Depressurization type drying device for powder and granular material

A drying device and technology for powder and granules, applied in the dryer of static materials, drying solid materials without heating, drying solid materials, etc., can solve the problems of high cost, high power consumption, and poor cleaning performance. Achieve the effect of improving cleaning performance, effective heating and drying, and shortening start-up time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] Embodiments of the present invention will be described below with reference to the drawings.

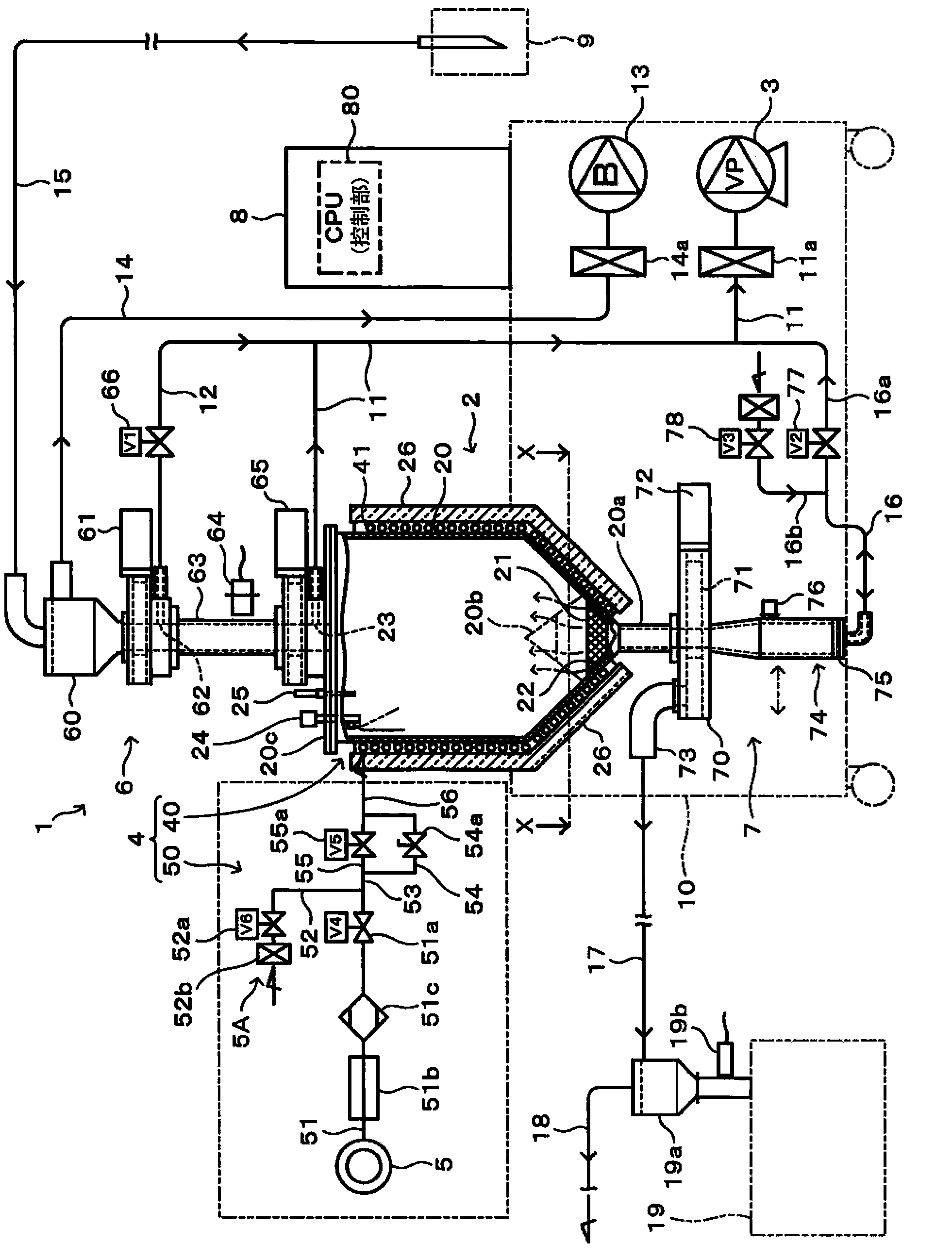

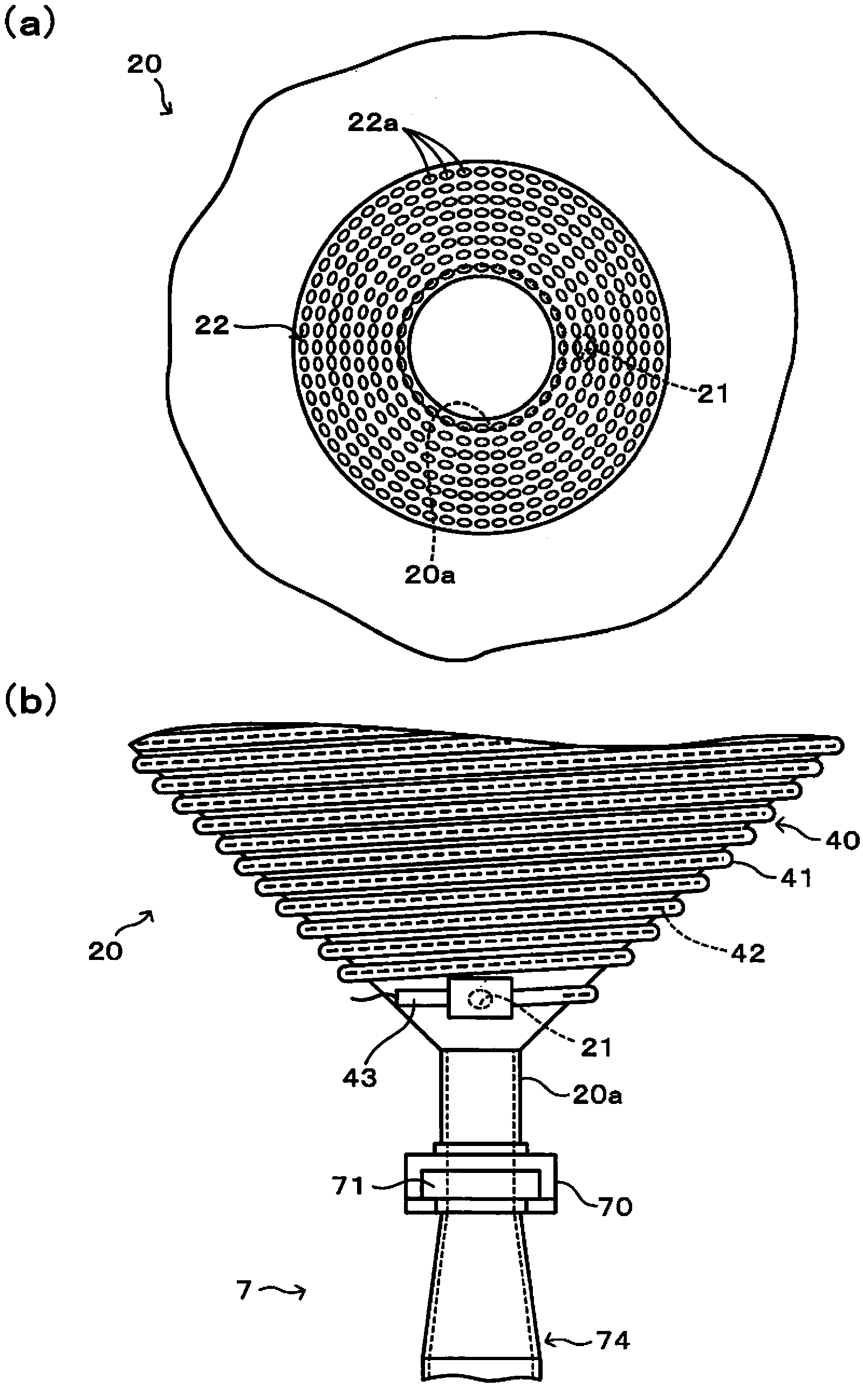

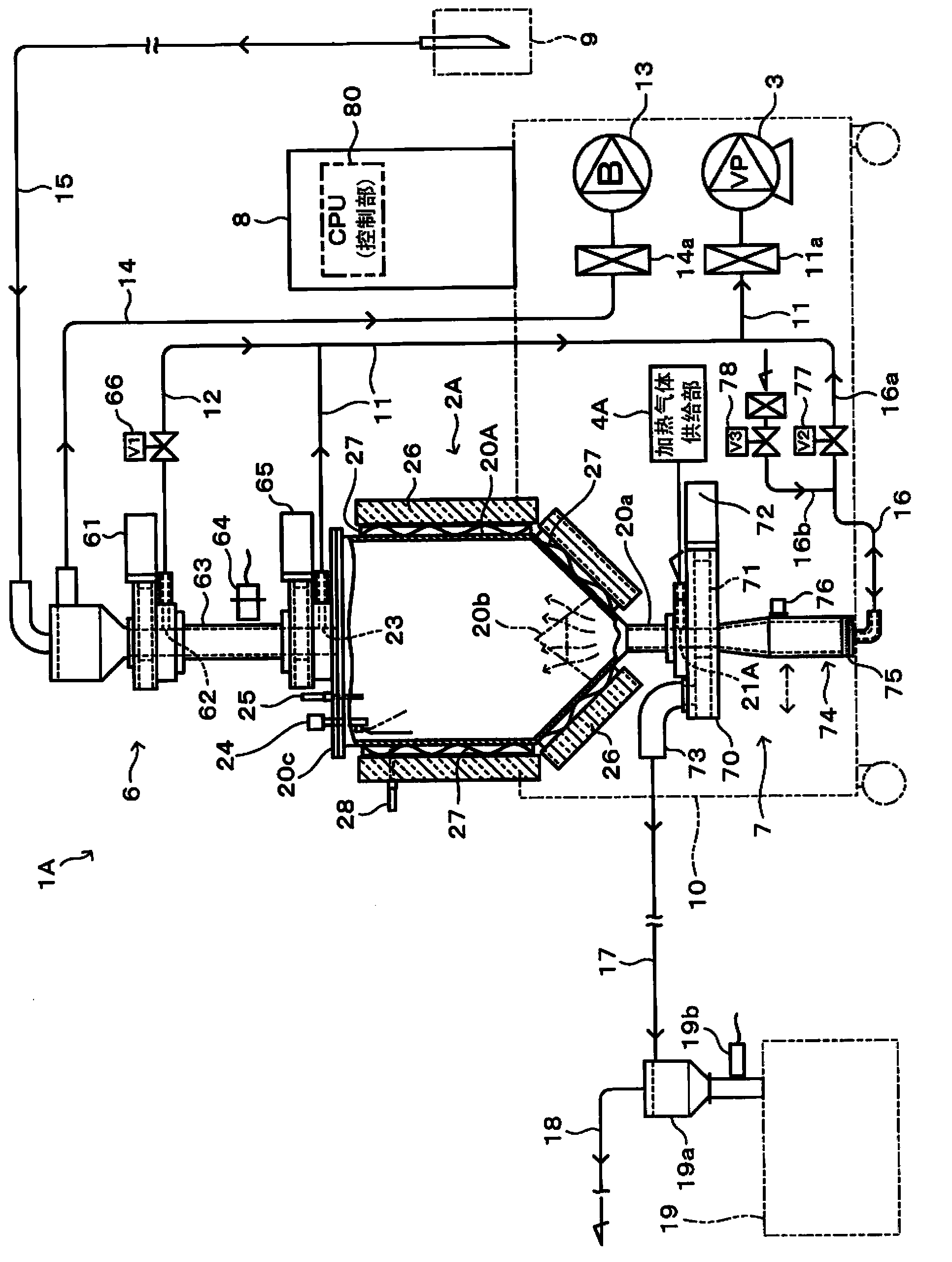

[0055] figure 1 and figure 2 It is an explanatory drawing for demonstrating the vacuum type drying apparatus of the granular material of 1st Embodiment.

[0056] In addition, in figure 1 , Figure 3 ~ Figure 7 In , a part of the pipeline (gas pipeline, powder or granular material conveying pipeline, etc.) through which the gas and the powder or granular material circulate is schematically indicated by a solid line.

[0057] In addition, in figure 2 In (b), the illustration of the heat insulating material 26 mentioned later is abbreviate|omitted.

[0058] The decompression drying device for powder and granular materials in the legend 1 such as figure 1 As shown, it is equipped with: a hopper part 2, which is provided with a hopper main body 20 as a storage tank for storing powder and granular materials; a decompression mechanism 3, which decompresses the inside of the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com