Patents

Literature

34results about How to "Improve heating and drying efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

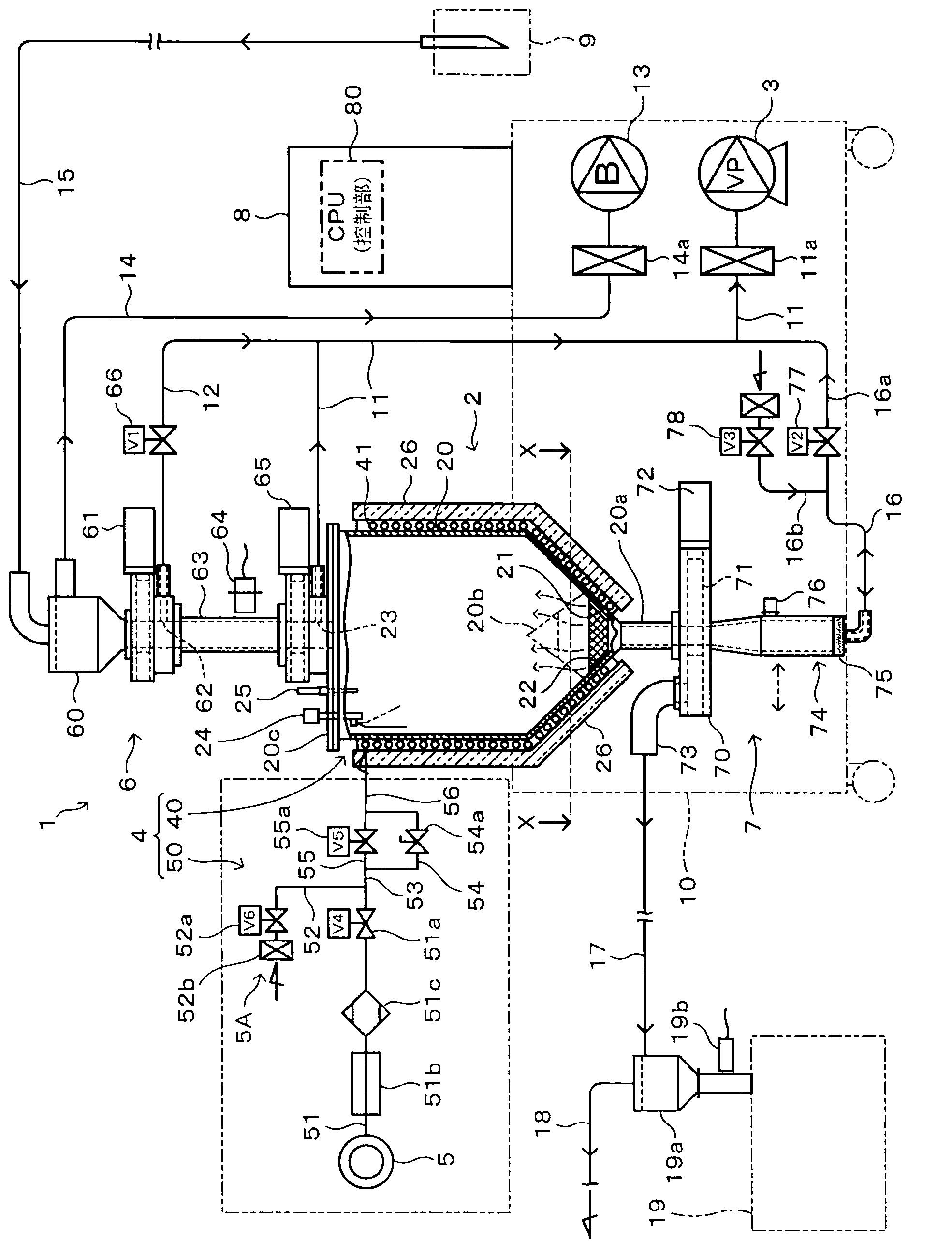

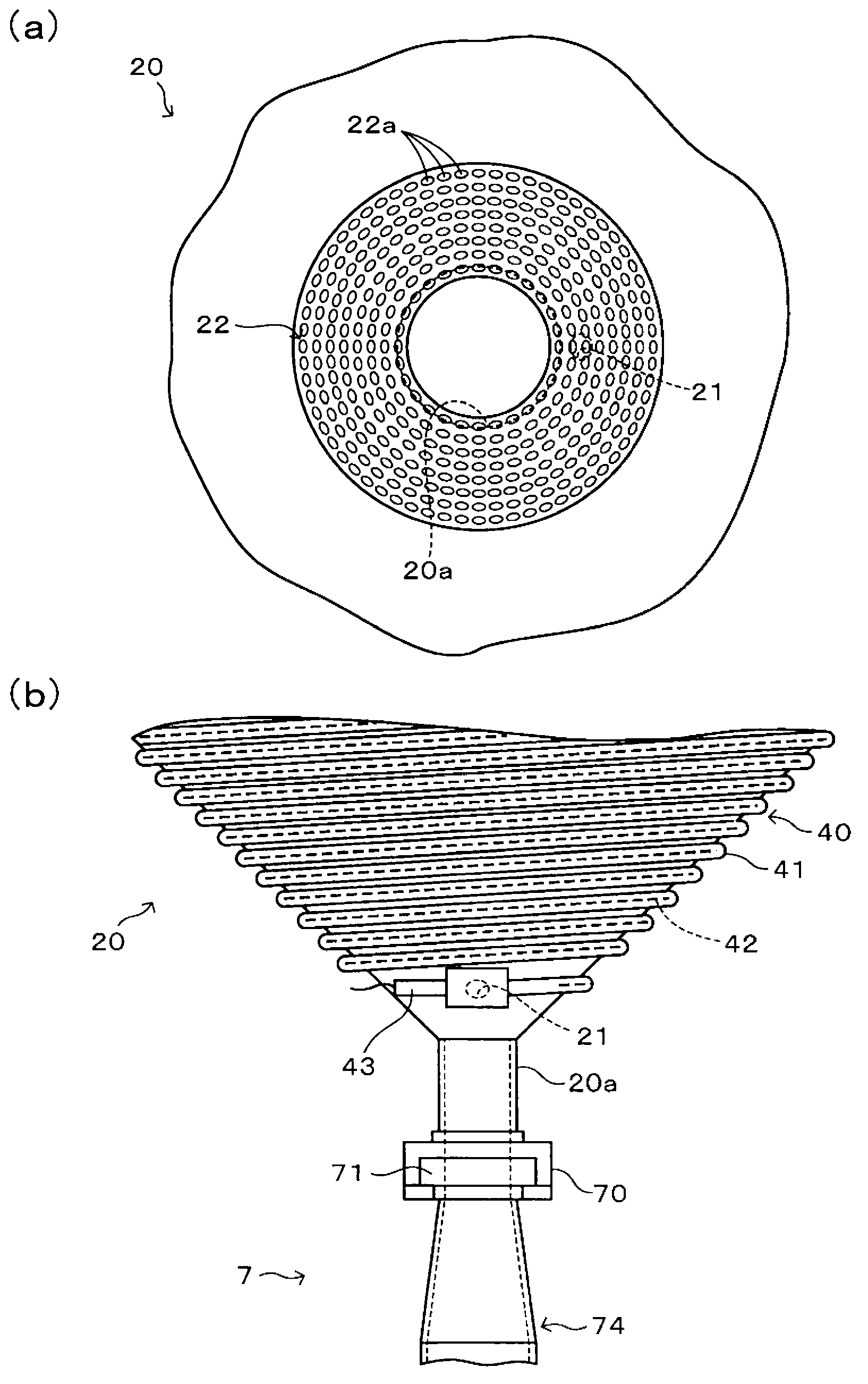

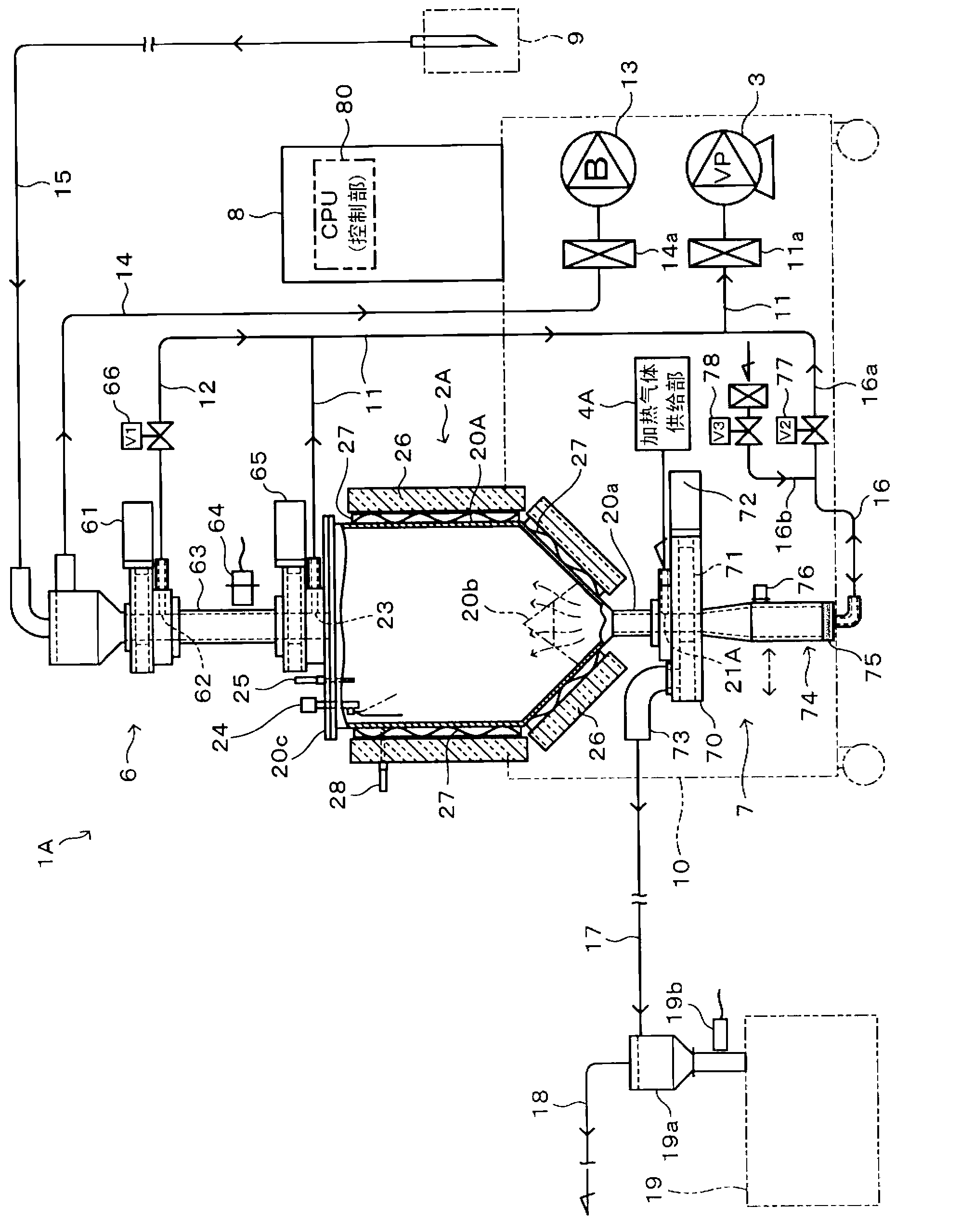

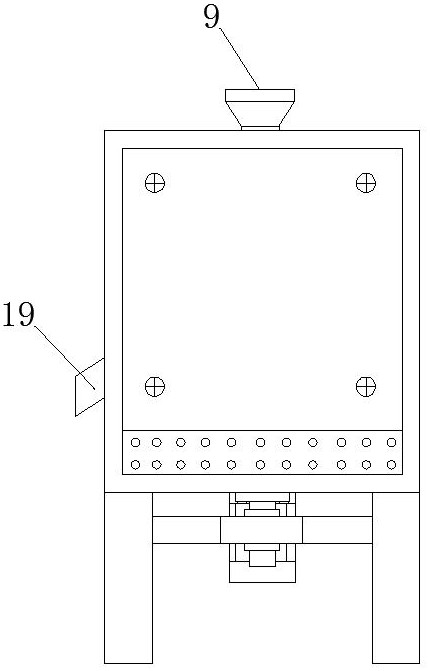

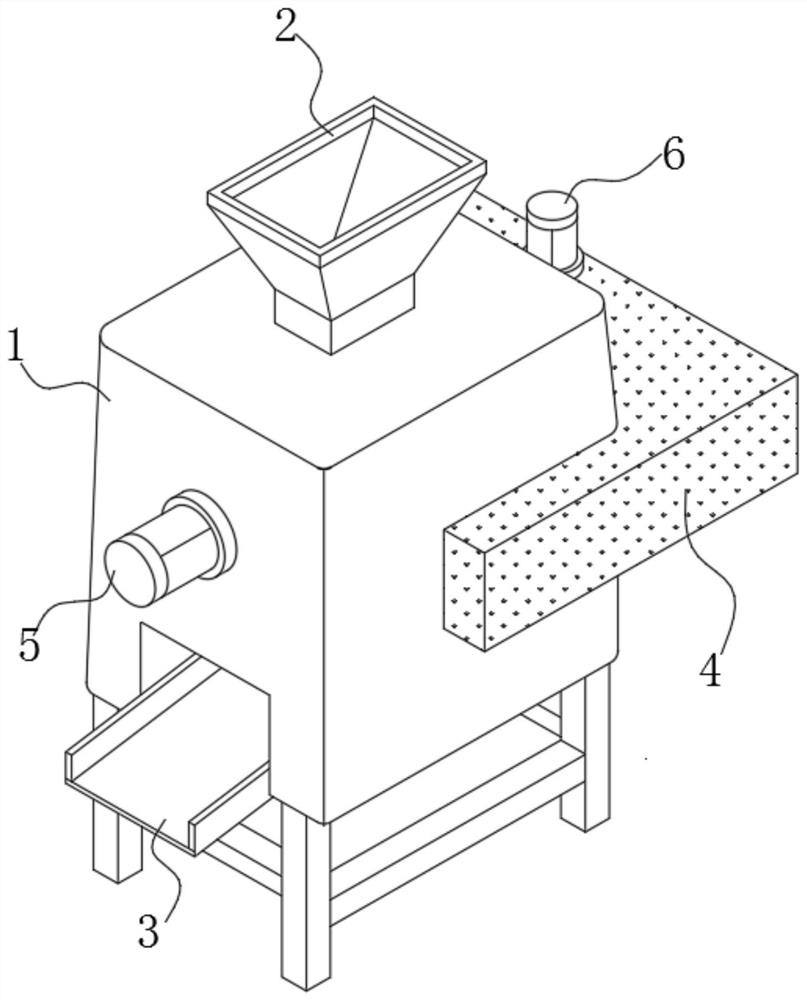

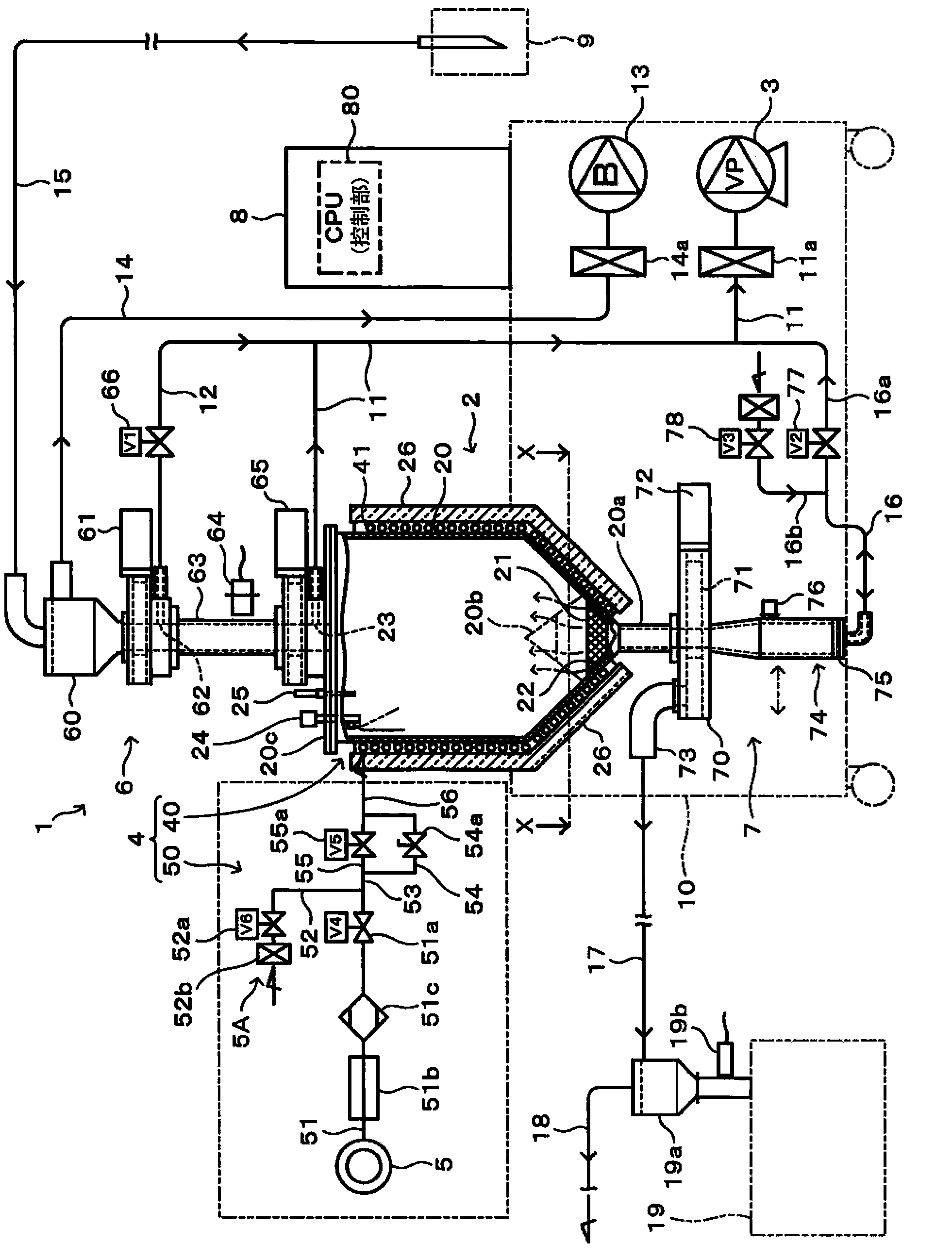

Depressurization type drying device for powder and granular material

ActiveCN102762346AReduce startup timeImprove cleanlinessDrying solid materials without heatDrying machines with local agitationProcess engineeringGas supply

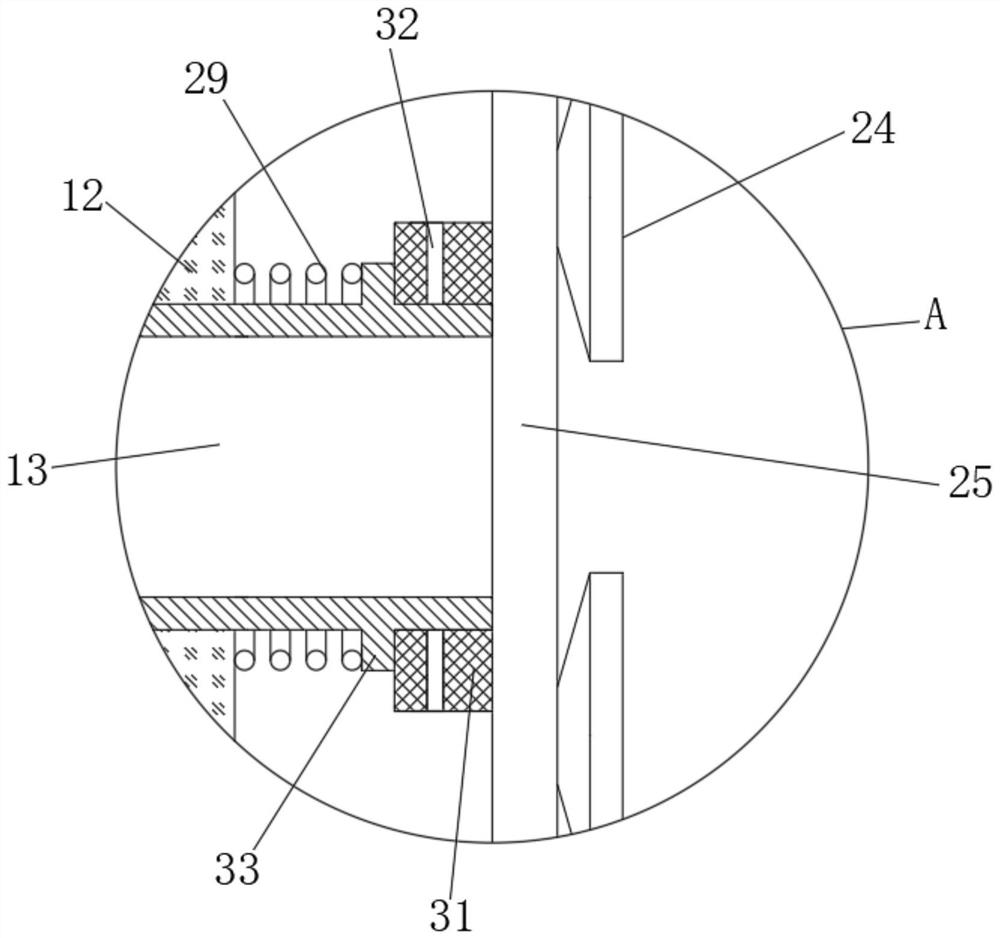

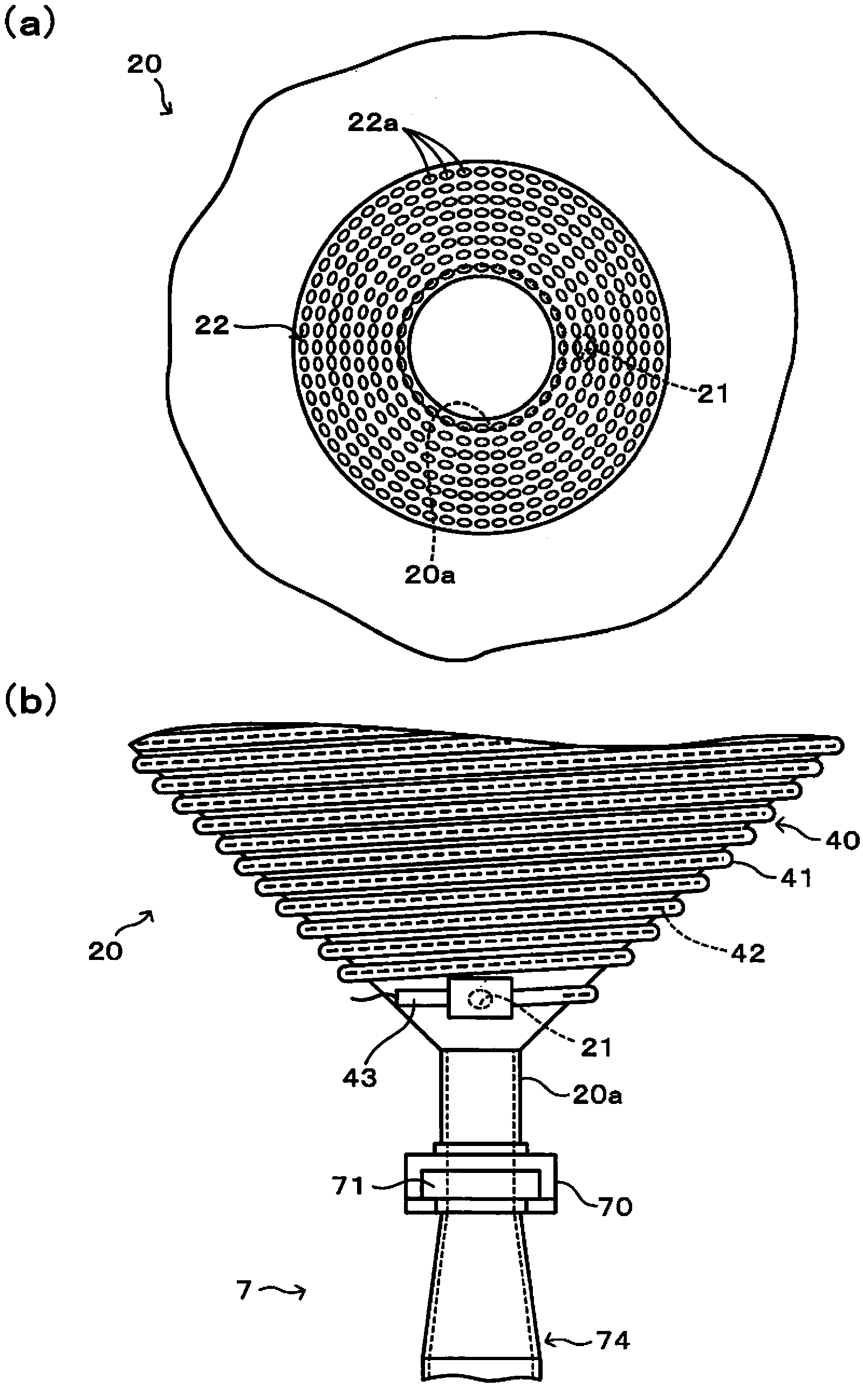

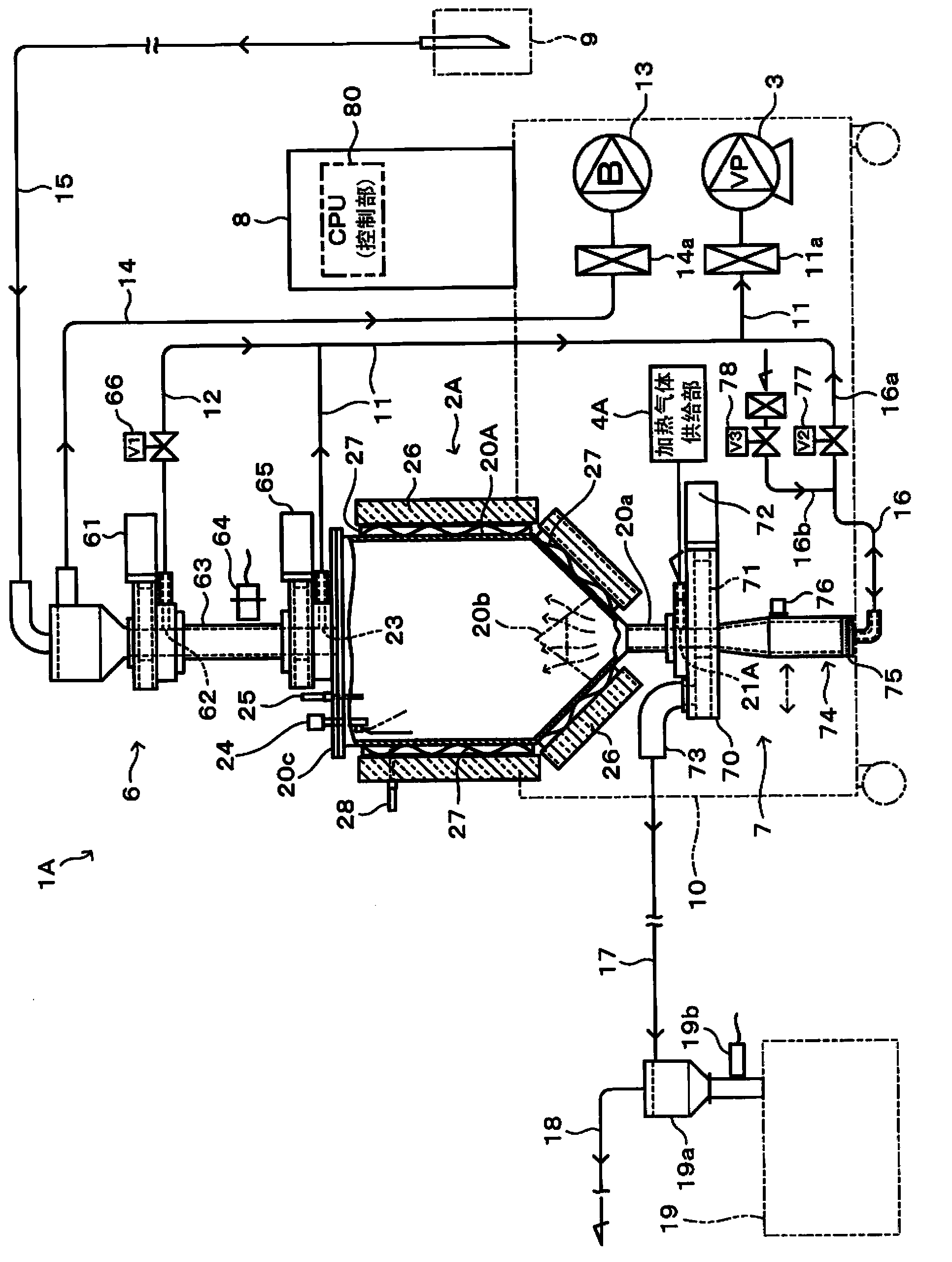

Disclosed is a depressurization type drying device (1) for powder and granular material comprising a hopper (20) for storing powder and granular material, and a depressurization means (3) for depressurizing the inside of the hopper, wherein the device is provided with hopper outer periphery heat retaining units (40, 26) arranged on the outer periphery of the hopper, a heated gas supply unit (4) for supplying heated gas to the hopper, and a control unit (80) for controlling the heated gas supply unit to supply gas which has been heated to a preset temperature.

Owner:MATSUI MFG

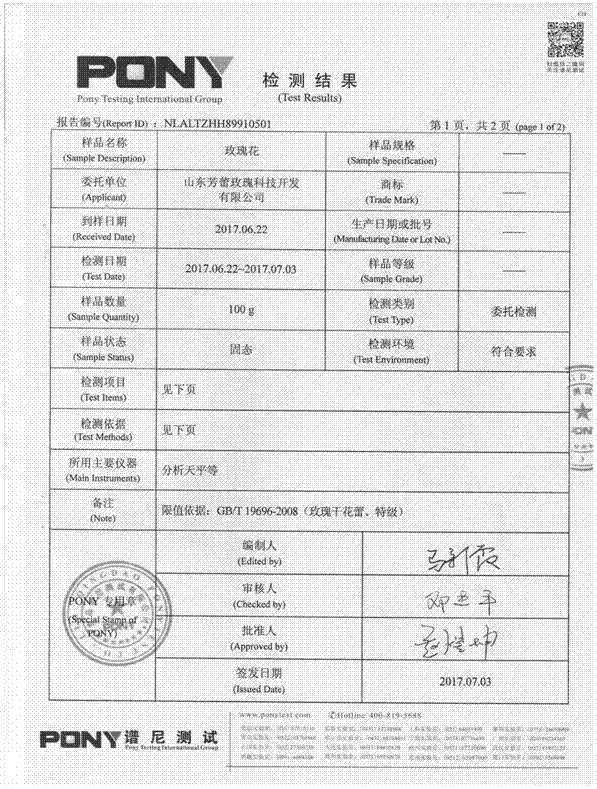

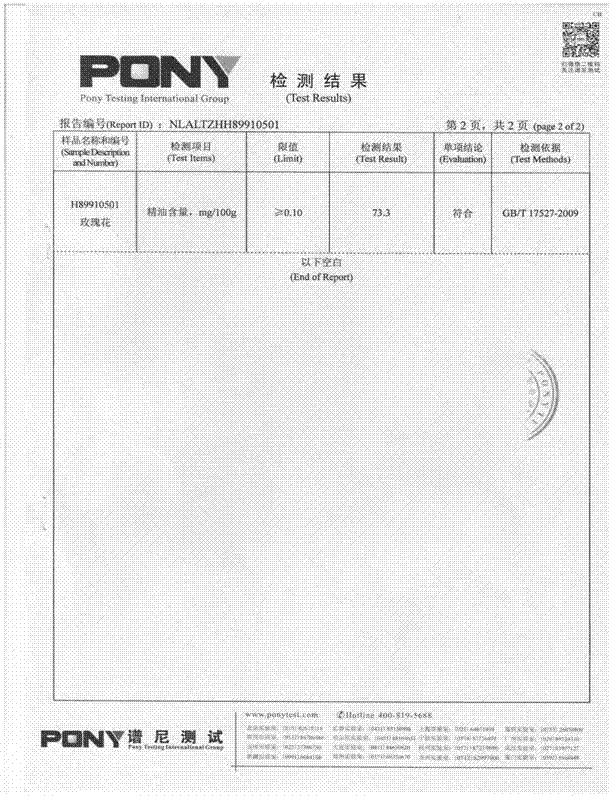

Rose drying equipment and method

InactiveCN107462047AFast heating and dryingHigh speedDrying solid materials with heatDrying machines with progressive movementsSteam condensationMicrowave

The invention discloses rose drying equipment and a method. The rose drying equipment comprises a rose shaping, color fixing and drying device, a rose microwave heating, sterilization and drying device and a rose steam condensation device, and further comprises a gas cyclic heating and drying rose device; the gas cyclic heating and drying rose device comprises a drying box; a rose drying chamber is mounted in the drying box; a support arm is mounted on the top wall of the rose drying chamber; and 10-12 inner circulation heat supply fans arranged on the support device are heating devices for heating the rose drying chamber and rose moisture collecting condensation devices. The rose drying equipment shortens the drying time of rosebuds and rose corollas, improves the drying efficiency, keeps the natural color and the luster of roses, can enable the dried rosebuds and rose corollas to reach consistent inner and outer colors, improves the quality and the grade of the rosebuds and the rose corollas, and improves natural nutritional ingredients and aroma of byproducts-rose cell sap.

Owner:山东芳蕾玫瑰科技开发有限公司

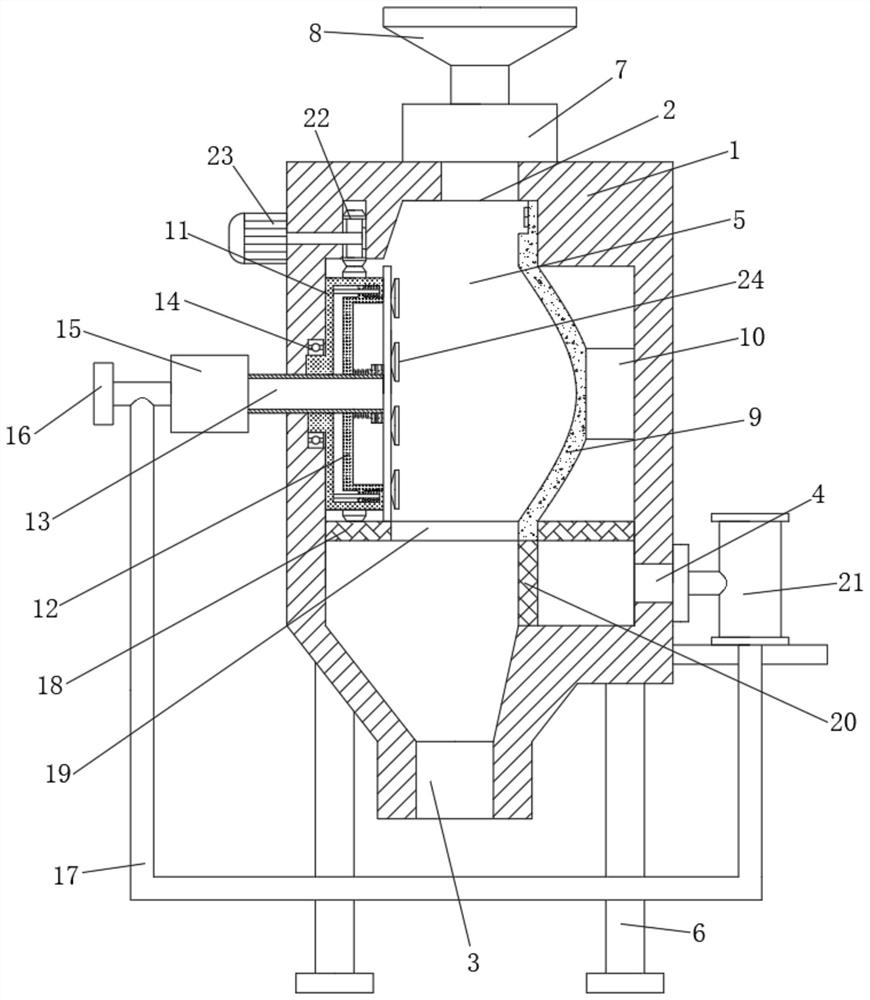

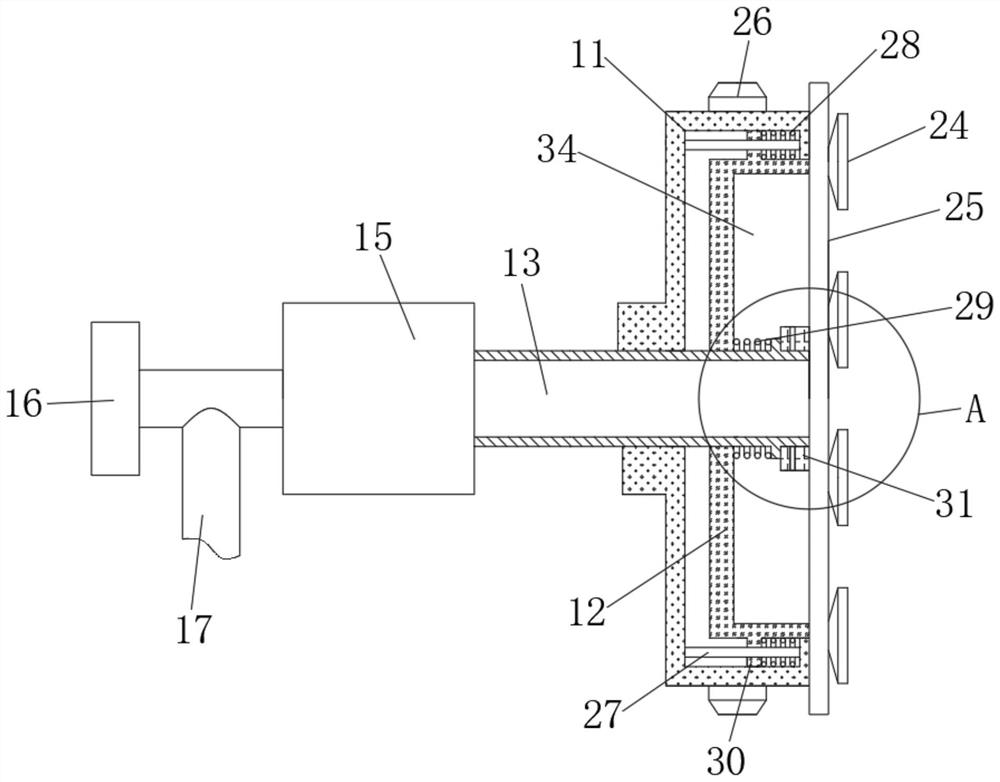

Experimental spray dryer for environment-friendly chemical production

InactiveCN111974012AAchieve rotational jettingFull impact contactGranulation by liquid drop formationEvaporation by sprayingThermodynamicsEngineering

The invention relates to the technical field of spray dryers, in particular to an experimental spray dryer for environment-friendly chemical production. The experimental spray dryer comprises a dryerbody, wherein a feeding hole is formed in the upper end of the dryer body; a discharge hole is formed in the lower end surface of the dryer body; an air outlet is formed in the right lower end of thedryer body; and an inner cavity of the dryer body is arranged to be a drying inner cavity. The experimental spray dryer has the beneficial effects that through cooperation of a gear and a gear ring, rotary jetting of hot air flow is achieved, so that hot air makes full impact contact with atomized liquid, the drying efficiency is greatly improved, and meanwhile, the flow of the hot air is guaranteed through impact between a spring and the pressure intensity of air inlet flow; by arranging transverse through holes and a buffering inner cavity, buffering of the airflow velocity is achieved, theimpact direction is vertical, the airflow is sprayed out of the spray head in an overflow mode, impact on the atomized liquid is reduced, the contact time is prolonged, and the heating and drying efficiency is further improved in cooperation with an arc-shaped heat conduction plate.

Owner:南昌升升科技有限公司

A kind of low-temperature cycle drying equipment and method for roses

ActiveCN106247776BFast heating and dryingReduce heating and drying timeDrying solid materials with heatDrying machines with progressive movementsWaxMicrowave

Owner:山东芳蕾玫瑰科技开发有限公司

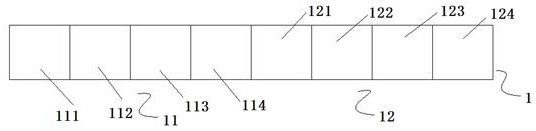

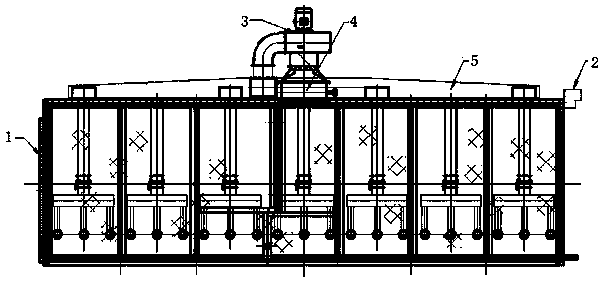

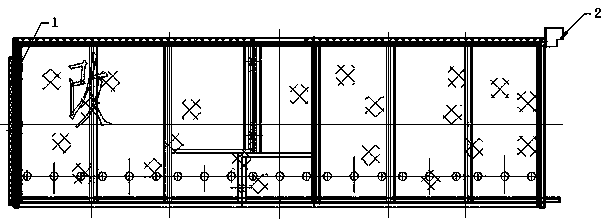

Furniture water paint drying system

ActiveCN110044139AAvoid energy wasteSpeed up evaporationDrying solid materials with heatWood treatment detailsLacquerEngineering

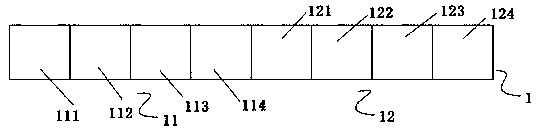

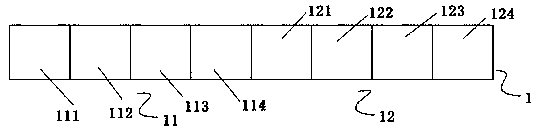

The invention provides a furniture water paint drying system. The furniture water paint drying system comprises a drying chamber and is characterized in that the drying chamber comprises a microwave heating chamber and a hot air convection heating chamber, and the microwave heating chamber and the hot air convection heating chamber are sequentially arranged; the microwave heating chamber comprisesa first microwave heating chamber, a second microwave heating chamber, a third microwave heating chamber and a fourth microwave heating chamber, and the first microwave heating chamber, the second microwave heating chamber, the third microwave heating chamber and the fourth microwave heating chamber are sequentially arranged; the hot air convection heating chamber comprises a first jet flow area,a second jet flow area, a first air convection area and a second air convection area, and the first jet flow area, the second jet flow area, the first air convection area and the second air convection area sequentially arranged; and the microwave heating chamber is a low-temperature area, and the hot air convection heating chamber is a high-temperature area. Compared with traditional heating anddrying by an oven, the heating and drying efficiency of the furniture water paint drying system is improved by dozens of times, more water is discharged from each heating and drying process, even thewater which is not exhausted in the previous processes can be discharged, so that the drying of surface paint of the furniture is further guaranteed.

Owner:惠州左右家私有限公司

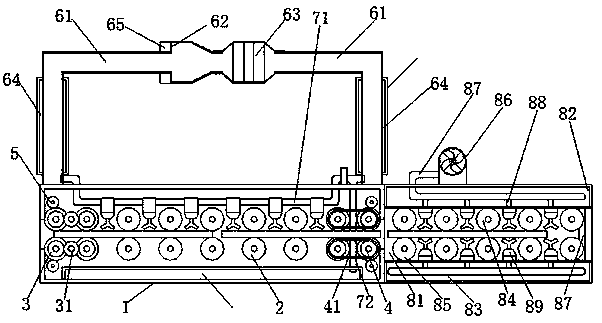

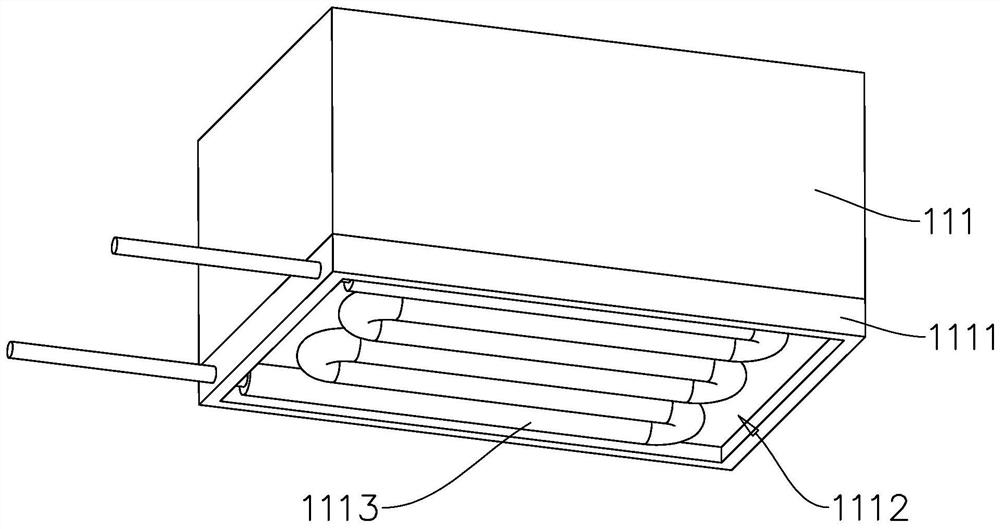

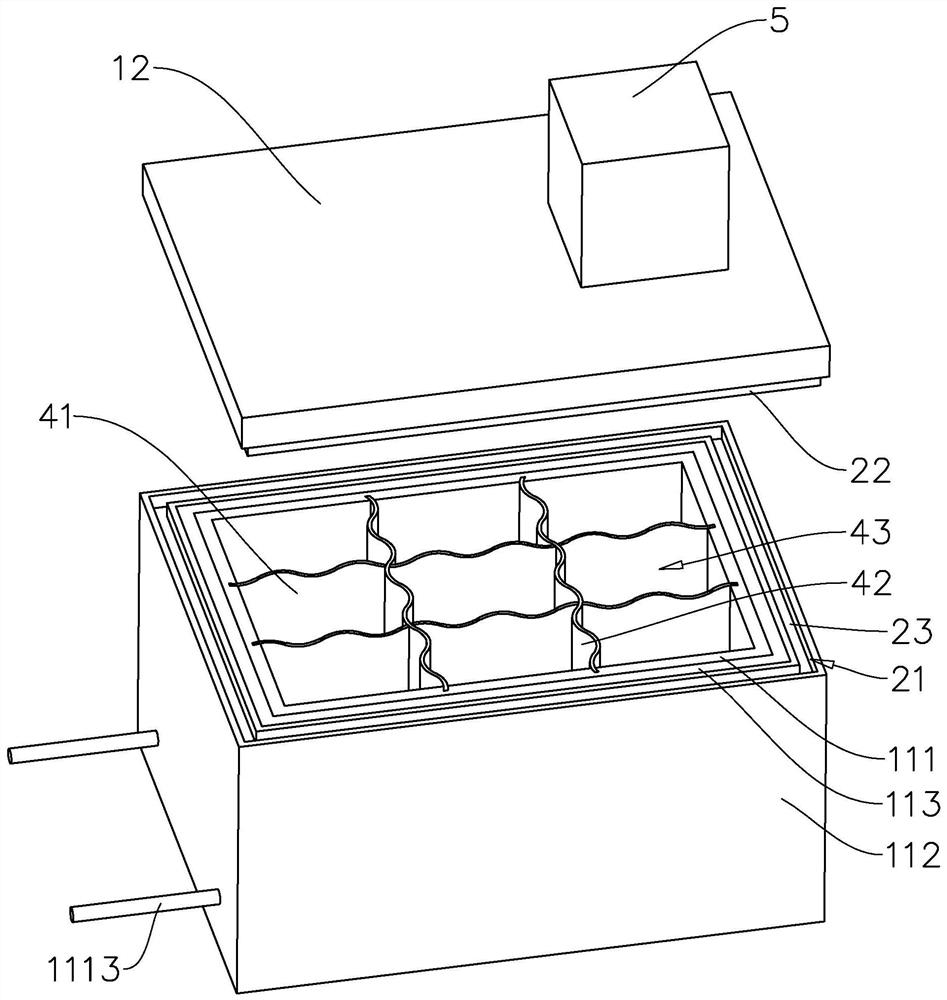

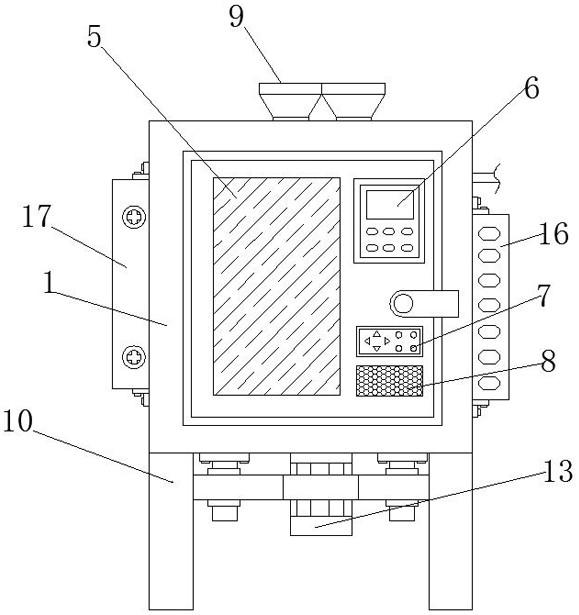

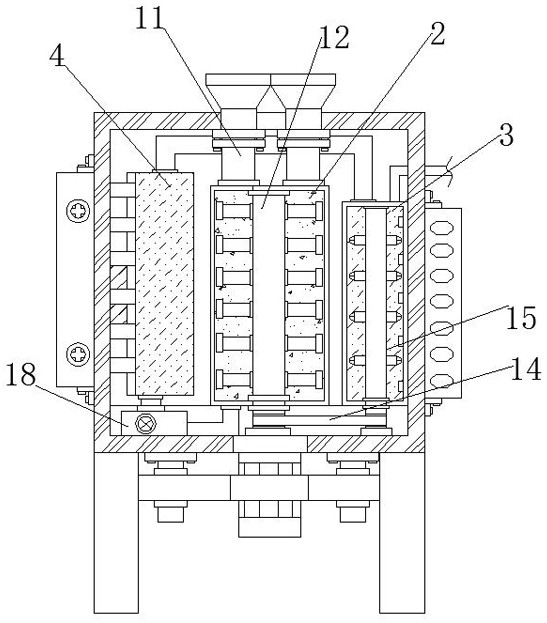

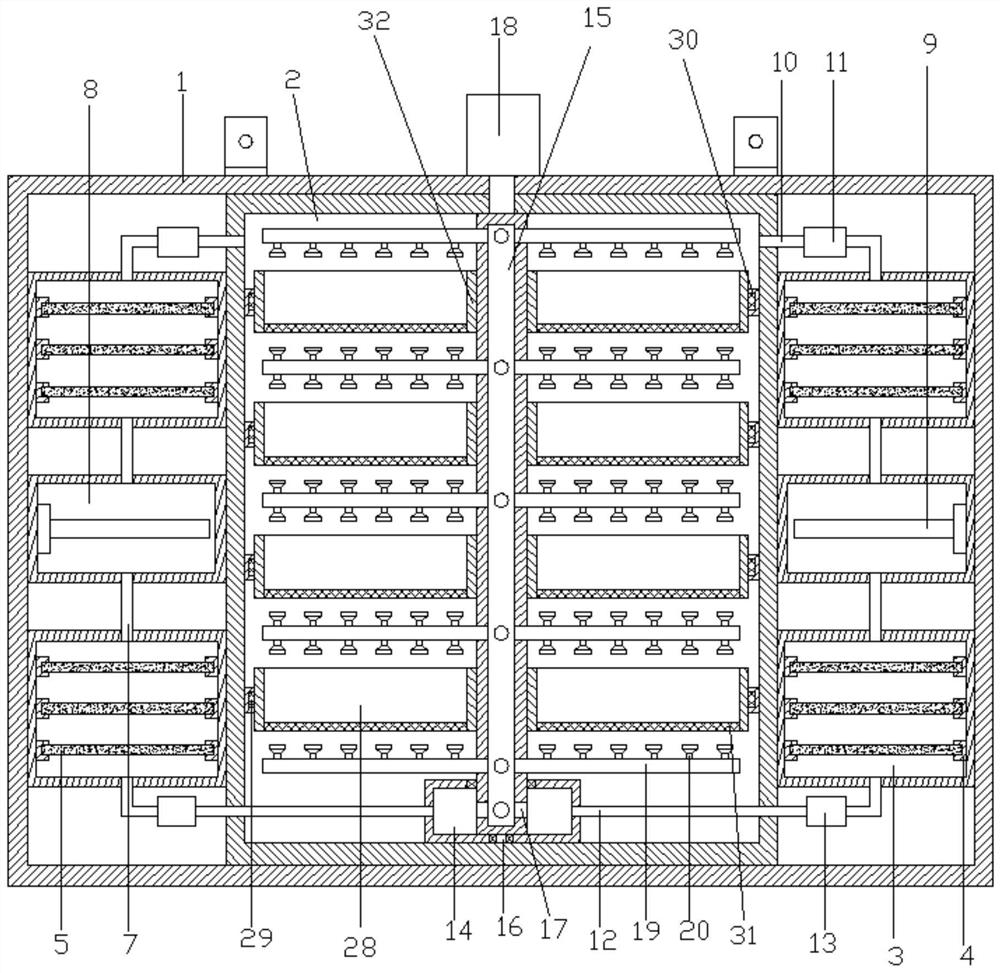

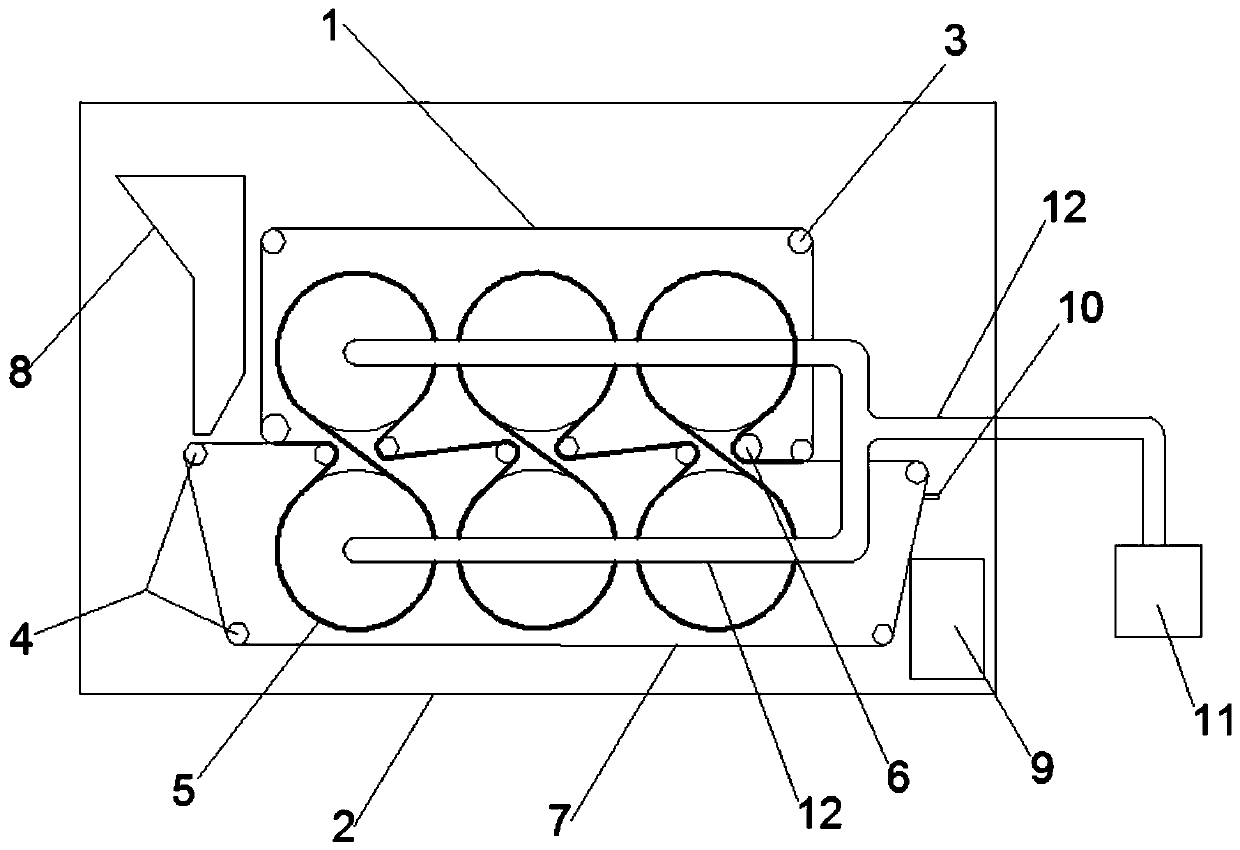

Oil heating single cabinet type battery vacuum intelligent drying equipment and drying method

ActiveCN112880314AFast heating rateImprove utilization efficiencyDrying solid materials without heatDrying chambers/containersHeating oilBattery cell

The invention relates to oil heating single cabinet type battery vacuum intelligent drying equipment and a drying method. The oil heating single cabinet type battery vacuum intelligent drying equipment comprises a drying box, a vacuum device and a heating oil tank. The drying box is provided with a heat-conducting plate which is provided with a mounting groove, and a heat conduction pipe is arranged in the mounting groove. The vacuum device is connected to the drying box and used for vacuumizing the drying box. The heating oil tank is provided with a heating oil cavity, heating oil is contained in the heating oil cavity, a heater is arranged in the heating oil cavity to heat the heating oil, the heating oil tank is provided with a heating oil inlet and a heating oil outlet, an oil pump is arranged at the heating oil outlet, the oil pump is provided with an oil pumping port and an oil feeding port, and the oil pumping port communicates with the heating oil outlet. The heat conduction pipe is provided with a heat conduction oil inlet and a heat conduction oil outlet, the heat conduction oil inlet communicates with the oil feeding port through a first oil pipe, the heat conduction oil outlet communicates with the heating oil inlet through a second oil pipe, and the oil pump drives heat conduction oil to circulate between the drying box and the heating oil tank. The oil heating single cabinet type battery vacuum intelligent drying equipment and the drying method have the effect of improving the heating and drying benefits of batteries.

Owner:深圳市鹏翔运达机械科技有限公司

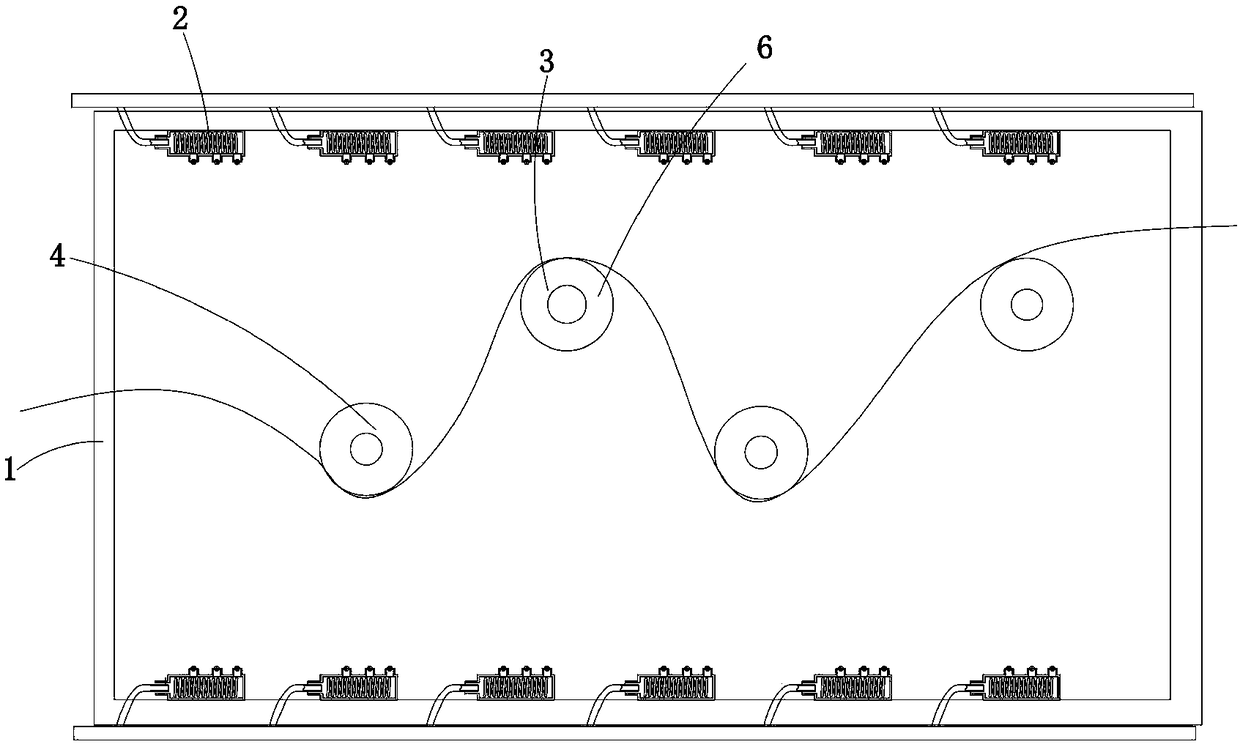

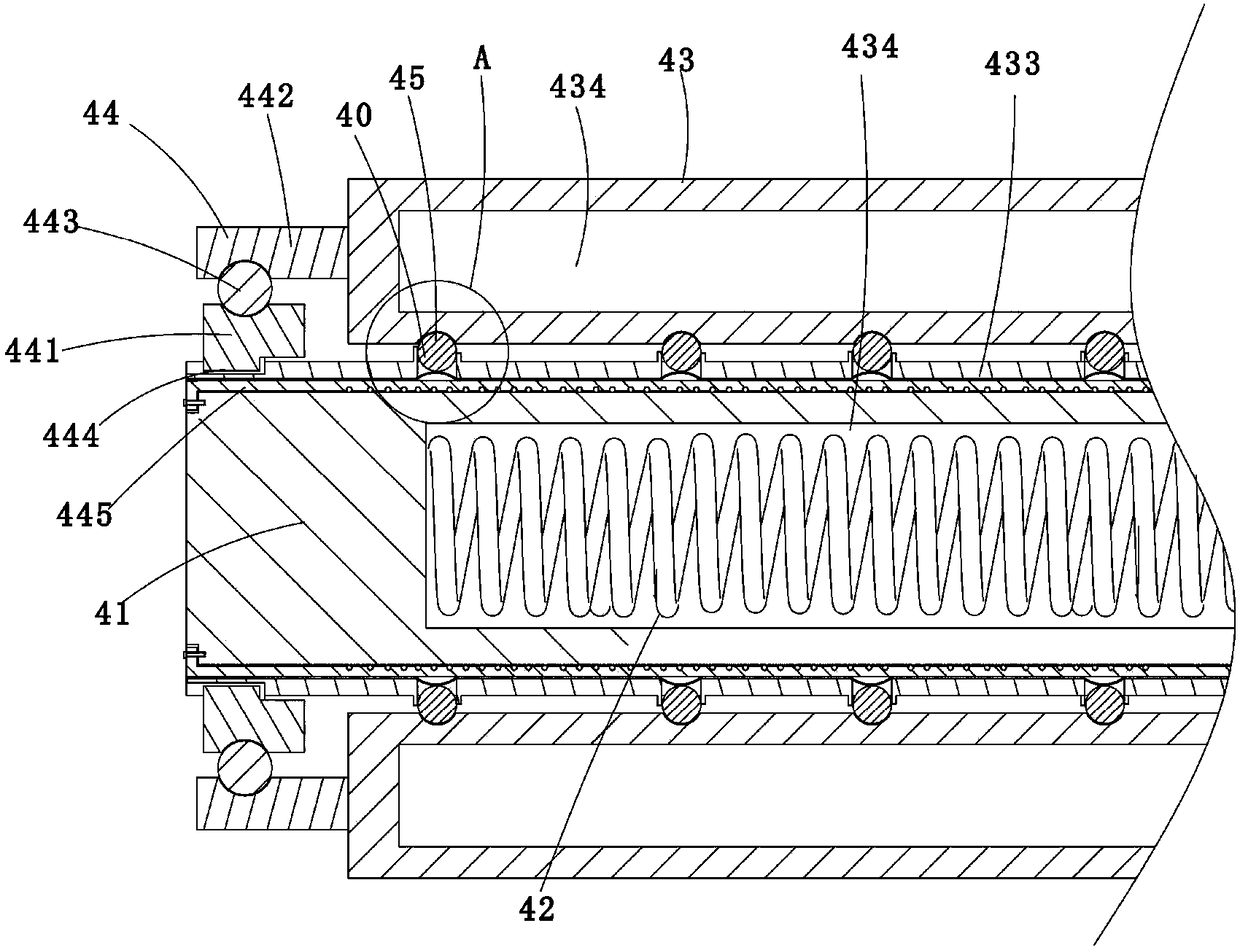

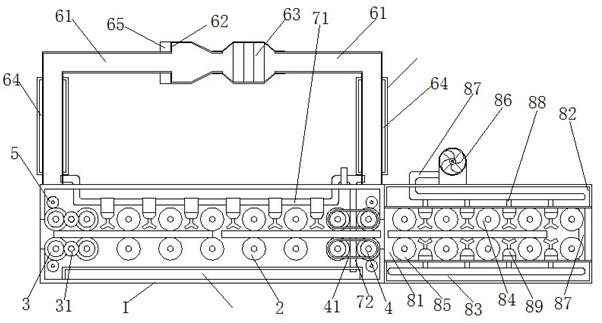

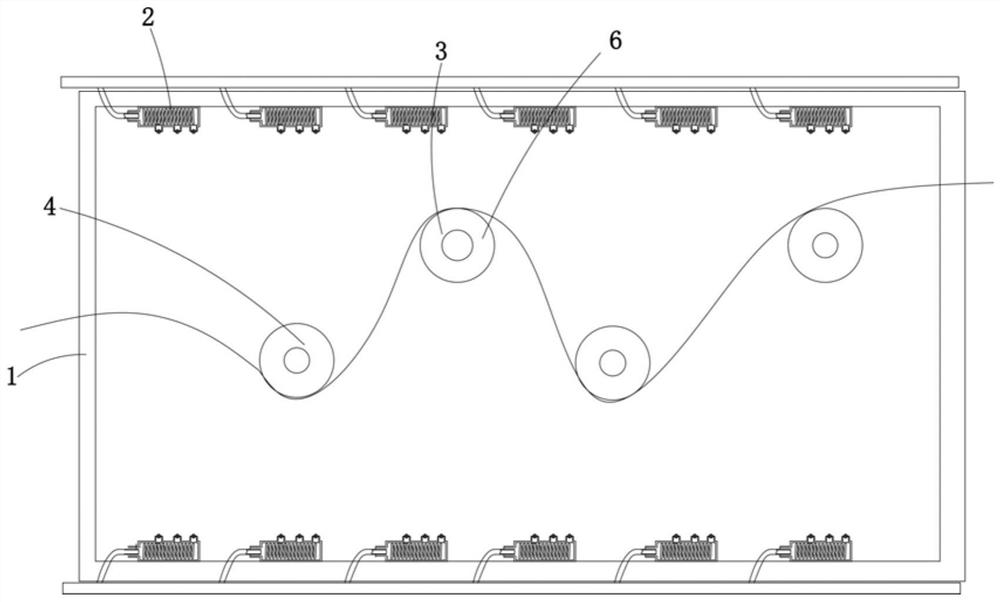

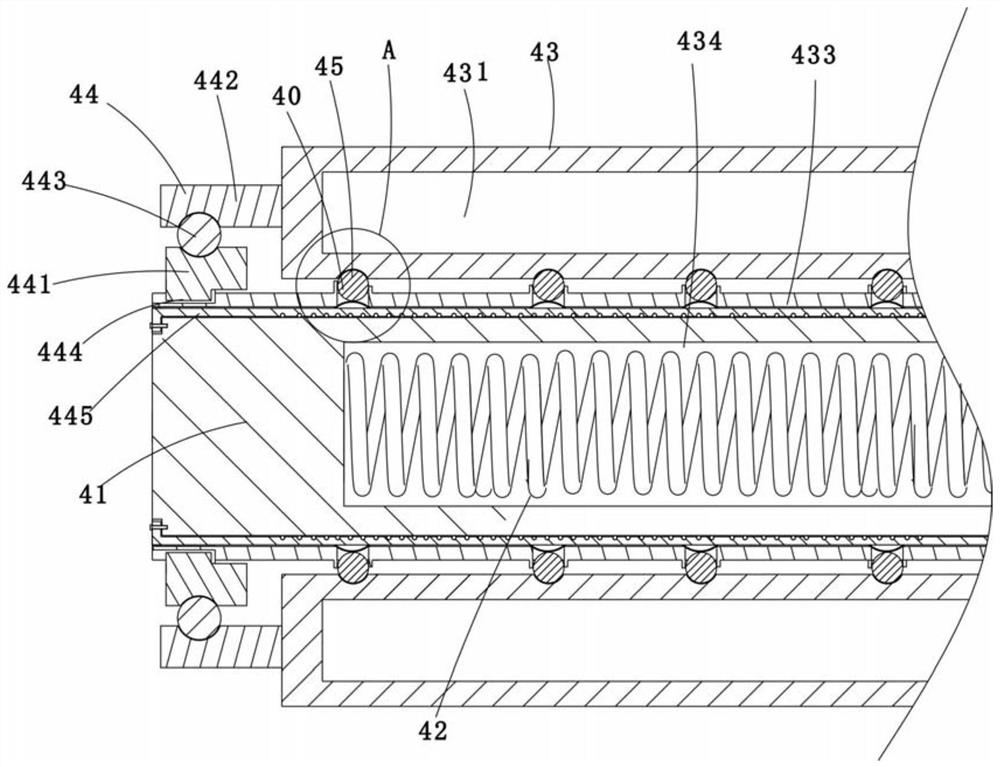

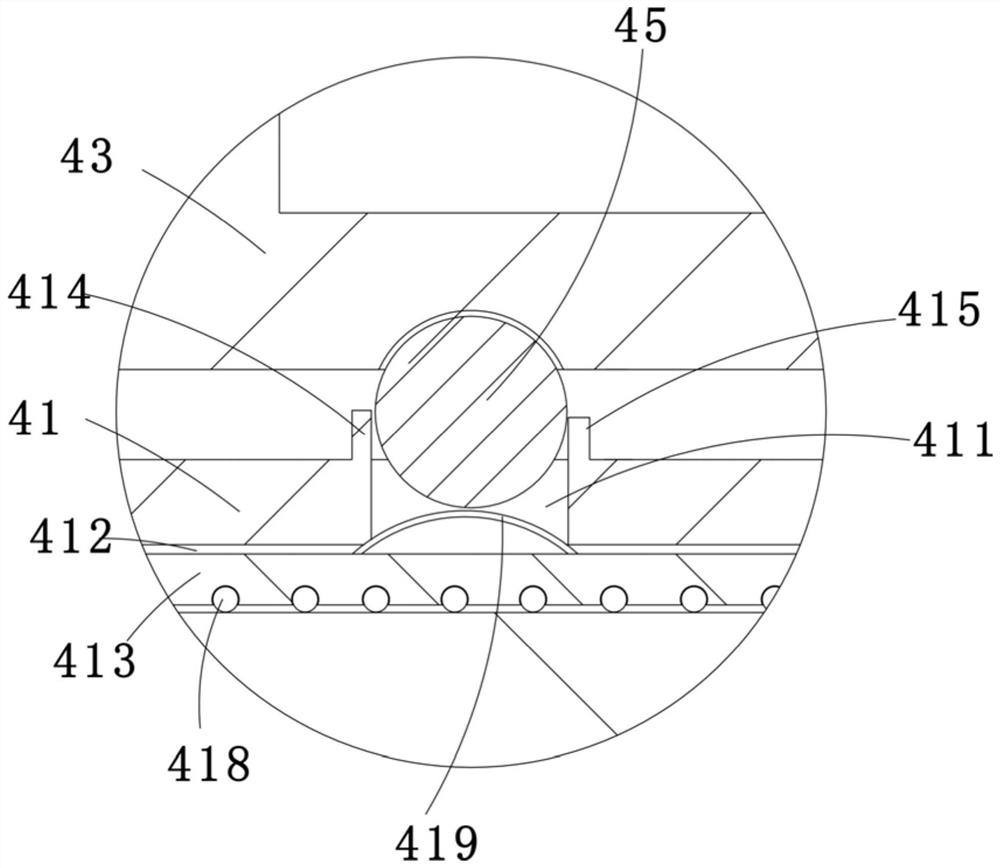

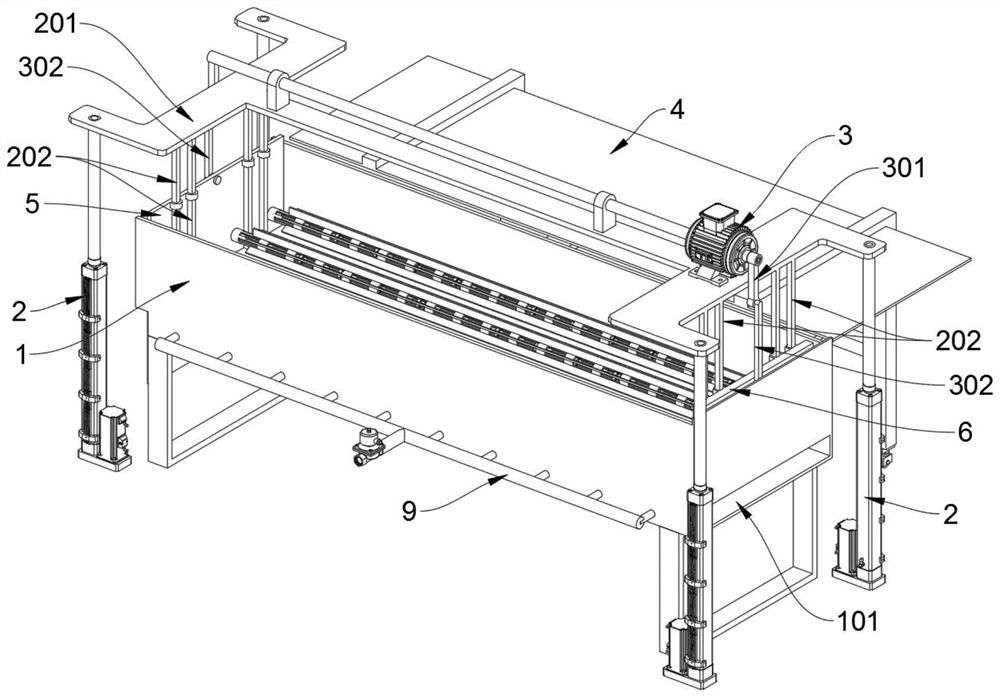

Cloth drying mechanism

ActiveCN108317839AIncrease temperatureImprove heating and drying efficiencyDrying machines with progressive movementsHeating arrangementEngineeringMechanical engineering

The invention discloses a cloth drying mechanism. The cloth drying mechanism comprises a box, heating devices arranged in the box and a cloth supporting device used for supporting cloth. The cloth supporting device comprises a driving roll component and a driven roll component capable of heating the cloth. The driven roll component comprises a heat transfer roll, a heating part arranged on the heat transfer roll in a penetration mode and a cloth guide roll rotatably arranged on the heat transfer roll in a sleeving mode. According to cloth drying mechanism, the driven roll component can be usedfor heating the cloth to increase the temperature of the cloth; the distance between the cloth drying mechanism and the cloth is small in the heating process; the cloth drying mechanism is centralized in temperature and good in heat transfer effect; the thermal utilization rate of a driven roll is increased; the cloth heating and drying efficiency is improved; the cloth drying mechanism has a lowrequirement for the temperature in a box, and energy can be saved effectively.

Owner:陈方玲

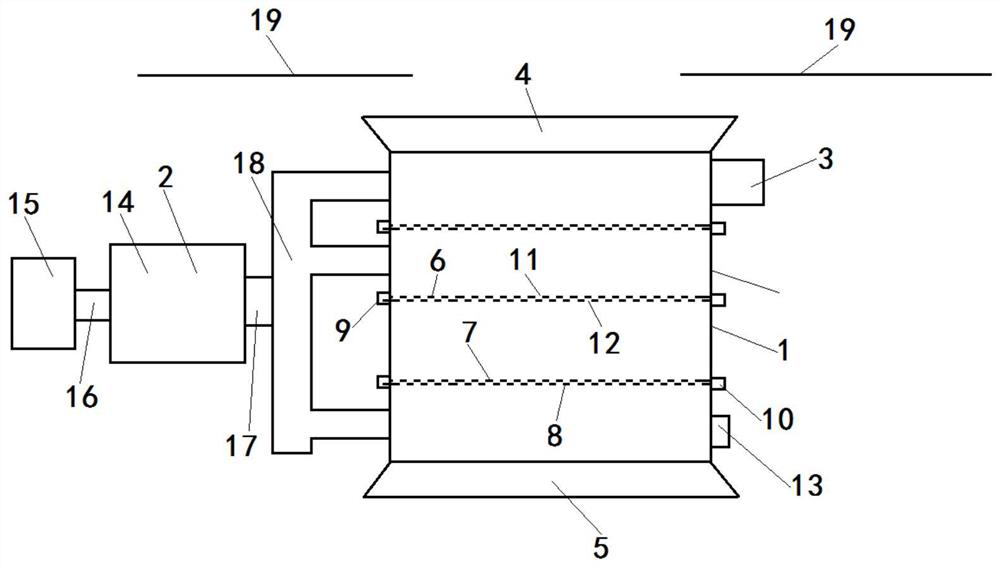

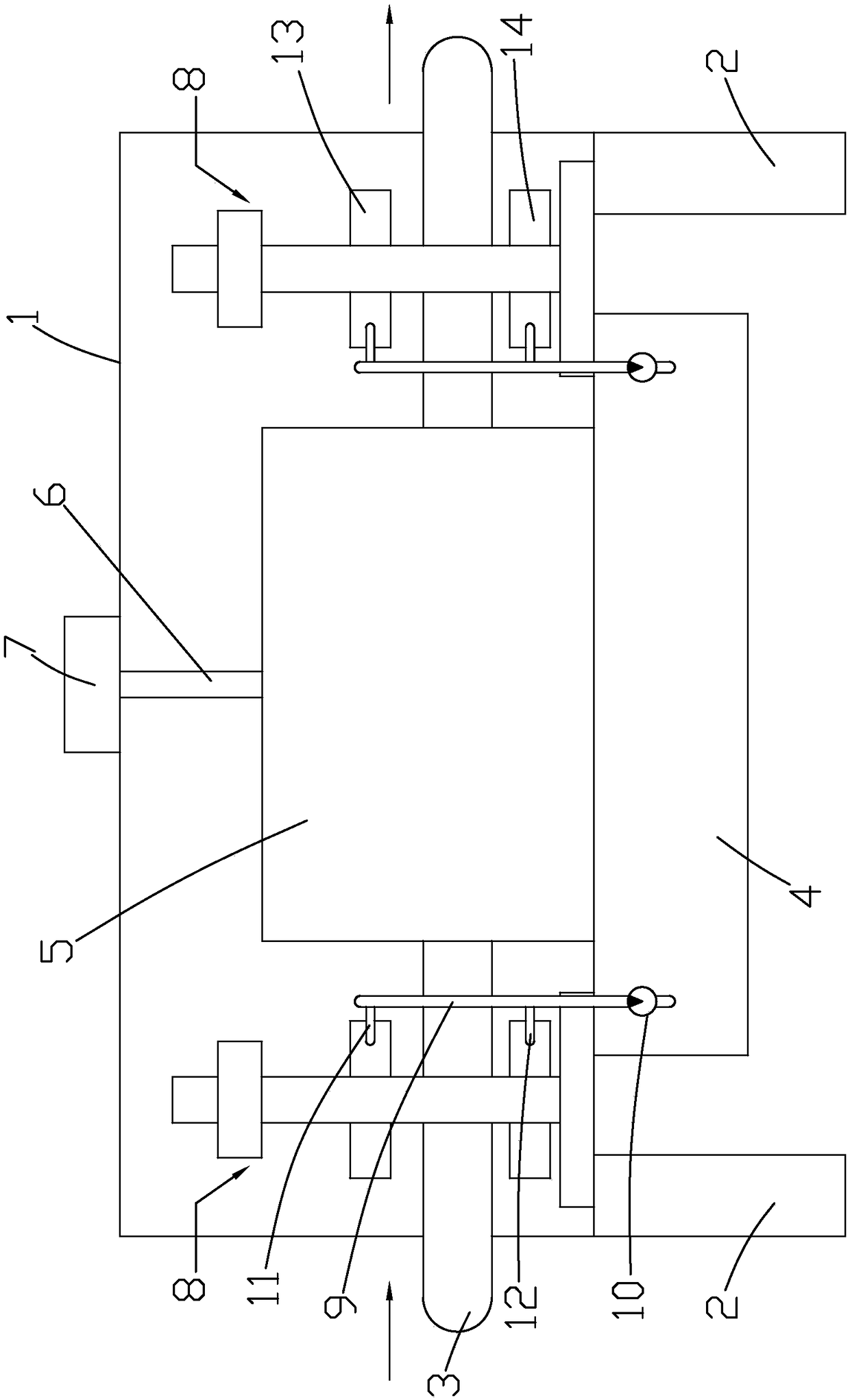

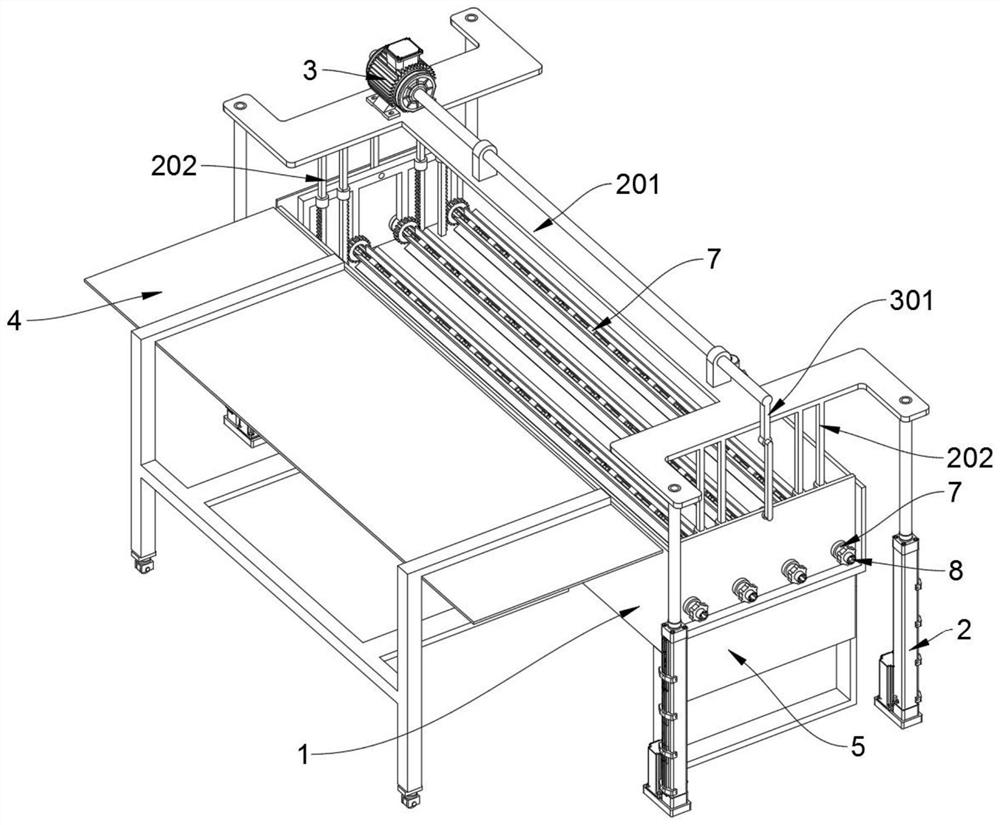

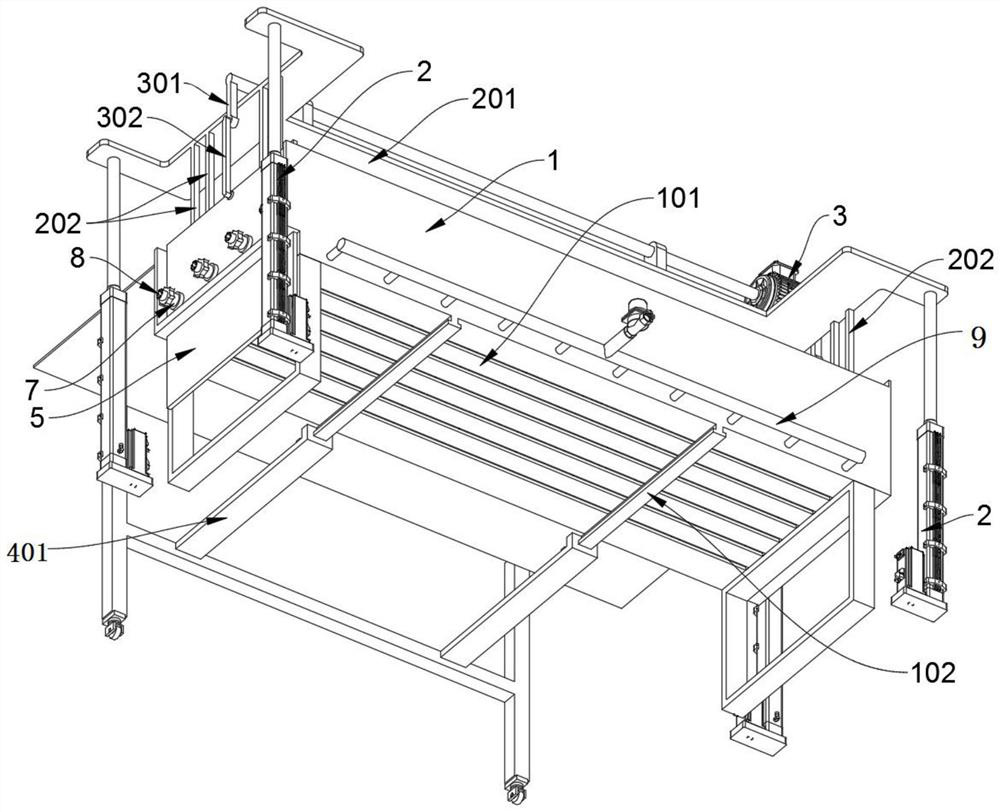

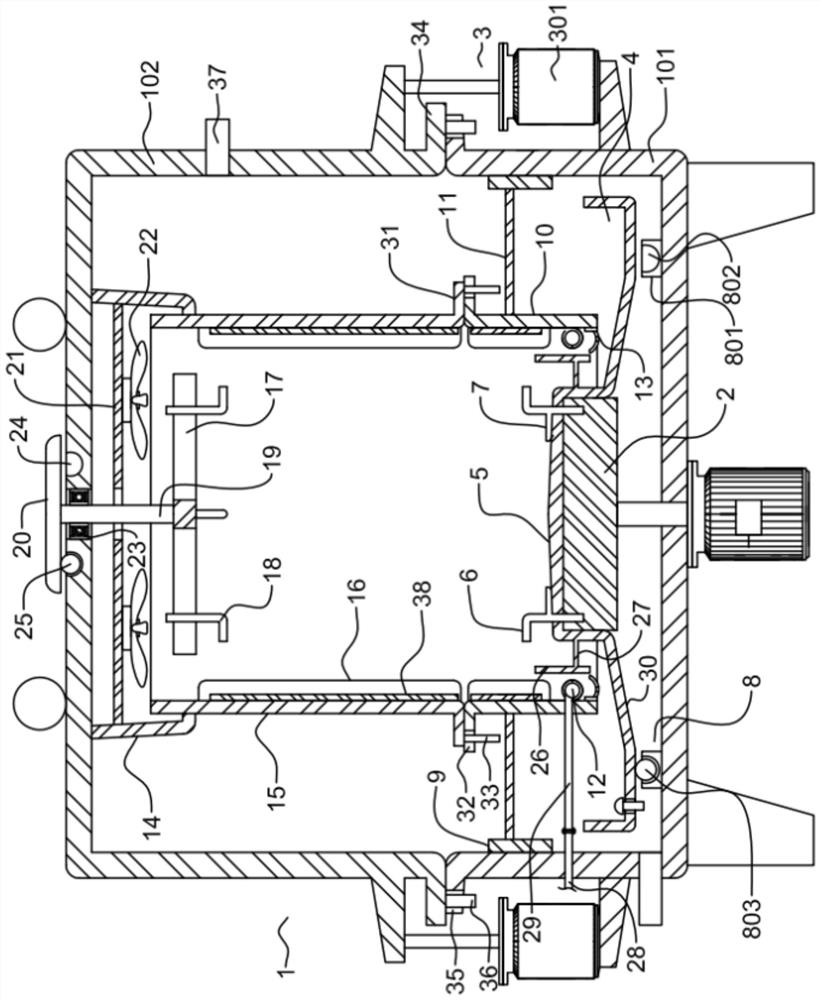

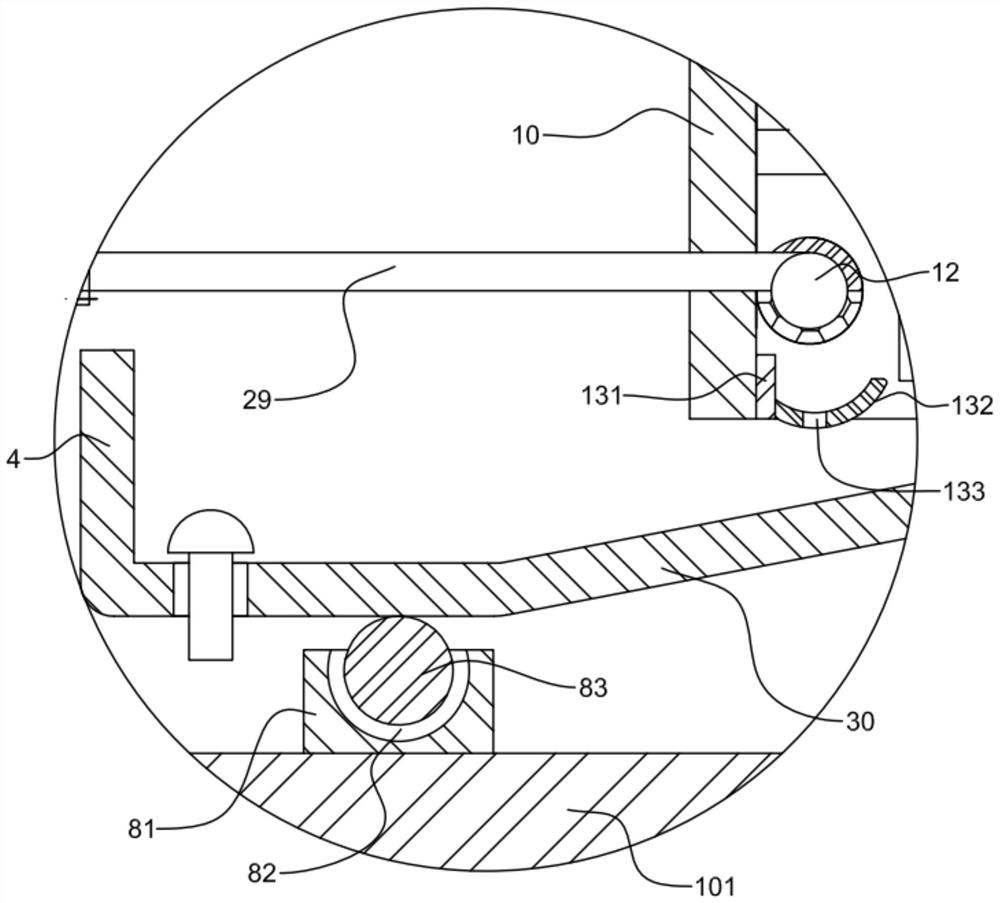

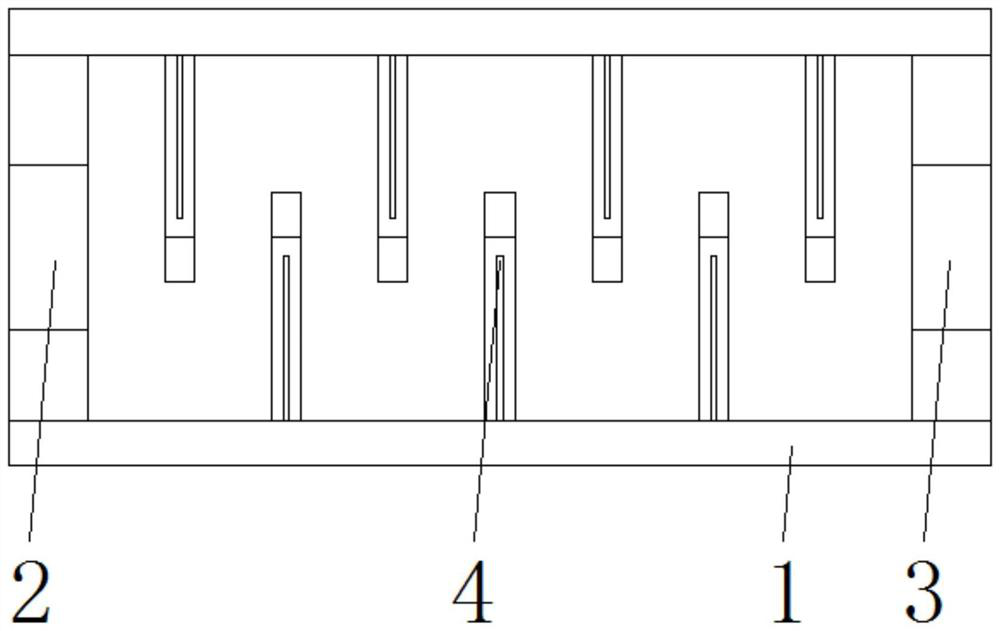

Intelligent food processing and drying system

InactiveCN111854403AIncrease temperatureMeet needsDrying gas arrangementsDrying solid materialsAgricultural engineeringMechanical engineering

The invention provides an intelligent food processing and drying system applied to the technical field of nut production. The upper part of a drying furnace body (1) of the intelligent food processingand drying system is provided with a feeding channel (4), the lower part of the drying furnace body (1) is provided with a discharging channel (5), a receiving plate (6) is set inside the drying furnace body (1), a fixed plate (7) of the receiving plate (6) is fixedly connected to the inner wall of the drying furnace body (1), one side of a movable plate (8) is clamped in a groove (9) on one sideof the drying furnace body (1), the other side of the movable plate (8) is connected to a telescopic cylinder (10) on the inner wall of the other side of the drying furnace body (1), the fixed plate(7) is provided with multiple slots I (11), and the movable plate (8) is provided with multiple slots II (12). The intelligent food processing and drying system provided by the invention has a simplestructure, and effectively improves the drying efficiency of nuts while being convenient and reliable to achieve reliable drying of nuts, thereby meeting the actual needs of food manufacturers.

Owner:ANHUI THREE SQUIRRELS ELECTRONICS BUSINESS

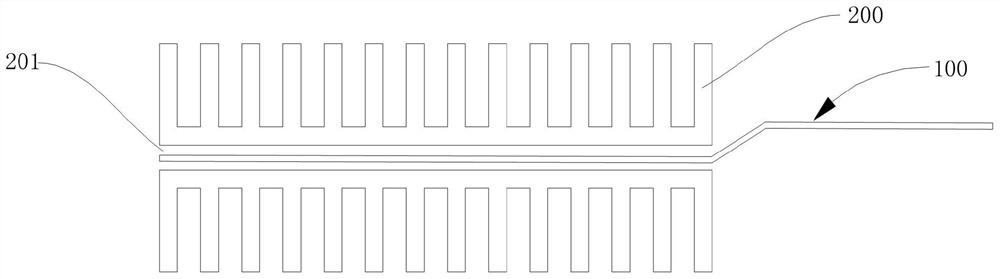

Floor sweeping robot and heating module thereof

PendingCN113384195AFast deliveryAvoid concentrationMachine detailsCleaning equipmentEngineeringHeating film

The invention relates to a heating module. The heating module comprises a heating film and a plurality of heat dissipation pieces, the heat dissipation pieces are arranged at intervals, a gap is formed between every two heat dissipation pieces, and the heating film is sequentially wound in the gaps. The heating film and the heat dissipation pieces are arranged, the heat dissipation pieces are sequentially arranged, the gaps are reserved between the heat dissipation pieces, the heating film is sequentially wound in the gaps, heat generated by the heating film can be quickly transferred to the heat dissipation pieces by electrifying and heating the heating film, the heat can be quickly diffused into the environment through the heat dissipation pieces, the heat transfer speed is high, the heating and drying efficiency of the heating module is greatly improved, heat concentration of the heating module is avoided, the phenomenon of local overheating is avoided, normal work of the heating module is guaranteed, and when the heating module is installed on a floor sweeping robot, the cleaning efficiency can be greatly improved.

Owner:张立强

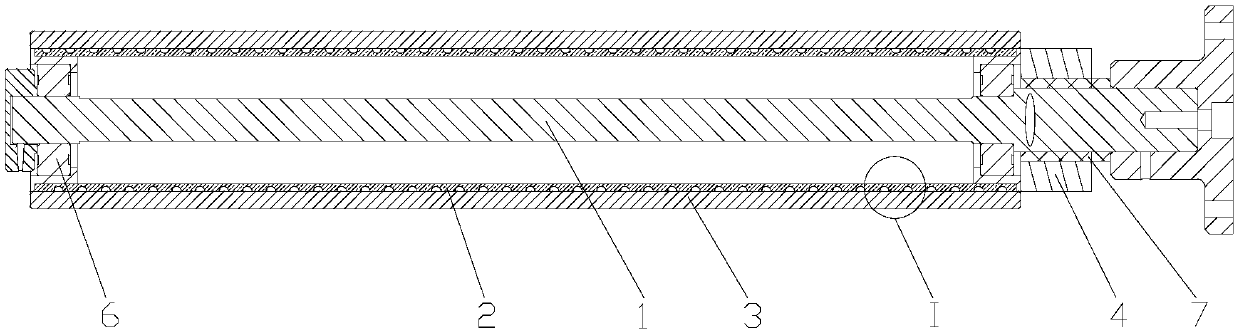

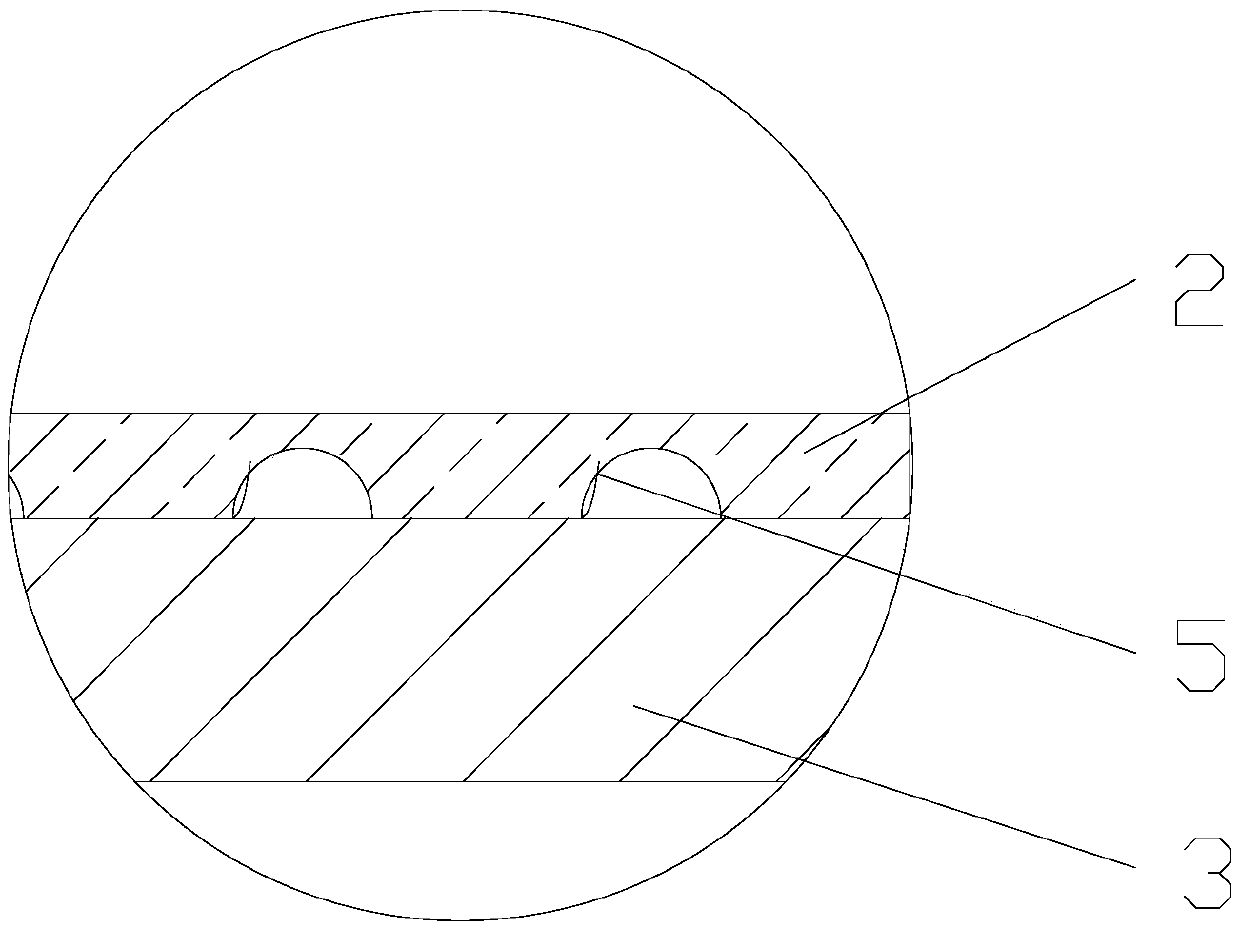

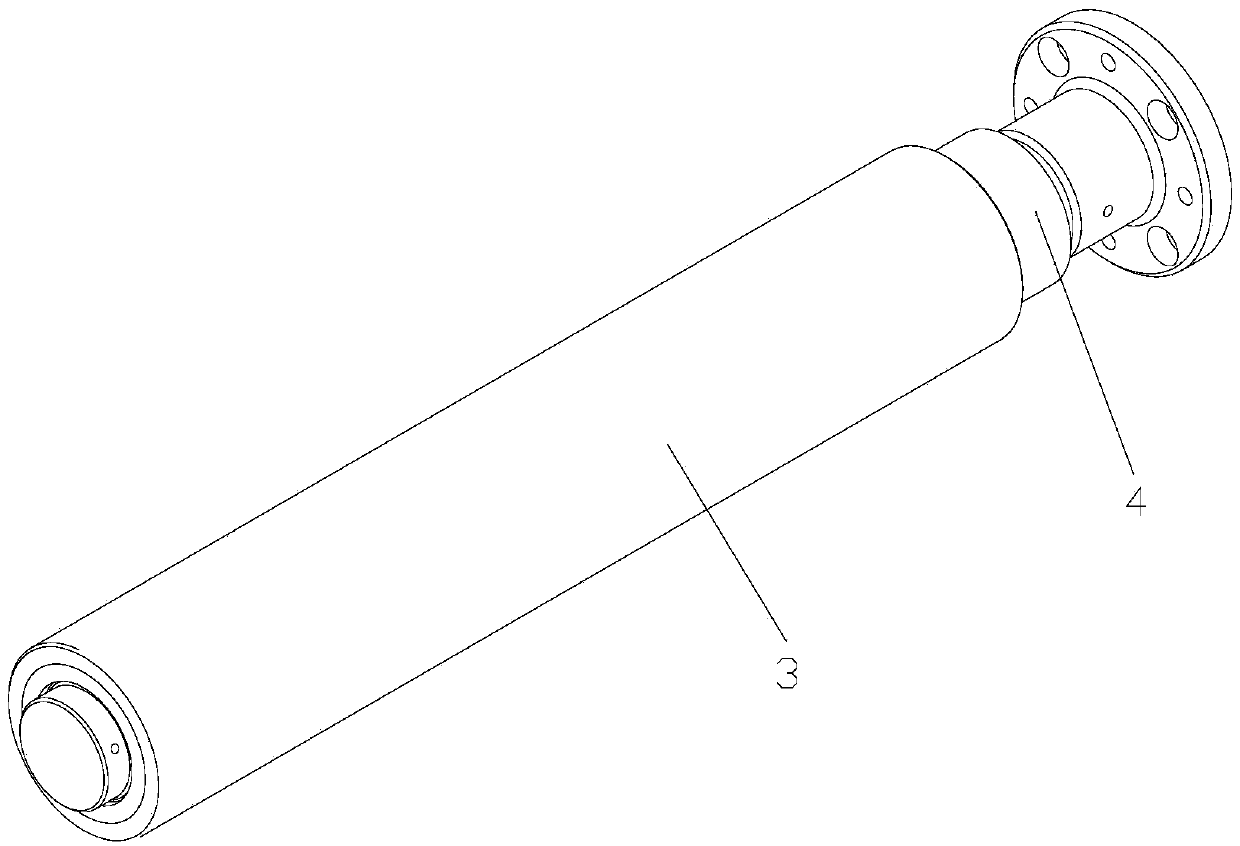

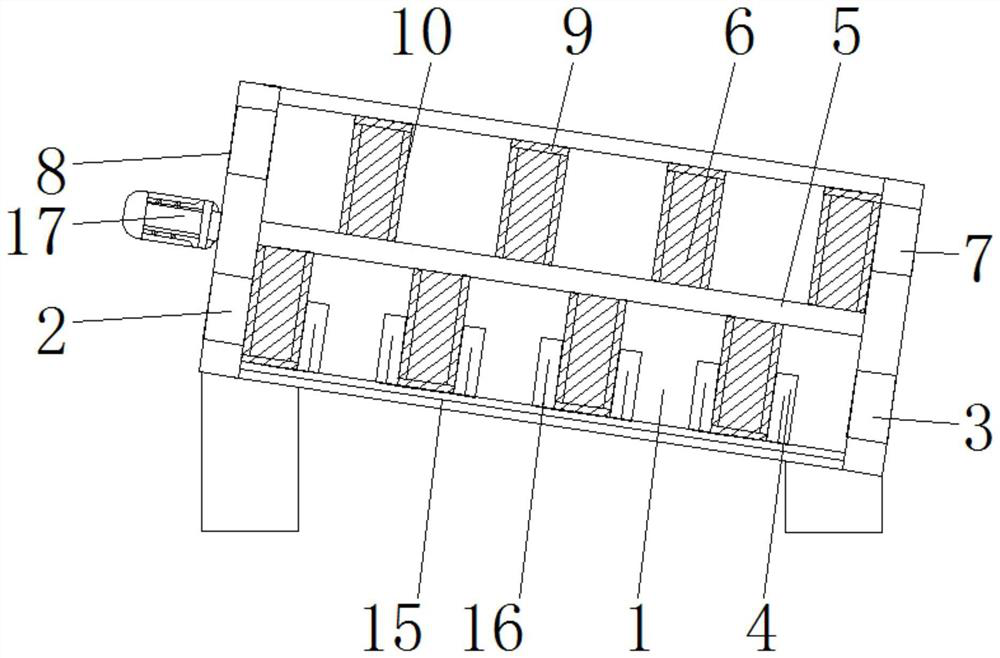

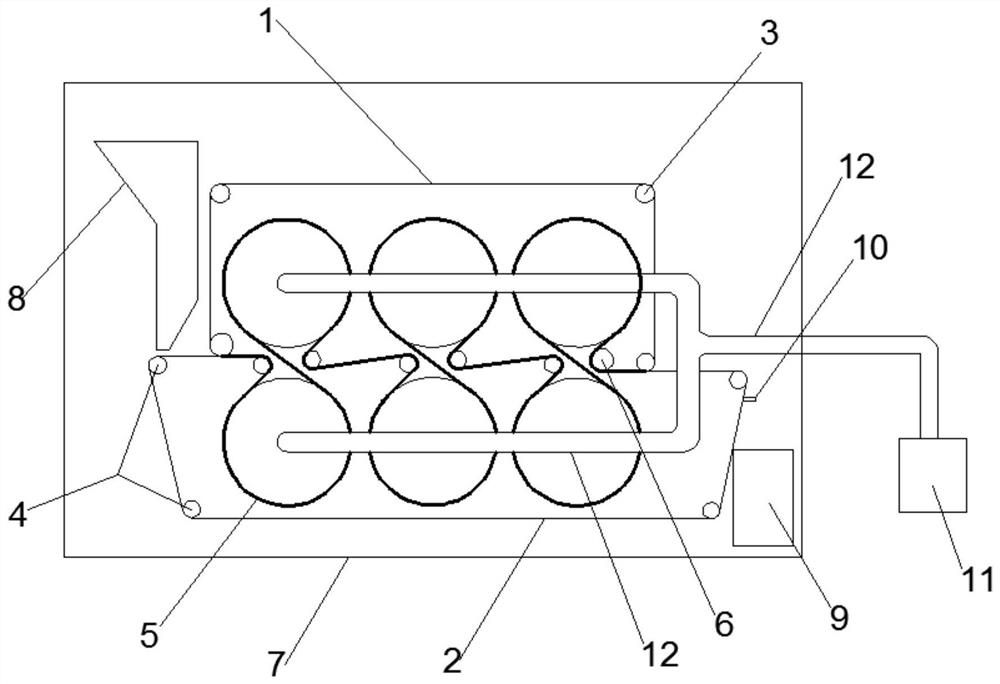

Automatic heating battery cell diaphragm rotary shaft device

PendingCN109539744AMeet drying requirementsReal-time control of heating and drying effectsDrying machines with progressive movementsCell component detailsPower batteryEngineering

The invention discloses an automatic heating battery cell diaphragm rotary shaft device. The automatic heating battery cell diaphragm rotary shaft device comprises a center shaft, a heating shaft, anouter shaft, a rotary conducting ring, heating wires and a controller, wherein two ends of the center shaft are fixed; the heating shaft is arranged on the center shaft in a sleeving mode; the two ends of the heating shaft are connected to the center shaft separately through a bearing; the heater wires are wound around outer circumference of the heating shaft; the outer shaft is fixedly connectedwith the heating shaft in a sleeving mode; the rotary conducting ring at one side of the outer shaft sleeves and is connected with the center shaft; the heater wires and the controller are respectively connected with the rotary conducting ring by signals. The advantages of the automatic heating battery cell diaphragm rotary shaft device are that through arrangements of the heating shaft and the heater wires and allocation of the rotary conducting ring, the battery cell diaphragm can be heated and dried synchronously while being wound around the automatic heating battery cell diaphragm rotary shaft device, so that the processing step of placing the battery cell diaphragm in an oven or low-humidity room for dewatering and drying is omitted, the production time of power batteries is shortenedto a great extent and production efficiency is improved.

Owner:ZHENJIANG CINNIC AUTOMATIC TECH CO LTD

Material drying unit

InactiveCN111023778AAvoid breakingGuaranteed qualityDrying solid materials with heatDrying gas arrangementsEngineeringAtmospheric sciences

The invention relates to a material drying unit, which comprises a hot air drying region and a cold air drying region. The hot air drying region is used for drying the materials by means of hot air; the cold air drying region is used for drying the materials by means of cold air; and a tempering region is arranged between the hot air drying region and the cold air drying region, and is used for buffering the temperature change from the hot air drying region to the cold air drying region or from the cold air drying region to the hot air drying region. Through setting the hot air drying region and the cold air drying region for drying materials by means of hot air and cold air correspondingly, and setting the tempering region between the hot air drying region and the cold air drying region,the materials pass through the tempering region firstly and then enter the hot air drying region after coming out of the cold air drying region, the temperature of the materials can be buffered in thetempering region to adapt to temperature changes, the materials are prevented from being overheated in the hot air drying region, and the quality of agricultural products is guaranteed.

Owner:河南省农业科学院农副产品加工研究中心

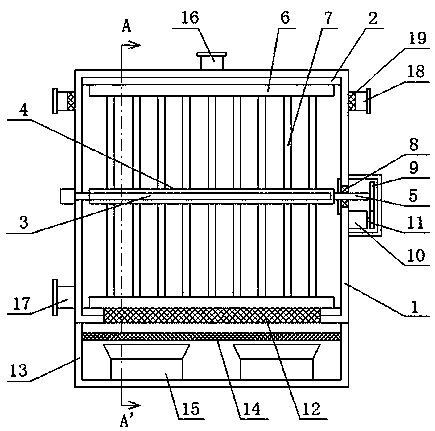

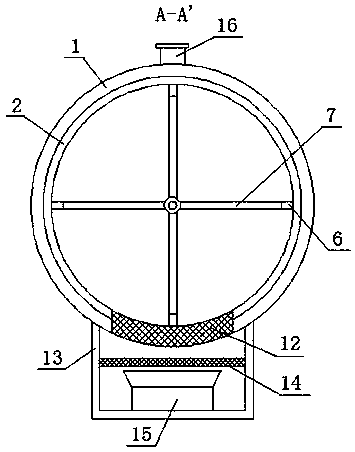

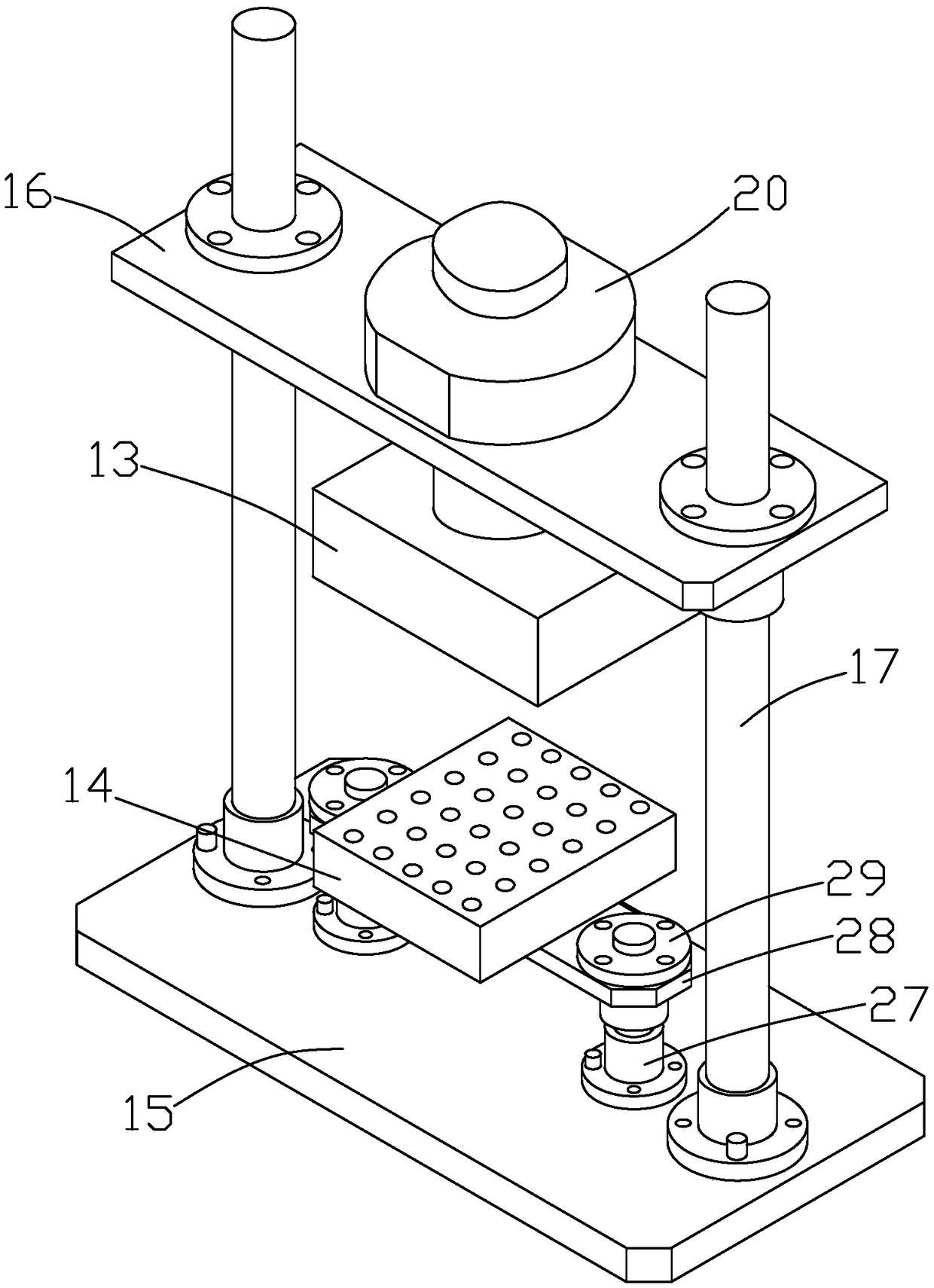

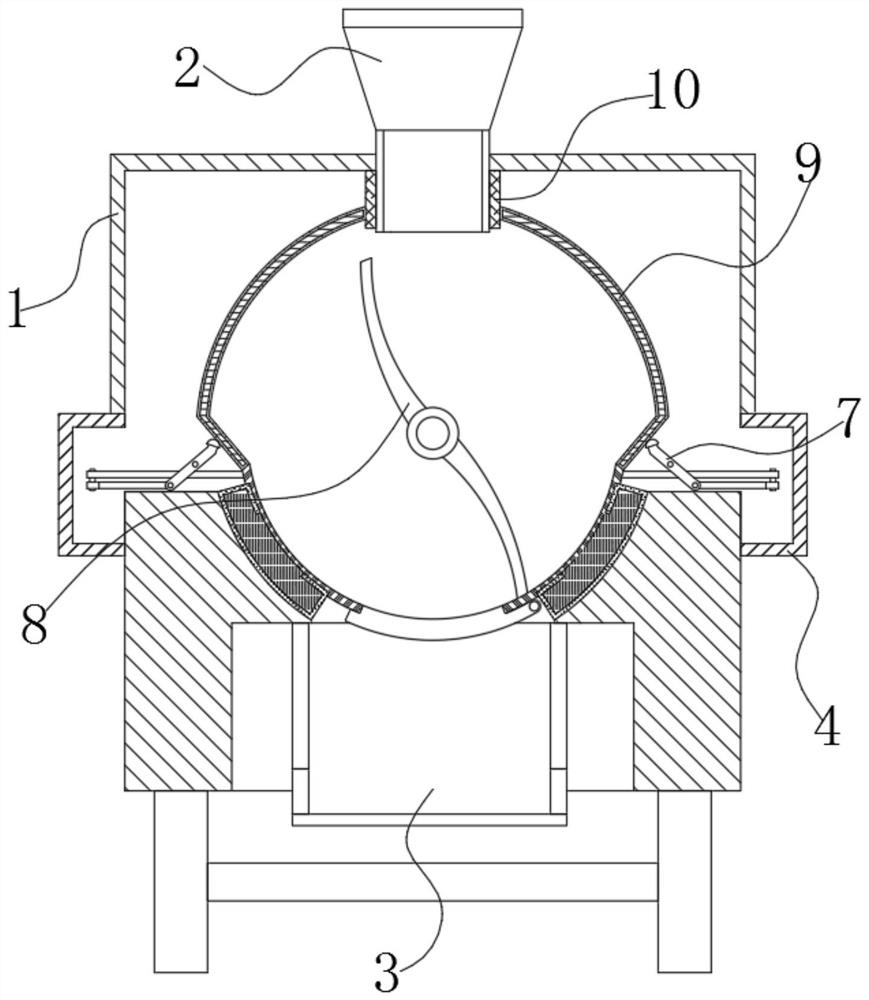

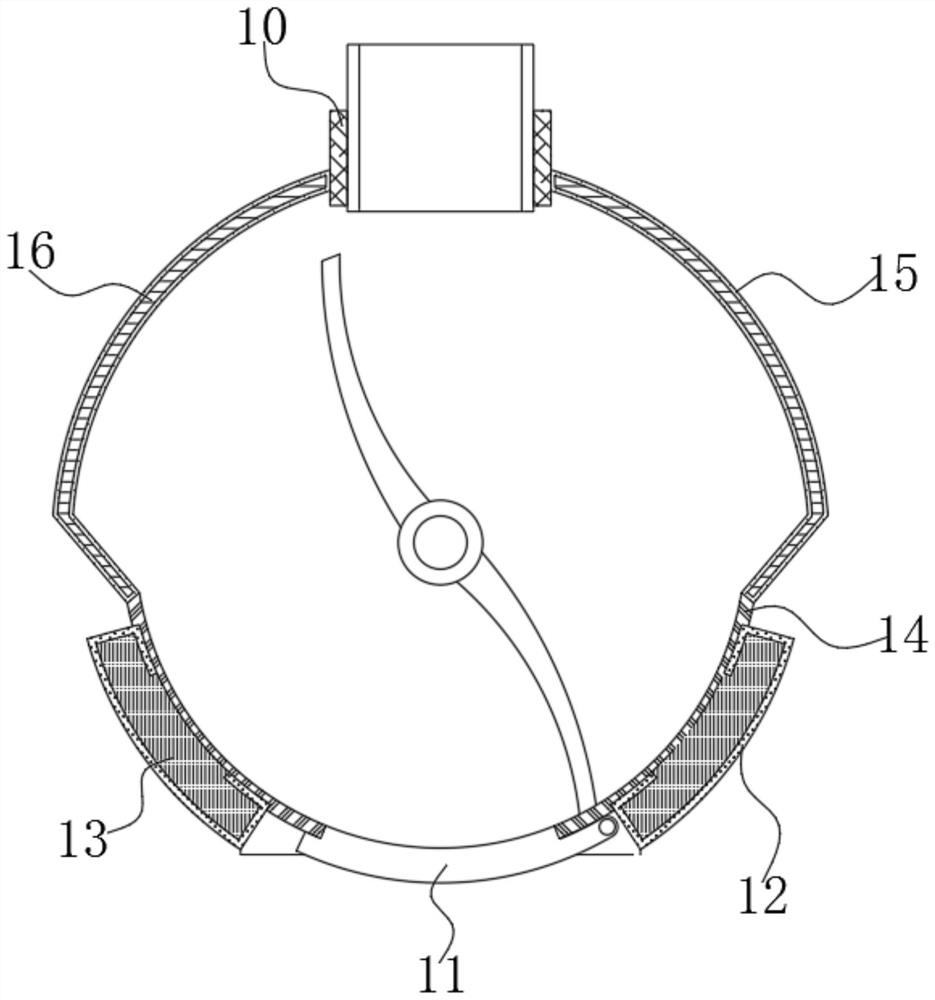

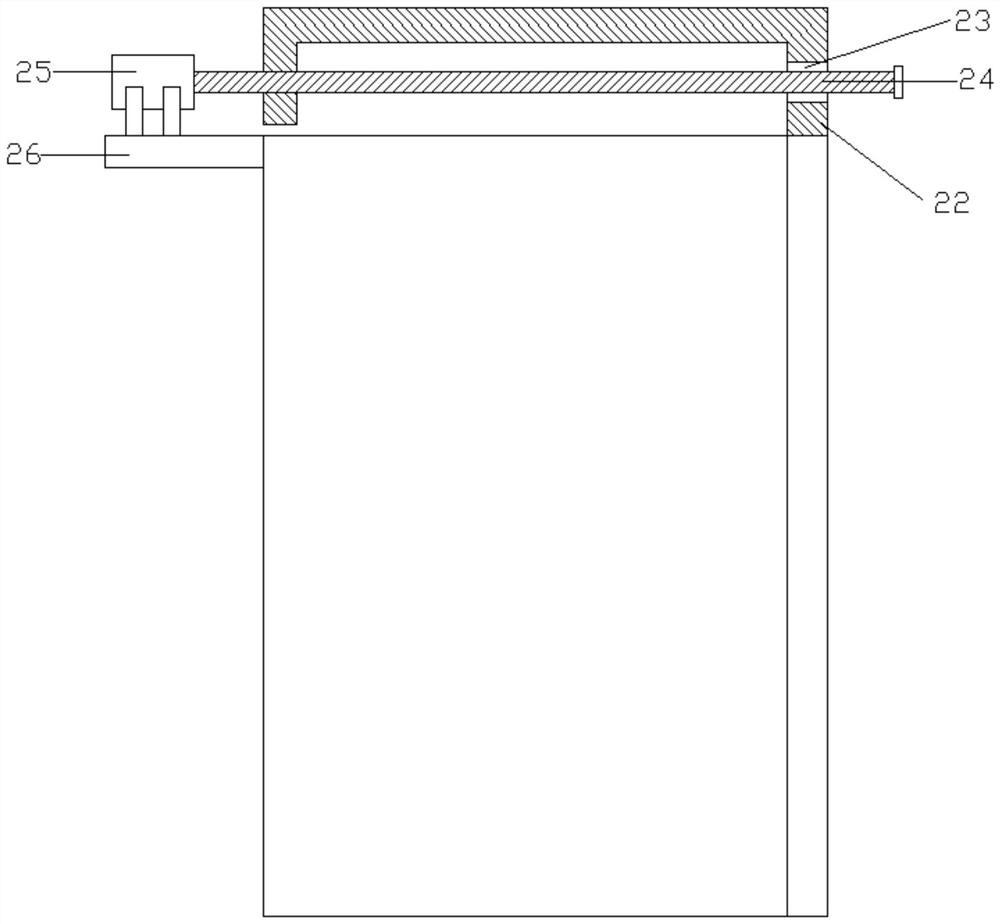

Drying device for pidotimod bulk pharmaceutical chemicals

InactiveCN108981332AHeating and dryingImprove heating and drying efficiencyDrying gas arrangementsDrying solid materialsEngineeringAir blower

The invention provides a drying device for pidotimod bulk pharmaceutical chemicals. The drying device comprises a hot cylinder drying assembly and a hot air drying assembly which are arranged up and down; the hot cylinder drying assembly comprises a drying tank, a drying cylinder is arranged in the inner cavity of the drying tank, a heat turning and shoveling assembly is further arranged in the middle of the drying tank, and the heat turning and shoveling assembly comprises a heating rod and a heat conduction rotating sleeve; and the hot air drying assembly comprises a cover body, a filter screen plate is arranged in the cover body, and hot air blowers are arranged below the filter screen plate. The drying device has the advantages that the drying cylinder can be used for heating and drying the bulk pharmaceutical chemicals, heat conduction shovel plates in the heat turning and shoveling assembly can stir-fry the bulk pharmaceutical chemicals continuously, so that the bulk pharmaceutical chemicals are scattered, then the bulk pharmaceutical chemicals can fully perform heat exchange with the drying cylinder, moreover, the heating rod in the heat turning and shoveling assembly is used for enabling the heat conduction shovel plates to heat and dry the bulk pharmaceutical chemicals while the heat conduction shovel plates turn and shovel the heat conduction shovel plates through heat conduction, and then the heating and drying efficiency can be effectively improved; and the hot air drying assembly is adopted, so that hot air is continuously blown into the inner cavity of the drying tank from the bottom of the drying tank, and further heating and drying the heat conduction shovel plates in the drying cylinder are achieved.

Owner:江苏又一城智能科技有限公司

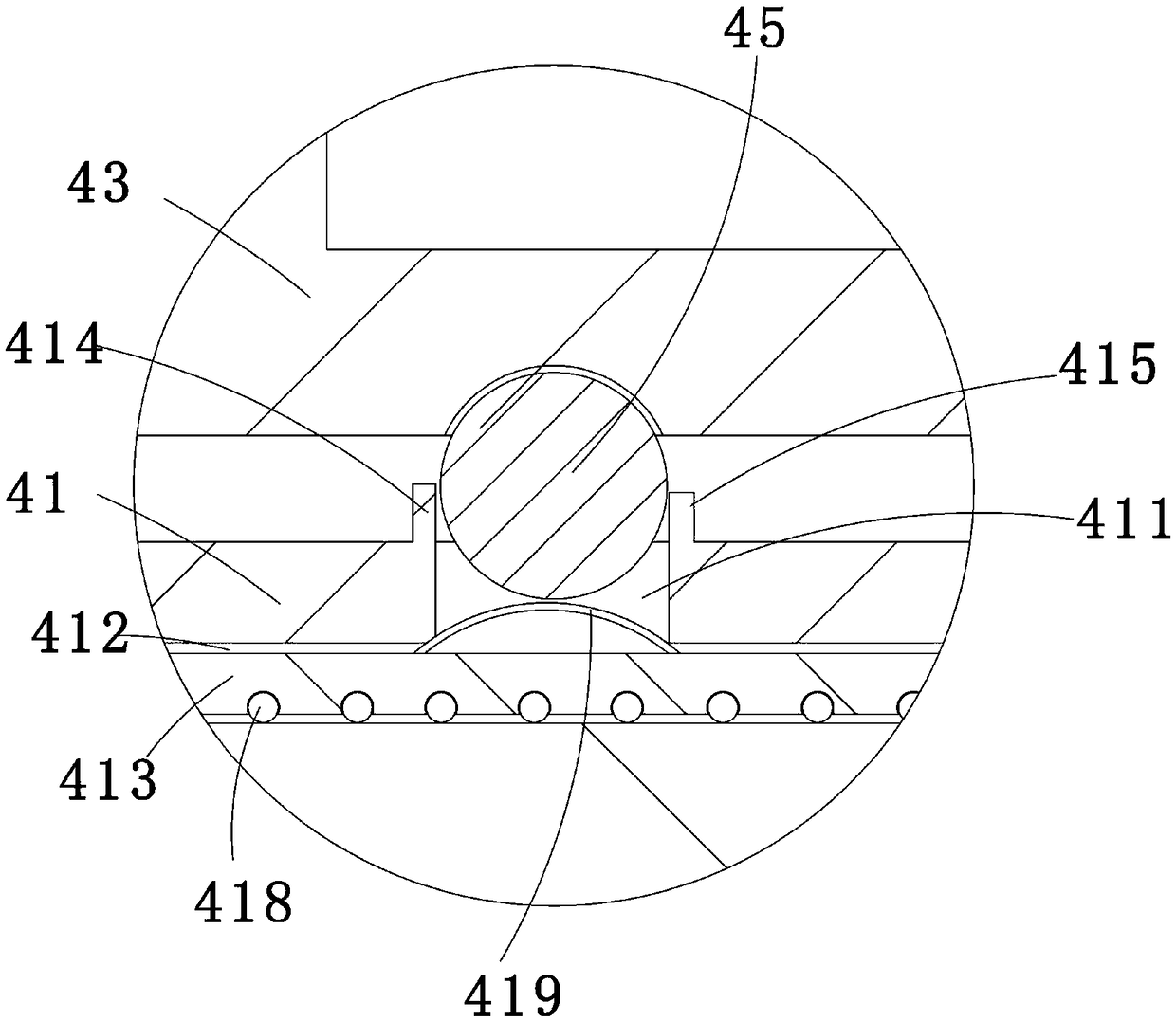

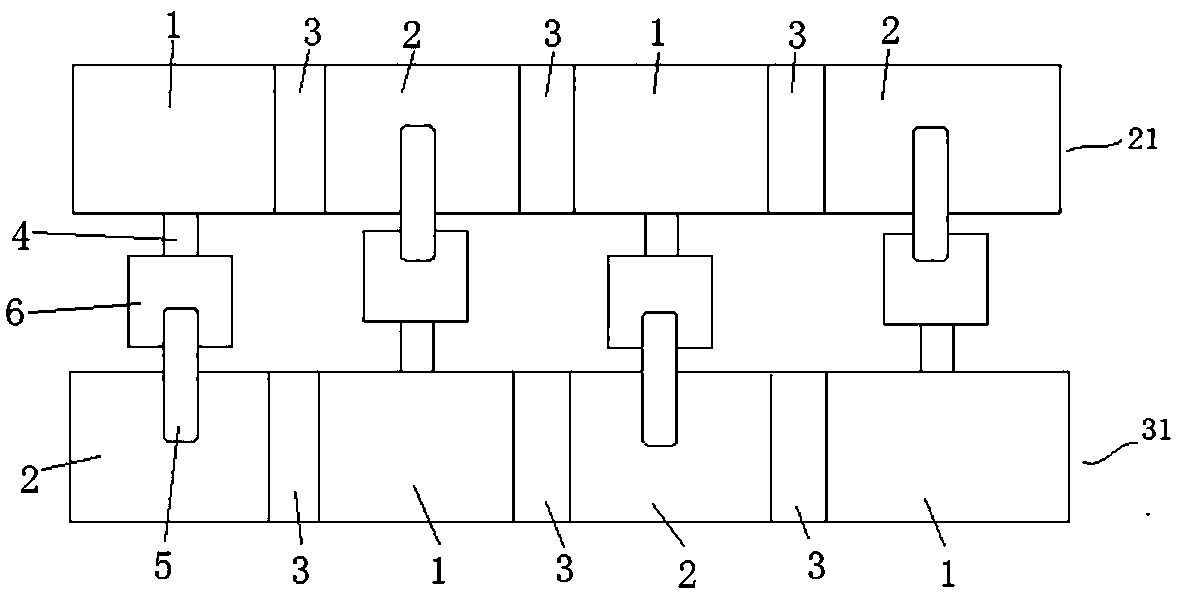

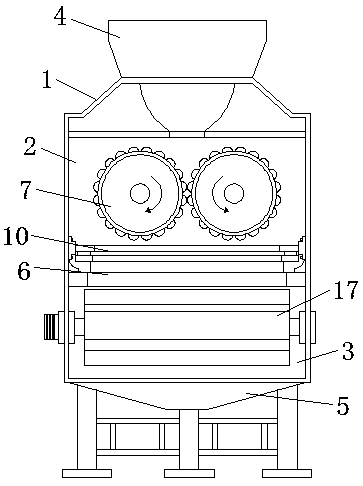

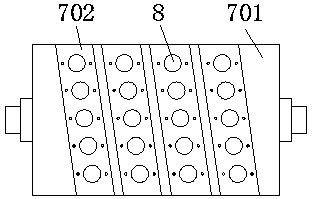

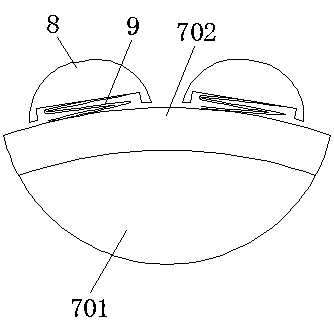

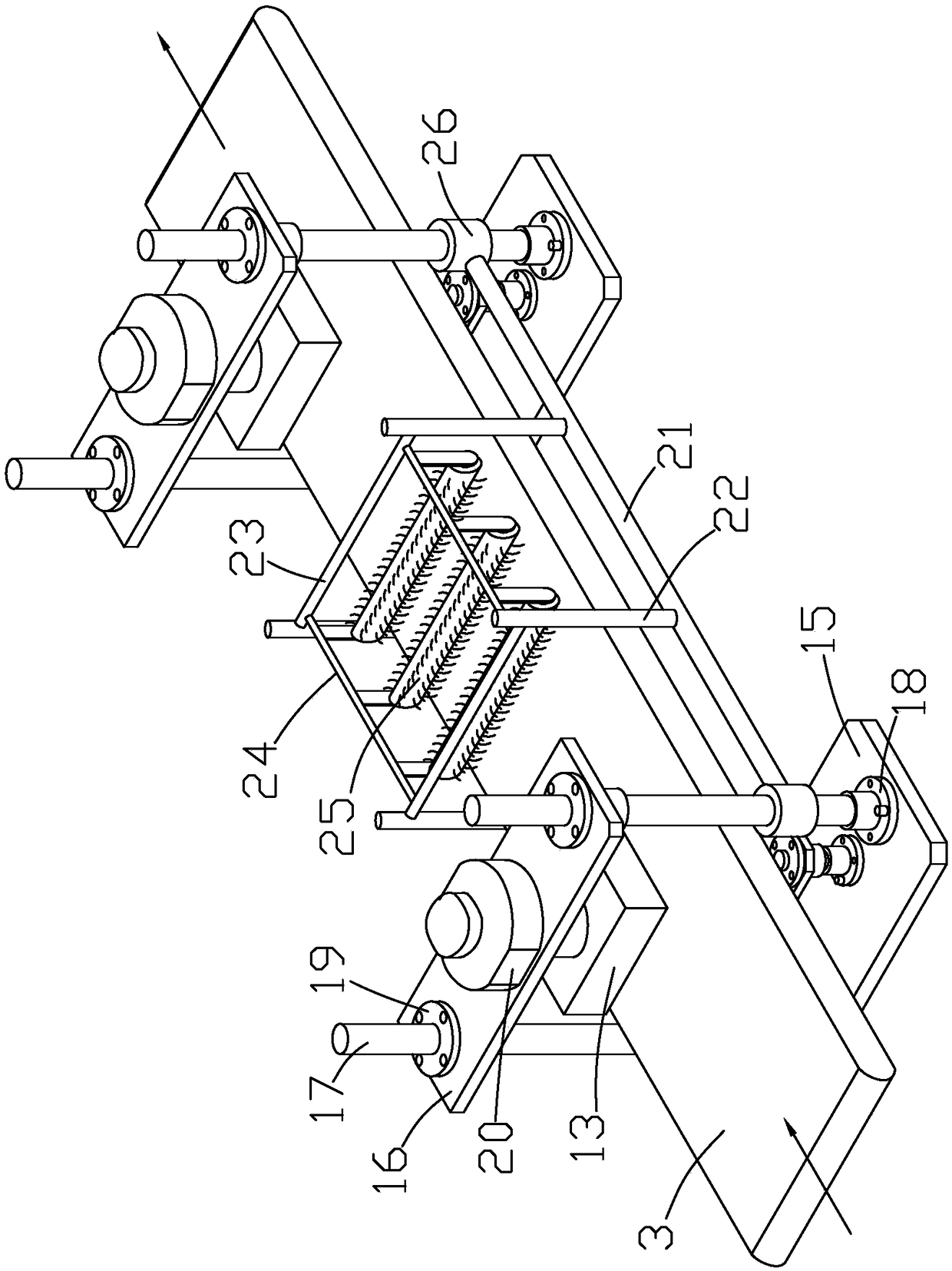

Crushing roller structure of filter cake dryer

InactiveCN108465513AReduce energy consumptionImprove heating and drying efficiencySievingScreeningEngineeringMechanical engineering

The invention discloses a crushing roller structure of a filter cake dryer. The crushing roller structure comprises paired crushing rollers, wherein the crushing rollers comprise roller bodies and gear hobbing belts, and the roller bodies are fixedly connected with rotating shafts. The gear hobbing belts are detachably and fixedly connected to the crushing rollers, the gear hobbings are uniformlydistributed on the gear hobbing belts, the gear hobbings are elastically connected to the gear hobbing belts, the linear speeds of the paired crushing rollers are different, and the gear hobbings of the paired crushing rollers are in contact with each other. According to the crushing roller structure of the filter cake dryer, by arranging the crushing roller structure in the dryer, a filter cake is crushed into granules and powder in a crushing mode, and then the filter cake is quickly heated and dried, the heating and drying efficiency are remarkably improved, the energy consumption of the dryer is reduced, and the shortcomings existed in an existing dryer are overcome.

Owner:张荣斌

Nano-silver paste large-scale production device

InactiveCN112473535AImprove practicalityAvoid wastingShaking/oscillating/vibrating mixersTransportation and packagingPeristaltic pumpSilver paste

The invention relates to the technical field of production equipment, in particular to a nano-silver paste large-scale production device which comprises a device body, a mixing box, a dispersing box and a heating box; a feeding port is formed in the top end of the device body, a rack is arranged at the bottom end of the device body, a through pipe is connected to the bottom end of the feeding port, and a stirring mechanism is arranged at the inner end of the mixing box. A motor is connected to the bottom end of the stirring mechanism, a belt is connected to one end of the motor, a dispersing mechanism is arranged at the inner end of the dispersing box, an ultrasonic oscillator is arranged at one end of the dispersing box and located on the outer side of the device body, a discharging portis connected to the back end of the dispersing box, a far infrared generator is arranged at one end of the heating box and located on the outer side of the device body, and the bottom end of the heating box is connected with a firstperistaltic pump. According to the device, all single devices are concentrated in the same device, so that the practicability of the production device is improved, andthe device is more efficient in use.

Owner:苏州柏特瑞新材料有限公司

Paper heating device used for color printing packaging

InactiveCN109279118AImprove stabilityImprove connection strengthPackagingProduction lineColor printing

The invention discloses a paper heating device used for color printing packaging. The device comprises a box body, supporting feet and a liquid storage box are arranged at the bottom of the box body,a paper conveying plate, a sweeping box, a first steam heating drying plate and a second steam heating drying plate are arranged in the box body, the paper conveying plate horizontally penetrates through the box body, a sweeping mechanism is arranged in the sweeping box, positioning mechanisms are symmetrically arranged on the two sides of the sweeping mechanism, the first steam heating drying plate and the second steam heating drying plate are both fixedly connected to the positioning mechanisms, and a water conveying pipe is arranged on the side face of the liquid storage box, and is connected with the first steam heating drying plate and the second steam heating drying plate through a first flow guide pipe and a second flow guide pipe. The device is simple in structure, and high in practicability, the temperature needed by heating in the paper machining process can be achieved, the running speed of a production line is improved, the stability of product quality is improved, the steam losses are greatly reduced, and the economic benefits are obvious.

Owner:嵊州市东浦天地彩印包装有限公司

A furniture water-based paint drying system

ActiveCN110044139BDehydration fastMeet drying requirementsDrying solid materials with heatWood treatment detailsThermodynamicsLacquer

The invention provides a furniture water-based paint drying system, which includes a drying chamber, which is characterized in that the drying chamber includes a microwave heating chamber and a hot air convection heating chamber arranged in sequence, and the microwave heating chamber includes a first heating chamber arranged in sequence. A microwave heating chamber, a second microwave heating chamber, a third microwave heating chamber, and a fourth microwave heating chamber, the hot air convection heating chamber includes a first spray area, a second spray area, a first convection area, and a Two convection zones; the microwave heating chamber is a low temperature zone, and the hot air convection heating chamber is a high temperature zone. Through the drying system of the present invention, compared with the traditional oven heating and drying, the efficiency of heating and drying is improved by dozens of times, and the water discharged by each heating and drying is more, and even the water that has not been exhausted in the previous processes can be discharged. , so as to better ensure the drying requirements of the furniture surface paint.

Owner:惠州左右家私有限公司

Cloth drying mechanism

ActiveCN108317839BIncrease temperatureImprove heating and drying efficiencyDrying machines with progressive movementsHeating arrangementHeat transmissionEngineering

The invention discloses a cloth drying mechanism, which comprises a box body, a heating device arranged in the box body, and a cloth supporting device for supporting the cloth; the cloth supporting device includes a driving roller part and a secondary The driven roller part; the driven roller part includes a heat transfer roller, a heating element passing through the heat transfer roller, and a rotatable cloth guide roller sleeved on the heat transfer roller. In the present invention, the driven roller part is set to heat the cloth and increase the temperature of the cloth; when the arrangement is heated, the distance between the cloth and the cloth is short, the temperature is concentrated, the heat transfer effect is good, the heat utilization rate on the driven roller is improved, and the For the efficiency of heating and drying the cloth, this setting method has low requirements on the temperature in the box, which can effectively save energy.

Owner:陈方玲

Sludge pre-drying carbonization treatment equipment

InactiveCN112079548AShorten drying timeReduce contentSludge treatment by de-watering/drying/thickeningSludge treatment by pyrolysisSludgeCarbonization

The invention discloses sludge pre-drying carbonization treatment equipment, relates to the technical field of sludge treatment, and solves the problems that existing sludge drying carbonization equipment lacks a dialysis removal structure for moisture in sludge, the moisture stored in the sludge is difficult to discharge and can only depend on heating evaporation, the evaporation drying process of the moisture is relatively long, and the sludge drying efficiency is relatively high. This reduces the efficiency of drying use. The sludge pre-drying carbonization treatment equipment comprises a drying box and a cover plate, the drying box comprises a hearth and T-shaped track strips, the drying box is of a rectangular structure as a whole, the hearth corresponding to the drying box in shape is welded to the bottom of the drying box, and six ventilation grooves are formed in the bottom of the hearth at equal intervals in a penetrating mode; and two T-shaped track strips are symmetrically welded at the bottom of the hearth in a hanging manner. Water in sludge can be dialyzed and discharged by the permeable pipe through the filter cloth on the permeable pipe, so that the content of waterin sludge can be quickly reduced, the drying time of sludge can be shortened, and the drying efficiency can be improved.

Owner:莱西市两山环境生态科技中心

Anti-oxidation paint surface drying device for motor production

ActiveCN113731766AImprove drying efficiencyImprove drying effectPretreated surfacesCoatingsRotational axisCircular disc

The invention relates to an anti-oxidation paint surface drying device for motor production. The device comprises a drying box and a rotary disc located in the drying box, the drying box comprises a barrel body and a cover body, a driving mechanism for driving the cover body to move is arranged on the outer side wall of the barrel body, and a liquid collecting box is buckled on the rotary disc; and a supporting mechanism used for supporting the liquid collecting box is arranged at the bottom in the barrel body, a screw pipe I is further connected into the barrel body in a screwed manner, a cylinder I located above the liquid collecting box is arranged in the screw pipe I, a circle of air inlet pipe is arranged at the bottom of the inner side wall of the cylinder I, and a cylinder II corresponding to the cylinder I is fixed to the top in the cover body through a hanging rod. Heating plates are arranged on the inner side wall of the cylinder II and the inner side wall of the cylinder I, a cross is further arranged in the cylinder II, an L-shaped screw II corresponding to an L-shaped screw I is connected to a rod body of the cross in a screwed manner, the cross is connected with a disc through a rotating shaft, a supporting frame is further arranged in the cover body, and a fan is arranged on the supporting frame. The device is simple in structure and convenient to use.

Owner:QUANNAN CHAOYA TECH

Soil remediation agent improver drying device

ActiveCN111879084AReduce energy transfer lossesImprove efficiencyDrying chambers/containersDrying solid materialsSoil remediationMechanical engineering

The invention discloses a soil remediation agent improver drying device which comprises an outer drying bin, a feeding port, a discharging port and an inner drying bin. The inner drying bin is arranged in the outer drying bin, the top of the inner drying bin is communicated with the feeding port, the bottom of the inner drying bin is connected with the discharging port, stirring blades are furtherrotationally arranged in the middle of the inner drying bin and used for stirring materials in the inner drying bin, the middle of the outer drying bin fixedly communicates with an installation bin,an oscillation assembly is arranged in the installation bin, the oscillation ends of the oscillation assembly are symmetrically arranged outside the inner drying bin, and therefore the inner drying bin can be oscillated; and attachments on the inner wall of the inner drying bin are reduced, and the drying effect is improved.

Owner:TONGREN UNIV

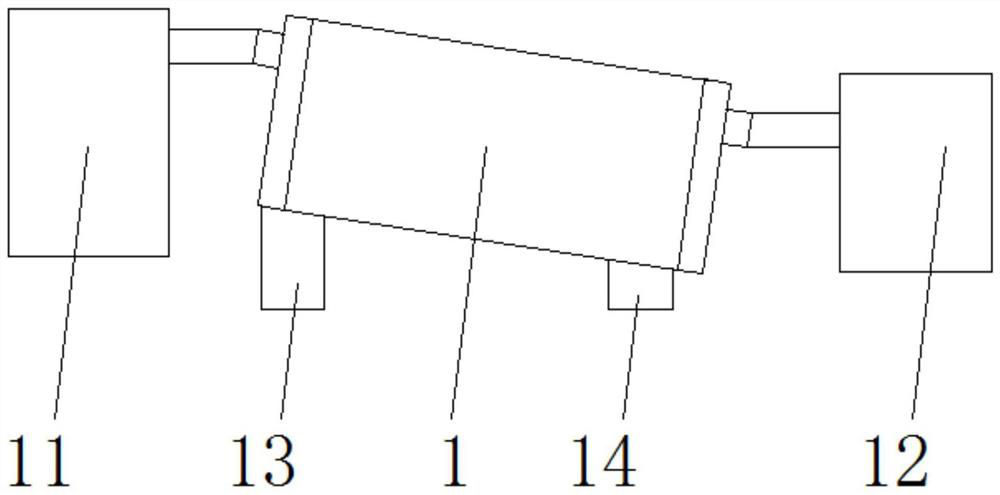

Depressurization type drying device for powder and granular material

ActiveCN102762346BImprove heating and drying efficiencyDrying solid materials without heatDrying machines with local agitationEngineeringProcess engineering

Disclosed is a depressurization type drying device (1) for powder and granular material comprising a hopper (20) for storing powder and granular material, and a depressurization means (3) for depressurizing the inside of the hopper, wherein the device is provided with hopper outer periphery heat retaining units (40, 26) arranged on the outer periphery of the hopper, a heated gas supply unit (4) for supplying heated gas to the hopper, and a control unit (80) for controlling the heated gas supply unit to supply gas which has been heated to a preset temperature.

Owner:MATSUI MFG

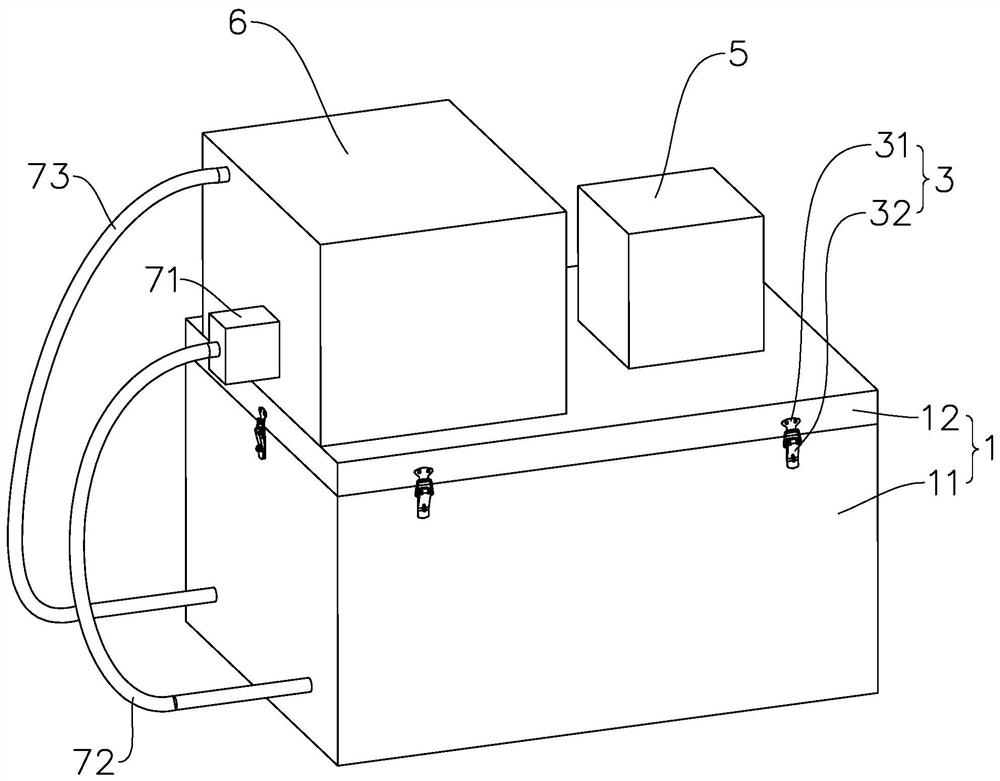

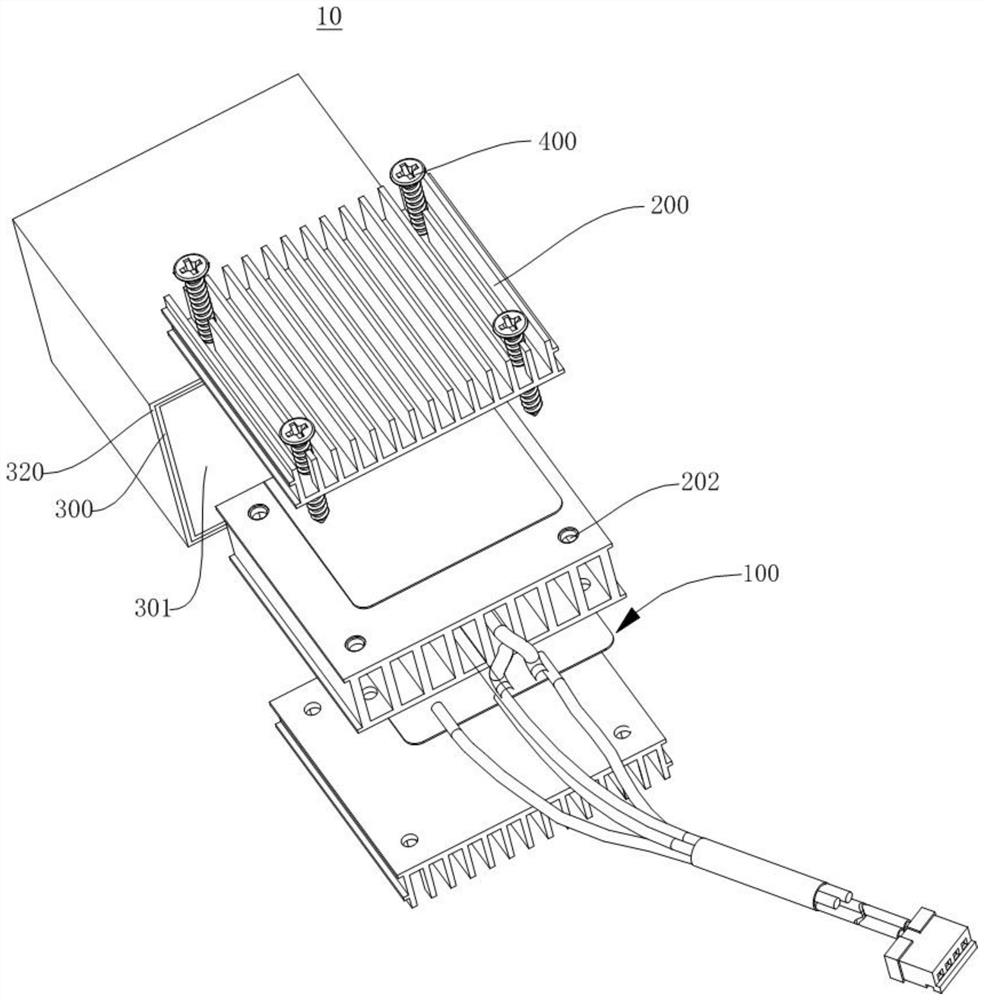

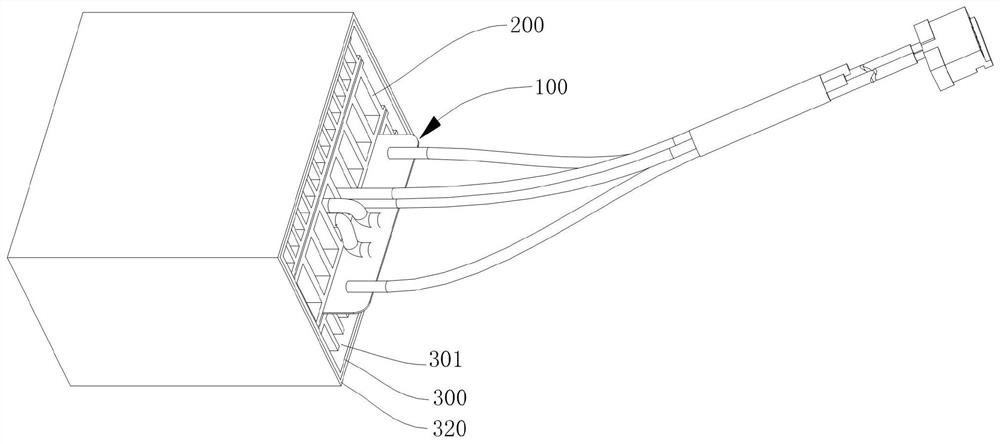

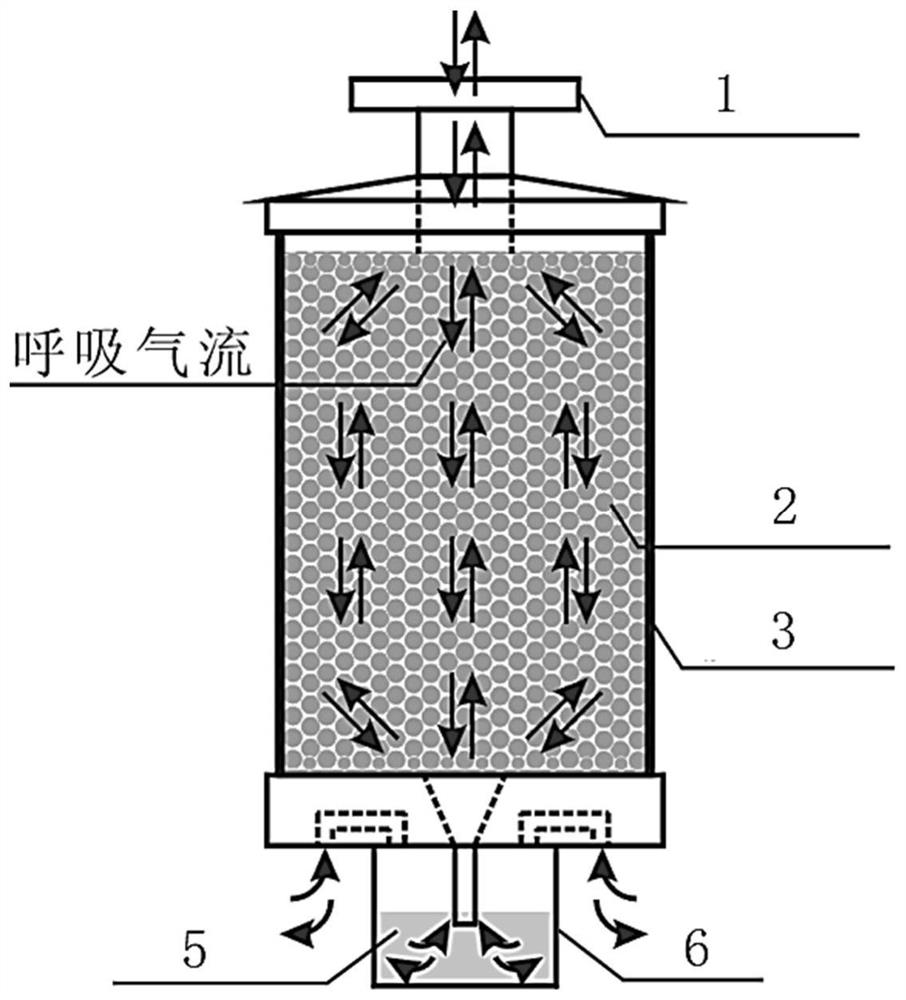

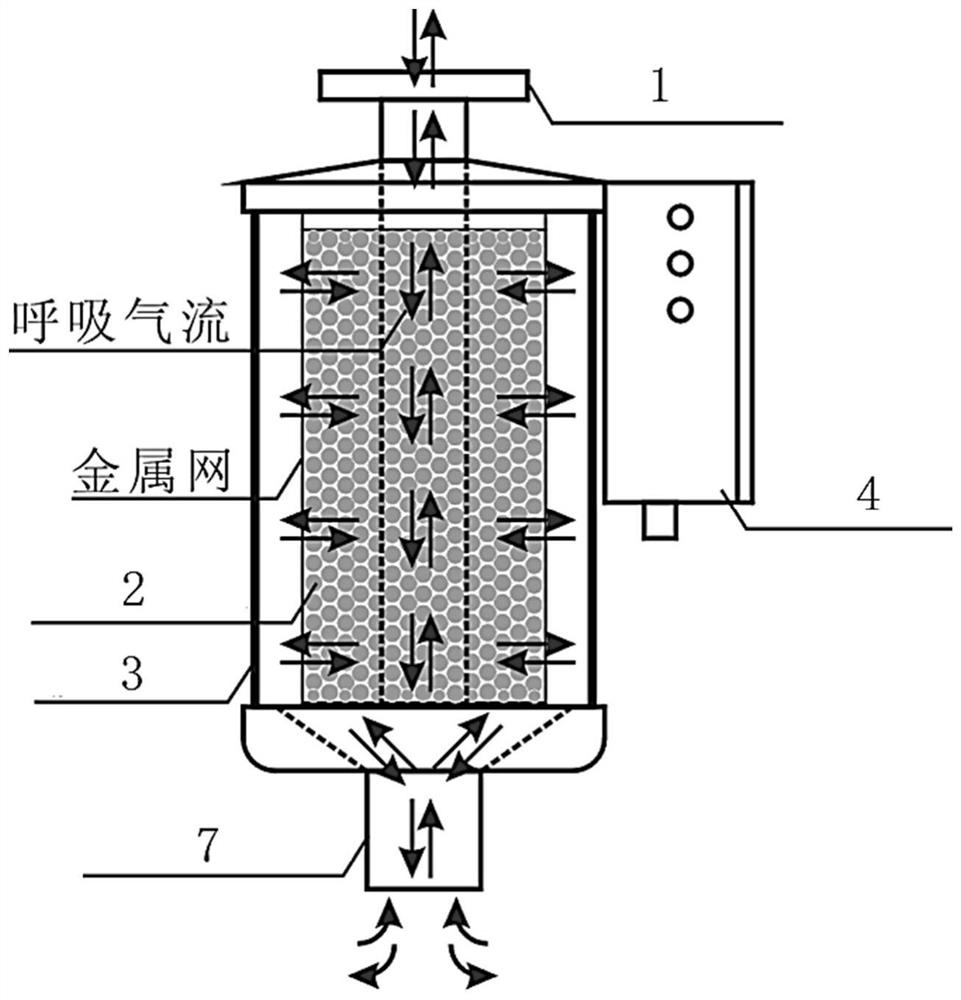

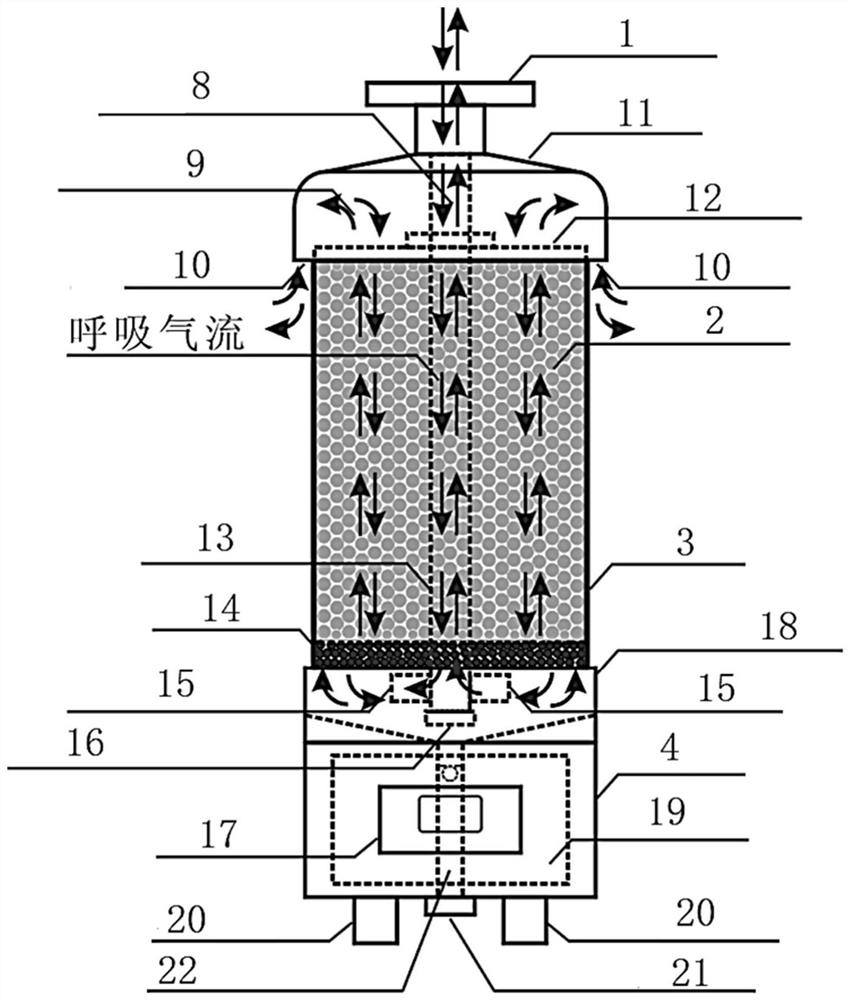

An upper air inlet and outlet type maintenance-free moisture absorber and its heating assembly and control method

ActiveCN110508104BEasy to detectAchieve dryingGas treatmentTransformers/inductances coolingActivated carbonThermodynamics

A maintenance-free dehydrator with air in and out at the upper part, its heating assembly and its control method. The interior of the rain cover forms an evaporation and condensation chamber, the diameter of the rain cover is larger than that of the dehydrator body, and a breathing channel is formed between the bottom inner wall of the rain cover and the top outer wall of the dehydrator body; the bottom of the dehydrator body is provided with a filtered air buffer chamber with The breathing tube with the flange installed is inserted from the top of the rainproof cover from top to bottom through the silica gel particle layer and the activated carbon layer and inserted into the filtered air buffer chamber. The filtered air buffer chamber communicates with the outside of the equipment through a pipe. At the drain port of the stop valve, a heating element is arranged in the silica gel particle layer, and a control box is arranged under the filtered air buffer chamber. The invention can directly discharge the water vapor generated during the heating and dehydration process of the silica gel, and the heating and drying efficiency of the silica gel is high.

Owner:陕西金源自动化科技有限公司

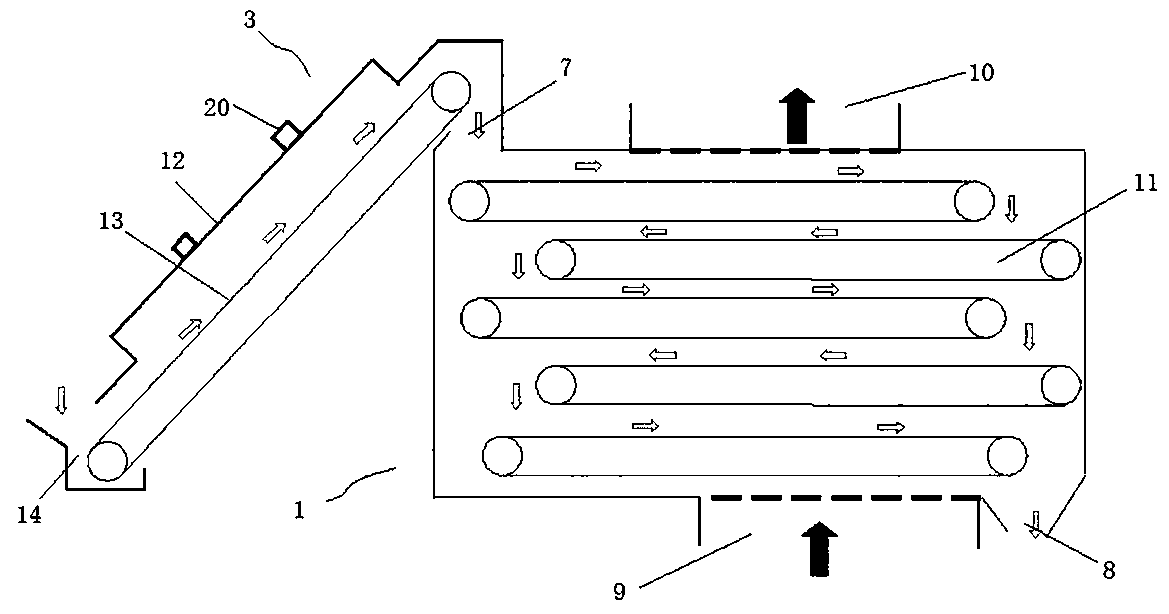

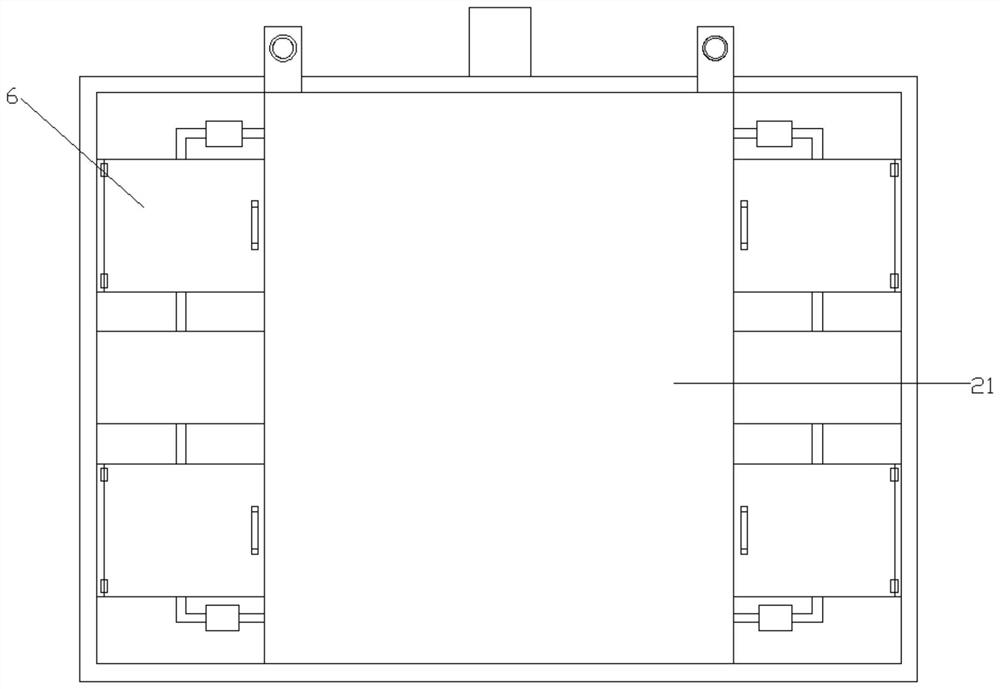

Efficient multi-layer dryer for textile auxiliary agent processing

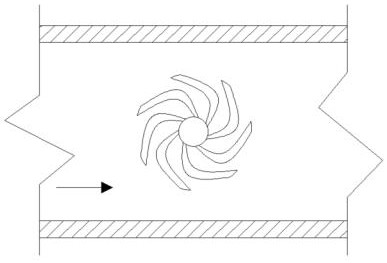

InactiveCN112451983AImprove drying efficiencyImprove heating and drying efficiencyEvaporator accessoriesProcess engineeringFan blade

The invention belongs to the technical field of dryers, and discloses an efficient multi-layer dryer for textile auxiliary agent processing. The efficient multi-layer dryer comprises a dryer body, a water inlet and a water outlet are respectively formed in two ends of the dryer body, at least four partition plates are arranged between the water inlet and the water outlet in the dryer body, and every two partition plates are arranged in a staggered manner; and a rotating rod is rotatably connected in the dryer body, and at least two fan blades are arranged on the surface wall of the periphery of the rotating rod at equal intervals. the partition plates and the fan blades are arranged in the dryer body, the partition plates are used for separating liquid, the heated evaporation area of the liquid is increased, the liquid drying efficiency is improved, the fan blades are driven to rotate by rotating the rotating rod, and the fan blades throw up and stir the the liquid, so that hot air entering the dryer body penetrates through the thrown-up liquid to heat the liquid and take away moisture in the liquid, the heating and drying efficiency of the liquid and the working efficiency of thedryer body are improved, and meanwhile, chemicals in the liquid are mixed more uniformly.

Owner:江门市新会区美亚化工有限公司

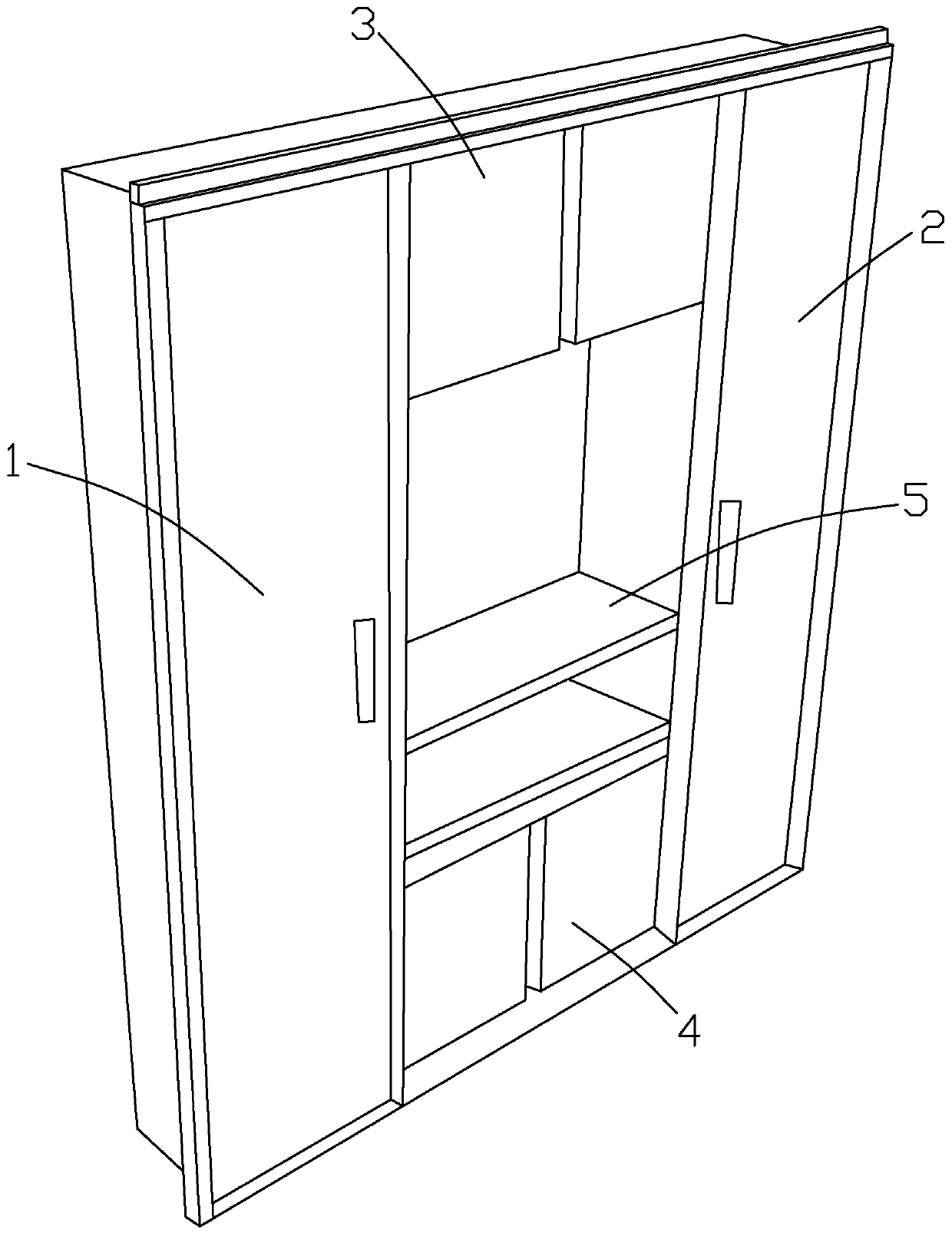

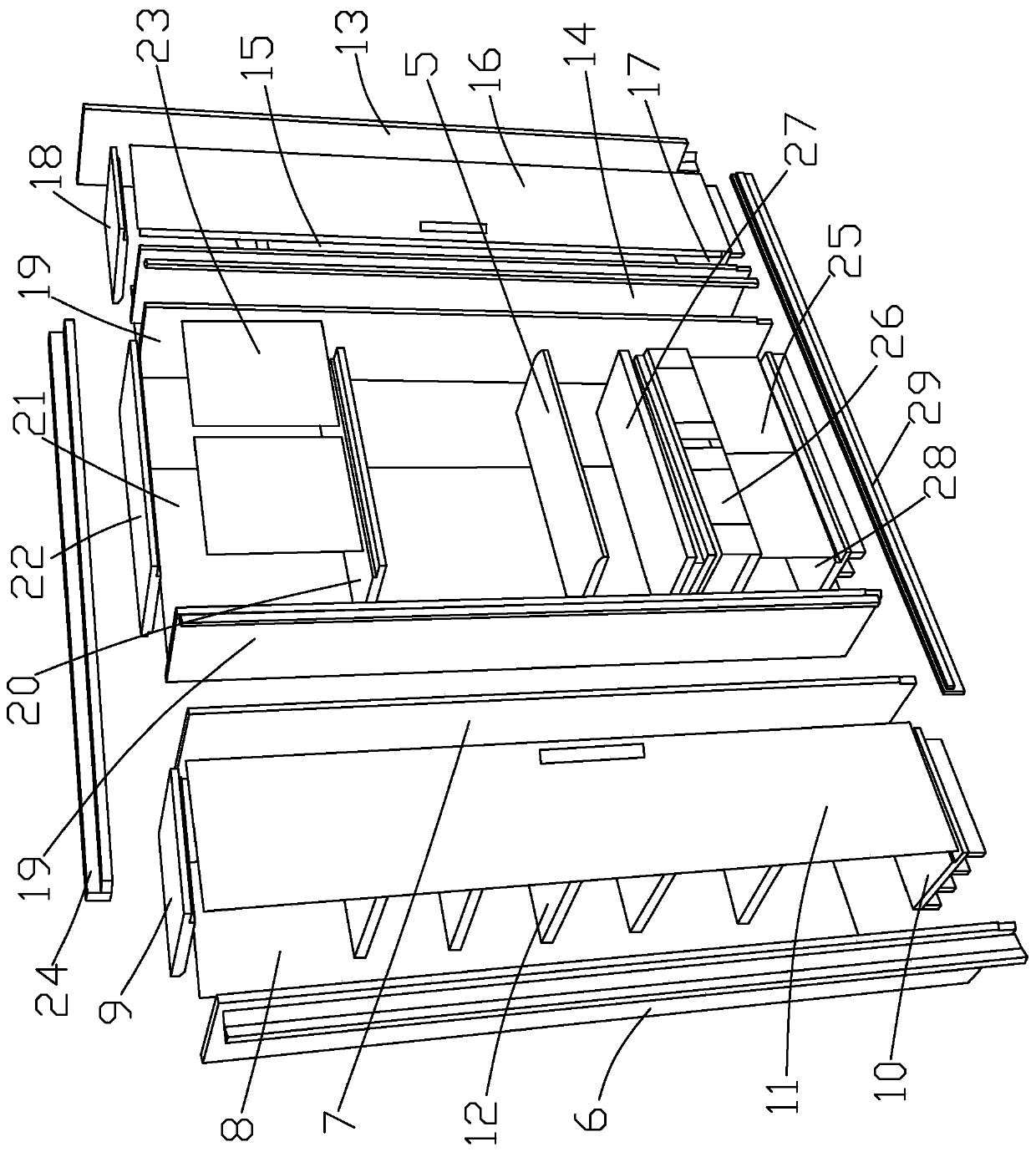

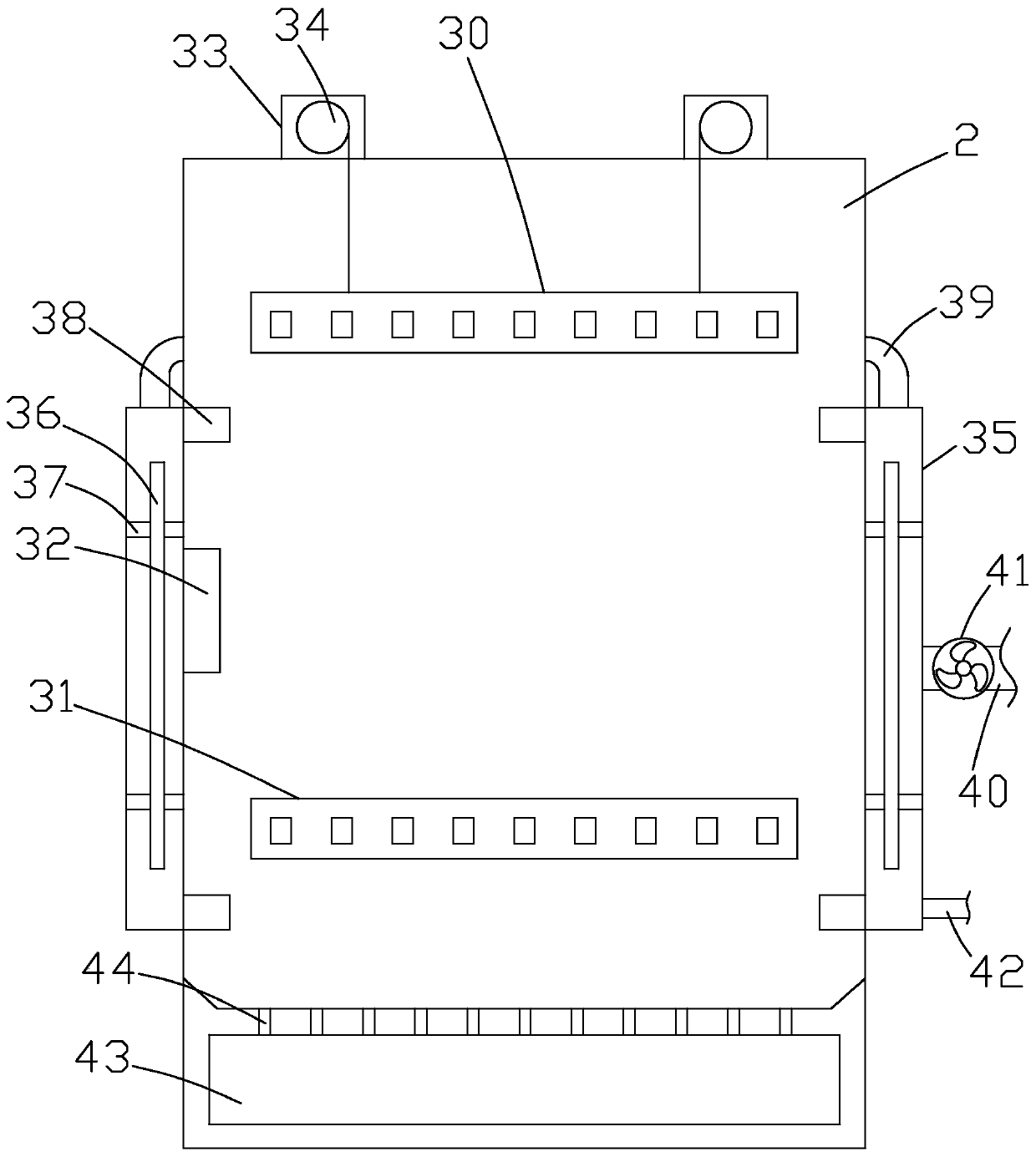

Multifunctional porch cabinet and mounting method thereof

PendingCN110367699AIncrease storage spaceEfficient separationWardrobesTextiles and paperPorchEngineering

The invention discloses a multifunctional porch cabinet and a mounting method thereof. The multifunctional porch cabinet comprises a dry object storage cabinet, a wet object storage cabinet, an auxiliary cabinet and a shoe cabinet; the dry object storage cabinet and the wet object storage cabinet are fixedly connected to the two sides of the shoe cabinet and the auxiliary cabinet respectively; andinner support plates are symmetrically arranged on the two sides of the shoe cabinet and the auxiliary cabinet. The method comprises the following steps: processing the dry object storage cabinet; processing the wet object storage cabinet; processing the auxiliary cabinet; processing the shoe cabinet; and splicing and mounting the porch cabinet. Through the design of the dry object storage cabinet and the wet object storage cabinet, dry clothes and wet clothes after entering a door can be hung in the dry object storage cabinet and the wet object storage cabinet of the porch cabinet respectively, so that the practicability of the porch cabinet is improved, centralized heating and drying treatment can be carried out on the wet clothes, the clothes are prevented from being mouldy due to long-time storage in the porch cabinet, and bacterial breeding is prevented; the mounting method improves the utilization rate of the porch cabinet; and the requirement of storing dry objects and wet objects at the same time can be met.

Owner:浙江图森定制家居股份有限公司

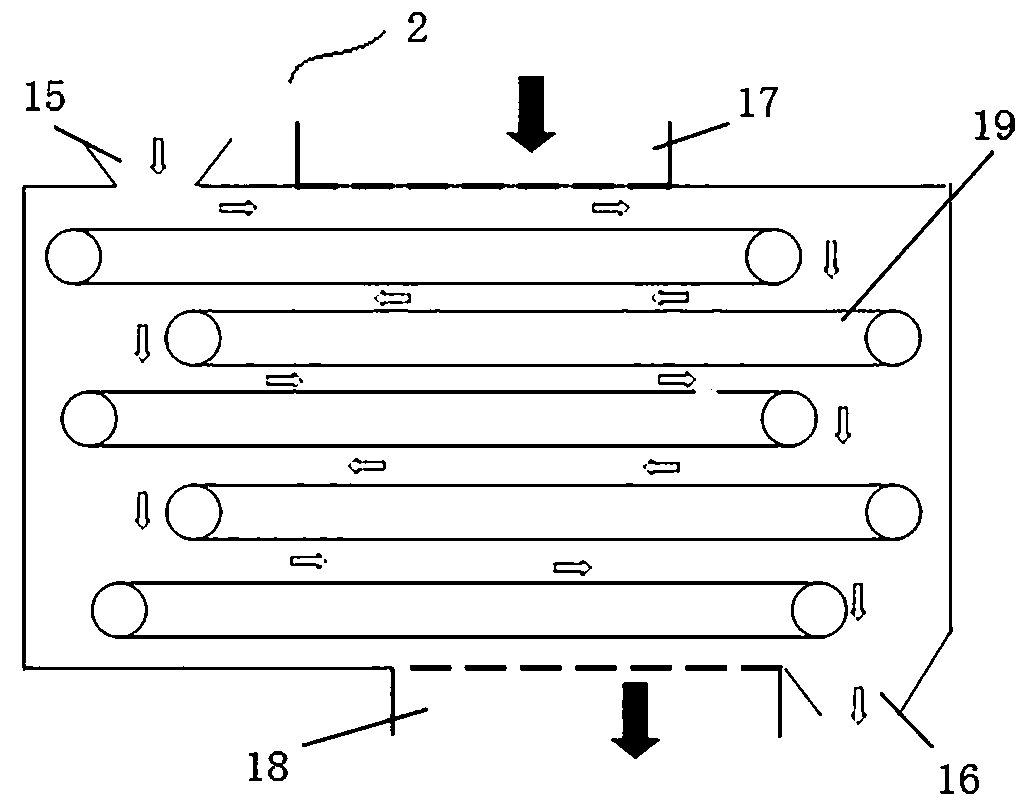

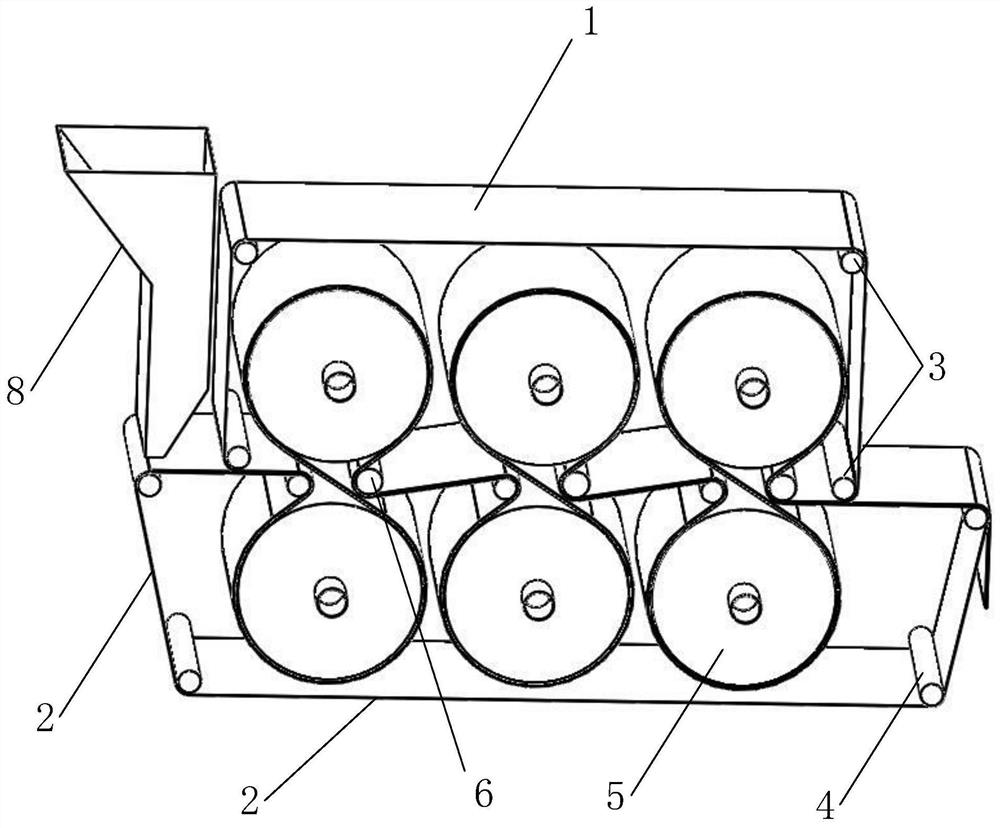

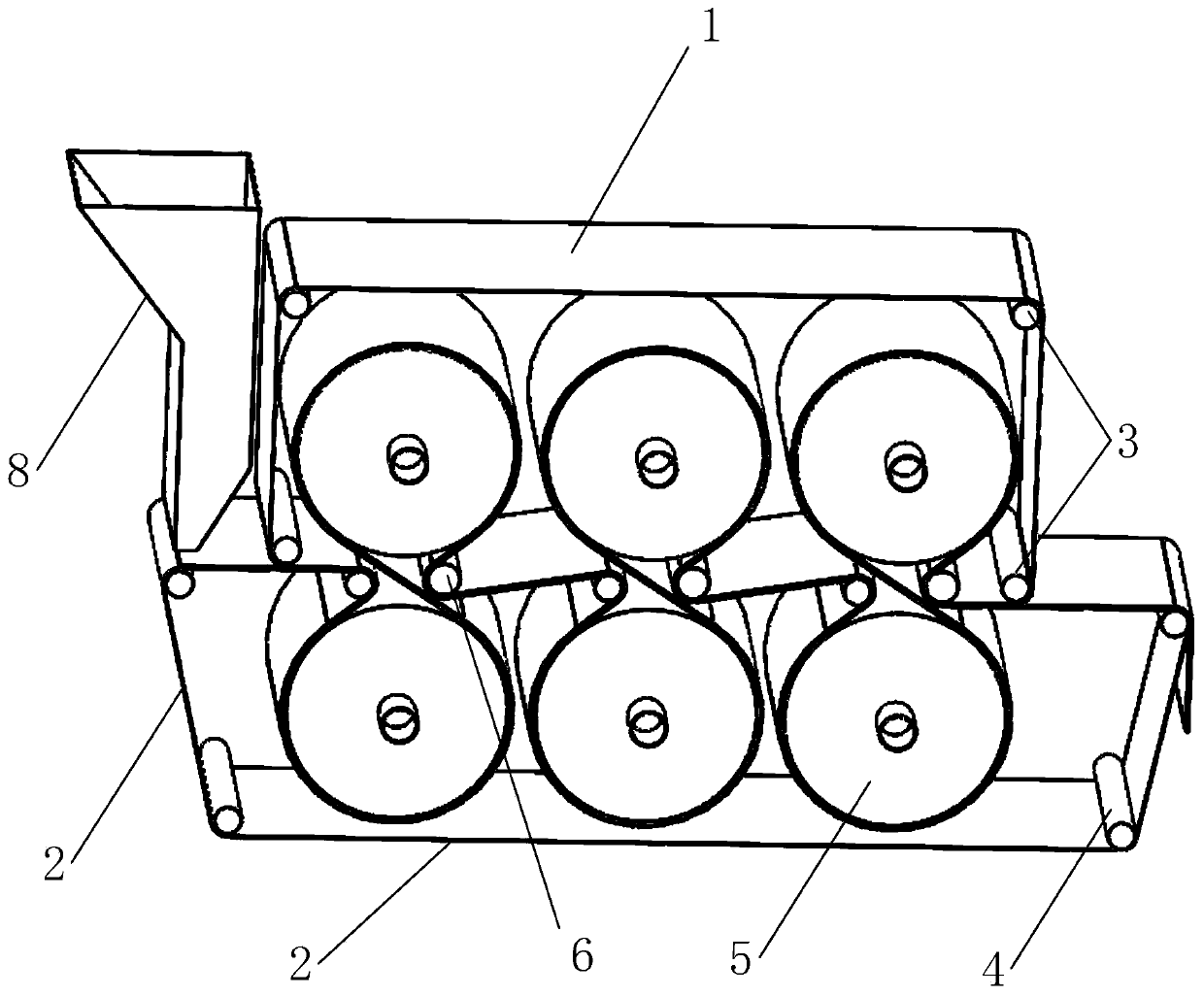

A roller drying structure and a dryer made of the structure

ActiveCN110779314BIncrease the areaImprove heating and drying efficiencyDrying solid materialsHeating arrangementThermodynamicsEngineering

The invention discloses a roller drying structure and a dryer made of the structure, comprising a first conveyor belt and a second conveyor belt, a plurality of first limiting rods, a plurality of second limiting rods, a plurality of drying Dry cylinder, a plurality of combined limit rods, the first drive rod from any one of the first limit rods, the first drive rod from any one of the first limit rods; the dryer also includes a fixed Bracket, heating device, feeding funnel, discharging box, and scraper blades In the present invention, through the setting of the first conveyor belt and the second conveyor belt, when the object to be dried is dropped onto the conveyor belt through the feeding funnel, the two conveyor belts Combined extrusion, the material to be dried is pressed into a flat structure, and at the same time, with the transmission of the conveyor belt, the material to be dried that is pressed into a flat structure is conveyed, so that it passes through multiple high-temperature drying cylinders in sequence, greatly It greatly increases the area where the material to be dried is in contact with the high-temperature environment, greatly improves the efficiency of its heating and drying, and reduces energy consumption.

Owner:SHANXI HEPO POWER GENERATION CO LTD

Rotatable drying device for food processing

InactiveCN112050562AEfficient dryingEffective absorptionDrying gas arrangementsDrying chambers/containersElectric machineryEngineering

The invention relates to the field of food processing, in particular to a rotatable drying device for food processing. The device comprises a support frame, wherein a heating and drying cavity is mounted in the middle of the support frame, a drying cavity is arranged on the outer side of the heating and drying cavity, the drying cavity is connected with a heating cavity through a connecting pipe,and the upper side of the drying cavity is connected with the heating and drying cavity through a circulating pipe; and the drying cavity is connected with a connecting cover through an air draft pipe, the bottom end in the connecting cover is connected with a rotating shaft through a connecting bearing, a rotating pipe is fixedly installed on the upper side of the rotating shaft, a ventilation opening is formed in the rotating pipe, exhaust pipes are arranged at the four corners of the rotating pipe, spray heads are distributed on the exhaust pipes, a second sealing door is arranged on the front side of the heating and drying cavity, a connecting piece is arranged on the upper side of the second sealing door, a threaded rod is in threaded connection with the rear end of the connecting piece, a second motor is arranged on the rear side of the threaded rod, and food storage grooves are fixedly formed in the upper end and the lower end of the rear side of a sealing plate. The device caneffectively facilitate the addition and removal of food, and is convenient for people to use.

Owner:盐池县荣桂昌食品科技有限公司

Efficient Yelansu extraction process

InactiveCN112316485AImprove efficiencyImprove extraction efficiencySolid solvent extractionGrain treatmentsRhizomeChemical engineering

The invention discloses an efficient Yelansu (a substance extracted from rhizomes of aspidistra elatior) extraction process. The process comprises the following steps of: firstly, selecting rhizomes of aspidistra elatior; secondly, performing high-speed grinding on the rhizomes of the aspidistra elatior in a bead grinding manner; thirdly, drying and heating the ground material obtained in the second step, the drying and heating process being accompanied by auxiliary operation of a stirring mechanism; fourthly, carrying out high-speed centrifugal treatment on the dried material in the third step through a disc stacking centrifugal machine; and fifthly, adding the powdery material subjected to high-speed centrifugation in the fourth step into water, carrying out water phase treatment, and carrying out primary filtration treatment after the material and the water are fully dissolved, so as to obtain a solution subjected to sufficient water phase treatment. When the ground material is dried and heated, a turbine stirring device is added, the turbine is driven by utilizing the pressure during material conveying, so that the turbine can stir the heated and dried material, the heating anddrying efficiency of the material is effectively improved, and the extraction efficiency of Yelansu is improved.

Owner:江苏一叶兰生物医疗科技有限公司

Roller type drying structure and dryer formed by structure

ActiveCN110779314AIncrease the areaImprove heating and drying efficiencyDrying solid materialsHeating arrangementStructural engineeringConveyor belt

The invention discloses a roller type drying structure and a dryer formed by the structure. A first conveyor belt, a second conveyor belt, a plurality of first limiting rods, a plurality of second limiting rods, a plurality of drying cylinders, a first drive rod taken from any one of the first limiting rods and a second drive rod taken from any one of the second limiting rods are included; and thedryer also comprises a fixed bracket, a heating device, a feeding funnel, a discharging box and a scraper. According to the roller type drying structure and the dryer, through the arrangement of thefirst conveyor belt and the second conveyor belt, when materials to be dried fall onto the conveyor belts through the feeding funnel, through combined extrusion of the two conveyor belts, the materials to be dried are pressed to be of flat structures; and meanwhile, along with transmission of the conveyor belts, the materials which are to be dried and are pressed to be of the flat structures are conveyed, the materials pass through the multiple high-temperature drying cylinders in sequence, the contact area of the materials to be dried and the high-temperature environment is greatly increased,the heating and drying efficiency is greatly improved, and energy consumption is reduced.

Owner:SHANXI HEPO POWER GENERATION CO LTD

Biomass fuel containing charcoal and processing method thereof

InactiveCN110317655AHigh combustion valueExtended burn timeBiofuelsSolid fuelsSodium BentoniteSludge

The invention discloses a biomass fuel containing charcoal. The biomass fuel comprises, by weight, 22-28 parts of sludge, 85-95 parts of sawdust, 35-45 parts of straw, 25-35 parts of straw stalks, 12-18 parts of Chinese parasol tree leaves, 55-65 parts of biomass charcoal powder, 45-55 parts of bentonite, 24-25 parts of a dechlorination agent, 15-20 parts of a denitrification agent activator, 17-22 parts of an igniting agent, 14-18 parts of a combustion improver, 9-15 parts of a dehydrating agent, 8-12 parts of sodium nitrate, 35-45 parts of coal slime, 5-7 parts of albarium and 13-14 parts ofkyanite. The fuel has the advantages that the biomass fuel has a high combustion value, long combustion time and no emission of harmful gas and acid gas after combustion, and at the same time, the addition of the igniting agent and the combustion improver makes the ignition point of the fuel greatly reduced and the fuel easy to ignite; the addition of the bentonite, the kyanite and the albarium makes the gas permeability improved and the heat energy utilization rate improved. The technical requirements are relatively low, the cost is relatively low, the heating rate is higher, heating is moreuniform, and the heating and drying efficiency is very high.

Owner:甘肃西能环保科技有限公司

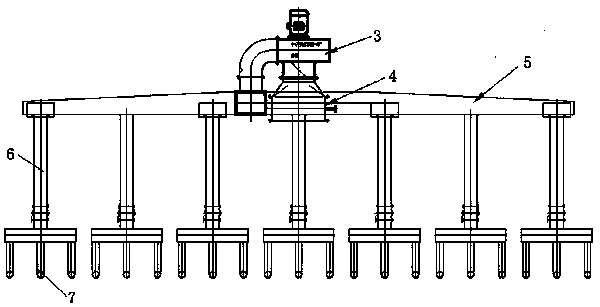

Outer box pre-heating device and method

InactiveCN103398549ASave energyReduce labor costsDrying solid materials with heatDrying gas arrangementsProcess engineeringUltimate tensile strength

The invention relates to the technical field of pipe production equipment and provides an outer box pre-heating device which utilizes external hot air to heat and dry a workpiece automatically. The outer box pre-heating device comprises a machine frame and an air supply pipe system, wherein the air supply pipe system sequentially comprises a fan, an exchanger, a main air duct and a plurality of branch air ducts. The main air duct is connected with the plurality of the branch air ducts, each branch air duct is provided with an air outlet, and the air outlets are formed in the machine frame. According to the outer box pre-heating device, the external hot air can be used for heating and drying the workpiece automatically, energy is saved, and production cost is reduced. Meanwhile, the workpiece only needs to be replaced simply and manually, other operations are all completed by the device, the operations which are difficult to complete manually can be completed, the automation degree is high, labor intensity is reduced, time and effort are saved, labor cost is saved, production safety is guaranteed, operation is simple and convenient, and heating and drying efficiency is improved. Meanwhile, the invention further provides an outer box pre-heating method.

Owner:GUANGDONG LIANSU TECH INDAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com