Soil remediation agent improver drying device

A technology of soil remediation agent and drying device, which is applied in the direction of drying, drying machine, non-progressive drying machine, etc., can solve the problems of inconvenient drying and discharging, and troublesome operation, so as to reduce the attachment on the inner wall and improve the Efficiency, the effect of improving the thermal insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

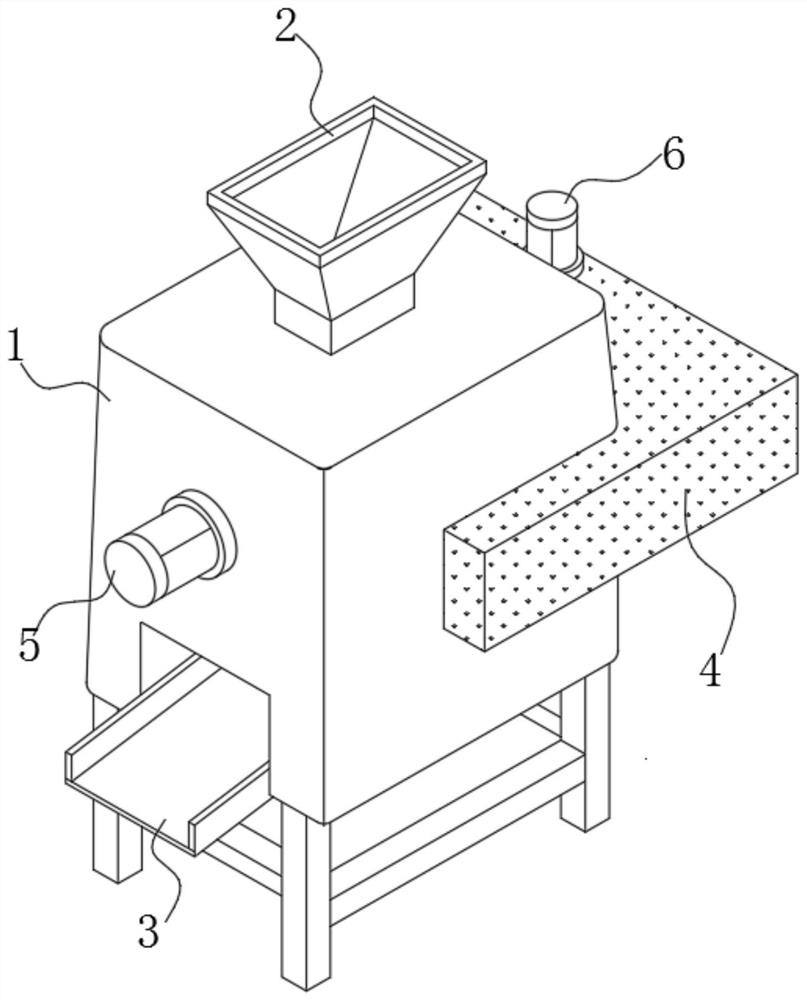

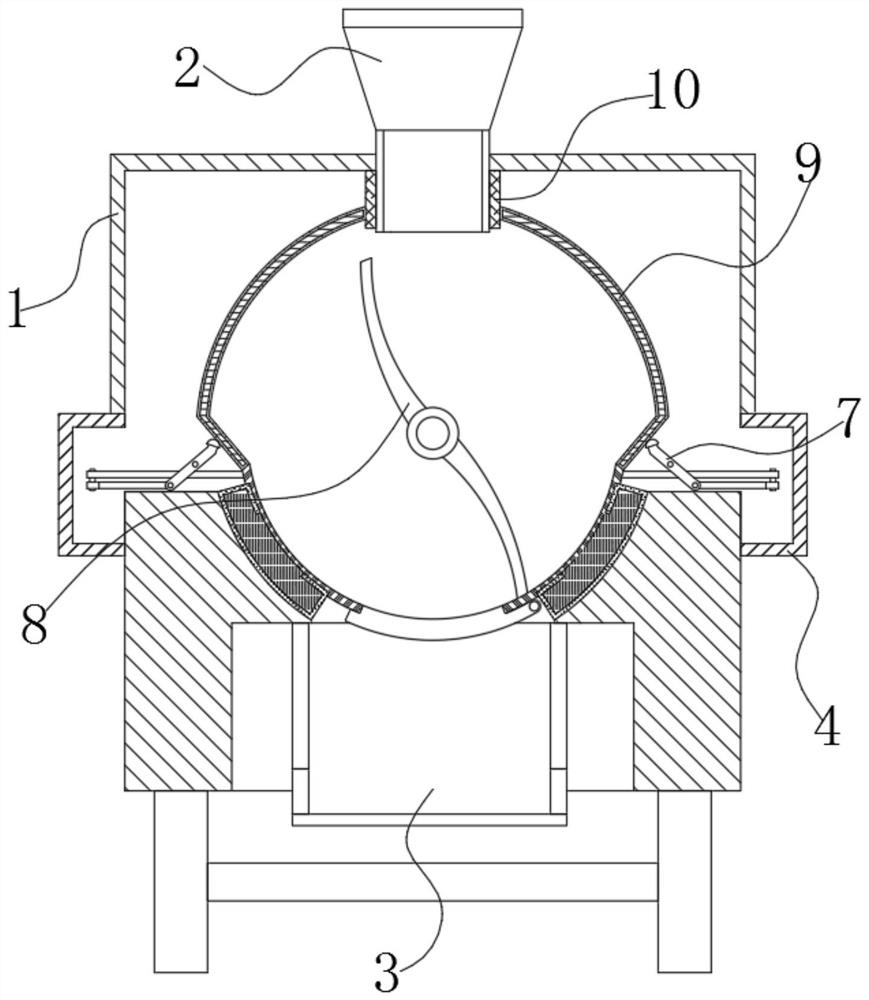

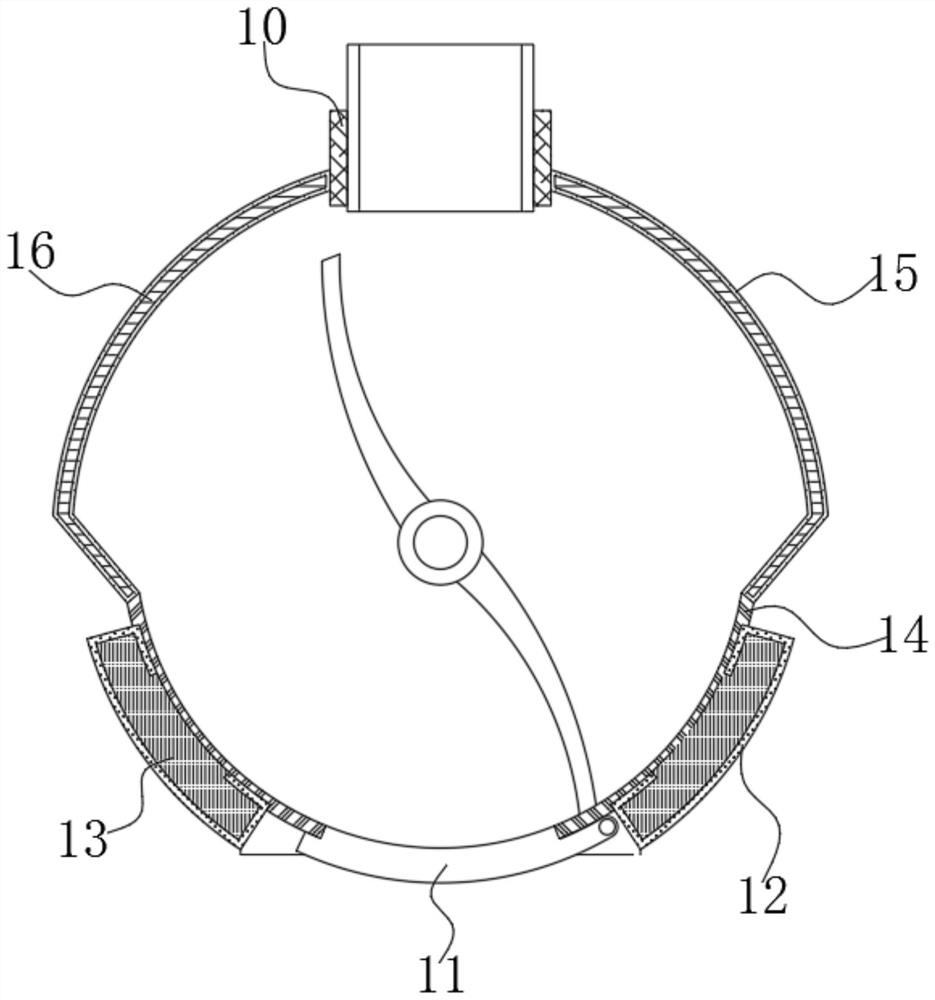

[0029] see Figures 1 to 5 , In the embodiment of the present invention, a soil remediation agent improving agent drying device includes a drying outer warehouse 1, a feeding port 2, a discharging port 3 and a drying inner warehouse 9, wherein the drying outer warehouse 9 The interior of 1 is provided with the drying inner bin 9, the top of the drying inner bin 9 is communicated with the feeding port 2, the bottom of the drying inner bin 9 is connected with the discharging port 3, and the drying The middle part of the inner warehouse 9 is also provided with a stirring blade 8, which is used for stirring the material body therein;

[0030] The middle part of the drying outer bin 1 is fixedly connected with an installation bin 4, and the installation bin 4 is provided with an oscillating component 7, and the oscillating end of the oscillating component 7 is symmetrically arranged on the outside of the drying inner bin 9, so as to be able to The drying inner bin 9 is oscillated ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com