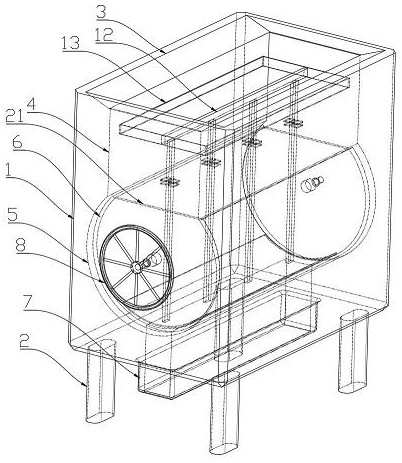

Building gravel screening device

A screening device, sand and gravel technology, applied in the direction of sieve, solid separation, grille, etc., can solve the problems of small sand particles falling, clogging of sieve holes, disadvantage, etc., to improve the utilization rate, increase the output, and improve the drop. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

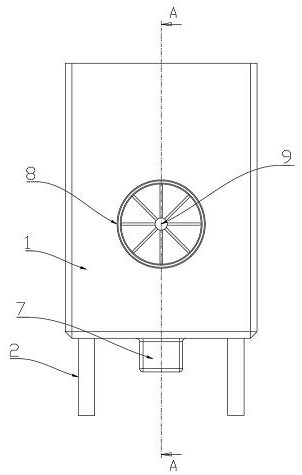

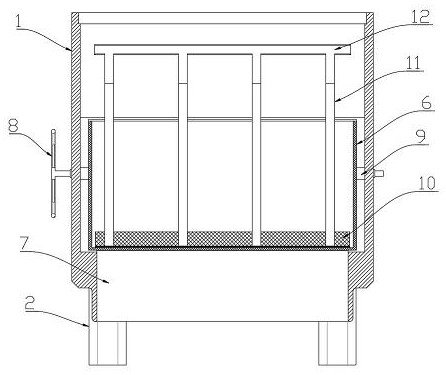

[0023] Please refer to the figure, in the embodiment of the present invention, a construction sand and gravel screening device includes a housing 1, legs 2, a filling port 3 and a discharge chamber 4; the legs 2 are fixed on the bottom of the housing 1, To support the shell 1, the filling port 3 is opened on the top of the shell 1, so that the sand and gravel are sent into the interior from the top of the shell 1, and the shell 1 is provided with a vertically downward material cavity 4, The filling port 3 communicates with the top of the feeding chamber 4 , so that the gravel entering the filling port 3 falls from the feeding chamber 4 .

[0024] The casing 1 is provided with a horizontal cylinder-shaped rotating screening chamber 5, the top of which is connected to the bottom of the feeding chamber 4, and the length of the feeding chamber 4 is equal to the length of the rotating screening chamber 5 , so that the sand and gravel falling in the unloading chamber 4 can all enter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com