Efficient Yelansu extraction process

A high-efficiency yelanin technology, applied in the field of high-efficiency yelanin extraction technology, to achieve the effects of improving extraction efficiency, improving efficiency, and improving purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] refer to figure 1 and figure 2 , a high-efficiency yelanin extraction process, comprising the following steps:

[0030] The first step is to select the rhizomes of spider eggs;

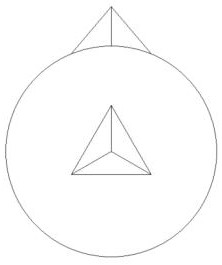

[0031] In the second step, the rhizome of the spider egg is ground at high speed by means of a bead mill; the grinding device of the spider egg is a glass bead high-speed grinder, and the bead filling degree of the grinder is 60%; each glass bead is equipped with at least one protrusion in the shape of a triangular pyramid;

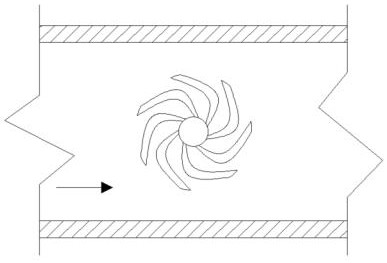

[0032] The third step is to dry and heat the grinding material in the second step. During the drying and heating process, it is accompanied by the auxiliary operation of the stirring mechanism; the temperature range of the drying and heating is 105°C, and the heating and drying device is a plate heat exchanger. When the heat exchanger is heated, the heat source is water at 65°C. After the plate heat exchanger incubates the material at 50°C for 20 minutes, the plate hea...

Embodiment 2

[0039] refer to figure 1 and figure 2 , a high-efficiency yelanin extraction process, comprising the following steps:

[0040] The first step is to select the rhizomes of spider eggs;

[0041] In the second step, the rhizome of the spider egg is ground at high speed by means of a bead mill; the grinding device of the spider egg is a glass bead high-speed grinder, and the bead filling degree of the grinder is 70%; each glass bead is equipped with at least one protrusion in the shape of a triangular pyramid;

[0042] The third step is to dry and heat the grinding material in the second step. During the drying and heating process, it is accompanied by the auxiliary operation of the stirring mechanism; the temperature range of the drying and heating is 105°C, and the heating and drying device is a plate heat exchanger. When the heat exchanger is heated, the heat source is water at 65°C. After the plate heat exchanger incubates the material at 50°C for 20 minutes, the plate hea...

Embodiment 3

[0049] refer to figure 1 and figure 2 , a high-efficiency yelanin extraction process, comprising the following steps:

[0050] The first step is to select the rhizomes of spider eggs;

[0051] In the second step, the rhizome of the spider egg is ground at a high speed by means of a bead mill; the grinding device for the spider egg is a glass bead high-speed grinder, and the bead filling degree of the grinder is 70%;

[0052] The third step is to dry and heat the grinding material in the second step. During the drying and heating process, it is accompanied by the auxiliary operation of the stirring mechanism; the temperature range of the drying and heating is 105°C, and the heating and drying device is a plate heat exchanger. When the heat exchanger is heated, the heat source is water at 65°C. After the plate heat exchanger incubates the material at 50°C for 20 minutes, the plate heat exchanger cools the material, and the cold source is water at 12°C; the stirring mechanism ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com