Roller type drying structure and dryer formed by structure

A dryer and roller technology, applied in the direction of dryer, drying, drying of solid materials, etc., can solve the problems of inconvenient evaporation of internal water, long time required for drying, affecting drying efficiency, etc. The effect of increasing the contact area, improving efficiency, and improving practicality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below with reference to the accompanying drawings and embodiments, and the mode of the present invention includes but not limited to the following embodiments.

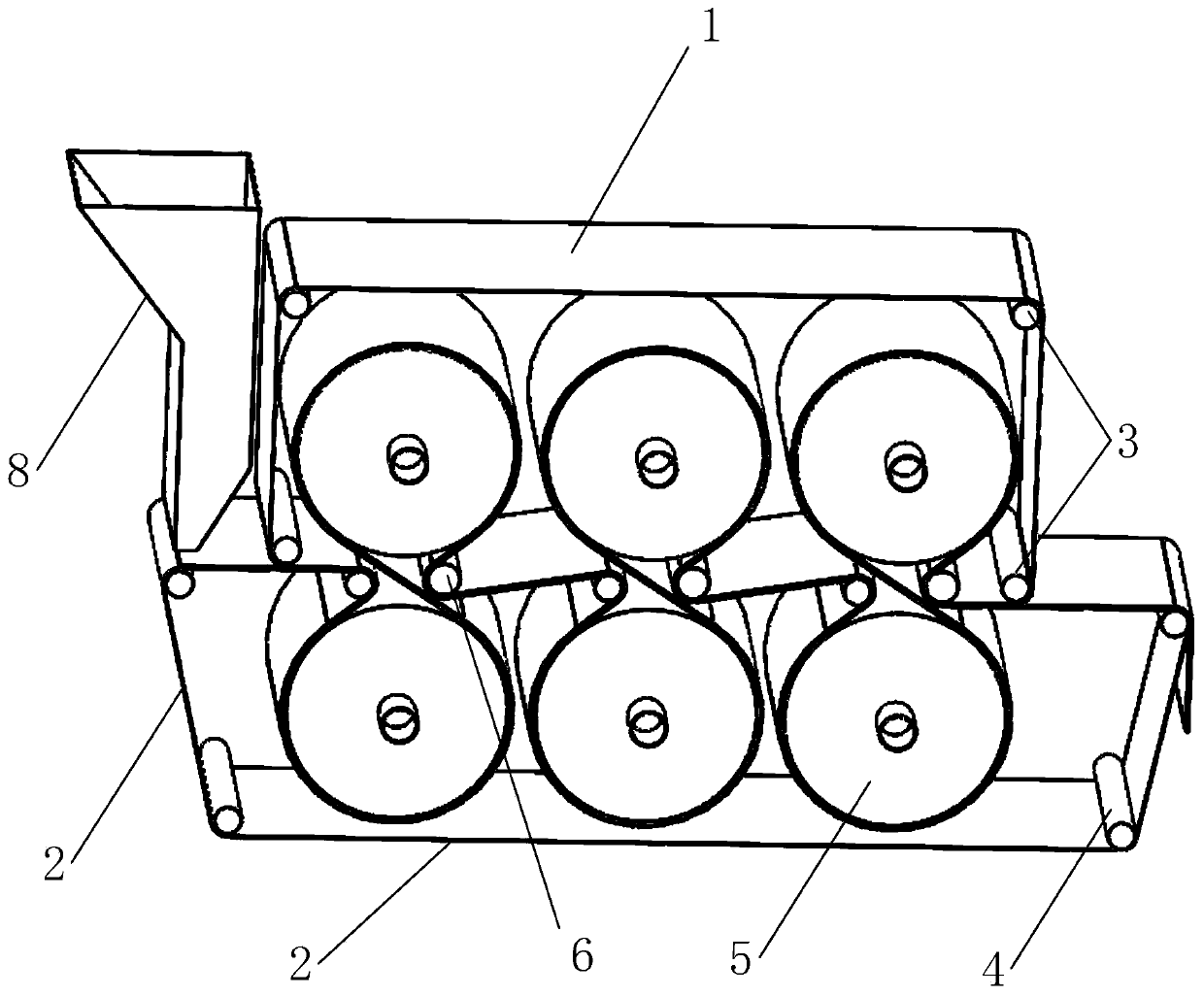

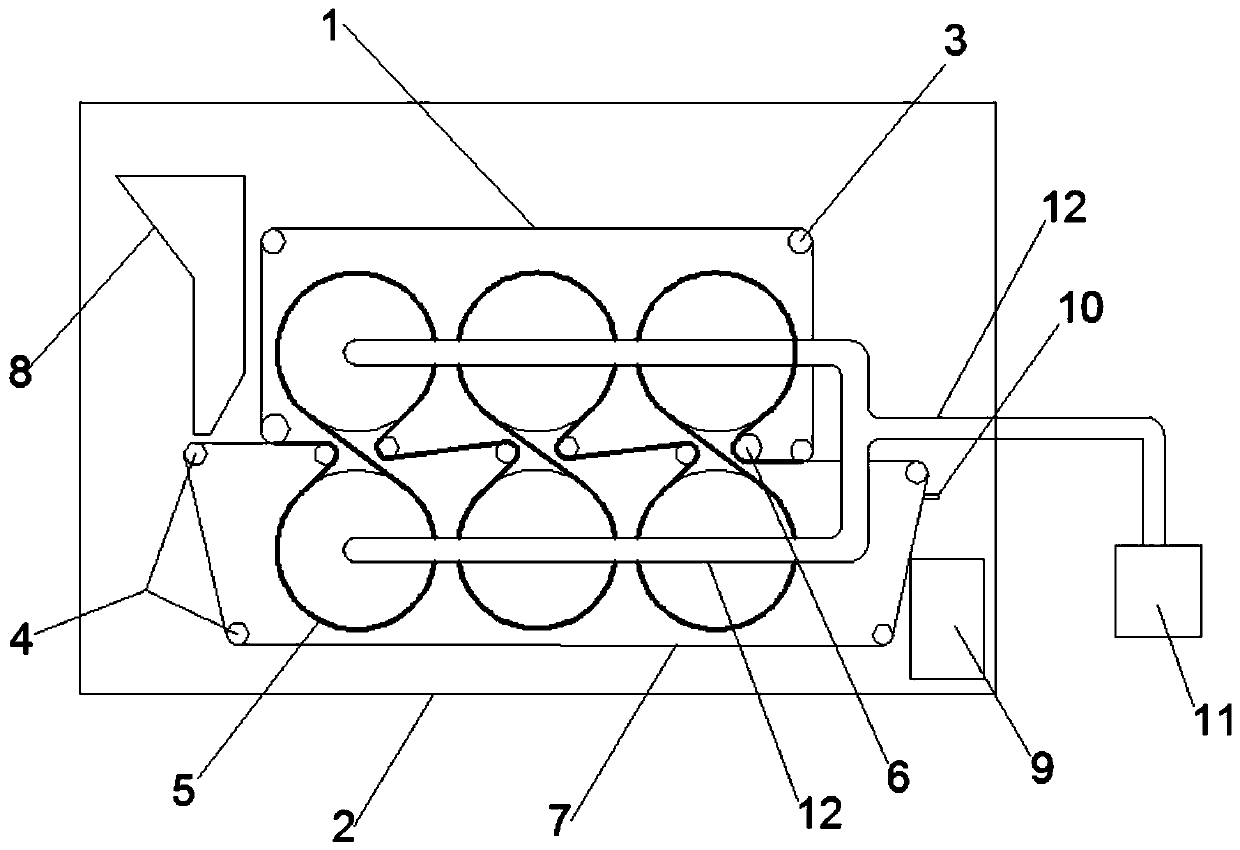

[0029] Such as Figure 1~2 Shown:

[0030] A roller drying structure, by pressing the material to be dried into a flat structure, increasing the area in contact with the ambient temperature and improving the drying efficiency, the specific structure includes a first conveyor belt 1 and a second conveyor belt 2. The combination of two conveyor belts clamps the materials to be dried; the first conveyor belt 1 is limited by the first limit rod 3, so that it can be driven within the range limited by the first limit rod 3, and the first limit rod 3 There are multiple positioning rods 3; the first limiting rod 3 can rotate freely, and one of them is used as the first driving rod to drive the first conveyor belt for transmission; the second conveyor belt 2 passes throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com