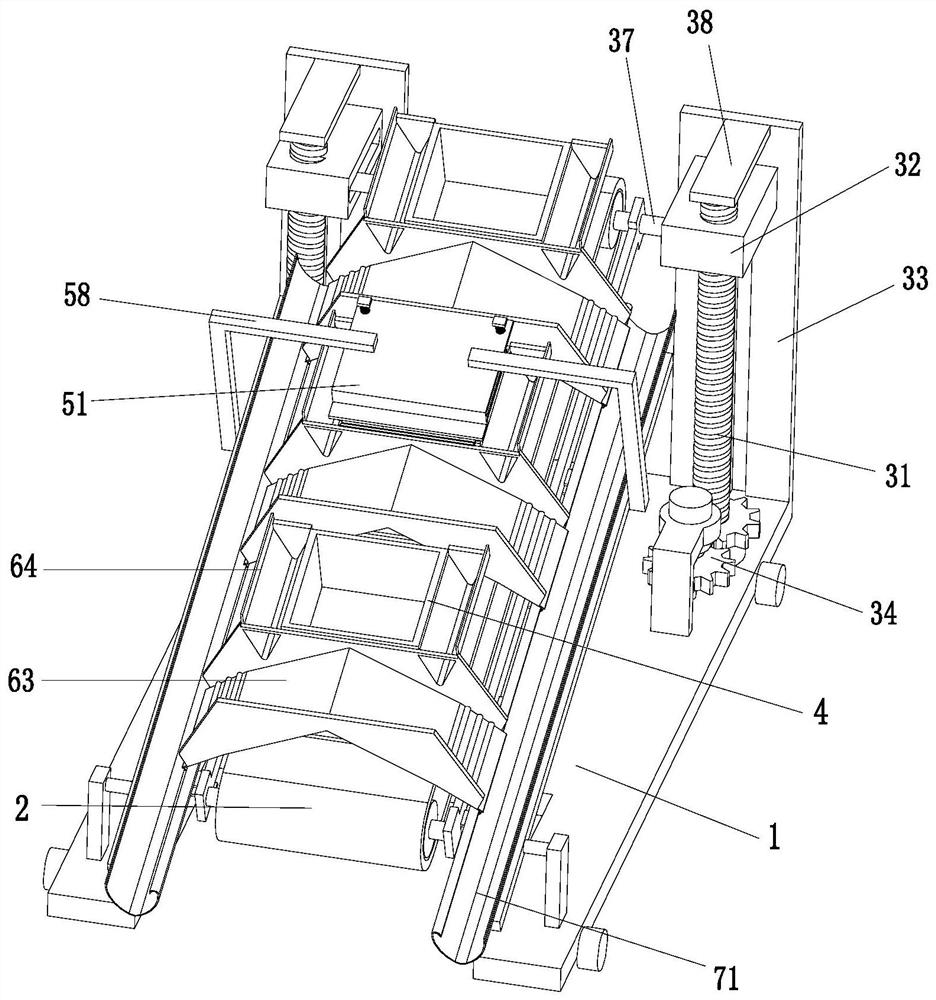

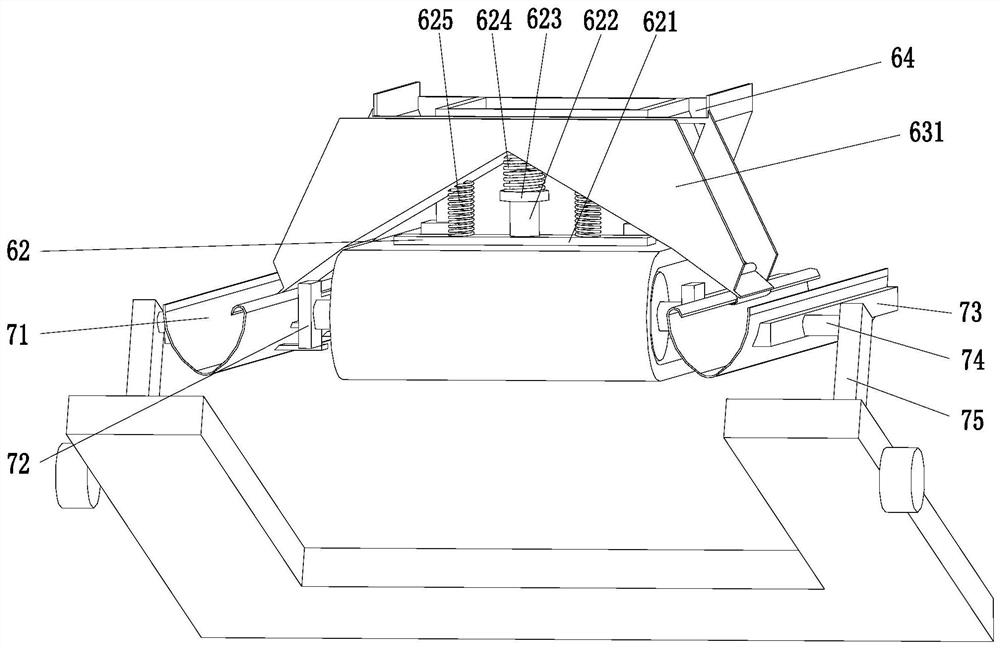

Quantitative conveying machine and conveying method for grain processing

ActiveCN110980134BReduce workloadReduce the scraping processConveyorsConveyor partsAgricultural engineeringGrain storage

The invention relates to a grain processing and quantitative conveying machine and a conveying method. The grain processing and quantitative conveying machine comprises a bottom plate, a conveyor belt, lifting mechanisms, material frames, a scraping mechanism, collecting devices and blanking mechanisms, wherein wheels are uniformly installed on the front side face and the rear side face of the bottom plate, the conveyor belt is aslant arranged above the bottom plate, the lifting mechanisms are symmetrically arranged at the front side and the rear side of the right end of the conveyor belt, thecollecting devices are uniformly installed on the upper end face of the conveyor belt, the blanking mechanisms are symmetrically arranged at the front side and the rear side of the conveyor belt andinstalled on the side face of the conveyor belt, the scraping mechanism is located at the upper side of the middle of the conveyor belt, the left end of the conveyor belt is installed on the bottom plate, the right end of the conveyor belt is connected with the lifting mechanisms, and the right side of each collecting device is provided with the corresponding material frame. By means of the grainprocessing and quantitative conveying machine, the problems that before grains are conveyed, a large amount of labor is needed to scrape grain piles in grain storage frames, the labor intensity is large, the grains scraped off from the grain piles need to be manually gathered together, and the workload is large can be solved.

Owner:桂林一帜米制品有限公司

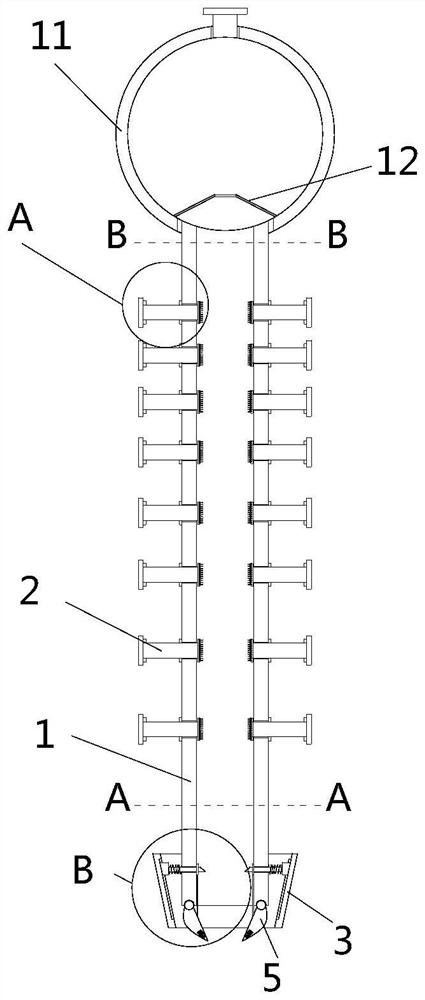

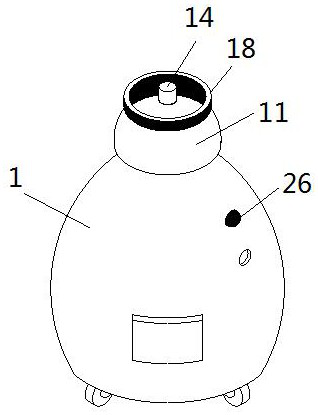

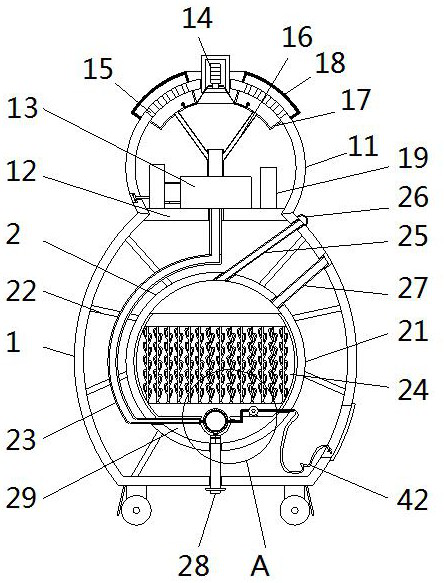

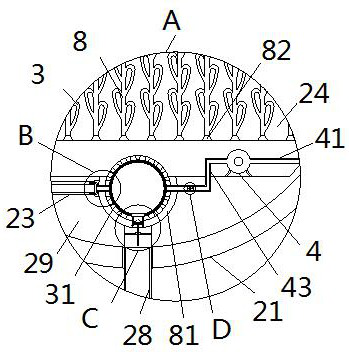

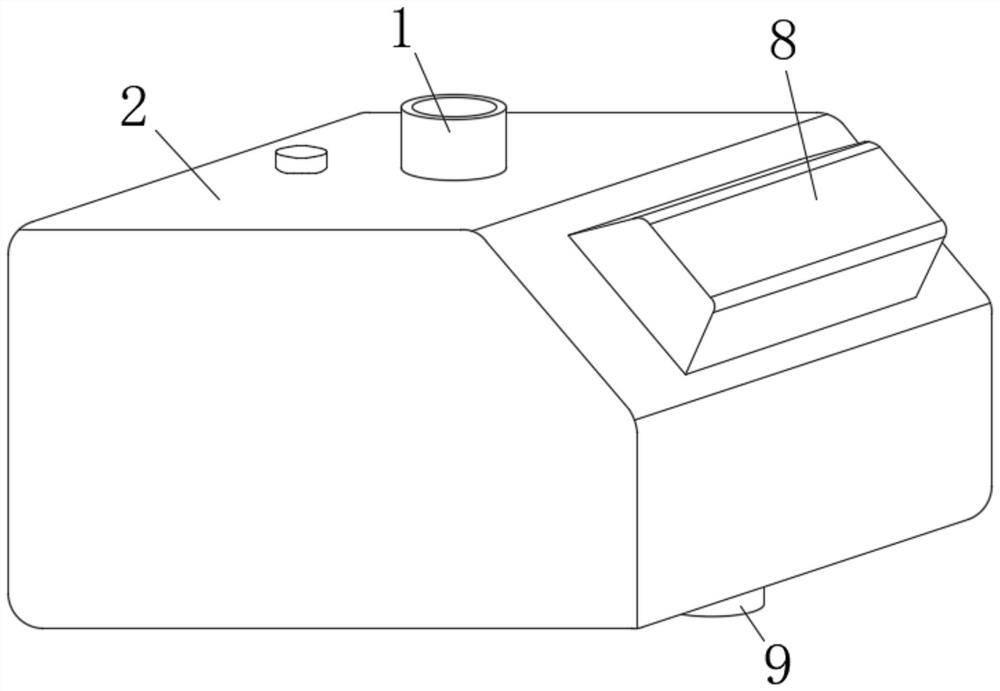

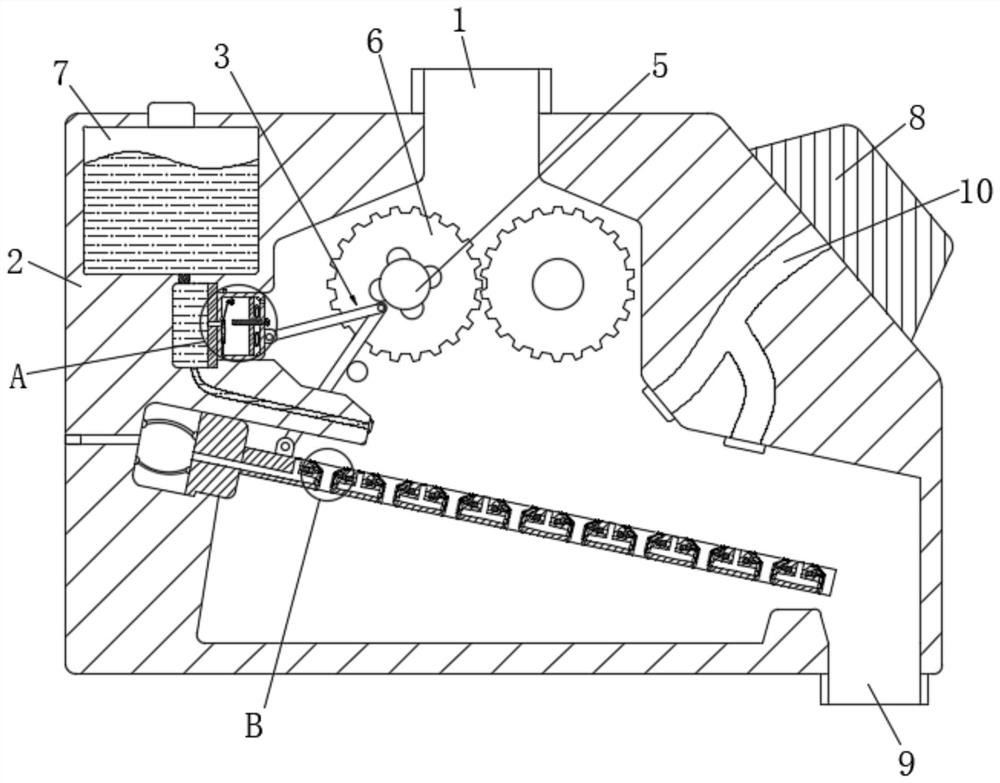

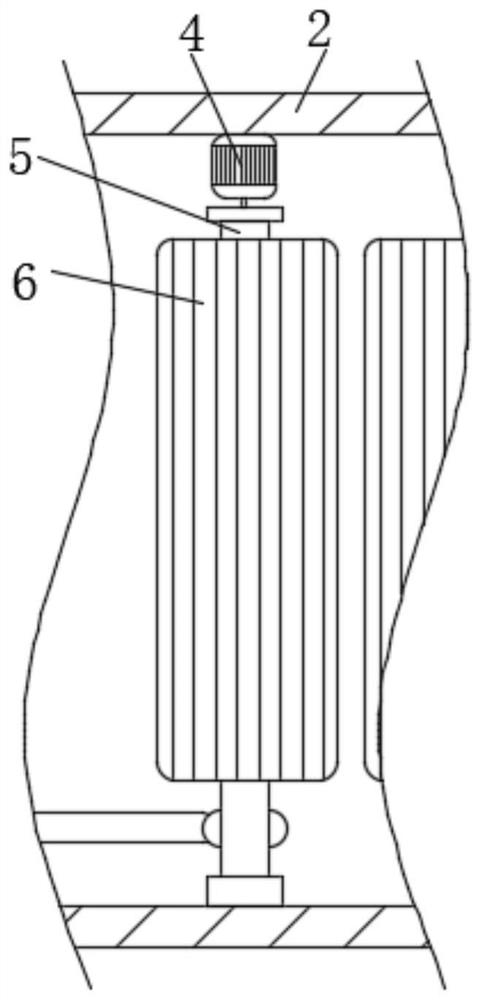

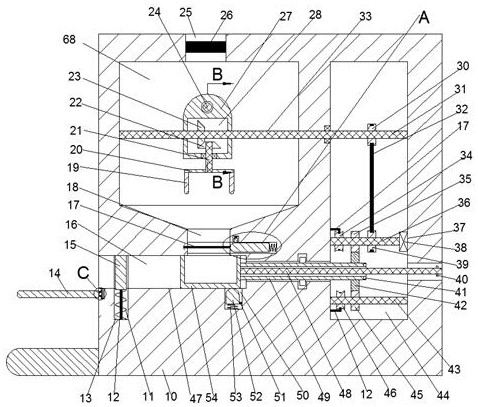

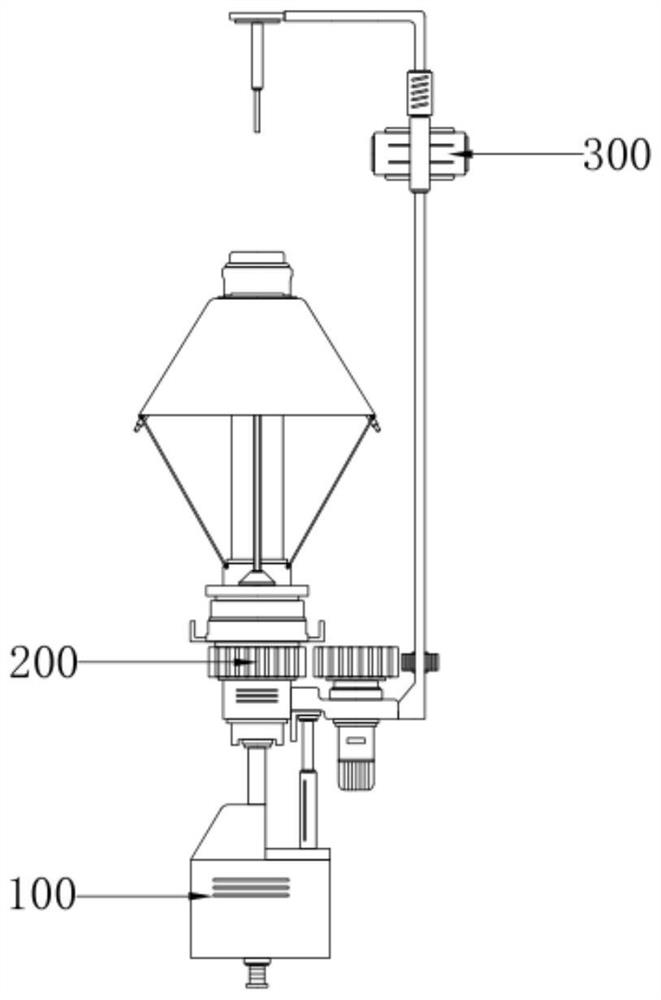

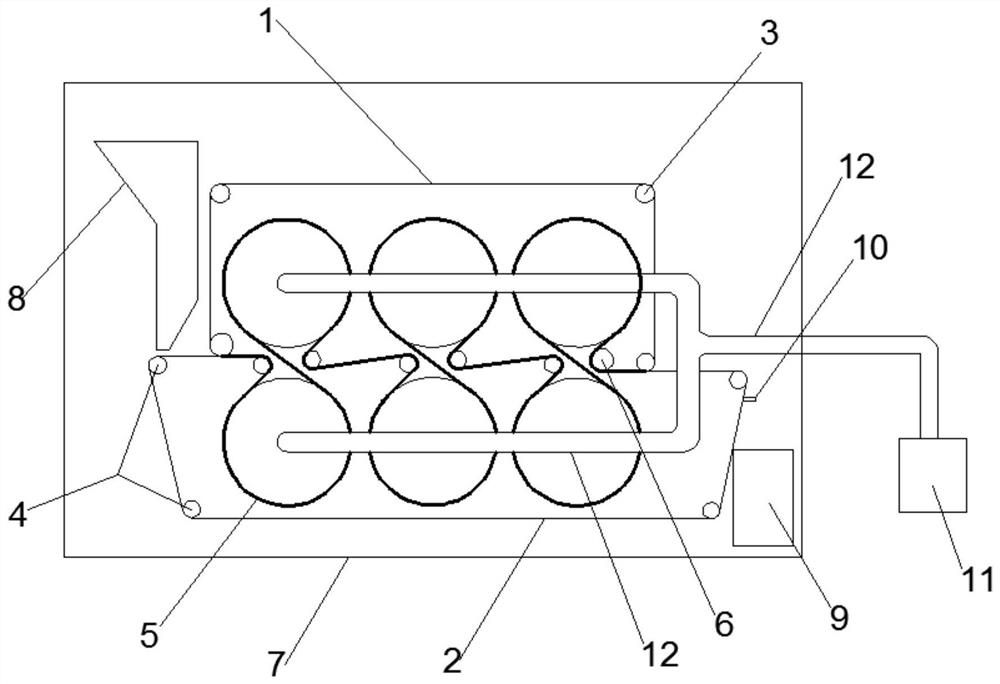

A convenient container for household milk powder for infants and young children

ActiveCN110683174BGuaranteed hygienic performanceImprove drop efficiencyPowdered material dispensingInternal fittingsProcess engineeringMechanical engineering

The invention discloses a convenient household infant milk powder taking tank which comprises a tank body. The tank body comprises a transmission cavity arranged at the right end in the tank body, a storage cavity is arranged on the left side of the transmission cavity, a transmission mechanism for providing power for a device is arranged in the transmission cavity, a stirring mechanism for stirring milk powder to enable the milk powder to fall smoothly is arranged in the storage cavity, and a taking mechanism for sending the milk powder out of the device is arranged at the left end in the tank body. According to the convenient household infant milk powder taking tank, the manual mode can be replaced for automatically and quantitatively taking the milk powder from the bottom, the sanitation of taking the milk powder is ensured, the difficulty of manually taking the milk powder from the milk powder tank is reduced, the stirring mechanism is further arranged in the milk powder tank, thefalling efficiency of the milk powder is improved, and the taking convenience of the milk powder is improved.

Owner:江苏卓燃高新科技有限公司

Treatment device used for removing water through inversion of inner wall and used for beverage bottle

The invention discloses a treatment device used for removing water through inversion of the inner wall and used for a beverage bottle, and relates to the technical field of bottle recovering. The treatment device comprises a bearing assembly, a guiding-in assembly and a knocking assembly; a fixing column is inserted into the top of a base table; a mounting block is arranged at the top end of a pull rod, and supporting rods are circumferentially hinged to the side wall of the mounting block at equal intervals; the knocking assembly is arranged on the right side of the guiding-in assembly. According to the treatment device, the guiding-in assembly extends into an inner cavity of the beverage bottle, a supporting rod and the support rods are matched, and high-pressure airflow is guided into a water blowing nozzle through a ventilation disc, so that water drops attached to the inner wall of a beverage pipe slide along the inner wall from top to bottom; meanwhile, a rotating gear drives a movable sleeve to rotate, the support rod structure is driven to rotate, under the action of the elastic reset structure, a hammering part intermittently impacts the outside of the beverage bottle, meanwhile, an ejector rod is driven to downwards impact the top of the beverage bottle, a gathering effect is achieved on the water drops attached to the interior of the beverage bottle, the water drops can be conveniently and rapidly blown out through cooperation with the guiding-in assembly, and the water removal efficiency is further improved.

Owner:张松周

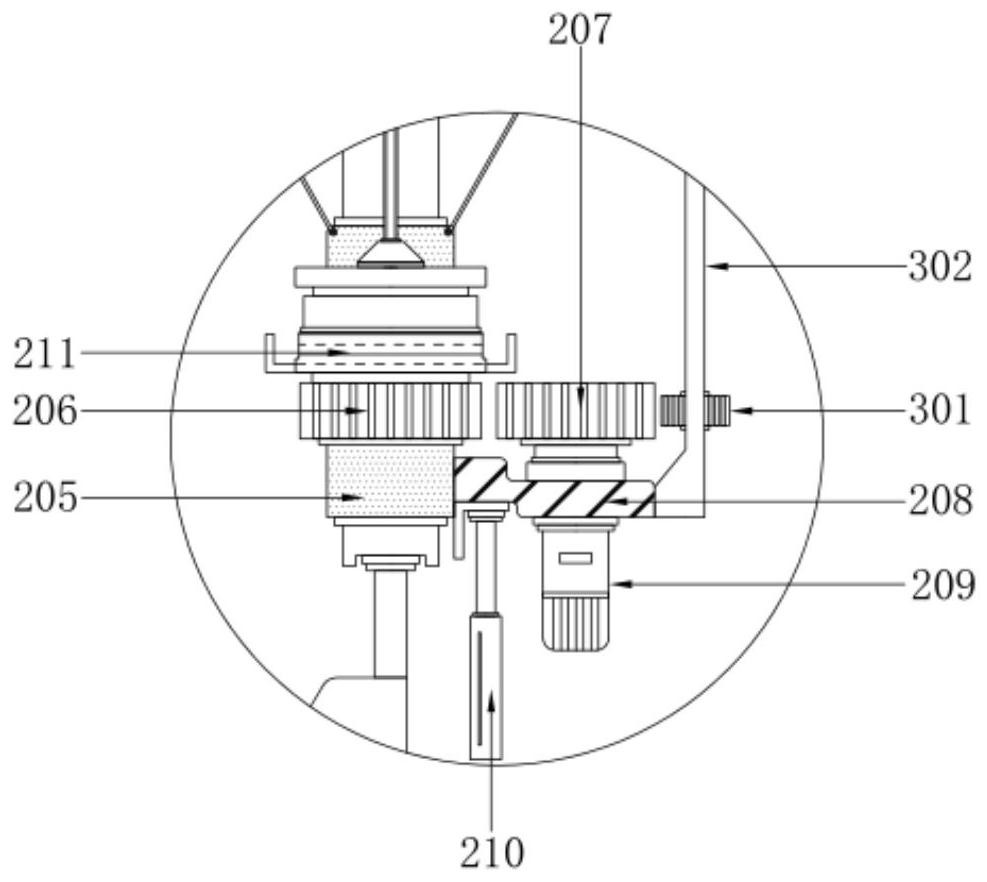

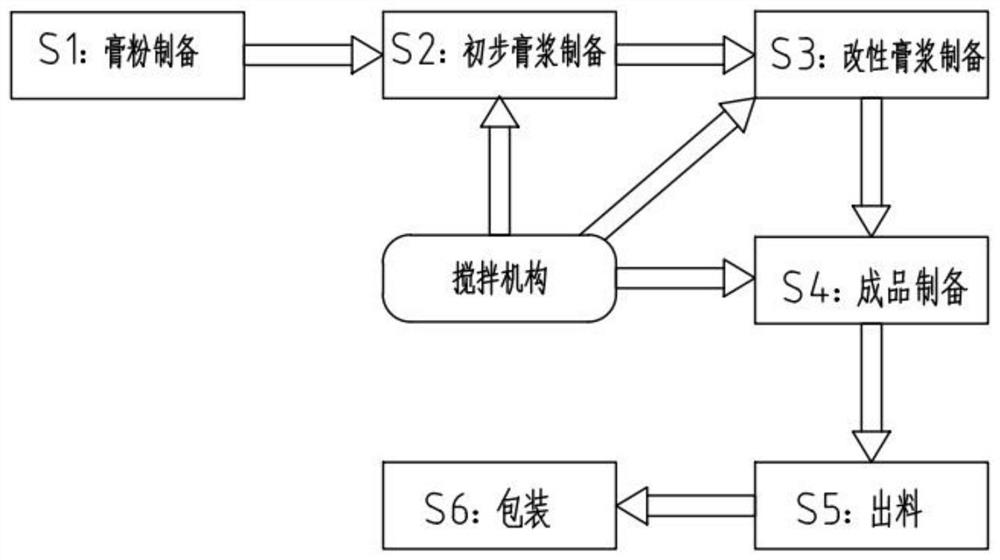

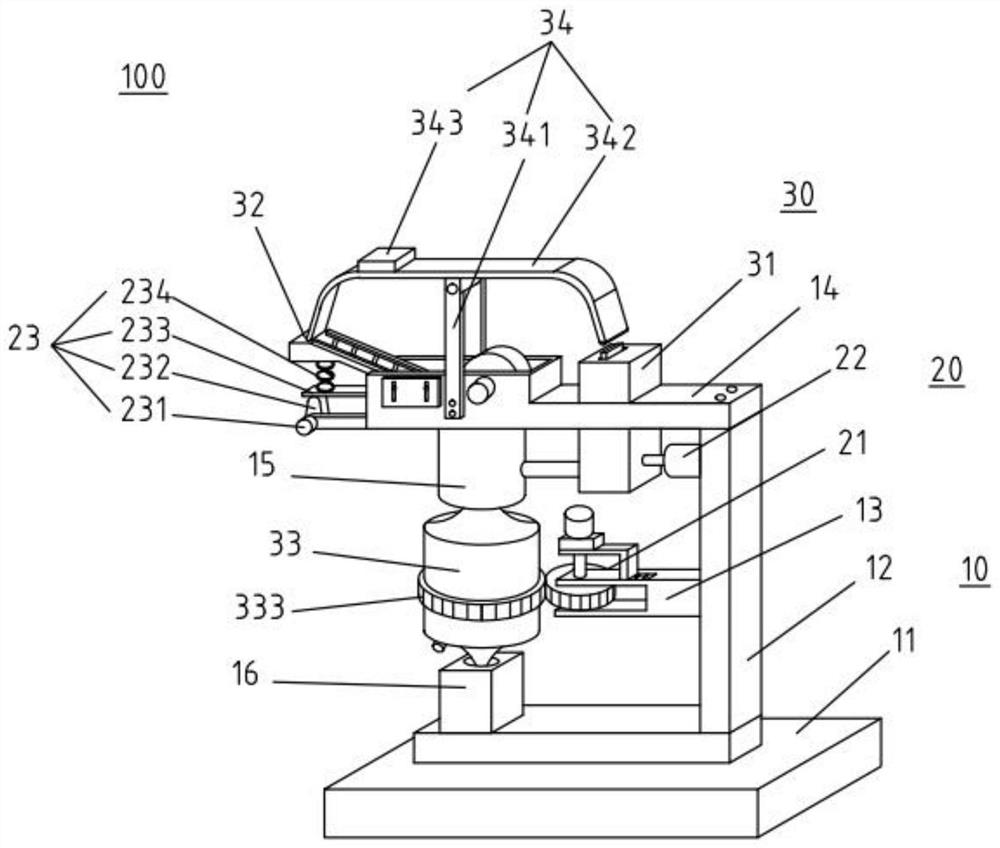

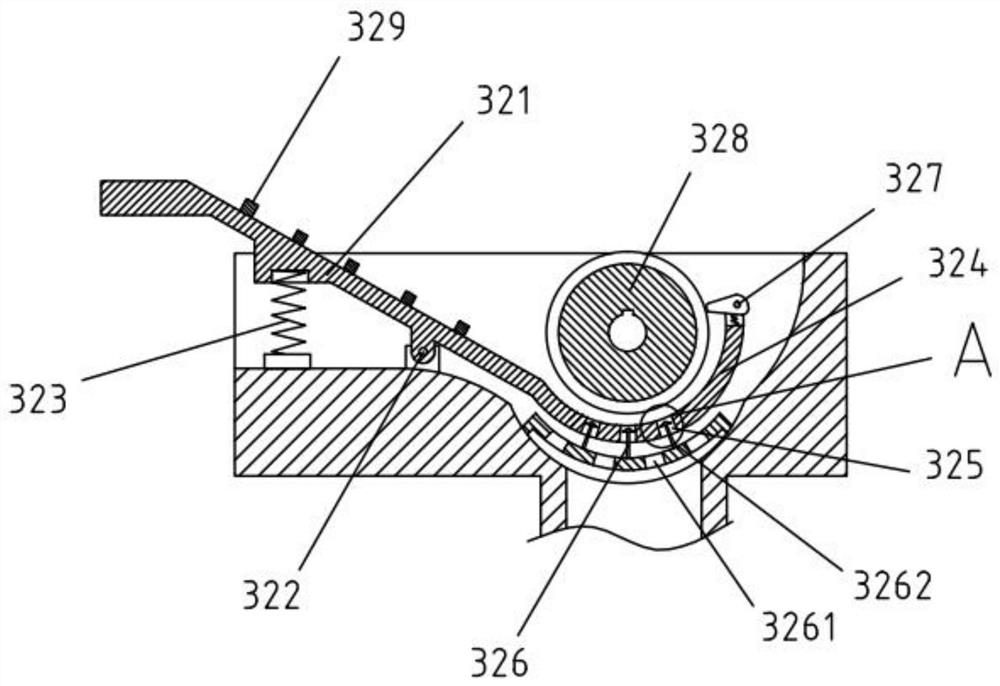

A kind of production technology of gypsum self-leveling material

ActiveCN111716536BAvoid problems that can easily cause cakingReasonable operationMixing operation control apparatusPretreatment controlPhosphogypsumSlurry

The invention discloses a production process of a gypsum self-leveling material. The specific production process steps are as follows: S1, preparation of paste powder: pulverizing the phosphogypsum, sieving, and dedusting to obtain initially refined phosphogypsum; S2, preparation of preliminary paste: Dilute the gypsum slurry, inject pure water, and use a stirring device to stir evenly to obtain the gypsum slurry in a diluted state; S3, preparation of modified plaster slurry: take the preliminary diluted gypsum slurry, graphene oxide, concentrated sulfuric acid, calcium salt solution, and Mix water ethanol and oleic acid, and use a stirring device to stir evenly, then repeatedly freeze and thaw, and finally perform drying treatment; S4, finished product preparation: sequentially take modified paste, water gypsum, cement, quartz sand and gypsum retarder Mix and stir evenly with a stirring device to obtain a gypsum self-leveling material; S5, discharging; S6, packaging.

Owner:浙江古思建筑科技有限公司

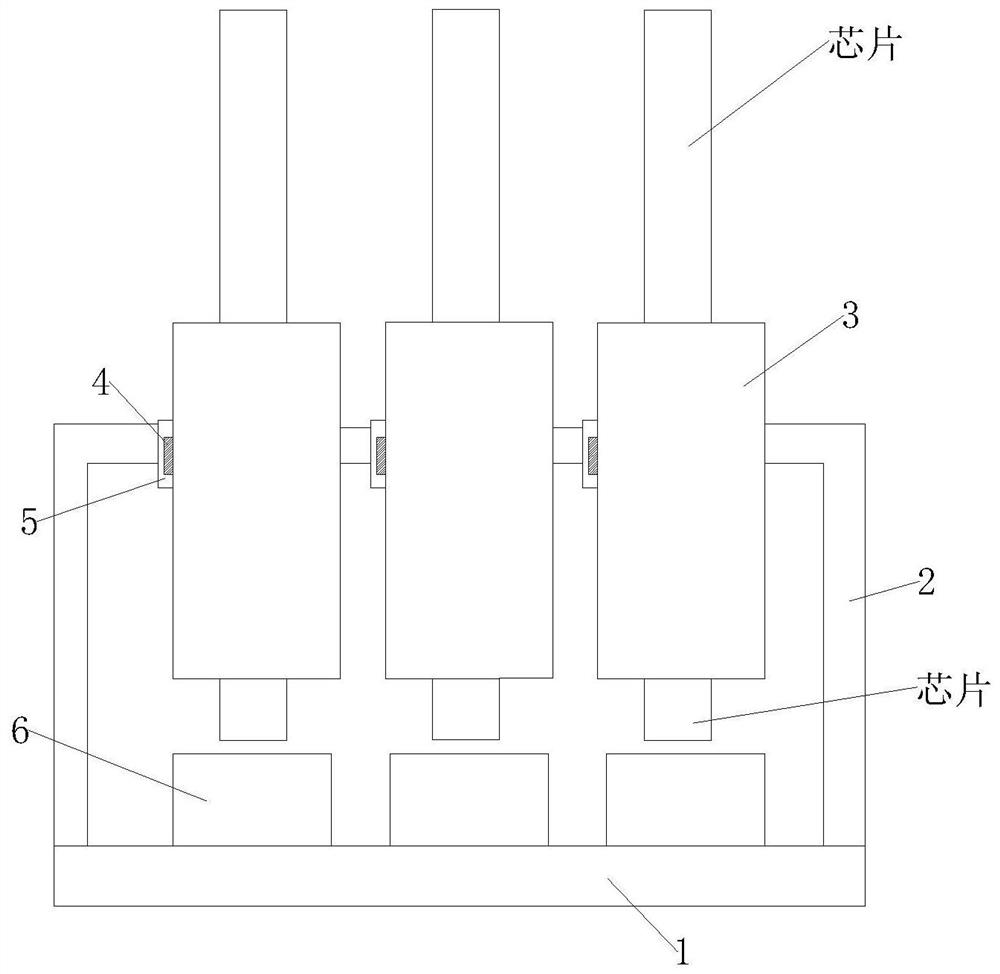

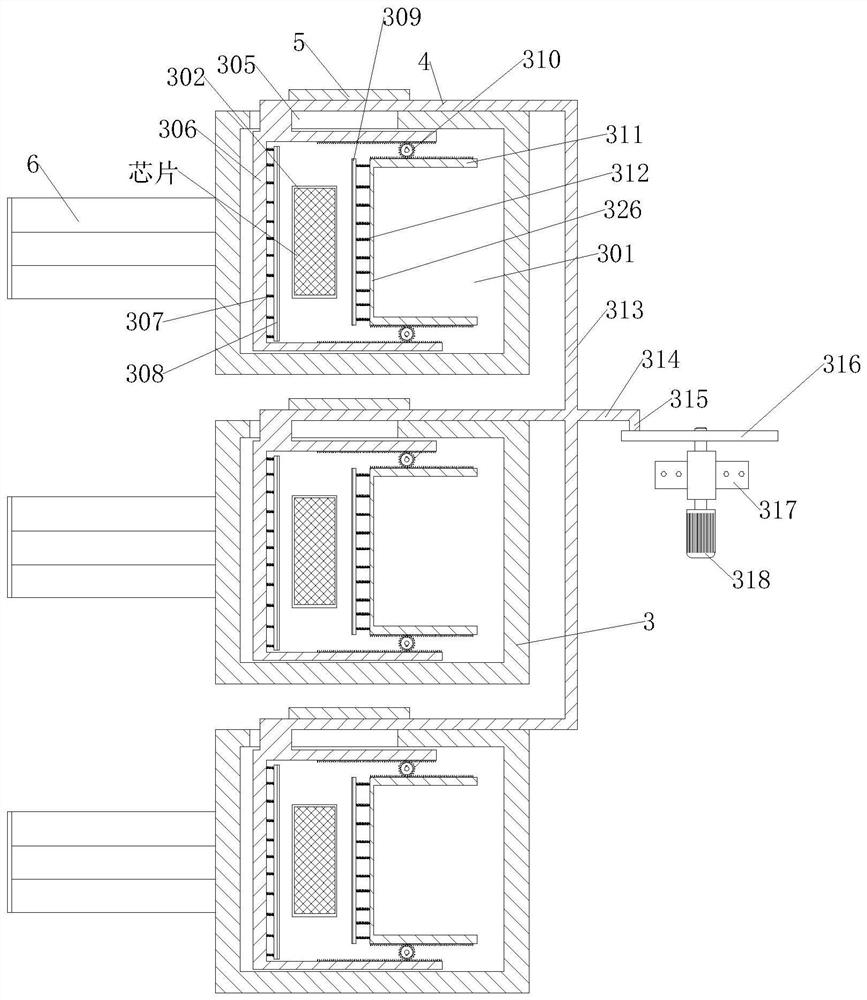

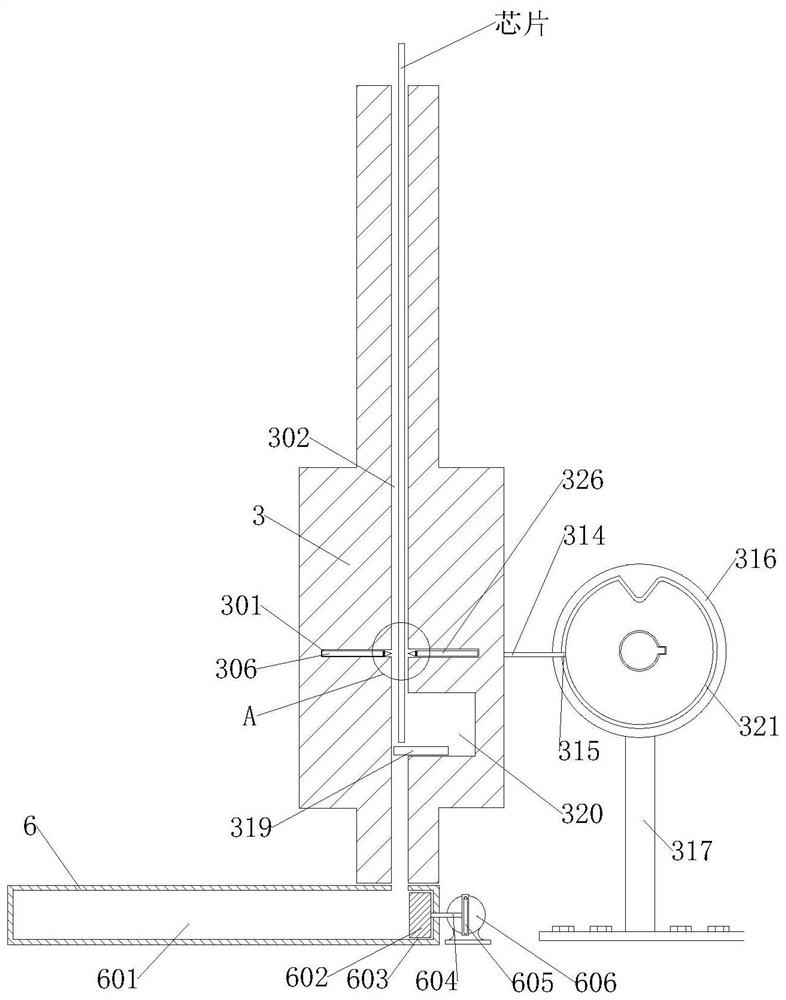

A continuous cutting and processing equipment for batch production of chips

ActiveCN112454440BNeatly collectedIncrease operating frequencyInsulating layers/substrates workingMetal working apparatusElectronic chipElectrical and Electronics engineering

The invention provides a continuous cutting and processing equipment for mass production of chips, which relates to the technical field of electronic chip production and processing, including a base, the base is a square plate structure placed horizontally, and support frames are symmetrically arranged on the left and right sides of the top of the base , the middle part of the top of the base is fixedly installed with a plurality of cutting boxes upright on the top of the base, each of the cutting boxes is fixedly installed on the top of the support frame, and the top of the base is equidistantly arranged with the same number of sorting boxes as the number of cutting boxes , each of the sorting boxes is horizontally installed on the bottom of the corresponding cutting box; the bottom supporting block of the present invention is stretched at the bottom of the bottom supporting rod through a threaded screw rod, and the distance between the bottom supporting block and the first knife is adjusted. height, and then control the distance between the first knife and the second knife after gate cutting the chip, adjust the gate cutting length of the chip, and then improve the gate cutting efficiency of the chip.

Owner:广东天浩智能科技有限公司

A feeding device for bleaching powder production

ActiveCN107804652BEasy to observe the feeding situationReduce leakageConveyorsCleaningEngineeringConveyor belt

The invention discloses a material conveying device for bleaching powder production. The material conveying device for bleaching powder production comprises a conveyor belt. Baffle blocks are mountedat the left and right ends of the conveyor belt; a transparent hood is fixedly mounted at the upper end of each baffle block; arc-shaped baffle plates are fixedly mounted at the left and right ends ofthe bottom of an inner cavity of the transparent hood; a slide rail is fixedly mounted at the bottom end of each arc-shaped baffle plate; a transverse plate is fixedly mounted at the upper end of theinner cavity of the transparent hood; fans are fixedly mounted on the left and right sides of the bottom end of the transverse plate; a material conveying pipe is inserted into the middle of the upper end of the transparent hood; a connector is fixedly mounted on the top of the right end of the inner cavity of the transparent hood; a telescopic rod is fixedly mounted at the bottom end of the connector through a rotary shaft; a baffle plate is fixedly mounted at the bottom end of the telescopic rod; and a rubber scraper blade is fixedly mounted at the bottom end of the baffle plate. By arranging the arc-shaped baffle plates, the fans and the rubber scraper blade, effects of conveying materials uniformly, reducing the outleakage of dust and reducing material waste in the conveying process are achieved.

Owner:黄骅市凯丰化工有限公司

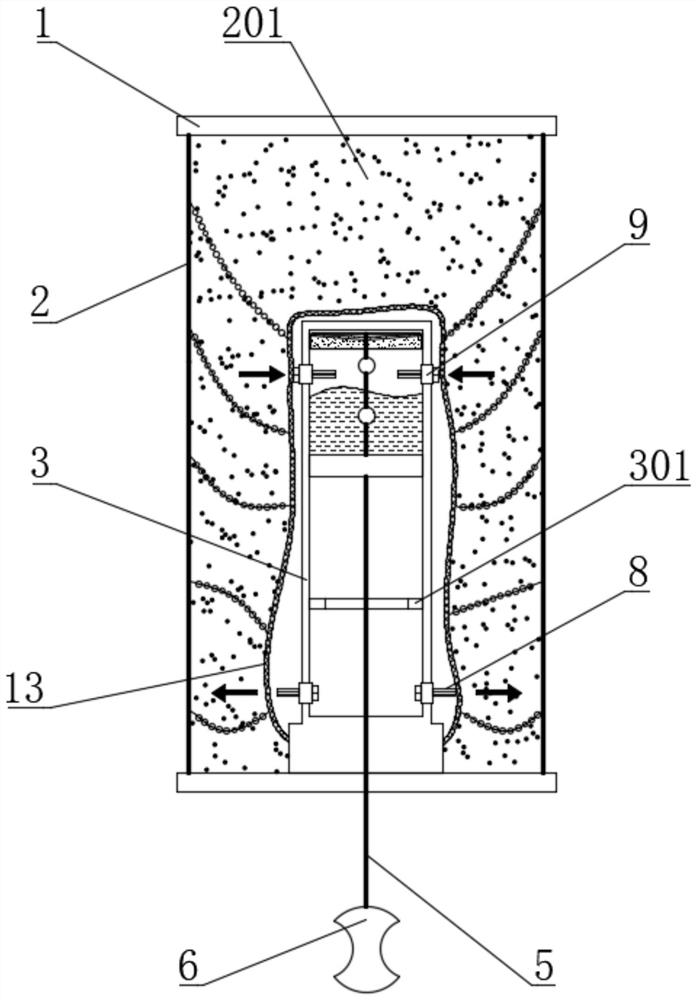

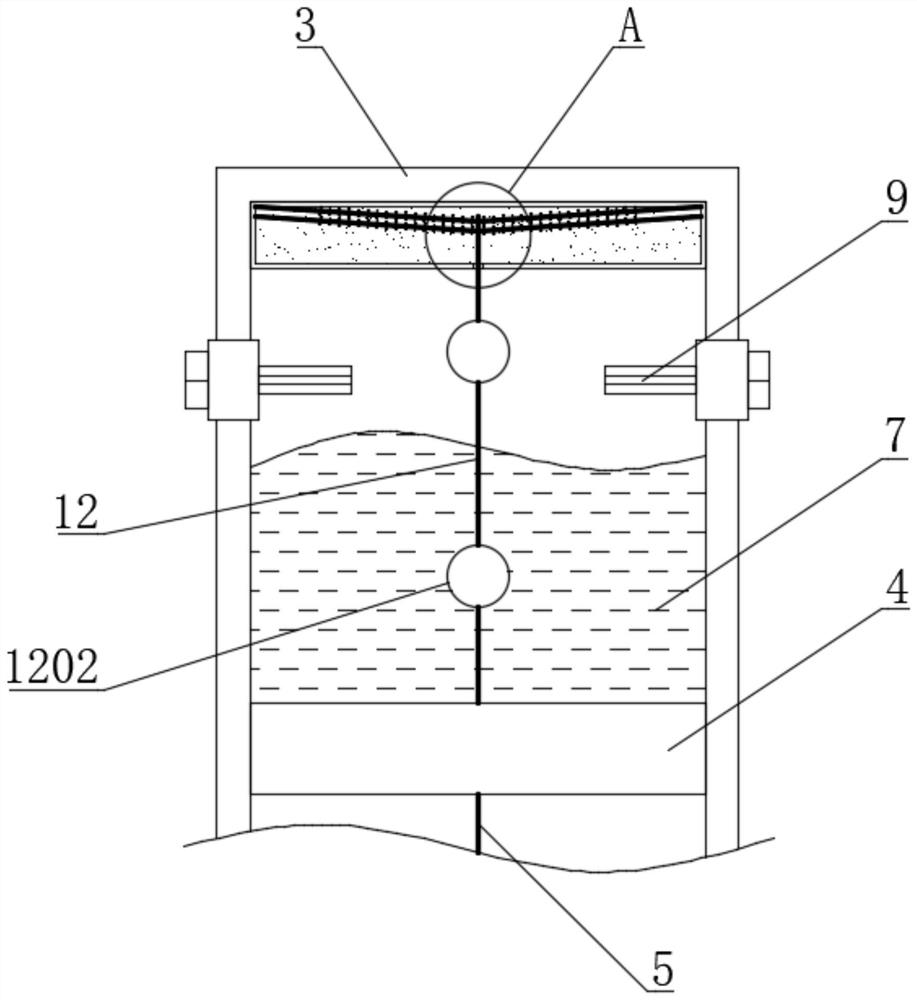

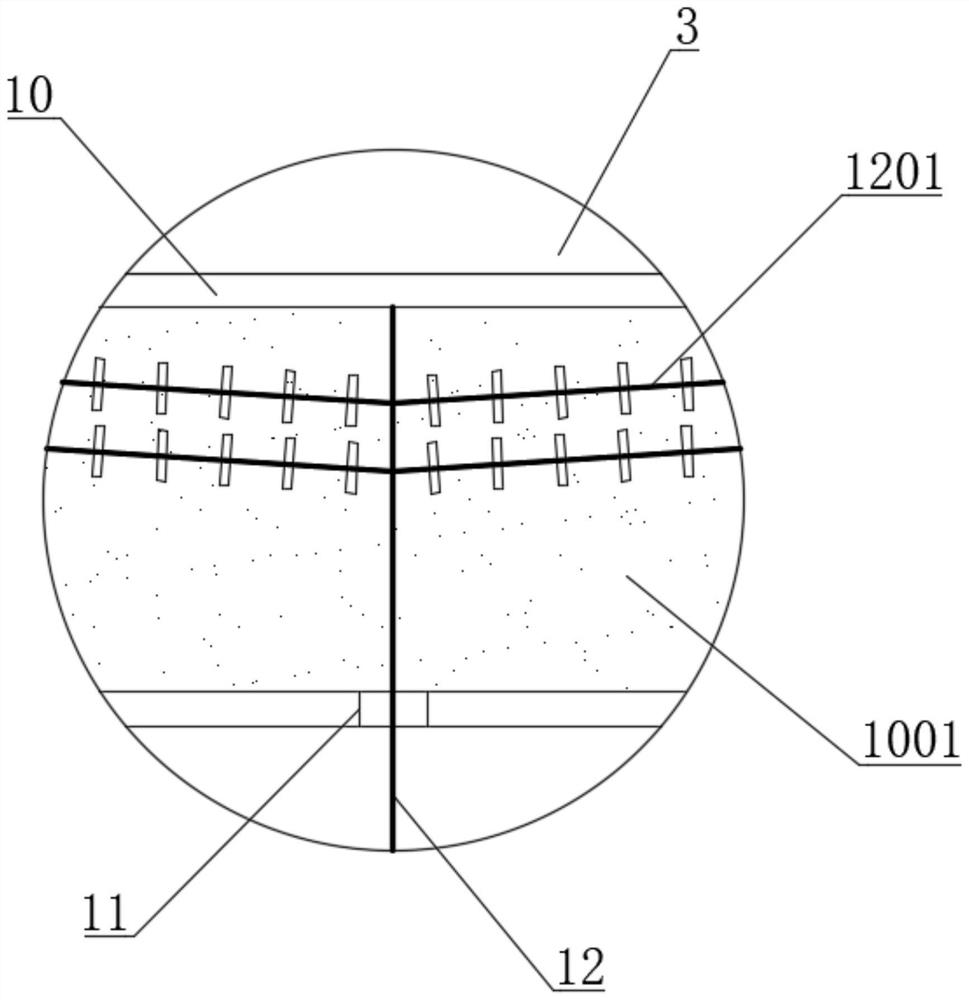

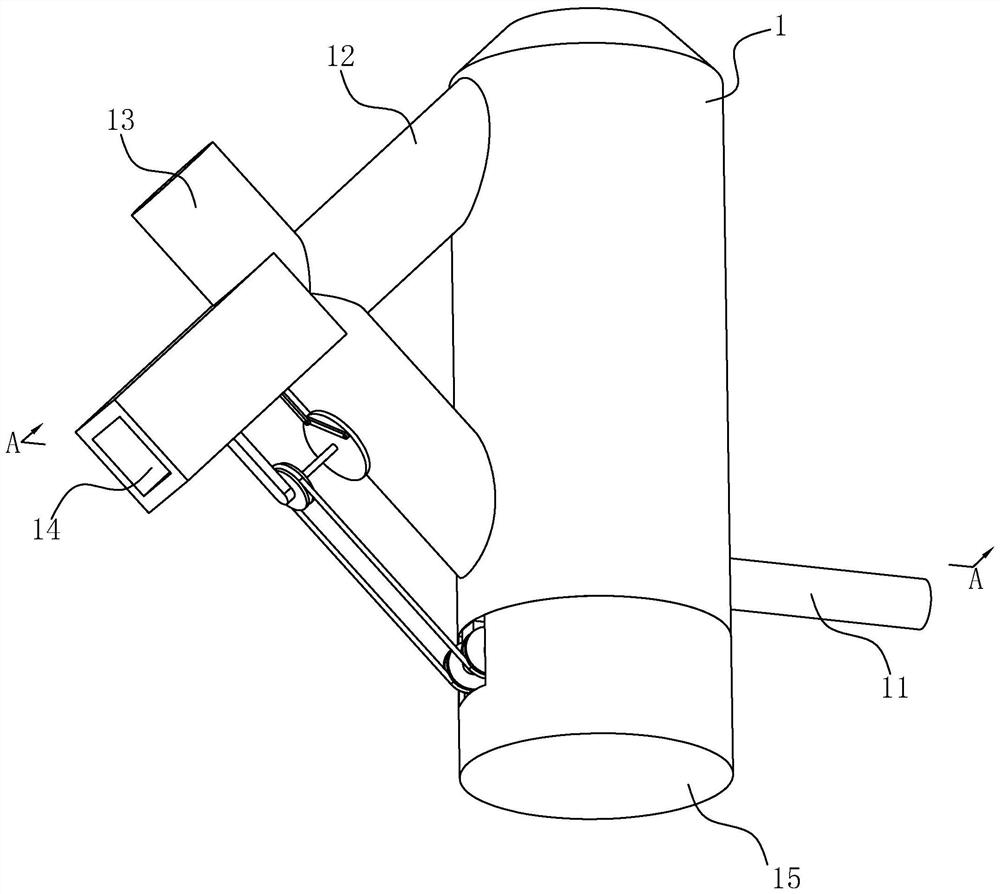

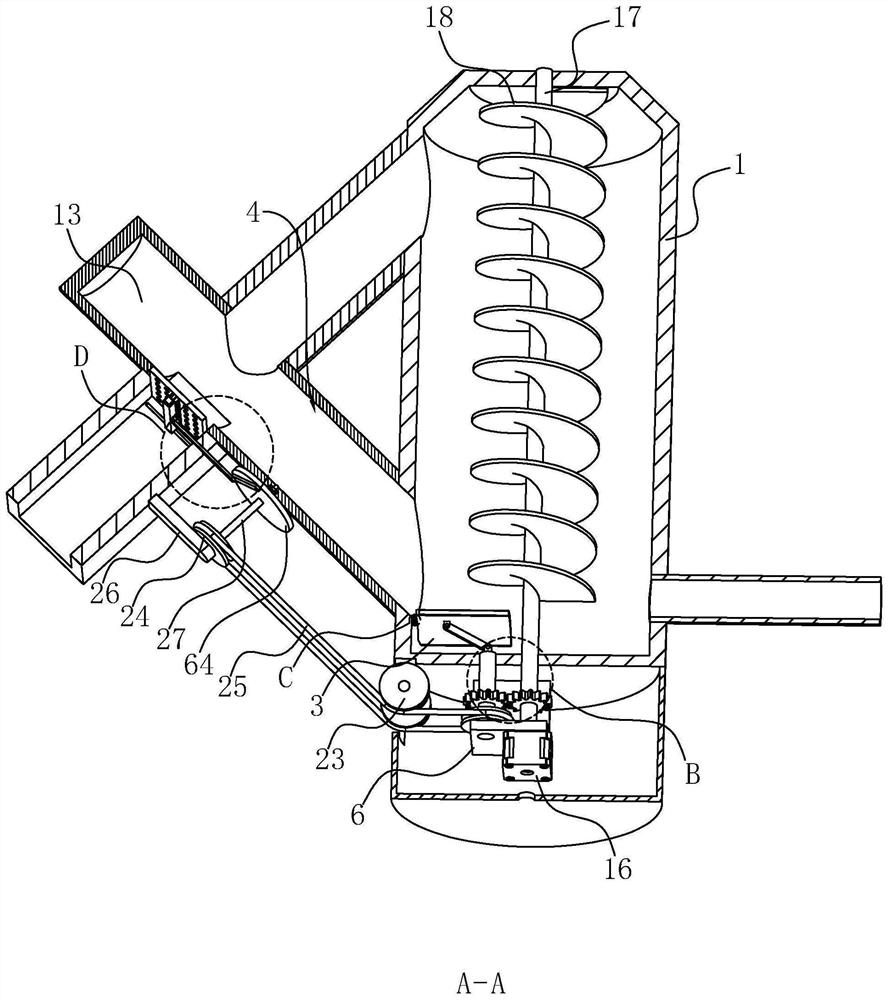

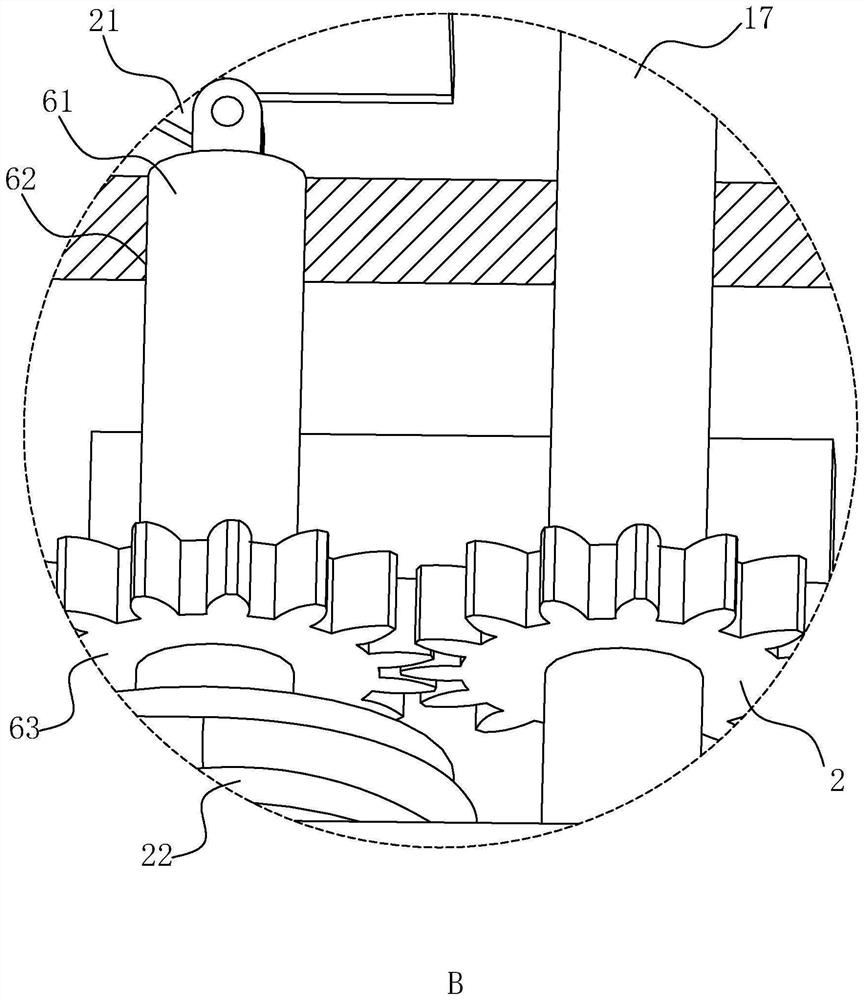

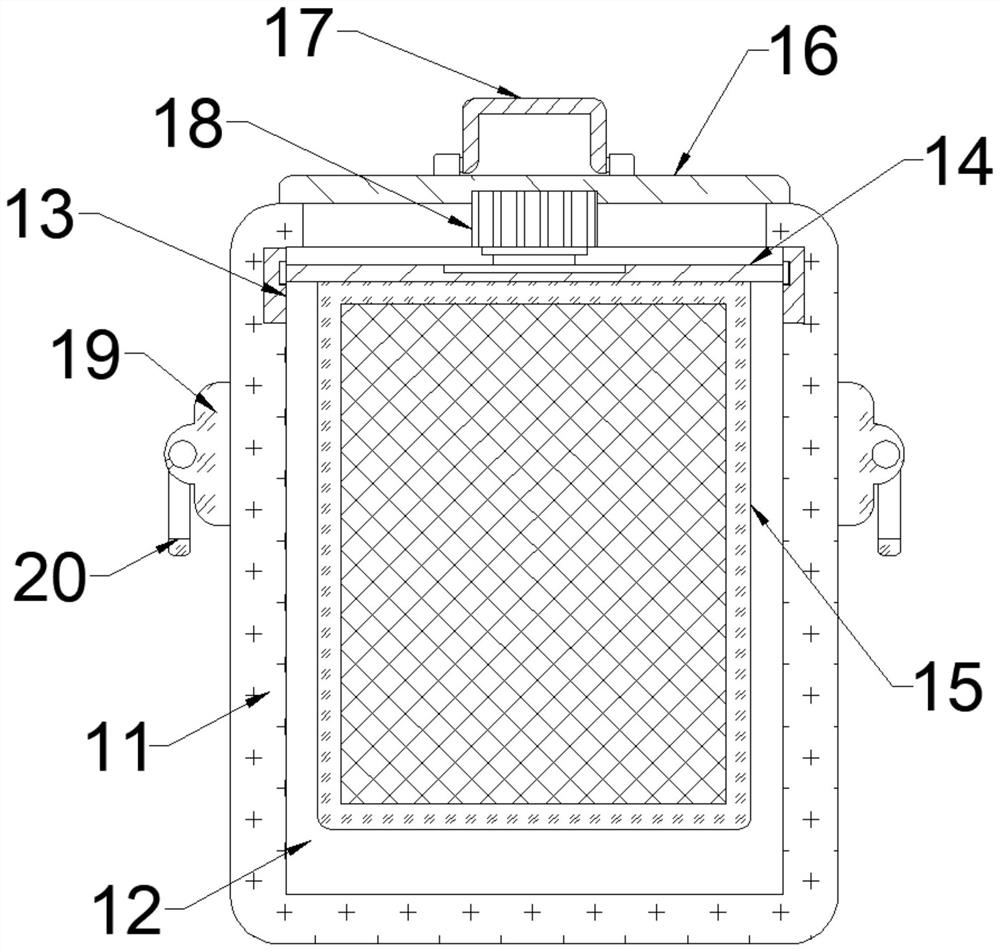

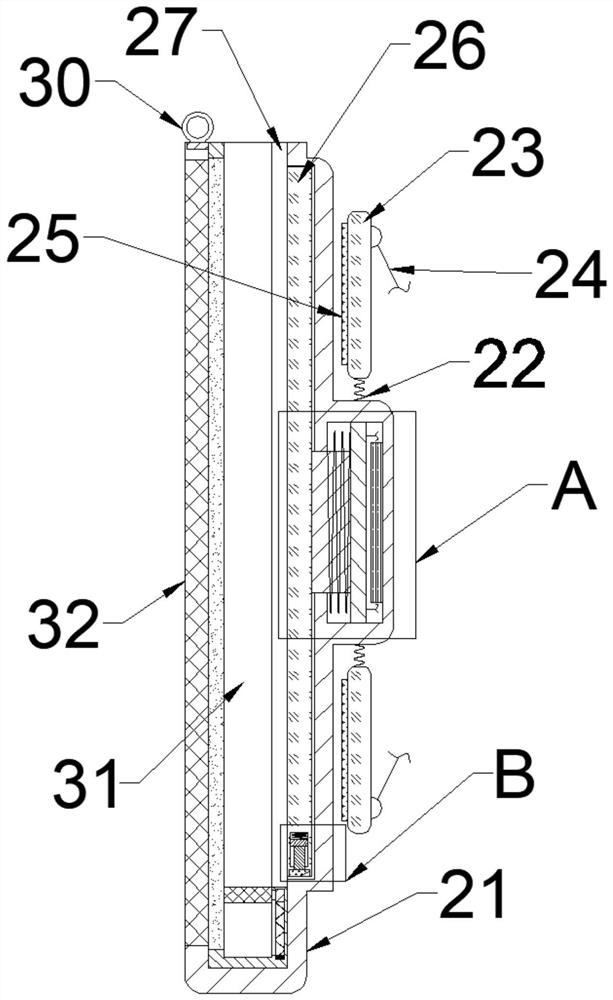

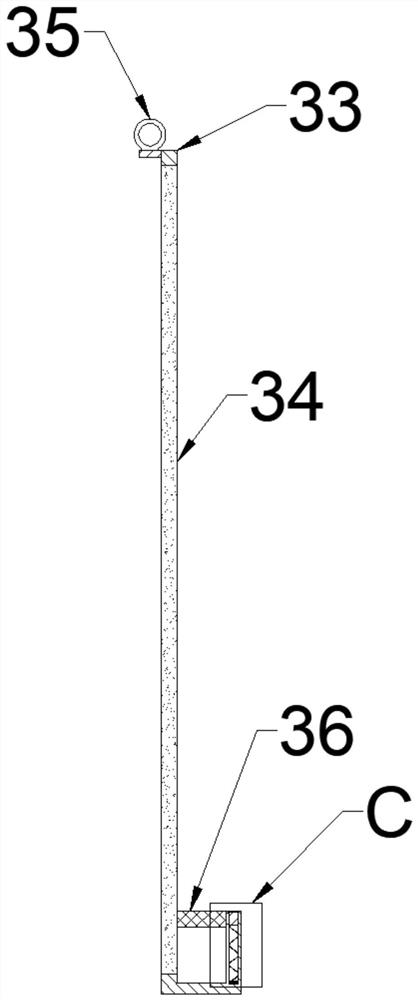

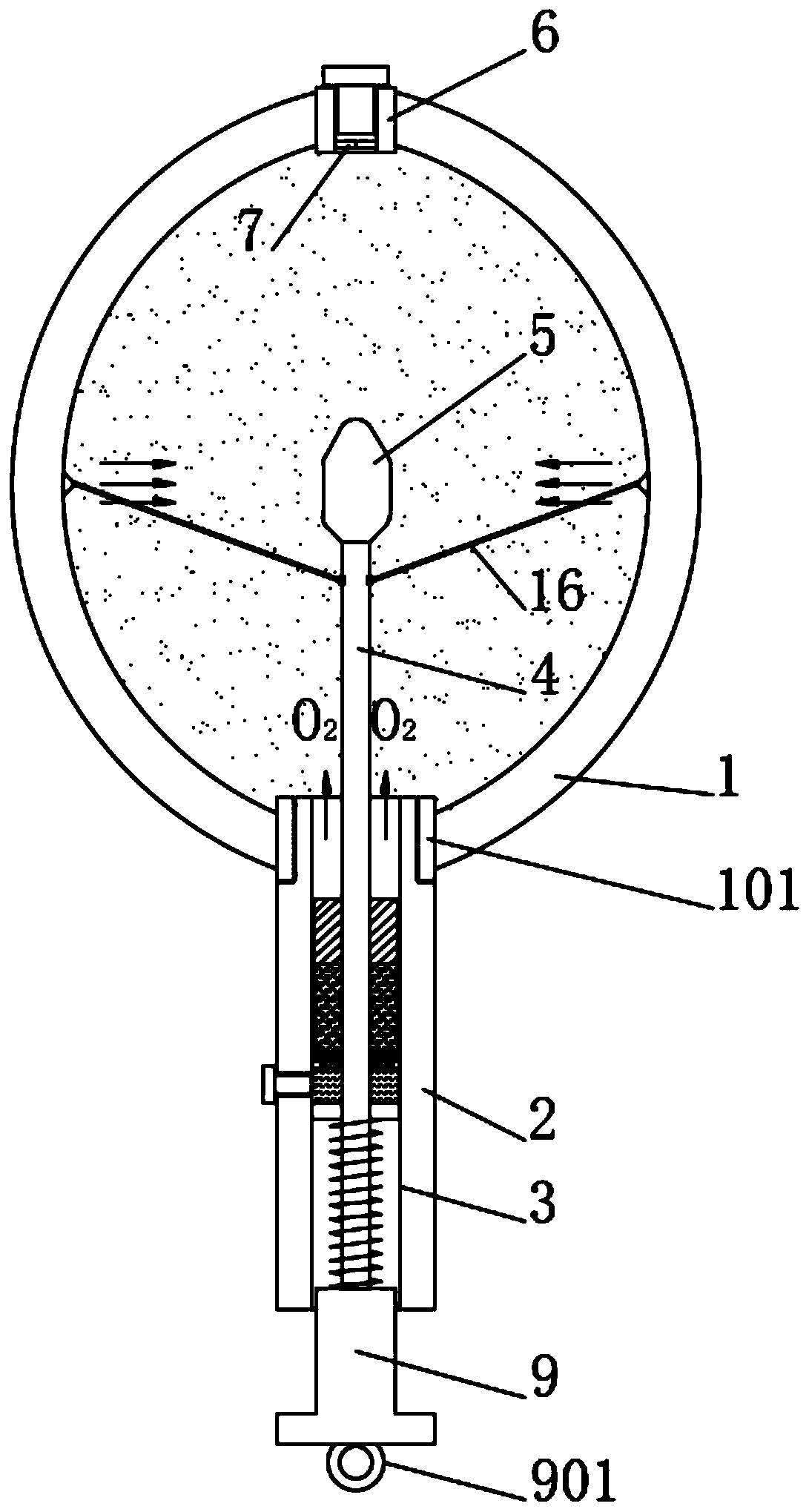

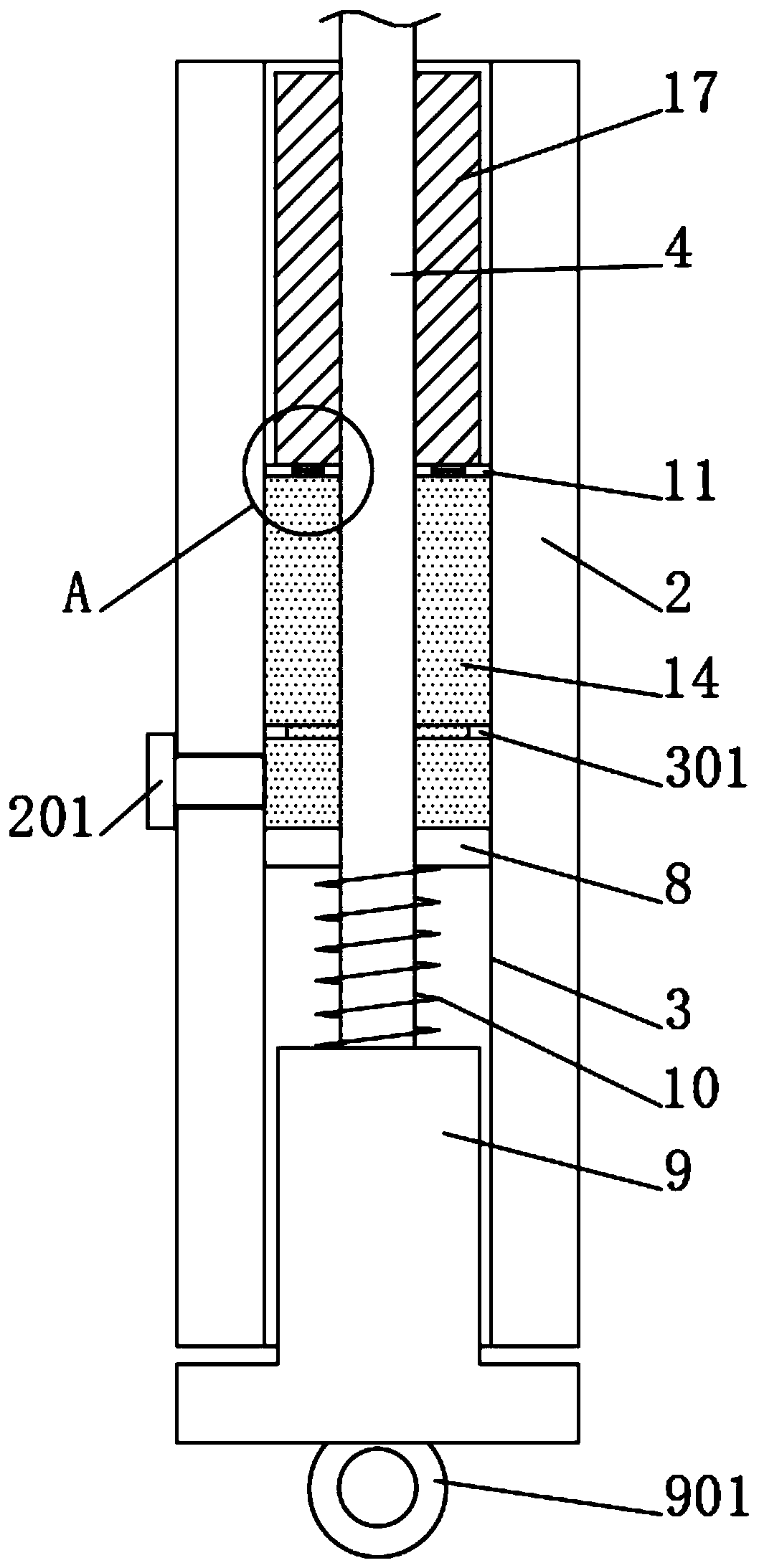

A tailing sand filling sand bin device

The invention relates to the field of mining equipment, in particular to a sand bin filling device for tailing sand, which includes a sand bin and a drop opening arranged on the bottom side of the sand bin. An auger shaft is rotatably connected to the middle of the sand bin, and the circumferential side wall of the lower part of the auger shaft is An auger is provided, the lower end of the auger shaft passes through the outlet and is hinged with a sliding sand tank, the right end of the sliding sand tank is provided with an adjustment piece, the left side of the adjustment piece is provided with an arc surface, and the upper part of the sand bin is provided with a driving auger shaft to rotate The driving assembly of the sand bin is symmetrically fixed and connected with the cylinder through the ring frame outside the middle part of the sand bin; the invention prevents the tailing sand from blocking the drop opening by rotating the auger in the sand bin, and at the same time adjusts the vertical movement of the left end of the sand slide tank. Adjust the falling and accumulating area of the tailings to realize the expansion of the accumulation area of the tailings. At the same time, the rotation of the sliding sand tank is driven by the auger shaft to further expand the accumulation area, which can reduce the tailings caused by excessive tailings accumulation to a certain extent. Collapse accidents, and avoid tailings clogging too high at the drop opening, and improve the falling efficiency of tailings.

Owner:铜陵有色股份安庆月山矿业有限公司

Circulating air suction and release type indoor formaldehyde removal device and use method

InactiveCN112097337AImprove absorption efficiencyAbsorption lastsLighting and heating apparatusDispersed particle separationChlorine dioxideSorbent

The invention discloses a circulating air suction and release type indoor formaldehyde removal device and a use method, and belongs to the technical field of air purification. According to the scheme,a vertical pulling rod is pulled downwards, on one hand, a movable round plug plate can be driven to move downwards, and therefore air on the lower side of the movable round plug plate is extruded outwards; a formaldehyde purification adsorbent in a side ventilation filter bag sleeve is dispersed by means of air flow, the possibility of mutual agglomeration of the formaldehyde purification adsorbent is reduced, and therefore the formaldehyde absorption efficiency of the formaldehyde purification adsorbent is improved; on the other hand, an elastic connecting rope in a built-in storage box canbe pulled downwards, effervescent powder in the elastic connecting rope is enabled to fall into a water solution, carbon dioxide gas can be generated, and the movable round plug plate is pushed to continue to move downwards; and meanwhile, by means of a generated chlorine dioxide solution, formaldehyde entering from a second gas path one-way valve can be absorbed, carbon dioxide and water are continuously generated, and therefore indoor formaldehyde is continuously absorbed.

Owner:夏汝心

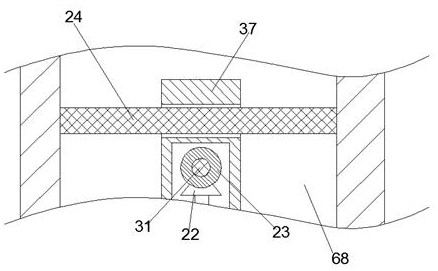

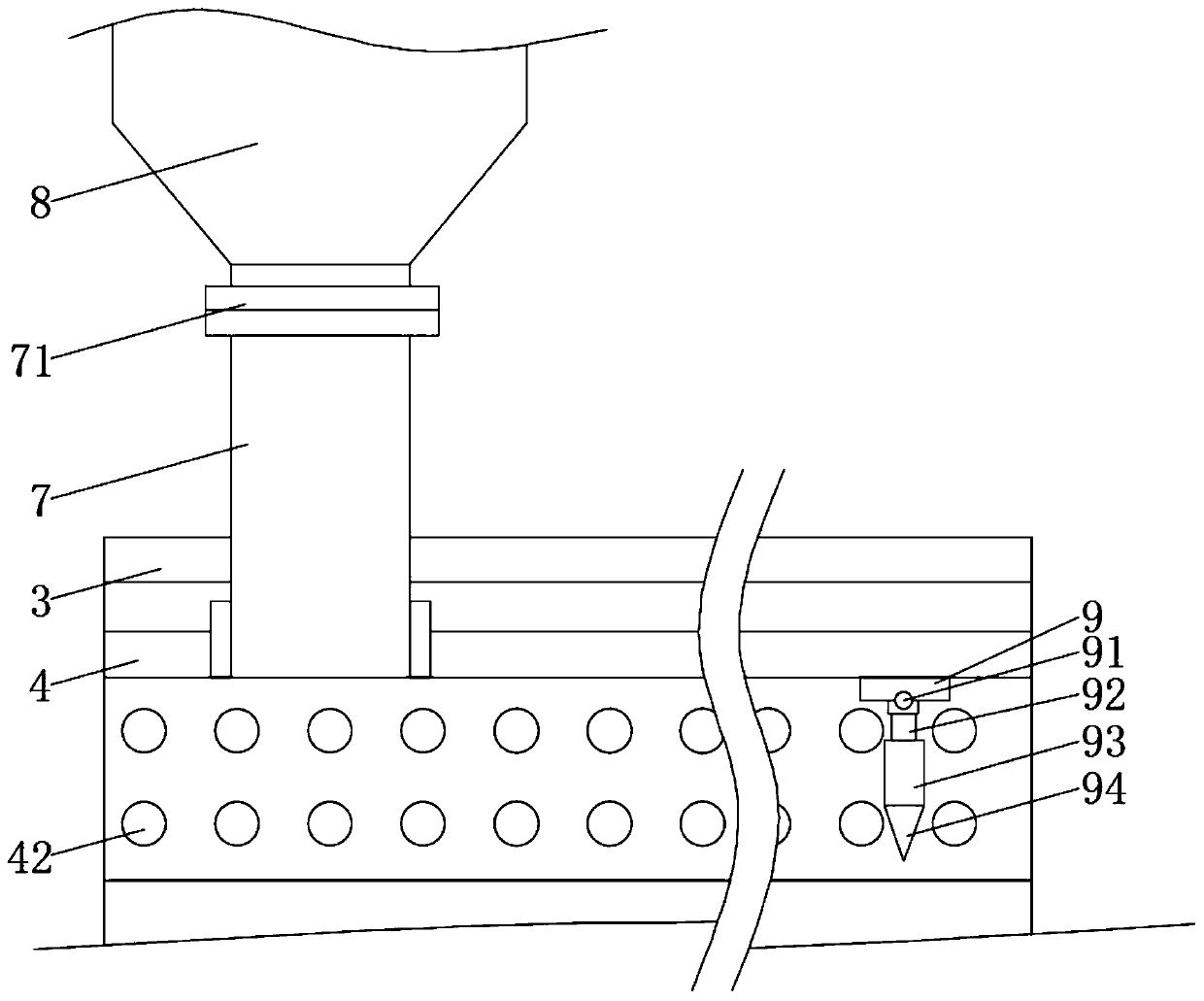

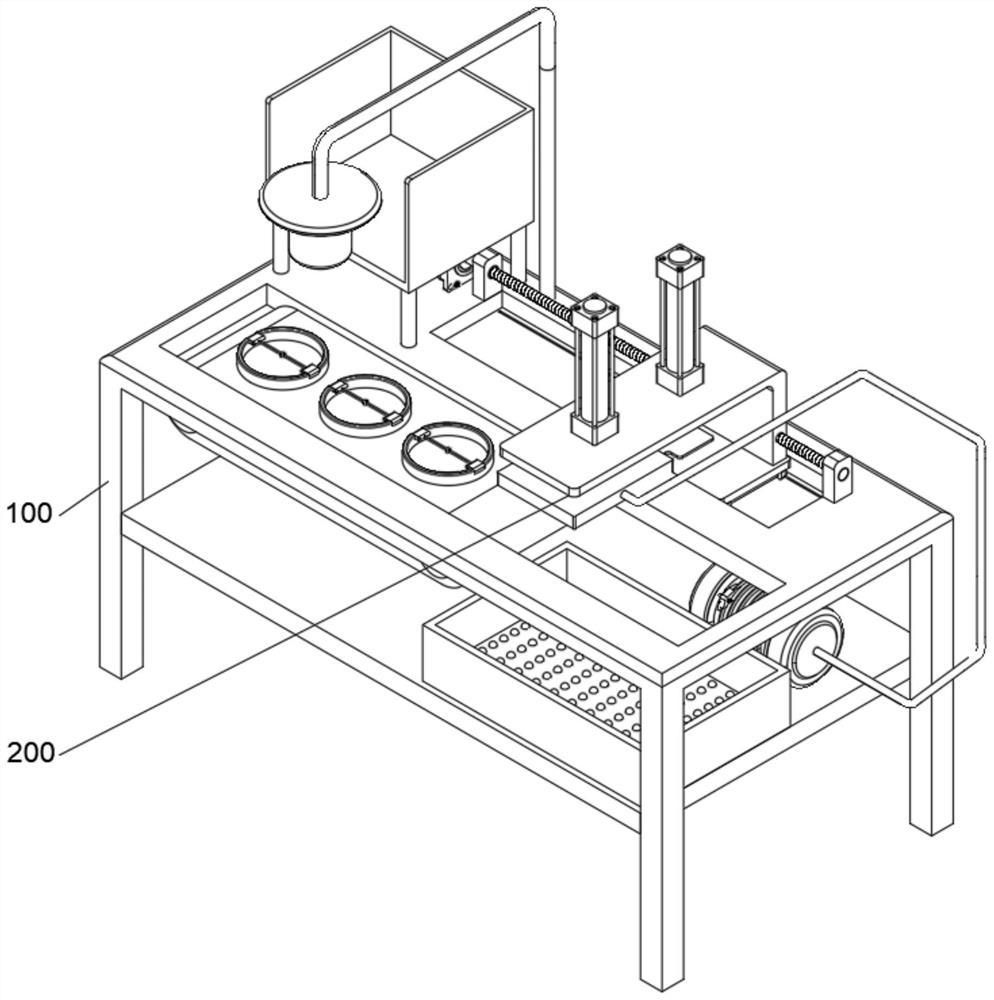

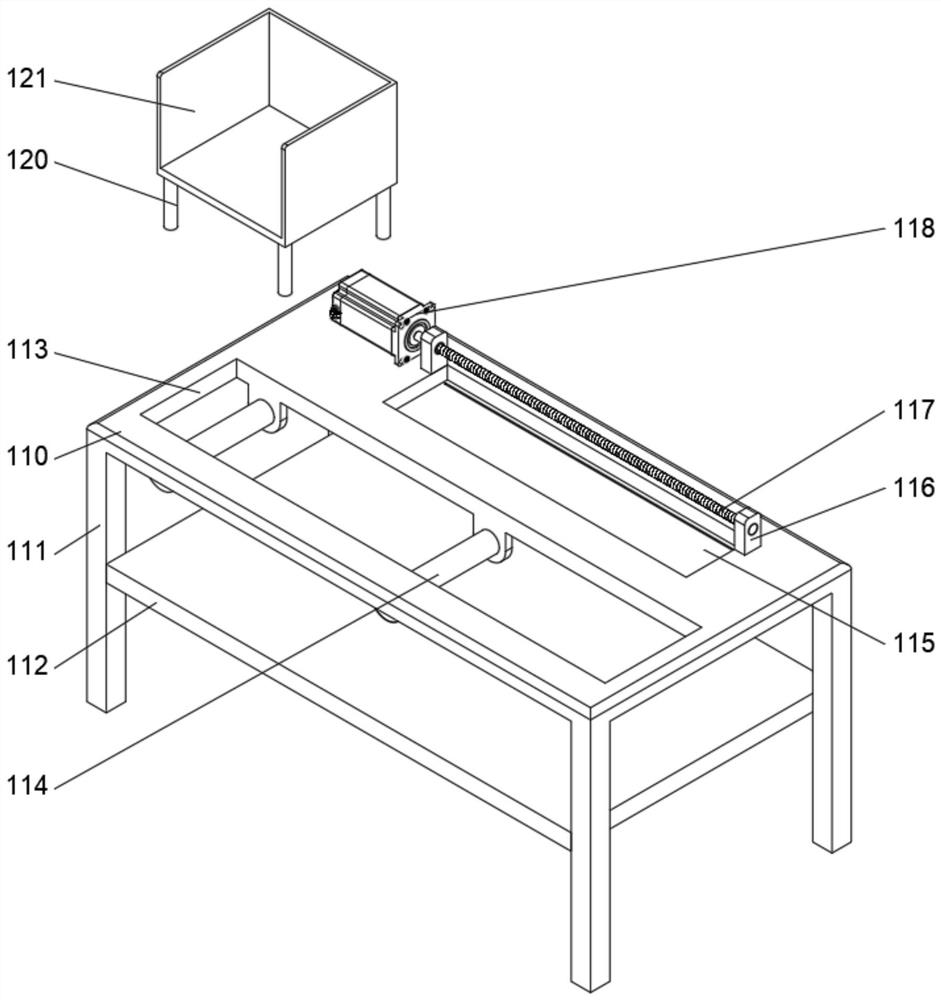

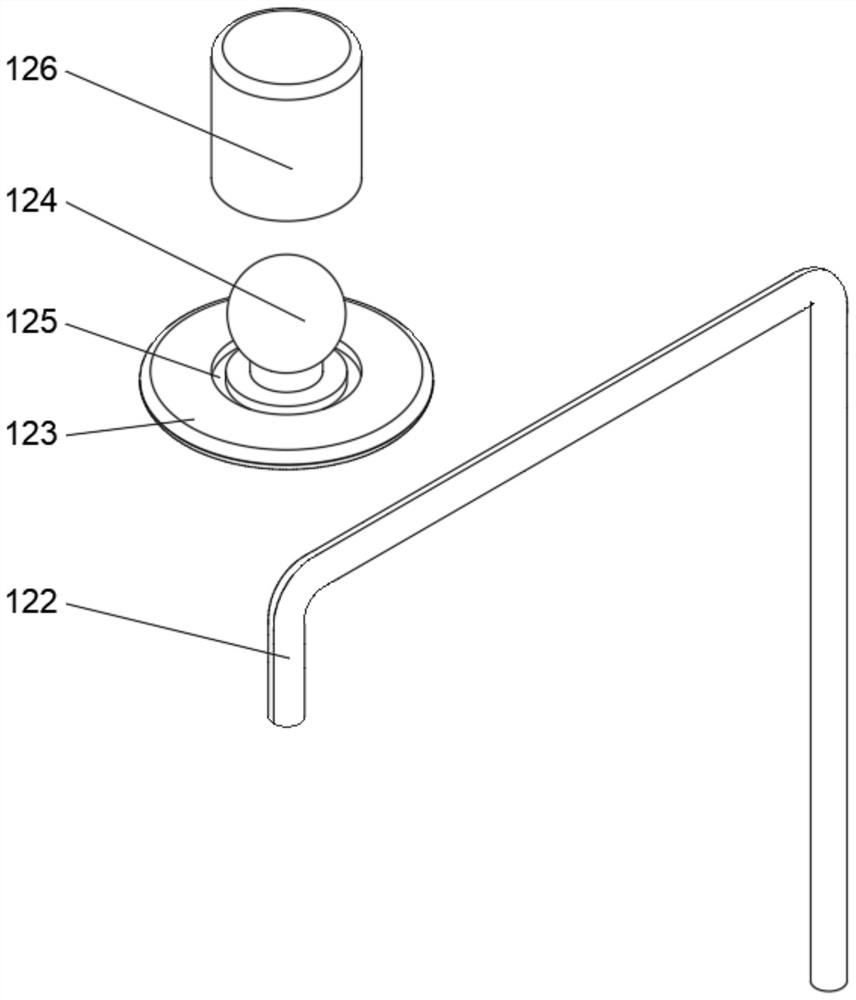

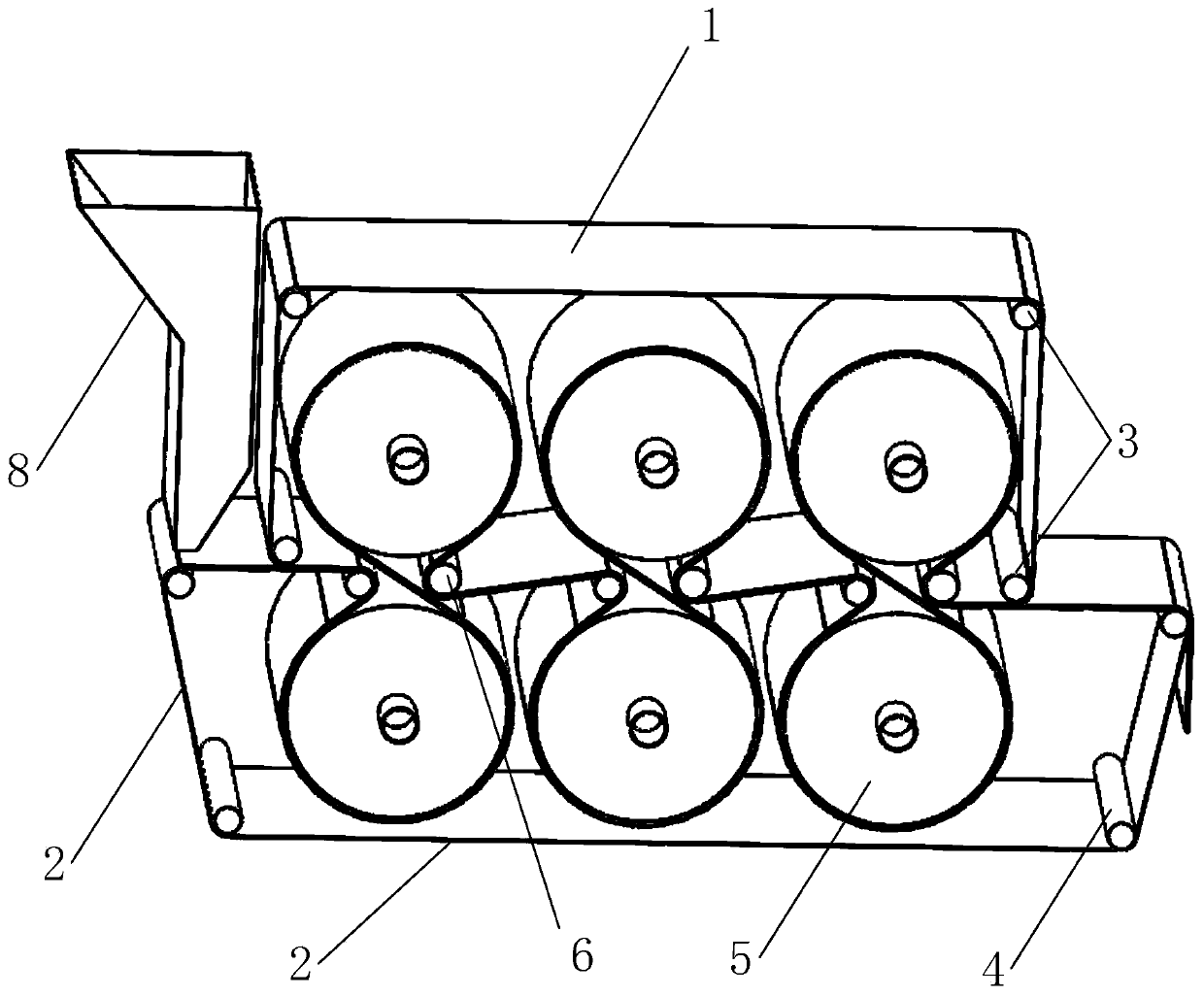

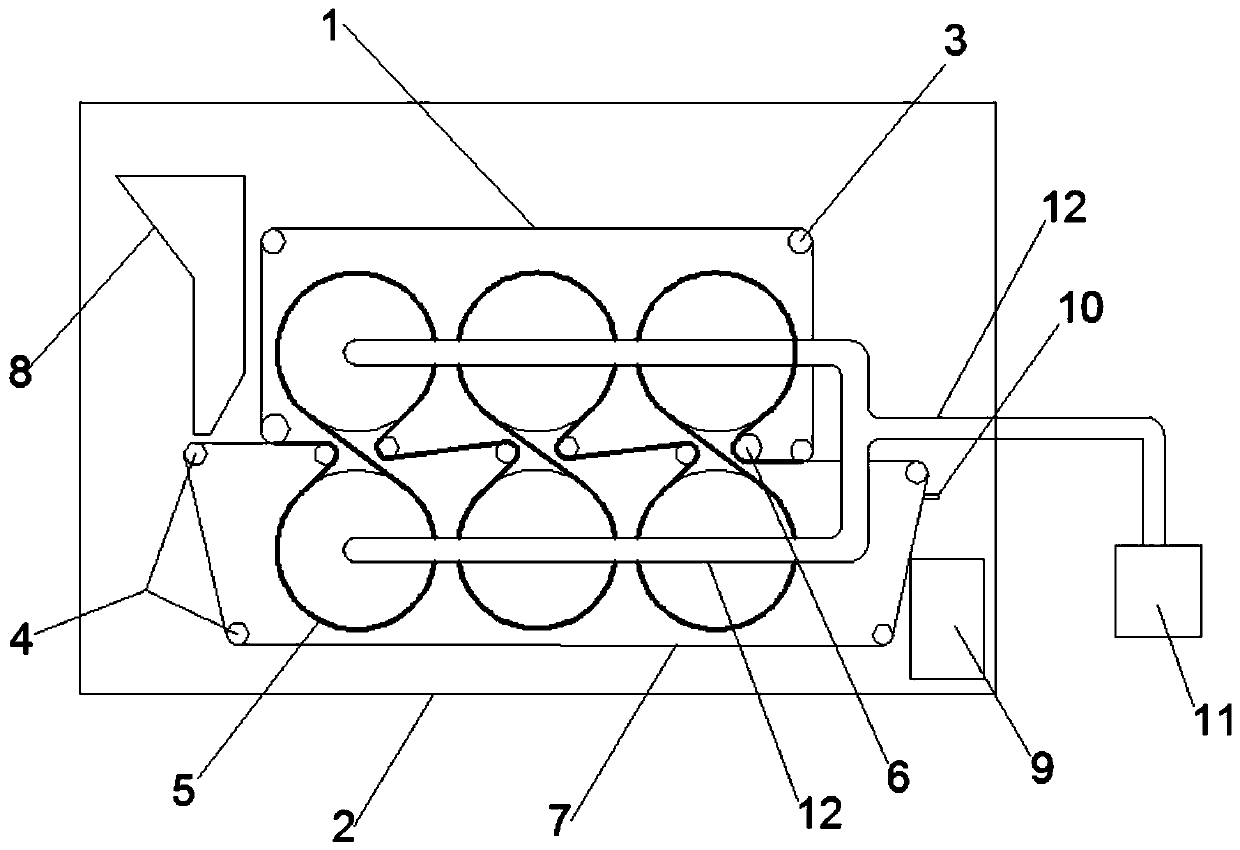

Automatic feeding system for raw material warehouse of asphalt mixing plant

ActiveCN113005849BImprove drop efficiencyEasy to cleanSievingScreeningAgricultural engineeringAsphalt

This application relates to the automatic feeding system of the raw material warehouse of the asphalt mixing plant, which belongs to the field of asphalt feeding, and includes a feeding tower, the outer peripheral surface of the feeding tower is fixed with a feeding pipe and a feeding pipe; the bottom end of the feeding pipe It is fixedly connected with the outer peripheral surface of the return pipe; the outer peripheral surface of the return pipe is provided with a discharge hole, and the inner peripheral surface of the discharge hole is fixed with a filter screen; the bottom surface of the filter screen is provided with a scraper along the length direction of the return pipe A brush is fixed on the top of the scraper; a driving device for driving the scraper to move is provided under the return pipe. The application has the effect of facilitating cleaning of the filter screen.

Owner:安徽虹达道路桥梁工程有限公司

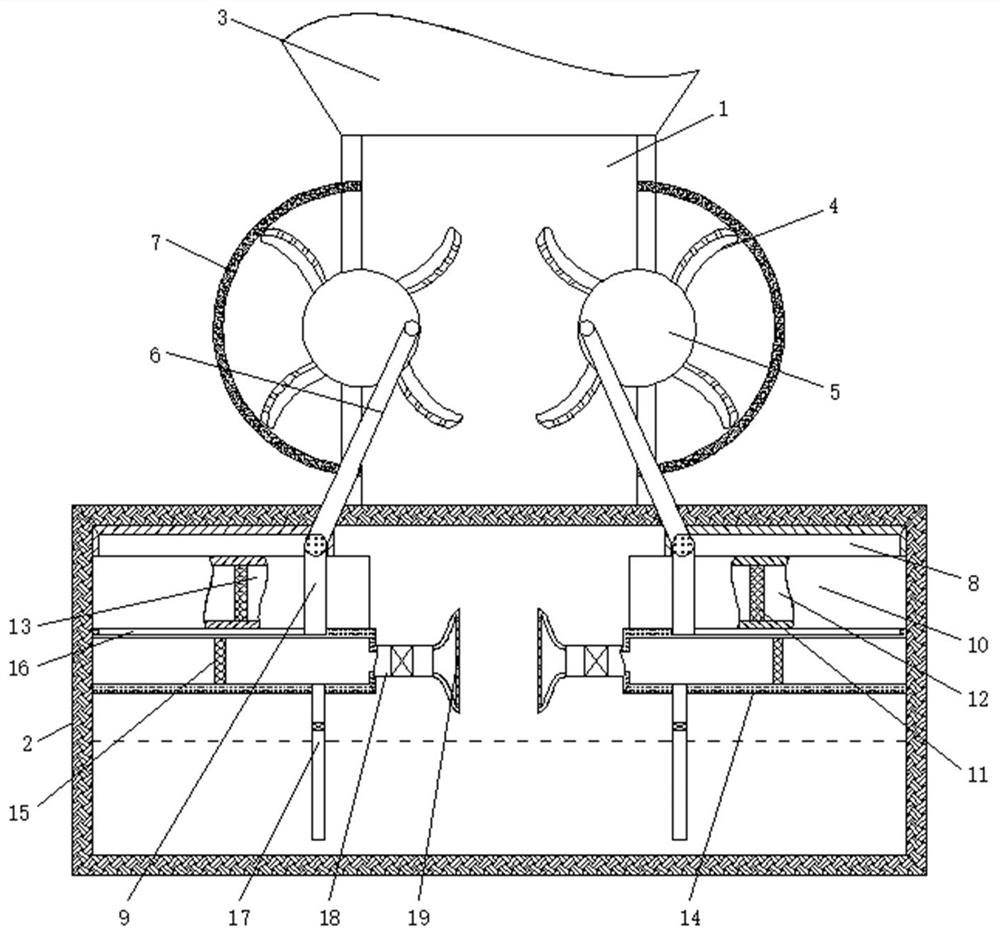

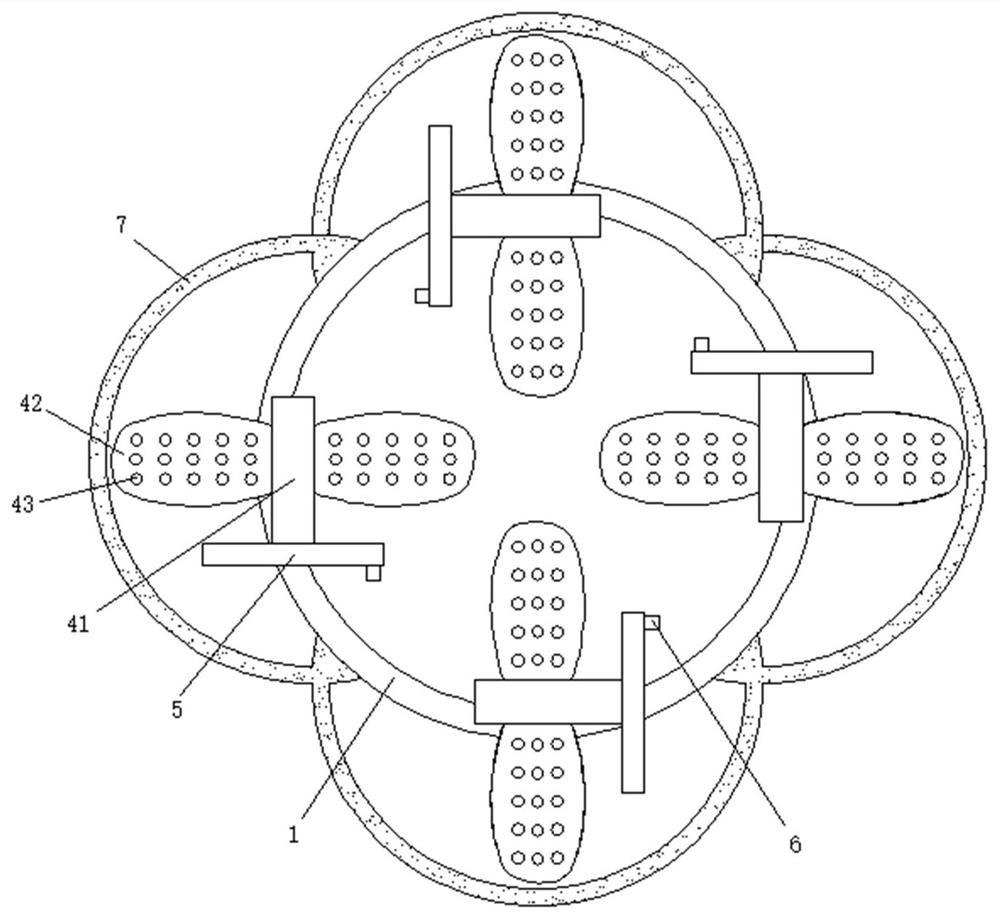

Honey extractor capable of preventing honeycomb honey chippings from flowing out and preventing honey from remaining

The invention relates to the related technical field of honey processing, and discloses a honey extractor capable of preventing honeycomb honey chippings from flowing out and preventing honey from remaining. The honey extractor comprises a honey extracting barrel; a honey cavity is formed in the honey extracting barrel; an adapter ring is fixedly installed in the honey cavity; a power rotating rod is rotatably installed in the adapter ring; a pushing and knocking honey extracting device is detachably mounted on the lower side of the power rotating rod; the pushing and knocking honey extracting device comprises a honey extracting plate; a honey extracting cavity is formed in the honey extracting plate; a functional groove is formed in the inner wall of the right side of the honey extracting cavity; and a pushing and squeezing plate is slidably mounted in the functional groove. According to the honey extractor capable of preventing the honeycomb honey chippings from flowing out and preventing the honey from remaining, through the arrangement of the pushing and knocking honey extracting device, the honey in the pushing and knocking honey extracting device containing honeycomb honey flows out into the honey cavity through a leakage net plate under the rotation of a centrifugal motor; and in the centrifugal honey extracting process, through the arrangement of an internal debris treatment device, debris in the honey is intercepted.

Owner:廖文朵

Inflation device for production of push type basketballs

InactiveCN112915497ALabor savingInflatable precisionHollow inflatable ballsStructural engineeringMechanical engineering

Owner:TIANCHANG ZHENGMU ALUMINUM TECH

A roller drying structure and a dryer made of the structure

ActiveCN110779314BIncrease the areaImprove heating and drying efficiencyDrying solid materialsHeating arrangementThermodynamicsEngineering

The invention discloses a roller drying structure and a dryer made of the structure, comprising a first conveyor belt and a second conveyor belt, a plurality of first limiting rods, a plurality of second limiting rods, a plurality of drying Dry cylinder, a plurality of combined limit rods, the first drive rod from any one of the first limit rods, the first drive rod from any one of the first limit rods; the dryer also includes a fixed Bracket, heating device, feeding funnel, discharging box, and scraper blades In the present invention, through the setting of the first conveyor belt and the second conveyor belt, when the object to be dried is dropped onto the conveyor belt through the feeding funnel, the two conveyor belts Combined extrusion, the material to be dried is pressed into a flat structure, and at the same time, with the transmission of the conveyor belt, the material to be dried that is pressed into a flat structure is conveyed, so that it passes through multiple high-temperature drying cylinders in sequence, greatly It greatly increases the area where the material to be dried is in contact with the high-temperature environment, greatly improves the efficiency of its heating and drying, and reduces energy consumption.

Owner:SHANXI HEPO POWER GENERATION CO LTD

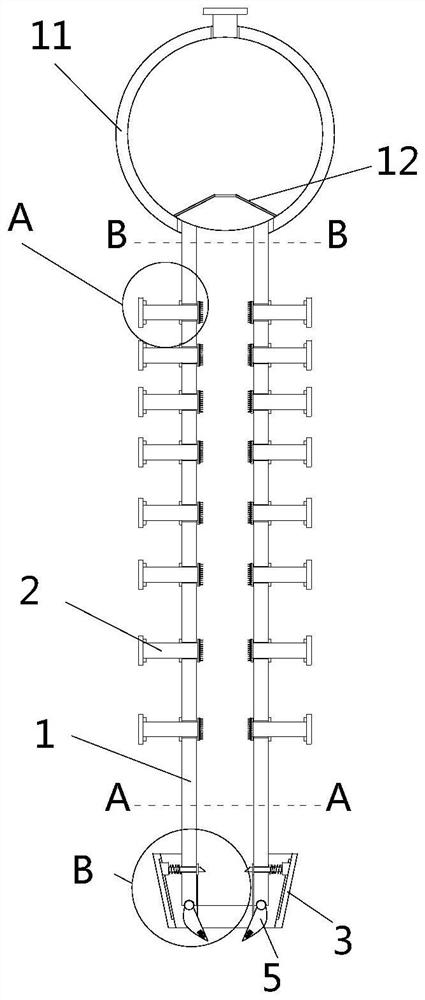

A portable psyllium collection device

ActiveCN112586185BImprove picking efficiencyThe problem of preventing explosion and fallingPicking devicesBiotechnologyMedicinal herbs

The invention relates to the technical field of medicinal herbs, and discloses a portable genus collecting device, comprising a picking tube, a collecting tube is fixedly installed on the top of the picking tube, and pressing devices distributed in an annular array are sequentially arranged on the outer wall of the picking tube from top to bottom. The pressing device includes a pressing rod, one end of the pressing rod extends into the picking cylinder cavity, and one end of the pressing rod is fixedly installed with a friction plate, and the inner wall of the friction plate is provided with a cleaning device. In the portable car-front son collecting device, by setting the cleaning device, when the permanent magnet A is pressed randomly and quickly, under the combined action of the mutual attraction and repulsion of the magnetic force, the permanent magnet C on the pressed friction plate is made Vibration occurs. The vibration of the permanent magnet C drives the hard bristles to vibrate continuously. When the hard bristles are shaking when approaching the outer wall of the psyllium, the vibrating hard bristles further improve the efficiency of the fruit falling. This further improves the picking efficiency of psyllium.

Owner:泉州台商投资区一创工业设计有限公司

Roller type drying structure and dryer formed by structure

ActiveCN110779314AIncrease the areaImprove heating and drying efficiencyDrying solid materialsHeating arrangementStructural engineeringConveyor belt

The invention discloses a roller type drying structure and a dryer formed by the structure. A first conveyor belt, a second conveyor belt, a plurality of first limiting rods, a plurality of second limiting rods, a plurality of drying cylinders, a first drive rod taken from any one of the first limiting rods and a second drive rod taken from any one of the second limiting rods are included; and thedryer also comprises a fixed bracket, a heating device, a feeding funnel, a discharging box and a scraper. According to the roller type drying structure and the dryer, through the arrangement of thefirst conveyor belt and the second conveyor belt, when materials to be dried fall onto the conveyor belts through the feeding funnel, through combined extrusion of the two conveyor belts, the materials to be dried are pressed to be of flat structures; and meanwhile, along with transmission of the conveyor belts, the materials which are to be dried and are pressed to be of the flat structures are conveyed, the materials pass through the multiple high-temperature drying cylinders in sequence, the contact area of the materials to be dried and the high-temperature environment is greatly increased,the heating and drying efficiency is greatly improved, and energy consumption is reduced.

Owner:SHANXI HEPO POWER GENERATION CO LTD

Contraction and expansion synchronous cleaning device based on atmospheric pollution detection equipment

InactiveCN111551675AIncrease air pressurePromote decompositionHollow article cleaningAir quality improvementParticulatesEngineering

The invention discloses a contraction and expansion synchronous cleaning device based on atmospheric pollution detection equipment and belongs to the technical field of atmospheric detection. According to the scheme of the contraction and expansion synchronous cleaning device based on atmospheric pollution detection equipment provided in the invention, during working, a fixing plug is stretched downwards; a connecting rod and a detection end head are driven to move downwards together; a flat pinching type collecting bags are pulled to be close to each other through the connecting string; the flat pinching type collecting bag is contracted into an ellipsoidal shape; meanwhile, hydrogen peroxide is extruded through the movable sealing ring; hydrogen peroxide can be promoted to be decomposedinto water and oxygen; oxygen penetrates through the release hole and the backflow type cotton column to enter the flat pinching type collecting bag; after the air pressure in the flat pinching type collecting bag is increased, the flat pinching type collecting bag is expanded, so that the falling efficiency of the particulate matters is improved, and after the sealing plug is unscrewed, the particulate matters can be driven to pass through the backflow type cotton column containing water in the gas backflow process in the flat pinching type collecting bag, so that the particulate matters arefully collected, and the gas passes through the adding hole and then is discharged.

Owner:顾晓杰

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com