Crushing roller structure of filter cake dryer

A technology of crushing rollers and dryers, applied in non-progressive dryers, dryers, drying gas layout, etc., can solve the problems of high cost of use, unfavorable reuse of filter cakes, and increased environmental protection pressure in chemical fertilizer plants. Improve efficiency and reduce energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with accompanying drawing, the present invention is described in detail.

[0024] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

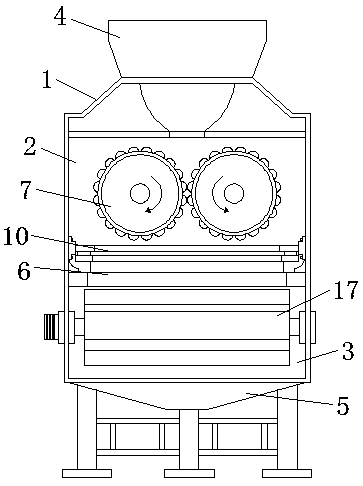

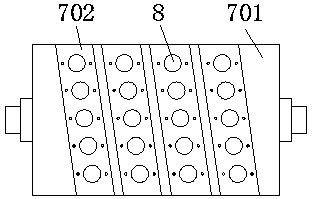

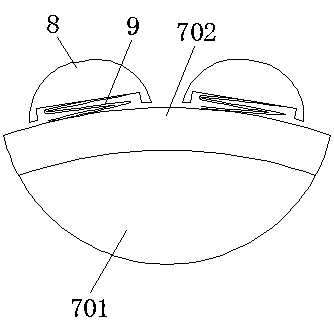

[0025] like Figure 1 to Figure 3 As shown, a filter cake dryer is mainly used to treat the filter cake produced in gelatin wastewater. The filter cake is produced by the sludge produced in the gelatin wastewater treatment process after being filtered by a filter press. The water content of the filter cake is Between 18-27wt%, the filter cake dryer includes a main casing 1, the main casing 1 is connected with a power device (the power device includes a motor and a reduction box), and inside the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com